Directional hydraulic centralized exploding device for improving gas permeability of coal seam

A technology of directional blasting and air permeability, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and mining, etc. It can solve problems such as the effect needs to be improved, the effect of increasing the permeability of the top of the coal seam is limited, and the workload of filling yellow mud rolls is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

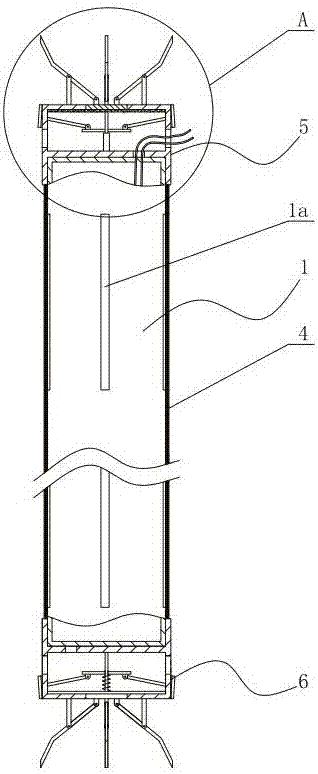

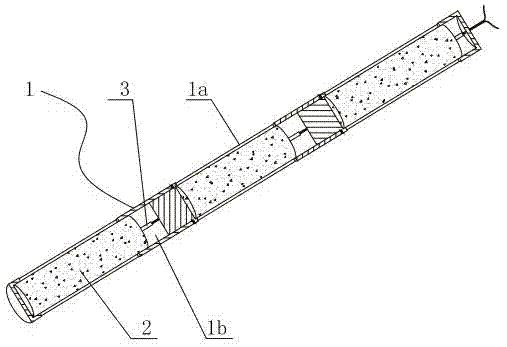

[0039] figure 1 , 3 and 5 show the specific structure of the directional hydraulic concentrated blasting device used to improve the gas permeability of the coal seam involved in the present embodiment, which includes a directional blasting tube 1, and the two ends of the directional blasting tube 1 are sealed by a cover plate, and the directional blasting tube 1 A plurality of energy release holes 1a are spaced apart on the outer peripheral surface of the directional blasting tube 1, and the energy releasing holes 1a communicate with the inner cavity of the directional blasting tube 1, and the inner cavity of the directional blasting tube 1 is filled with explosive rolls 2 and detonators 3, and the directional blasting tube 1 A layer of high-pressure plastic film 4 is wrapped on the outer peripheral surface of the wall, the energy release hole 1a is covered by the high-pressure plastic film 4, and the top of the directional blasting tube 1 is connected with a hole for blocking...

Embodiment 2

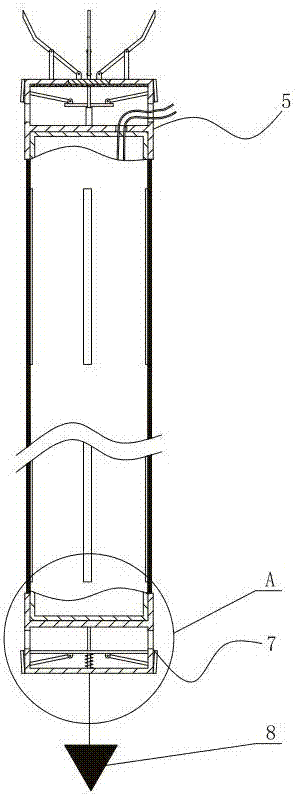

[0047] See figure 2 , 3 As shown in and 6, the difference between embodiment 2 and embodiment 1 is that the structure of the plugging assembly connected to the bottom end of the directional blasting tube 1 is different from that of embodiment 1. Specifically, in this embodiment, the directional blasting tube 1 The bottom end of the third plugging assembly 7 is installed, the third blocking assembly 7 also includes a hollow tubular body 5a, the top of the tubular body 5a is provided with a top cover 5a1, and the inner cavity of the tubular body 5a is provided with a partition 5a2, the partition The plate 5a2 divides the inner chamber of the tubular body 5a into a connection chamber 5a3 on one side and a pressure chamber 5a4 on the other side. Matching screw connection structure, the bottom end of the directional blasting pipe 1 is screwed into the connection chamber 5a3 and fixedly connected with the tubular body 5a, and the outer peripheral surface of the tubular body 5a is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com