Patents

Literature

177results about How to "Guaranteed blocking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water plugging device for petroleum pipeline maintenance

ActiveCN104819361AImprove the sealing effectReduce stress concentrationPipe elementsPetroleumStress concentration

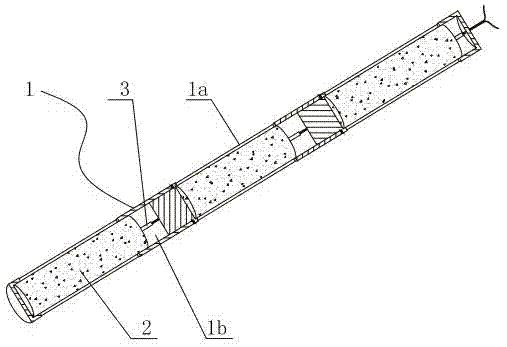

The invention discloses a water plugging device for petroleum pipeline maintenance. The water plugging device comprises a gasbag body and an exhaust pipe which is arranged at the end of the gasbag body. A plurality of grooves are formed in the outer circumferential wall of the middle of the gasbag body. Two elastic metal sheets are arranged in each groove in a spaced mode, and the bent part in each elastic metal sheet is fixedly provided with a reinforcing pad. When the gasbag body is inflated, the two elastic metal sheets in each groove deform to expand outwards in the radial direction of the gasbag body. Pressure in a gasbag is gradually increased, elastic deformation is made to occur to the elastic metal sheets, and the elastic metal sheets expand outwards in the radial direction of the gasbag body until the elastic metal sheets make contact with the inner wall of a pipeline. In the outward expansion process, elastic force generated by the deformation of the elastic metal sheets directly acts on scale on the inner wall of the pipeline and crushes the scale; the reinforcing pads fixed on the elastic metal sheets can weaken the impact strength between the scale and the elastic metal sheets, and the problem of stress concentration of the elastic metal sheets is solved.

Owner:JIANGSU PROVINCE JINFENG PETROLEUM MACHINERY MFG CO LTD

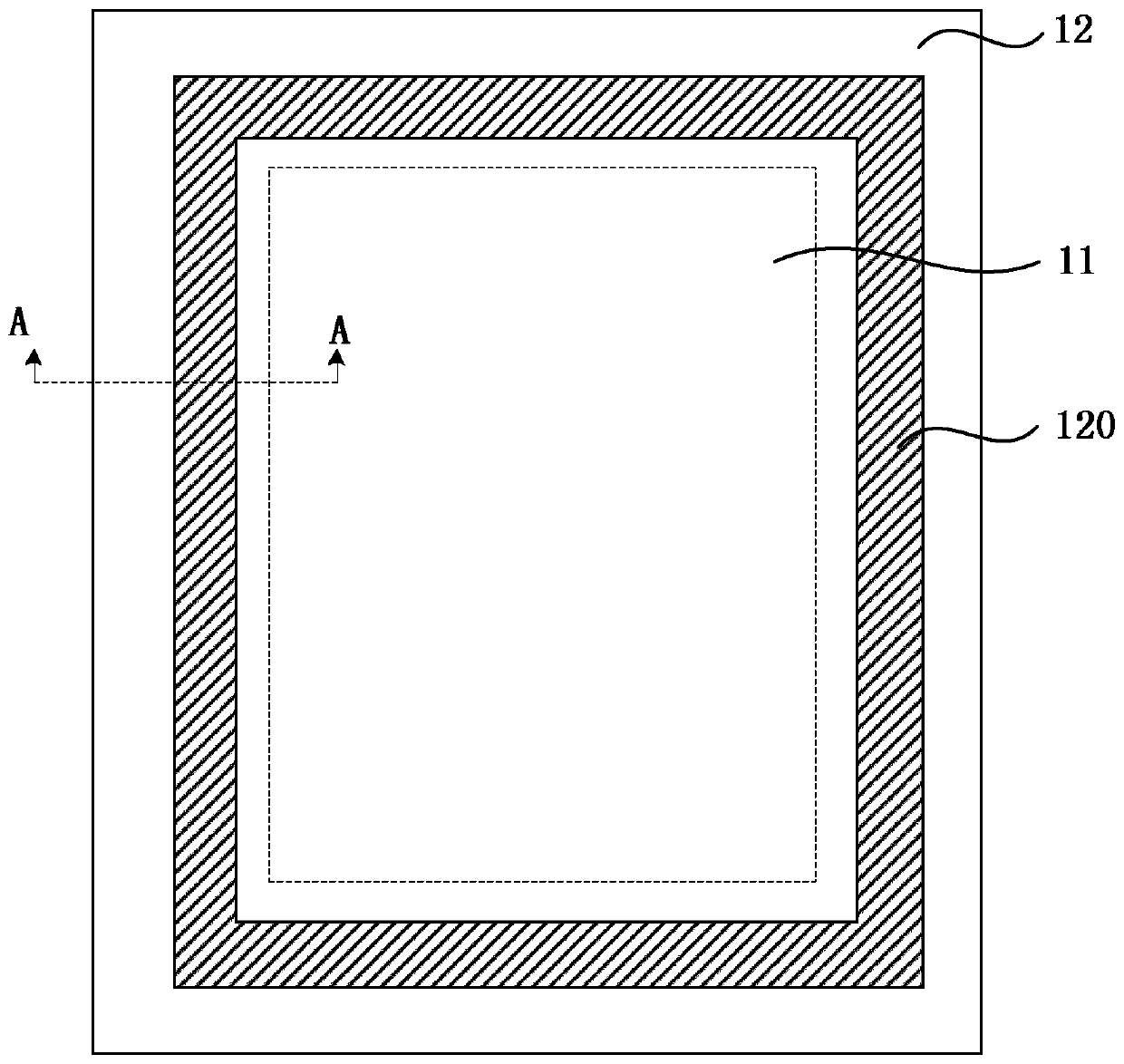

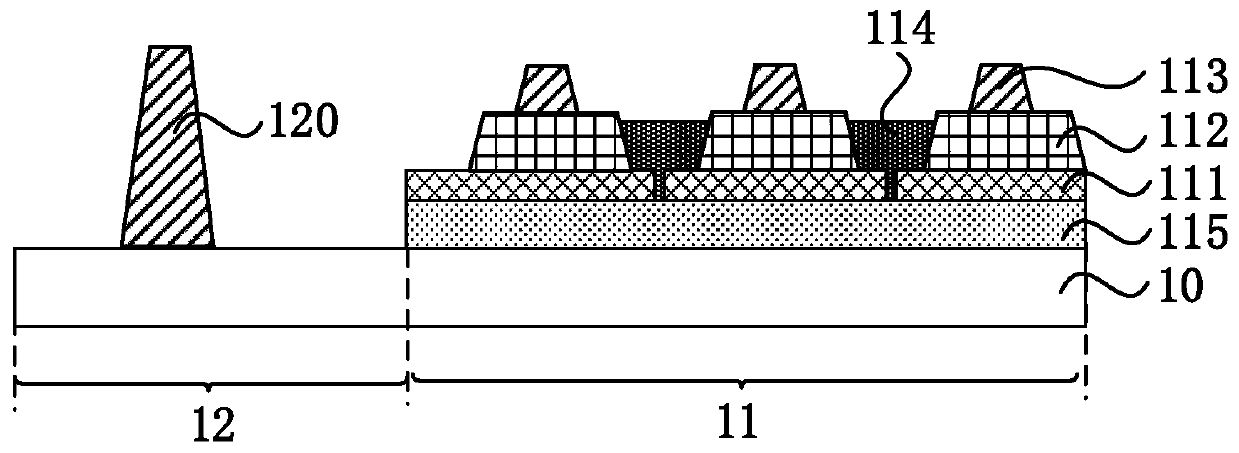

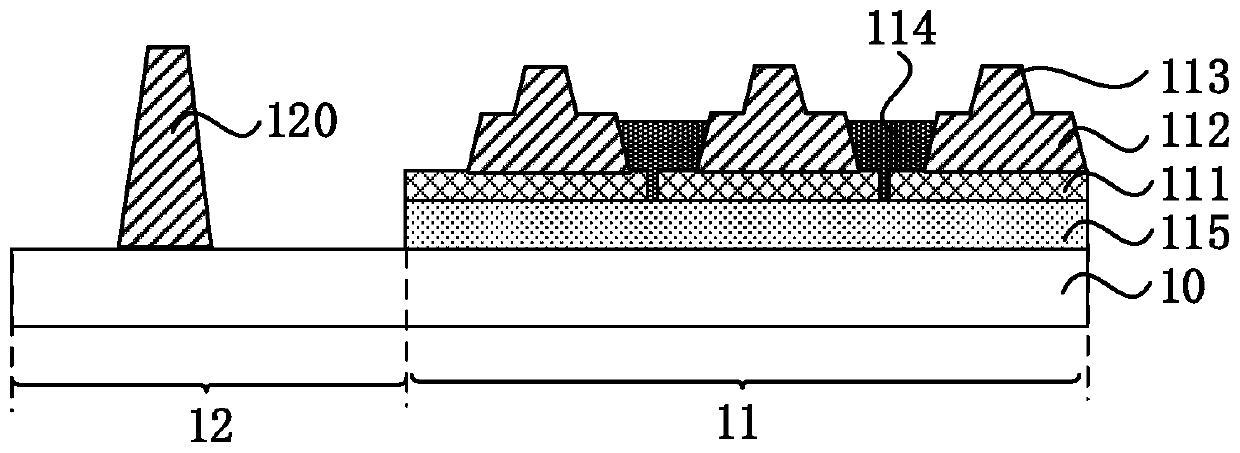

Display panel, display device and preparation method of display panel

InactiveCN109713023AReduce borderReduce production processSolid-state devicesSemiconductor/solid-state device manufacturingBlock effectDisplay device

The invention discloses a display panel, a display device and a preparation method of the display panel. The display panel comprises a substrate. The substrate comprises a display area and a non-display area surrounding the display area. The non-display area is provided with a retaining wall, and the retaining wall surrounds the display area. The display area is provided with a planarization layer, a pixel definition layer and supporting columns. The pixel definition layer is arranged on one side, far away from the substrate, of the planarization layer. The supporting columns are arranged on one side, far away from the substrate, of the pixel definition layer. The retaining wall, the supporting columns and at least one layer of the pixel definition layer and the planarization layer are made of the same material. According to the scheme of the embodiment of the invention, the preparation precision of the retaining wall is improved. The blocking effect of the retaining wall on a thin film packaging layer is ensured, and the frame of the display panel is reduced.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

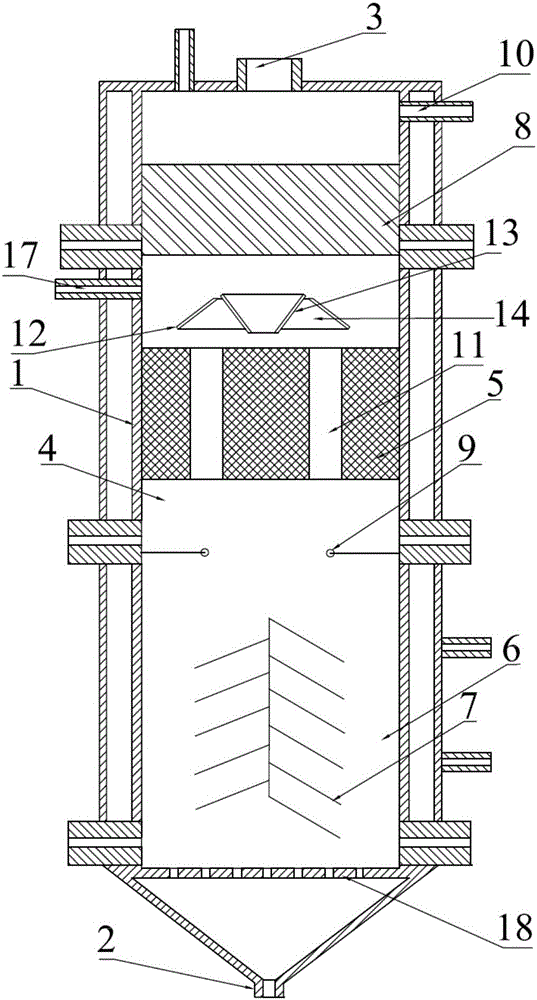

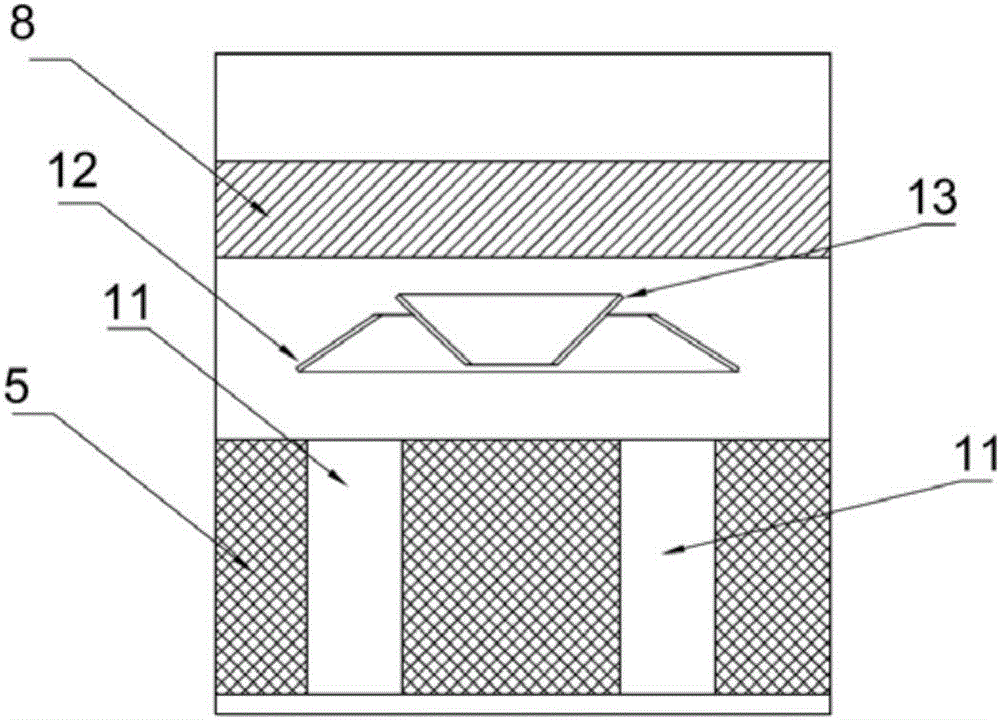

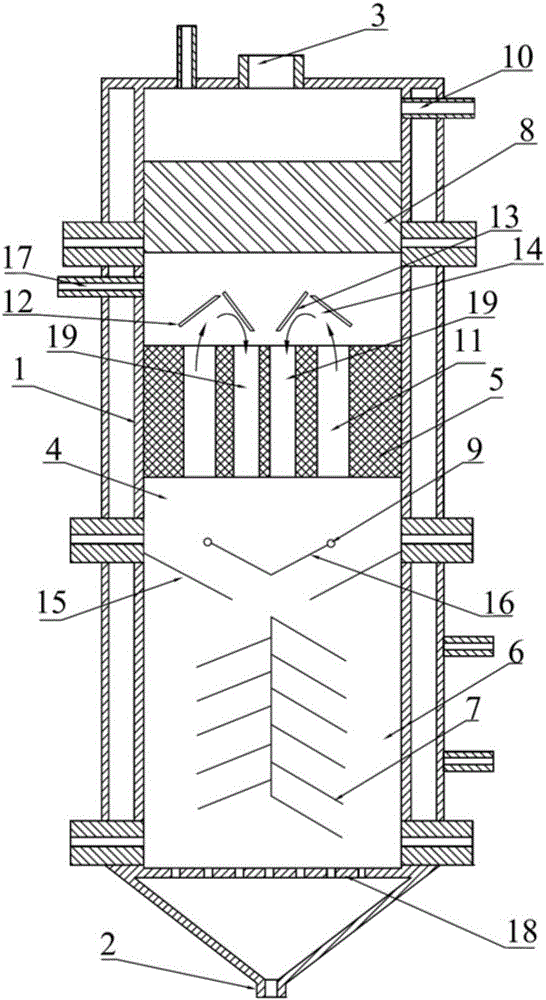

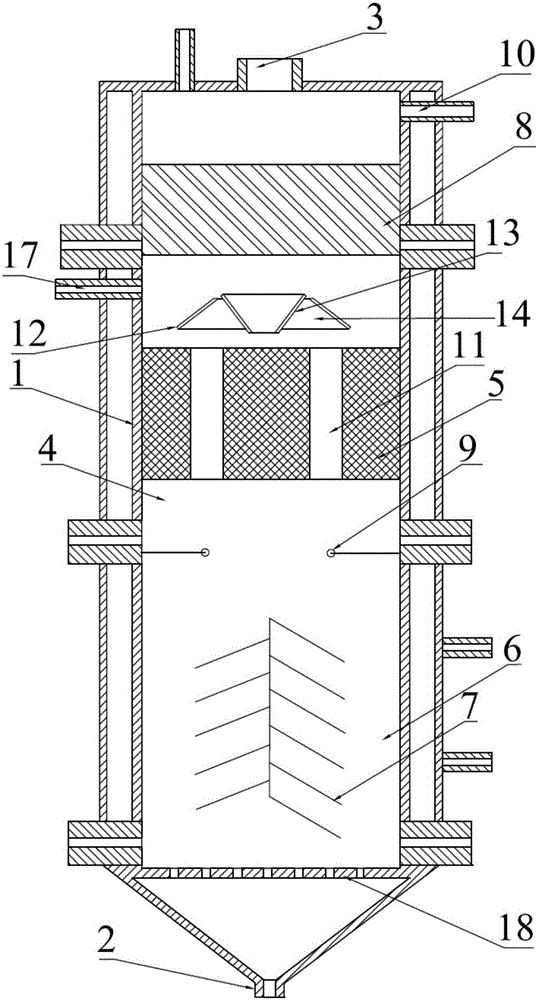

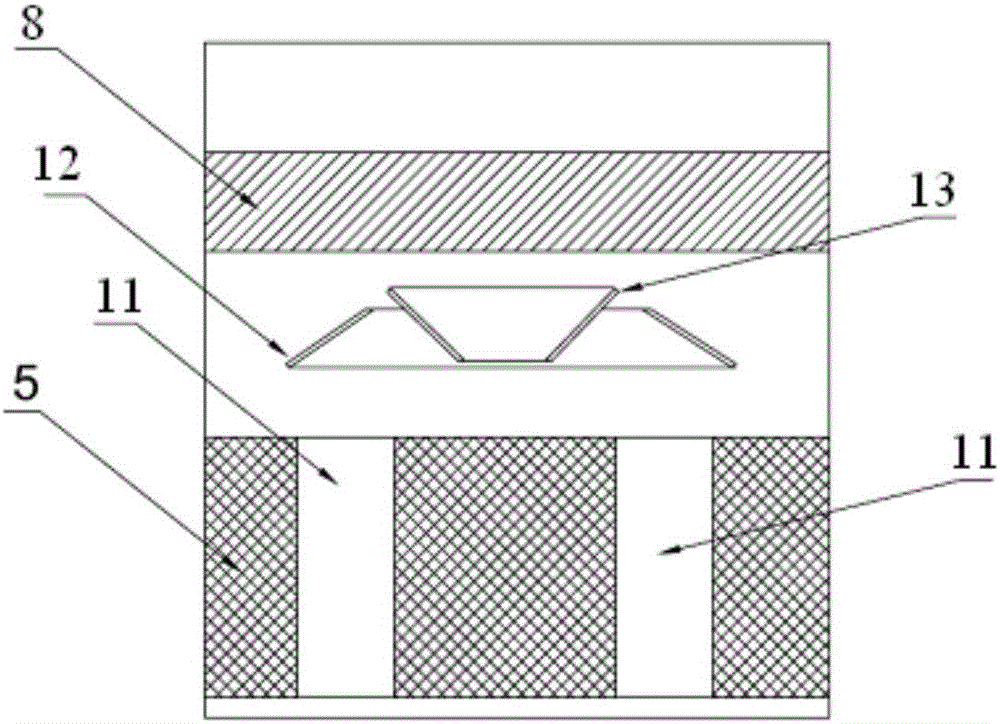

Completely autotrophic nitrogen-removal reactor and nitrogen-removal process

ActiveCN106277327AAvoid pollutionAvoid cloggingTreatment with aerobic and anaerobic processesDenitrifying bacteriaWastewater

The invention provides a completely autotrophic nitrogen-removal reactor. A nitrosation-anaerobic ammonia oxidation region is arranged on the upper part of a reactor barrel, a first packing assembly is arranged in the nitrosation-anaerobic ammonia oxidation region, anaerobic ammonium oxidation bacteria are attached to the inner layer of the surface of the first packing assembly, and nitrosobacteria are attached to the outer layer of the surface of the first packing assembly; a denitrification region is arranged on the lower part of the reactor barrel; a second packing assembly attached with denitrifying bacteria is arranged on the denitrification region; a film assembly is arranged at the top end of the nitrosation-anaerobic ammonia oxidation region; a water outlet communicates with a water outlet side of the film assembly; an aeration device is arranged in the nitrosation-anaerobic ammonia oxidation region and is positioned below the first packing assembly; and a first three-phase separator is arranged between the first packing assembly and the film assembly. By the reactor, pollution and blocking of the film assembly are prevented effectively, the effect of treating waste water is enhanced, and whole completely autotrophic nitrogen-removal reaction can be carried out efficiently and stably.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Light emitting diode epitaxial wafer and manufacturing method therefor

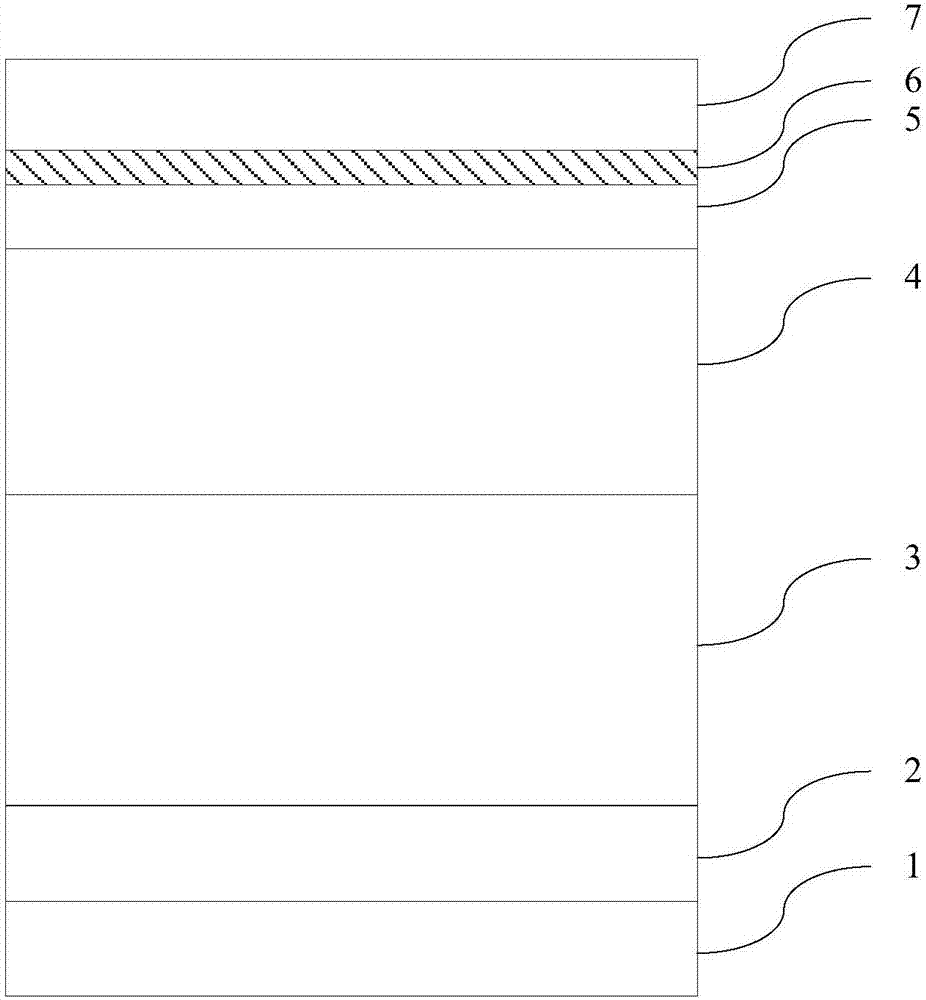

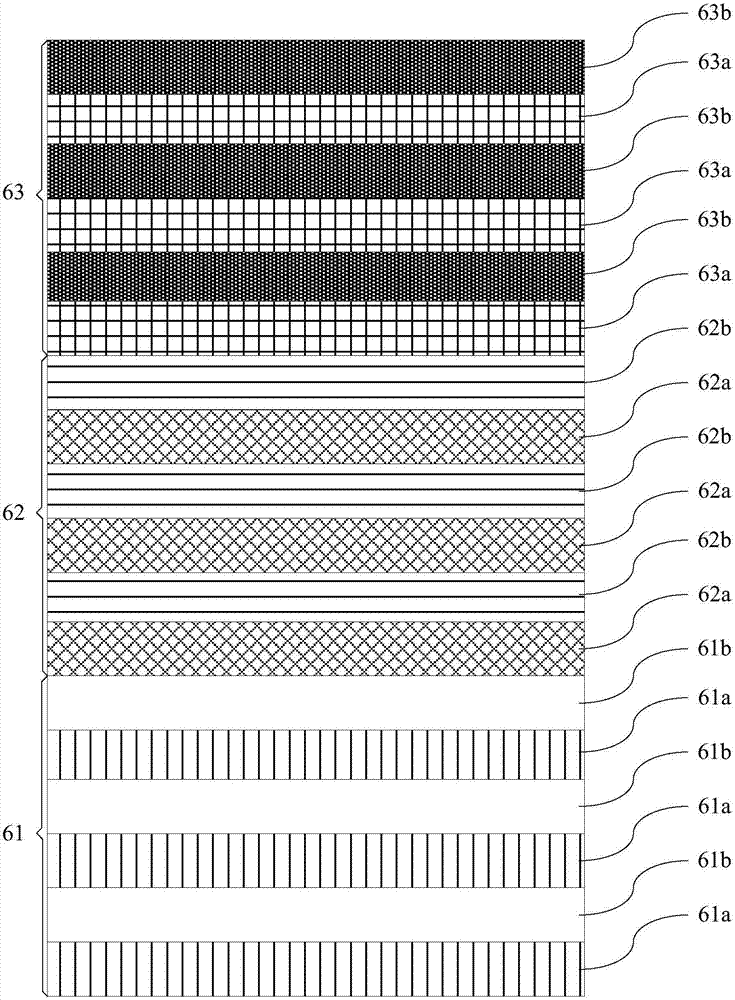

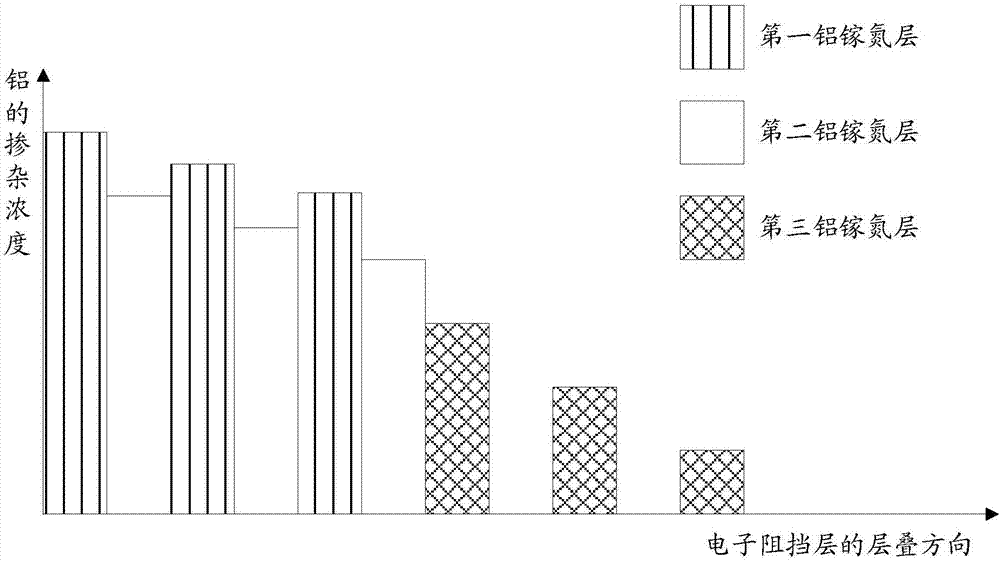

ActiveCN107195738APrevent proliferationImprove luminous efficiencySemiconductor devicesMagnesium dopingNon doped

