Patents

Literature

148results about How to "Put in smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

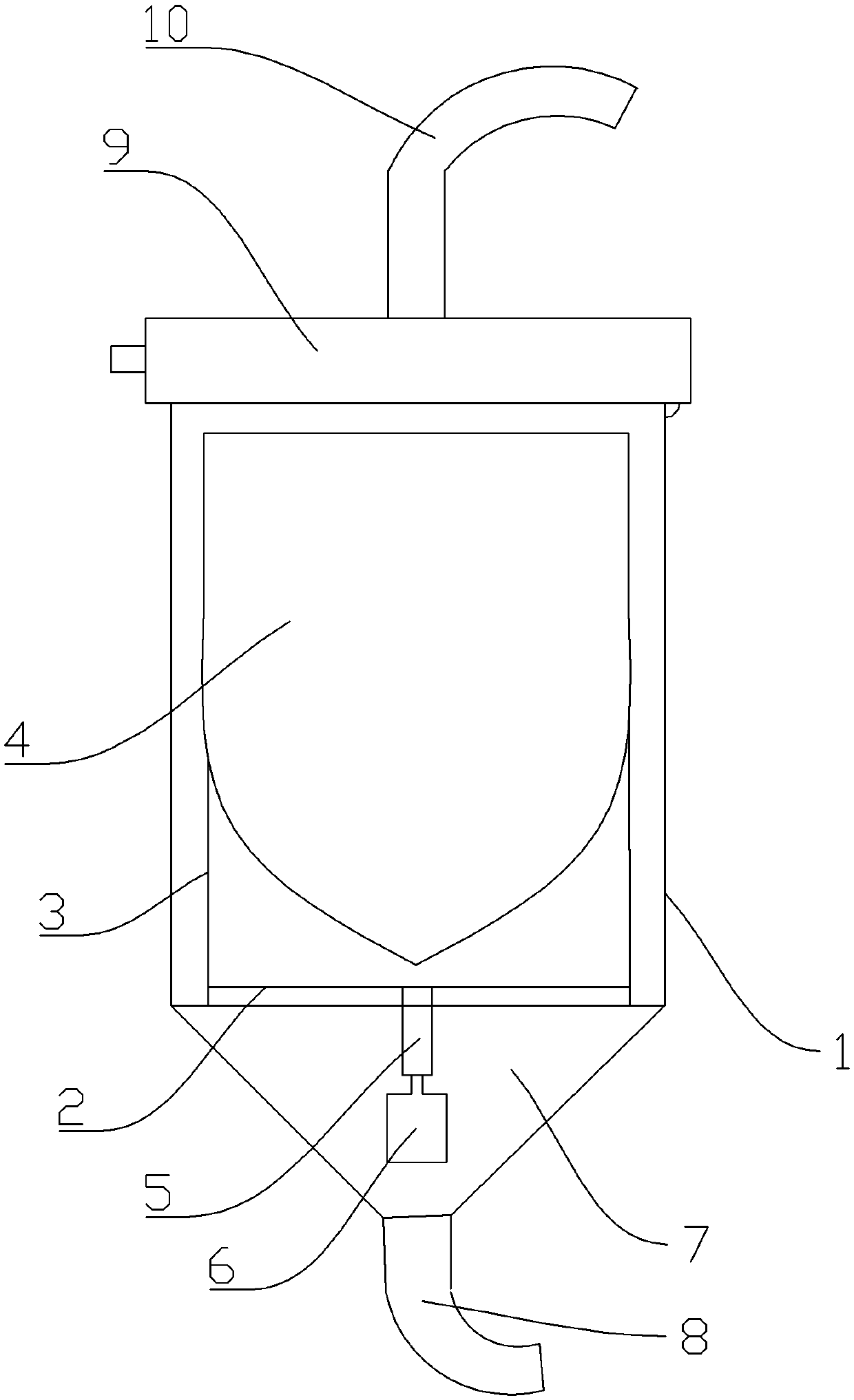

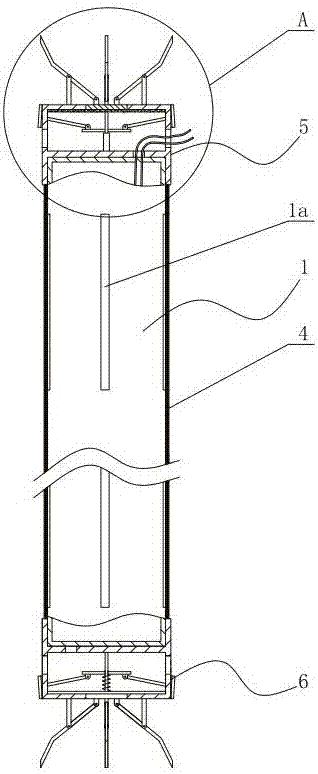

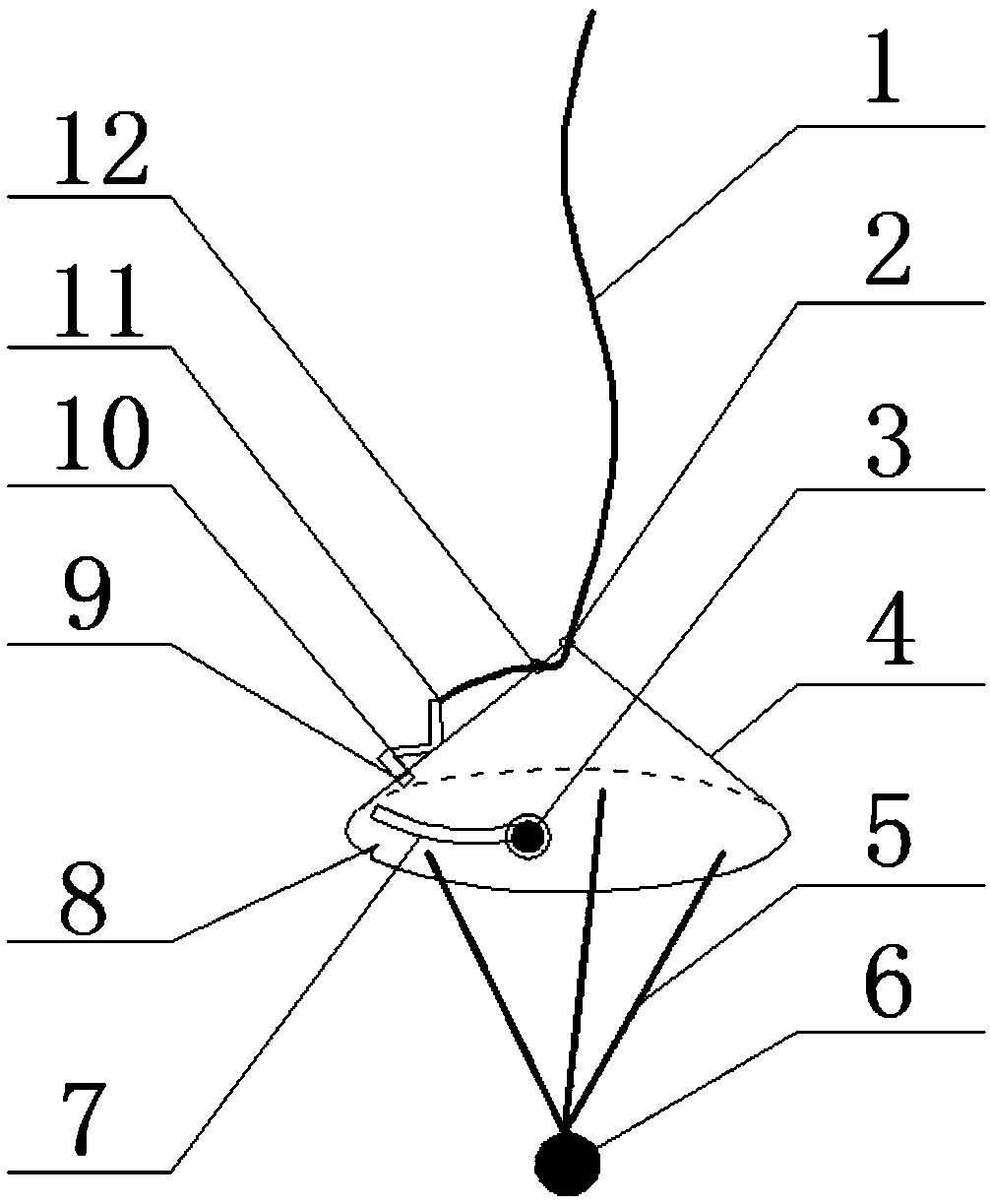

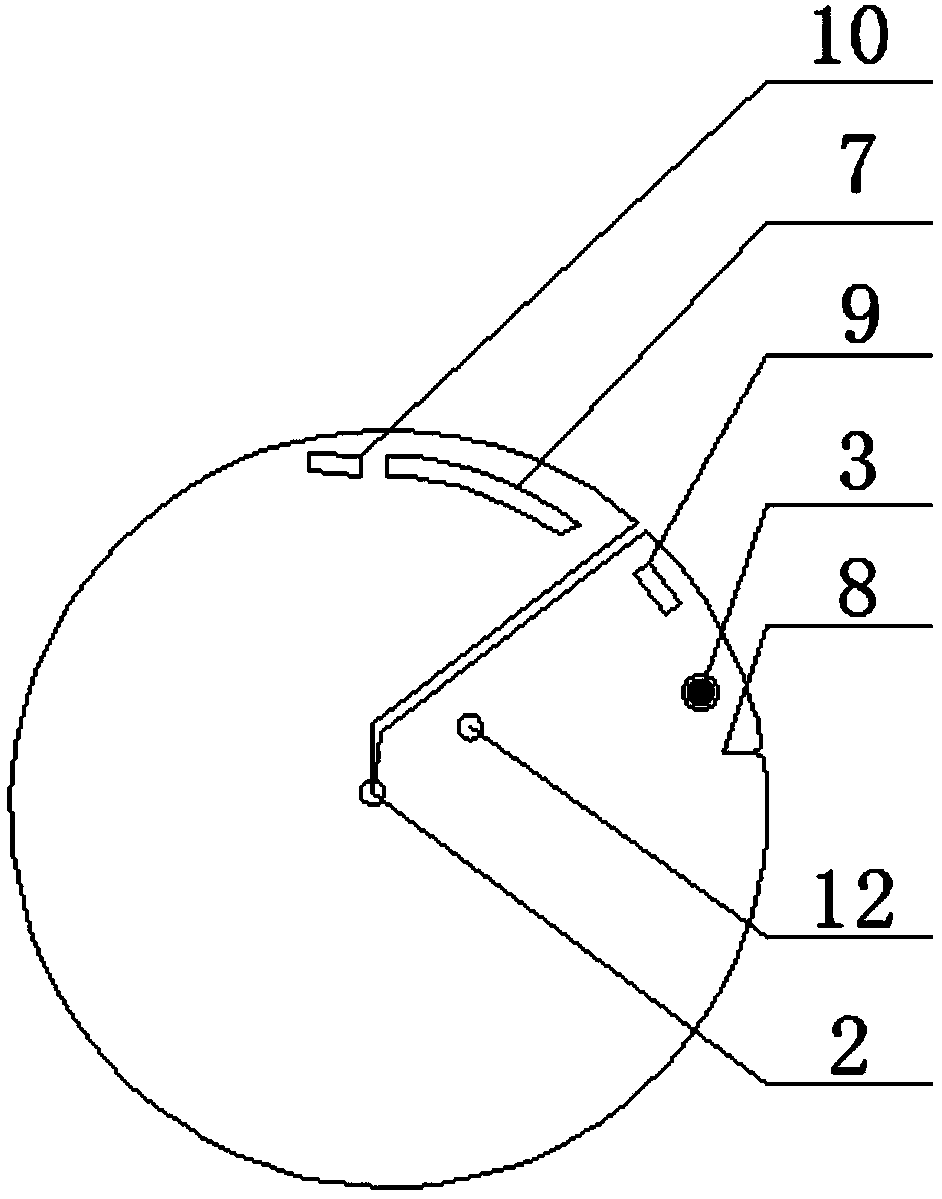

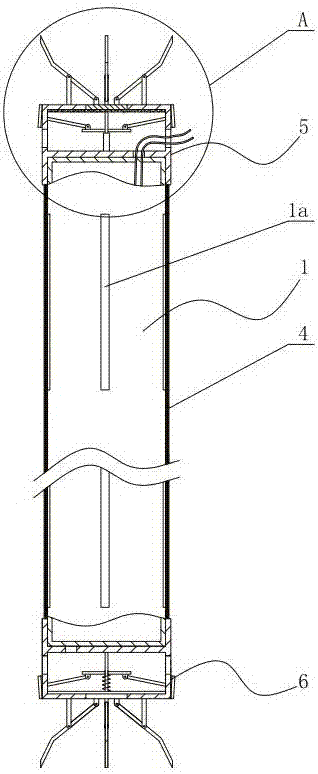

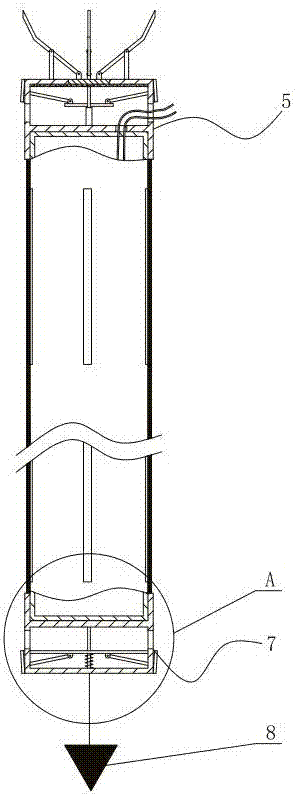

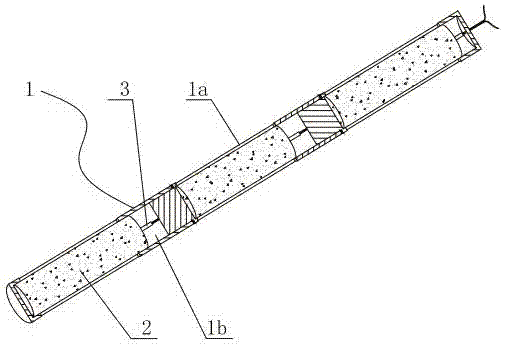

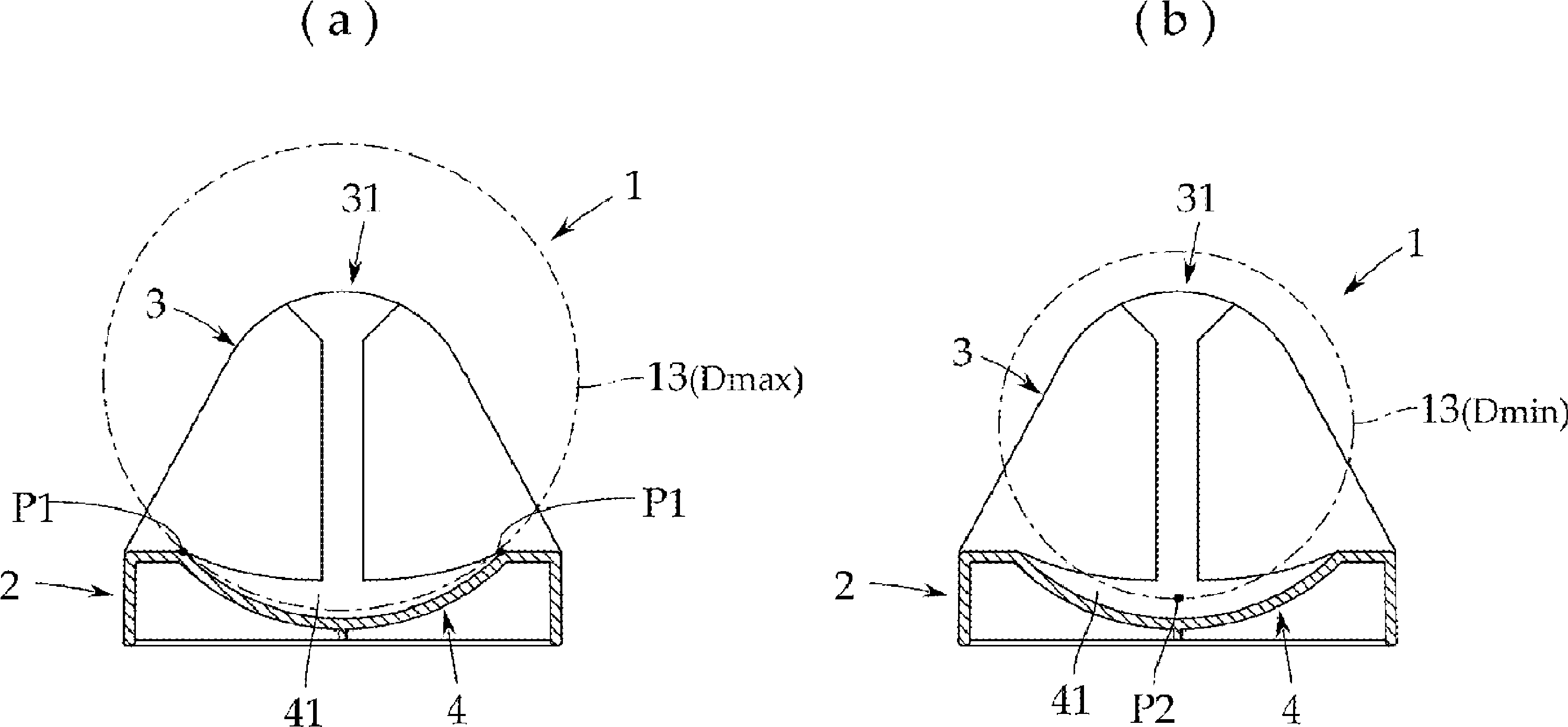

Novel anchoring grouting anchor rod and construction method thereof

ActiveCN108979692ASolve the anchorSolve the problem of insufficient groutingAnchoring boltsClimate change adaptationPre stressPre stressing

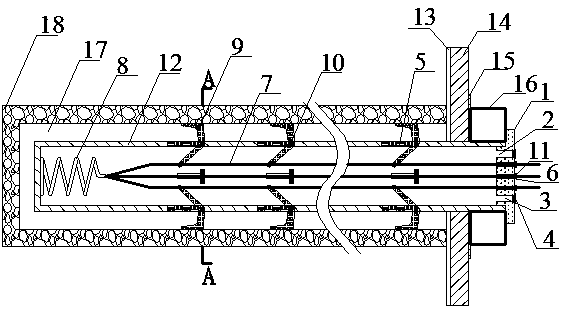

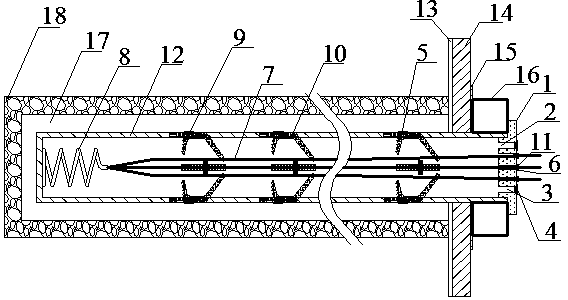

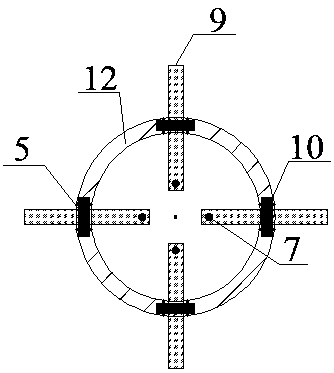

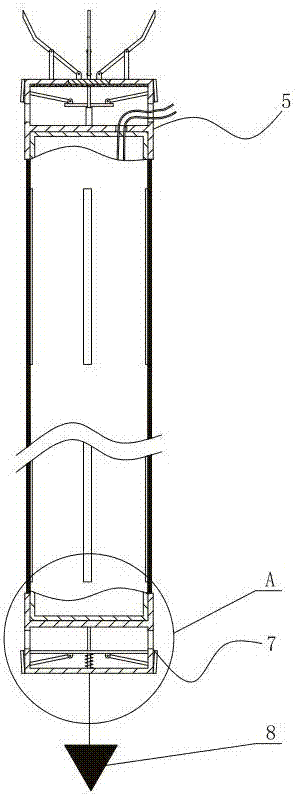

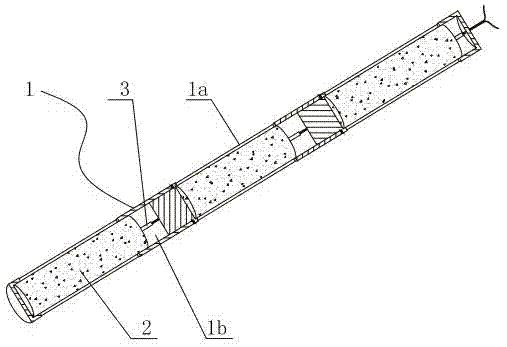

The invention discloses a novel anchoring grouting anchor rod and a construction method thereof. The novel anchoring grouting anchor rod is formed by a grouting system, an anchoring system and a fastening system. The grouting system comprises a cover, a vent hole, a grouting hole, a slurry plug, and overflow holes and various parts work together to ensure that slurry is full and tightly bonded. The anchoring system is formed by anchoring holes, a steel strand, a high-strength spring, an anchor claw, a rotating shaft and a steel strand clamp, initial anchoring force can be provided for the anchor rod, the anchor claw has barbs and rotates under the traction of the steel strand and closely attaches to a surrounding rock, and anchor removal is effectively prevented. The fastening system is formed by an anchor rod body, a slurry stop pad, a tray, a washer and a high-strength nut. After the slurry is solidified, the pre-stress can be provided for the grouting anchor to control the deformation of the surrounding rock. According to the invention, an anchor claw rotation design is employed, the anchor claw closely attaches to the surrounding rock, sufficient anchoring force is provided toprevent the anchor removal, and vent holes are set to ensure a pouring effect. The application defect of an existing grouting anchor is solved, and the novel anchoring grouting anchor rod and the construction method have the advantages of anchor removal prevention, high adaptability and good grouting effect.

Owner:SHANDONG UNIV OF SCI & TECH

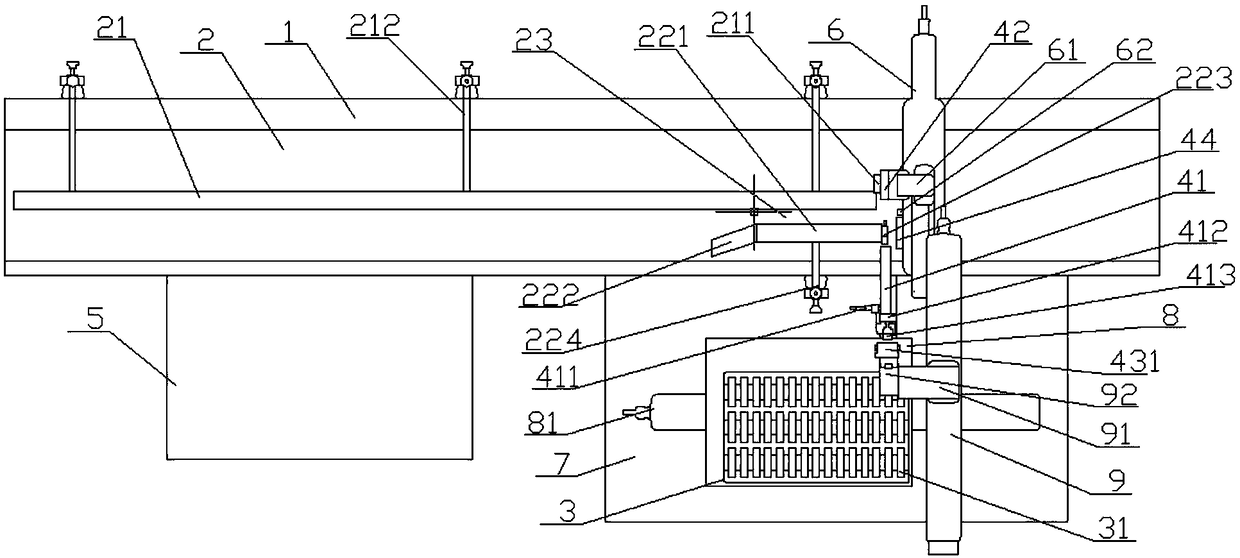

Automatic packing device on cheese packaging conveying equipment

The invention discloses an automatic packing device on cheese packaging conveying equipment. The automatic packing device is arranged above two first packing conveyor belts and a second packing conveyor belt and comprises a cylinder claw opening mechanism and a transmission unit. Cheese on the first packing conveyor belts can be grabbed by the cylinder claw opening mechanism, the cylinder claw opening mechanism comprises a horizontal connecting frame, a first pneumatic manipulator assembly and a second pneumatic manipulator assembly, the horizontal connecting frame is connected with the lower side of the transmission unit, and the first pneumatic manipulator assembly and the second pneumatic manipulator assembly are arranged on the lower side of the horizontal connecting frame and can horizontally move towards each other in the direction perpendicular to conveying directions of the first packing conveyor belts. The automatic packing device has the advantages that two cheese groups which are respectively positioned on the first pneumatic manipulator assembly and the second pneumatic manipulator assembly can approach each other and accordingly can be stably arranged in cartons, and vibration due to excessively large spaces between the two cheese groups and influence on the quality of products can be prevented.

Owner:SHISHI JULING MACHINERY TECH CO LTD

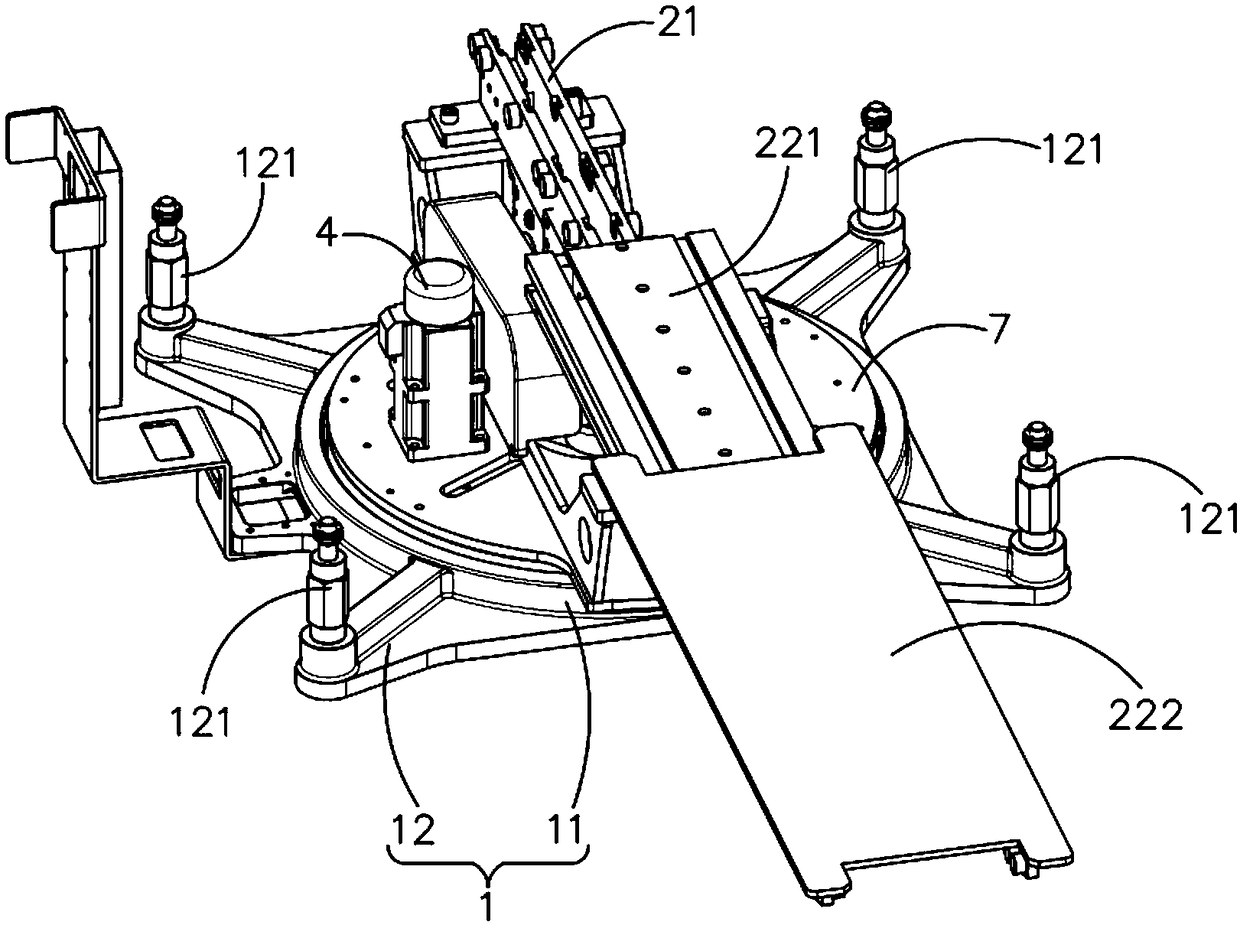

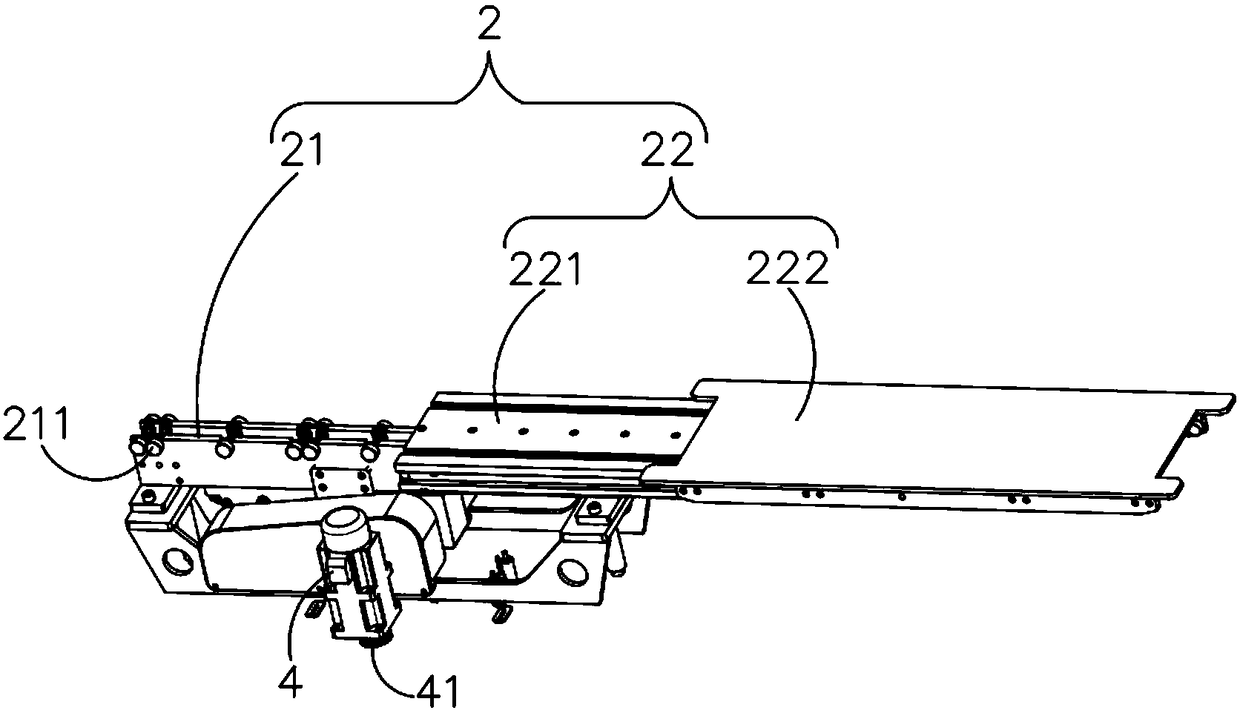

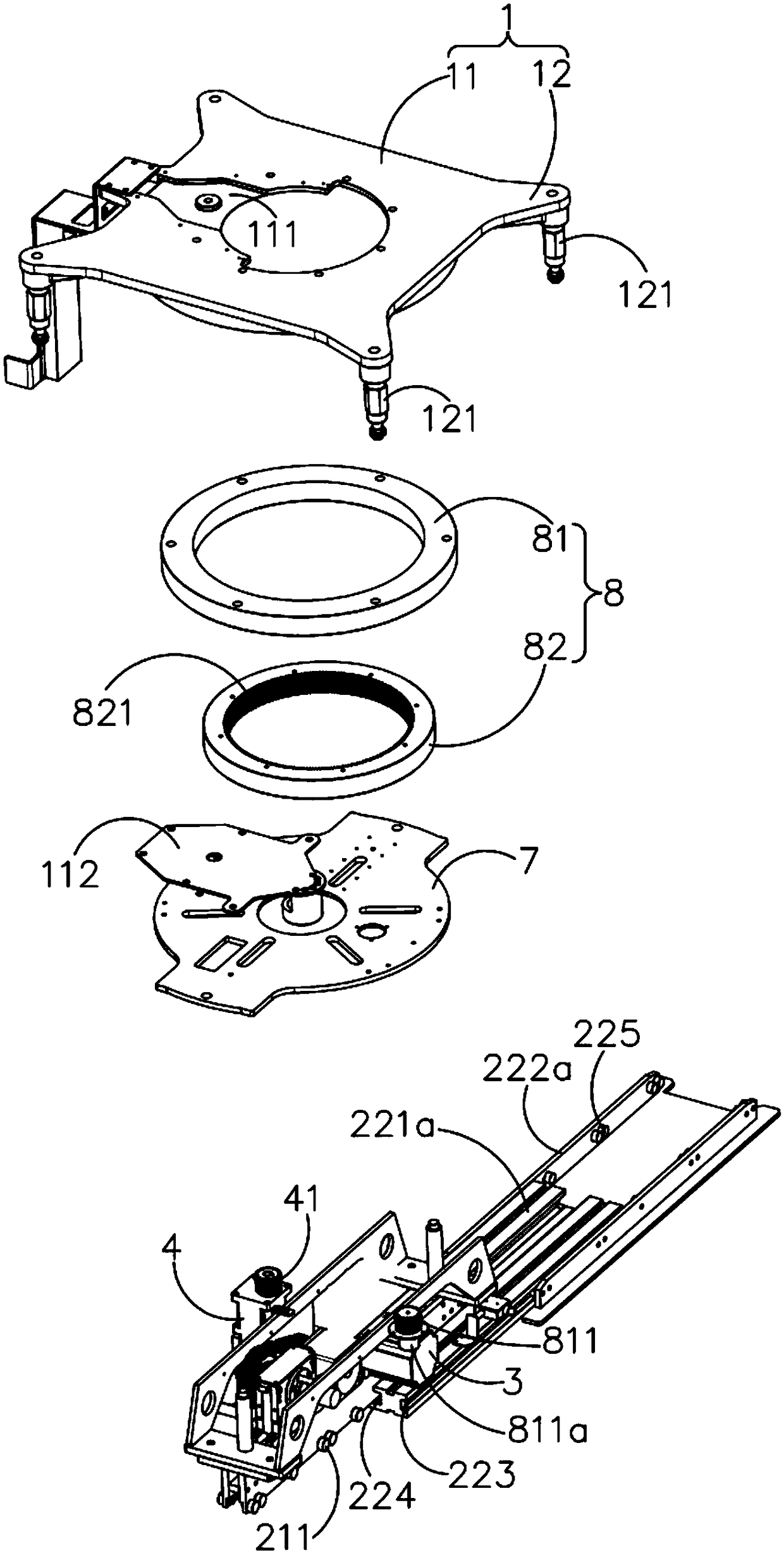

Rotary telescoping fork and AGV (Automatic Guided Vehicle)

