Preparation method of gas sensor based on metal phthalocyanine and use method of gas sensor

A gas sensor and metal phthalocyanine technology, applied in the field of preparation of gas sensors, can solve the problems of inability to detect at room temperature, slow response and recovery speed, etc., and achieve the effects of improving gas sensor response speed, recovery speed, and synthesis speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

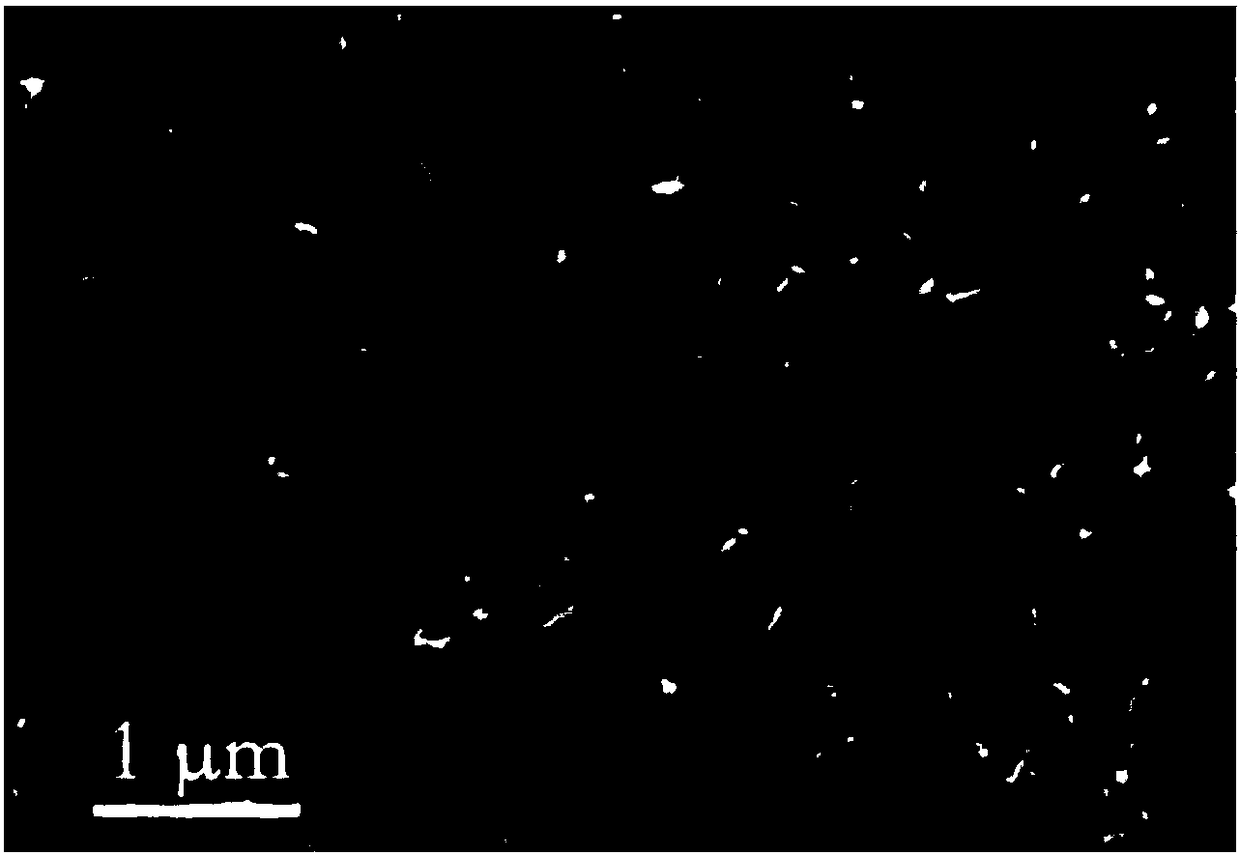

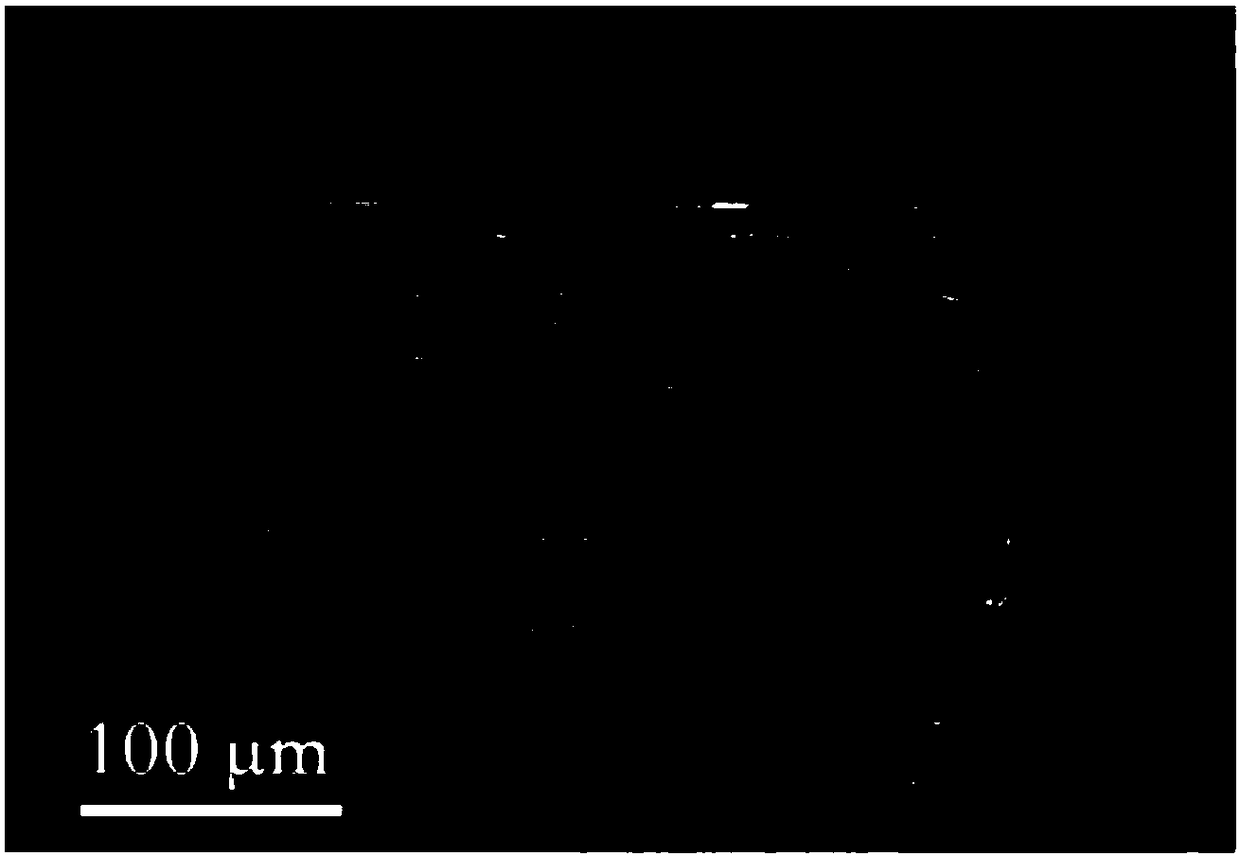

[0039] This embodiment provides a method for preparing a gas sensor based on metal phthalocyanine: dissolve metal phthalocyanine in a mixed solution of DMF and water, the mass ratio of DMF and water is 1:1, and drop it on the electrode to form a covering The metal phthalocyanine film on the electrode has an average film thickness of 200nm; the metal phthalocyanine film is composed of nanofibers, and the average length of the nanofibers is 200nm; the electrode is an interdigitated electrode.

[0040] The preparation of described metal phthalocyanine comprises the following steps:

[0041] Step 1: Trimellitic anhydride, urea, CoCl 2 And after ammonium molybdate is mixed and ground into powder according to the molar ratio of 400:2500:150:1, the ground powder is added into a container, heated to 200°C, and kept for 12 hours;

[0042] Step 2: Soak the product obtained in step 1 with 1mol / L hydrochloric acid for 14 hours, filter and wash to make the pH of the product reach 7;

[0...

Embodiment 2

[0049]According to Embodiment 1, this implementation provides a method for using a metallophthalocyanine-based gas sensor, comprising the following steps:

[0050] Step 1: Place the sensor in a closed cavity, fill it with dry air, and apply a voltage of 0.5V to the sensor;

[0051] Step 2: Introduce 50ppm of NO into the airtight cavity 2 Gas and maintain the concentration of gas atmosphere;

[0052] Step 3: Fill the airtight cavity with dry air, and irradiate the sensor with a laser with a wavelength of 395nm and a power of 50mW to make NO 2 For desorption, the laser irradiation incident angle is 0°, and the laser irradiation distance is 10 cm.