The invention discloses a light emitting diode epitaxial wafer and a manufacturing method therefor, and belongs to the technical field of a semiconductor. The epitaxial wafer comprises a substrate, a buffer layer, a non-doped gallium nitride layer, an N type gallium nitride layer, a multi-quantum-well layer, an electron barrier layer and a P type gallium nitride layer; the electron barrier layer comprises a first sub layer, a second sub layer and a third sub layer; the first sub layer comprises multiple first aluminum gallium nitride layers and multiple second aluminum gallium nitride layers which are stacked alternately; the second sub layer comprises multiple third aluminum gallium nitride layers and multiple first indium gallium nitride layers which are stacked alternately; the third sub layer comprises gallium nitride layer and second indium gallium nitride layers which are stacked alternately; the aluminum doping concentration in the first aluminum gallium nitride layers and the second aluminum gallium nitride layers is greater than that in the third aluminum gallium nitride layers; the first indium gallium nitride layers, the gallium nitride layers and the second indium gallium nitride layers are all doped with magnesium; the magnesium doping concentration in the first indium gallium nitride layers is lower than that in the gallium nitride layers and the second indium gallium nitride layers. By virtue of the light emitting diode epitaxial wafer and the manufacturing method therefor, hole injection can be improved and LED light emitting efficiency can be improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

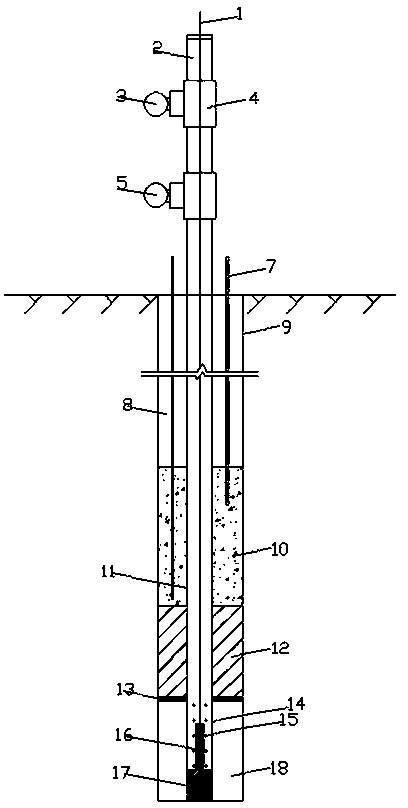

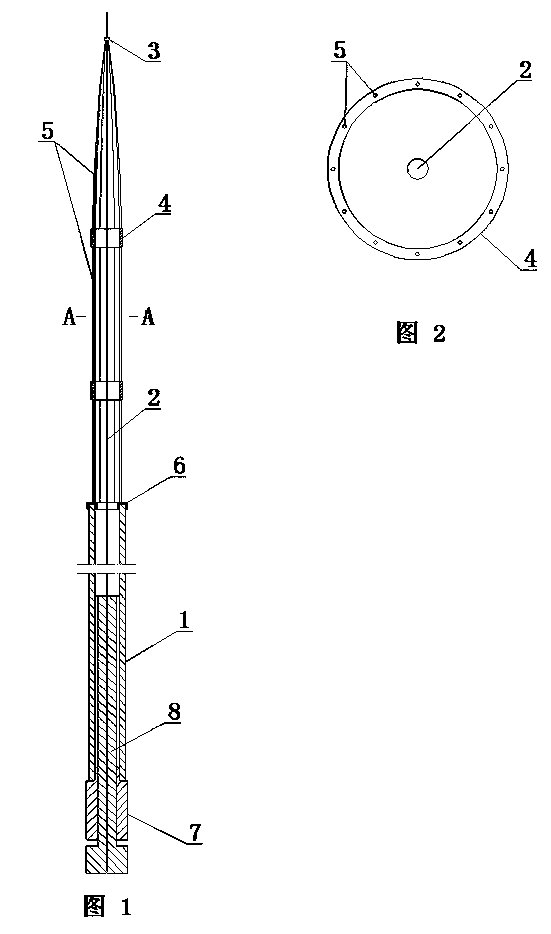

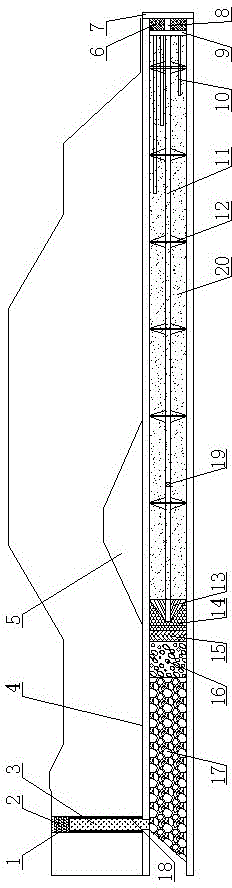

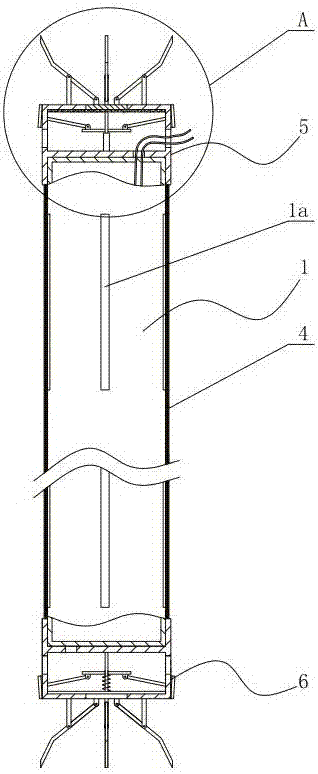

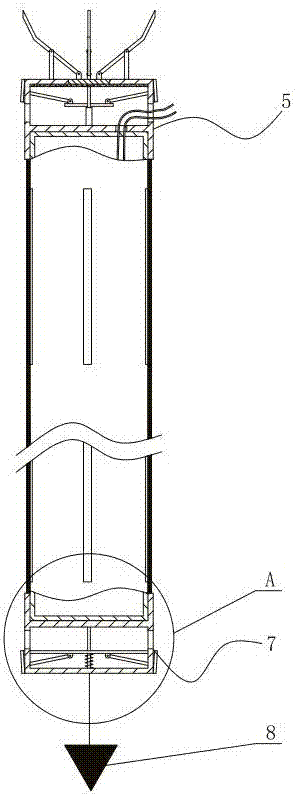

Observation instrument embedded blockage system for drilling hole high-pressure packer test

The invention discloses an observation instrument embedded blockage system for a drilling hole high-pressure packer test. The system is provided for solving the problem of the failed observation as the observation instrument is easily cemented by sequent poured cement (mortar) serous liquid in the pouring process of the existing observation instrument for the drilling hole high-pressure packer test. The embedded blockage system comprises a test observation hole, a permeation prevention section arranged in the test observation hole and a sleeve penetrating through the permeation prevention section; the bottom and top of the sleeve are provided with a plug respectively; the observation instrument is arranged in the lower pipe of the sleeve and is connected with an external connected cable; a test cavity is formed among the sleeve, the bottom of the permeation prevention section and the inner wall of the bottom of the observation hole; the test cavity is communicated with the sleeve by a water passing hole; the permeation prevention section is formed by a cement paste plug, an expansion cement paste plugging section and a geotextile section which are sequentially arranged from the port to bottom of the test observation hole. The observation instrument embedded blockage system for the drilling hole high-pressure packer test is simple in structure and convenient to operate, and can effectively ensure the reliability of embedded blockage of the observation instrument.

Owner:POWERCHINA ZHONGNAN ENG

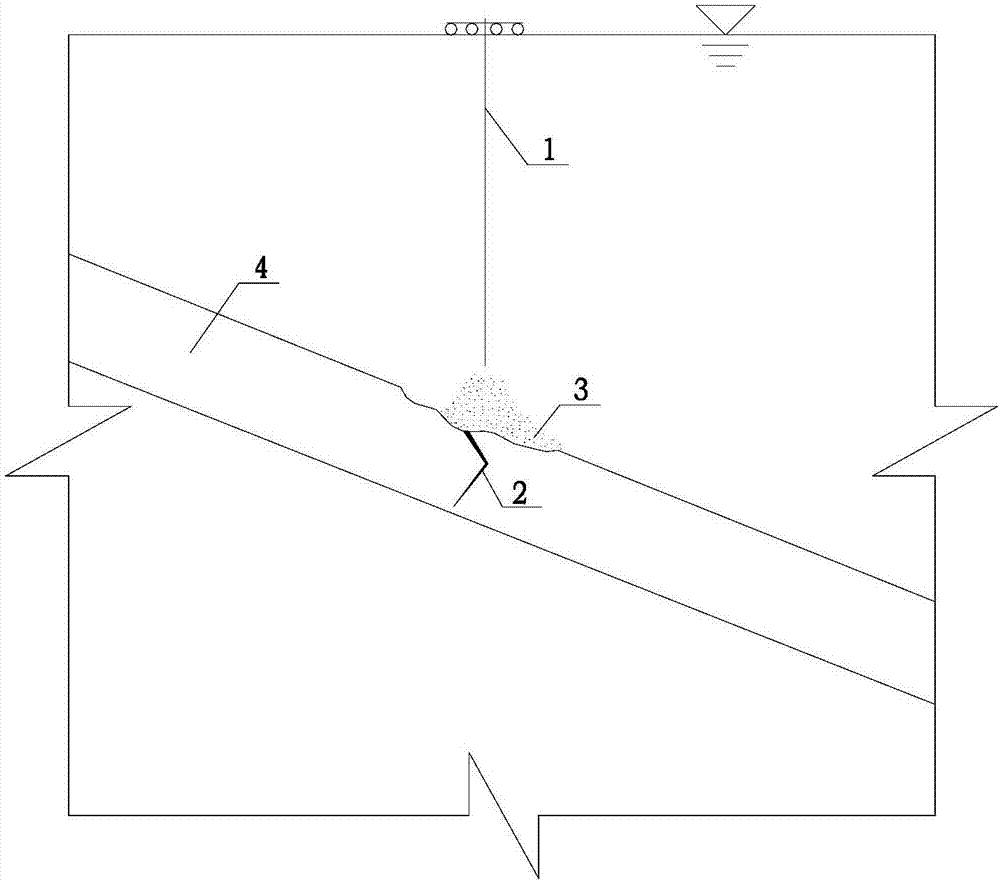

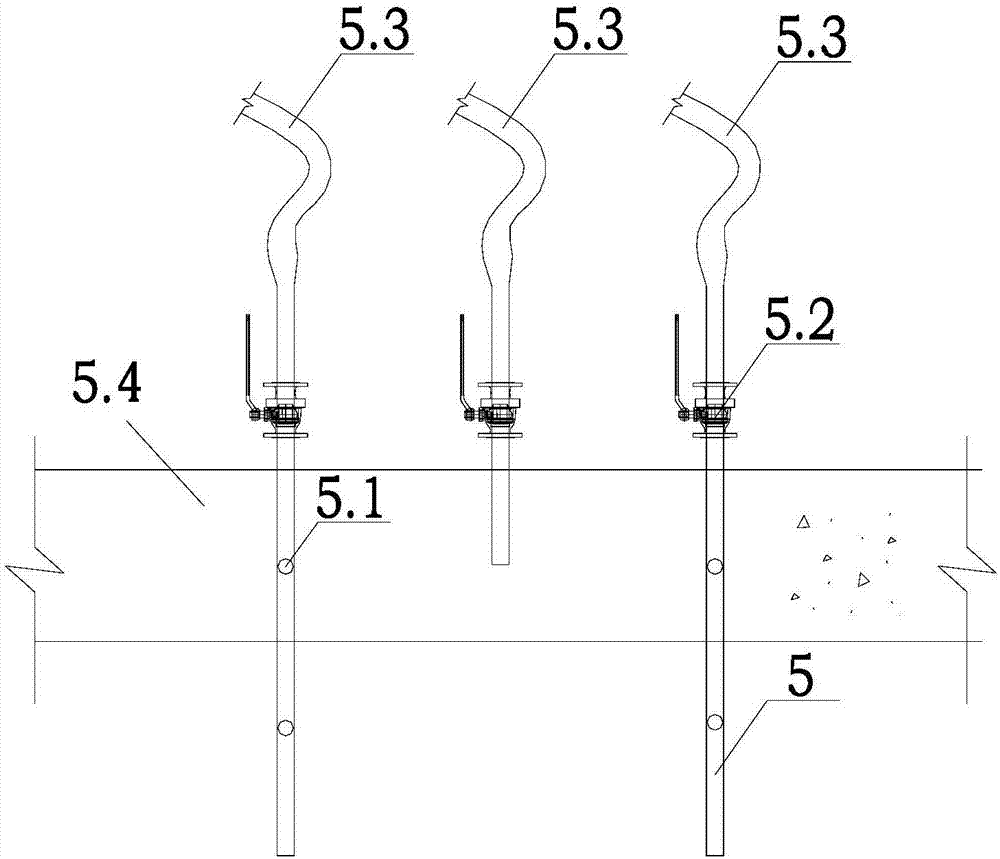

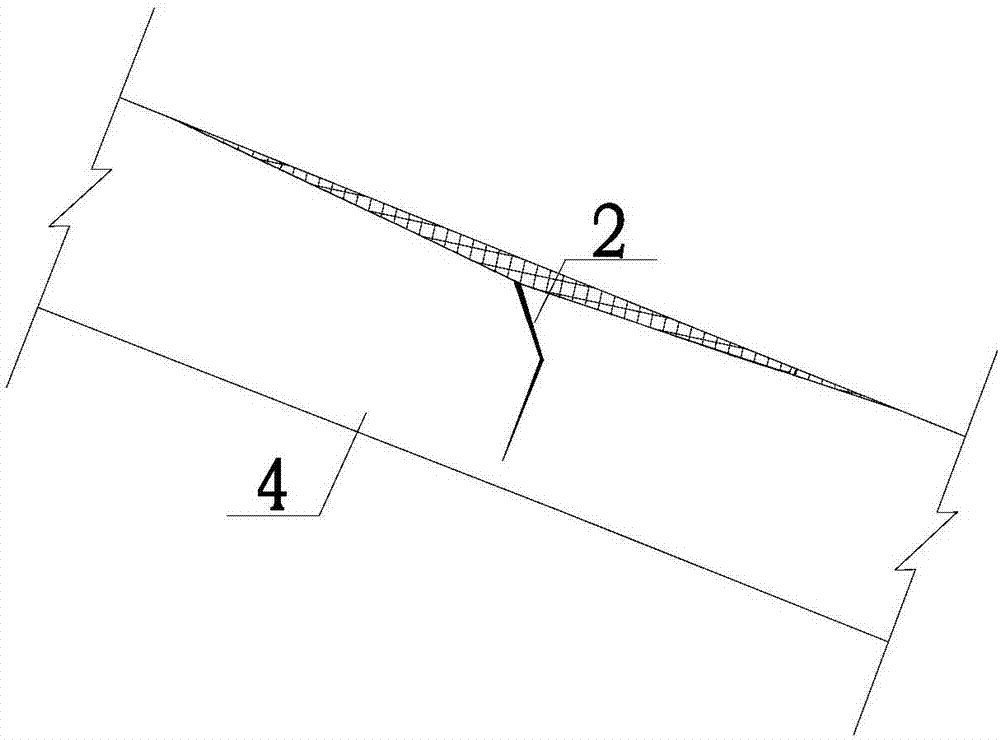

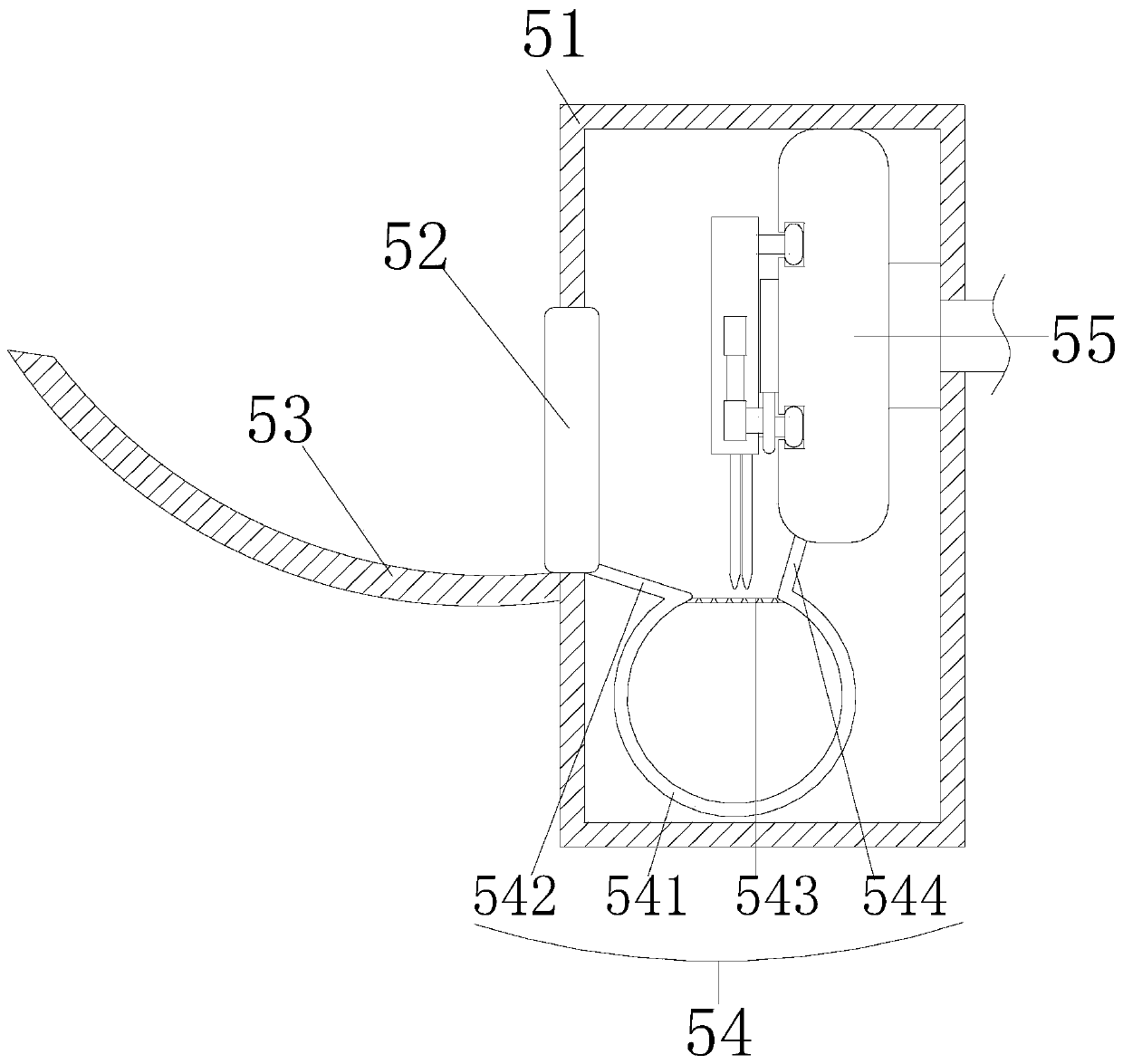

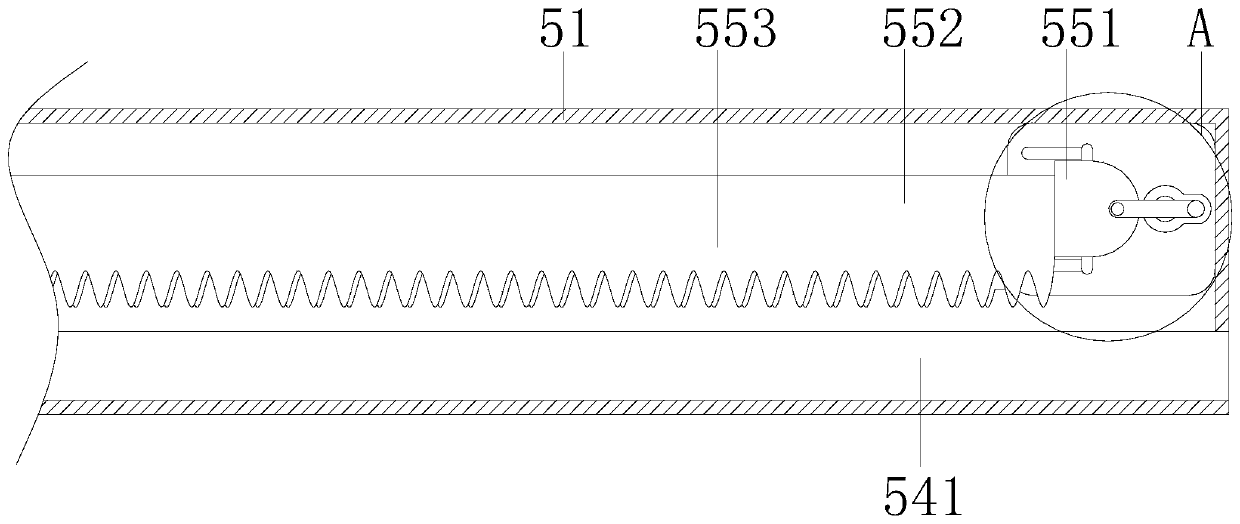

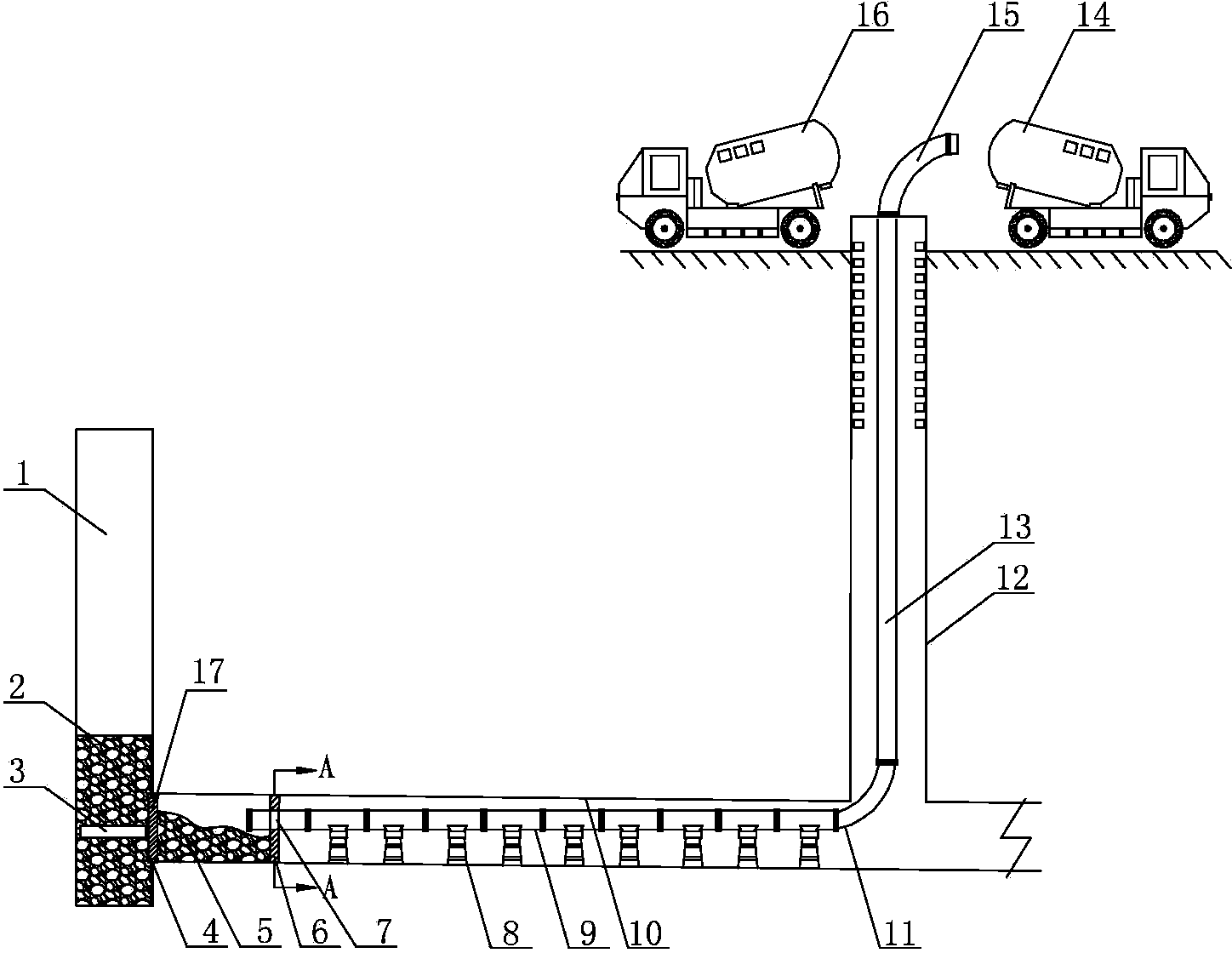

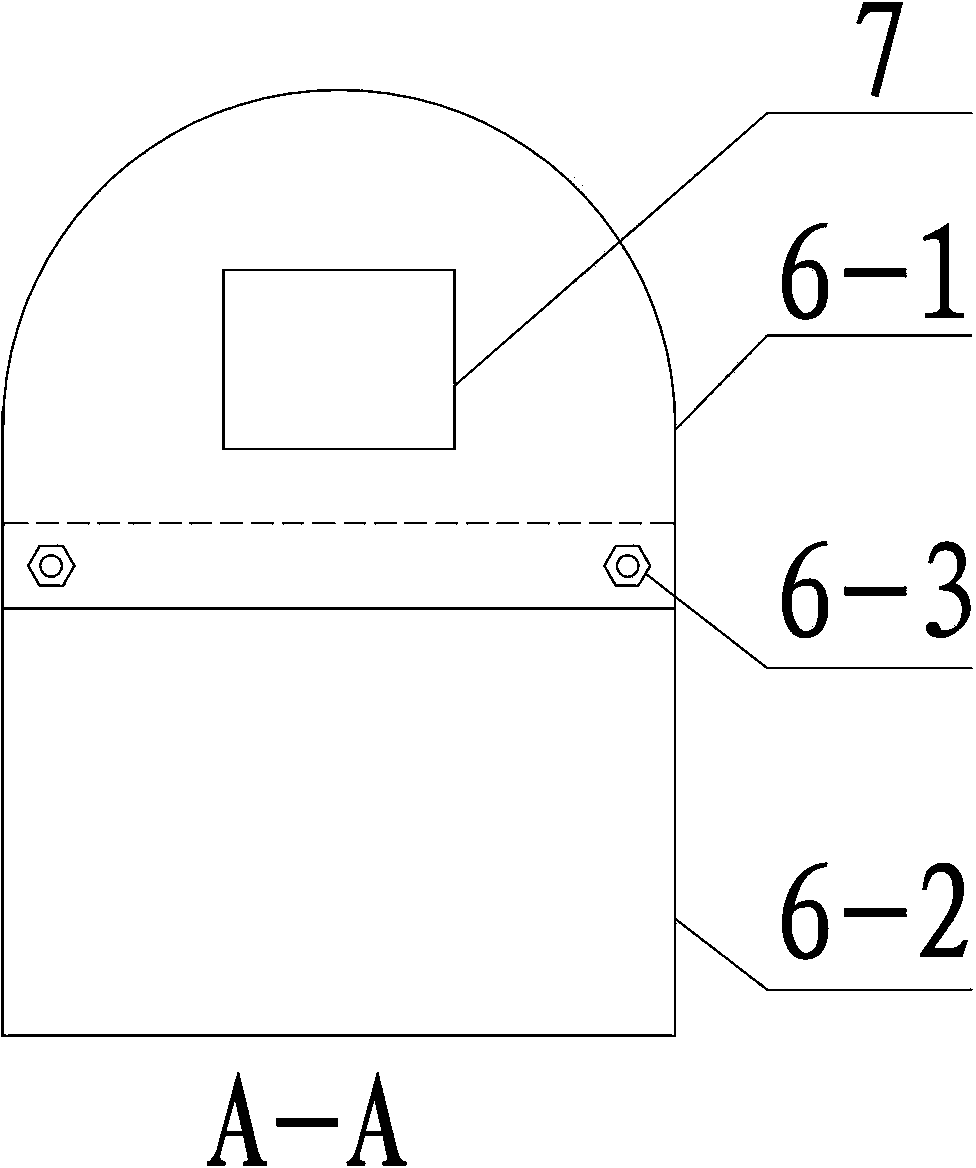

Concrete face rockfill dam leakage underwater blocking structure and method

PendingCN107012832AEffective restoration of support conditionsReduce benefit lossEarth-fill damsRock-fill damsWater flowPermeation

