Powder covering substrate heating CH3NH3PbI3 perovskite film preparation method

A technology of CH3NH3I covering the substrate, applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve the problems of high process conditions, long reaction time, complicated process steps, etc., and achieve simple and good film forming process absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Powder covered substrate heating CH of the present invention 3 NH 3 PB 3 The specific implementation of the perovskite film preparation method is as follows.

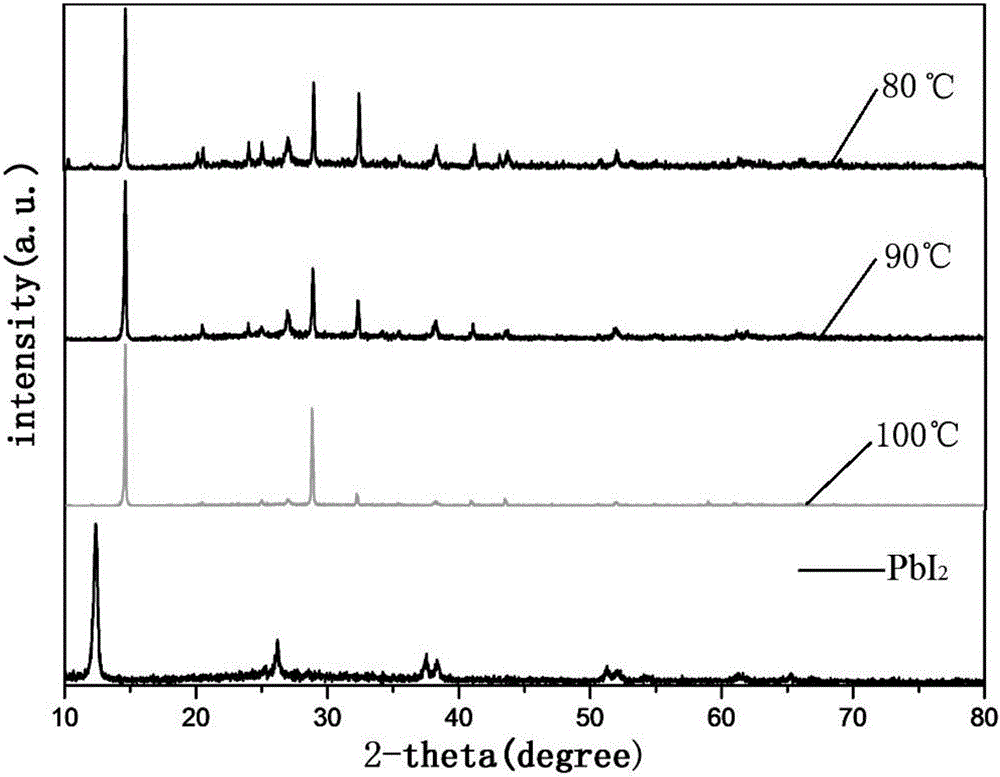

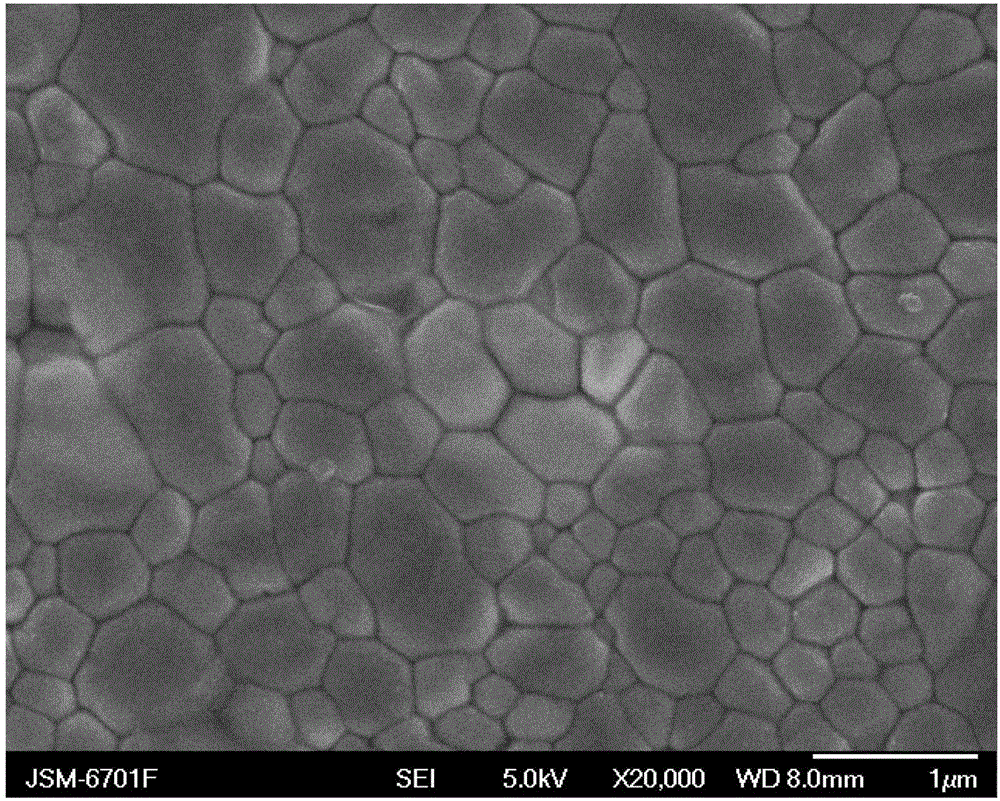

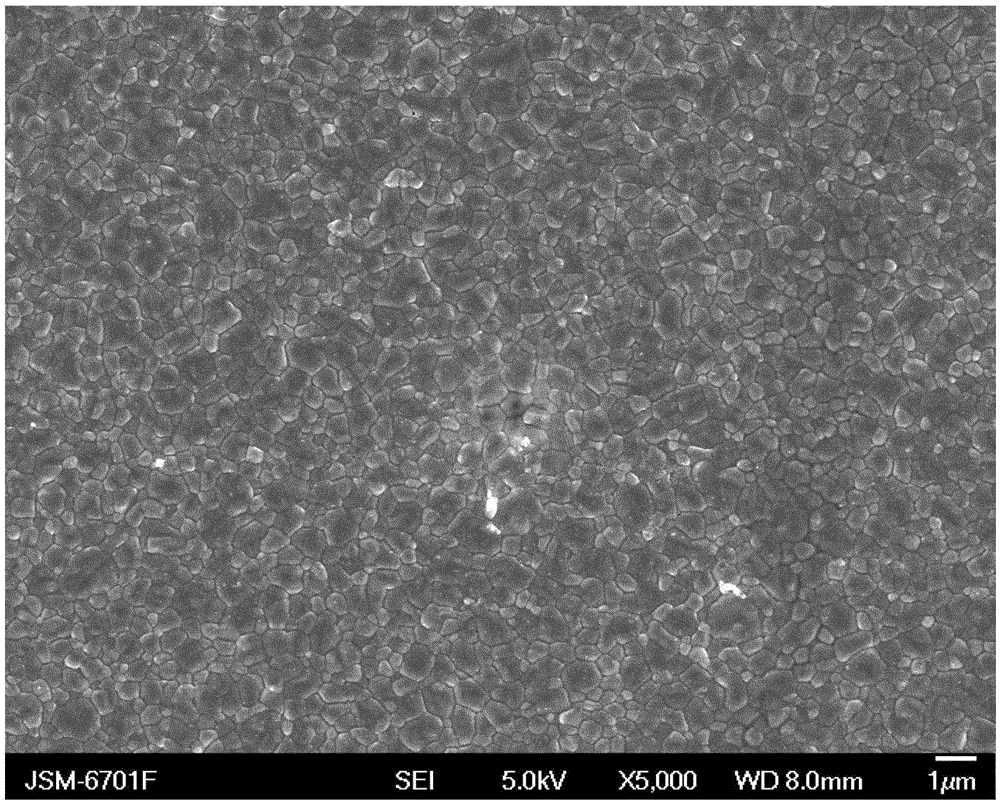

[0010] According to the ratio of 300mg:1mL PbI 2 The solid powder was dissolved in DMF solvent (N,N-dimethylformamide), stirred at 60°C for 4-6 hours, and the orange-yellow transparent PbI was obtained. 2 solution. The PbI 2 The solution was added dropwise onto the cleaned FTO glass, and thermally spin-coated on the FTO glass in a vacuum spin coater to form a uniform PbI 2 thin film, and then the PbI 2 The film is placed in a drying oven and dried at a temperature of 70-100°C for 20-60 minutes.

[0011] HI (hydroiodic acid) and CH 3 NH 2 The solution (methylamine) was added to a round bottom flask at a molar ratio of 1:1, stirred in an ice bath for 2 h, and then rotary evaporated at 50 ° C for 1 h to obtain CH 3 NH 3 I (methylammonium iodide) initial product. The primary product was washed successivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com