Patents

Literature

304 results about "Interdigitated electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biosensor with interdigitated electrodes

InactiveUS7022218B2Immobilised enzymesBioreactor/fermenter combinationsOxidoreductaseInterdigitated electrode

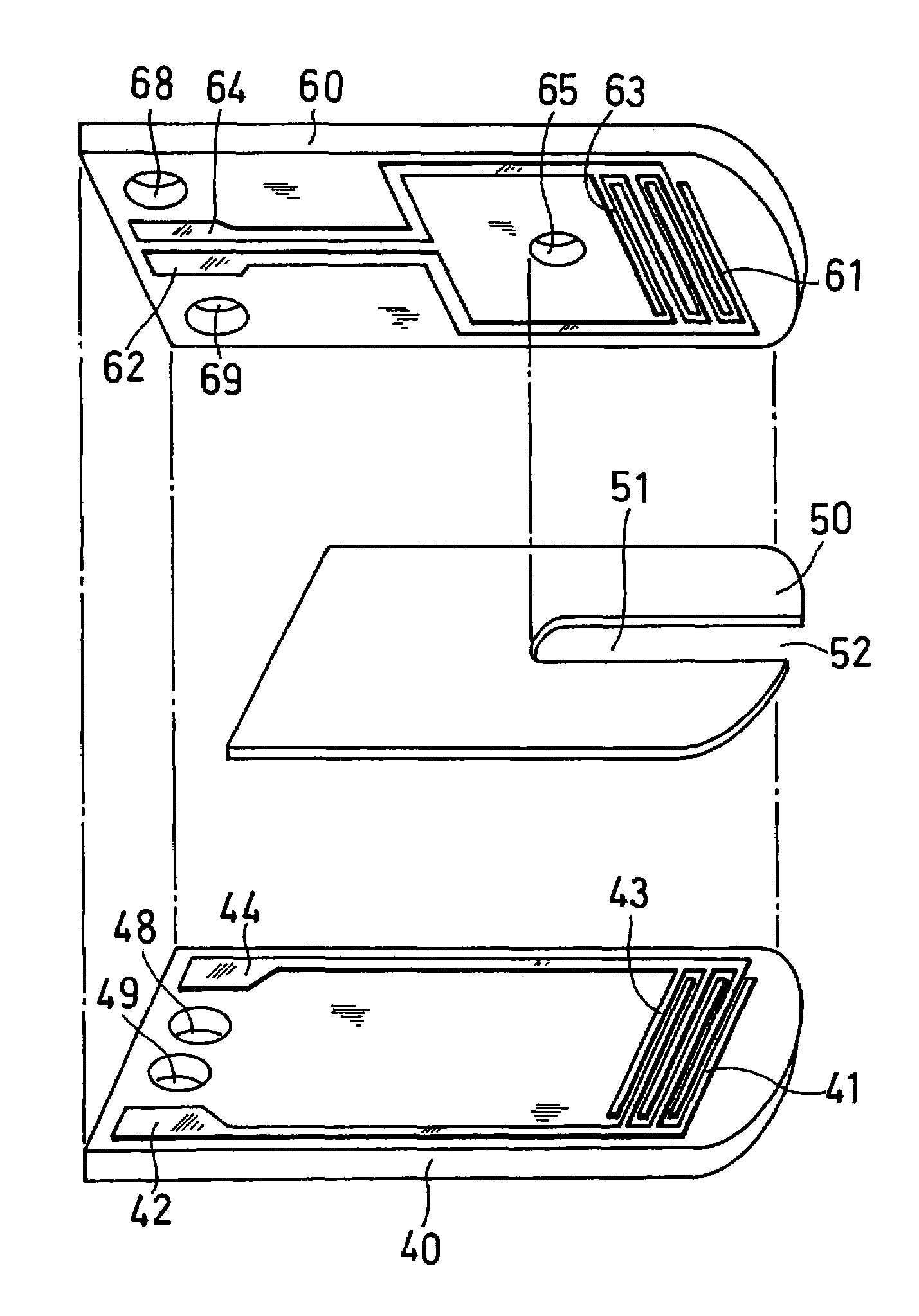