The invention discloses a concrete face rockfill dam leakage underwater blocking structure and method. The method is characterized by comprising the following steps that 1, underwater clogging material pouring is carried out, wherein a clogging material (3) is poured on a clearance opening (2) through a guide pipe (1), and the clogging material (3) is carried to the lower portion of a face plate (4) through permeation water flow; and 2, a grout pipe is pre-buried, wherein the pre-buried grout pipe (5) is a seamless steel floral pipe with the diameter not smaller than 2 cm, the length of the pre-buried grout pipe (5) penetrates the face plate to enter a padding layer (6) for the depth of 50 cm, a pentalobe grout hole (5.1) is formed in the side wall of the lower middle portion of the pre-buried grout pipe (5), and a valve (5.2) is arranged at the top of the pre-buried grout pipe (5) and guided to a water surface grout platform (5.4) through a grout hose (5.3). The defects that in the prior art, after leakage occurs, if leakage is not treated in time, fine materials in padding materials are constantly taken away by water flow, leakage is constantly deteriorated, and safety of a dam is threatened are overcome, and the beneficial effects of being convenient to construct, high in efficiency and capable of blocking a leakage channel within a short time are achieved.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

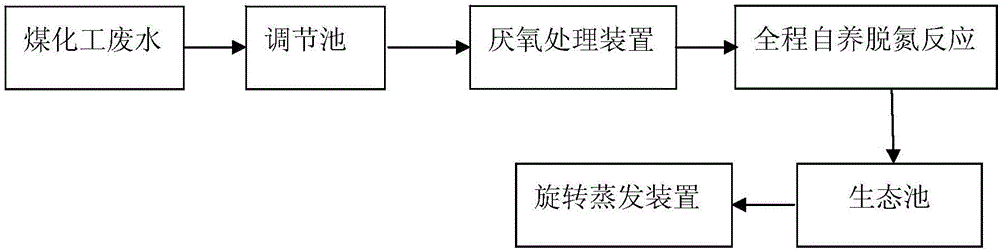

Ecological pool and efficient coal chemical engineering waste water treatment combined process and system

ActiveCN106495328AEffective absorptionAchieve absorptionMultistage water/sewage treatmentNature of treatment waterNitrogen removalWater treatment system

The invention provides an ecological pool and an efficient coal chemical engineering waste water treatment system and process based on the ecological pool. The system comprises an adjusting pool, an anaerobic treatment device, a whole-process autotrophic nitrogen removal reactor, the ecological pool and a rotary evaporation device which are sequentially connected and arranged. The adjusting pool is used for adjusting the pH value of coal chemical engineering waste water and adding a flocculant for treatment; the waste water treated by the anaerobic treatment device enters the whole-process autotrophic nitrogen removal reactor for nitrogen removal; the ecological pool is provided with a nanofiltration membrane device, an ecological floating bed is arranged on the water level of the ecological pool, and an aeration device is arranged on the bottom layer of the ecological pool. Filtrate obtained after filtering of the nanofiltration membrane device enters the rotary evaporation device. Clean effluent quality is obtained through the adjusting pool, the anaerobic treatment device, the whole-process autotrophic nitrogen removal reactor, the ecological floating bed and the aeration device in the ecological pool, blocking of a nanofiltration membrane can be effectively reduced, and the service life of the nanofiltration membrane can be prolonged. The whole process has the advantages of being low in energy consumption and free of secondary environmental pollution.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

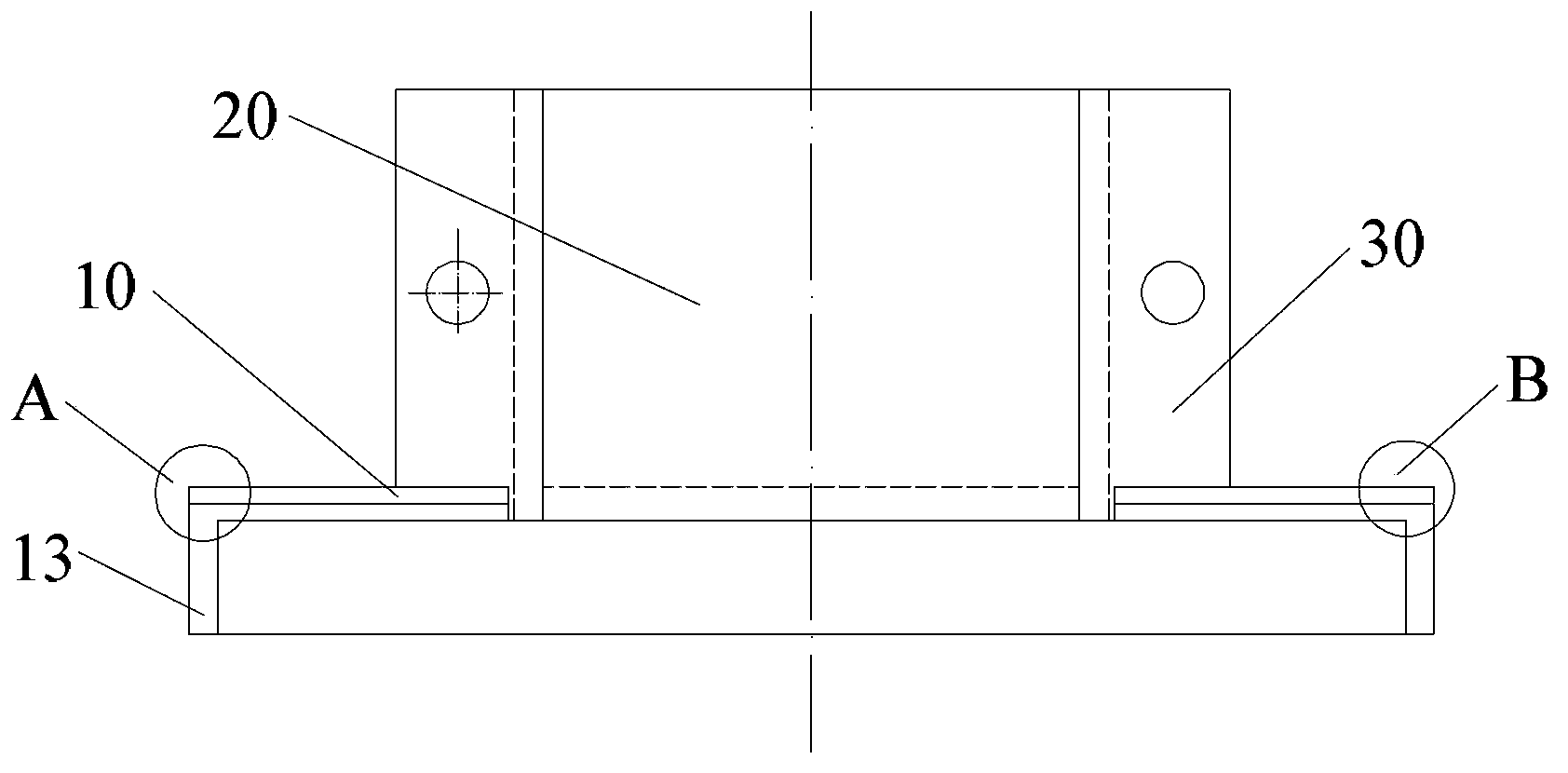

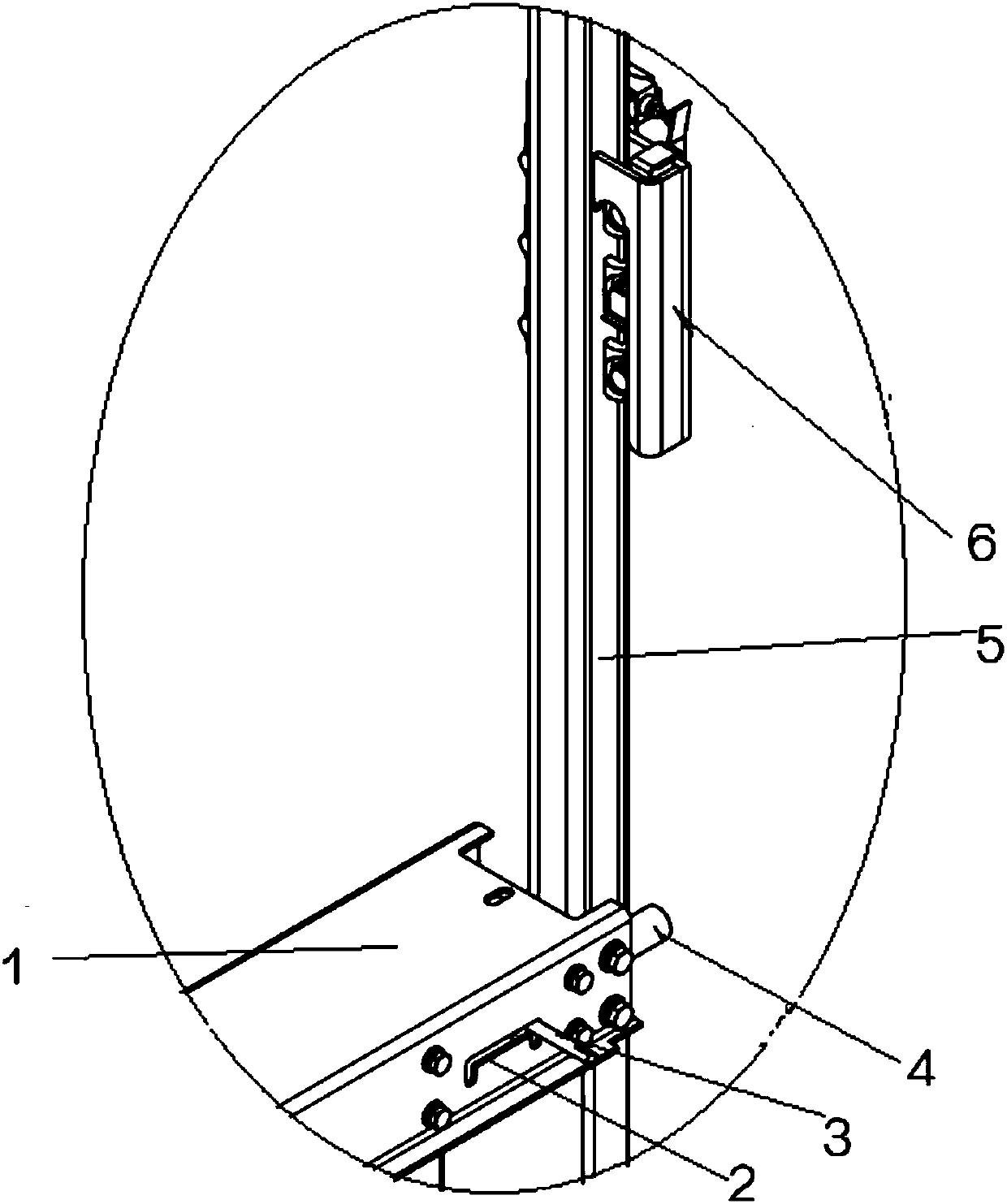

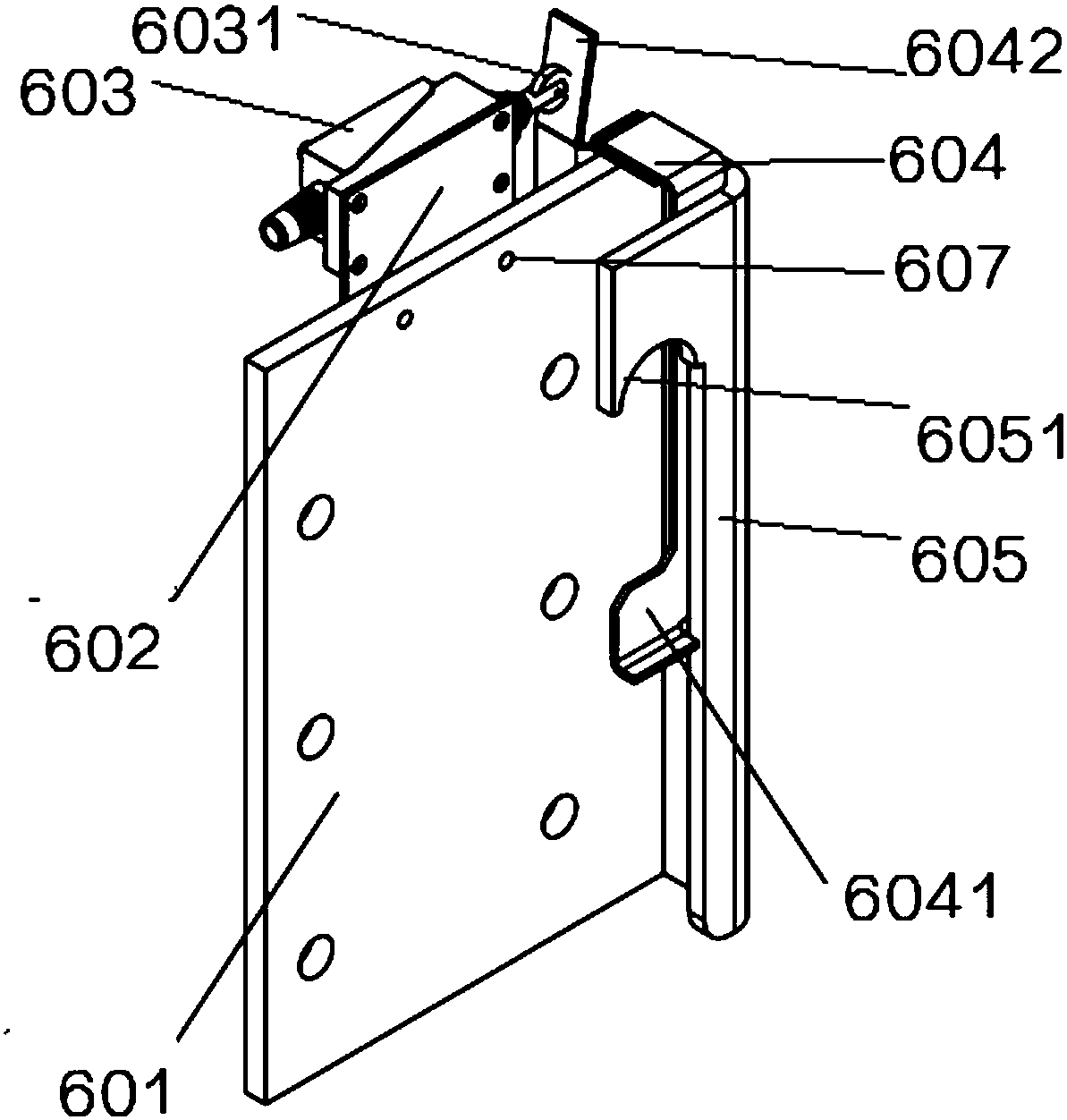

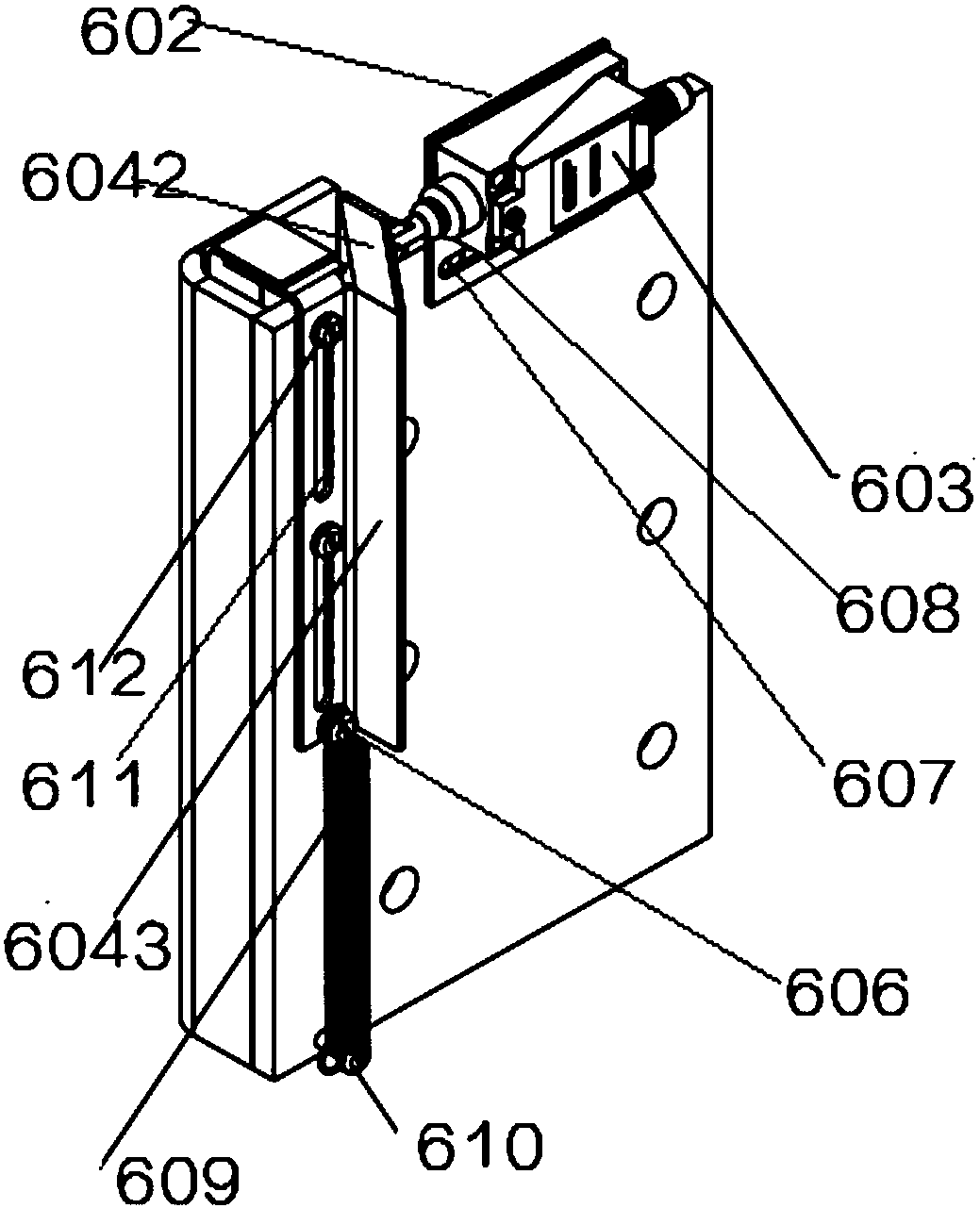

Bracket used for cable plugging

ActiveCN103545723AGuaranteed blocking effectSubstation/switching arrangement casingsEngineeringMechanical engineering

