Traditional poultry eggs compound nano material coating-film fresh-keeping method

A composite nanomaterial, coating film preservation technology, applied in the direction of coating protective layer to preserve eggs, etc., can solve the problems of increasing white pollution, low production efficiency, high packaging cost, and achieve good preservation effect, good compactness, and improve commodity properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

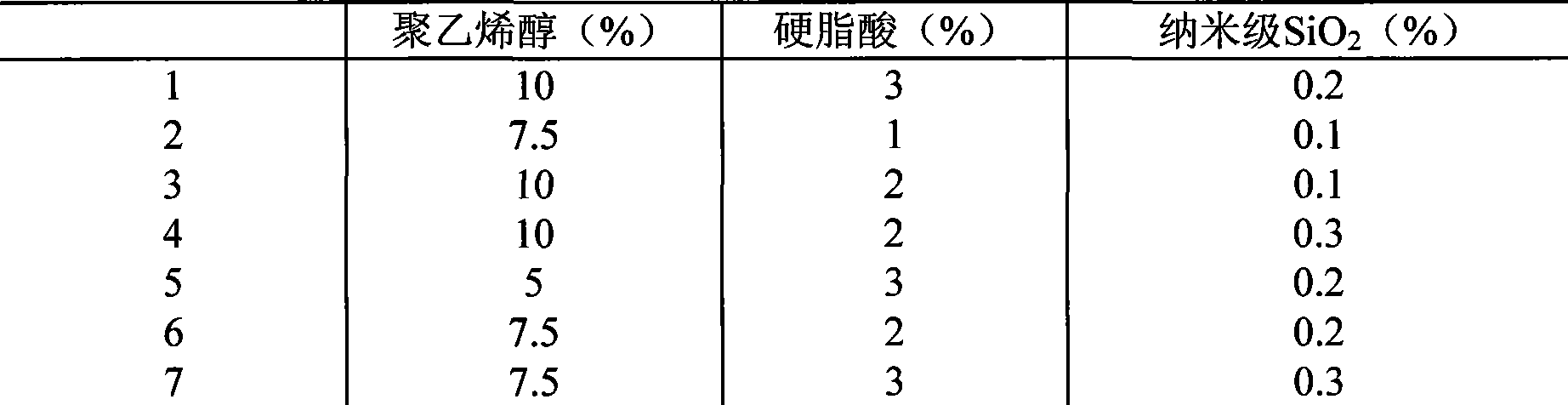

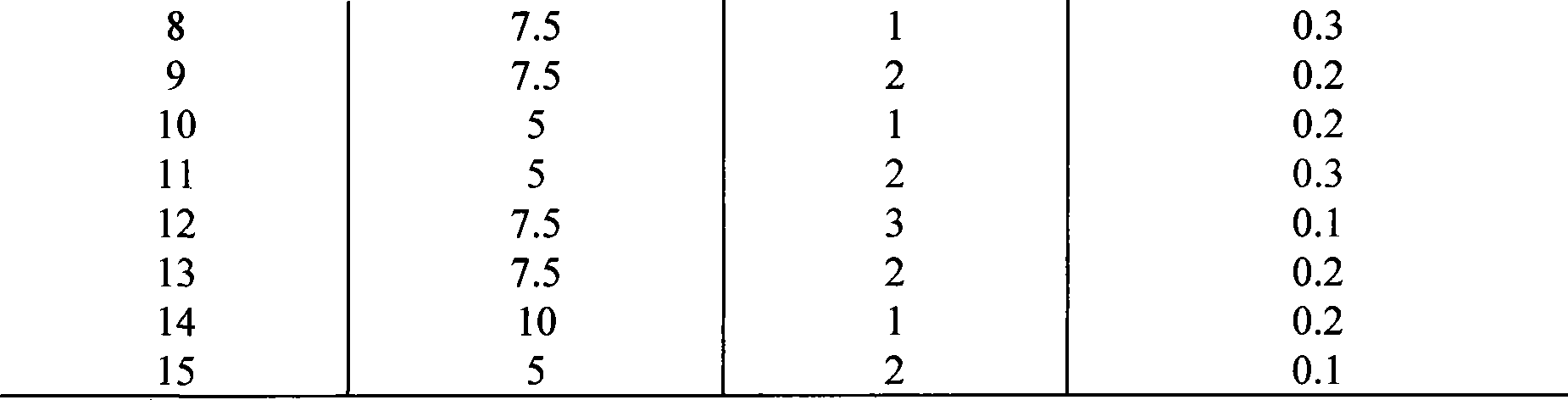

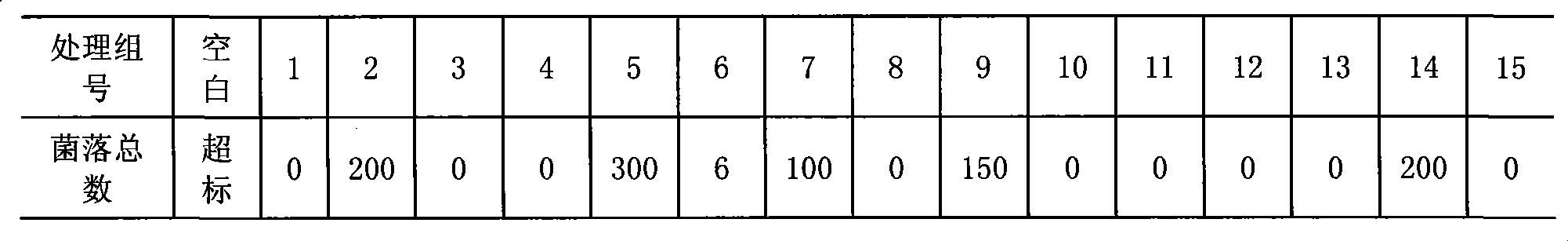

[0014] The traditional poultry and egg product composite nano-material coating film preservation technology of the present invention, polyvinyl alcohol, stearic acid and nano-scale SiO of the composite nano-material coating agent 2 The mass ratio with water was prepared respectively according to the 15 test groups of the response surface design of Table 1, and the preparation method was: polyvinyl alcohol and nano-scale SiO 2 Soak in normal temperature water for 3 hours according to the proportion, then heat and stir to 80-85°C to dissolve completely and mix evenly; dissolve stearic acid in 95% ethanol with a mass / volume ratio of 1:20, heat and stir to dissolve it completely , when the temperature of polyvinyl alcohol and stearic acid solution reaches 80-85 DEG C at the same time, mix them, keep them warm and stir for 10-50 minutes, and make a uniform emulsion to complete the preparation of the composite nanomaterial coating agent.

[0015] Table 1 Response surface experim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com