The invention discloses a rotary telescoping fork. The rotary telescoping fork comprises a supporting seat, a fork body, a first driving mechanism and a second driving mechanism, wherein the fork bodycomprises a fixed fork body, and a multi-stage telescopic fork body which is glidingly connected to the fixed fork body; the fixed fork body is rotatably arranged on the supporting seat; the first driving mechanism is arranged on the fixed fork body and is connected to the multi-stage telescoping fork body, and the multi-stage telescoping fork body is driven to telescope relative to the fixed fork body through the first driving mechanism; the second driving mechanism is arranged on the supporting seat and is fixedly connected to the fixed fork body, and the fork body is driven to rotate relative to the supporting seat through the second driving mechanism. Additionally, the invention also discloses an AGV. The AGV comprises the abovementioned disclosed rotary telescoping fork. With the adoption of the rotary telescoping fork and the AGV, goods with different sizes can be forked, and moreover, the goods conveying quality can be effectively ensured.

Owner:YONEGY LOGISTICS AUTOMATION TECH

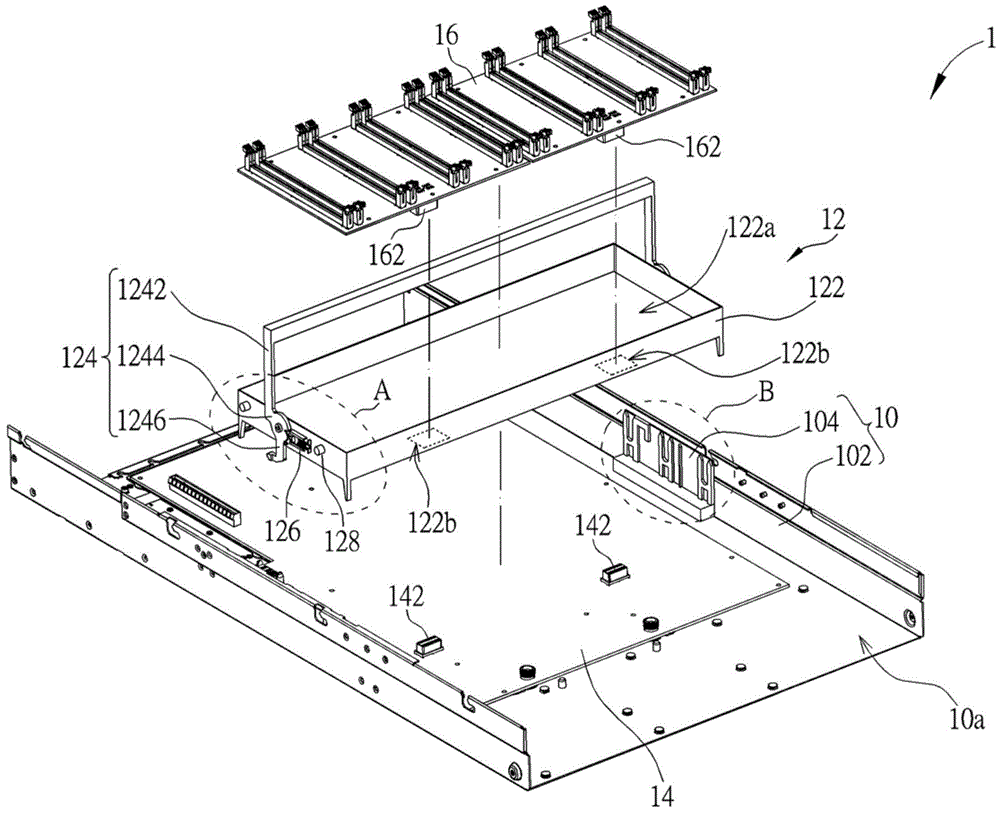

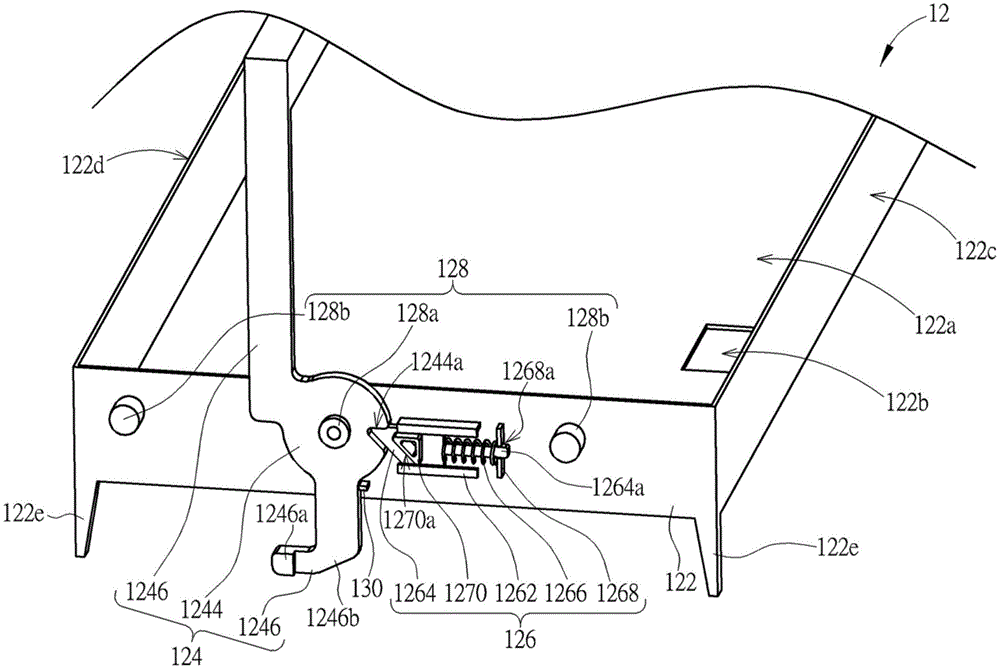

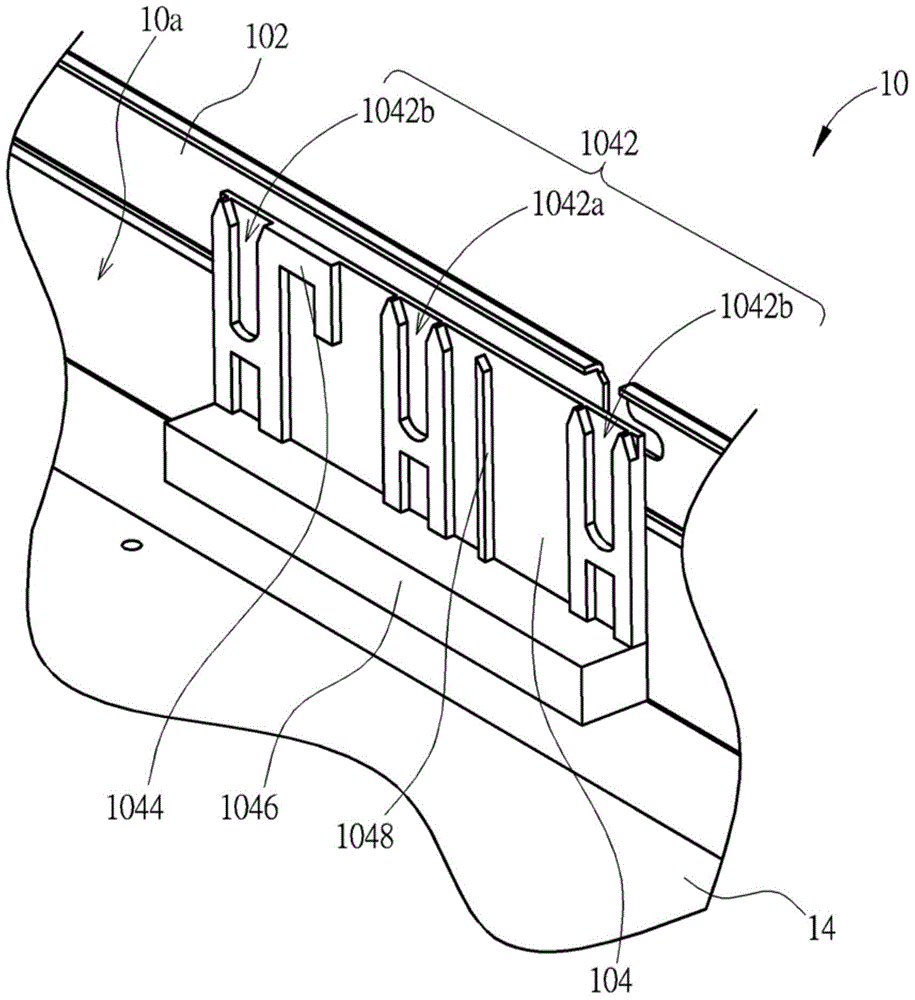

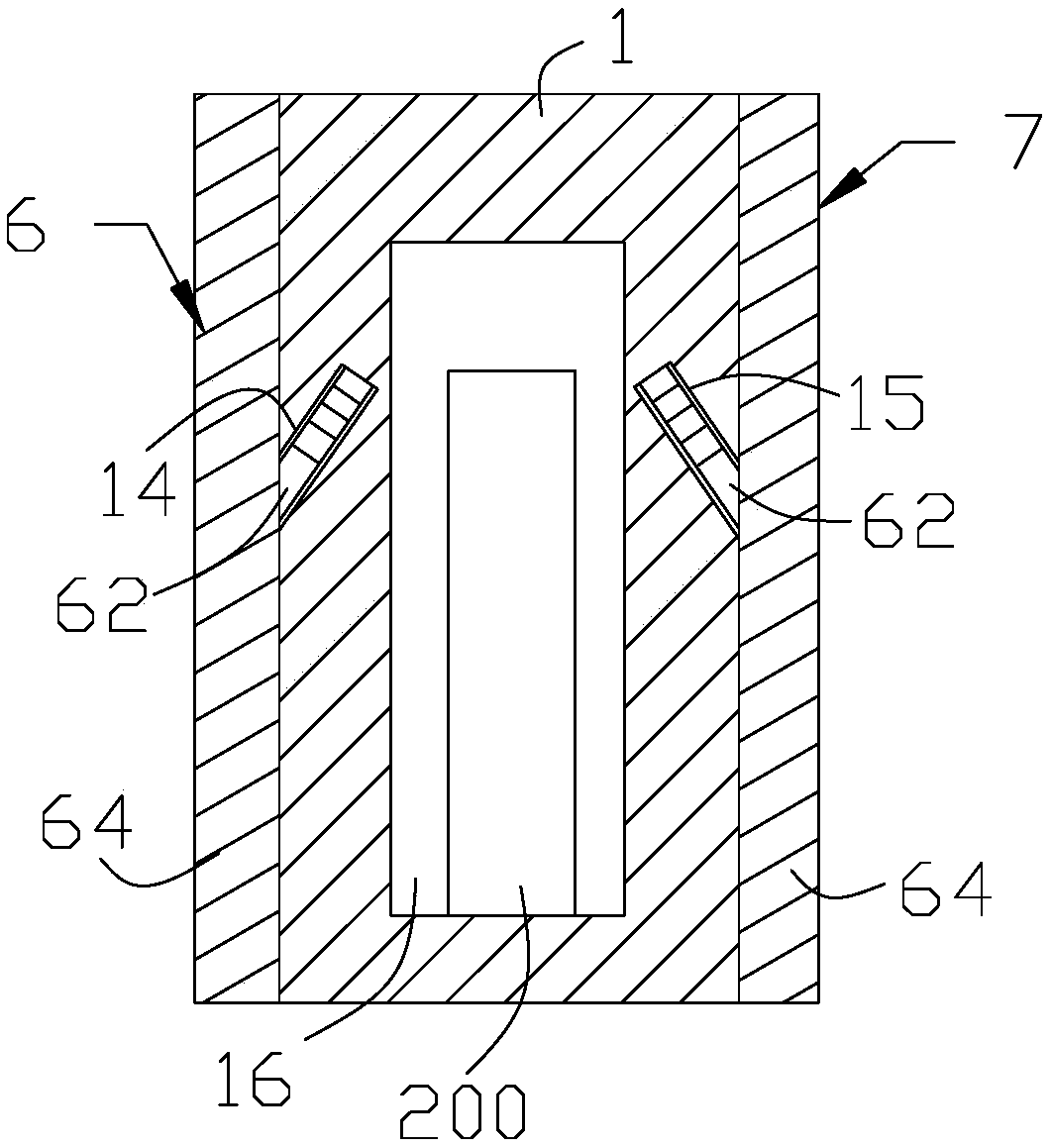

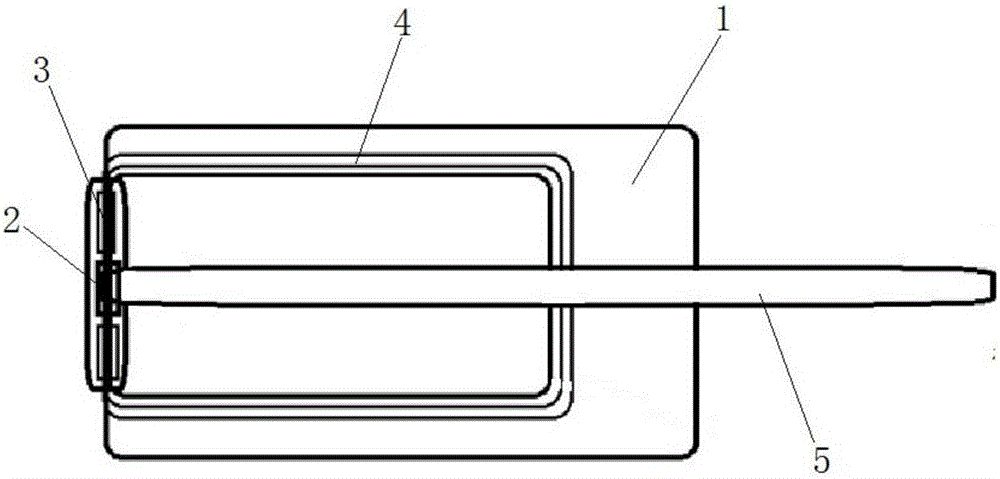

Removable cage and electronic apparatus

ActiveCN104460877AReliable electrical connectionPut in smoothlyDigital processing power distributionLocking mechanism

The invention discloses a removable cage and an electronic apparatus. The electronic apparatus includes an apparatus casing and a removable cage. The removable cage includes a cage body, a carry handle, and a locking mechanism disposed on the cage body. The carry handle includes a pivotally-connecting part, pivotally connected to the cage body, a handle body, and a pushing part. The handle body and the pushing part are oppositely connected to the pivotally-connecting part. The locking mechanism includes a latching part and an unlocking part. The latching part can be engaged into a lock slot of the pivotally-connecting part so that the carry handle is fixed relative to the cage body for carrying the cage body. The unlocking part can be driven to disengage the latching part from the lock slot. By the lever rule, the carry handle can move the cage body into the apparatus casing further or move the cage body reversely to depart from the apparatus casing.

Owner:WISTRON CORP

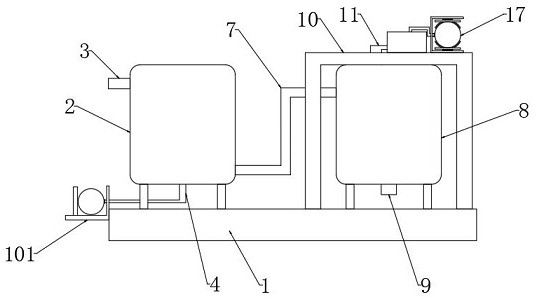

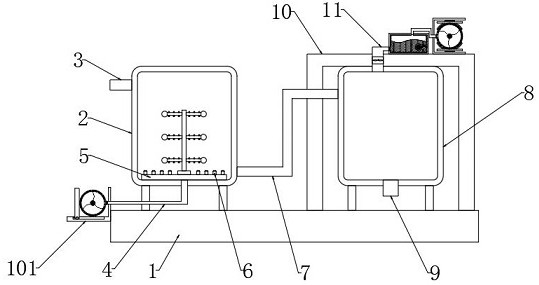

Integrated dehydrating drying machine for parts

The invention relates to dehydrating equipment used in the industry, in particular to an integrated dehydrating drying machine used for cleaned parts of an electroplating production line. A dehydrating mechanism and a drying mechanism are arranged inside a machine shell. The dehydrating mechanism comprises a rotating plate installed at the bottom of the machine shell. An installing frame is arranged on the rotating plate. A net-shaped part barrel is arranged inside the installing frame. A water-draining cavity is formed between the outer wall of the part barrel and the inner wall of the machine shell. A rotating shaft is fixedly connected to the center of the rotating plate. A motor is arranged at the bottom of the rotating shaft. The dry mechanism comprises a barrel cover arranged at the top of the machine shell. A hot gas pipe leading to the part barrel is arranged on the barrel cover. A conical water-collecting tank is further arranged at the bottom of the machine shell. The water-collecting tank is communicated with the water-draining cavity. A water-draining pipe is arranged in the lowest position of the water-collecting tank. According to the integrated dehydrating drying machine for the parts, the process of transfer transportation is reduced, the two machining operations are conducted simultaneously, and hence the machining efficiency is greatly improved; drying of the parts is complete; the rotating shaft is not arranged in the part barrel, and after drying is completed, the parts in the part barrel can be scooped out directly and do not need to be grabbed one by one, so that the manpower is saved, and the efficiency is improved.