Owner:STATE GRID CORP OF CHINA +2

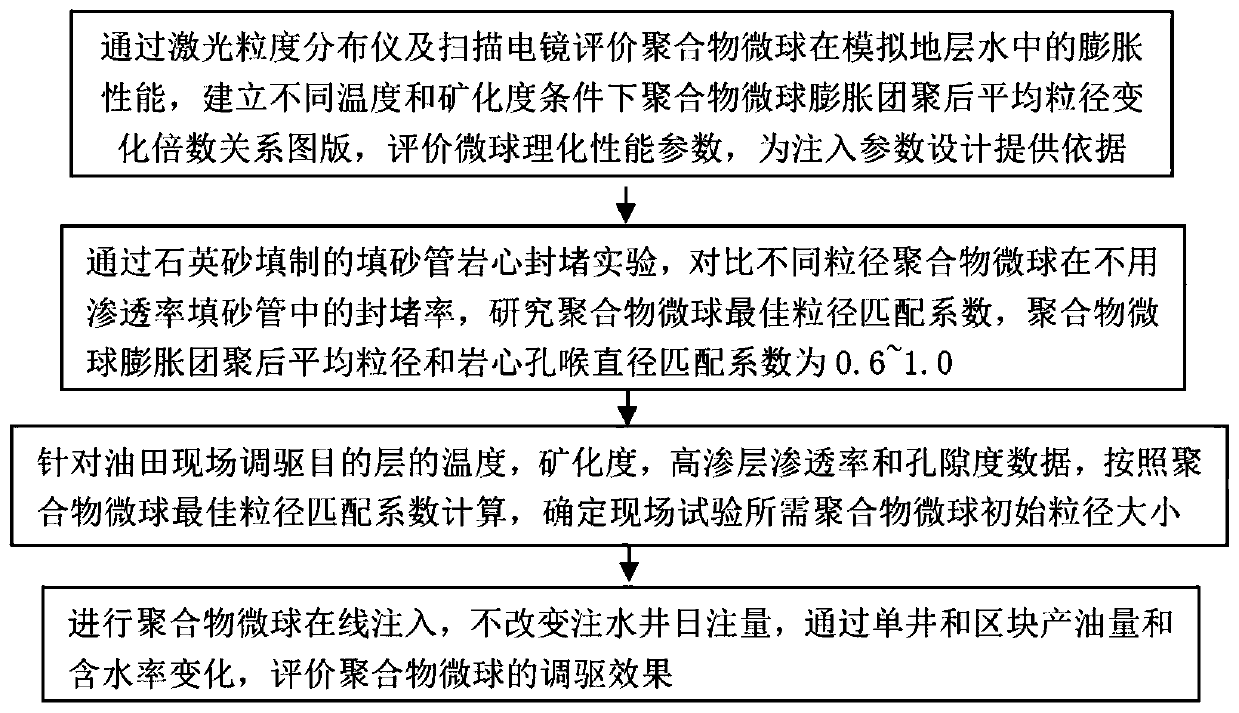

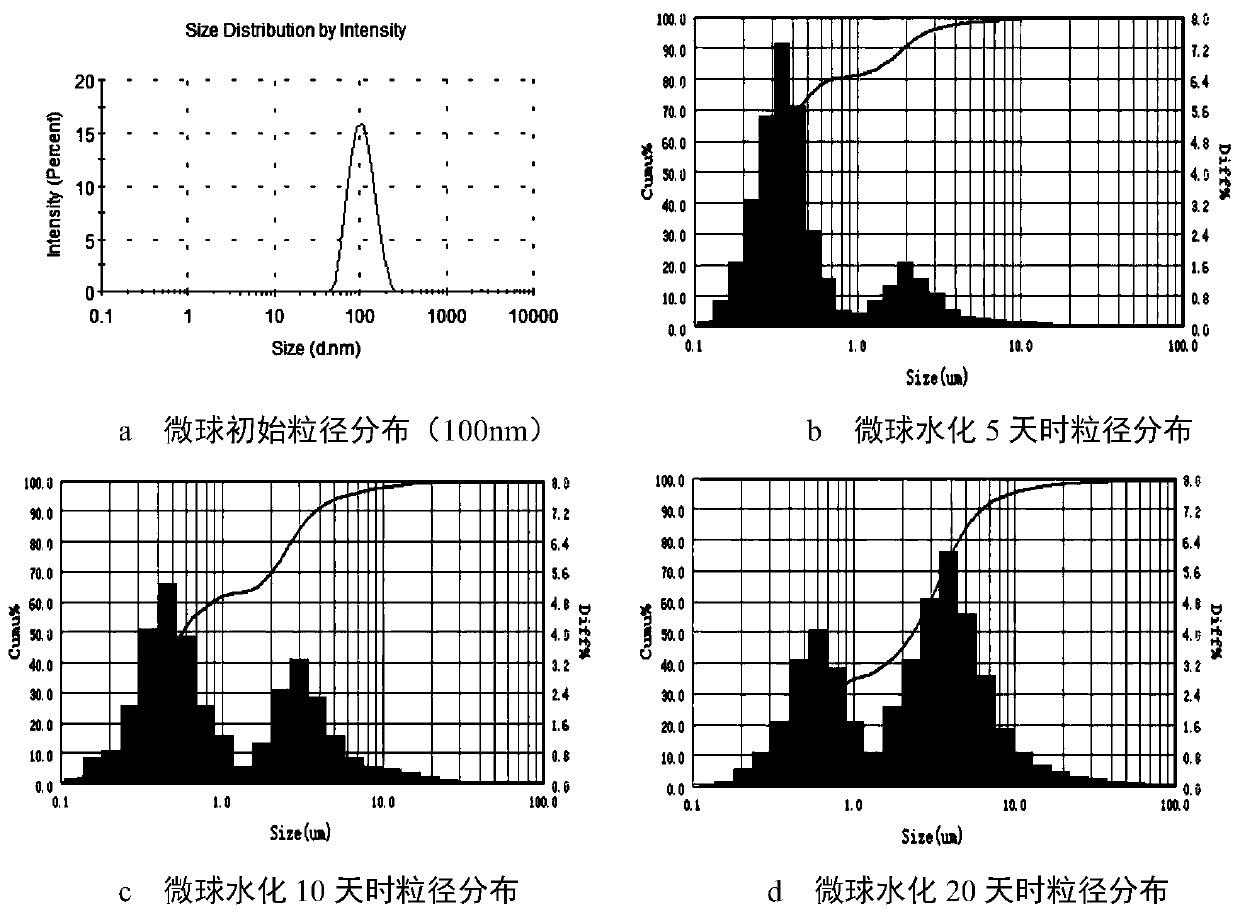

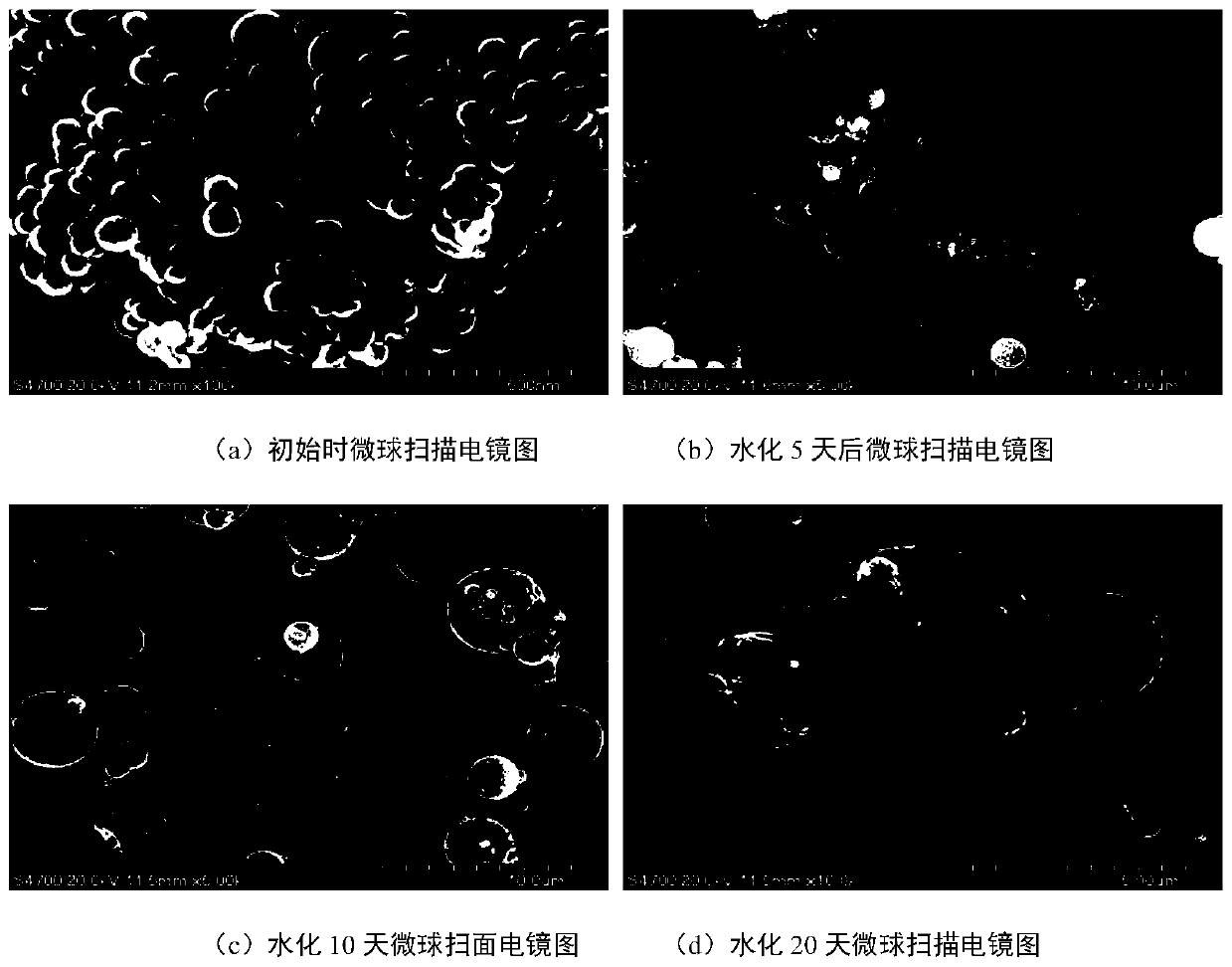

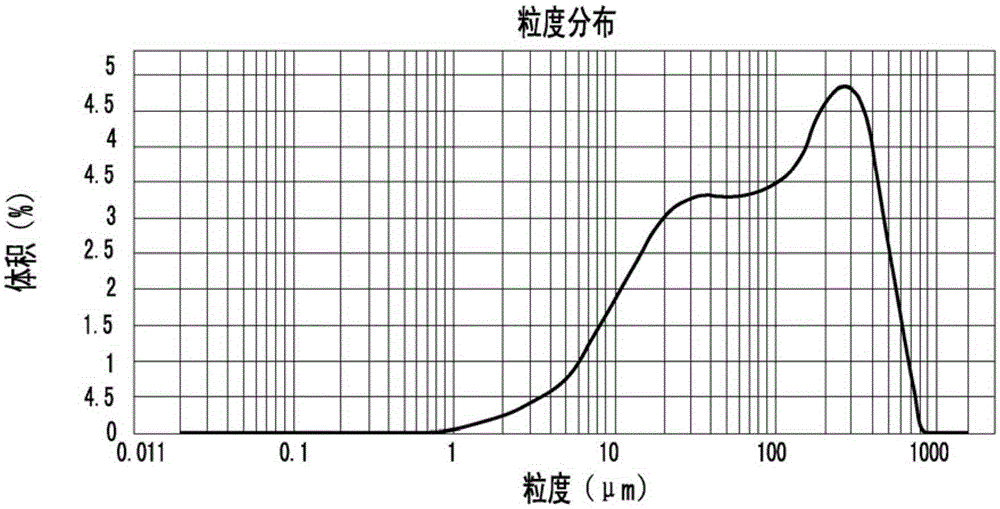

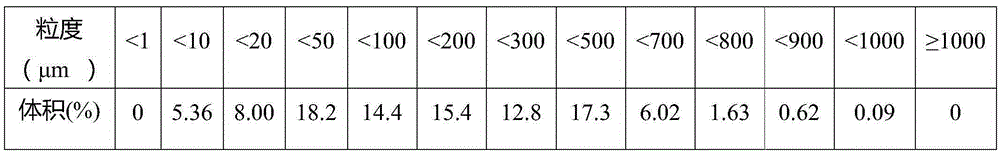

Polymer microsphere deep profile control and flooding injection particle size selection method

InactiveCN110094201AGuaranteed blocking effectGuarantee the effect of on-site adjustment and driveClimate change adaptationFluid removalPolymer scienceMicrosphere

The invention discloses a polymer microsphere deep profile control and flooding injection particle size selection method. The polymer microsphere deep profile control and flooding injection particle size selection method comprises the following steps: 1, an average particle size change multiple relationship chart after polymer microspheres are expanded and agglomerated under conditions of different temperatures and mineralization degrees is established; 2, an optimal particle size matching factor is introduced; 3, calculation is conducted according to the optimal particle size matching factorof polymer microspheres, and the particle size of the polymer microspheres required by a field test is determined; and 4, according to the determined particle size of the polymer microspheres, on-lineinjection of the polymer microspheres is conducted, the daily injection amount of a water injection well is not changed, and the profile control and flooding effect of the polymer microspheres is evaluated through the block daily oil yield and a water content change curve. Polymer microsphere deep profile control and flooding injection particle size selection is determined by simulating the profile control and flooding process of the polymer microspheres in porous media under laboratory conditions.

Owner:PETROCHINA CO LTD

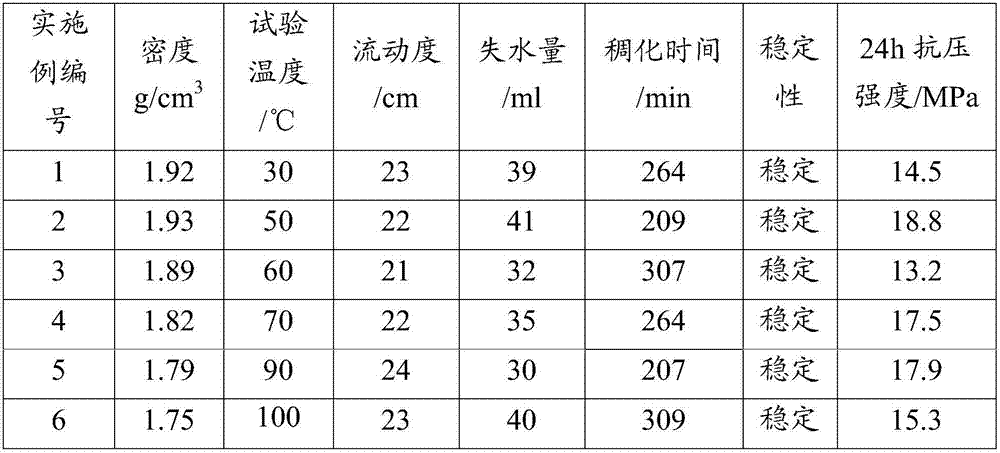

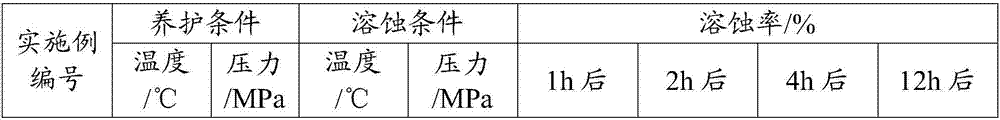

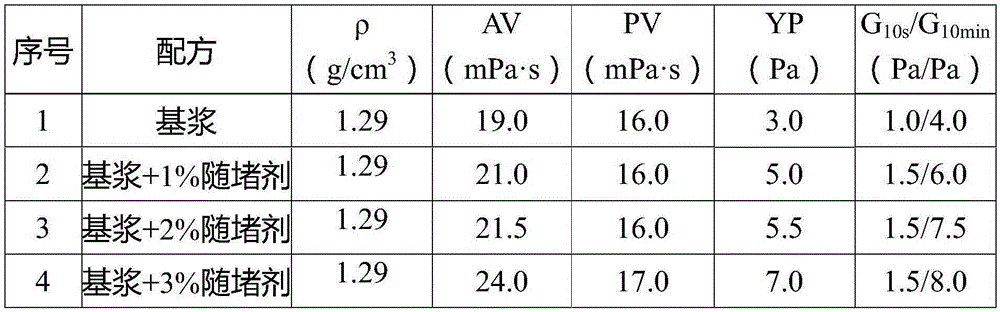

Acid-soluble cement temporary plugging agent and preparation method thereof

The invention discloses an acid-soluble cement temporary plugging agent and a preparation method thereof, and belongs to the field of oil well cementation. The temporary plugging agent comprises, by weight part, 1 part of reheated magnesia, 0.5-1.0 part of magnesium chloride, 0.05-0.15 part of magnesium carbonate, 0.1-0.4 part of calcium carbonate, 0.01-0.05 part of sodium tripolyphosphate, 0.005-0.01 part of ultrafine silica, 0.01-0.04 part of ammonium phosphate, 0.01-0.05 part of a retarder, 0.03-0.06 part of a fluid loss additive, and 0.3-0.6 part of water. According to the provided acid-soluble cement temporary plugging agent, the retarder can adjust the setting time of the acid-soluble cement temporary plugging agent and makes the acid-soluble cement temporary plugging agent suitable for an oil well of 30-100 DEG C, so that it is ensued that an oil well with relatively high temperature is temporarily plugged. The fluid loss additive can improve the plugging ability of the acid-soluble cement temporary plugging agent and reduces the water loss of the acid-soluble cement temporary plugging agent, so that the plugging effect on the reservoir is ensured. The acid-soluble cement temporary plugging agent is wide in application range, good in temporary plugging effect, and suitable for large-scale popularization and application.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

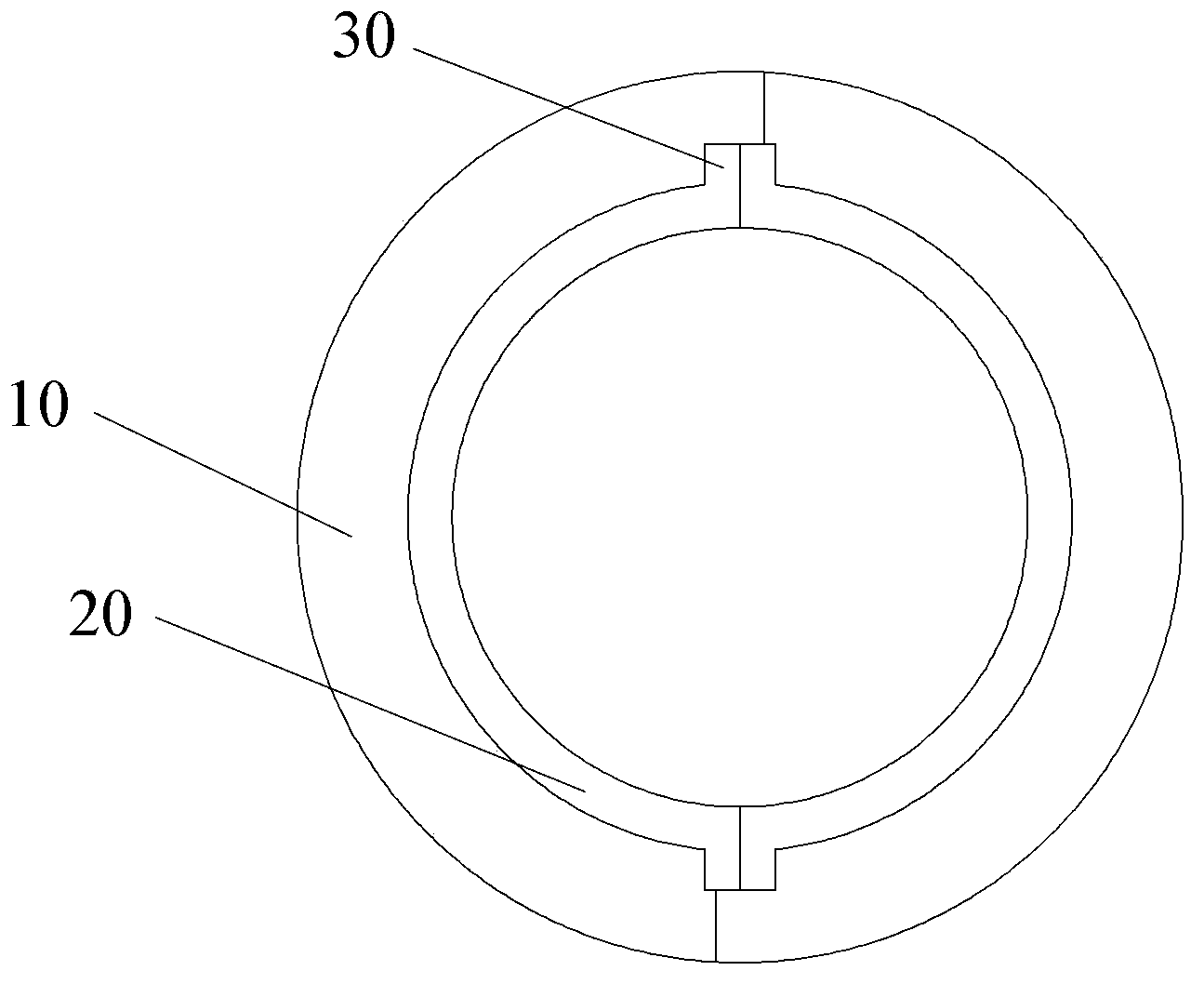

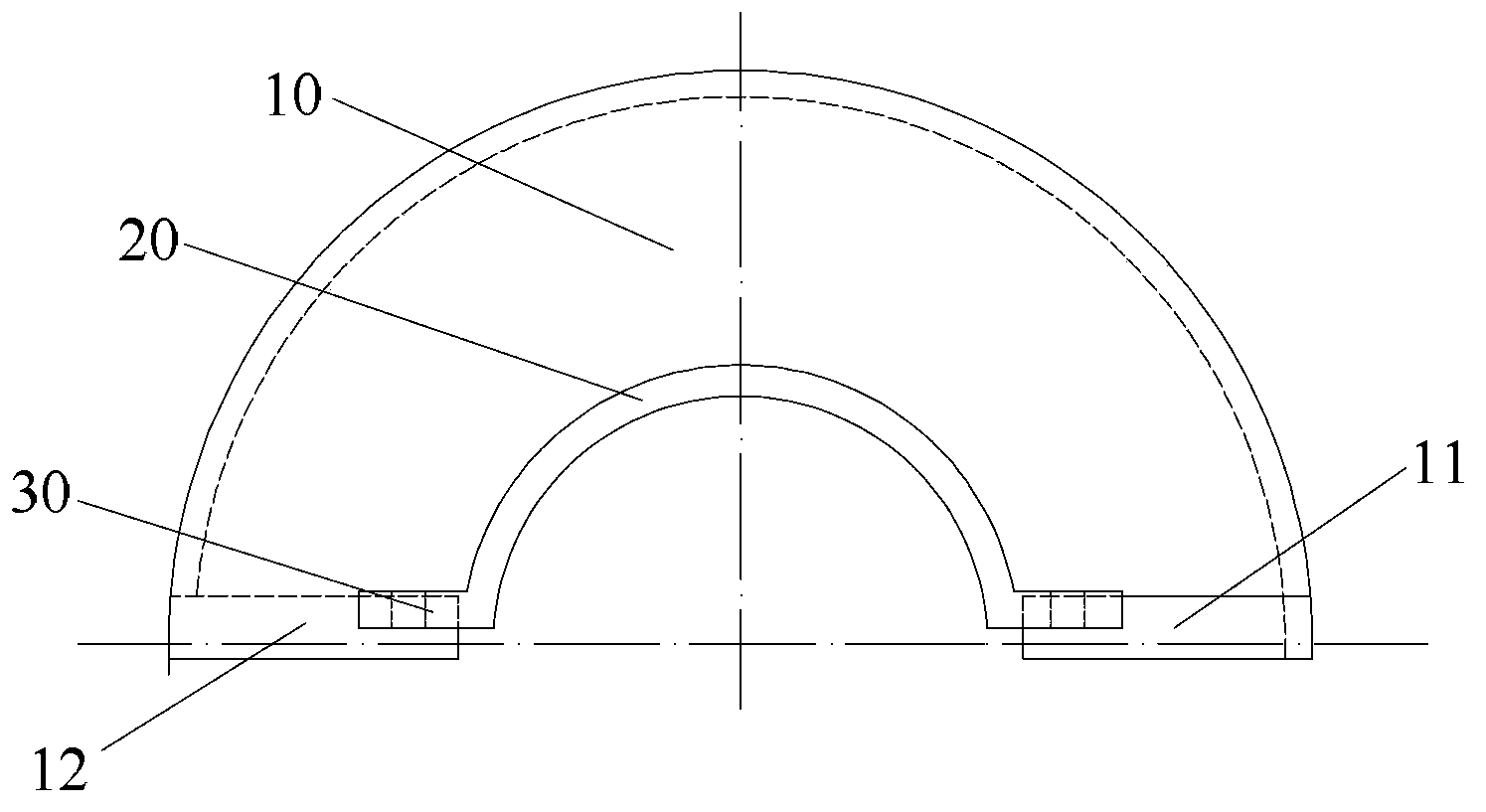

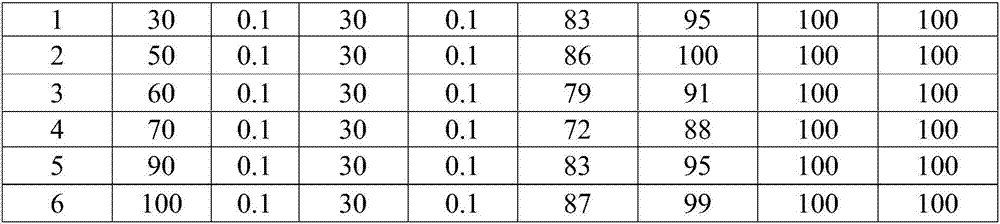

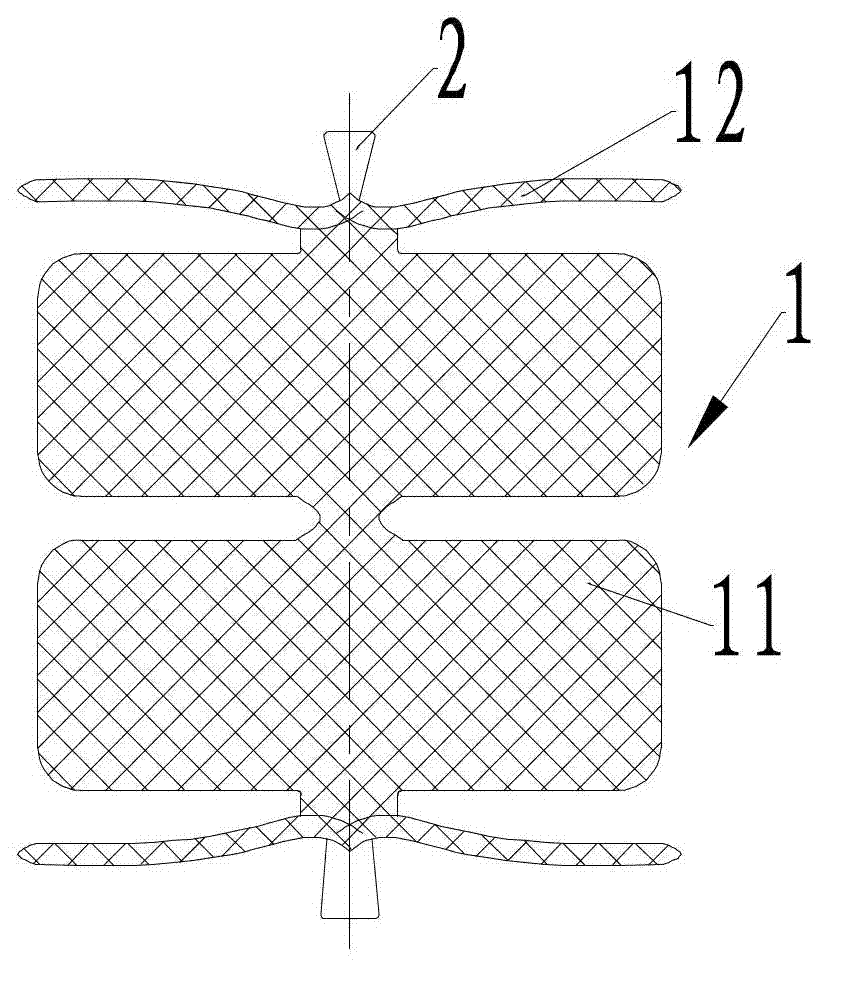

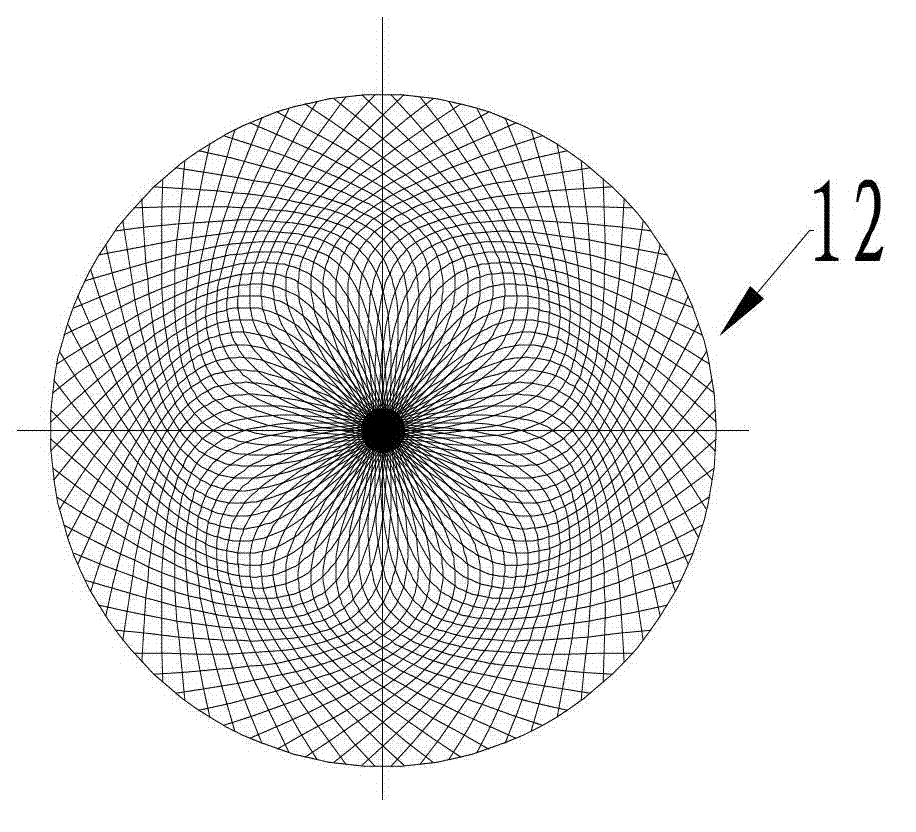

Occluder

InactiveCN102805673AGuaranteed blocking effectReduce section diameterProsthesisCircular discPolyester

The invention discloses an occluder for treating congenital heart diseases. The occluder comprises a support and metal sleeves. The support comprises disks located at two ends of the support and a waist located between the disks. The support with a mesh structure and a hollow interior is braided by shape memory alloy metal wires. The metal sleeves are disposed at the centers of the two disks. Since polyester fiber membrane in the support is removed, possibility of hemolysis and immunological rejection of a patient is reduced, occlusion effectiveness of the occluder is guaranteed, section diameter of the occluder entering a conveyer is reduced, and optimal treating opportunities are provided for more patients.

