Acid-soluble cement temporary plugging agent and preparation method thereof

A temporary plugging agent, acid-soluble technology, applied in the field of oil well cementing, can solve problems such as temporary plugging of untargeted reservoirs, and achieve the effect of wide application, reducing water loss and ensuring permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

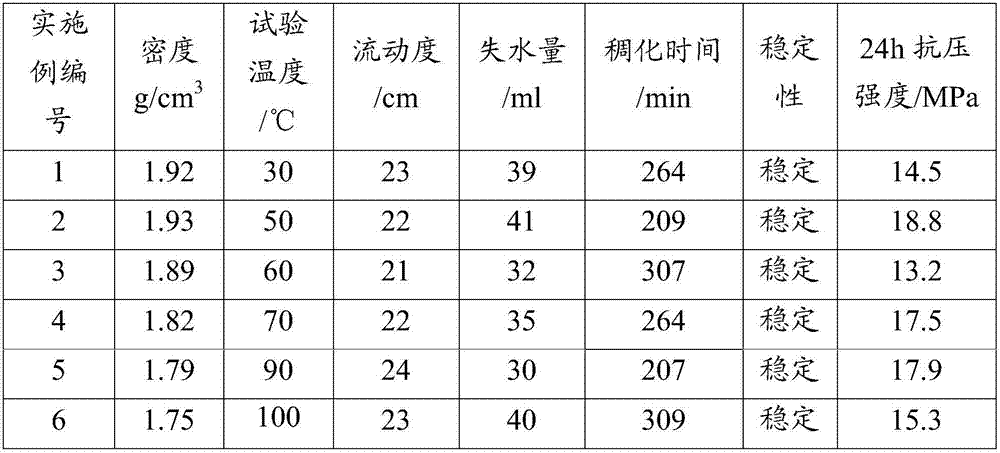

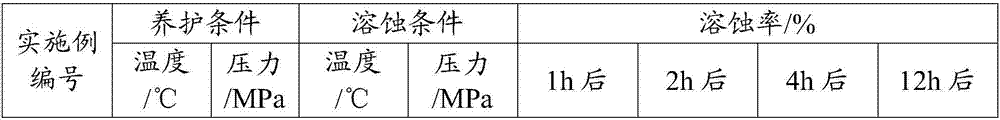

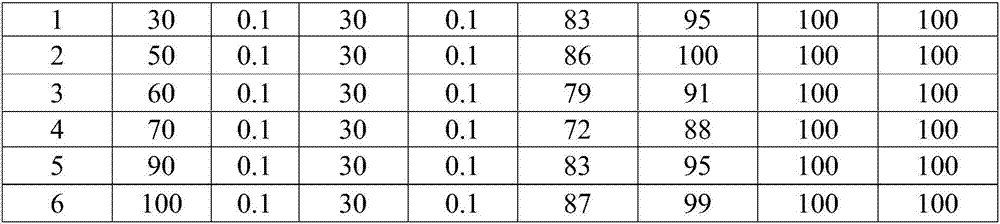

Examples

preparation example Construction

[0034] In the second aspect, the embodiment of the present invention provides a method for preparing an acid-soluble cement temporary plugging agent, which specifically includes the following steps:

[0035] Prepare a mixed solution of setting retarder, fluid loss reducer, magnesium chloride, sodium tripolyphosphate and water, prepare a mixed dry powder of dead burnt magnesia, superfine silica, ammonium phosphate, magnesium carbonate and calcium carbonate, and mix The dry powder and the mixed solution are added into the blade stirrer and stirred to obtain the acid-soluble cement temporary plugging agent.

[0036] Specifically, for the preparation process of acid-soluble cement temporary plugging agent, refer to the preparation method of oil well cement described in Chapter 5 of GB / T19139-2012, and determine the type of blade agitator that should be used accordingly. At the same time, the stirring speed is selected as 12000rpm, and the mixing time is selected as 35s, so that th...

Embodiment 1

[0044] This embodiment provides an acid-soluble cement temporary plugging agent, which includes the following components by weight: 1 weight part of dead-burned magnesia, 0.5 weight part of magnesium chloride, 0.1 weight part of magnesium carbonate, 0.3 Calcium carbonate of parts by weight, sodium tripolyphosphate of 0.01 parts by weight, superfine silicon dioxide of 0.006 parts by weight, ammonium phosphate of 0.02 parts by weight, retarder of 0.01 parts by weight, fluid loss reducing agent of 0.03 parts by weight, 0.38 parts by weight of water.

[0045] Among them, dead-burned magnesite is prepared by calcining magnesite at 1400°C, the average particle size of ultrafine silica is 10nm, and the retarder is a copolymer of organic phosphoric acid and maleic anhydride to reduce dehydration. The agent is a terpolymer of 2-acrylamide-2-methylpropanesulfonic acid, acrylic acid, and N-vinylpyrrolidone.

[0046] Specifically, the copolymer of organic phosphoric acid and maleic anhyd...

Embodiment 2

[0051] This embodiment provides an acid-soluble cement temporary plugging agent, which includes the following components by weight: 1 weight part of dead-burned magnesia, 0.6 weight part of magnesium chloride, 0.08 weight part of magnesium carbonate, 0.4 Calcium carbonate of parts by weight, sodium tripolyphosphate of 0.03 parts by weight, superfine silicon dioxide of 0.01 parts by weight, ammonium phosphate of 0.03 parts by weight, retarder of 0.03 parts by weight, fluid loss reducer of 0.04 parts by weight, 0.36 parts by weight of water.

[0052] Among them, dead-burned magnesite is prepared by calcining magnesite at 1500°C, the average particle size of ultrafine silica is 30nm, and the retarder is a copolymer of organic phosphoric acid and maleic anhydride to reduce dehydration. The agent is a terpolymer of 2-acrylamide-2-methylpropanesulfonic acid, acrylic acid, and N-vinylpyrrolidone.

[0053] Specifically, the copolymer of organic phosphoric acid and maleic anhydride is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com