Owner:CHONGQING PENGLEI AUTO PARTS CO LTD

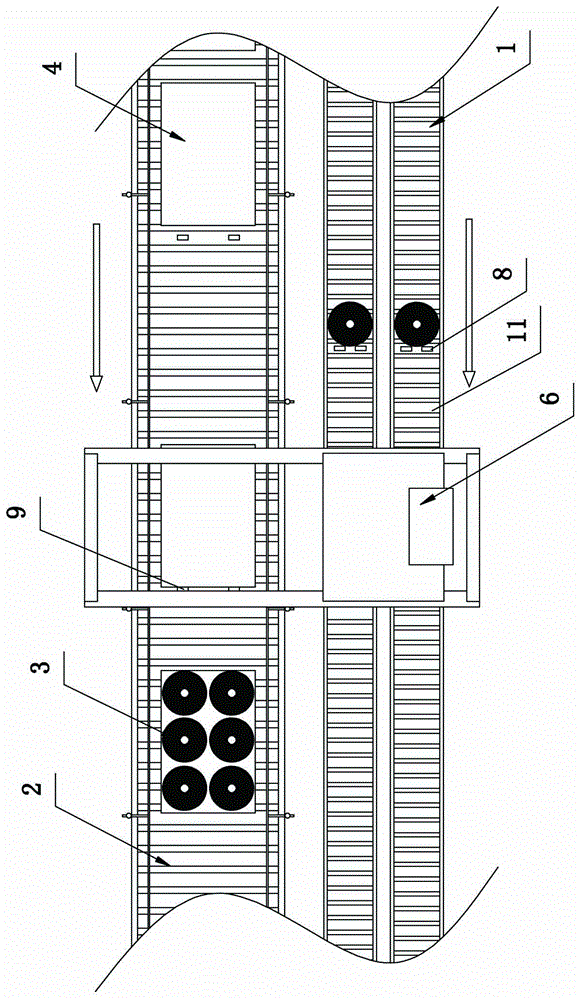

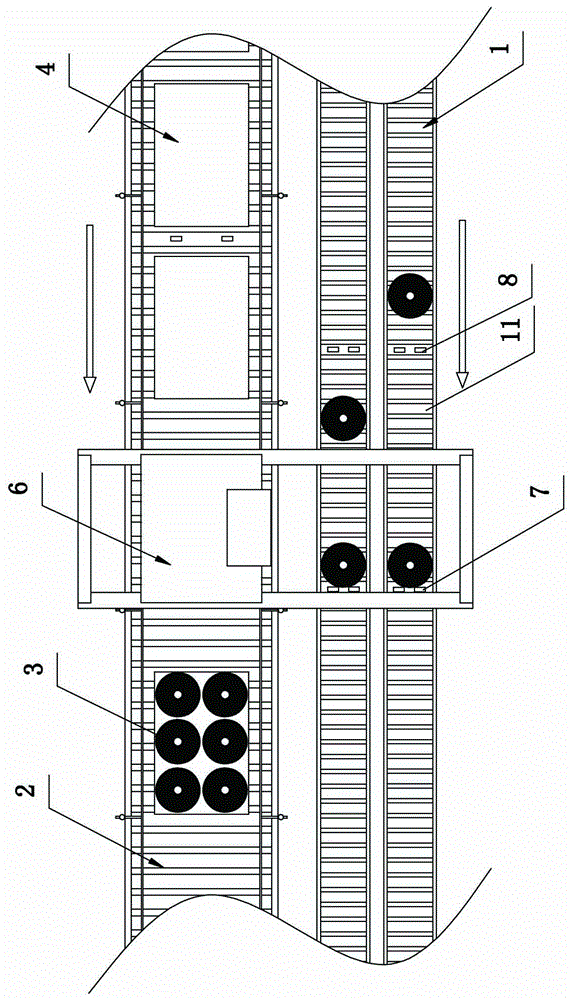

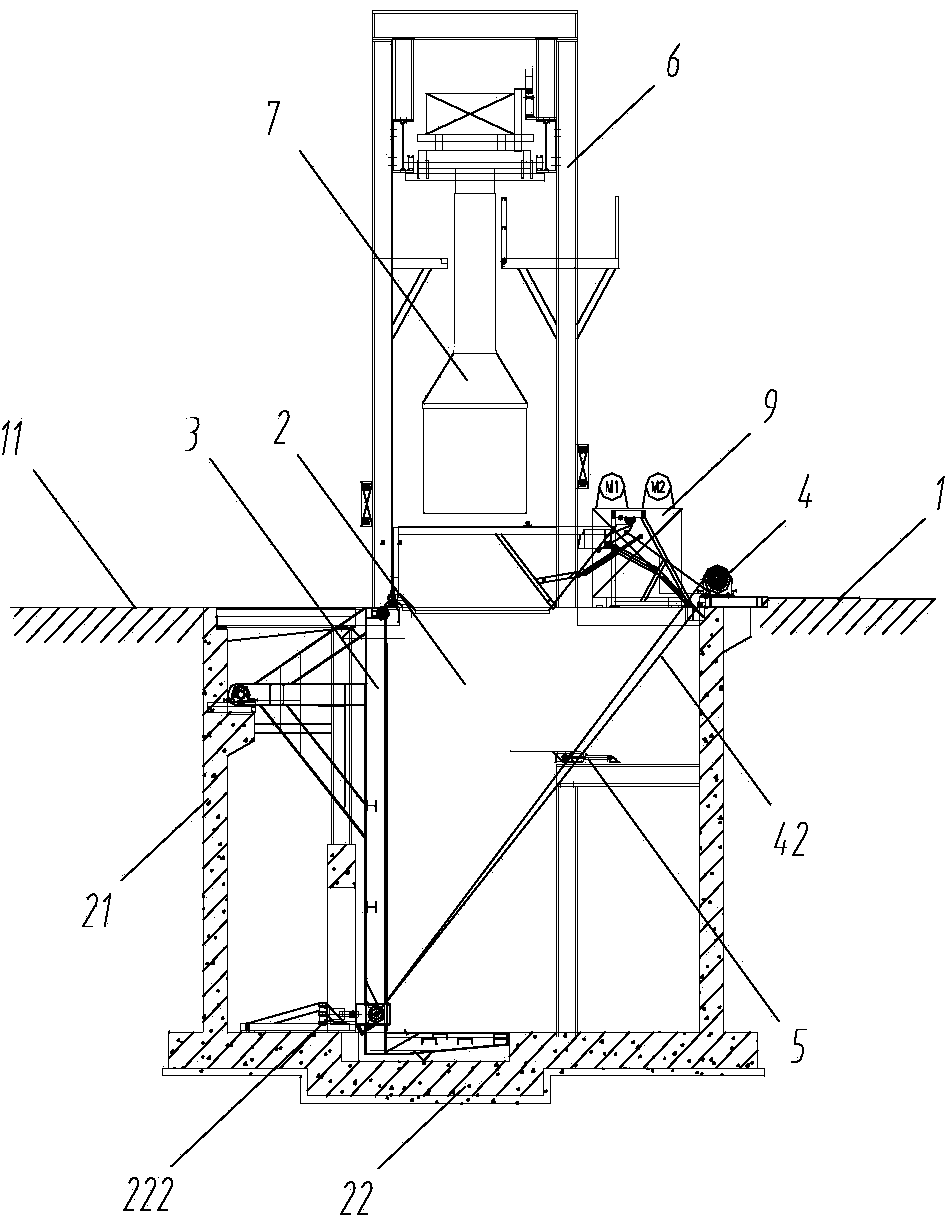

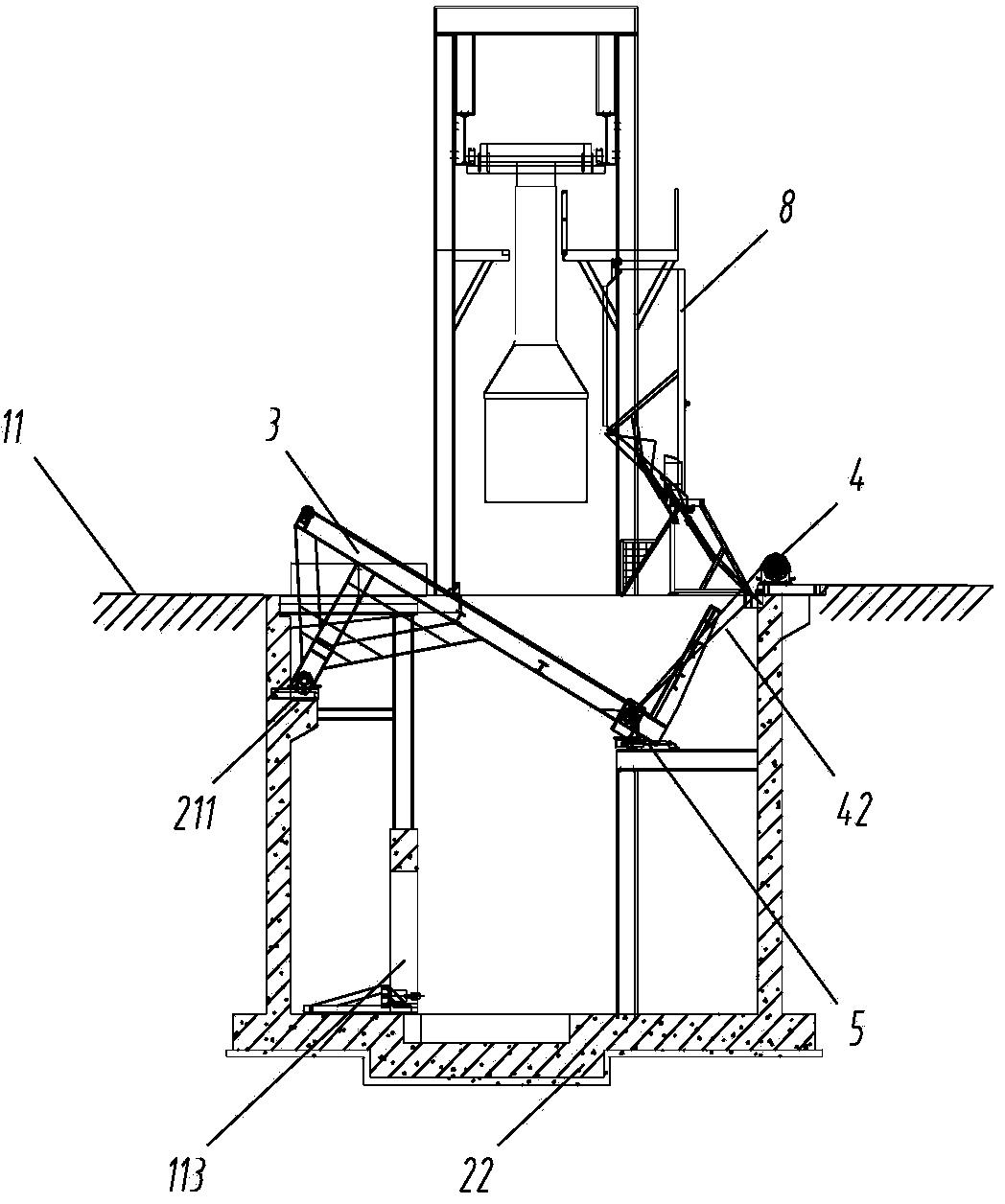

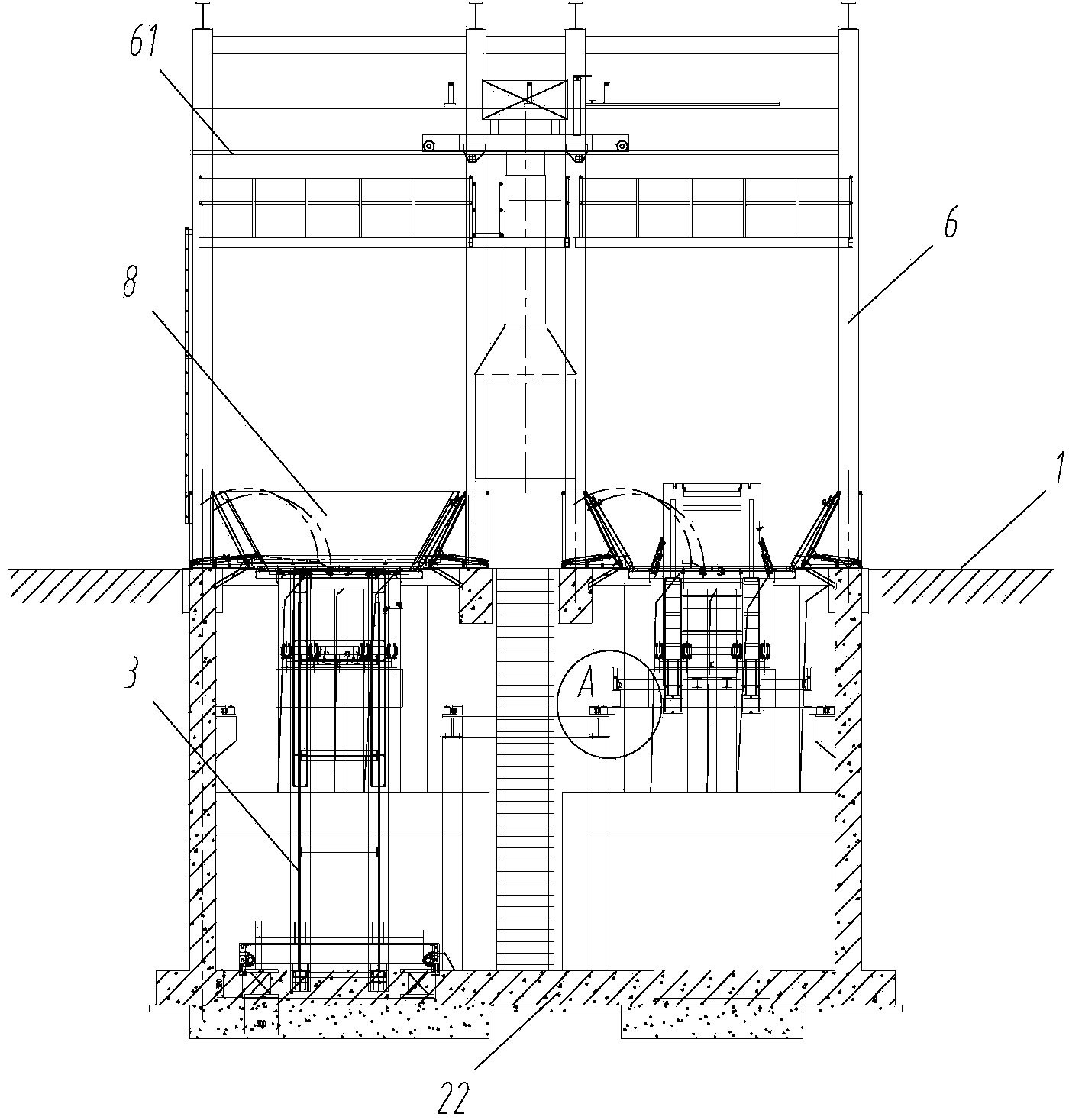

Flat-in and flat-out type garbage transfer station and operating method thereof

ActiveCN103818671ALower the altitudeImprove efficiencyRefuse transferringLoading/unloadingService efficiencyLand area

The invention relates to a flat-in and flat-out type garbage transfer station and an operating method of the garbage transfer station. According to the technical scheme, the flat-in and flat-out type garbage transfer station comprises a datum surface used for forming a carrying body of the garbage transfer station. The garbage transfer station is characterized by further comprising a foundation pit, a turnover mechanism and a lifting mechanism, wherein the datum surface extends downwards to form a space which is the foundation pit used for containing a garbage container; the turnover mechanism is arranged in the foundation pit and used for turning over the garbage container; the lifting mechanism is used for driving the turnover mechanism; the datum surface comprises the working surface of a vehicle loaded with garbage. Compared with the prior art, according to the garbage transfer station and the operating method, ground space which must be occupied is greatly reduced, construction cost is lower, and therefore the garbage transfer station is more suitable for being constructed in a city with a small land area. In this way, the service efficiency of the unit land area is improved, and predominant technical progress is embodied.

Owner:CN NL WASTE SOLUTION

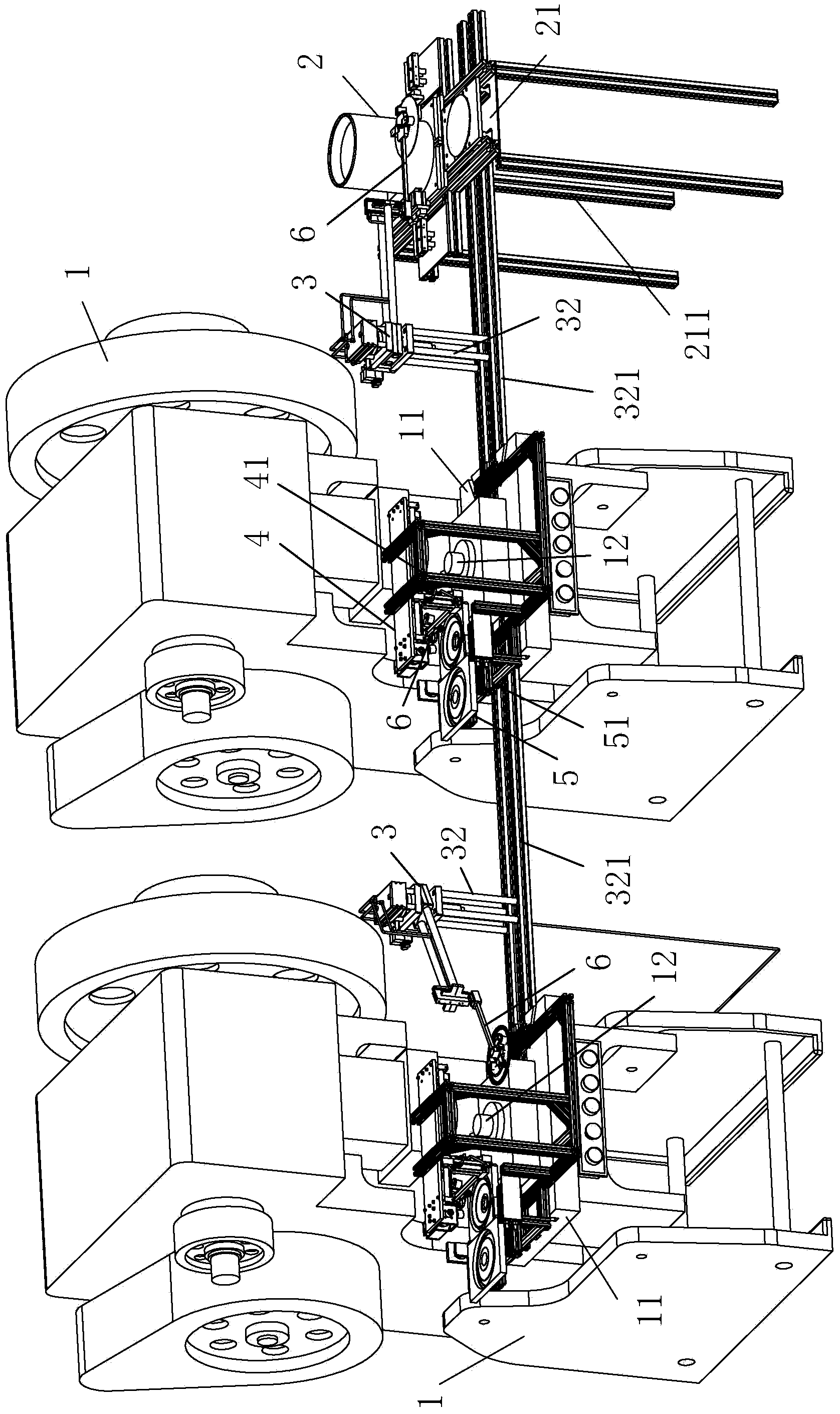

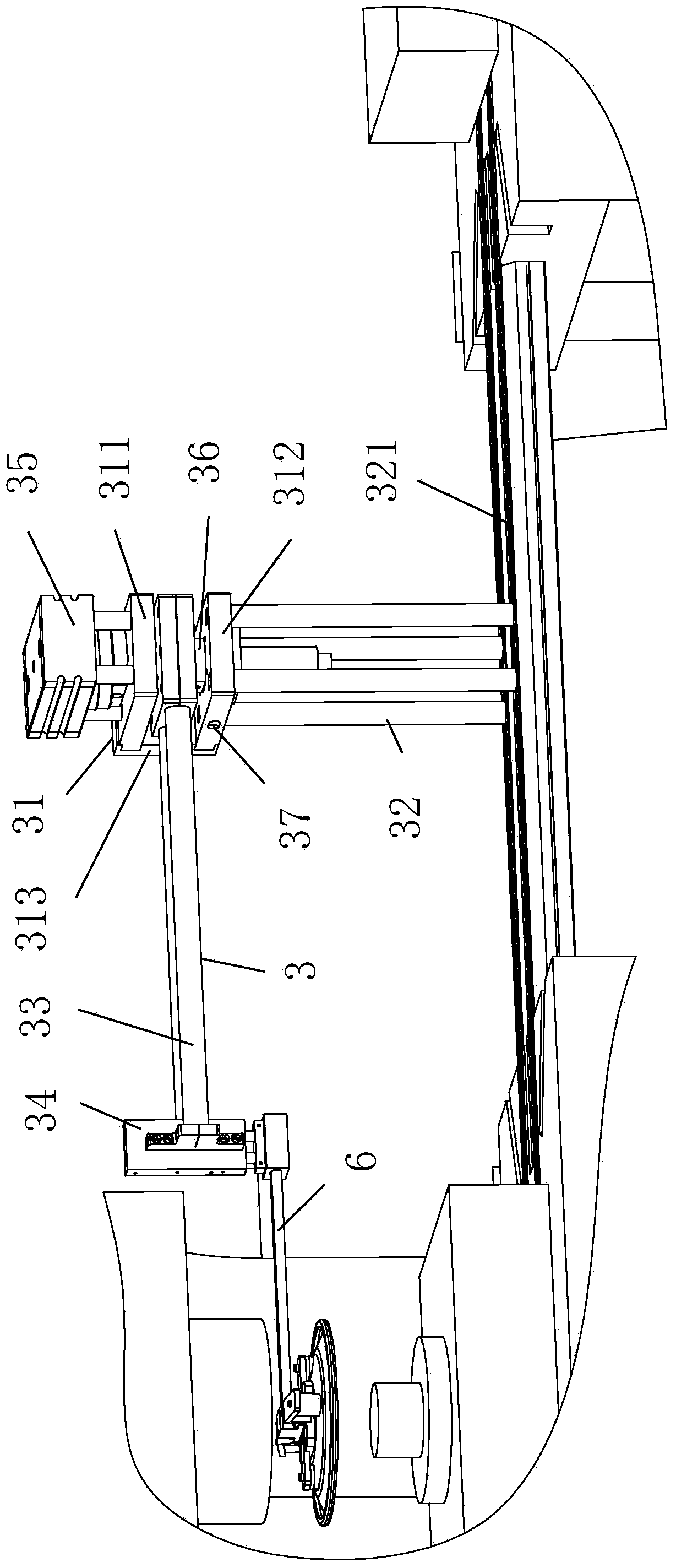

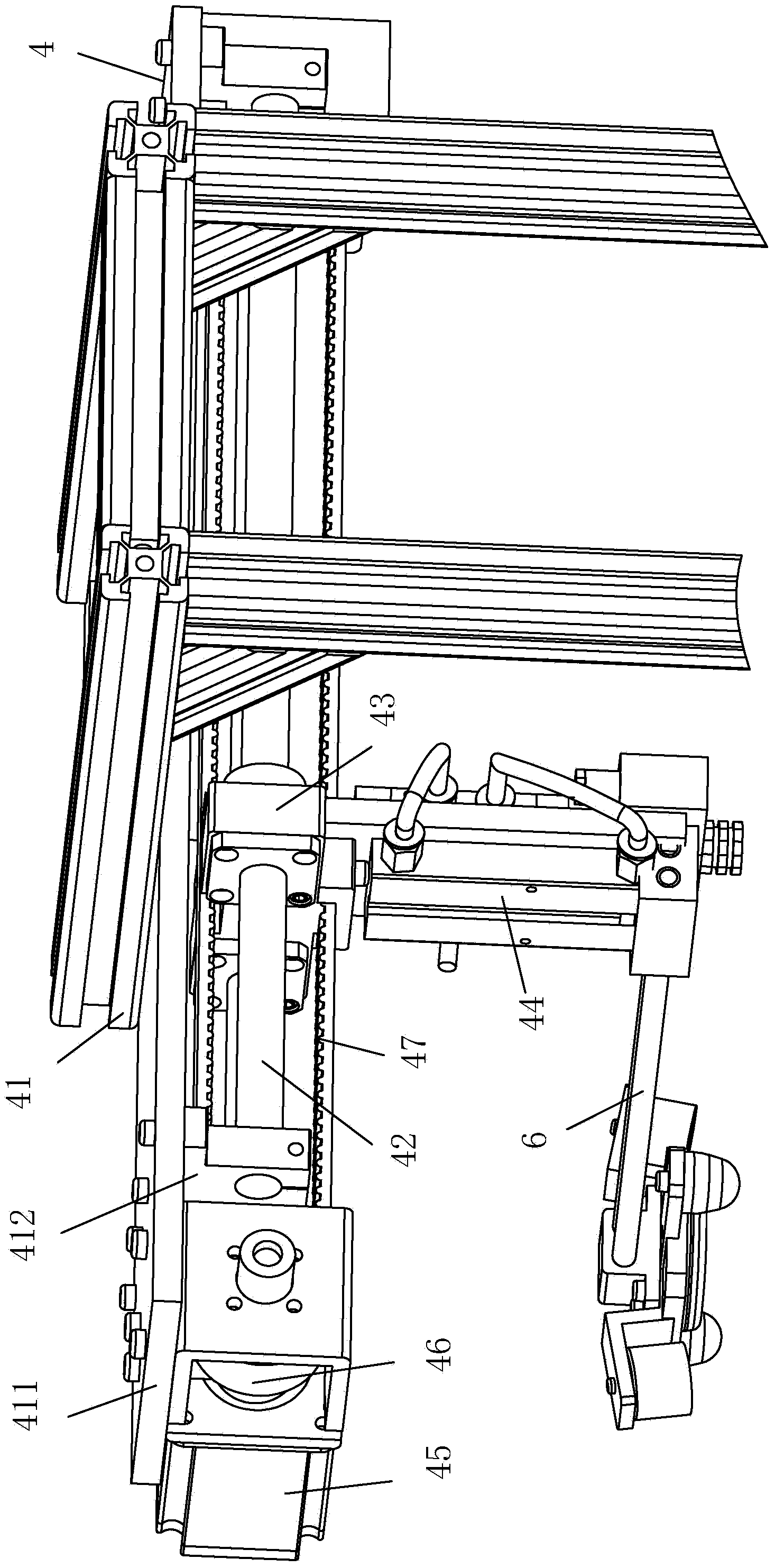

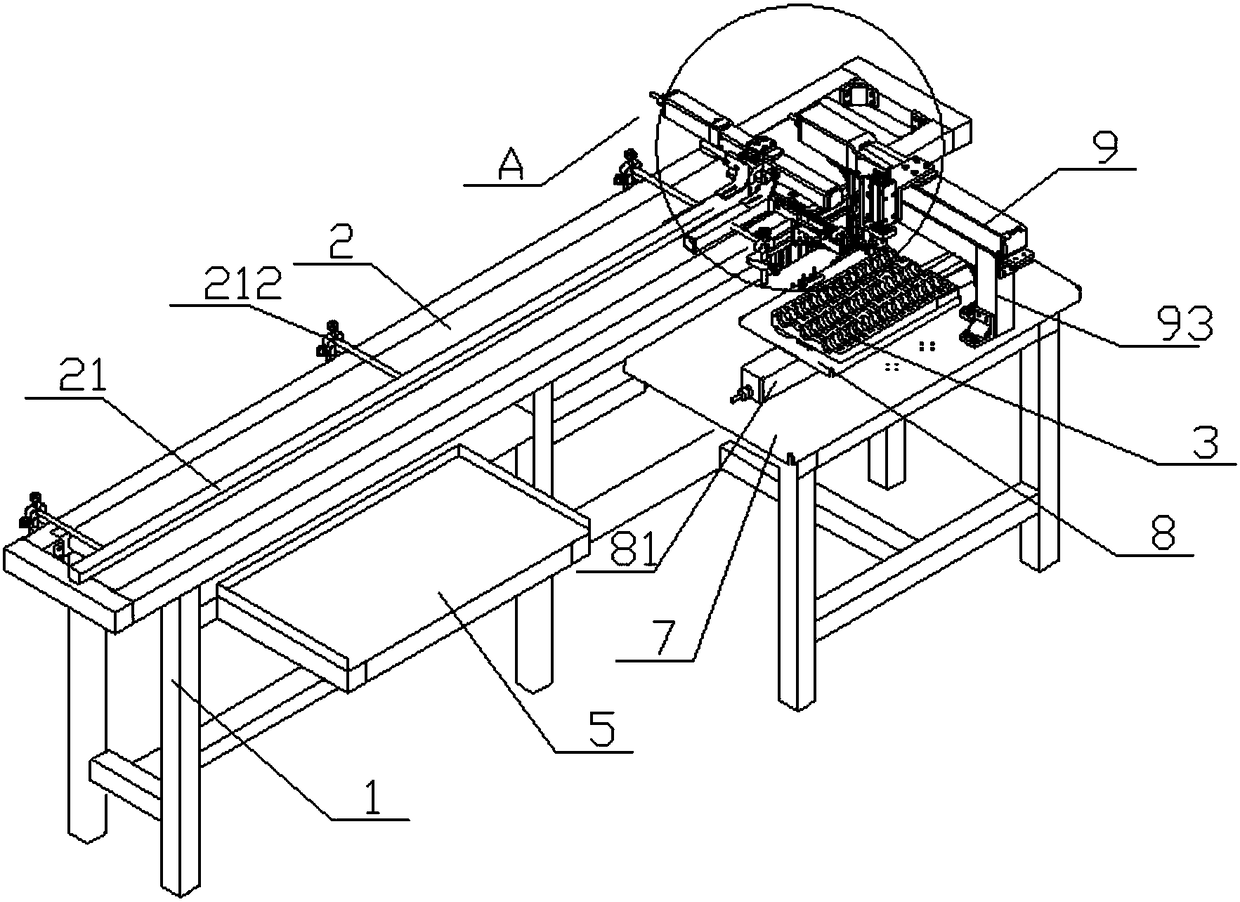

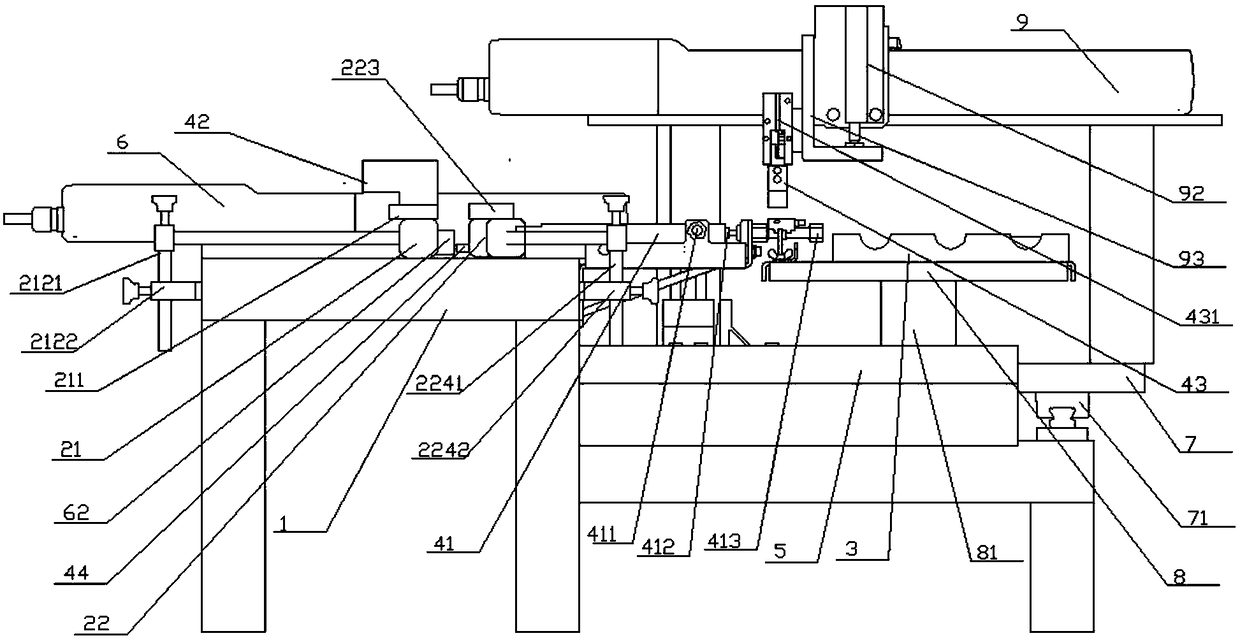

Double-stamping-station plate material conveying device

ActiveCN103433398AImprove efficiencySimple structureMetal-working feeding devicesPositioning devicesEngineeringMachining

The invention relates to the field of stamping devices and aims at providing a double-stamping-station plate material conveying device which comprises two stamping machines with lower die seats. The double-stamping-station plate material conveying device further comprises a plate material dividing mechanism, two plate rotating mechanisms, a transverse moving mechanism and a plate turning mechanism. The plate material dividing mechanism is located on one side of one stamping machine. One plate rotating mechanism is located between the plate material dividing mechanism and one stamping machine. The transverse moving mechanism is located on the front side of one stamping machine. The plate turning mechanism is located on the other side of one stamping machine. The other plate rotating mechanism is located between the plate turning mechanism and the other stamping machine. The double-stamping-station plate material conveying device is high in efficiency of dividing plate materials, turning, moving and shifting paths, can not make mistakes easily, and is favorable to the organization of production line machining.

Owner:浙江安统汽车部件有限公司

Automatic permanent magnet product dividing and box packing equipment

PendingCN108583995AGuaranteed accuracySave the area occupied by the stationPackaging automatic controlEngineeringMechanical engineering

The invention discloses automatic permanent magnet product dividing and box packing equipment which comprises a rack, a conveyor belt, a loading device and a loading box, wherein the loading device comprises a storage groove, a first push block and an air claw; the storage groove and the conveyor belt are perpendicularly and fixedly arranged on the rack; the first push block is positioned on the second side close to the second end of the conveyor belt and is in sliding fit with the rack; the air claw is in sliding fit with the rack, can move up and down and can move horizontally in the lengthdirection of the storage groove; and the air claw is driven by a third air cylinder. The automatic permanent magnet product dividing and box packing equipment is suitable for box packing operation ofpermanent magnet products with multiple specifications, realizes general utilization of the products with multiple specifications, is integrally designed, reduces the equipment station occupied area,can reduce the investment cost compared with the original equipment with the single specification, can automatically adjust the key sizes including box packing position, quantity and the like according to the product specification requirement, greatly improves the working efficiency, ensures the precision of the box packing quantity, and lowers the strength of manual labor.