Owner:SHANGHAI SHAPE MEMORY ALLOY

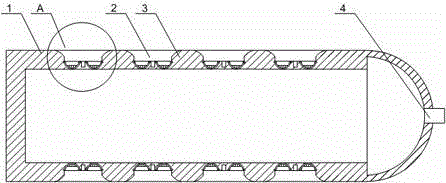

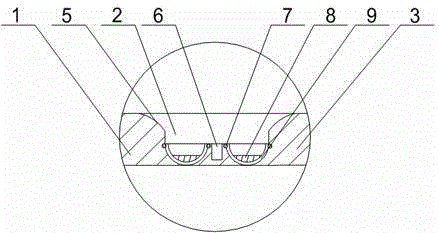

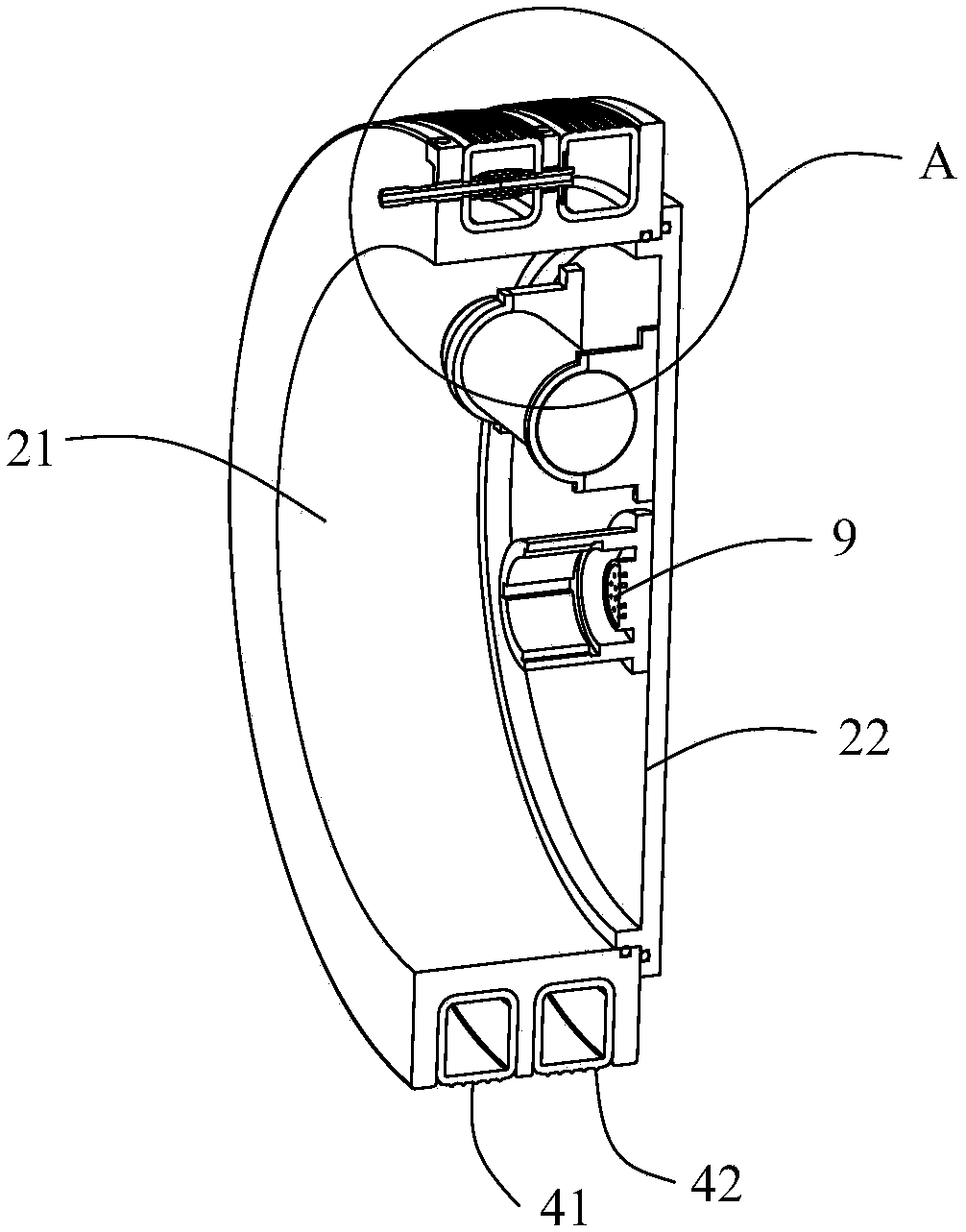

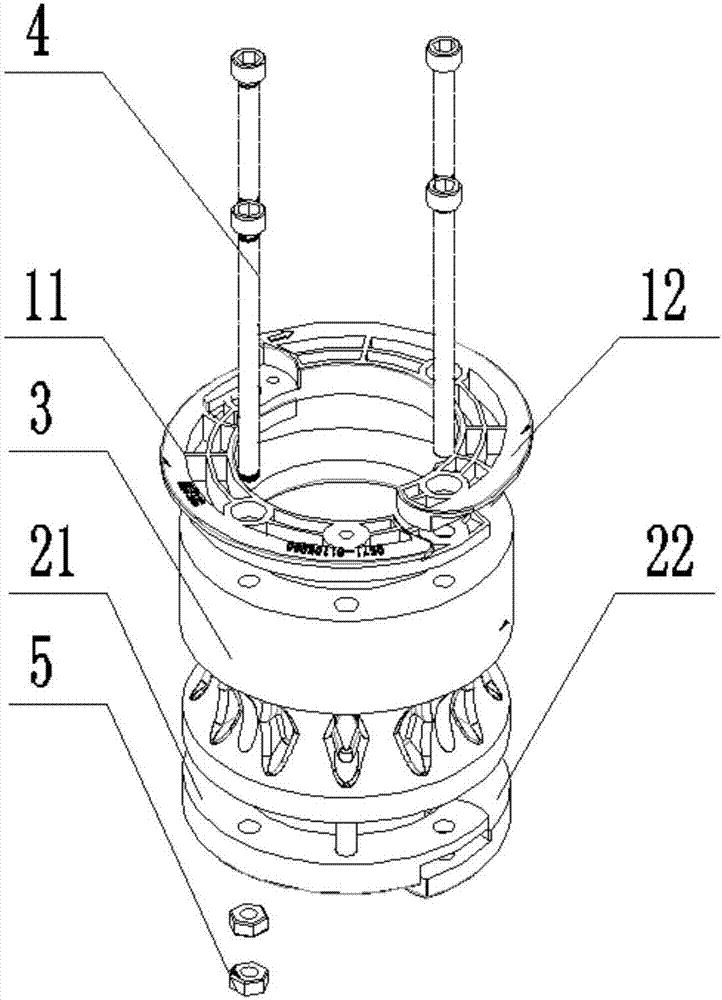

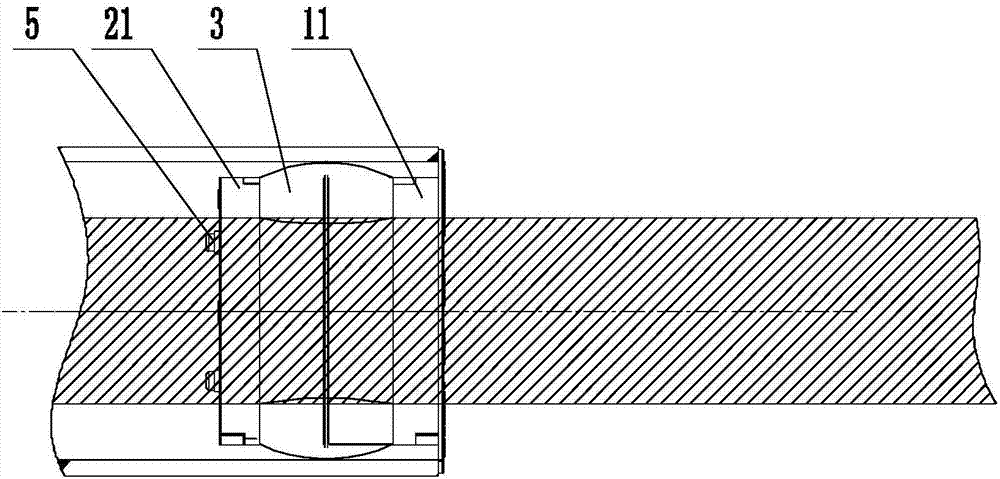

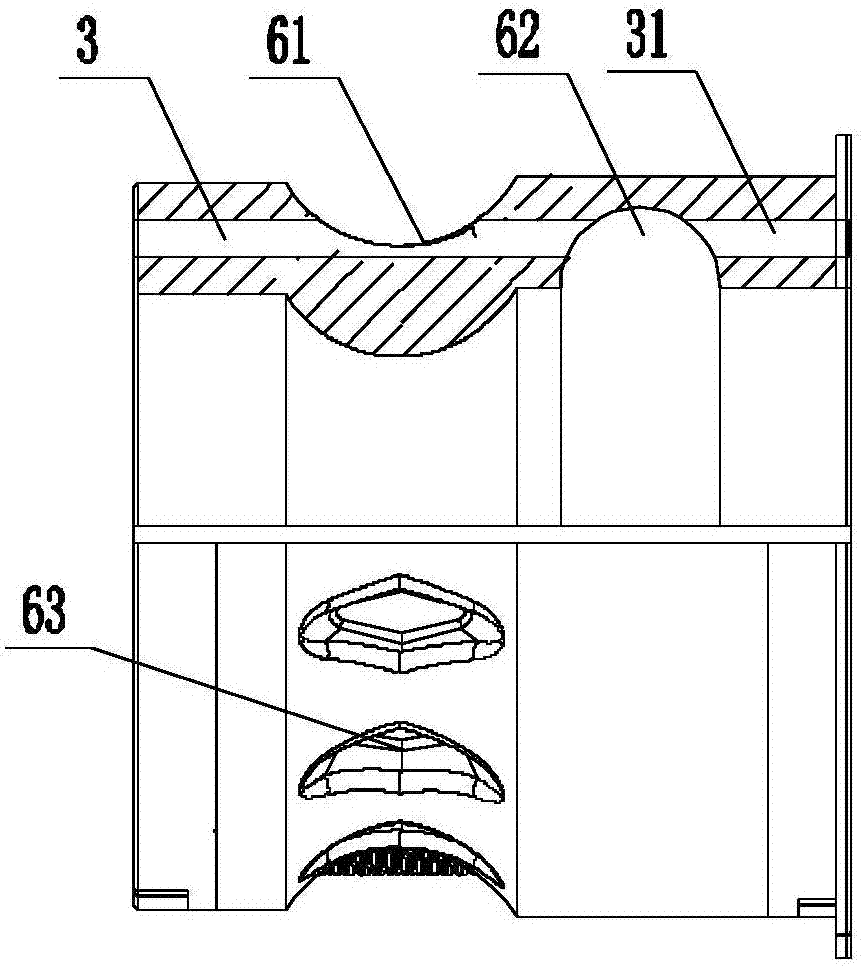

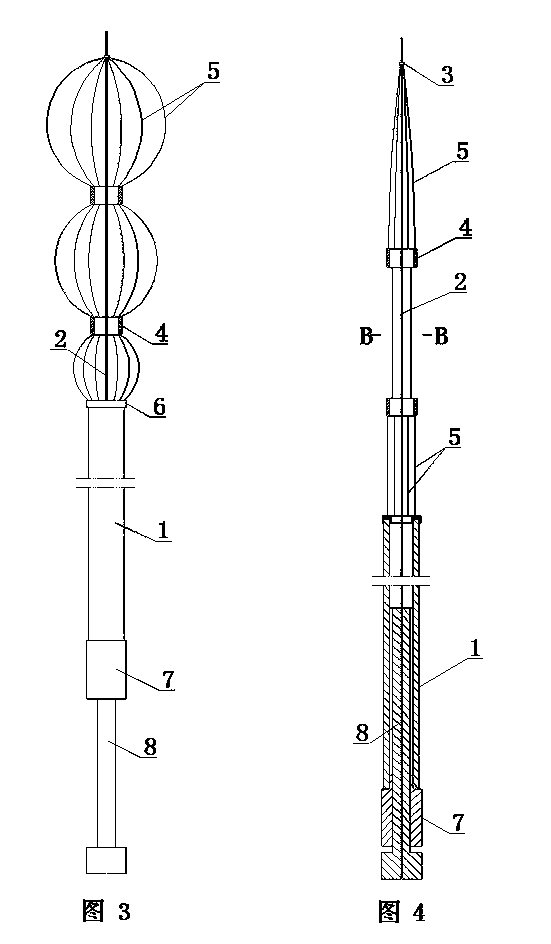

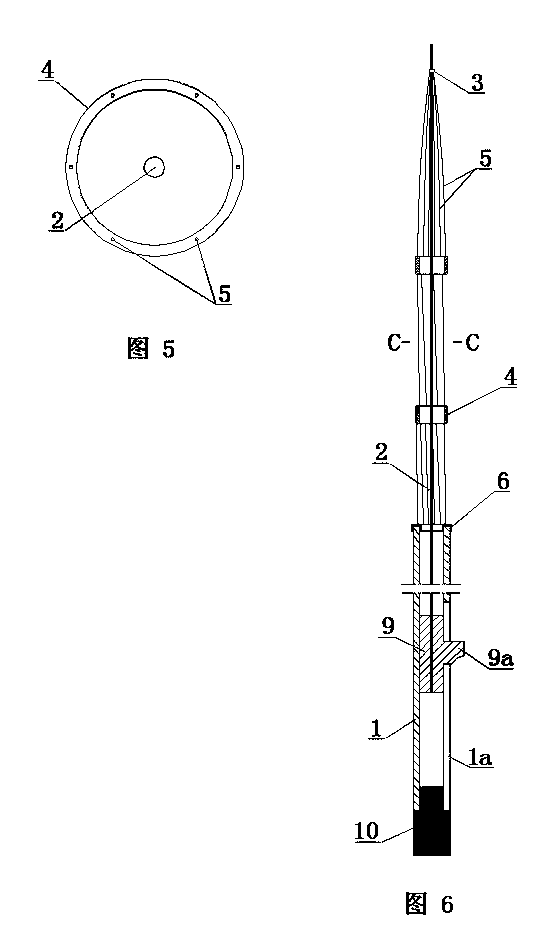

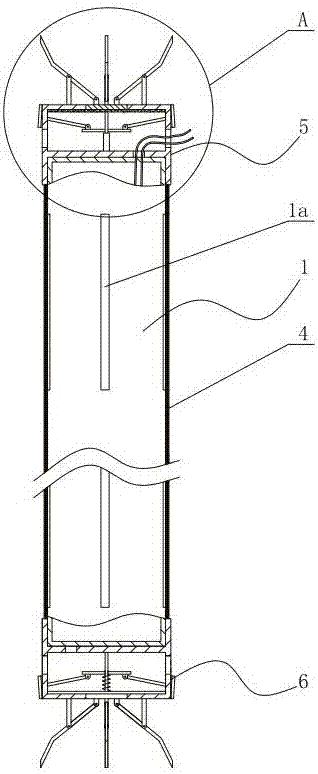

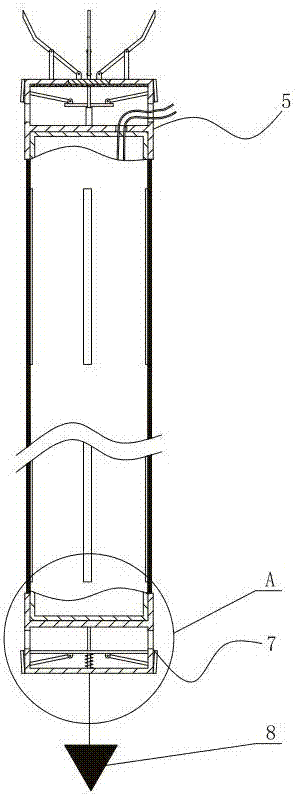

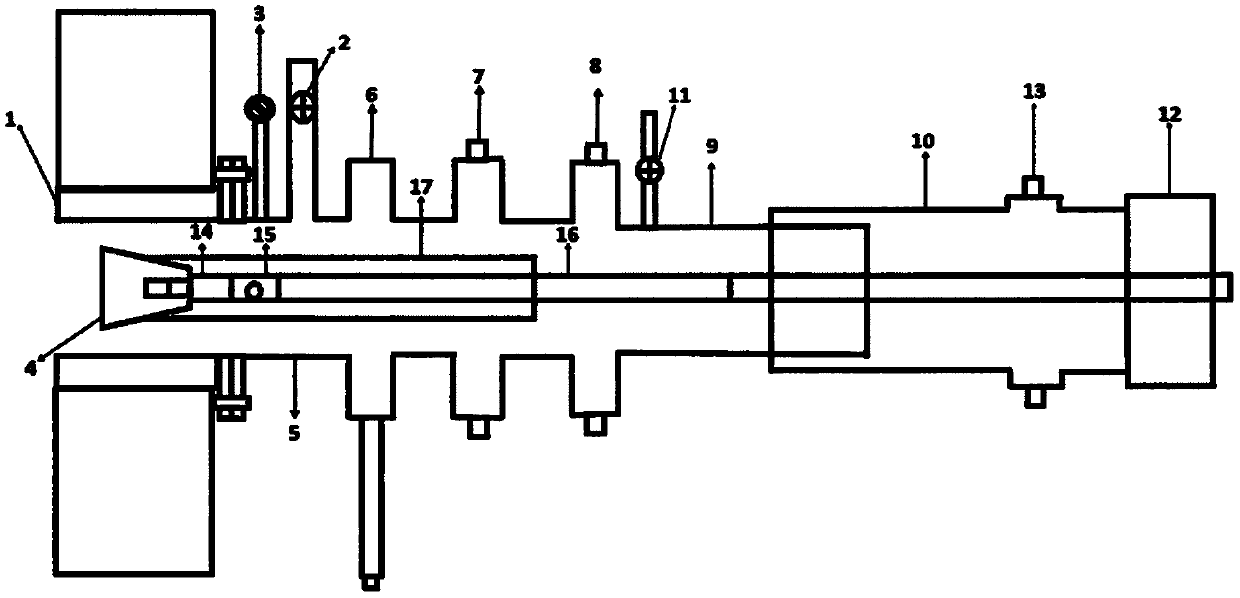

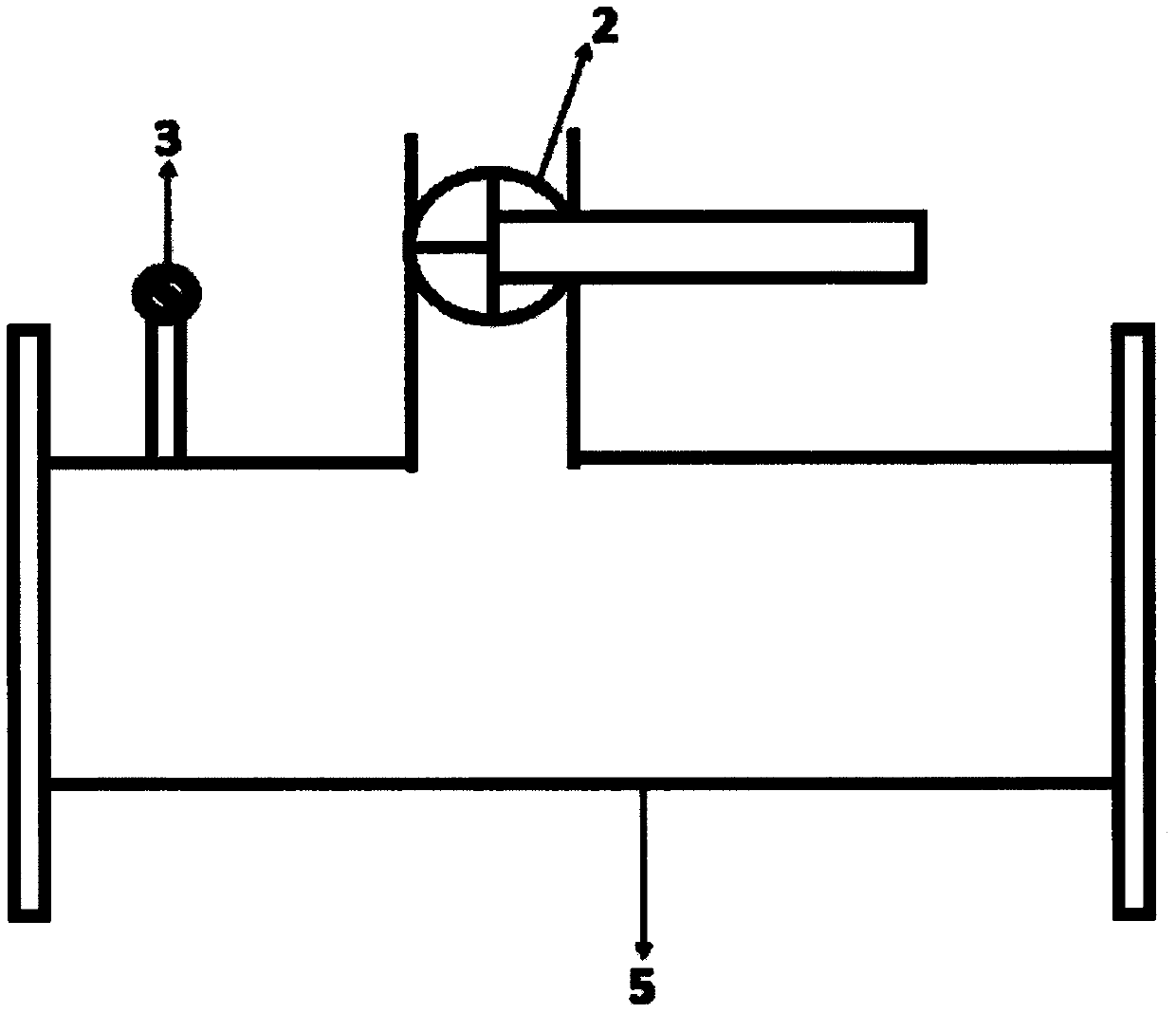

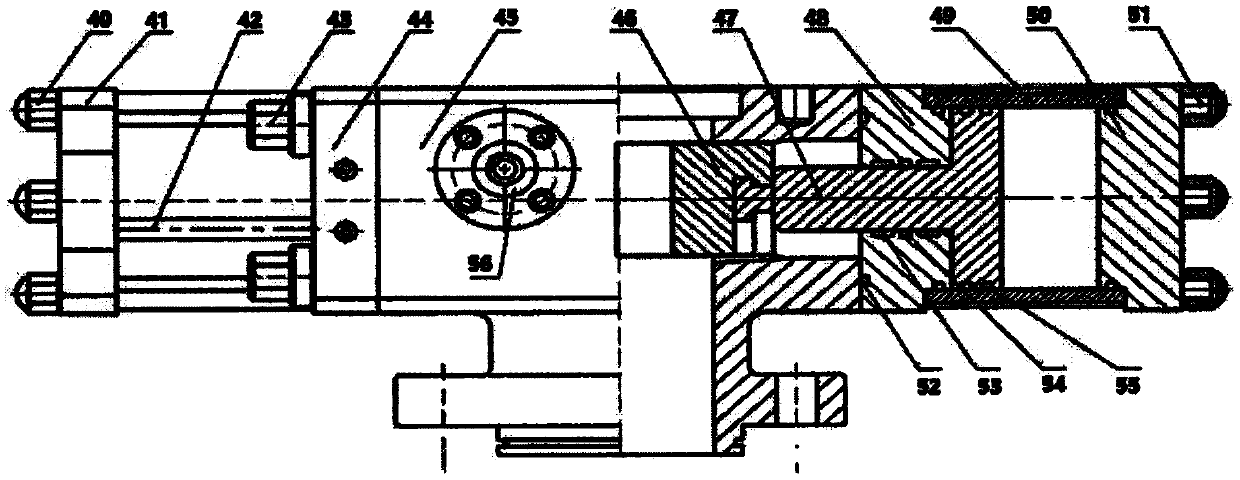

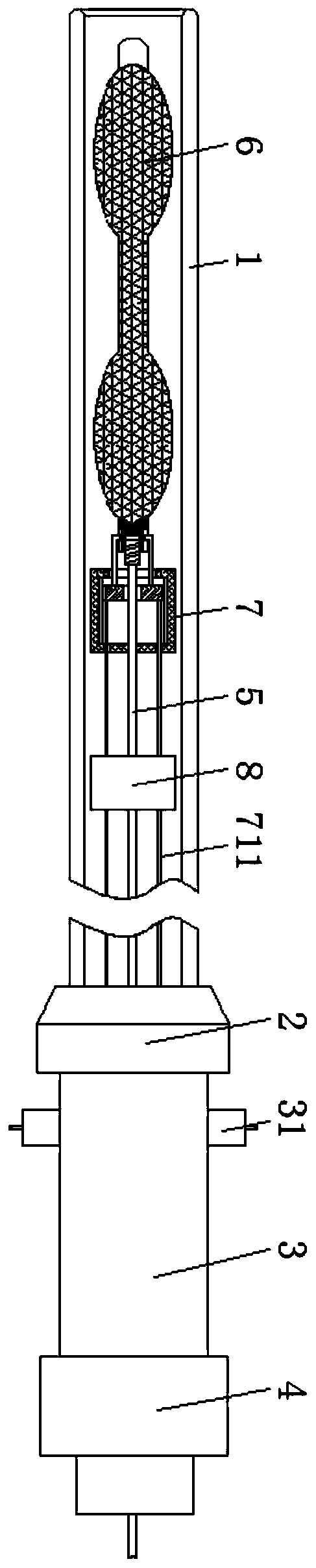

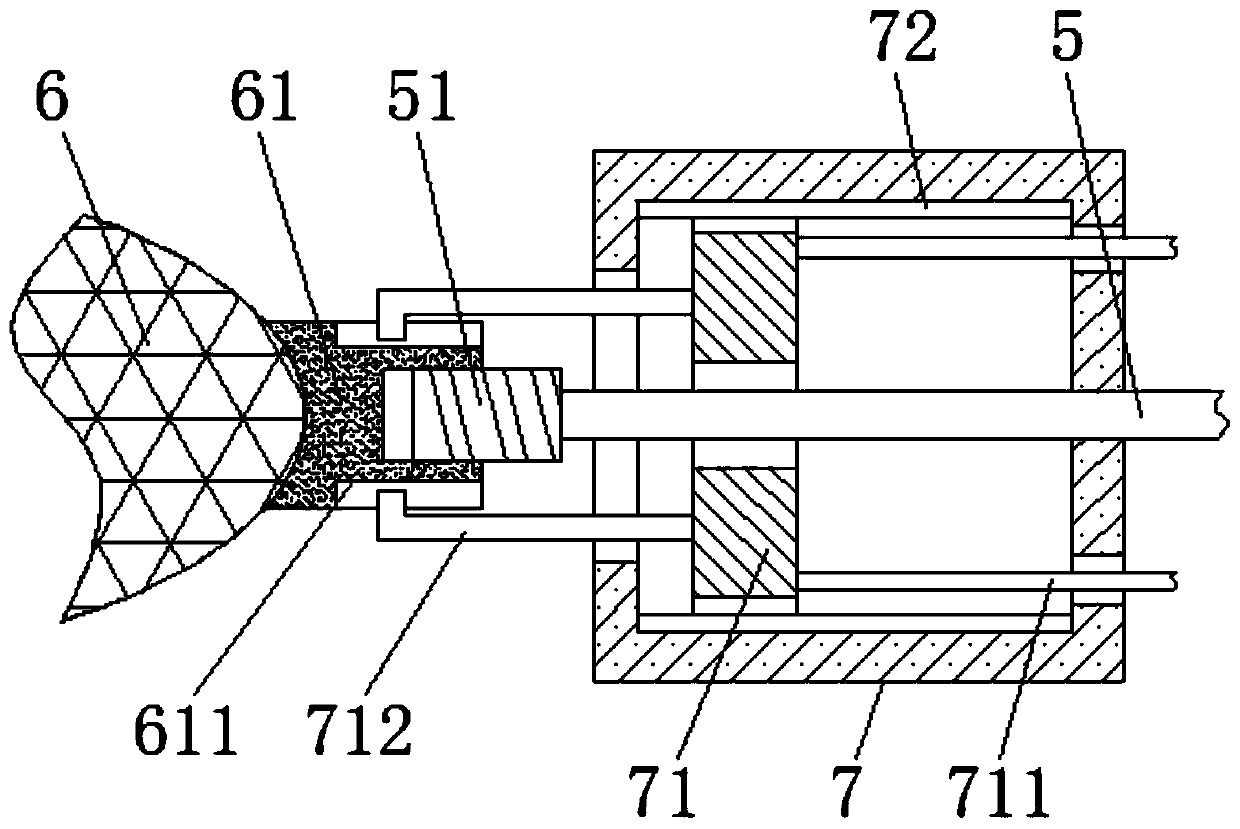

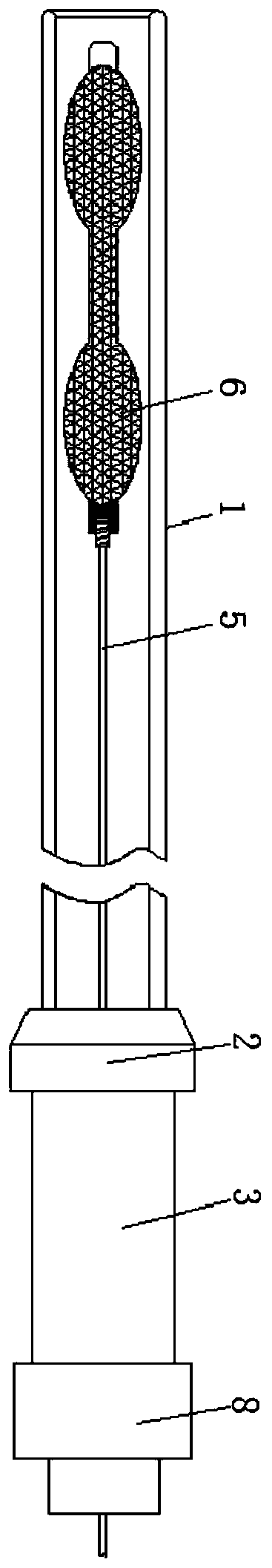

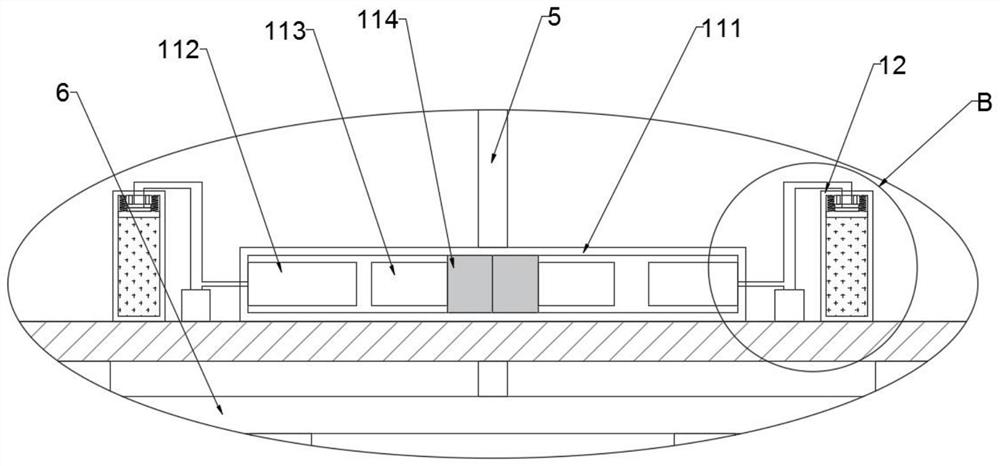

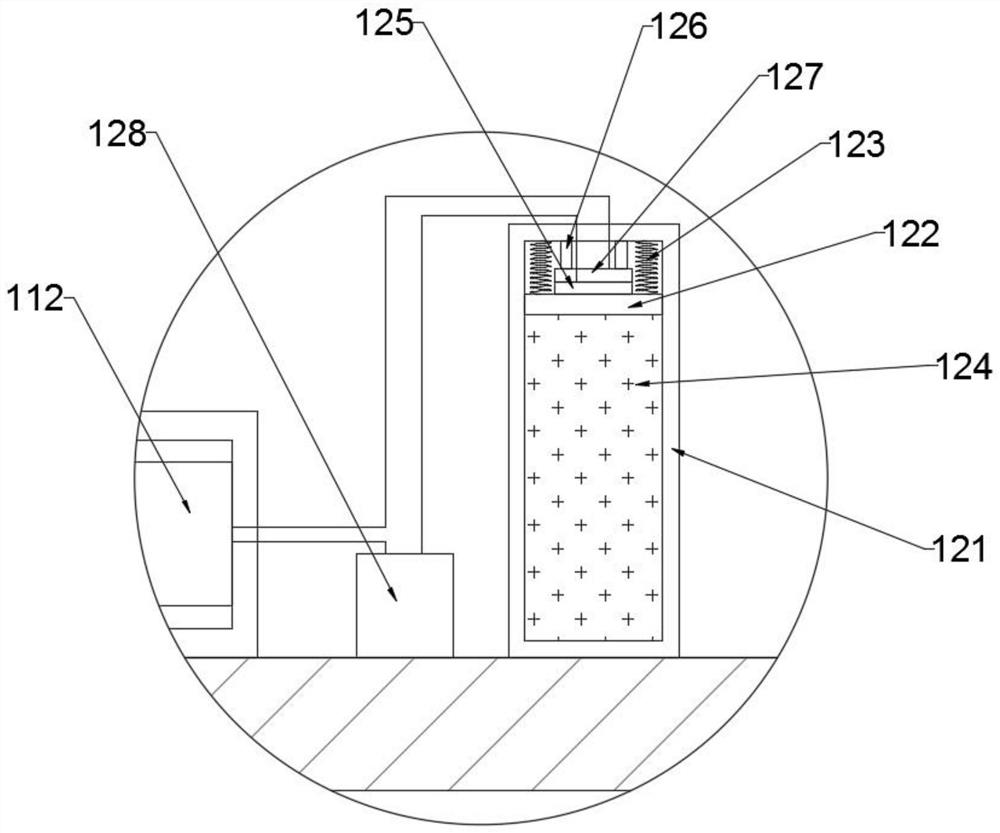

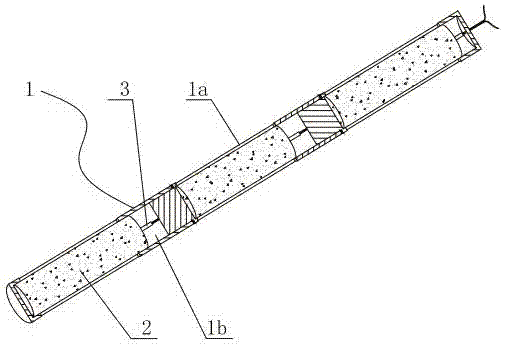

Air bag pipeline plugging device

ActiveCN108662347AGuaranteed blocking effectGuaranteed plugging reliabilityPipe elementsEngineeringControl valves

The invention provides an air bag pipeline plugging device. The device comprises a supporting frame arranged at a closed opening mode, and a long handle installation tool which extends in the axial direction of a pipeline, an air bag assembly, an air source, a control valve set and an installation seat are installed on the supporting frame, the air bag assembly is provided with at least two air bags which are installed on the periphery of the supporting frame, the plurality of air bags are arranged in the axial direction of the pipeline, the air source is connected with an air nozzle of each air bag through an air supply pipeline, the control valve set is arranged on the air supply pipeline so as that the air source is enabled to independently inflate the air bags, and the end, close to the supporting frame, of the long handle installation tool is detachably connected with the installation seat. Under the condition that the single air bag is damaged, the pipeline can still be plugged and can work normally, so that the pipeline plugging effect and reliability are guaranteed; and the supporting frame can be conveniently conveyed into the pipeline through the connection between the long handle installation tool and the installation seat, the supporting frame can be fixed on the inner wall of the pipeline after the air bag are inflated, and the pipeline can be plugged, and therefore, the installation of the supporting frame is very convenient.

Owner:STATE NUCLEAR POWER PLANT SERVICE

Following-drilling plugging agent and preparation technology thereof

The invention provides a following-drilling plugging agent. The following-drilling plugging agent comprises limestone powder, aluminum oxide, quicklime powder, sodium bentonite, an expanding agent, methyl glucosides and mineral fibers; the diameter of the the mineral fibers is smaller than or equal to 60 microns, the length ranges from 0.5 mm to 1 mm, and the mineral fibers can bear the temperature over 170 DEG C. A preparation technology of the following-drilling plugging agent comprises the steps of mixing, grinding and stirring. The following-drilling plugging agent is applied to stratum leakage of pores with the diameters of the pore throat smaller than or equal to 1 mm and microcracks with the widths of cracks smaller than or equal to 1 mm in well drilling, a mud cake can be rapidly formed, the microcracks with different widths can be plugged, and therefore the purposes of following-drilling leakage prevention and leakage stoppage are achieved; good compatibility is achieved, the following-drilling plugging agent can be suitable for drilling fluid with different densities for different systems, effective plugging for leakage of the microcracks can be achieved, the preparation technology is simple, and operation is convenient.

Owner:CHINA PETROCHEMICAL CORP +2

Plugging device for cable protection pipe

PendingCN107370111ASimple structural designGuaranteed blocking effectCable inlet sealing meansScrew threadElectric cables

The invention discloses a plugging device for a cable protection pipe. A first pressing plate, a rubber sealing piece and a second pressing plate are arranged in sequence and can be pushed into the cable protection pipe in a matched manner, a passage for a cable to pass through is formed at the middle parts of the first pressing plate, the rubber sealing piece and the second pressing plate together, one end of a bolt passes through a through hole and a fourth opening of the second pressing plate in sequence to be in screw-thread fit with a nut from a third opening of the first pressing plate. According to the plugging device for the cable protection pipe through an optimal design, the structural design is optimal, the rubber sealing piece is clamped by the two pressing plates, one end of the bolt passes through the through hole from the first pressing plate to be matched with the nut on the side, away from the first pressing plate, of the second pressing plate, by means of force screwing the bolt and the nut, the inner wall clings to the outer wall of the cable after the rubber sealing piece is deformed, the outer wall clings to the inner wall of the cable protection pipe, the plugging effect for the end of the cable protection pipe is guaranteed, waterproof and moisture-proof effects are achieved, and simultaneously the position of the cable inside the cable protection pipe is fixed.

Owner:宁国市盛邦密封件技术有限公司

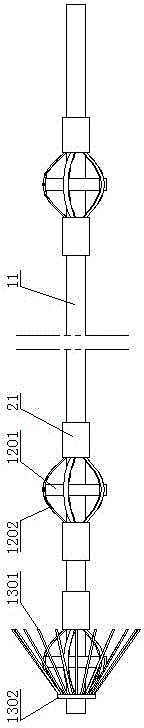

Multi-section foldable ureter plugging device

