Safety plugging structure and mounting and demounting method thereof

A safe and blocking technology, which is applied in water supply installations, waterway systems, buildings, etc., can solve the problems of sealing failure, wall collapse, casualties, etc., to facilitate the sealing construction, prevent sudden collapse, and ensure construction quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described in conjunction with the following examples.

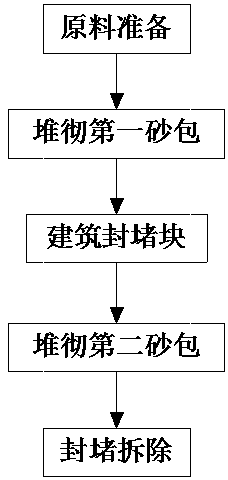

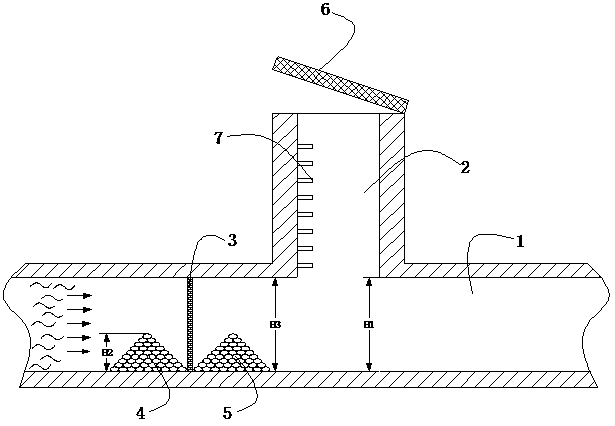

[0034] like Figure 1-2 As shown, a method for installing and removing a safety sealing structure includes the following steps:

[0035] (1) Raw material preparation: measure the size of the pipeline 1 that needs to be plugged according to the on-site working environment, and then calculate the required plugging raw materials;

[0036] (2) Stacking the first sand bag 4: Manually transport the raw materials to the inside of the pipeline through the inspection well 2, and at the same time, accumulate a certain amount of sand bags inside the pipeline along the direction of water flow, that is, on the upstream side;

[0037] (3) Construction of blockage block 3: in the pipeline after step (2), construct a blockage block 3 suitable for the size of the inner diameter of the pipeline on the back of the first sand bag 4 along the flow direction;

[0038] (4) Stacking the second sand bag 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com