Owner:京磁材料科技股份有限公司

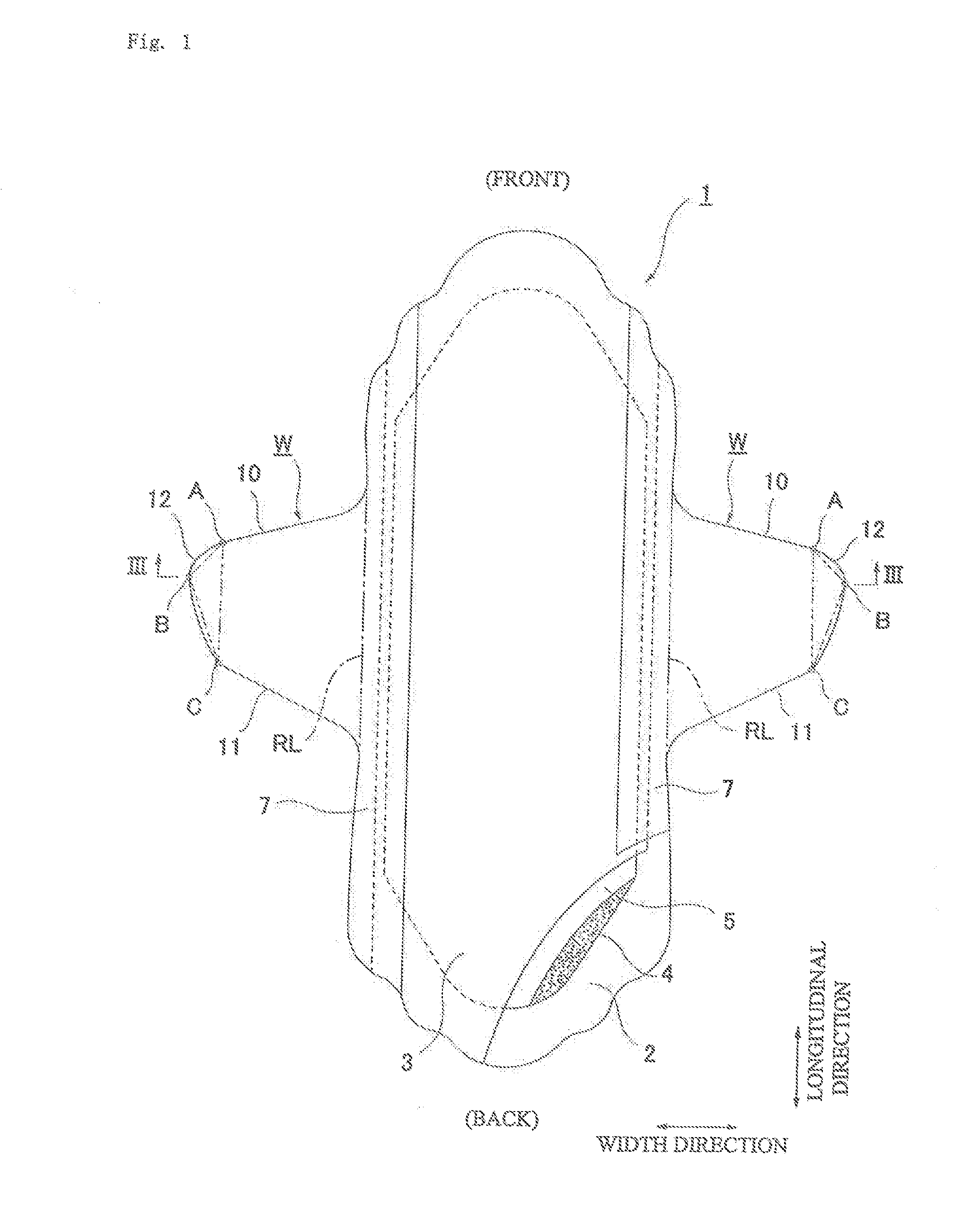

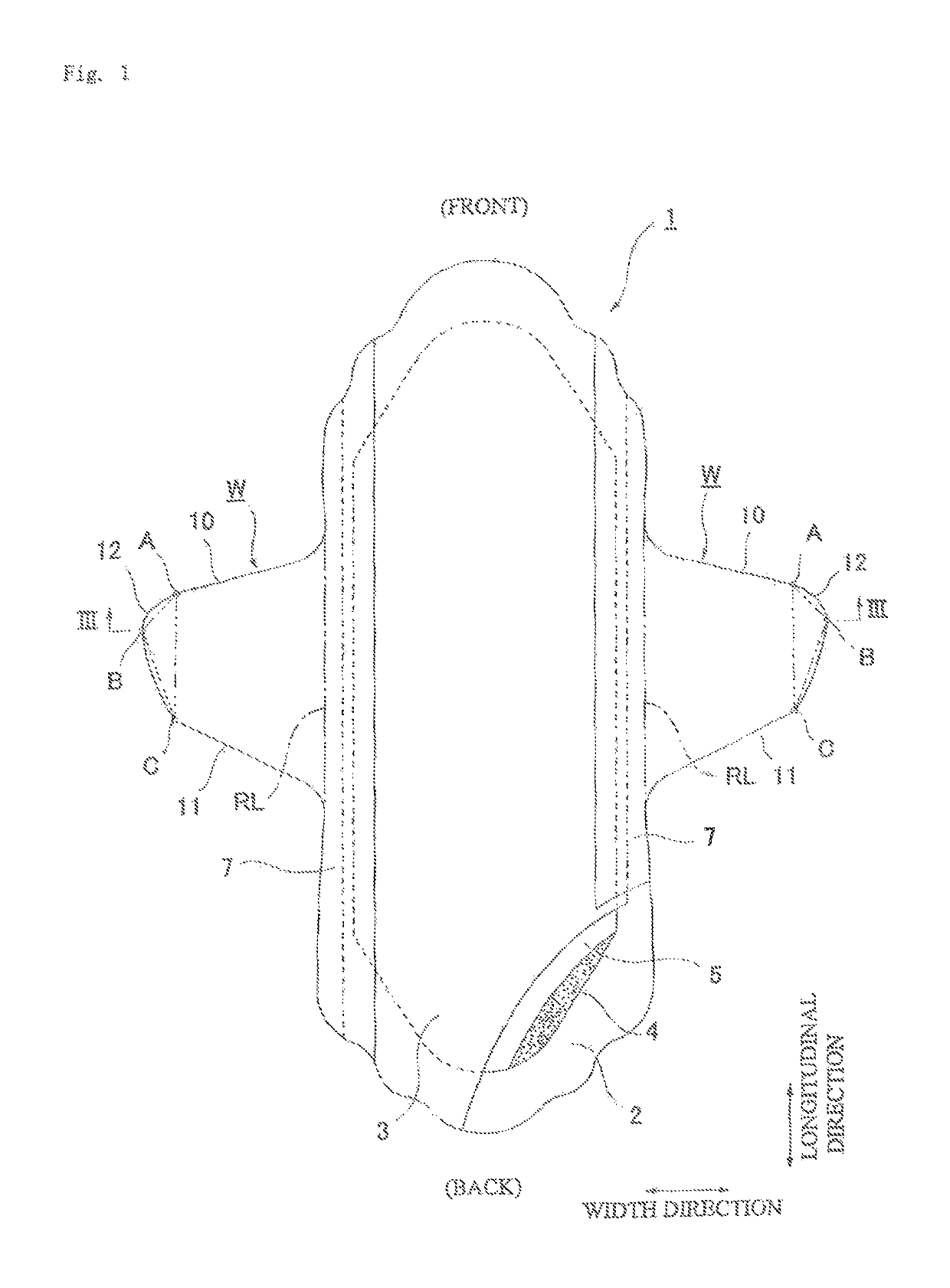

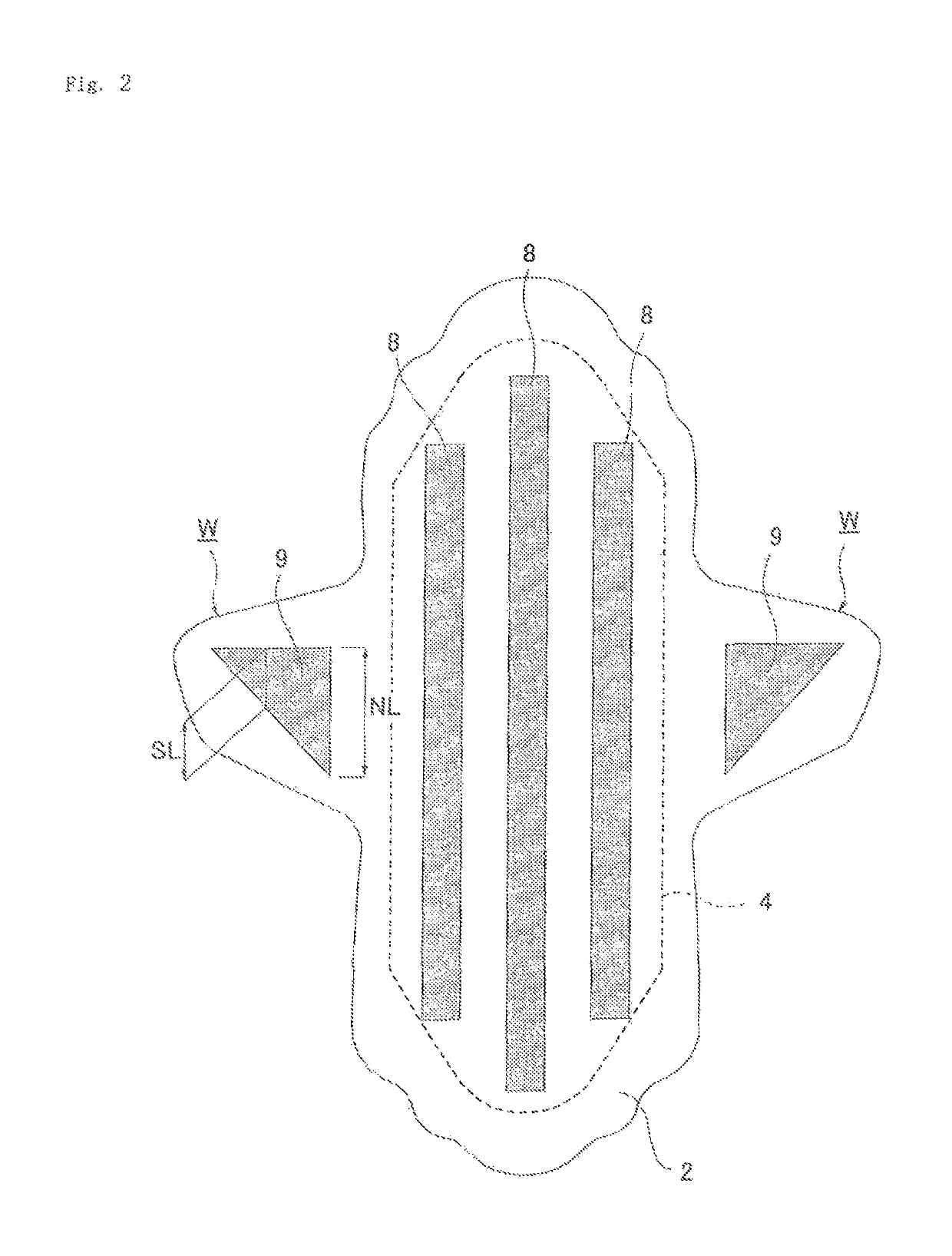

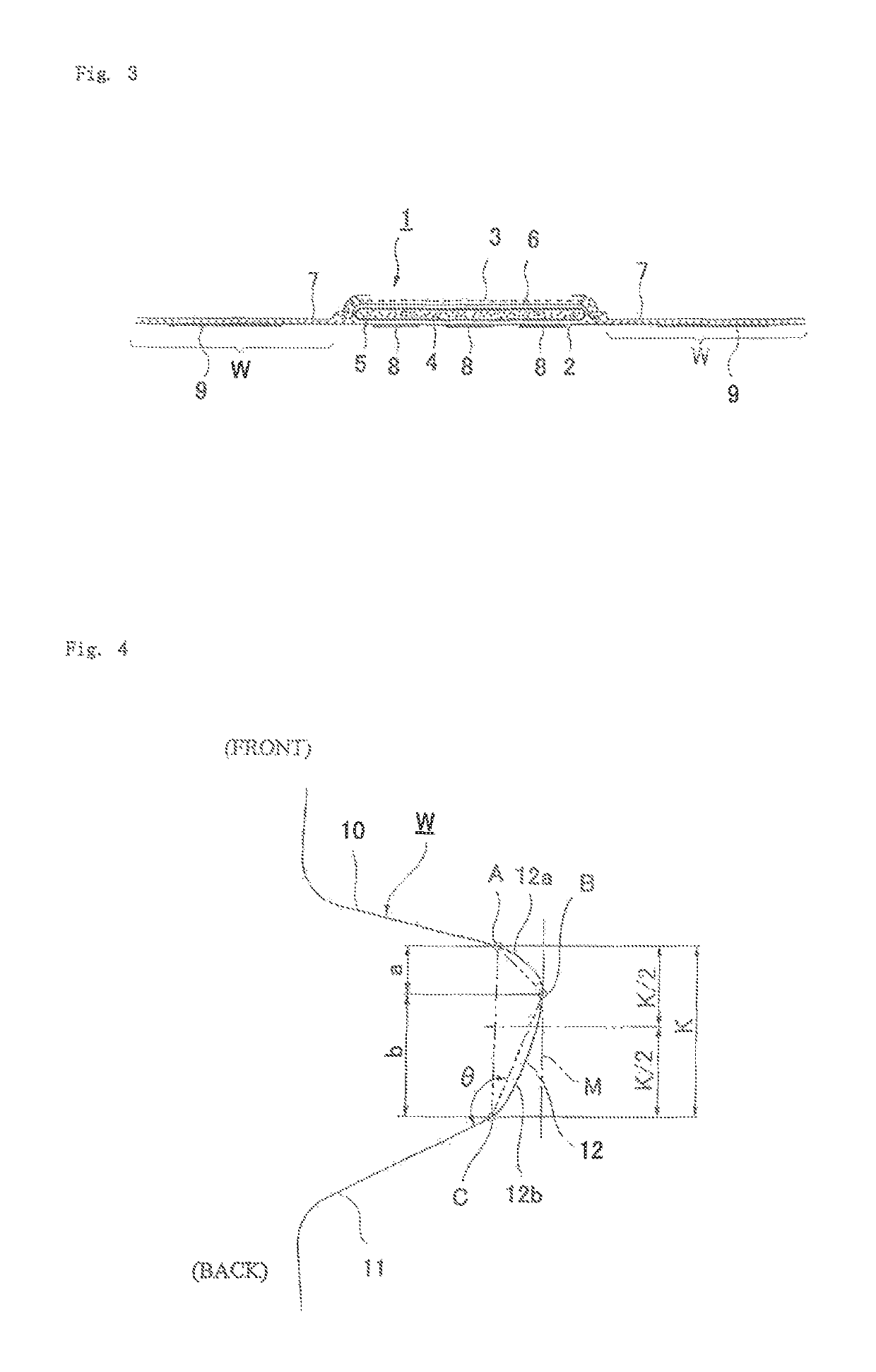

Absorbent article

ActiveUS20160361210A1Easily perform operationFixed securitySanitary towelsBandagesEngineeringMechanical engineering

Owner:DAIO PAPER CORP

Portable and adjustable wheel parking device

The invention relates to a portable and adjustable wheel parking device, which comprises side fixed supports, a front fixed support, a wheel front baffle, a left movable support, a right movable support, a fixed core shaft and a movable shaft, wherein the lower ends of the side fixed supports are detachably connected with the wheel front baffle, the front ends of the side fixed supports are detachably connected with the front fixed support, the fixed core shaft penetrates through a round pipe on the movable shaft, the movable shaft rotates freely around the fixed core shaft, the rear ends of the side fixed supports are detachably connected with the fixed core shaft, and the wheel front baffle, the left movable support and the right movable support form a cam structure to realize the locking and the loosening of a wheel. The portable and adjustable wheel parking device has the beneficial effects that 1, the structure is novel and practical, the demand for parking a motorcycle or an electric vehicle at different places, especially places with loose and soft soil can be met, and the motorcycle or the electric vehicle can be parked more stably and reliably; and 2, the portable and adjustable wheel parking device is suitable for clamping motorcycle wheels with different sizes and widths.

Owner:青岛东陆科技有限公司

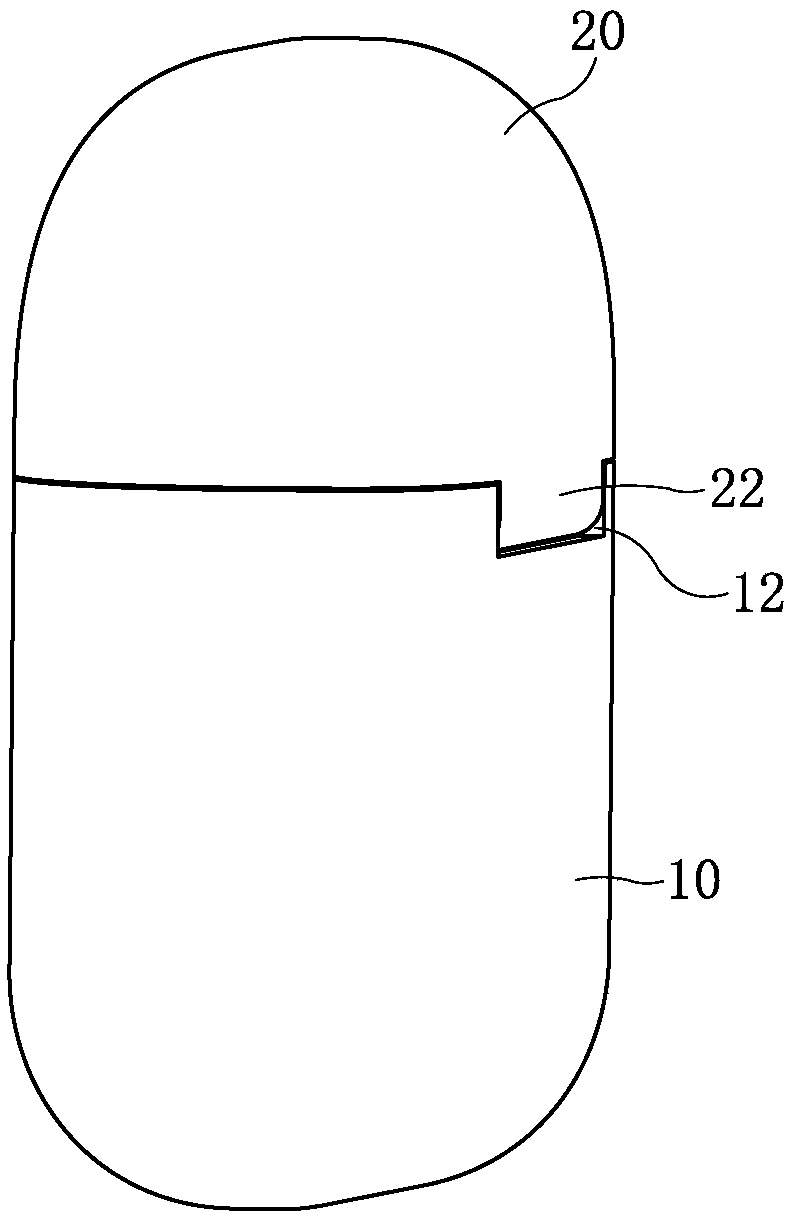

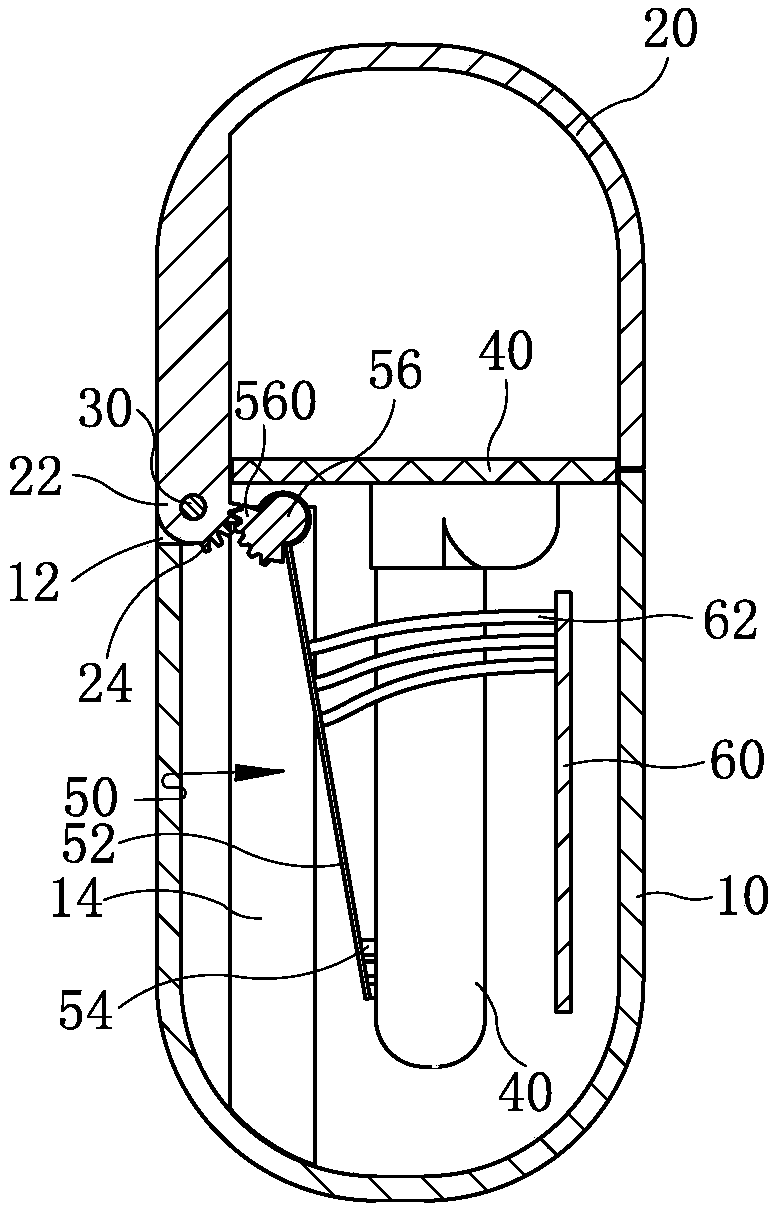

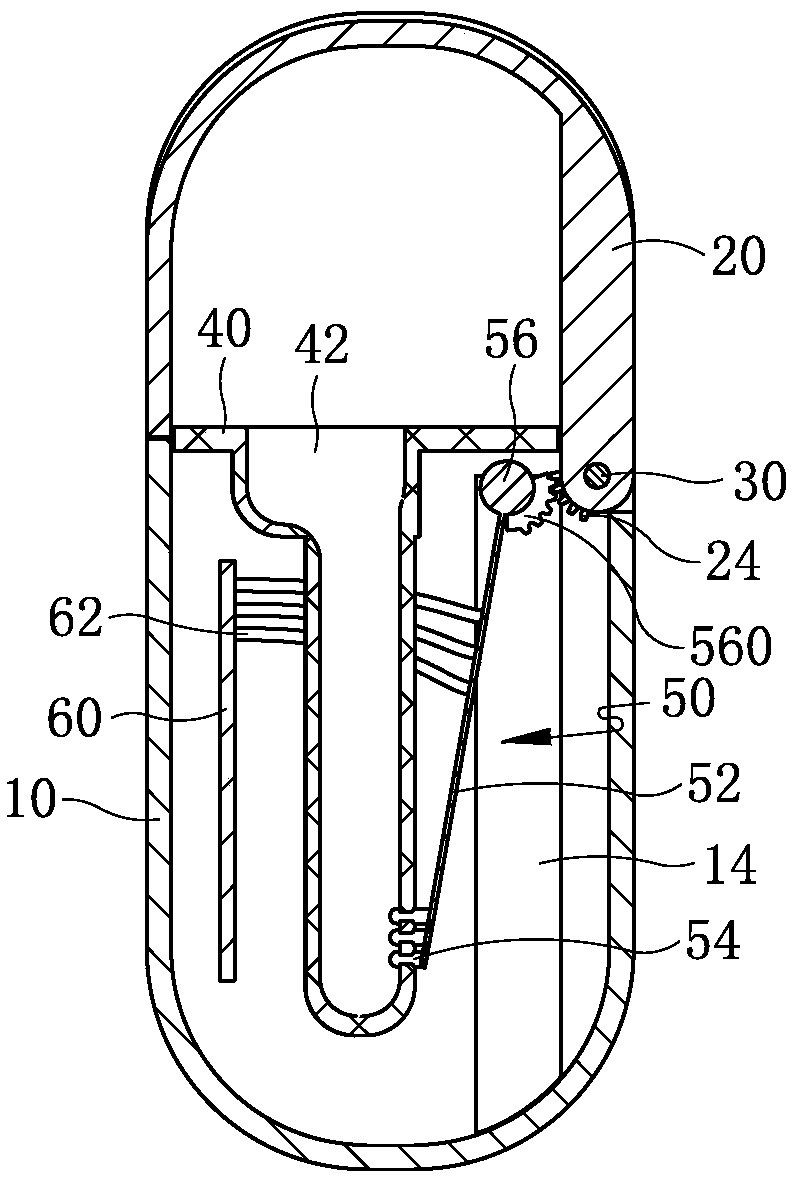

Earphone charging box

ActiveCN108882088AImplement updateRealize chargingMicrophonesLoudspeakersElectrical connectionEngineering

The invention discloses an earphone charging box and relates to the technical field of an electroacoustic product. The earphone charging box comprises a shell and a cover body which are hinged together by a hinged shaft; earphone accommodation cavities are formed in the shell; contact through holes are formed at positions on the side walls of the earphone accommodation cavities, which correspond to contacts of an earphone; a first rotation part is arranged at a position where the cover body and the shell are hinged; a spring plate component is mounted in the shell; one end of the spring platecomponent is rotationally mounted in the shell by a rotating shaft; a second rotation part in transmission connection with the first rotation part is arranged on the rotating shaft; and electrical connection contacts which can be removed from and inserted into the contact through holes when the cover body is opened and closed are formed at the other end of the spring plate component. According tothe earphone charging box disclosed by the invention, when the earphone is put into or taken out, the surface of the earphone cannot be damaged, the earphone also cannot be clamped and the earphone issmooth to plug and pull.

Owner:GEER INTELLIGENT TECH CO LTD

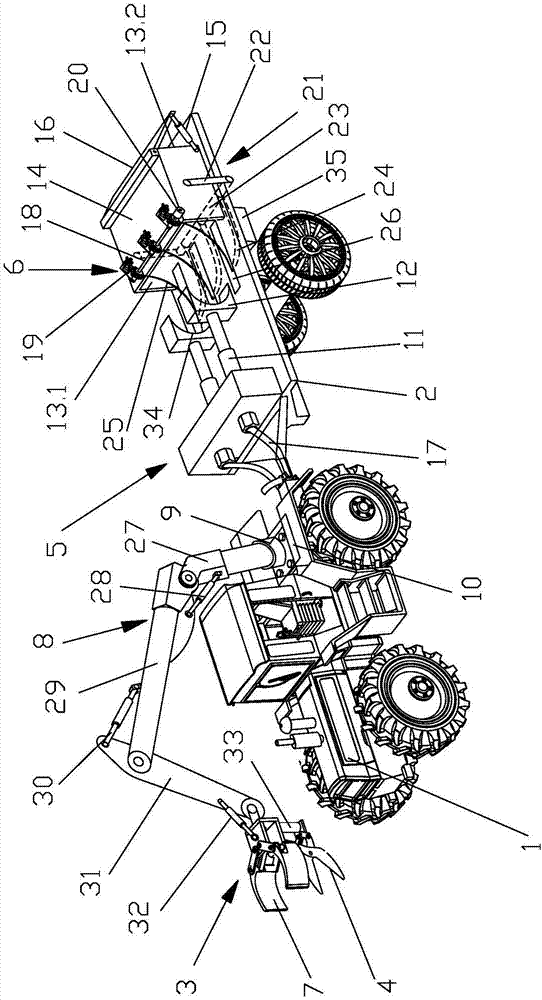

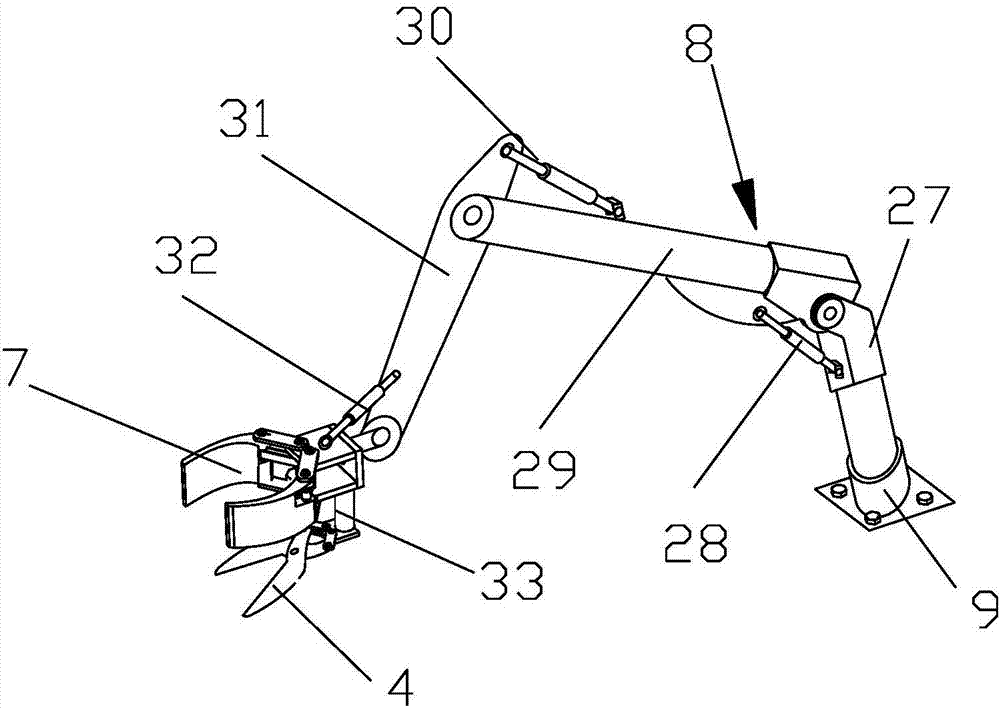

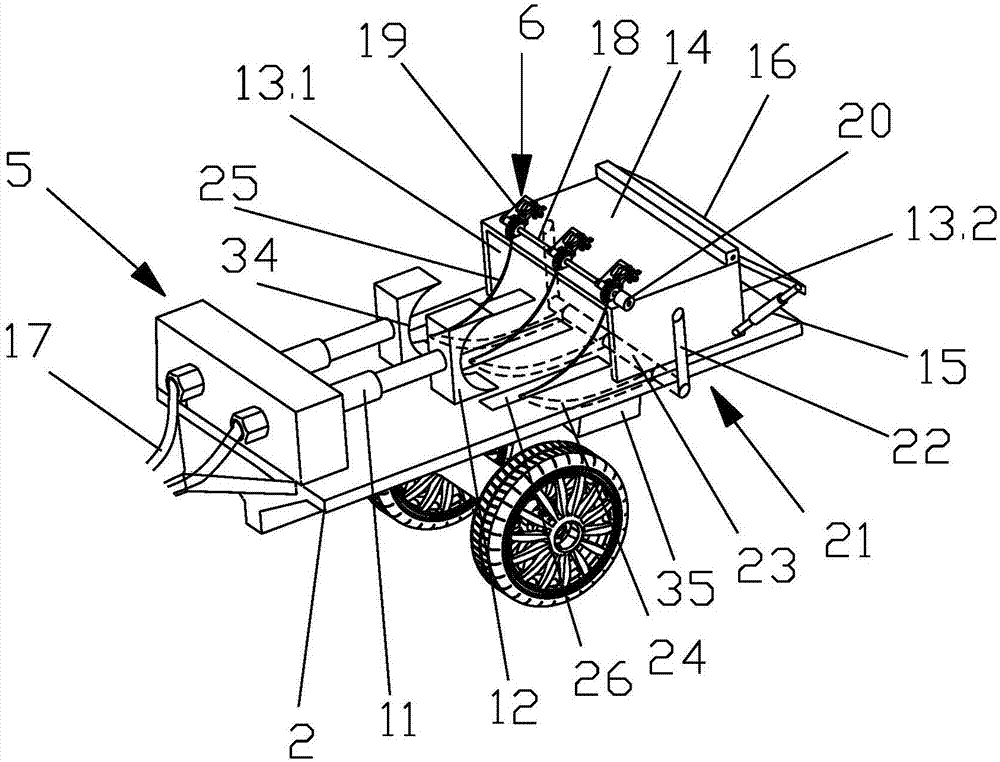

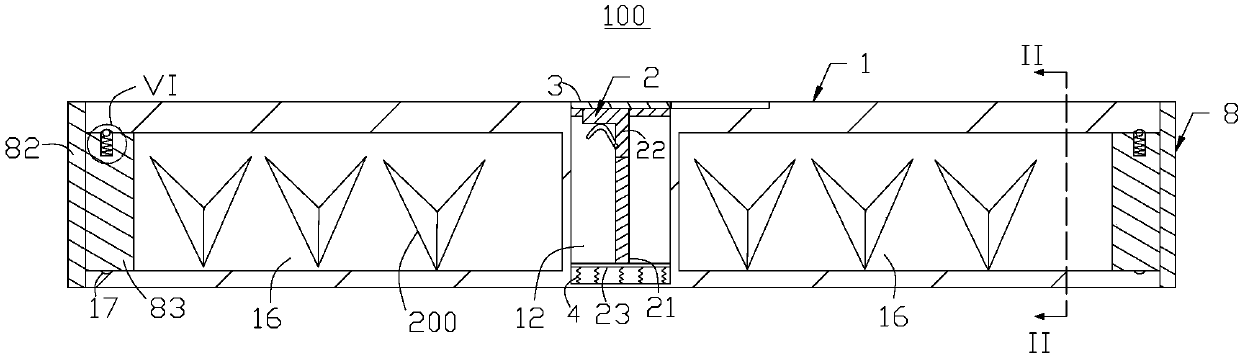

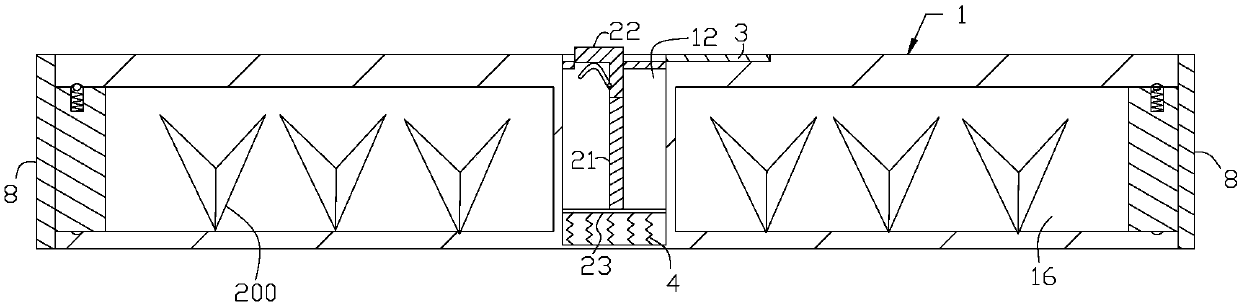

Agricultural and forestry waste picking and bundling device

PendingCN107027434AHigh densityFlexible transportLoadersCrop conditionersAgricultural scienceAgricultural engineering

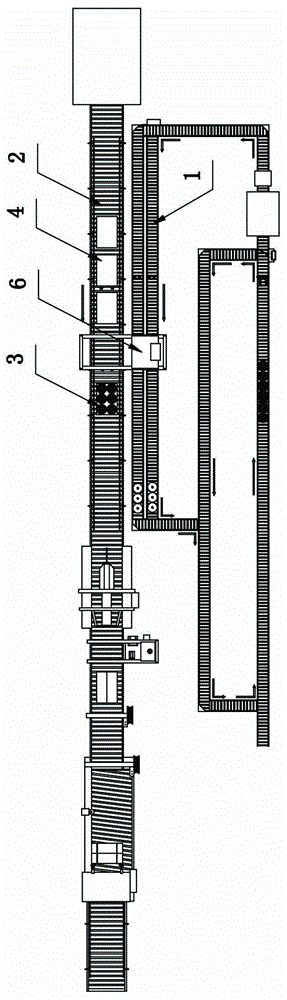

The invention discloses an agricultural and forestry waste picking and bundling device. The device is installed on a tractor and used for picking and bundling agricultural and forestry waste. A frame is connected with the tail portion of the tractor in a hung mode. The device comprises a picking mechanism, a harvesting mechanism, a hydraulic compression mechanism and a bundling mechanism. The picking mechanism comprises a hydraulic grasper and a mechanical arm assembly used for driving the hydraulic grasper to move up and down and rotate circumferentially, and the mechanical arm assembly is installed on a rear axle of the tractor. The harvesting mechanism is arranged under the hydraulic grasper and fixedly connected with the hydraulic grasper. The tractor provides work and traction power for the agricultural and forestry waste picking and bundling device, and the device is flexible in transfer and work, can adapt to mountain work, greatly increases the density of biomass fuel in the transport state, improves transport efficiency, and reduces the transport cost.