The invention discloses a multi-section foldable ureter plugging device belonging to the technical field of medical equipment. The technical key points are as follows: the multi-section foldable ureter plugging device comprises a guide pipe, wherein a guide wire is arranged in the guide pipe in a penetrating manner, a thready plugging structure is formed at the free end of the guide pipe, and consists of a first positioning ring, a connecting ring and metal filaments, the first positioning ring is fixed on the guide wire, the connecting ring is sheathed at the periphery of the guide wire between the first positioning ring and a guide pipe, and the metal filaments are uniformly distributed along the circumferential direction of the guide wire and are connected between the first positioning ring, the connecting ring and the free end of the guide pipe; and the guide wire at the fixed end of the guide pipe is pulled, and the alls sections of the metal filaments can retract along the axial direction of the guide pipe so as to form a plurality of circular or elliptical plugging nets. The multi-section foldable ureter plugging device has the advantages that the structure is compact, the expanding diameter of the plugging structure can be adjusted according to demands so as to adapt to the structure of the expanded ureter, the operation is convenient and the using effect is good, and is used for ureteroscopic lithotripsy.

Owner:徐桂彬 +1

Directional hydraulic centralized exploding device for improving gas permeability of coal seam

The invention discloses a directional hydraulic centralized exploding device for improving the gas permeability of a coal seam, and relates to the technical field of coal seam permeability improvement. The directional hydraulic centralized exploding device for improving the gas permeability of the coal seam comprises a directional exploding tube, wherein the two ends of the directional exploding tube are sealed by cover plates; a plurality of energy release holes are formed in the outer circumferential surface of the directional exploding tube at intervals; the energy release holes are communicated with the inner cavity of the directional exploding tube; the inner cavity of the directional exploding tube is filled with explosive rolls and detonators; the outer circumferential surface of the directional exploding tube is coated with a high-pressure plastic thin film; the energy release holes are covered by the high-pressure plastic thin film; the top end of the directional exploding tube is connected with a first plugging assembly for plugging a blast hole during explosion so as to prevent explosion fragments from being upwardly ejected along the blast hole. Through coupling of explosion gas and water which is left in the blast hole and the coal seam after a hydraulic fracturing operation, the directional hydraulic centralized exploding device can greatly improve the development degree of a fracture in the coal seam; in addition, the blast hole of the directional hydraulic centralized exploding device is not required to be filled with a yellow clay roll before explosion, so that the directional hydraulic centralized exploding device is very convenient to operate.

Owner:HUNAN INST OF TECH

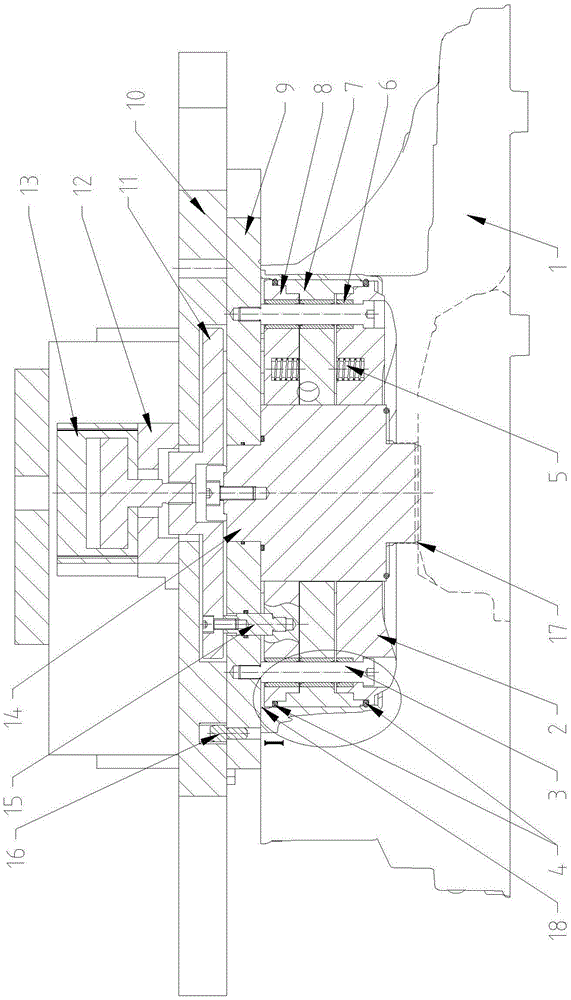

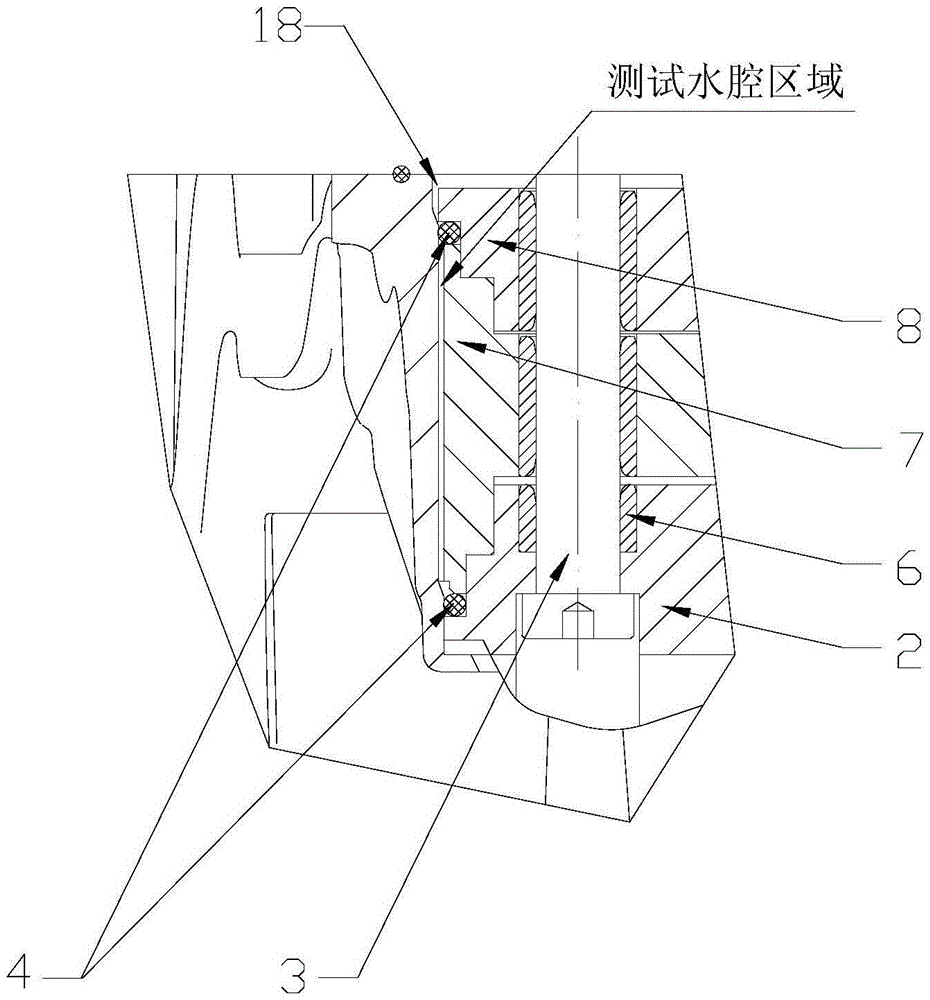

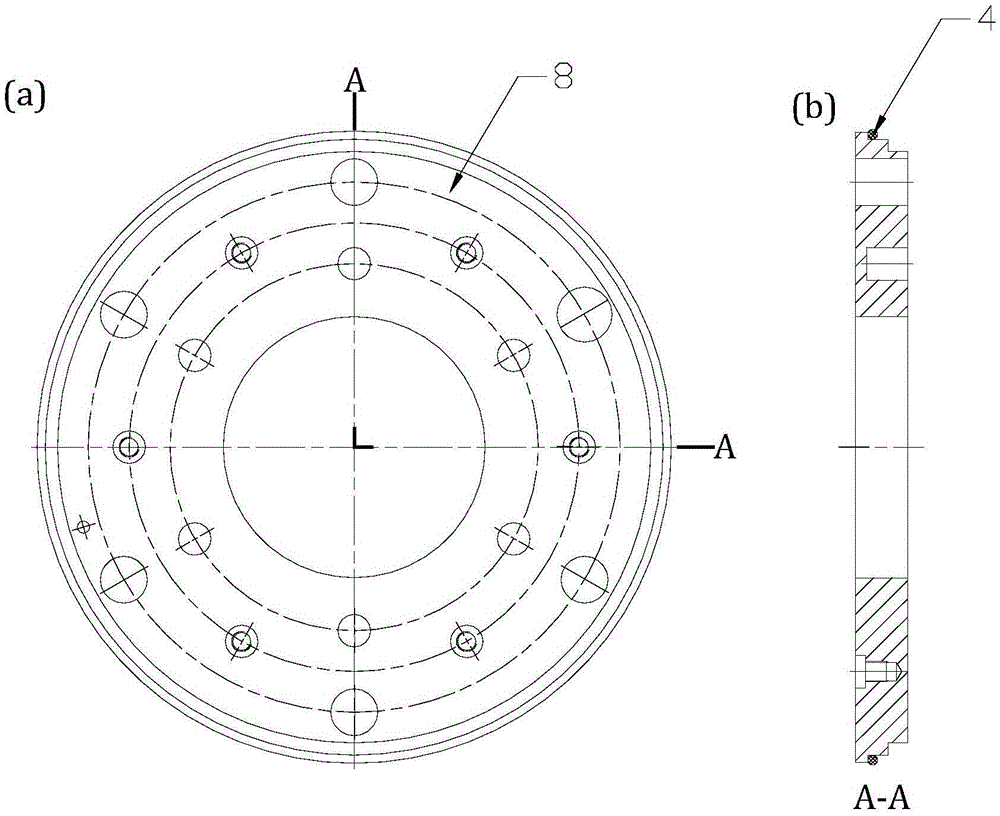

Dual-layer compound seal blocking mechanism

ActiveCN105485342ALarge room for renovationHigh degree of flexibilityEngine sealsFluid-tightness measurementInterference fitEngineering

The invention belongs to the technical field of gearbox housing seal tests, and relates to a dual-layer compound seal blocking mechanism. The blocking mechanism is arranged in a blocking hole and specifically comprises a clamping oil cylinder component, a blocking plate, an upper blocking disc, a lower blocking disc and a middle disc. The clamping oil cylinder component and the upper blocking disc are fixedly connected, and the blocking plate is arranged between the clamping oil cylinder component and the upper blocking disc. The upper blocking disc, the lower blocking disc and the middle disc are in interference fit and are provided with seal rings and elastically connected. During clamping, automatic sealing of the blocking hole can be achieved by means of pushing of an oil cylinder and compressing of the seal rings, automatic reset can be achieved through a balance spring during releasing, cost is reduced, and the flexibility of a machine tool is improved.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS +1

Liner tube feeding device and liner tube feeding method for horizontal drill hole under pressure

PendingCN111206877AEliminate blocking of horizontal boreholesPlay a supporting roleDirectional drillingSealing/packingBlowout preventerScrew thread

The invention relates to a liner tube feeding device and a liner tube feeding method for a horizontal drill hole under pressure. The liner tube feeding device comprise a plurality of liner tubes, a plurality of drill rods and an orifice pressure-maintaining device for the horizontal drill hole, wherein matched screw threads are arranged at the two ends of the liner tubes; the inner diameter of each liner tube is larger than the outer diameter of each drill rod; the orifice pressure-maintaining device is provided with a liner tube channel suitable for the liner tubes to insert and penetrate through, and comprises a three-way pipe short section, a gate valve, a first liner tube clamper, a blowout preventer, a first barrel, a second barrel, a second liner tube clamper and a ring-shaped sealerconnected sequentially from front to back; the first barrel is in threaded connection with the second barrel; and a screw-thread buckle type between the first barrel and the second barrel is the sameas a screw-thread buckle type between the two liner tubes in threaded connection. Through the liner tube feeding device and the liner tube feeding method for the horizontal drill hole under pressureprovided by the invention, the liner tubes can be sequentially connected and fed into the horizontal drill hole under pressure, and the liner tubes located in the drill hole can completely eradicate the occurrence of the phenomenon that collapsing holes block the drill hole, so that the long-time safety and unobstruction of a gas production channel of the drill hole is ensured, and the continuousstability of the coalbed gas extraction rate is ensured.