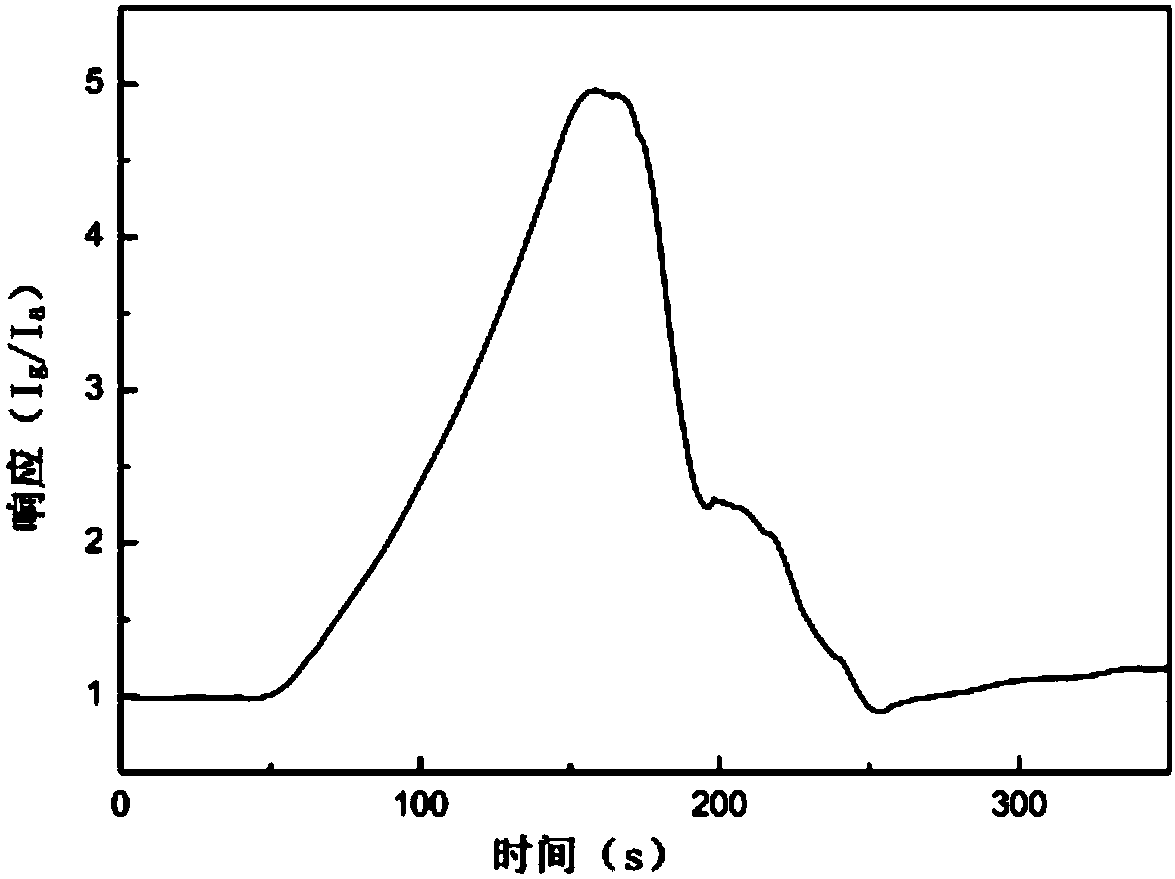

[0053] image 3 It is the NO that the sensor is placed in the concentration of 50ppm in this embodiment 2 The gas sensitivity response map measured in the gas, the recovery part is assisted by laser irradiation. Among them, Ig is the current value after the test gas is passed through, and Ia is the current value when the dry air ...

Embodiment 3

[0055] This embodiment provides a method for preparing a gas sensor based on metal phthalocyanine: dissolve metal phthalocyanine in a mixed solution of DMF and water, the mass ratio of DMF and water is 2:1, and drop it on the electrode to form a covering The metal phthalocyanine film on the electrode has an average film thickness of 100nm; the metal phthalocyanine film is composed of nanofibers, and the average length of the nanofibers is 100nm; the electrode is an interdigitated electrode.

[0056] The preparation of metal phthalocyanine comprises the following steps:

[0057] Step 1: Trimellitic anhydride, urea, NiCl 2 And after ammonium molybdate is mixed and ground into powder according to the molar ratio of 400:3000:180:4, the ground powder is added into the container, heated to 220°C, and kept for 18 hours;

[0058] Step 2: soak the product obtained in step 1 with 1.5mol / L hydrochloric acid for 18 hours, filter and wash to make the pH of the product reach 7.5;

[0059]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com