Owner:格薪源生物质燃料有限公司

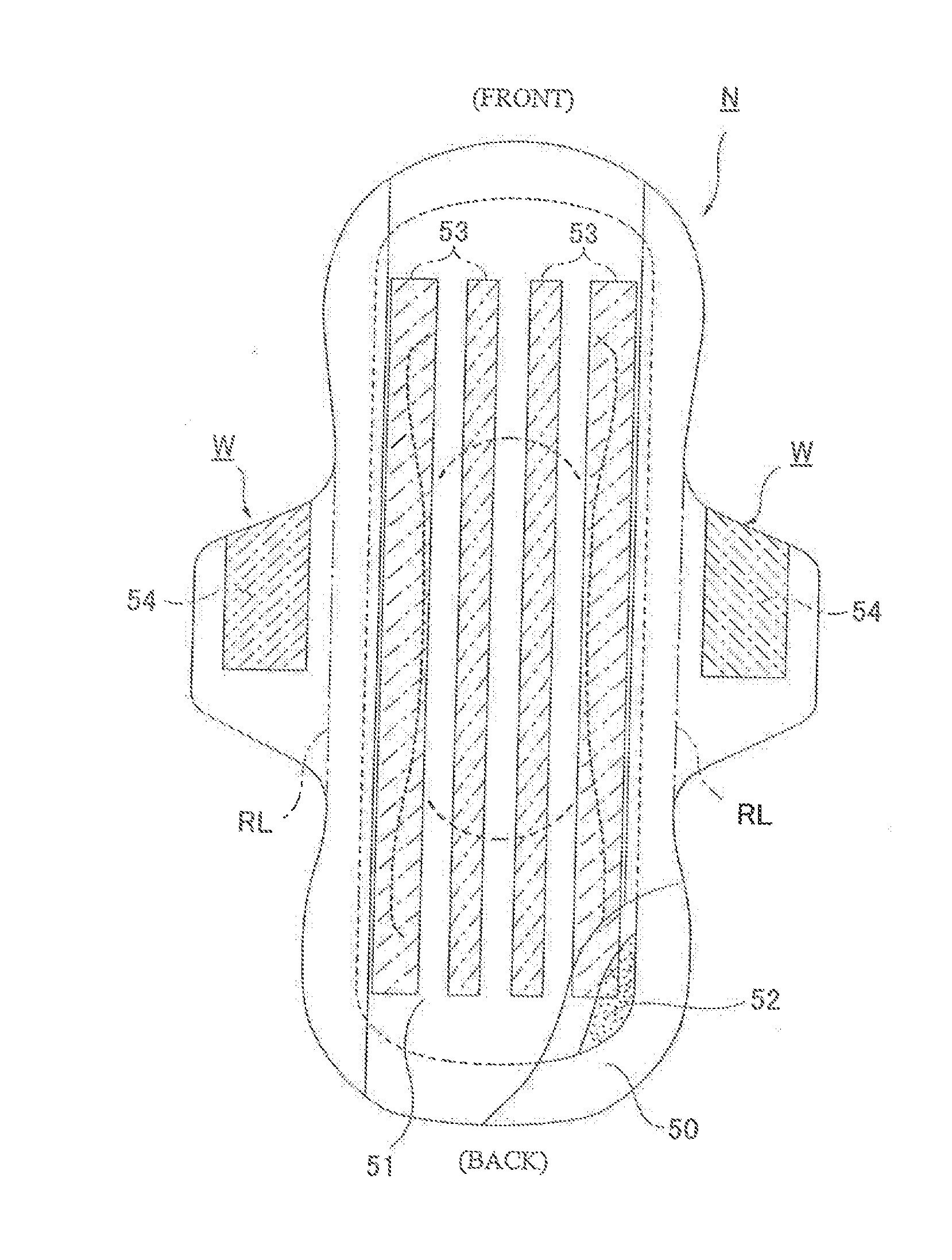

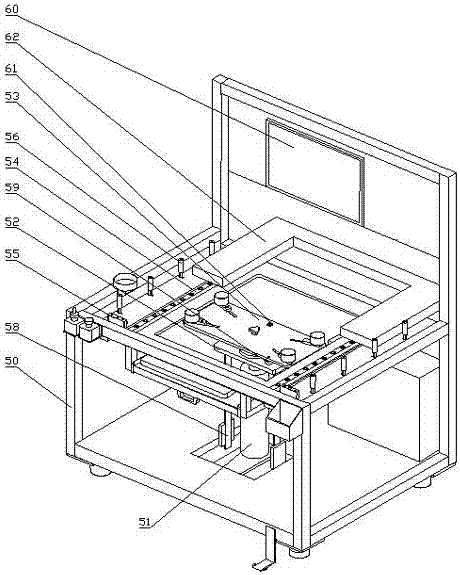

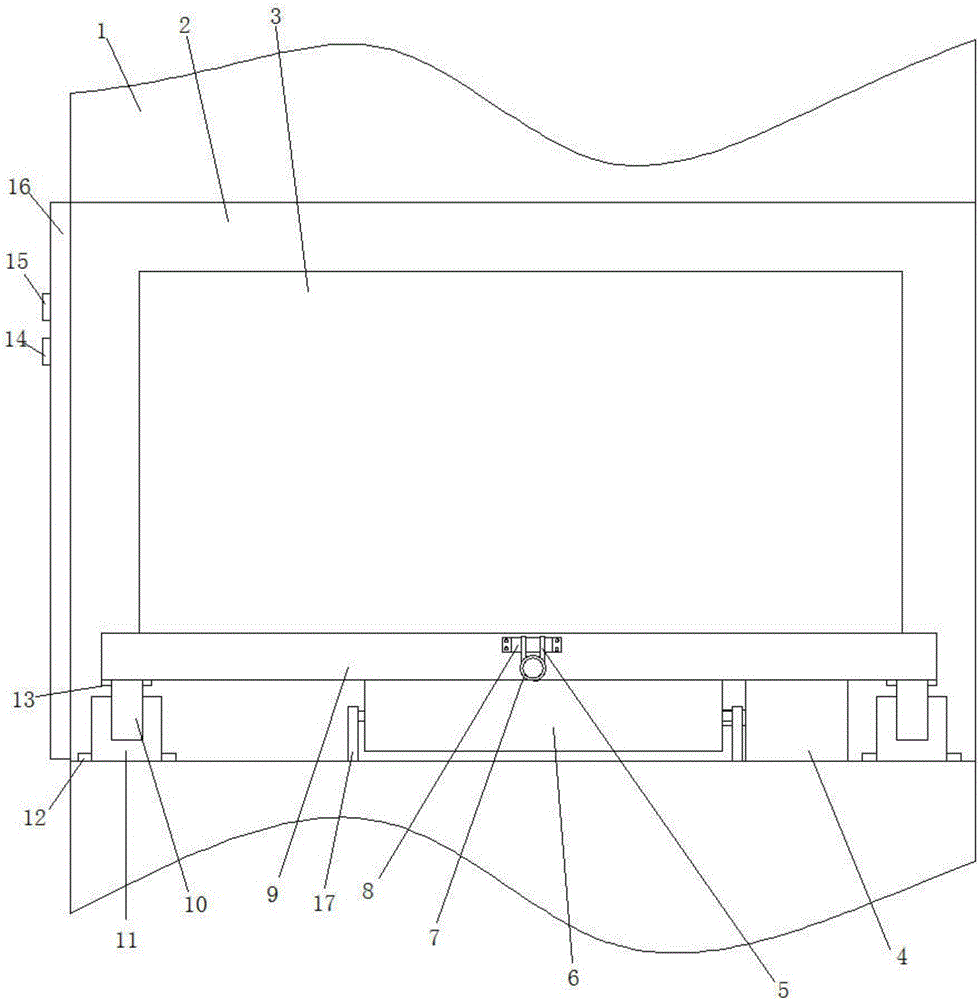

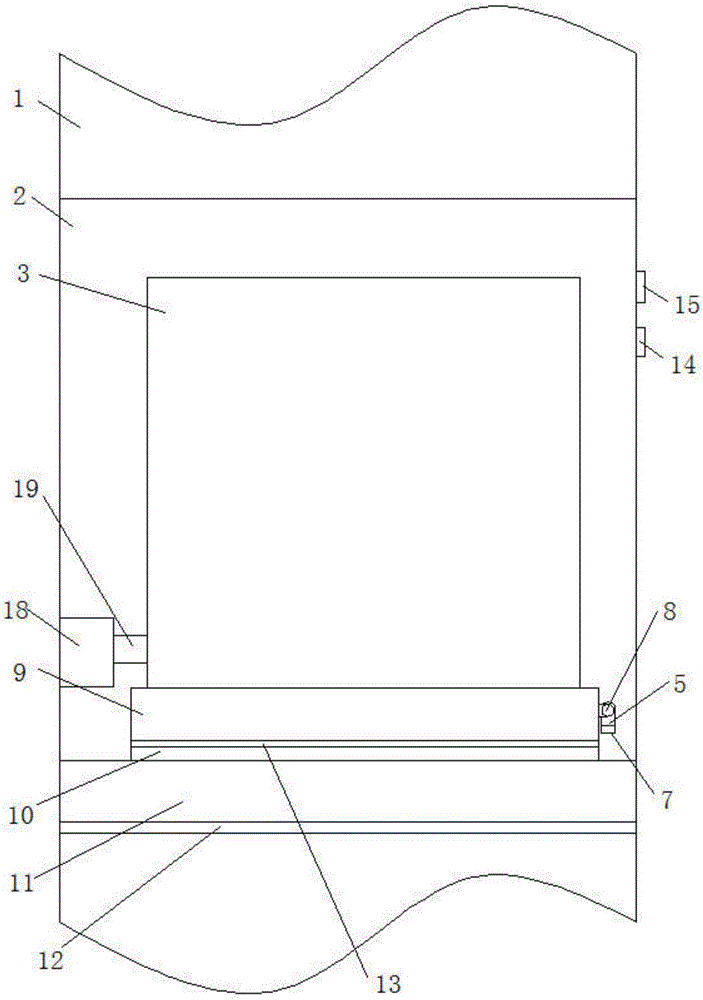

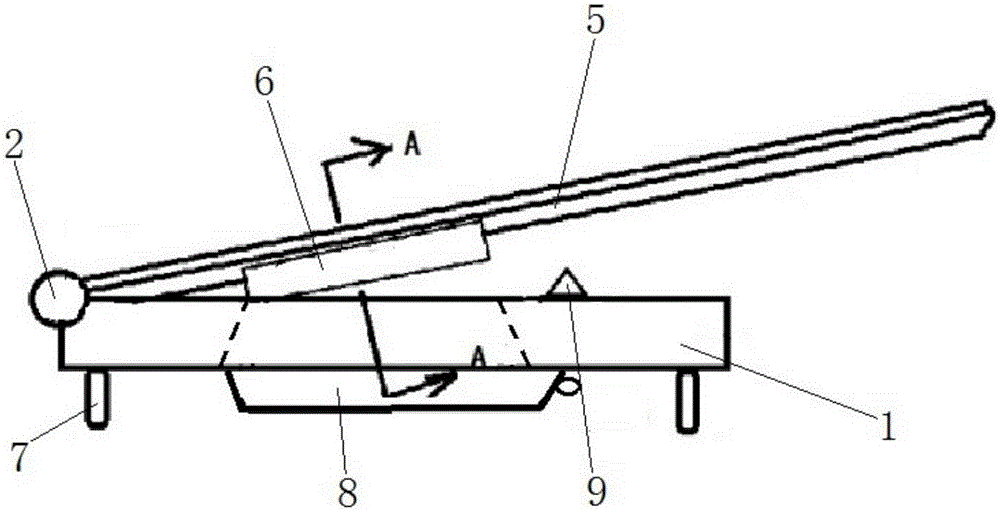

Vehicle skylight glass curvature detection platform

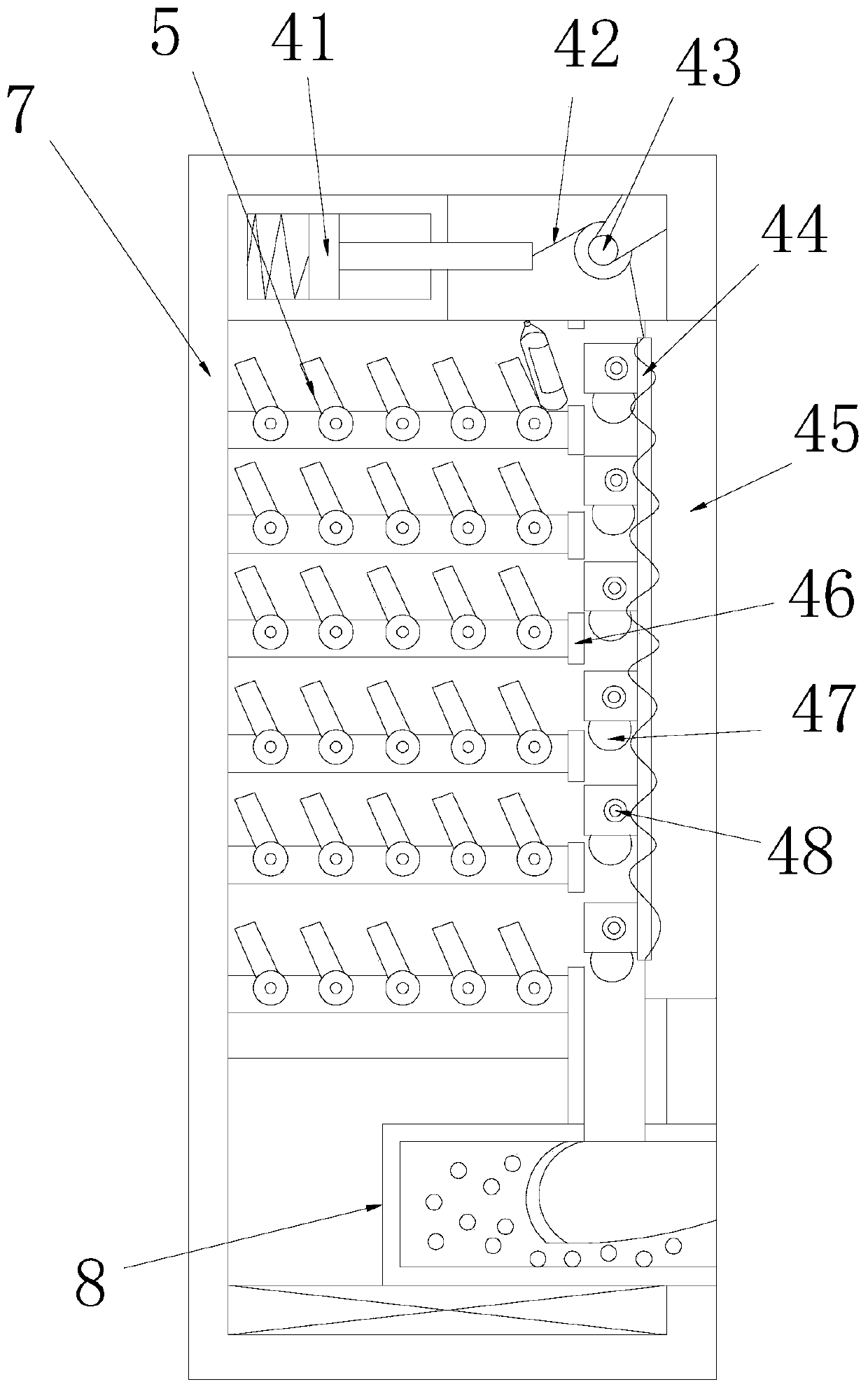

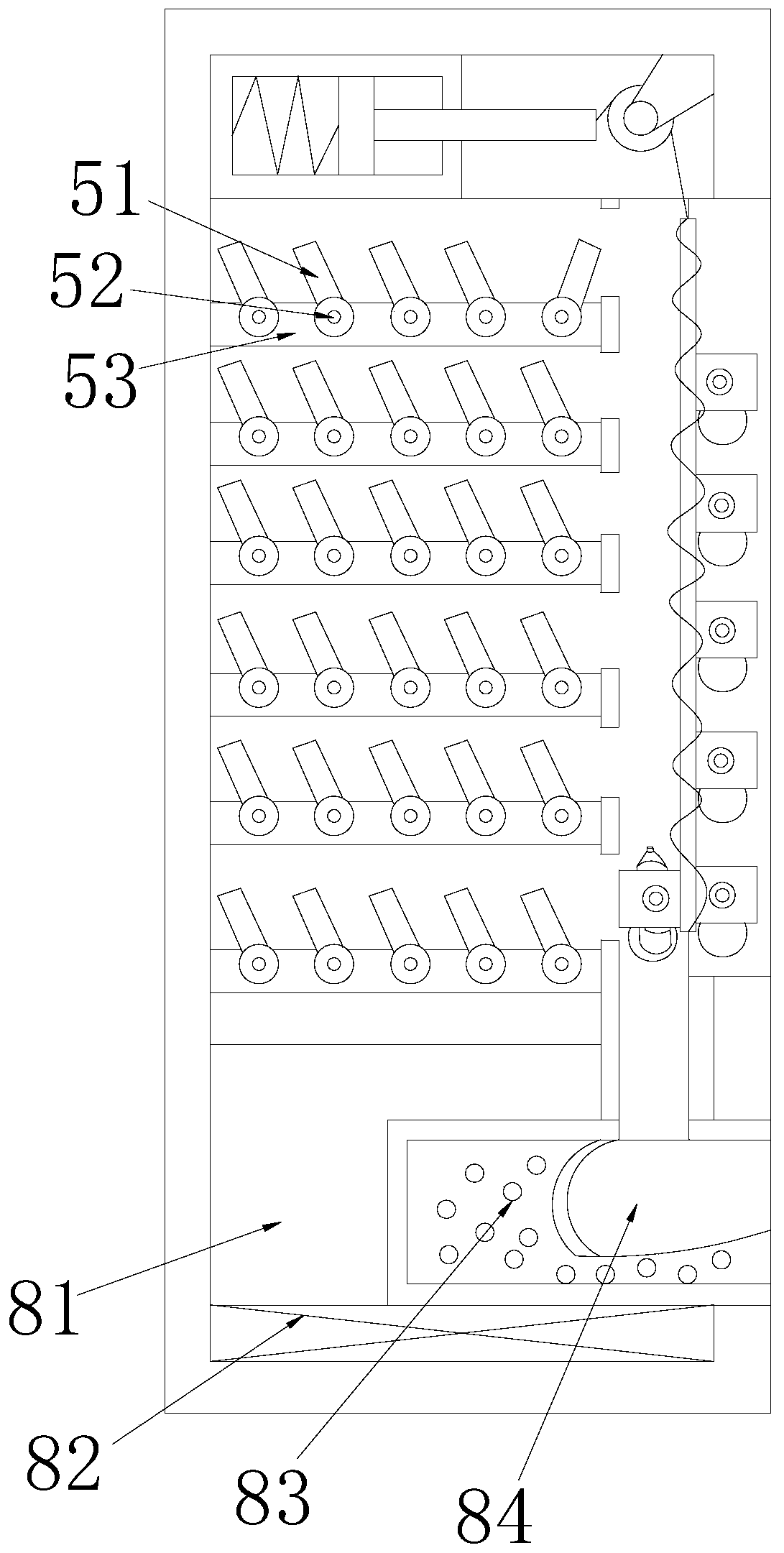

PendingCN107063164AQuick and easy accessPut in smoothlyMechanical measuring arrangementsEngineeringSkylight

A vehicle skylight glass curvature detection platform comprises a rack body (50), a glass support device and a detection tool location device. The glass support device comprises a support cylinder (51), a detection rotary table (52), a glass supporting plate (53) and a rotary locking cylinder (59). The detection tool location device comprises a pair of universal ball raceways (54), one ends of the universal ball raceways (54) are provided with stop blocks (55), the universal ball raceways (54) are installed on the rack body (50) and located at two sides of the glass support device, and one sides of the universal ball raceways (54) are respectively provided with a set of guide rollers (56). According to the vehicle skylight glass curvature detection platform, the detection tool can be stably put at the bottom portion of the glass, the detection value is accurate, the glass taking and putting are simple and rapid, and the vehicle skylight glass curvature detection platform has good practical values.

Owner:秀卓自动化设备(湖北)有限公司

Directional hydraulic centralized exploding device for improving gas permeability of coal seam

The invention discloses a directional hydraulic centralized exploding device for improving the gas permeability of a coal seam, and relates to the technical field of coal seam permeability improvement. The directional hydraulic centralized exploding device for improving the gas permeability of the coal seam comprises a directional exploding tube, wherein the two ends of the directional exploding tube are sealed by cover plates; a plurality of energy release holes are formed in the outer circumferential surface of the directional exploding tube at intervals; the energy release holes are communicated with the inner cavity of the directional exploding tube; the inner cavity of the directional exploding tube is filled with explosive rolls and detonators; the outer circumferential surface of the directional exploding tube is coated with a high-pressure plastic thin film; the energy release holes are covered by the high-pressure plastic thin film; the top end of the directional exploding tube is connected with a first plugging assembly for plugging a blast hole during explosion so as to prevent explosion fragments from being upwardly ejected along the blast hole. Through coupling of explosion gas and water which is left in the blast hole and the coal seam after a hydraulic fracturing operation, the directional hydraulic centralized exploding device can greatly improve the development degree of a fracture in the coal seam; in addition, the blast hole of the directional hydraulic centralized exploding device is not required to be filled with a yellow clay roll before explosion, so that the directional hydraulic centralized exploding device is very convenient to operate.

Owner:HUNAN INST OF TECH

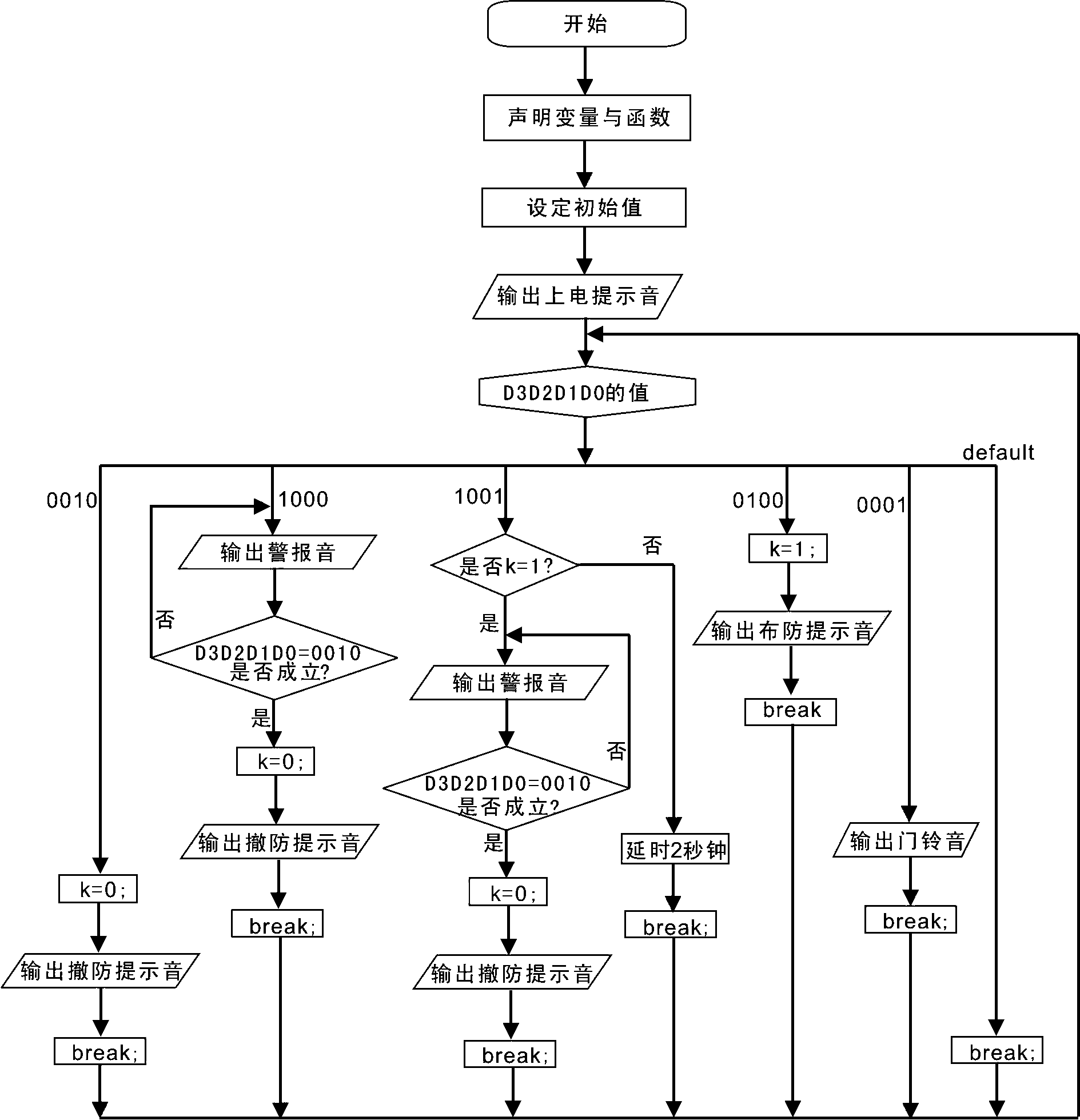

Wireless remote control 626 alarm

InactiveCN103366476AReduce volumeSimple structureTransmission systemsElectric/electromagnetic audible signallingMicrocomputerMicrocontroller

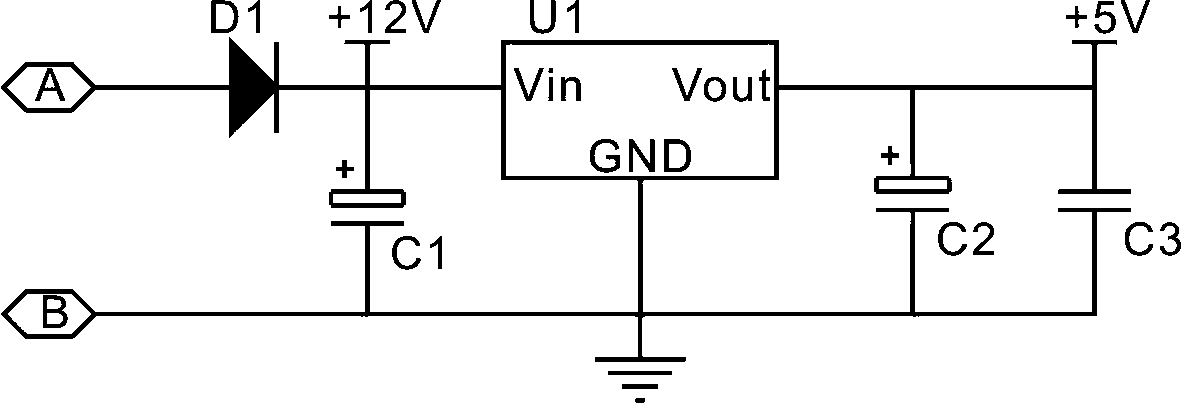

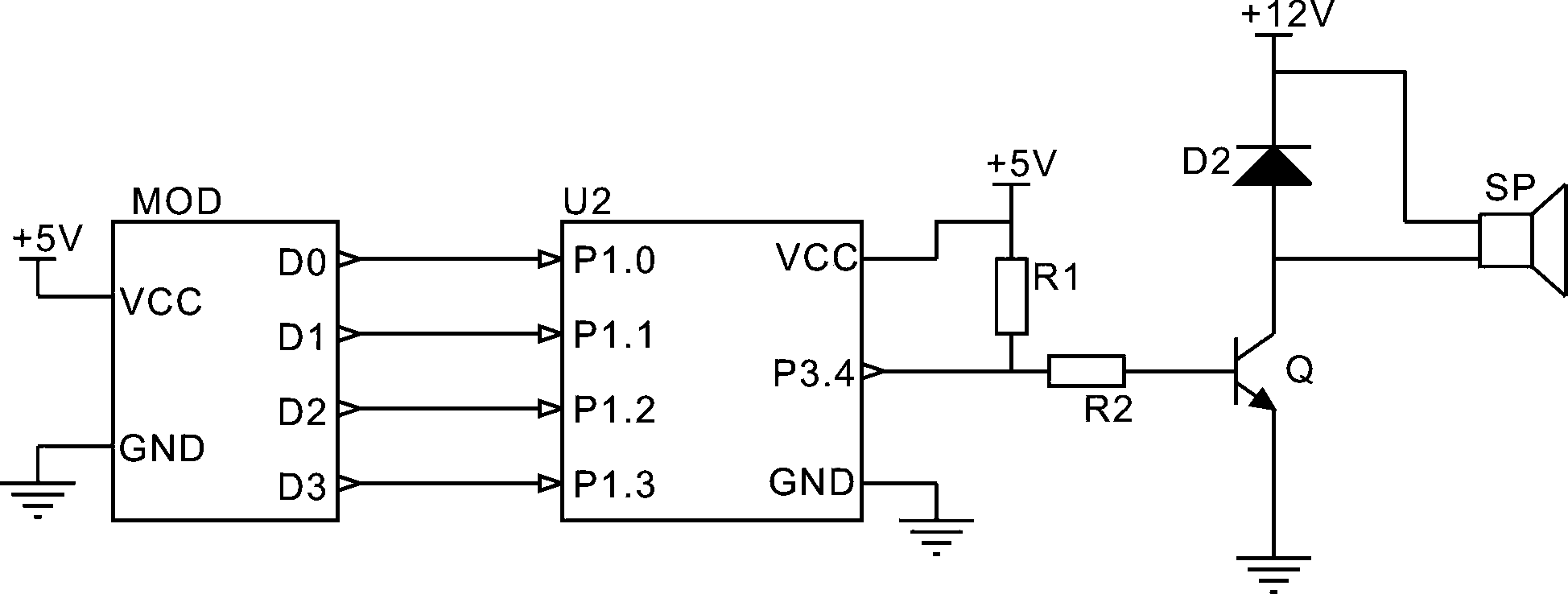

The invention relates to a wireless remote control 626 alarm which can be matched with a wireless remote controller and a wireless detector for use by matching codes. A horn is used as an electroacoustic converting device, and wireless alarm host circuits composed of a power supply circuit, a wireless receiving decoding circuit, a single chip microcomputer control circuit and a horn driving circuit are all integrated into a hollow cavity in the horn. The wireless alarm host circuits are connected with an external direct-current power supply only through one power supply line. The wireless remote control 626 alarm is used through single chip microcomputer programming and is matched with the wireless remote controller and the wireless detector for use. The wireless remote control 626 alarm can have any one function or any two functions or all of three functions including a high-volume wireless doorbell function, a wireless remote-control alarm function and a wireless remote-control alarm function.