Owner:张海轩

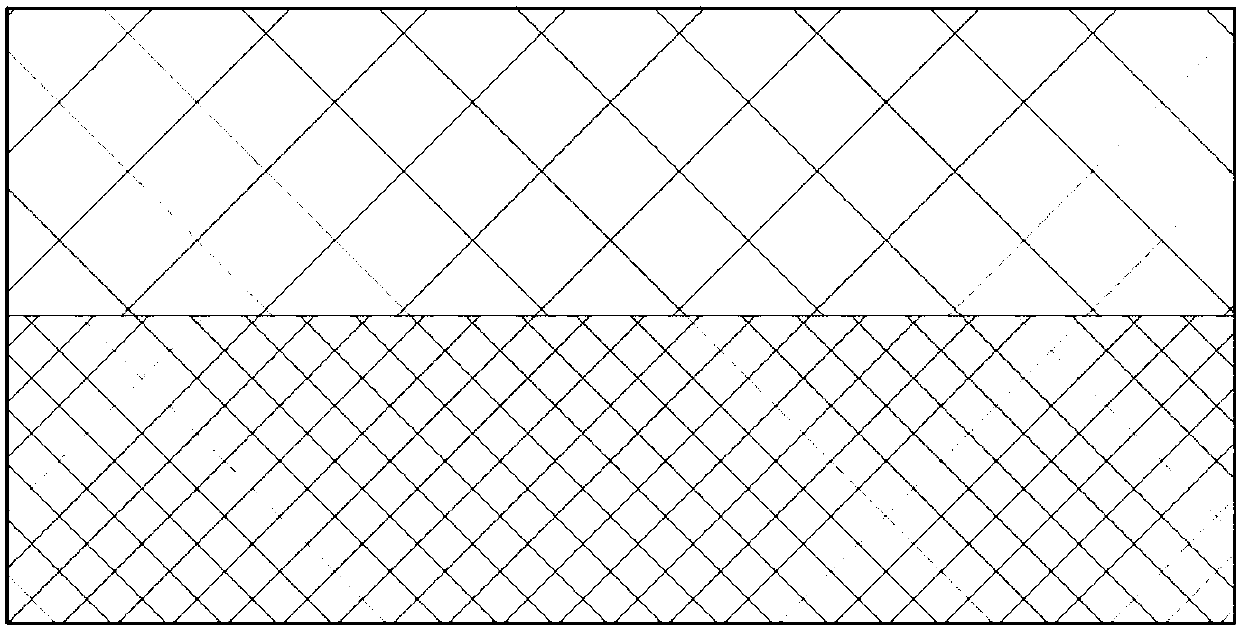

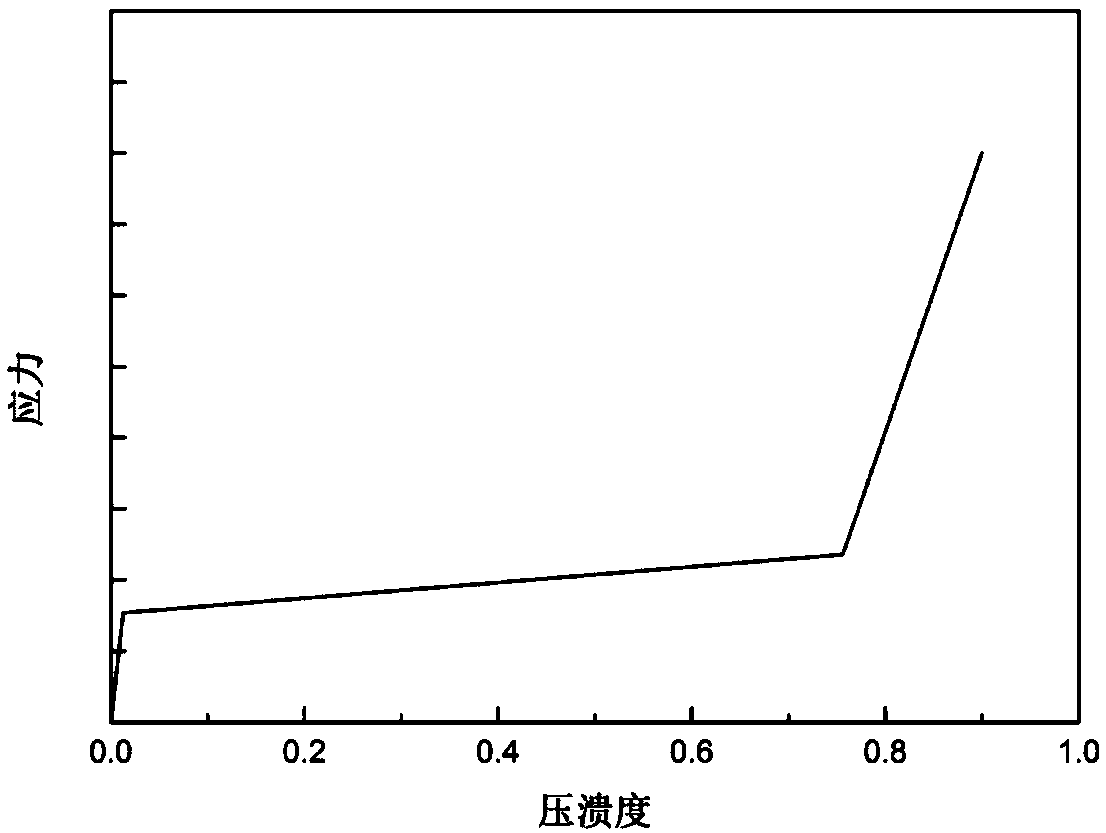

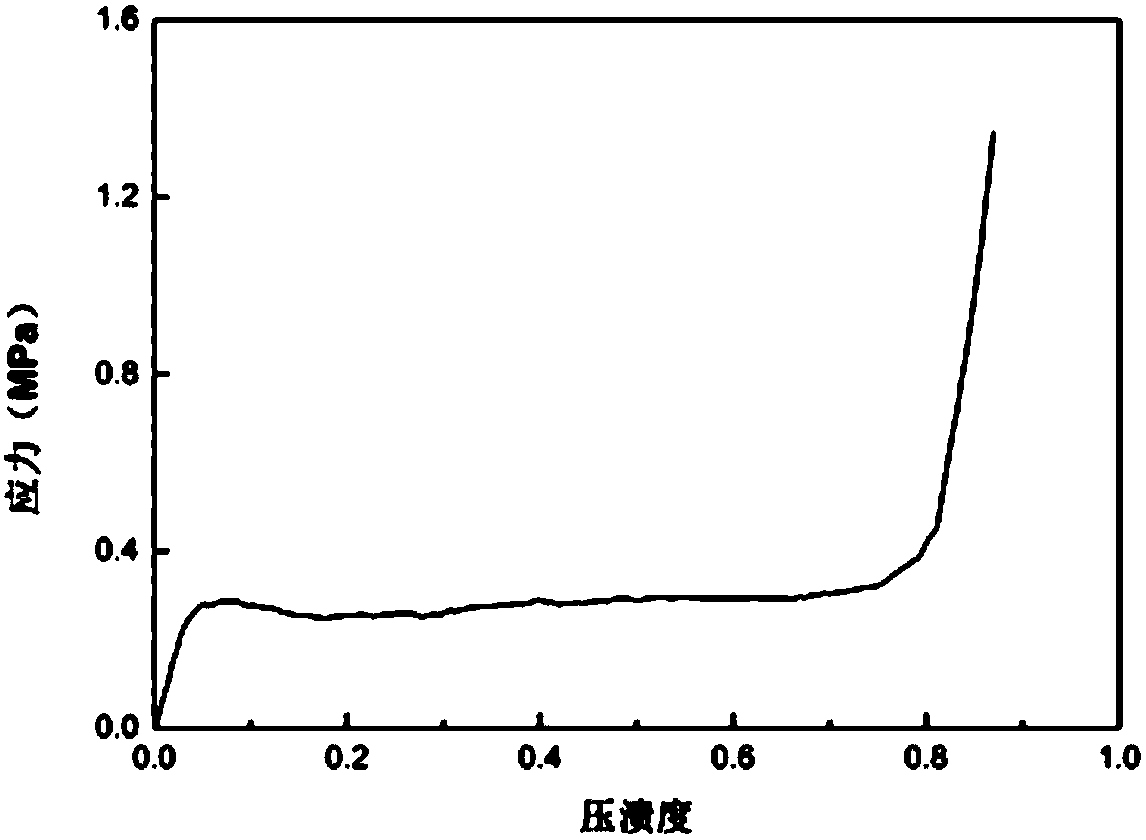

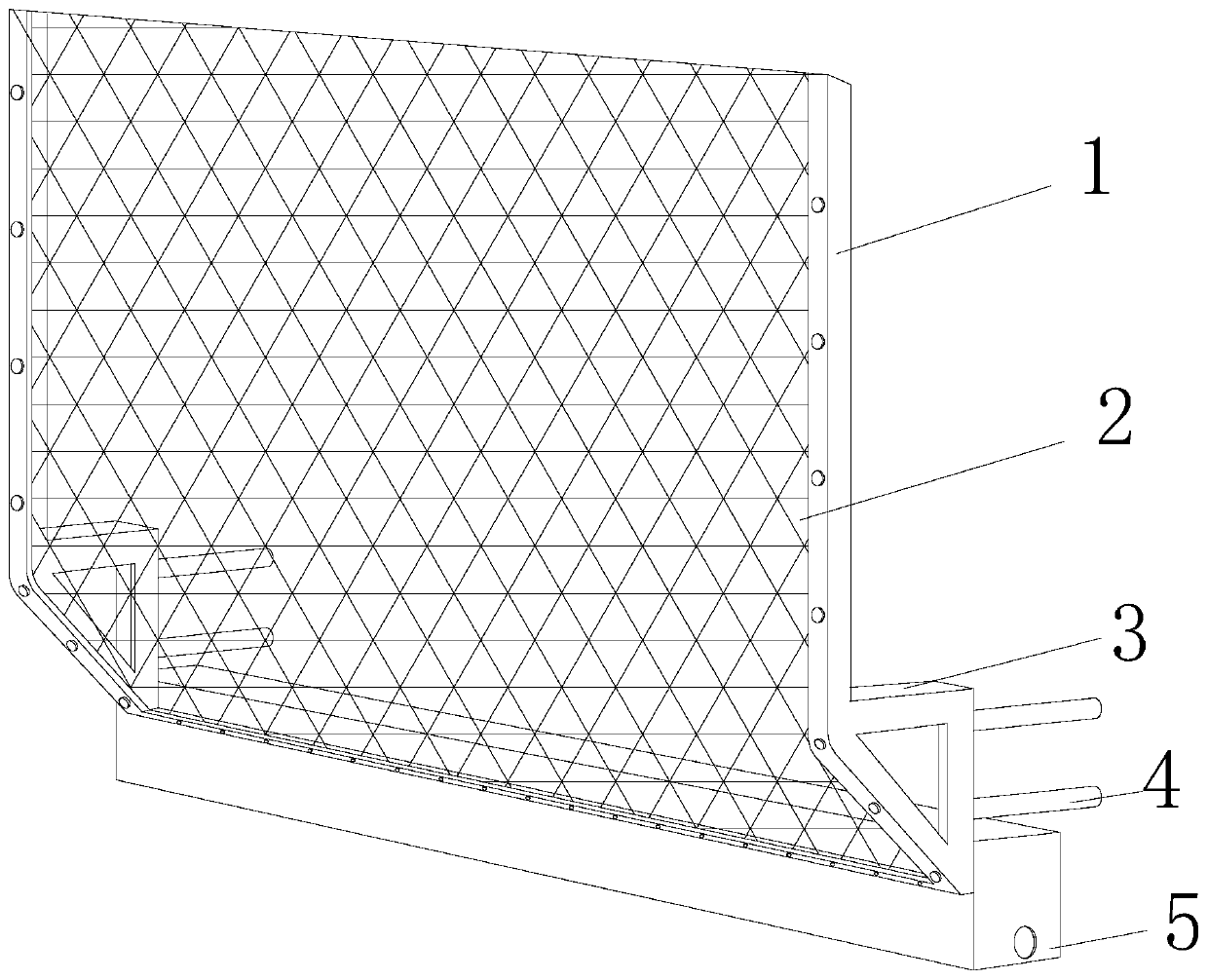

Layered buffer energy absorption structure body for EMAS (Engineered Material Arresting System) and preparation method

ActiveCN110344298AGuaranteed blocking effectEnsure safetyTemporary pavingsEnergy absorptionMaterials science

The invention discloses a layered buffer energy absorption structure body for an EMAS (Engineered Material Arresting System) and a preparation method. The layered buffering energy absorption structurebody is formed by bonding buffer energy absorption materials with different strength from top to bottom, and the strength of the different layers increases from top to bottom. The preparation methodcomprises the following step of bonding each layer of material according to the strength being increased sequentially from top to bottom, wherein the bonding mode is a prefabricated body bonding typeor a layered pouring type. According to the layered buffering material disclosed by the invention, aircrafts with different specifications can be effectively blocked, and the preparation method is simple.

Owner:HANGKE TECH DEV

Method and device for blocking return water pipeline of tailing pond

ActiveCN104452788AControlling Water Leakage ProblemsImprove securityFoundation engineeringBlock effectEngineering

The invention relates to a method and device for blocking a return water pipeline of a tailing pond. The method is characterized in that the return water pipeline is found outside a primary dam of the tailing pond, the blocking device is pushed into the return water pipeline, the return water pipeline is found in the tailing pond again, a vertical shaft is drilled and communicated with the return water pipeline, the return water pipeline is blocked for the first time by being filled with iron sand, nonwoven geotechnical cloth, gravel and pouring concrete, and the return water pipeline is blocked for the second time by being filled with cement mortar through a main supporting pipe and a grout pipe at the outlet of the return water pipeline. According to the method, the construction is convenient, safety and reliability are achieved, the problems of high construction difficulty and difficult guarantee of blocking effect in an existing technology for blocking a return water pipeline of a tailing pond are radically solved, the return water pipeline of the tailing pond is effectively blocked, and return water in the tailing pond is prevented from seeping, so that the safety running of the tailing pond is realized.

Owner:ANSTEEL GRP MINING CO LTD

Mechanical stopping device on villa elevator

The present invention provides a mechanical stopping device on a villa elevator. The mechanical stopping device on the villa elevator comprises a fixed support and an L-shaped support arranged on oneside of the fixed support and stretching out; the side, provided with the L-shaped support, of the fixed support is connected with a U-shaped shaft ramp in a sliding manner; the end portion of the side, stretching into the portion between the fixed support and the U-shaped shaft ramp, of the U-shaped shaft ram is provided with a shaft ramp head folding and protruding outwards; a position switch isconnected to the fixed support in a sliding manner; the U-shaped shaft ramp is provided with a blocking sheet which is folded and turned over outwards; the end portion of the blocking sheet is provided with an inclined guiding blocking sheet; the end portion of the position switch is rotationally connected with a rolling wheel; a plug pin capable of being adjusted in a stretching and shrinking manner is arranged on a cross beam; and a hook stretching out is arranged on the end portion of the side, close to the position switch, of the L-shaped support. The mechanical stopping device on the villa elevator is simple in structure, is automatically switched between a work state and a non-work state, and is not needed to be manually adjusted by maintenance personnel, dual stopping on an elevator can be achieved, the safety performance is higher, reliability is higher, and the safety of a worker is further guaranteed.

Owner:TIANJIN ORAC ELEVATOR

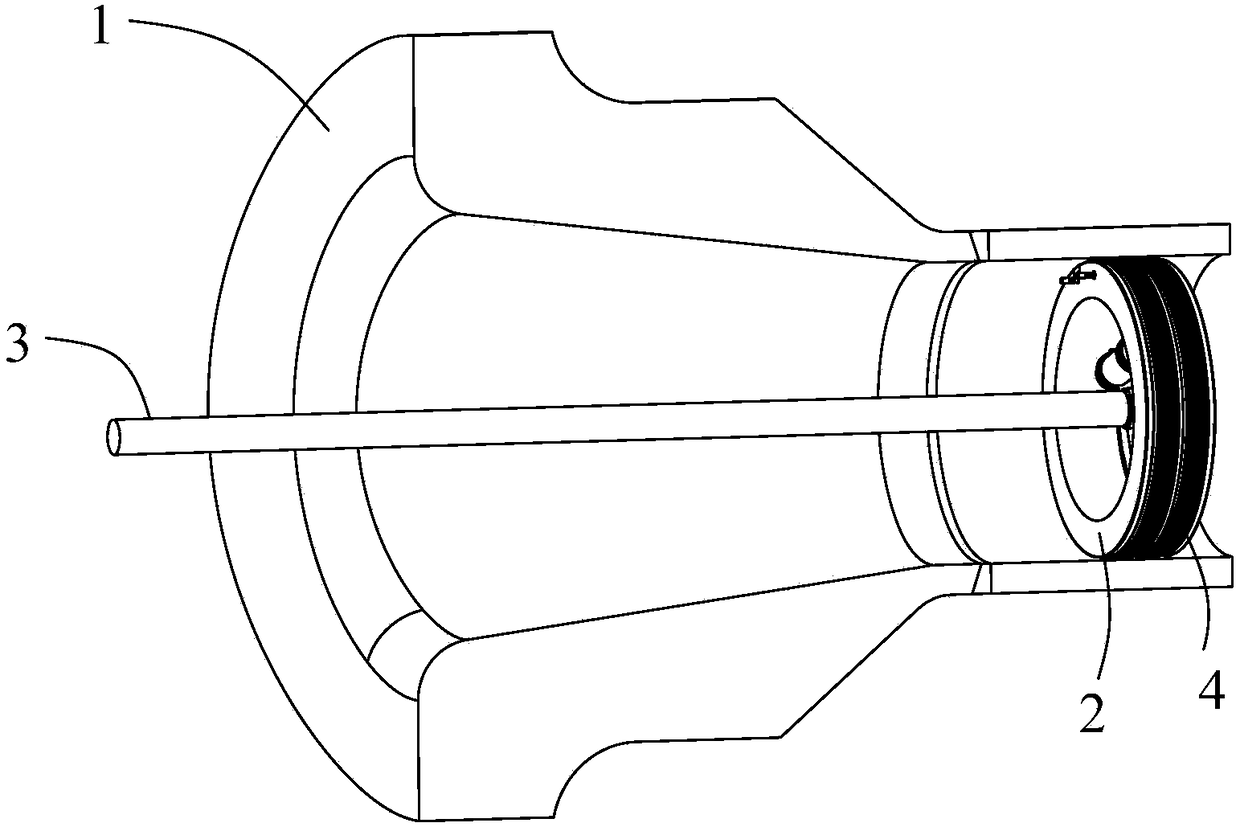

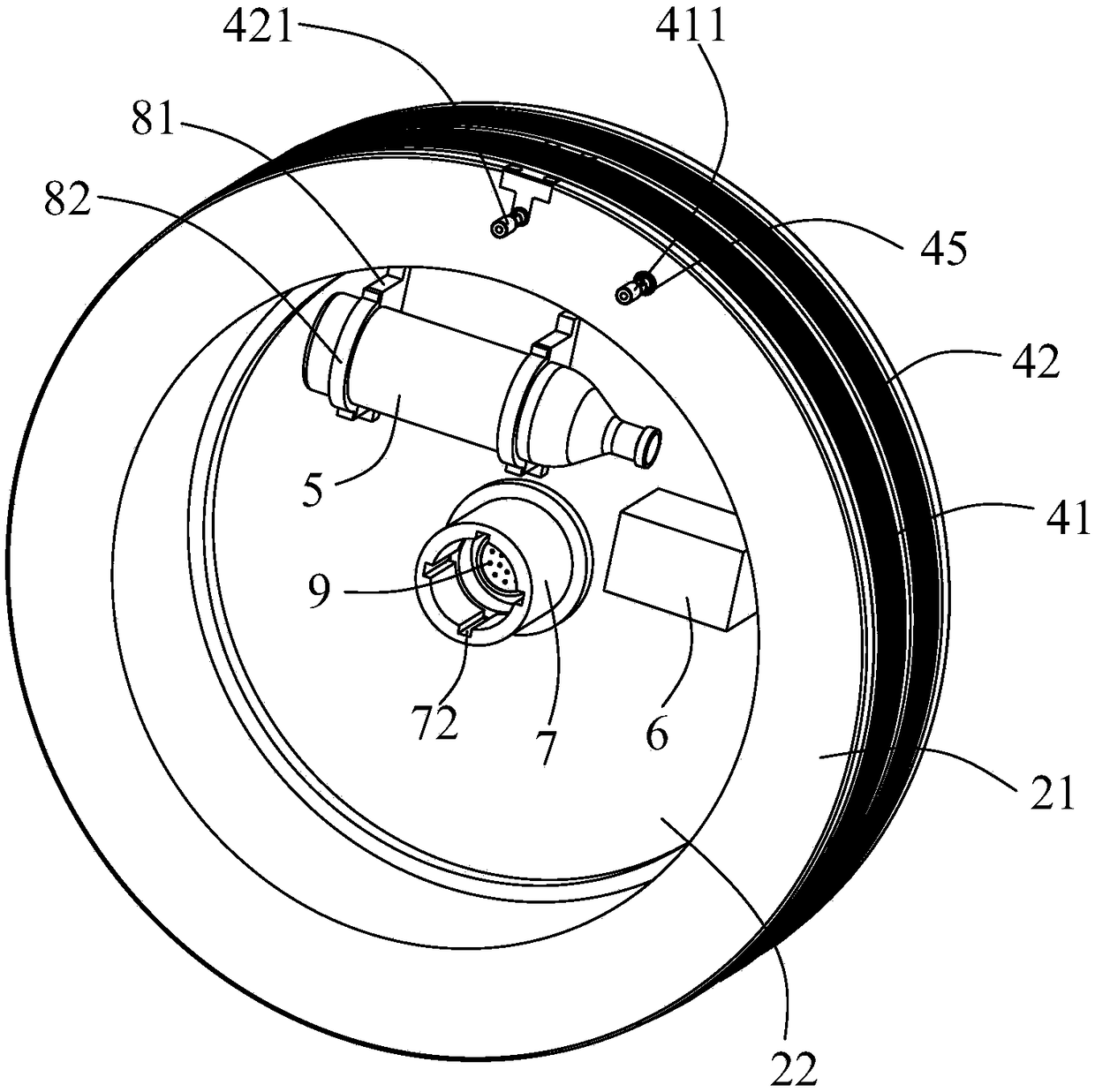

Conveying device for interventional therapy of congenital heart disease in surgical department

The invention relates to the field of interventional therapy instruments for heart diseases and discloses a conveying device for interventional therapy of the congenital heart disease in the surgicaldepartment. The device comprises a conveying sheathing canal, a connector, a hemostasis device, a transfer device, a pushing steel cable, a connection body, a plugging device and a cannula; the cannula of one side of the plugging device is in threaded connection with the connection body of one end of the pushing steel cable. According to the conveying device for interventional therapy of the congenital heart disease in the surgical department, by pulling an adjustment steel cable, under limit of a limit tube structure to a sliding body, the sliding body and the limit tube structure are bent relative to a fixing tube structure, so that the plugging device is bent relative to the fixing tube structure, when the long axis of the aorta is vertical to the ventricular septal defect direction ofthe heart valve, the plugging device is controlled to be vertical relative to the fixing tube structure, and it is guaranteed that when placed, the plugging device cannot be pulled by the pushing steel cable; it is guaranteed that the plugging device completely fits the plugging defect part, and the plugging effect is effectively guaranteed.

Owner:心弦跳动生物医疗科技(青岛)有限公司

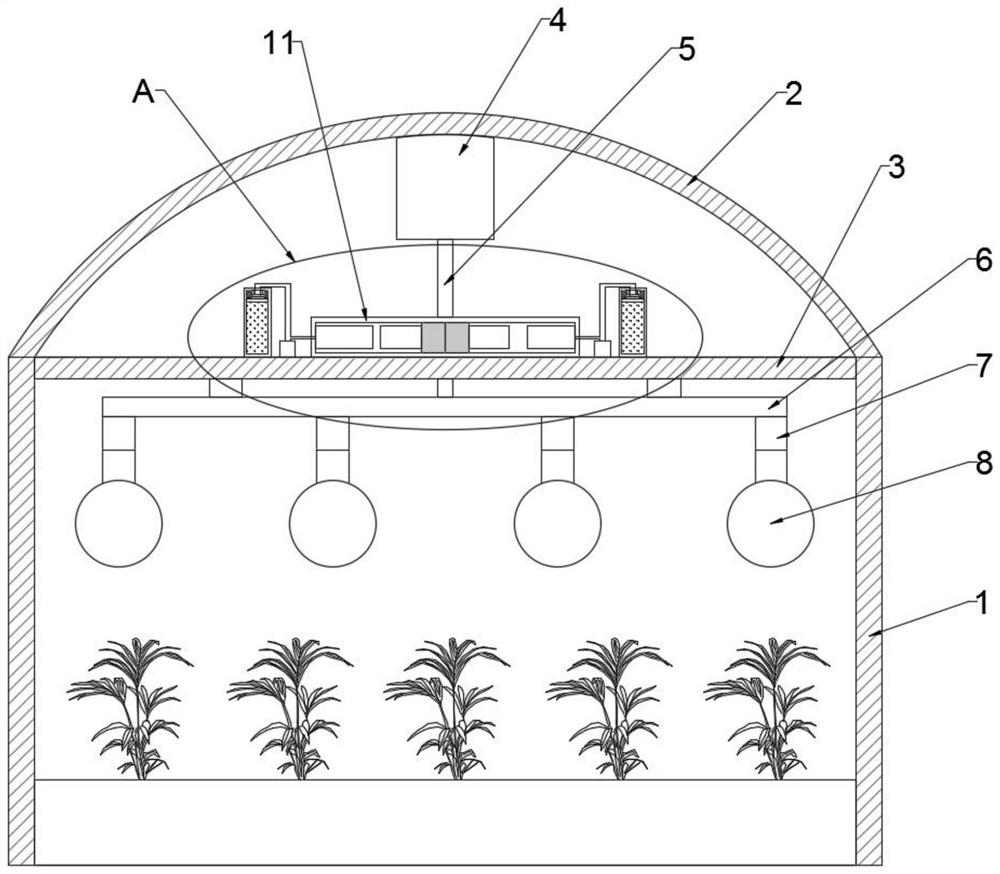

Self-adjusting yield-increasing greenhouse

InactiveCN111937650AIncreased sensitivity to thermal deformationPrecise control processClimate change adaptationGreenhouse cultivationPhotosynthesisAgricultural engineering

The invention discloses a self-adjusting yield-increasing greenhouse, and belongs to the technical field of agricultural planting equipment. The self-adjusting yield-increasing greenhouse comprises agreenhouse body and a greenhouse roof connected with the top end of the greenhouse body, wherein the outer sides of the greenhouse body and the greenhouse roof are wrapped with PE films, and a supporting cross rod is fixed at the joint between the greenhouse body and the greenhouse roof; and a diluted hydrochloric acid storage barrel is fixed to the inner top of the shed roof, a liquid outlet pipeis connected to the bottom end of the diluted hydrochloric acid storage barrel, a liquid distribution pipe is connected to the lower side wall of the supporting cross rod, the liquid outlet pipe is arranged in correspondence to to a water inlet of the liquid distribution pipe, and a liquid outlet control mechanism is connected between the liquid outlet pipe and the liquid distribution pipe. Carbon dioxide generated by reaction in spherical air bags can be used for promoting photosynthesis of plants in the greenhouse, and ammonium chloride in the spherical air bags is brought out to fertilizeland when the carbon dioxide is sprayed out so that growth of the plants in the greenhouse can be promoted, and the purpose of effectively increasing the yield is achieved; and the whole process can be self-adjusted, the whole device is simple in structure and low in cost, and the device is suitable for wide-range use.

Owner:刘学亮

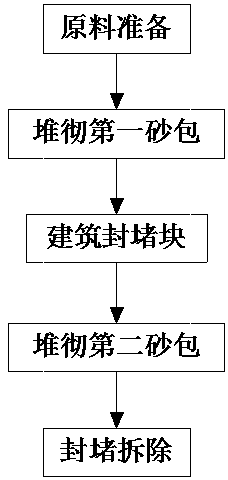

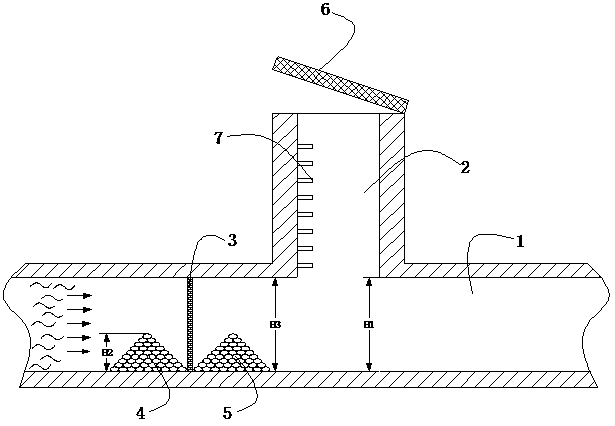

Safety plugging structure and mounting and demounting method thereof

The invention discloses a mounting and demounting method of a safety plugging structure. The mounting and demounting method comprises the following steps that (1) raw materials are prepared, specifically, a pipeline needing to be plugged is measured according to the field environment, and required plugging raw materials are calculated; (2) first sand bags are piled, specifically, the raw materials are manually transmitted into the pipeline through an inspection well, and meanwhile, the sand bags are piled in the pipeline in the water flow direction; (3) a plugging block is constructed, specifically, the plugging block is constructed on the rear parts of the first sand bags in the water flow direction; (4) second sand bags are piled, specifically, the sand bags are piled on the rear part of the plugging block in the water flow direction; and (5) plugging demounting is conducted, specifically, through protection of the second sand bags, the upper half part of the plugging block is demounted, then the second sand bags are moved away in sequence, then through protection of the first sand bags, the lower half part of the plugging block is demounted, finally, the first sand bags are moved away in sequence, thus whole plugging demounting work can be completed, wherein the inner diameter of the pipeline is set to be H1, the piling height of the sand bags is set to be H2, the height of a plugging wall is H3, H1 is equal to H3, and H1 is greater than 2*H2.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

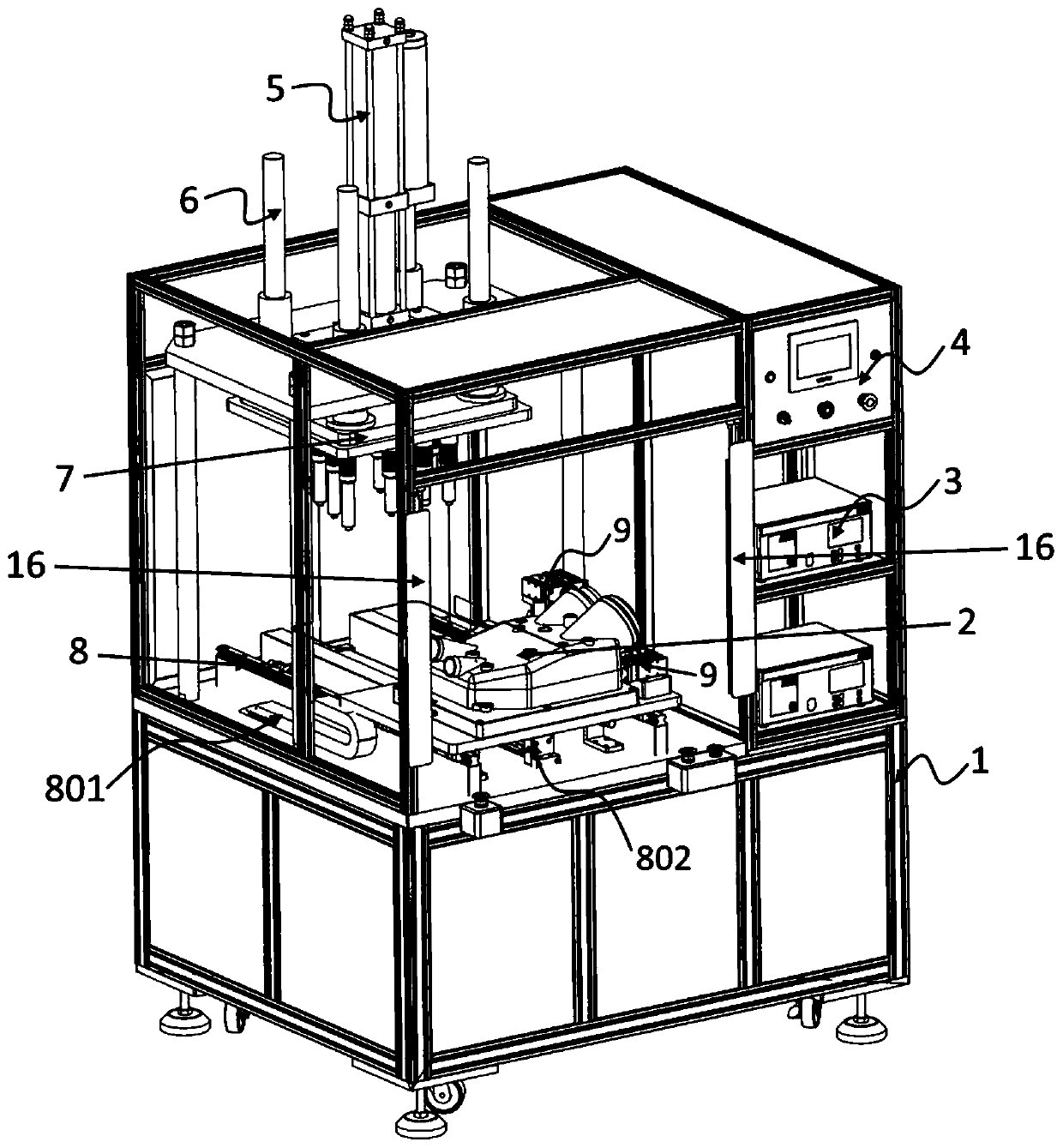

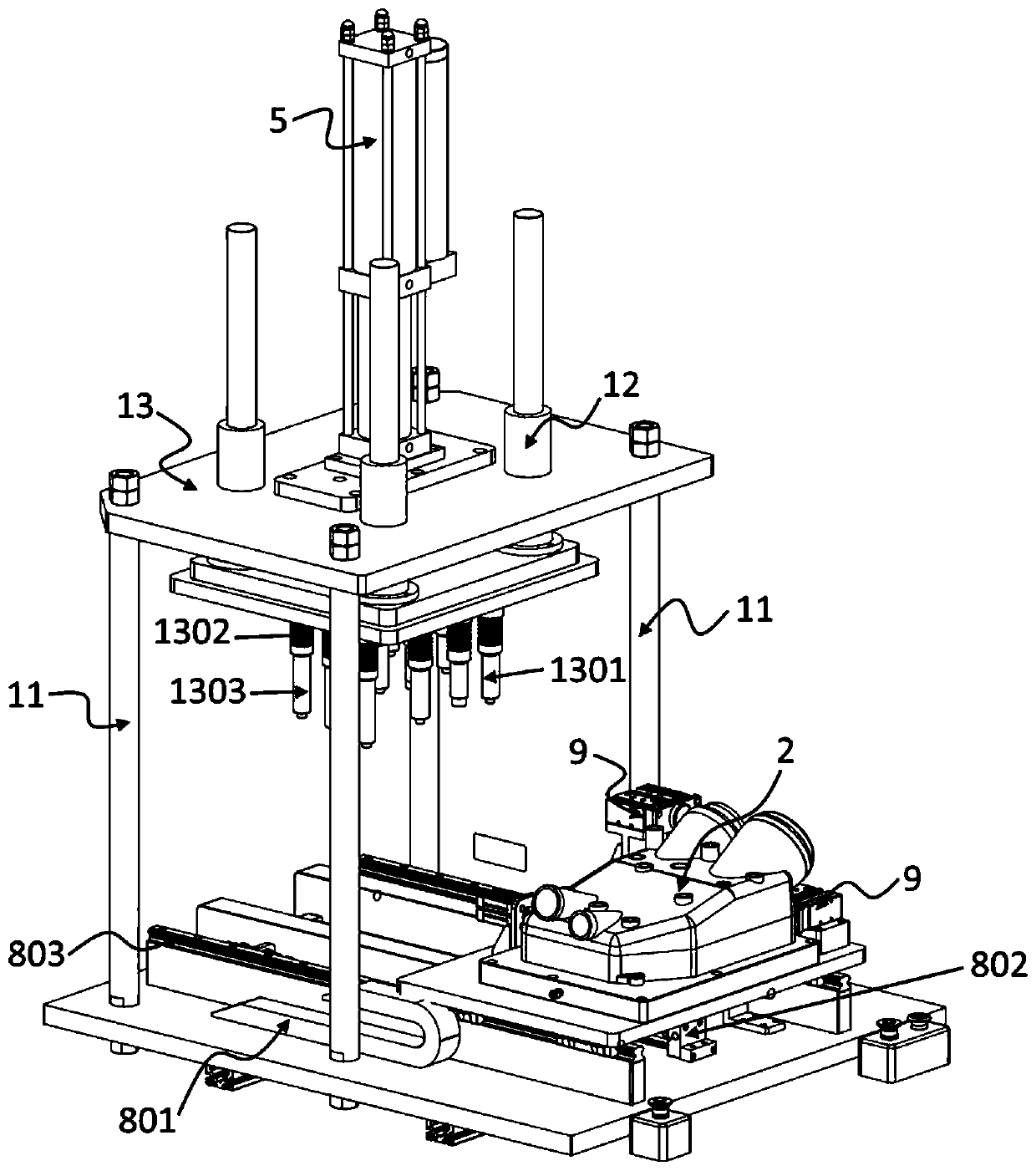

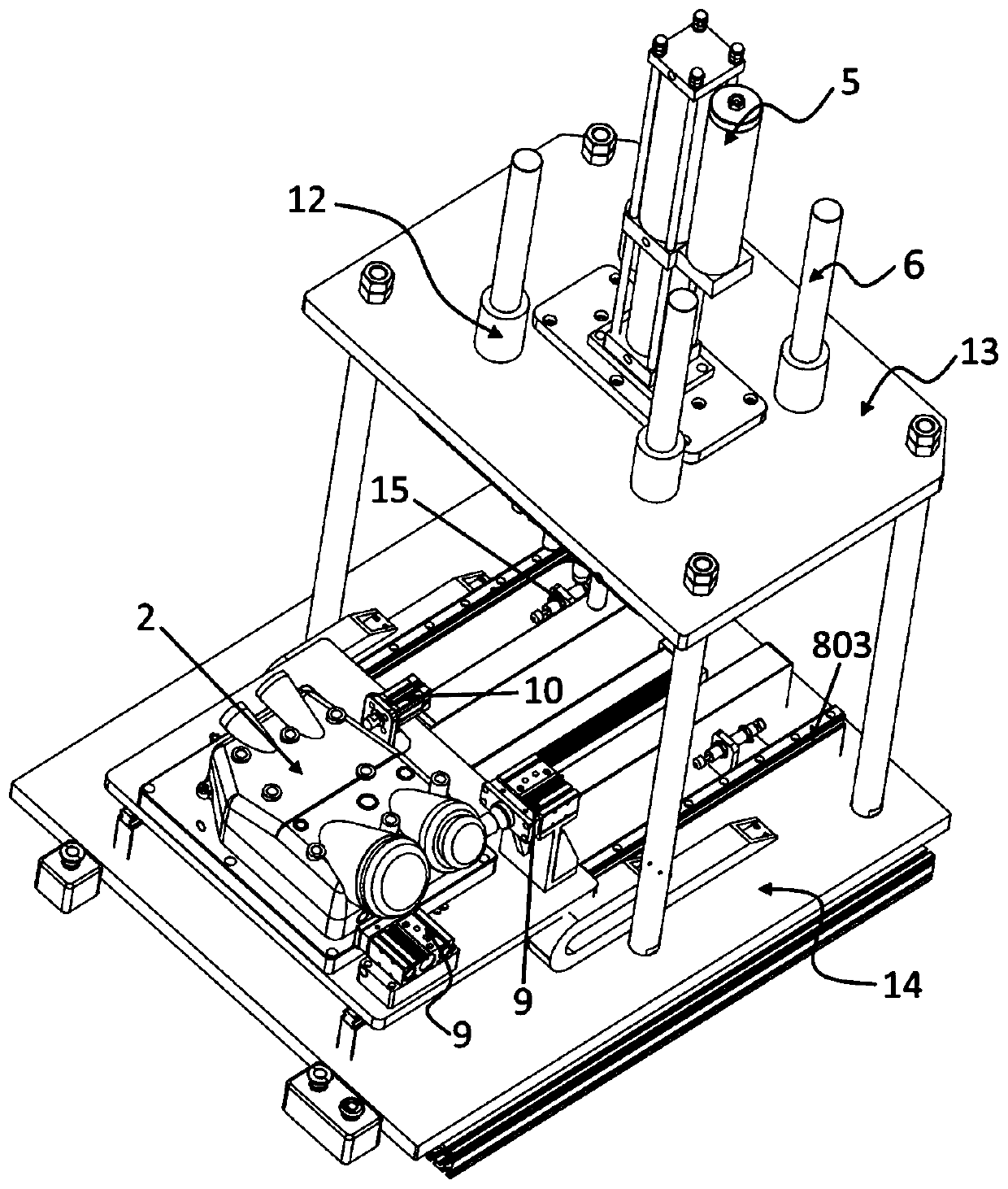

Automobile oil filter air tightness test automation device and test method thereof

InactiveCN110146236AGuaranteed blocking effectImprove the blocking effectMeasurement of fluid loss/gain rateTest tubeEngineering

The invention relates to an automobile oil filter air tightness test automation device and a test method thereof. A positioning detecting assembly is used to position and detect a workpiece to be detected. A pressing assembly is used, and in particular pressure generated by a gas-liquid boosting cylinder is used to press the workpiece to be detected. A spring pressure head assembly contacts the upper surface of the workpiece to be detected. A side plate hole of the workpiece is plugged by a plugging cylinder. A vent hole in the upper surface of the workpiece is plugged by a plugging head. An ATEQF620 air tightness leak detector is connected with a test tube connector for air tightness testing. The gas-liquid boosting cylinder can generate predetermined downforce to ensure the plugging effect. A sealing ring which matches the contour of the workpiece to be detected is arranged on a positioning detecting seat. The sealing ring can ensure that no gap is between the lower surface of the workpiece to be detected and the positioning detecting seat. The plugging effect is further enhanced. A sliding assembly, the positioning detecting assembly and the pressing assembly match each other, so that the overall device has the advantages of high motion continuity and high efficiency.

Owner:NANJING HANMINGZHI INTELLIGENT TECHNOLOGY CO LTD

Bridge anti-falling object net capable of automatically cleaning fallen leaves and garbage

ActiveCN110878540AAvoid corrosionPrevent fallingRoad cleaningBuilding material handlingAgricultural engineeringMechanical engineering

The invention discloses a bridge anti-falling object net capable of automatically cleaning fallen leaves and garbage. The net structurally comprises a vertical support, a blocking net, a triangular reinforcing frame, a screw rod and a falling object sucking and collecting device. The blocking net is arranged between the two vertical supports and fixedly connected with the vertical supports in a clamping mode, the triangular reinforcing frame is arranged below the vertical supports and is of an integrally-formed structure, the screw penetrates through the front surface and the rear surface of the triangular reinforcing frame and is connected with a bridge screw, and the falling object sucking and collecting device is arranged below the rear portion of the triangular reinforcing frame and connected with the triangular reinforcing frame through electric welding. Through arranging the fallen object suction and collection device, through methods of sucking, chopping and sucking, greening plants planted on the bridge or fallen leaves, falling on the anti-falling object net, of vegetation on the two sides of the bridge are collected and cleaned. Fallen leaves are prevented from rotting and corroding the iron net after being exposed to wind and sun on the anti-falling object net, the blocking effect of the anti-falling object net is guaranteed. Meanwhile, the fallen leaves are prevented from falling off due to corrosion, bridge falling object prevention is achieved, and safety under a bridge is guaranteed.

Owner:绍兴市览海环保科技有限公司

Blocking system and blocking method for tailing-pond flood discharge tower

ActiveCN103410120ASolve the problem of undeliverableStable deliveryFoundation engineeringMarine site engineeringEngineeringBlock method

The invention relates to a blocking system and a blocking method for a tailing-pond flood discharge tower. The blocking system comprises a transverse water return pipeline connecting an old tower of the tailing-pond flood discharge tower to a new tower of the tailing-pond flood discharge tower. The blocking system is characterized in that a transverse blocking and grouting pipeline connected with the new tower is arranged in the transverse water return pipeline, a blocking steel plate and a screw rod are arranged at the joint of the old tower and the transverse water return pipeline, water pipeline partitions are arranged in the transverse water return pipeline at intervals of 5-6m, the transverse blocking and grouting pipeline is arranged in the transverse water return pipeline through supports, a C-shaped elbow is connected at a corner joint of a vertical blocking pipeline and the transverse blocking and grouting pipeline through flanges, and a C-shaped elbow is further arranged at the top of the vertical blocking pipeline. The blocking system and the blocking method have the advantages that materials are less prone to blocking pipelines during transporting, blocking efficiency is effectively improved, cost is reduced, and construction period is shortened.

Owner:ANSTEEL GRP MINING CO LTD

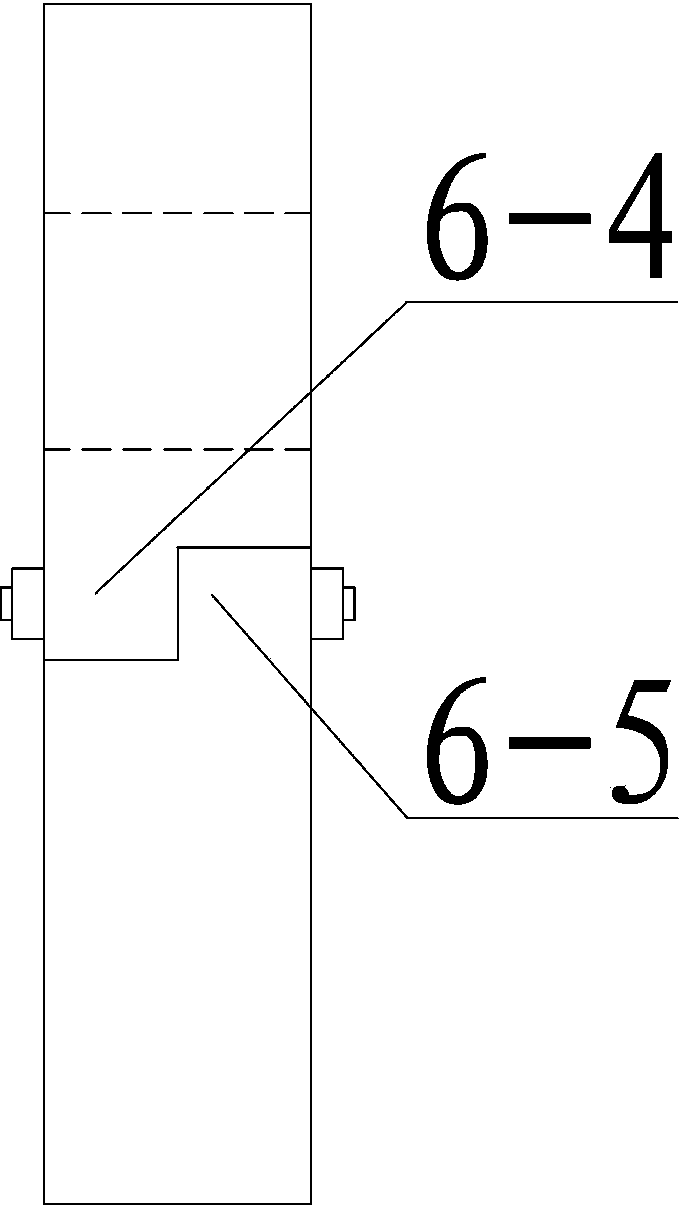

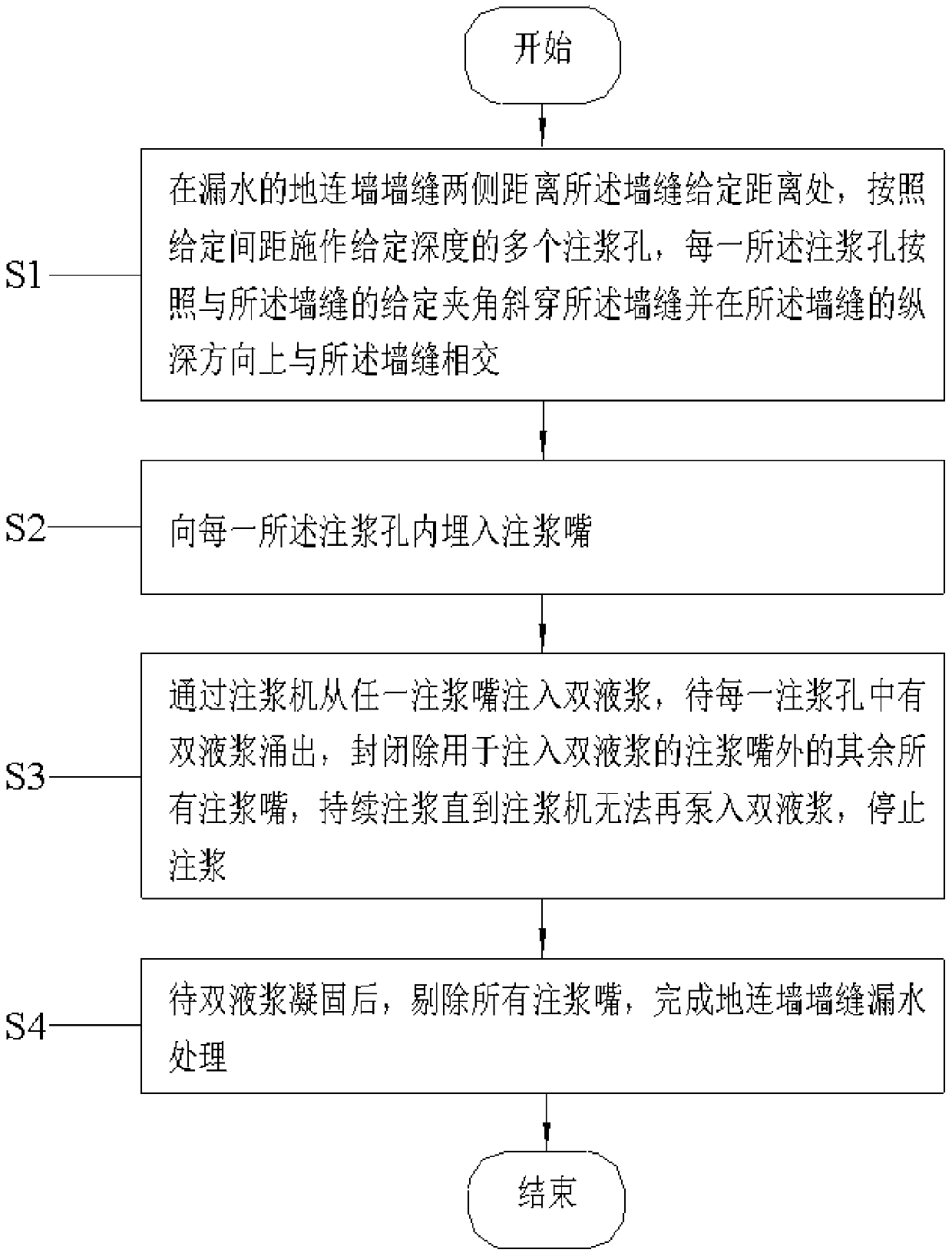

Construction method for treating water leakage of wall joint of ground connecting wall

InactiveCN109826238ASolve the inaccurate blockingGuaranteed blocking effectArtificial islandsUnderwater structuresStructural engineeringComing out

The invention provides a construction method for treating water leakage of a wall joint of a ground connecting wall, which comprises the following steps of: S1) from two sides of the wall joint of theground connecting wall with water leakage to a given distance, constructing a plurality of grouting holes with given depths according to a given distance, wherein each grouting hole obliquely penetrates through the wall joint according to a given included angle with the wall joint and intersects with the wall joint in the depth direction of the wall joint; S2) embedding a grouting nozzle into each grouting hole; S3) injecting double-liquid slurry from any grouting nozzle through a grouting machine, and sealing all the grouting nozzles except for the grouting nozzles for injecting the double-liquid slurry when the double-liquid slurry comes out form each grouting hole, continuously grouting until the grouting machine cannot pump the double-liquid slurry, and stop grouting; S4) after the double-liquid slurry solidifies, removing all the grouting nozzles and completing the leakage treatment of the wall joint of the ground connecting wall. According to the construction method, the water leakage position is accurately blocked according to the water leakage position of the ground wall joint, so that the problems of overhigh blocking cost and blocking waste in the prior art can be solved.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Method for improving coal seam permeability by adopting directional hydraulic concentrated blasting

ActiveCN107503728AIncrease the degree of crack developmentIncrease impactFluid removalUnderwater explosionDetonation

The invention provides a method for improving the coal seam permeability by adopting directional hydraulic concentrated blasting and relates to the technical field of coal seam antireflection. The method comprises the following steps: step 1, drilling a blast hole in a coal seam, then performing hydraulic pre-splitting antireflection on the coal seam by utilizing the drilled blast hole, prohibiting the extraction of water remaining in the blast hole after hydraulic pre-splitting antireflection and ensuring that the water surface in the blast hole is at least higher than 2 m of the upper part of the coal seam; step 2, putting a directional hydraulic concentrated blasting device in the blast hole and sinking into the water surface; and step 3, detonating the directional hydraulic concentrated blasting device to detonate under the water and finish the antireflection operation. The method provided by the invention has the benefits that firstly, the hydraulic pre-splitting antireflection is performed on the coal seam, and then the directional hydraulic concentrated blasting device with a specific structure is detonated in the water remaining in the blast hole; through the coupling of detonation gas with the water remaining in the blast hole and the coal beam after hydraulic fracturing operation, the fracture development degree in the coal seam can be greatly improved; and through the method, before blasting, a yellow mud roll is not required to be poured in the blast hole, so that the operation is very convenient.

Owner:HUNAN INST OF TECH

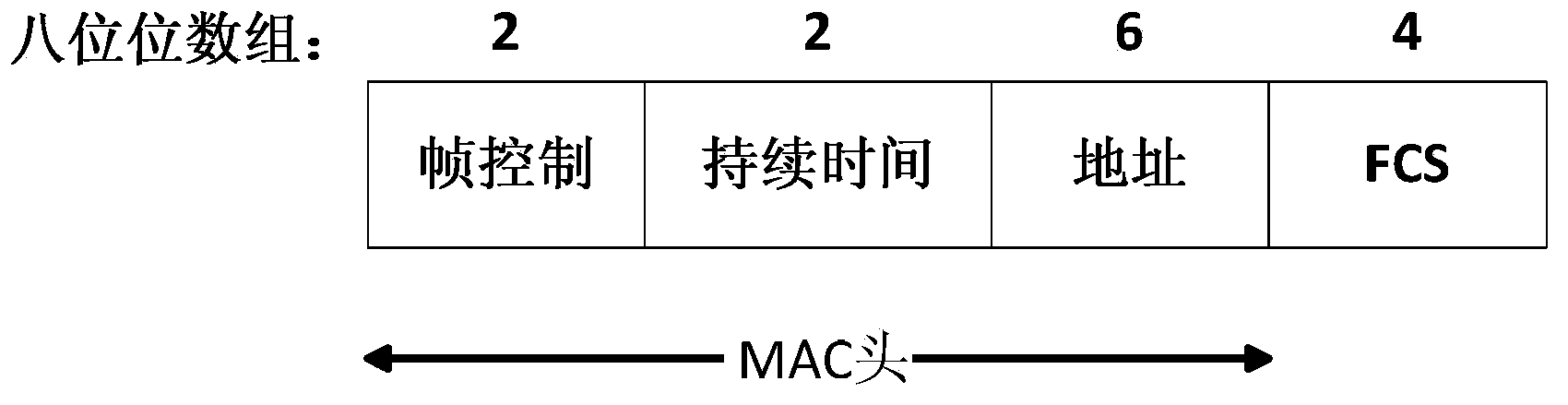

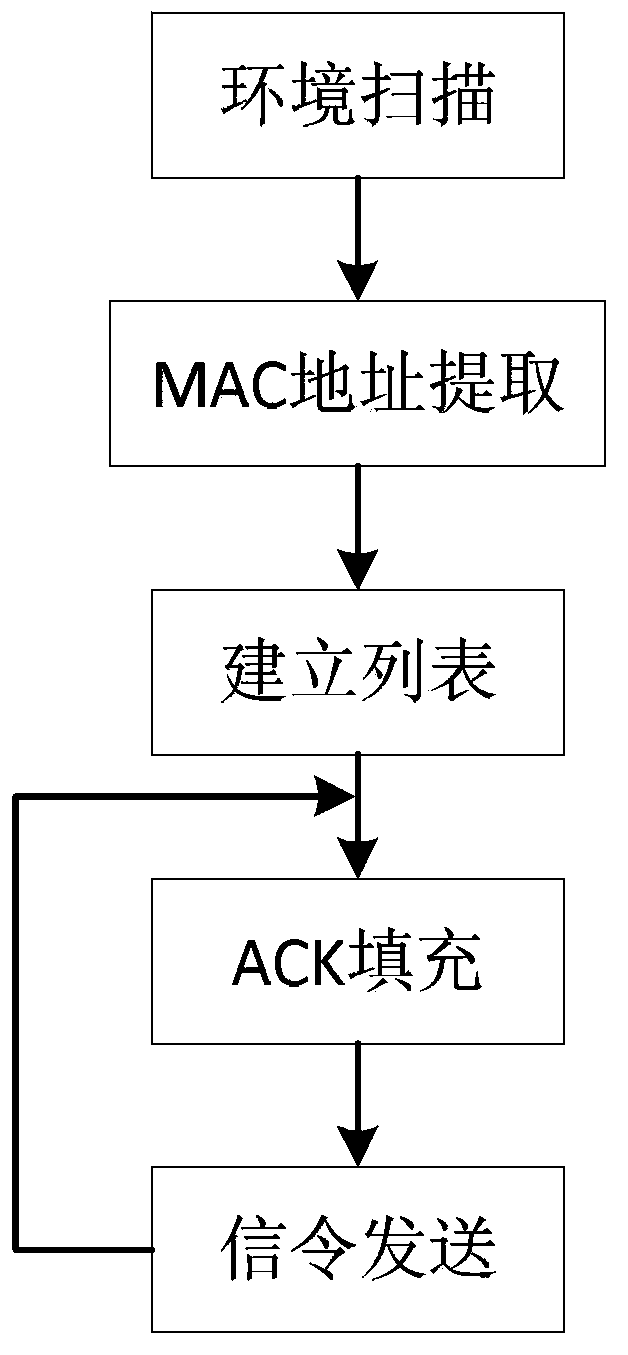

Communication managing and controlling method for wireless local area network

ActiveCN104333859AThe blocking effect is stableImprove applicabilityAssess restrictionNetwork topologiesPresent methodComputer terminal

The present invention discloses a communication managing and controlling method for a wireless local area network. The present method includes that 1) a network card drive of a blocking device is modified so as to enable the blocking device to send blocking frames at intervals no greater than the short interframe space (SIFS); 2) the blocking device scans the surrounding wireless local area network environment, and obtains MAC addresses of an access point (AP) and a terminal (STA) working in a to-be-blocked channel; 3) the blocking device establishes a channel MAC address list including all MAC addresses of all the access points (Aps) and terminals (STA) to be blocked of the channel regarding each channel; and 4) the blocking device fills the MAC address in the channel MAC address list of the channel into a destination address field of a blocking frame and then sends the blocking frame regarding each channel to be blocked. The communication managing and controlling method greatly increases information security of secret units or regions, and has a small effect on the surrounding electromagnetic environment.

Owner:INST OF INFORMATION ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com