Owner:郑玉龙

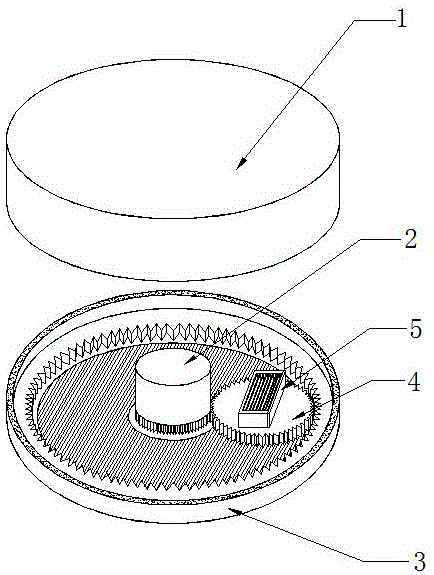

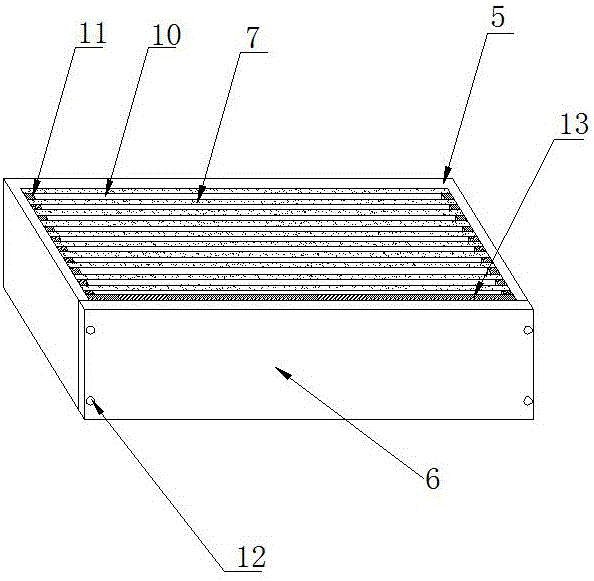

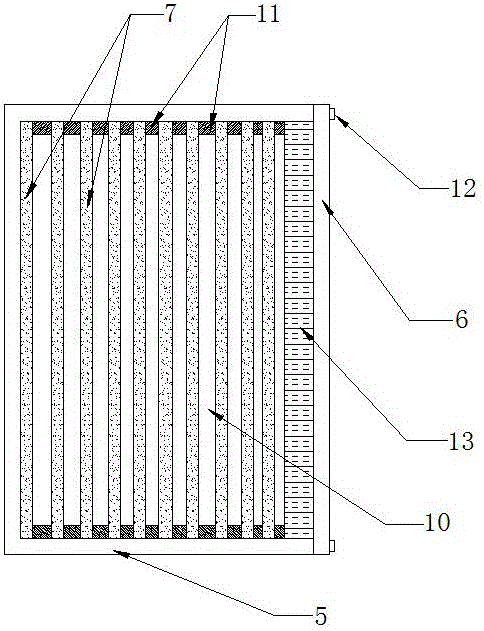

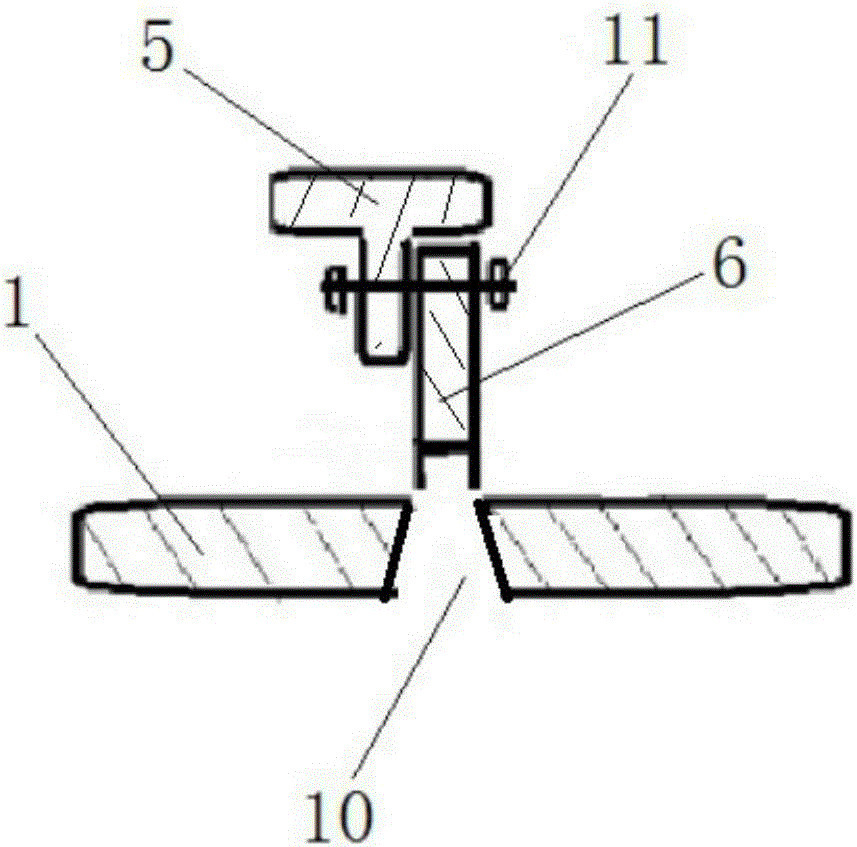

Polishing device for side surface of mobile phone glass

InactiveCN105965344ASave electricityAvoid scratchesEdge grinding machinesGrinding drivesMobile phoneCushion

The invention discloses a polishing device for a side surface of mobile phone glass. The polishing device comprises a grinding head, a rotating shaft, a rotary disc, an epicyclic gear and a loading box, wherein the rotating shaft is mounted in the central position of the rotary disc; sawtooth structures which mesh with the epicyclic gear are arranged on the inner edge of the rotary disc and the outer side of the rotating shaft; the loading box is arranged on the epicyclic gear; three side surfaces and the bottom surface of the loading box are fixed connection structures; the other side surface of the loading box is a movable fixing panel; tooth grooves with uniform intervals are formed in the bottom of the loading box; rubber spacers are arranged at the tops of the tooth grooves; grilles are arranged in the tooth grooves; glass placing grooves are formed between the grilles; and vertical rubber cushion blocks having the same width with the glass placing grooves are arranged at the two ends of the glass placing grooves. On the whole, the polishing device has the advantages that the production efficiency is high, the fixation is firm, and the polishing effect is good, and the phenomenon that the mobile phone glass is broken and scratched during the polishing process can be avoided.

Owner:HENAN COMYOUNG ELECTRONICS

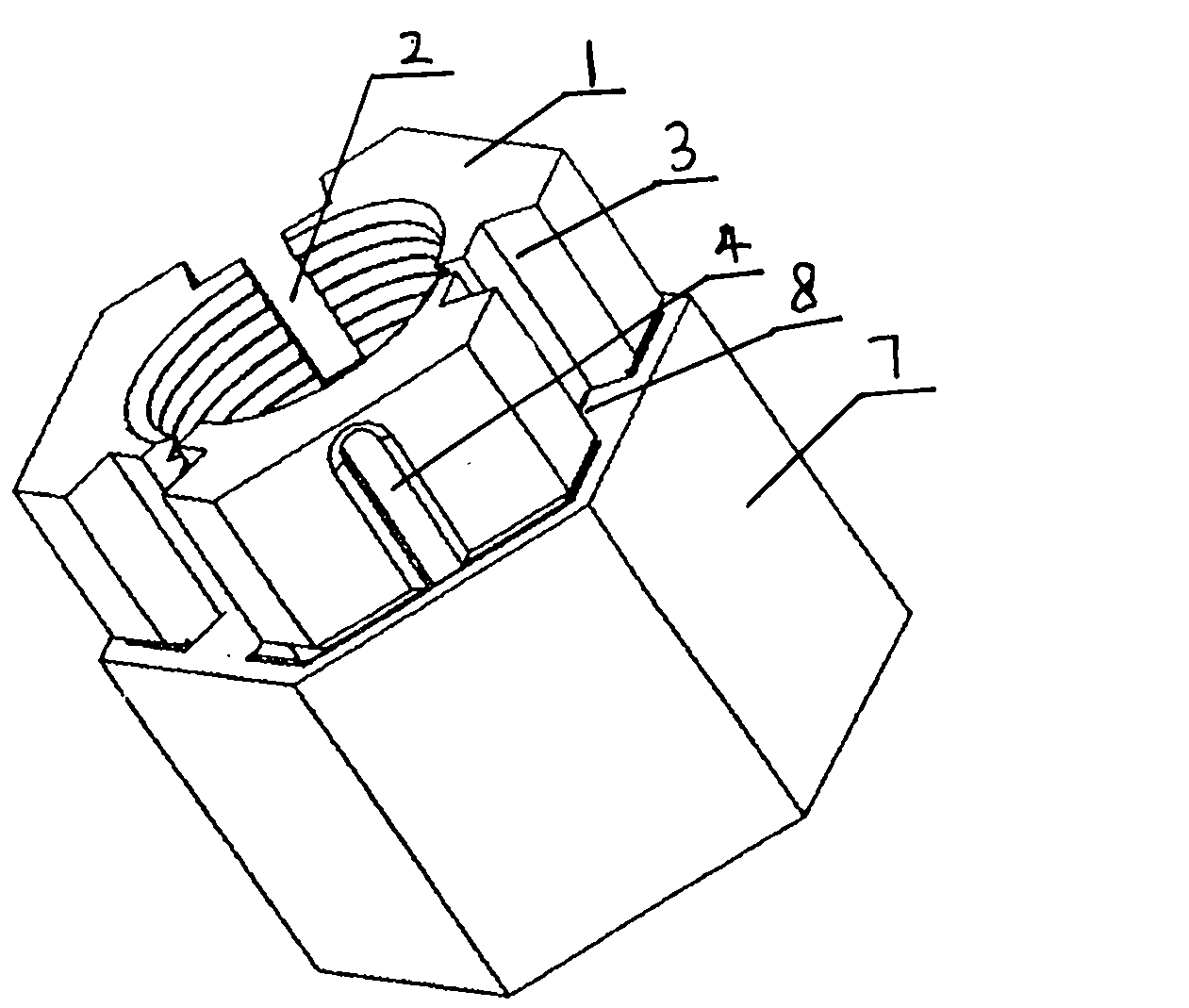

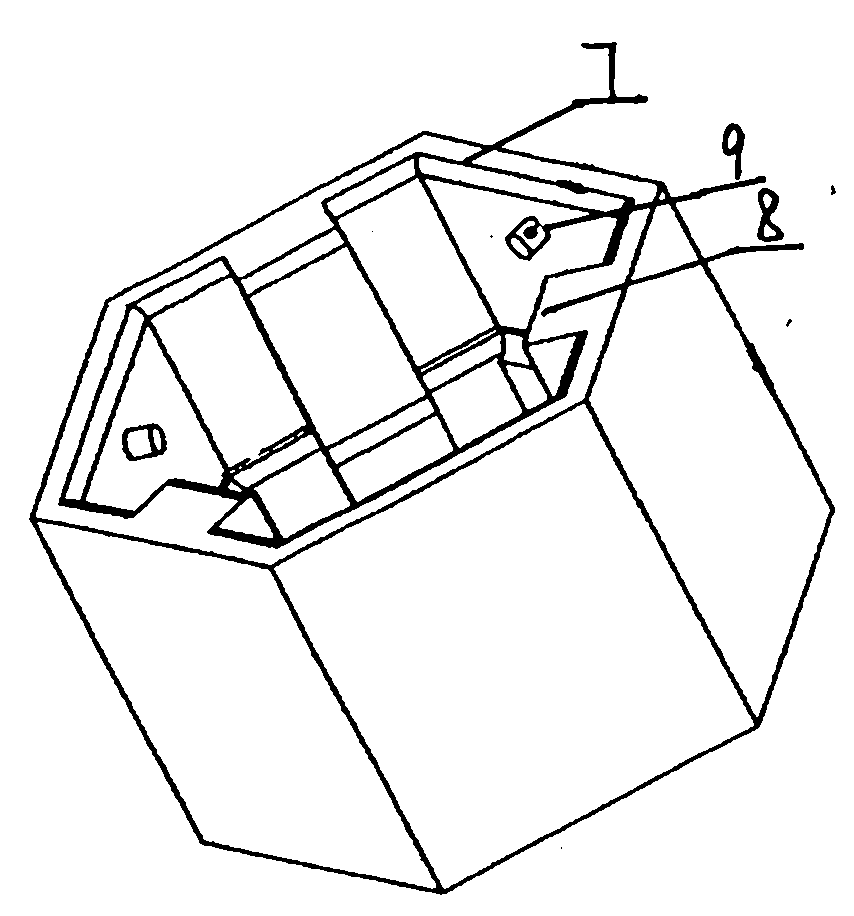

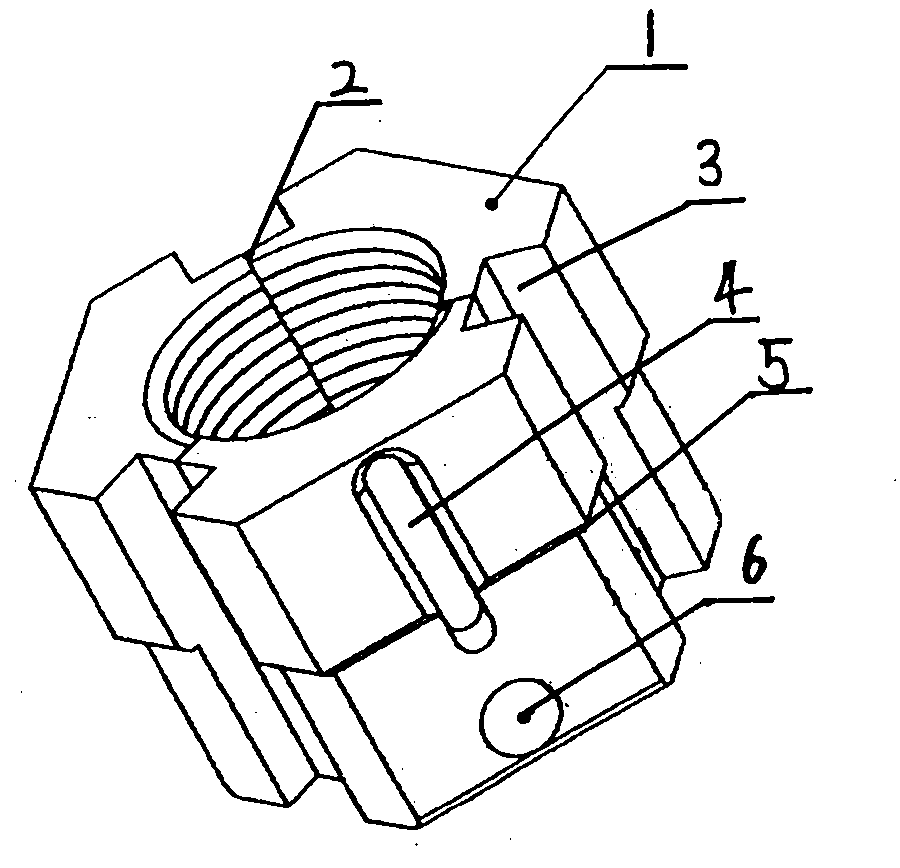

Quick detachable nut

The invention relates to a nut, in particular to a quick detachable nut, which comprises a nut and is characterized in that the middle parts of three spaced prismatic faces of the nut are respectively provided with a vertical fracture; both sides of the fracture at the outer side of the nut are respectively provided with a groove; the upper parts of the outer sides of the rest of three prismatic faces of the nut are respectively provided with a vertical trough; the middle parts of the outer sides of the rest of three prismatic faces of the nut are respectively provided with a step facing the inner side; the transversal middle positions of the lower parts of the outer sides of the rest of three prismatic faces of the nut are respectively and internally provided with a magnet; the outer side of the nut is provided with a nut jacket matched with the nut; and the corresponding faces of the inner side of the nut jacket are respectively provided with lugs which correspond to the fractures and locating pins which correspond to the troughs. Therefore, the quick detachable nut has a simple structure, convenience in use and rapidness in detachment.

Owner:张瑜

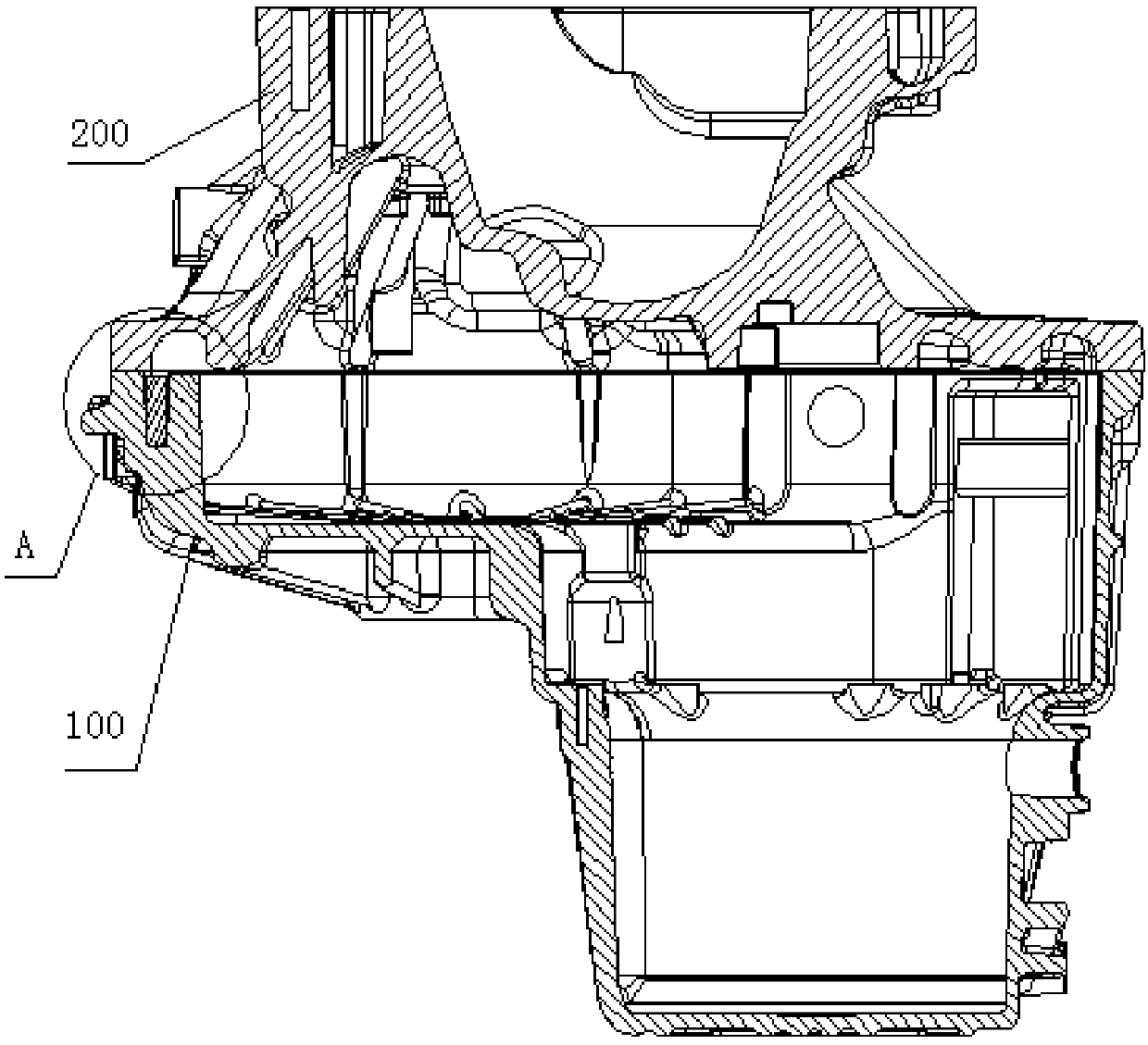

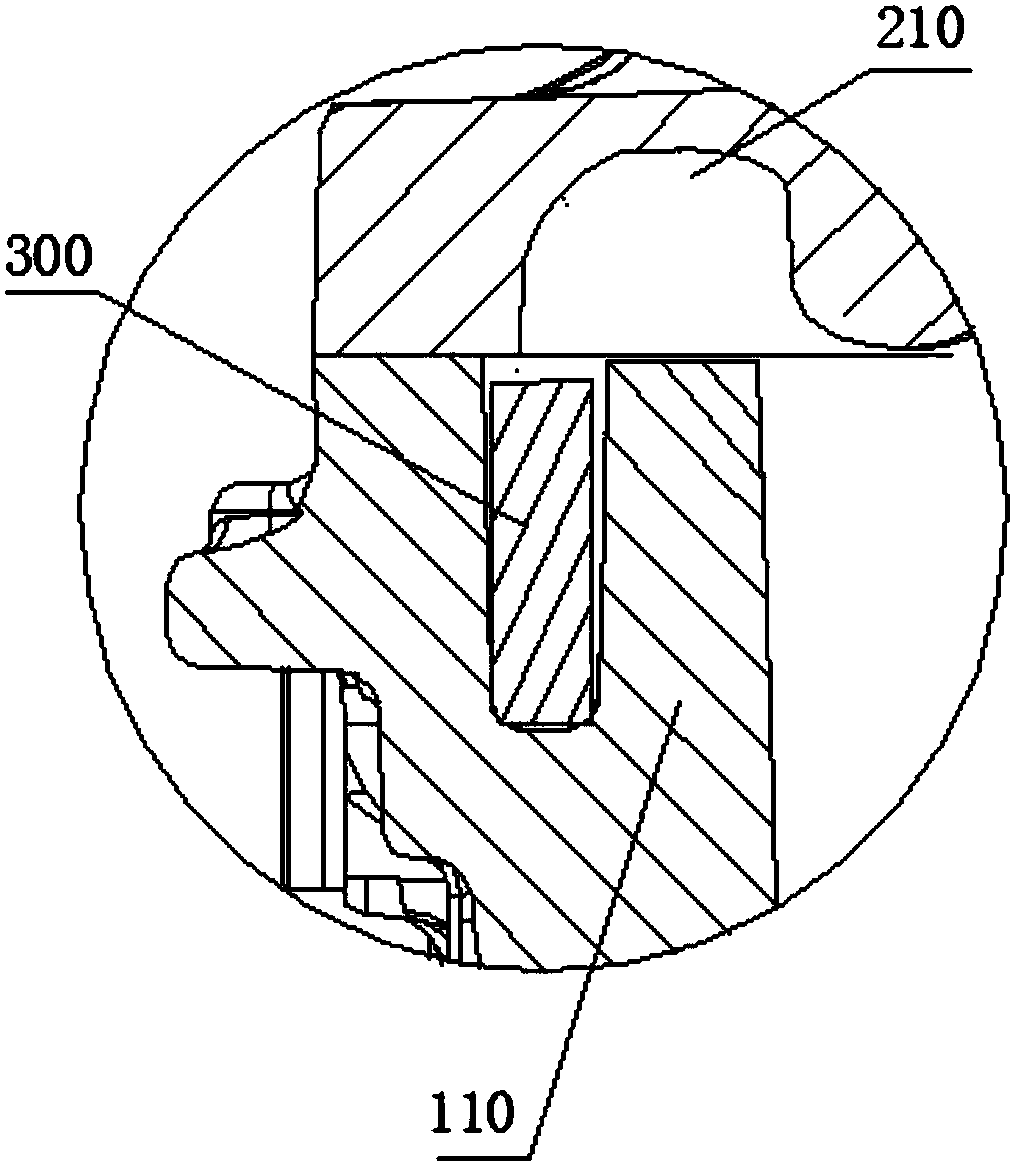

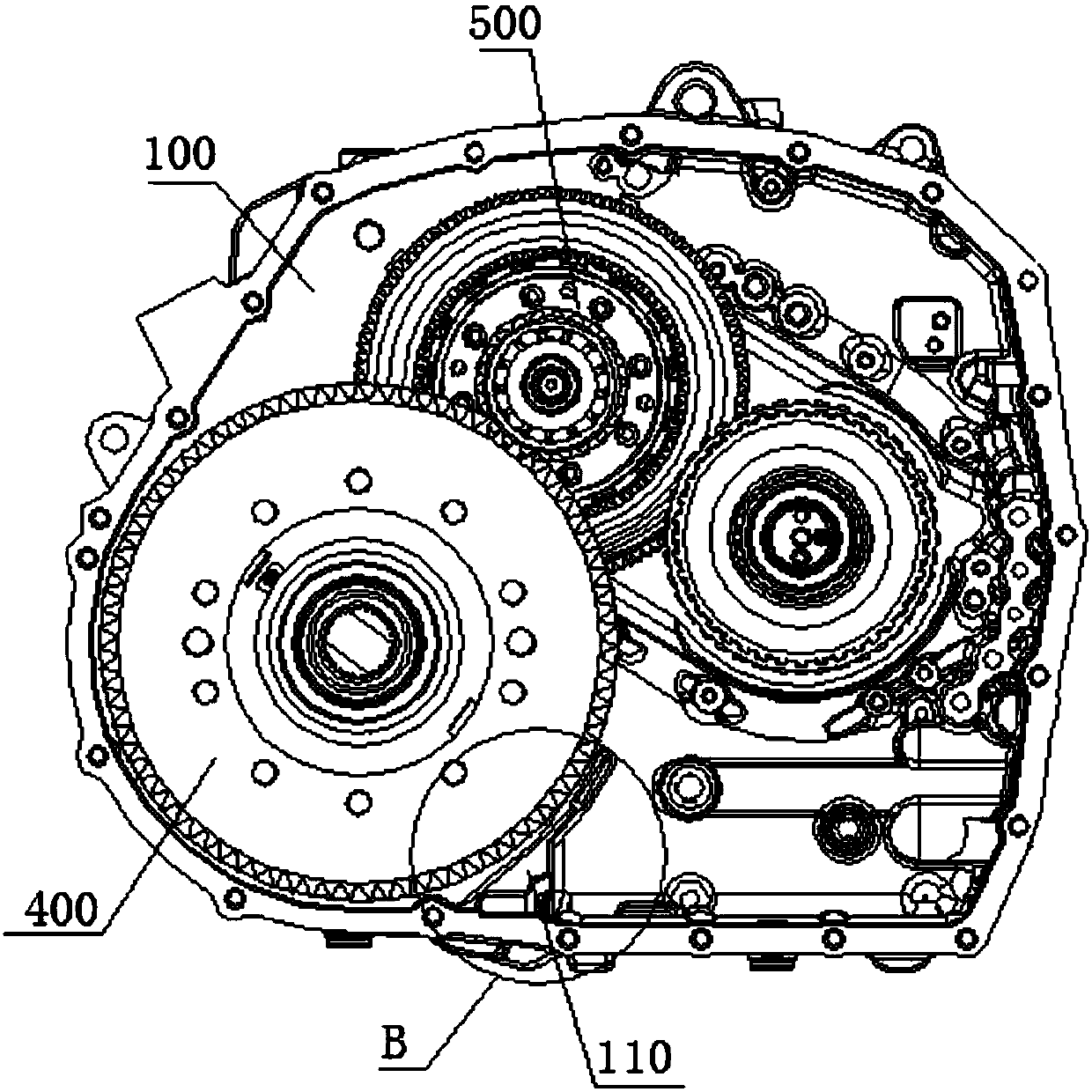

Transmission and automobile

The invention relates to the technical field of transmission devices, in particular to a transmission and an automobile. The above transmission comprises a main shell, a torque converter shell and a magnet. A protruding part is arranged on the main shell. The protruding part is located on the peripheral side of a transmission gear and is located below the oil level of working oil in the main shell. An opening formed in the protruding part faces a containing groove of the torque converter shell, the magnet is clamped in the containing groove, and the side, facing the torque converter shell, ofthe magnet abuts against the torque converter shell. The above automobile comprises the above transmission. By means of the above transmission and the above automobile, iron chip in the working oil inthe shell can be attracted, and damage to other parts having high requirement for cleanliness of iron chip is reduced.

Owner:SHENGRUI TRANSMISSION

Switch cabinet circuit breaker entrance and exit control mechanism

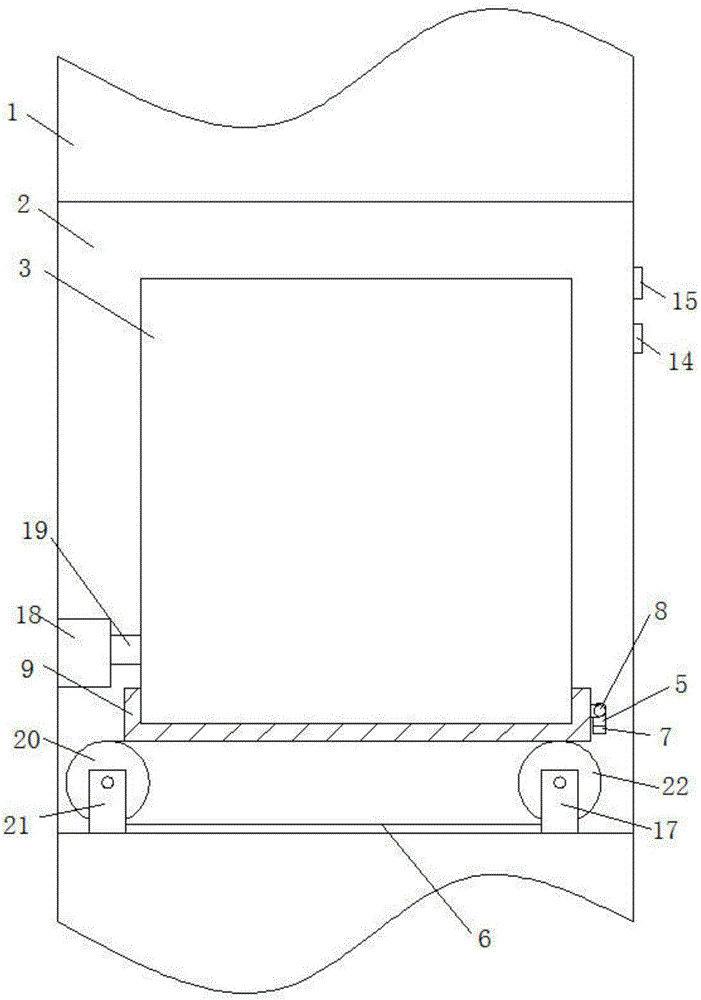

ActiveCN106025838AEasy to take outEasy to put inSubstation/switching arrangement detailsDrive wheelCircuit breaker

The invention relates to a switch cabinet circuit breaker entrance and exit control mechanism. The switch cabinet circuit breaker entrance and exit control mechanism comprises a cabinet body, an externally-arranged power supply and a motor, wherein a circuit breaker chamber is arranged in the cabinet body, a circuit breaker is arranged in the circuit breaker chamber, the front side of the circuit breaker chamber is provided with a chamber door corresponding to the cabinet body, the bottom part of the circuit breaker is fixedly provided with a supporting frame, the supporting frame is fixedly provided with strip-shaped sliding blocks at two sides of the bottom part, sliding grooves are fixedly formed in the bottom part of the circuit breaker chamber in correspondence to the sliding blocks, and the sliding blocks are arranged in the sliding grooves in a slidable manner; a driving wheel and a driven wheel are connected at the bottom part of the circuit breaker chamber and between the sliding grooves on two sides of the supporting frame in a rotated manner; the driving wheel is arranged on one side, away from the chamber door, in the circuit breaker chamber, and the driven wheel is arranged on one side, close to the chamber door, in the circuit breaker chamber; and a conveying belt surrounds the driving wheel and the driven wheel, and the outer side of the conveying belt is pressed against the bottom part of the supporting frame; and the externally-arranged power supply is connected with the motor through a circuit, the motor is installed in the circuit breaker chamber, and an output end of the motor is connected with the driving wheel and drives the driving wheel to rotate forwards and backwards. The switch cabinet circuit breaker entrance and exit control mechanism has the beneficial effects of being simple in structure, convenient in maintenance and installation, and safe and reliable.

Owner:XINJIANG TBEA AUTOMATIC EQUIP

Portable clothes hanger

The invention provides a portable clothes hanger. While the portable clothes hanger is carried, a hanging hook can be slid to a storage position along a containing channel, and the opening of the containing channel is closed by using a cover body, the hanging hook is contained in the containing channel of a support body at this time, the exposed hanging hook is prevented from damaging clothes, andafter the hanging hook is contained in the support body, the floor space of the clothes hanger can be reduced, and the carrying is more convenient. While the clothes is hanged, the cover body is opened, the hook part of the hanging hook is ejected out of the containing channel under the action of an elastic part, and the hanging hook is conveniently pulled out of the containing channel.

Owner:柳州旭至自动化科技有限公司

Leather sample making device

InactiveCN106525529APut in smoothlyIncrease pressureWithdrawing sample devicesPreparing sample for investigationEngineeringMechanical engineering

The invention discloses a leather sample making device. The device comprises a base plate, wherein the base plate is connected with a handle through a rotary shaft provided with a reset spring, and elastic clamps are arranged on two sides of the rotary shaft and connected with a fixing frame; a cutter is arranged on the handle, cutting edges are formed on four side edges of the cutter, and a space as large as a leather sample is formed in each cutting edge; a notch matched with the cutter is formed in the base plate. The device works in a slope line intersection point contact manner and effectively solves the technical problems that a making device is large in size and weight due to the fact that a cutter and leather are in rectangular perimeter type linear contact and super-large pressure is required in the prior art when a leather sample with the size of 50*3 mm<2> is made once, the device is simple and manual operation is convenient.

Owner:SHAANXI UNIV OF SCI & TECH

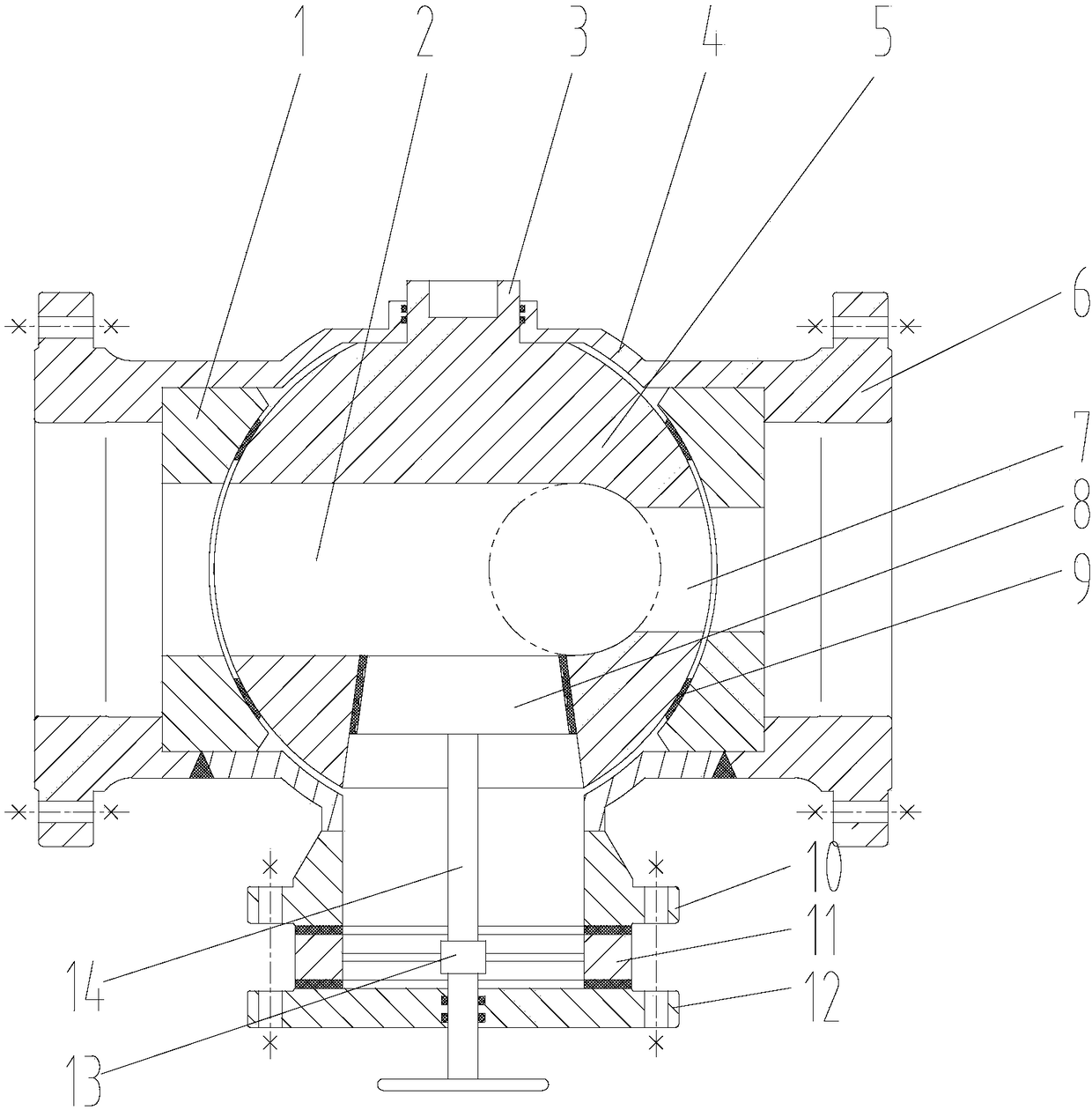

Vibration resistant type pipe cleaning valve

The invention relates to the technical field of pipe cleaning valves, and discloses a vibration resistant type pipe cleaning valve. The valve comprises a shell, and a ball body arranged in the shell;an inlet channel is formed in the ball body, an outlet channel is coaxially arranged at the position, corresponding to the inlet channel, of the ball body, the diameter of the outlet channel is smaller than the diameter of the inlet channel, an inlet and outlet channel is vertically formed in the bottom of the ball body, a discharge opening is formed in the position, corresponding to the inlet andoutlet channel, of the bottom of the shell, a flange assembly is arranged at the position corresponding to the discharge opening, a plunger column matched with the inlet and outlet channel is arranged in the inlet and outlet channel, and can seal the inlet and outlet channel, the lower end of the plunger column is fixedly connected with a rod body, and the lower end of the rod body extends out ofthe flange assembly downwards. A valve base is arranged outside the inlet channel and the outlet channel of the ball body in abutting joint manner, and the other end of the valve base is in abut joint with the shell. The vibration resistant type pipe cleaning valve can avoid material remaining, vibration caused by turbulent flow is avoided, and taking and putting of the pipe cleaning device are not affected; and the valve is simple in structure, stable in work and easy and convenient to operate.

Owner:SICHUAN KAITZ VALVE MFG

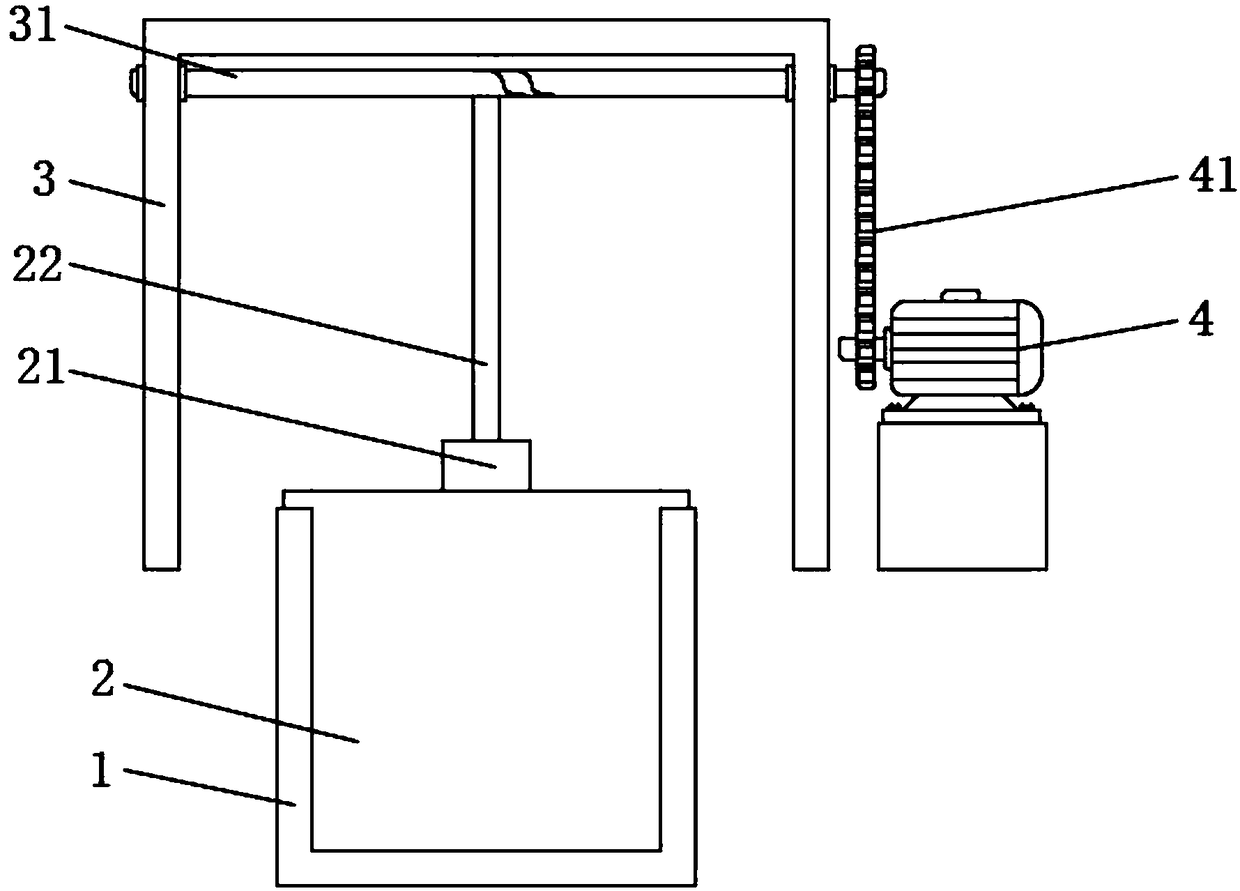

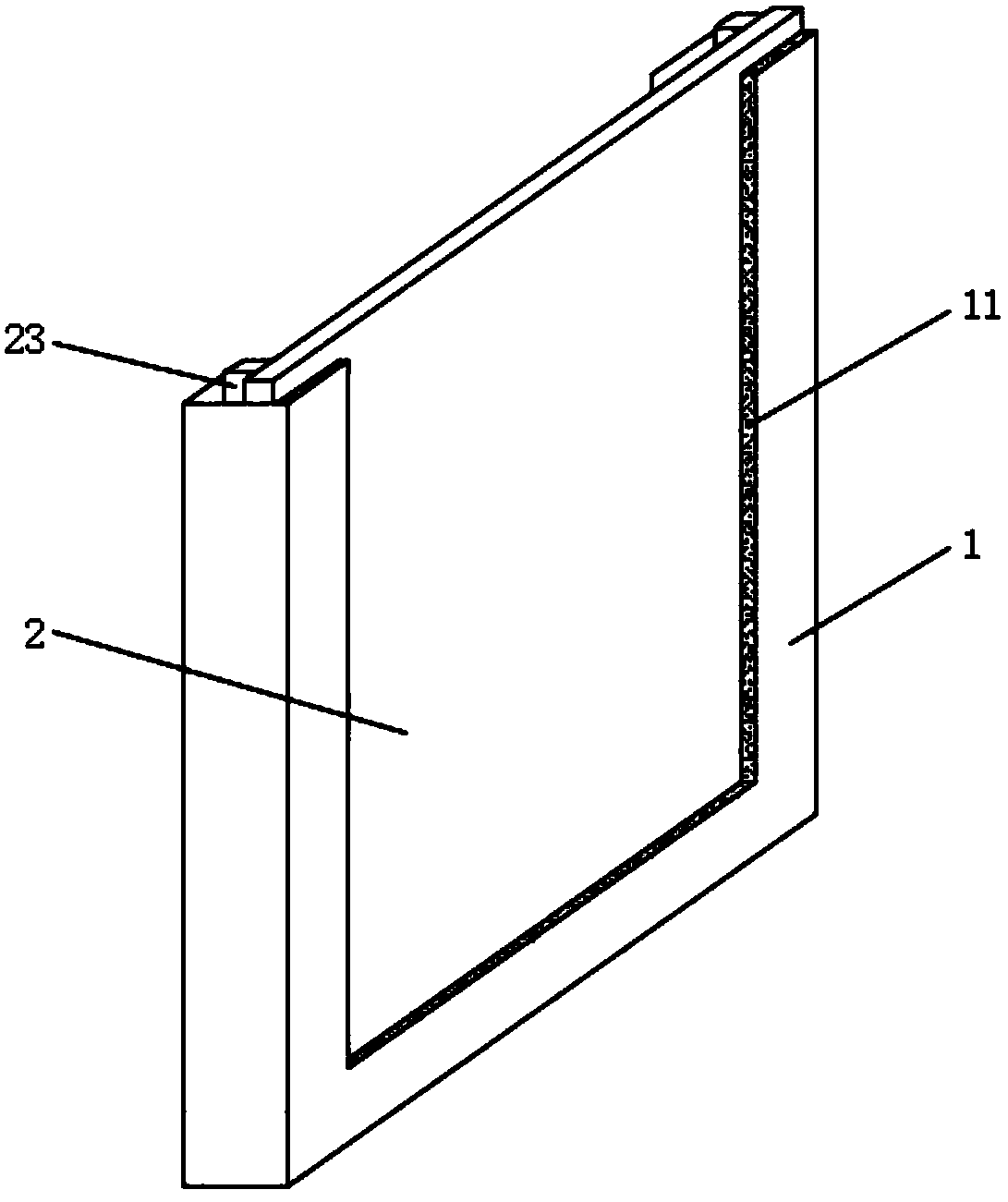

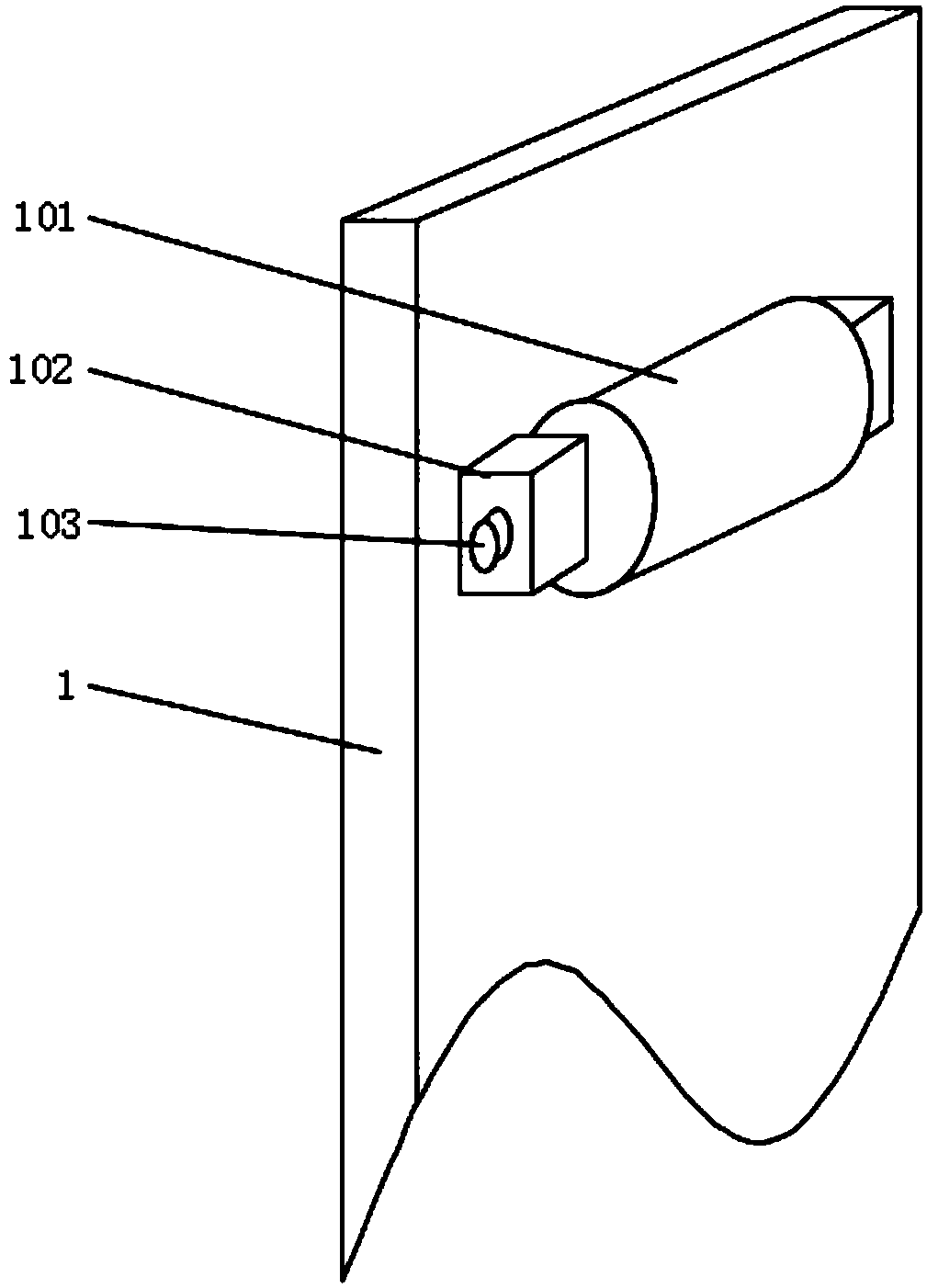

Special gate lifting device for water conservancy and hydropower

The invention discloses a special gate lifting device for water conservancy and hydropower. The device comprises an edge frame and a gate; the gate is arranged in the edge frame; a lifting frame is arranged above the gate; a motor is arranged on one side of the lifting frame; a wedge structure is arranged on one side of the gate; the wedge is narrow in lower end and wide in upper end; in the gatedescending process, due to the effect of the wedge, the gate slowly moves to the side with a rubber pad; when the gate is descended to the bottom, the wedge is totally fed in the edge frame to fully fill the edge frame, so that the gate tightly presses the rubber pad to reduce a gap therebetween, the tightness of the gate is effectively improved, and penetration of water currents is reduced; a roller structure is arranged in the edge frame; when the gate is ascended or ascended, the wedge is contacted with a pulley; and due to the effect of the roller, the gate is hoisted and placed more smoothly and easily, so that the burden of the motor is relieved, and the service life of the motor is prolonged.

Owner:ANHUI CAREMIC CONSULTING CO LTD

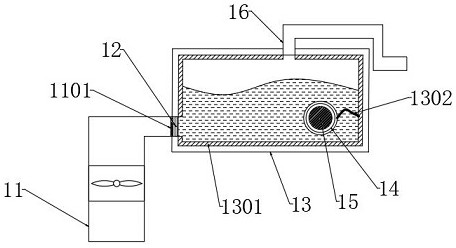

A kind of supercritical extraction equipment for pharmaceutical

ActiveCN113476894BStir violentlyEasy to separateRotary stirring mixersTransportation and packagingReservoir bagEnvironmental engineering

The invention discloses a supercritical extraction equipment for pharmacy, which belongs to the field of supercritical extraction equipment. It is a supercritical extraction equipment for pharmacy. This scheme can realize that the supercritical carbon dioxide is sprayed out by the nozzle and mixed with the liquid medicine, and the supercritical carbon dioxide is sprayed out through the connecting pipe. Import it into the separation tank to separate it. After the separation, the carbon dioxide and the liquid organic matter are mixed and introduced into the water tank through the exhaust pipe, and then through the impact on the air bag during introduction, the air bag shakes in the water tank to clean the water in the water tank. Agitation makes the organic matter dissolve in water, while carbon dioxide is introduced into the air storage bag through the air duct, and then the air storage bag gradually increases, and after expansion, the repulsion of the main magnetic ball by the secondary magnetic ball makes the air bag agitate more in the water tank Intensive, in order to improve the separation of organic matter and carbon dioxide, and finally insert it into the intake pipe, and squeeze the gas through the nozzle to mix with the newly added liquid medicine, so as to achieve the effect of repeated use.

Owner:JIANGSU GAOKE PHARM EQUIP CO LTD

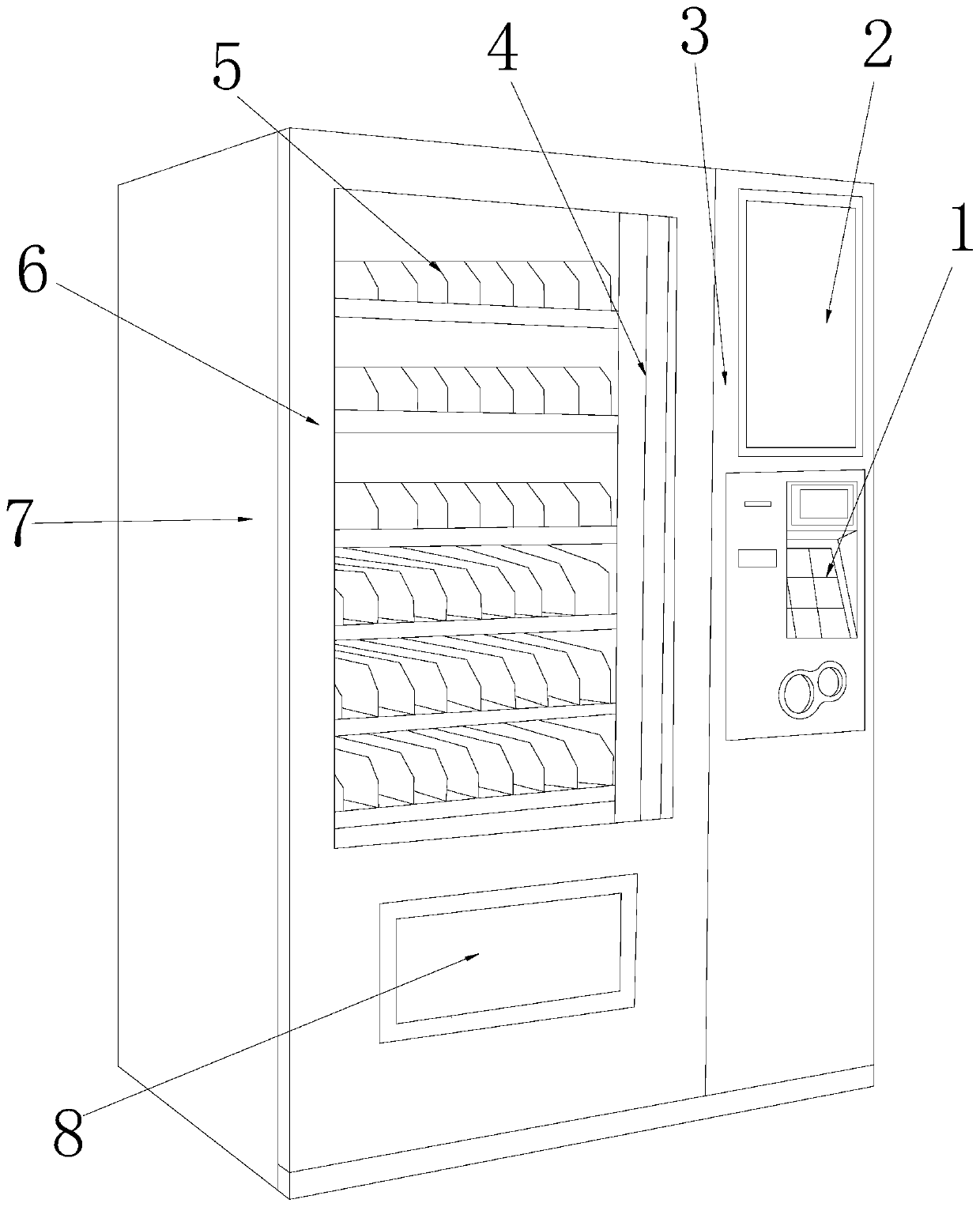

Chute suspension loop drawstring bag type commodity storage device for vending machine

ActiveCN110033554AEasy to carryEasy to carry drinks on the goCoin-freed apparatus detailsApparatus for dispensing discrete articlesRough surfaceFrictional coefficient

The invention discloses a chute suspension loop drawstring bag type commodity storage device for a vending machine. The commodity storage device comprises a key board groove, a display screen, an electric cabinet, a drawstring bag storage frame, commodity carrying separating platforms, a front door panel, a square box shell cover and a commodity pick-up bottom groove. The commodity storage devicedisclosed by the invention realizes the effects that the drawstring bag storage frame is applied and cooperates with the commodity carrying separating platforms, and each bottled beverage at a high layer receives an electronic control turn-over output on a corresponding inclined supporting plate and pushes a corresponding cotton core sleeve groove; meanwhile, a corresponding suspension loop drawstring bag and a corresponding arc-shaped retaining ring are erected at a corresponding opening and are stored, and nylon ropes keep straight to tighten an opening of a corresponding rubber band bag, thus when a carbonate beverage bottle is put into a storage bag and output, a silk material of the storage bag and a rough surface of the inner wall of the cotton core sleeve groove conveniently form interaction force with a frictional coefficient increased and reduce speed and inertia effect of gravity, a bottle body is stably put into the commodity pick-up bottom groove, the retailed commodity forms an elevator type steady displacement effect when going up and down, a sponge structure prevents fluid in a bottle from being bumped and lost, a bagged manner is convenient for taking out the commodity, and delivery protection is more comprehensive.

Owner:舒城点为云智能科技有限公司

Non-inflation air spacer

The invention relates to a non-inflation air spacer. The non-inflation air spacer comprises an elastic-deformed conical energy collecting shell; the energy collecting shell forms an inner and outer layer overlap structure at a joint part; inner and outer layers are clamped and fixed with one end of a buckle through a clamping groove; the buckle forms a prying bar structure through middle butting;the clamped end of the buckle is deviated from the clamping groove through triggering of the other end of the prying bar; the energy collecting shell is fixedly connected with a scale rope through a rope clamping port at a large end; an inner section of the scale rope is inserted in and out in sequence from a first through hole and a second through hole at the top and the upper part of the energycollecting shell; an inner end, penetrating out of the second through hole, of the scale rope is fixed at the other end of the buckle; and the energy collecting shell is connected with a counterweightthrough a fixed rope. The non-inflation air spacer has the following beneficial effects: an air spacing construction method can be realized without inflating; no influence is from weather conditionsand dry and wet environments; and a conical energy collecting cavity with a downward tip can guarantee the bombing energy to be mainly acted on the hole walls to promote uniform crushing of rocks on the hole orifices and the hole walls, so that the punching phenomenon is reduced, and the blasting effect is improved.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

Absorbent article

ActiveUS10258513B2Fixed securityImprove rigiditySanitary towelsBaby linensMechanical engineeringEngineering

Owner:DAIO PAPER CORP

Method for improving coal seam permeability by adopting directional hydraulic concentrated blasting

ActiveCN107503728AIncrease the degree of crack developmentIncrease impactFluid removalUnderwater explosionDetonation

The invention provides a method for improving the coal seam permeability by adopting directional hydraulic concentrated blasting and relates to the technical field of coal seam antireflection. The method comprises the following steps: step 1, drilling a blast hole in a coal seam, then performing hydraulic pre-splitting antireflection on the coal seam by utilizing the drilled blast hole, prohibiting the extraction of water remaining in the blast hole after hydraulic pre-splitting antireflection and ensuring that the water surface in the blast hole is at least higher than 2 m of the upper part of the coal seam; step 2, putting a directional hydraulic concentrated blasting device in the blast hole and sinking into the water surface; and step 3, detonating the directional hydraulic concentrated blasting device to detonate under the water and finish the antireflection operation. The method provided by the invention has the benefits that firstly, the hydraulic pre-splitting antireflection is performed on the coal seam, and then the directional hydraulic concentrated blasting device with a specific structure is detonated in the water remaining in the blast hole; through the coupling of detonation gas with the water remaining in the blast hole and the coal beam after hydraulic fracturing operation, the fracture development degree in the coal seam can be greatly improved; and through the method, before blasting, a yellow mud roll is not required to be poured in the blast hole, so that the operation is very convenient.

Owner:HUNAN INST OF TECH

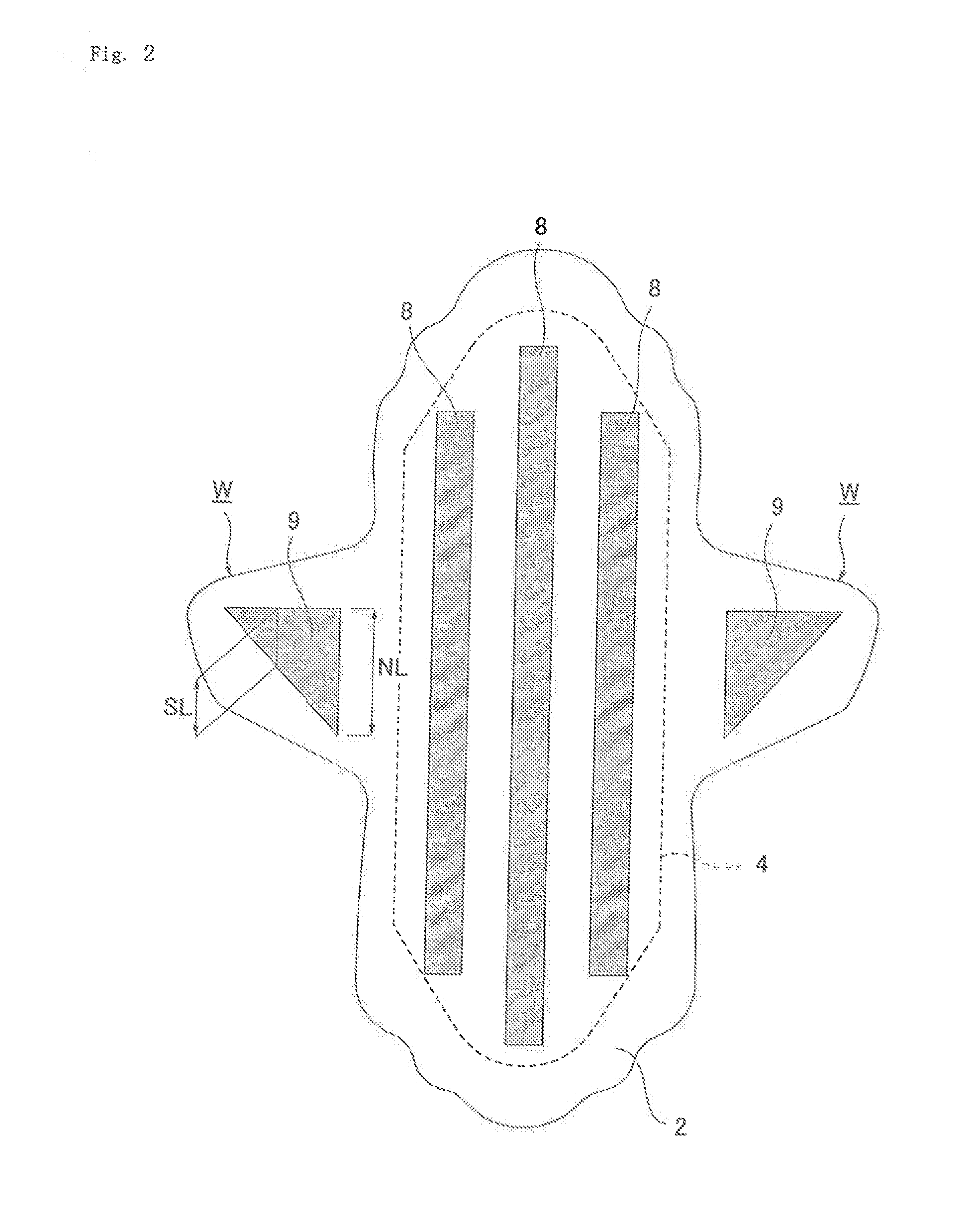

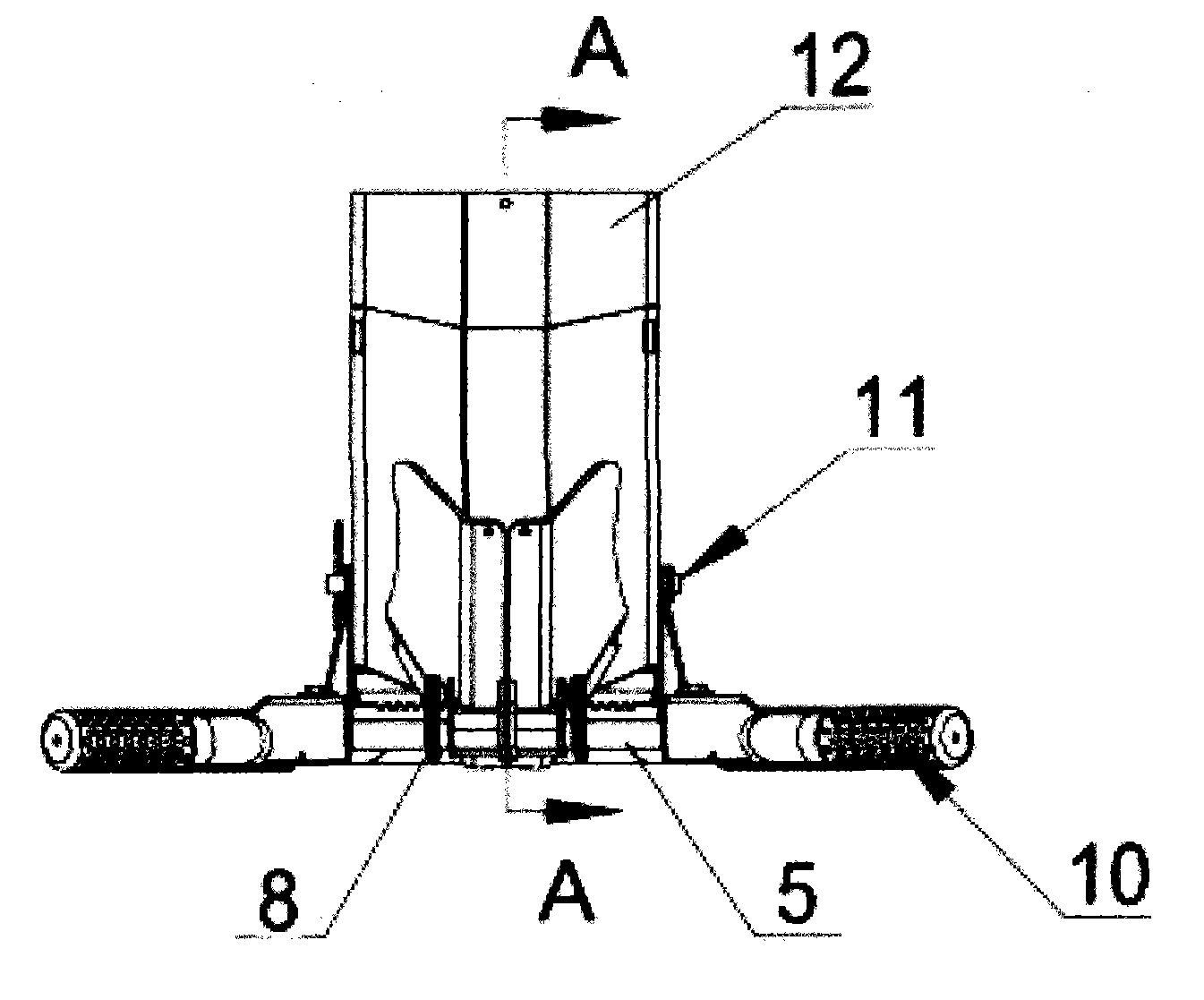

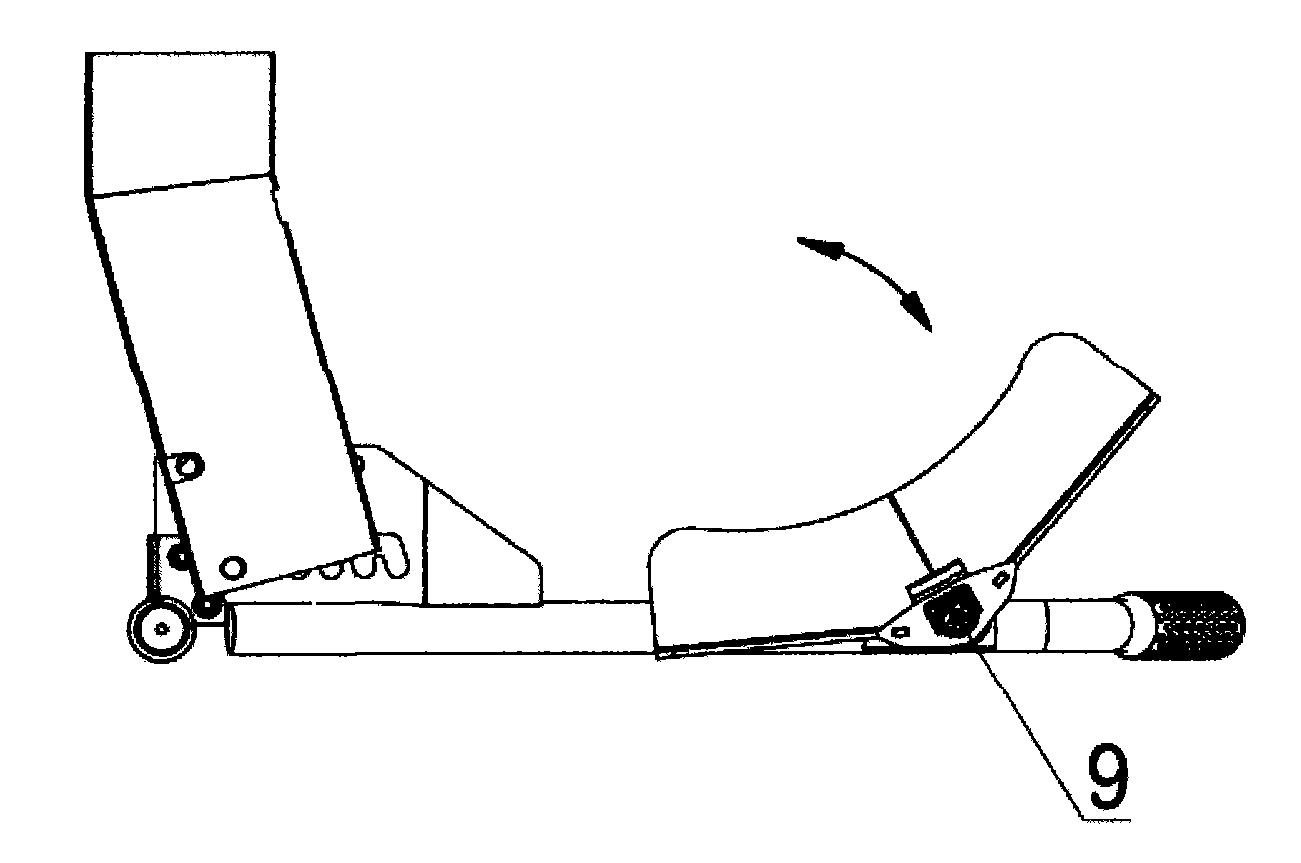

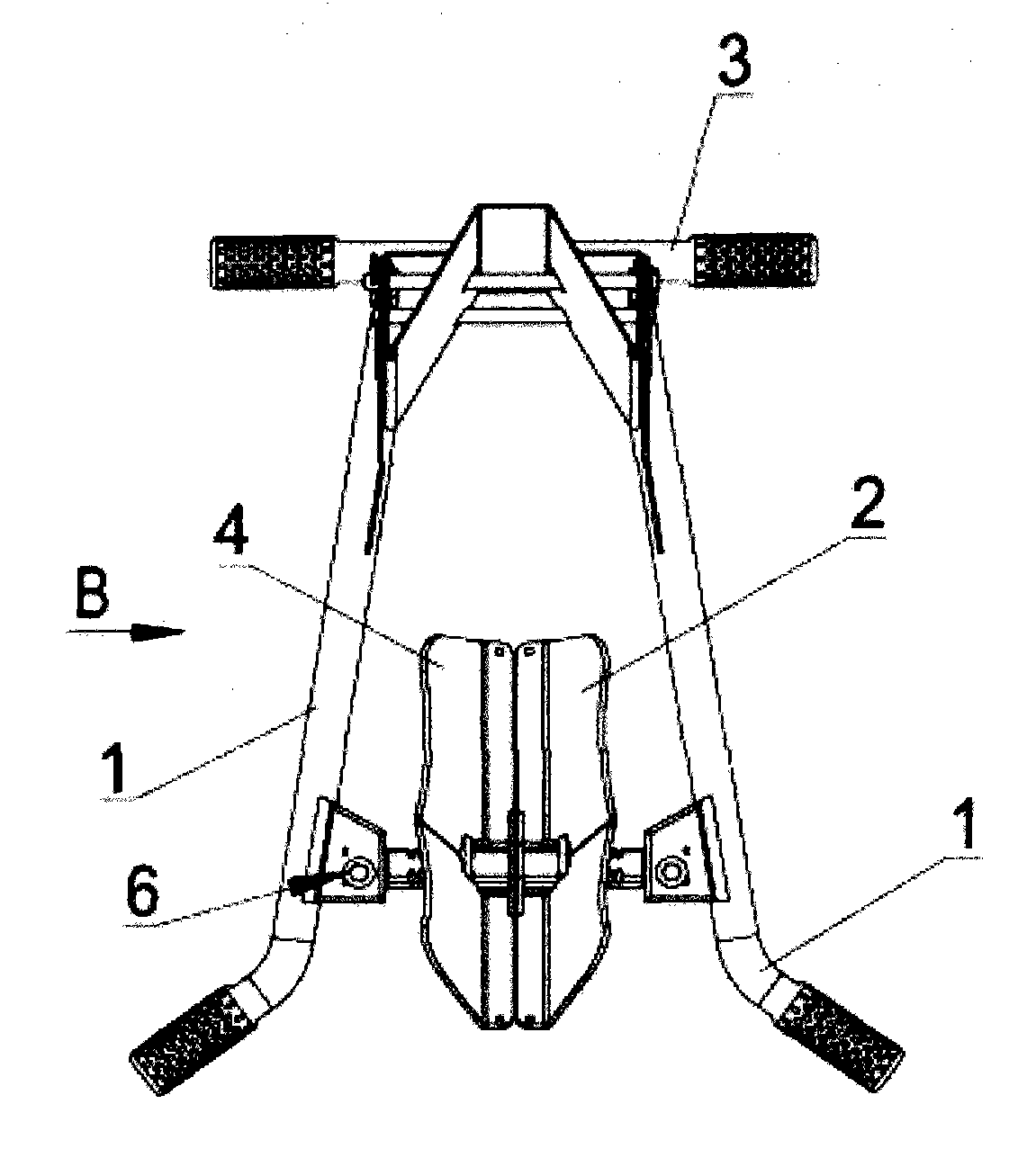

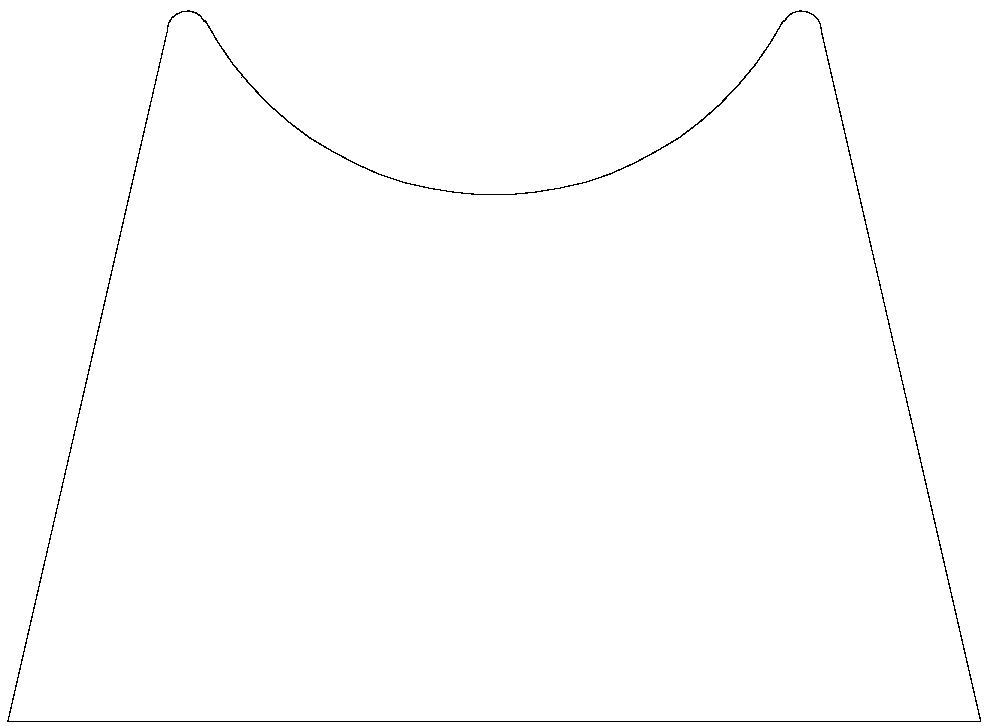

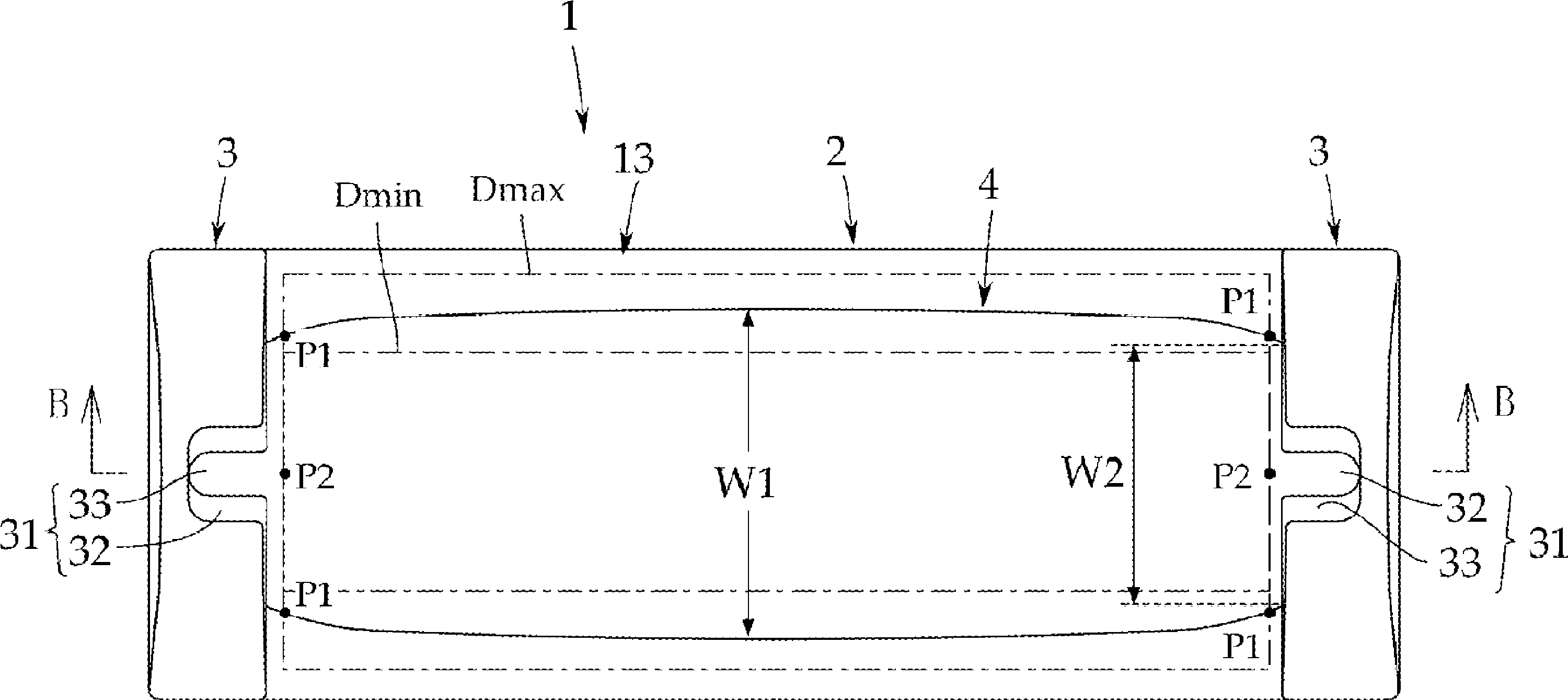

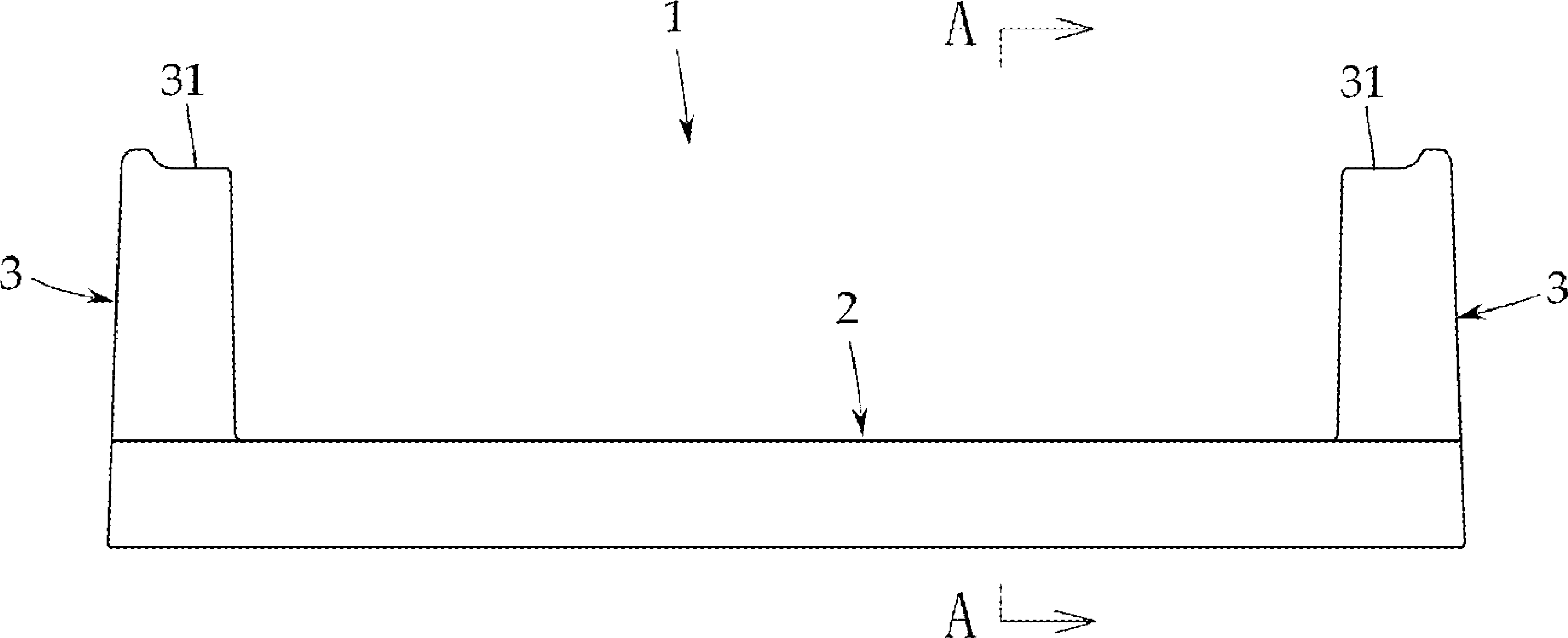

Stand for adhesive cleaning tool

Provided is a stand for an adhesive cleaning tool that can store an adhesive cleaning tool easily with a single touch. A carrying surface (4) on which an adhesive tape roll (13) is loaded is formed in a boat-bottom shape on the upper surface of a base plate (2) that is placed on the floor so as to support the roll end of the adhesive cleaning tape roll (13) and the two ends thereof are held by side plates (3, 3).

Owner:NITOMS INC

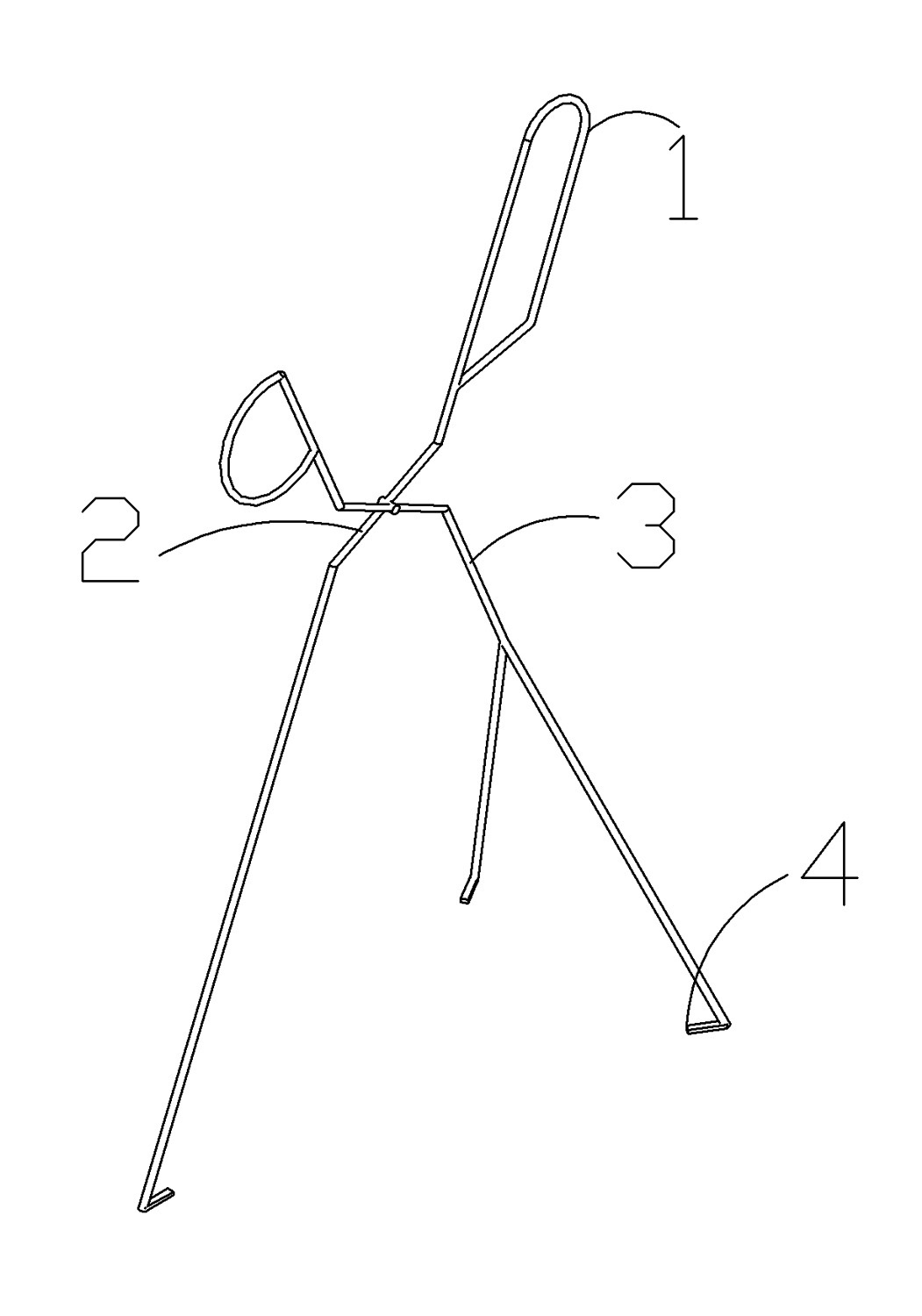

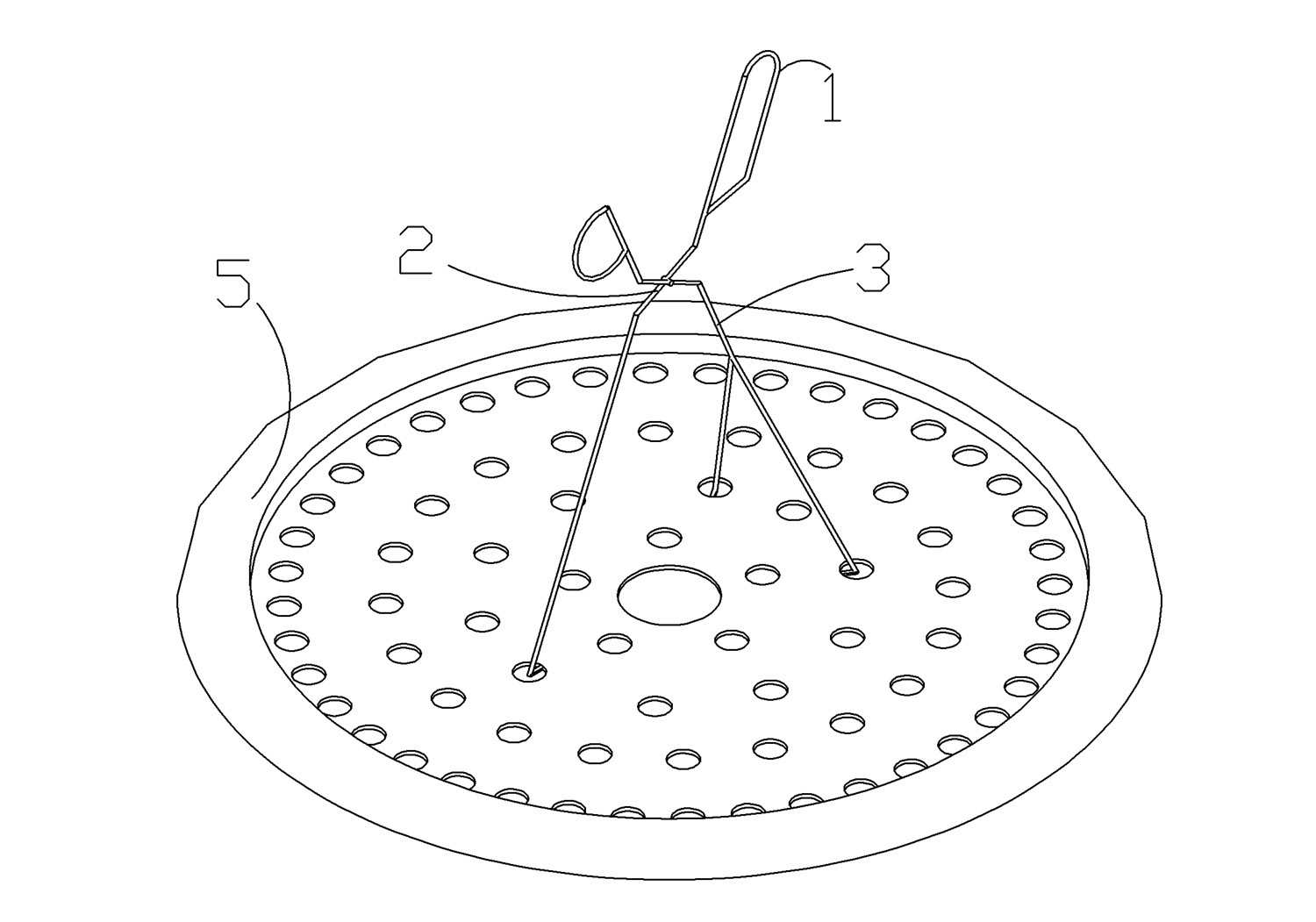

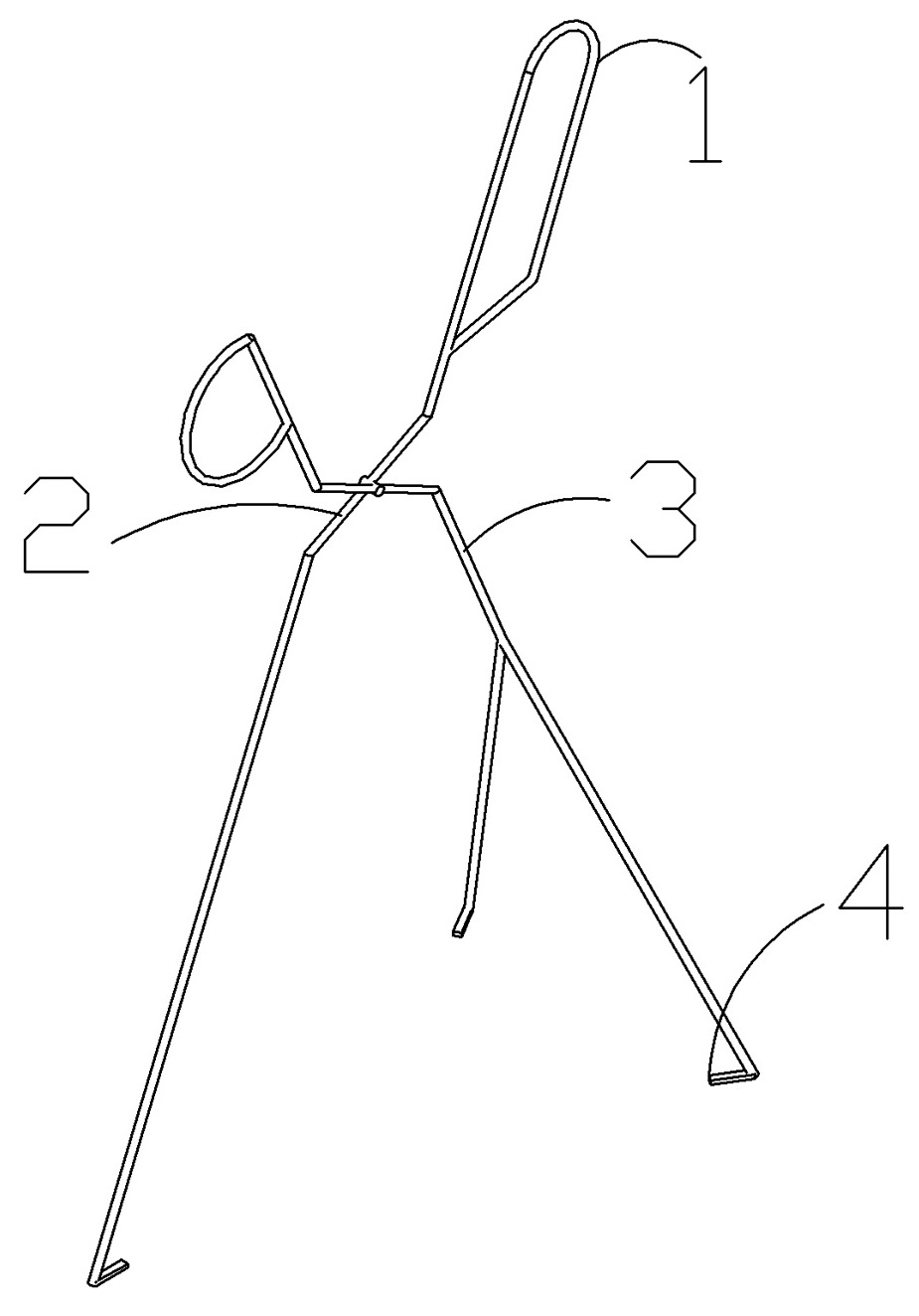

Grate clamp

The invention discloses a grate clamp which is mainly characterized by comprising a handle, a clamp shoulder and clamp arms, wherein the upper parts of the clamp arms are the clamp shoulder and are crossed and movably connected on the clamp shoulder; the upper part of the clamp shoulder is the handle; the number of the clamp arms is three or four; and the tail ends of the clamp arms are oppositely provided with small hooks. When in use, the grate clamp extends into a pot, the small hooks at the tail ends of the clamp arms nip the handle through air holes of a grate, the clamp arms are folded up and then the three small hooks stick the edges of the air holes and three points decide one plane, thus, the grate can be rapidly and stably lifted from the hot pot so that food on the grate cannot fall off. Due to the fact that the technical scheme is adopted, compared with the prior art, the invention has the advantages of simple structure and convenience in use.

Owner:王旭乐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com