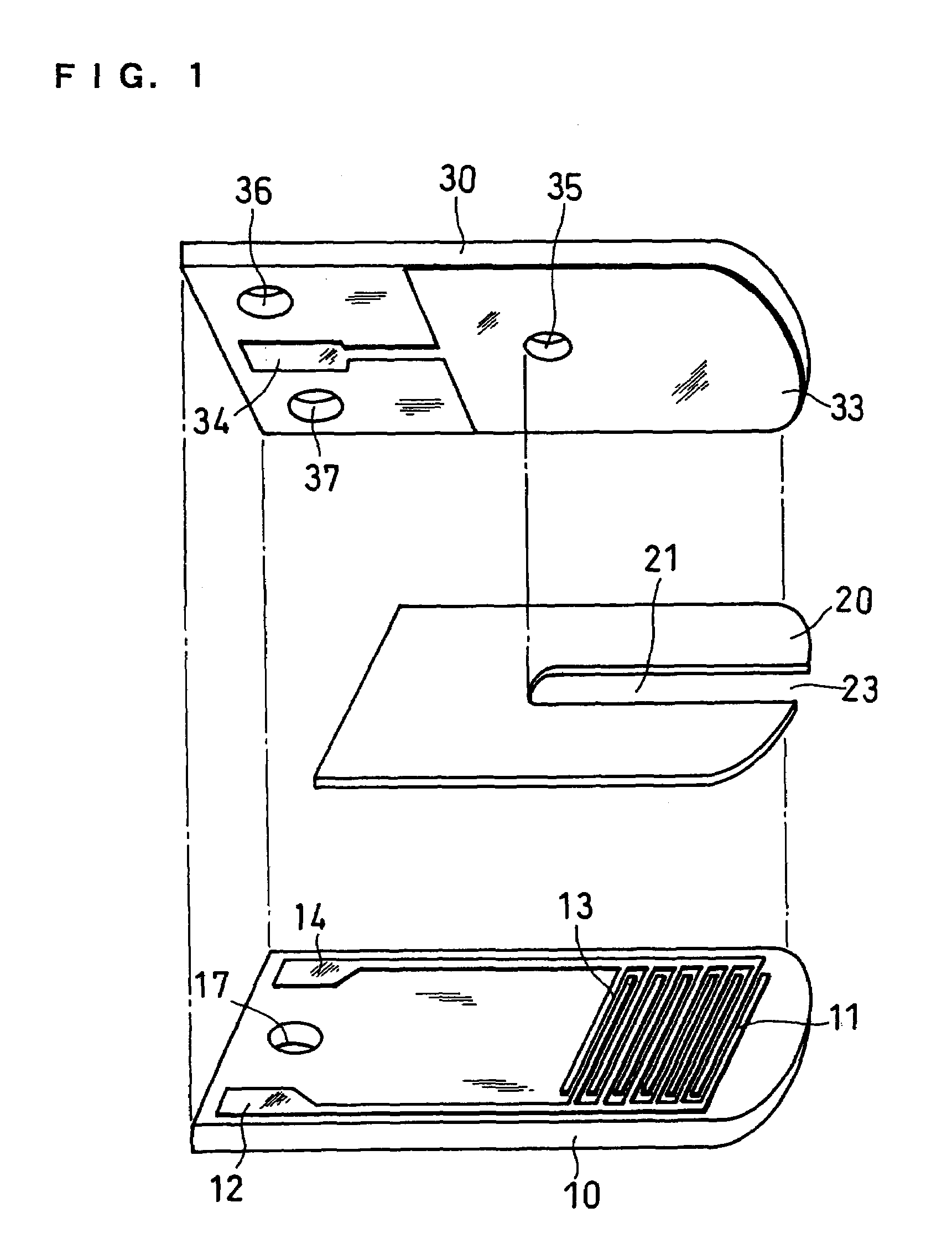

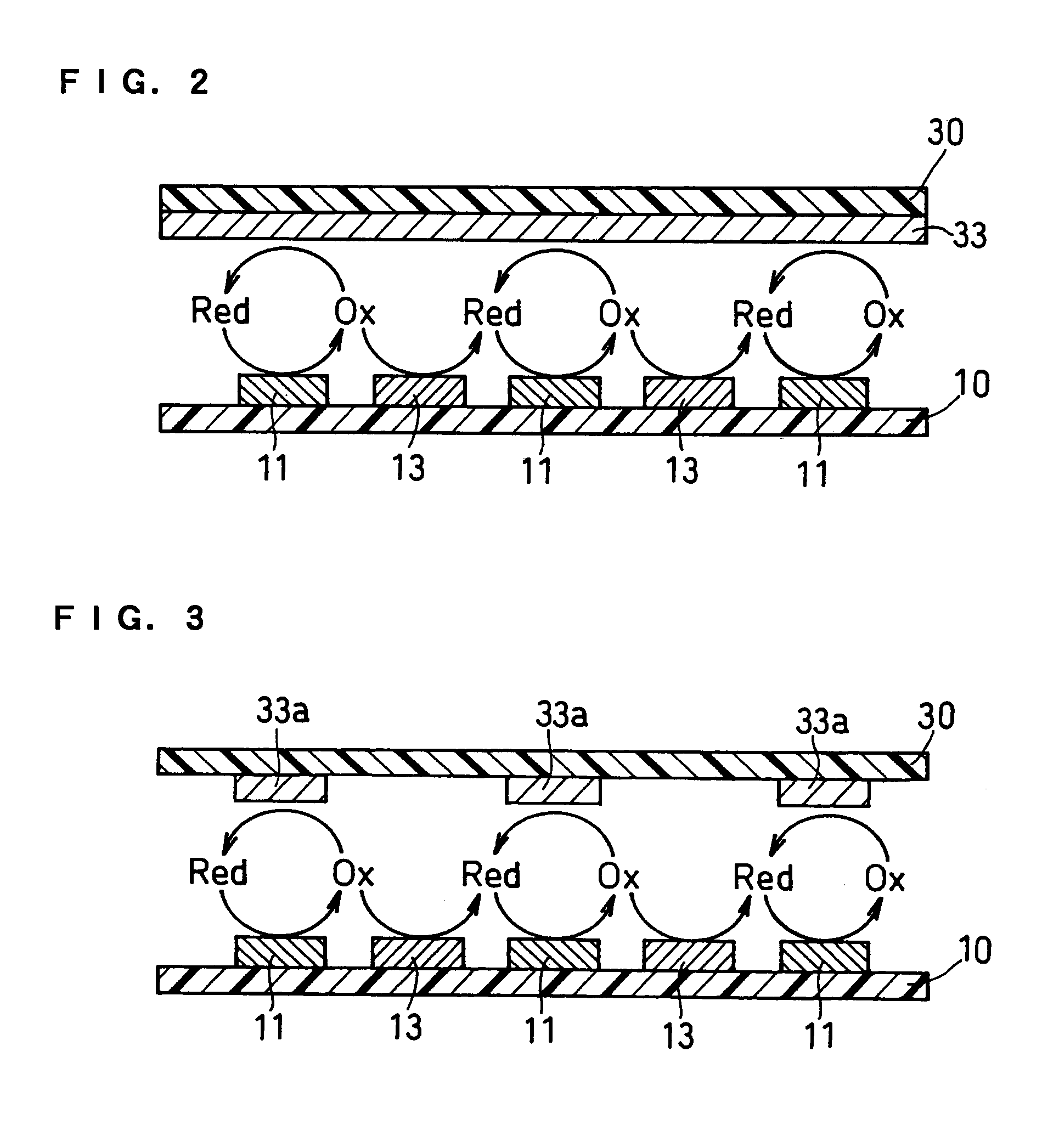

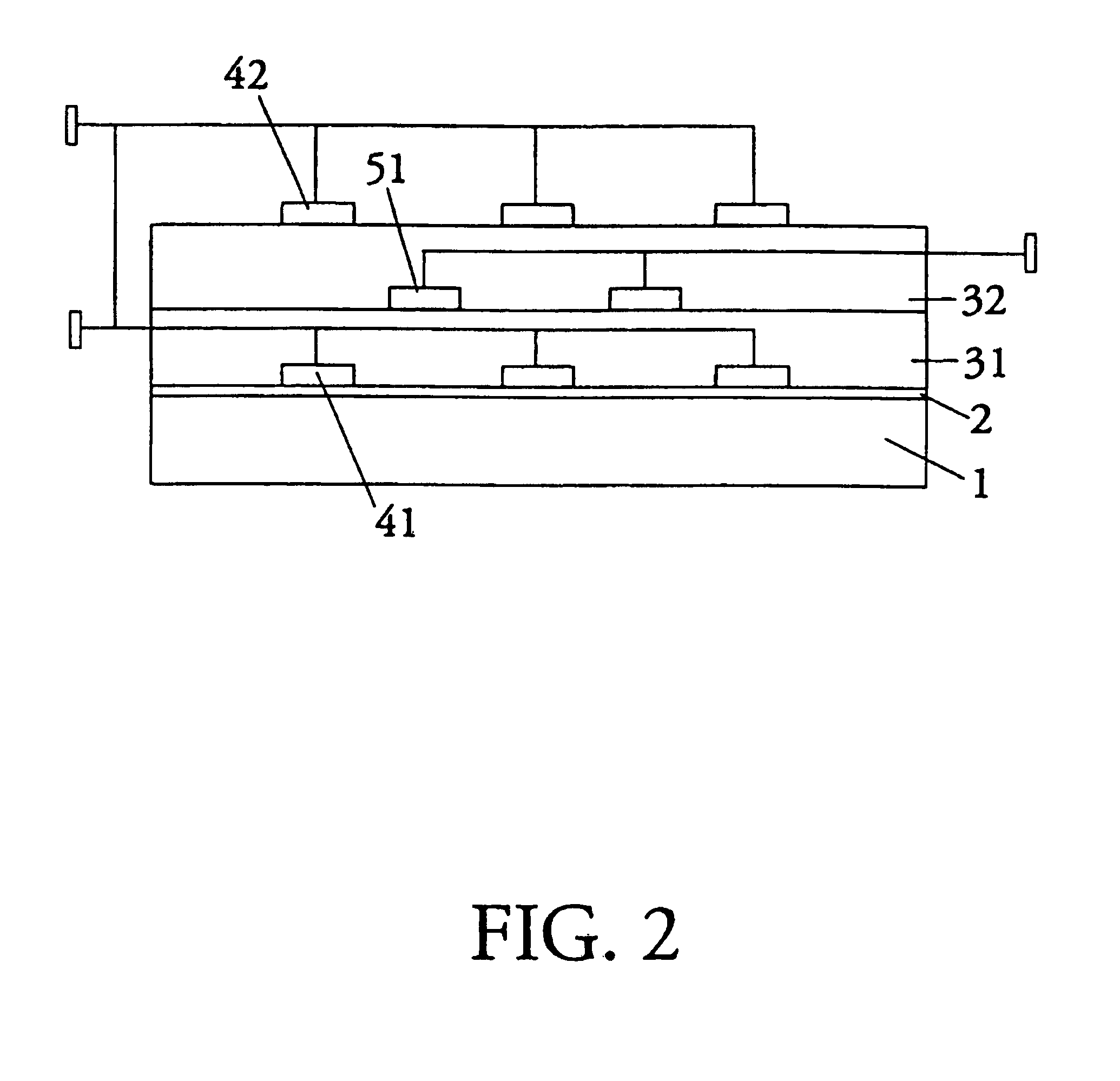

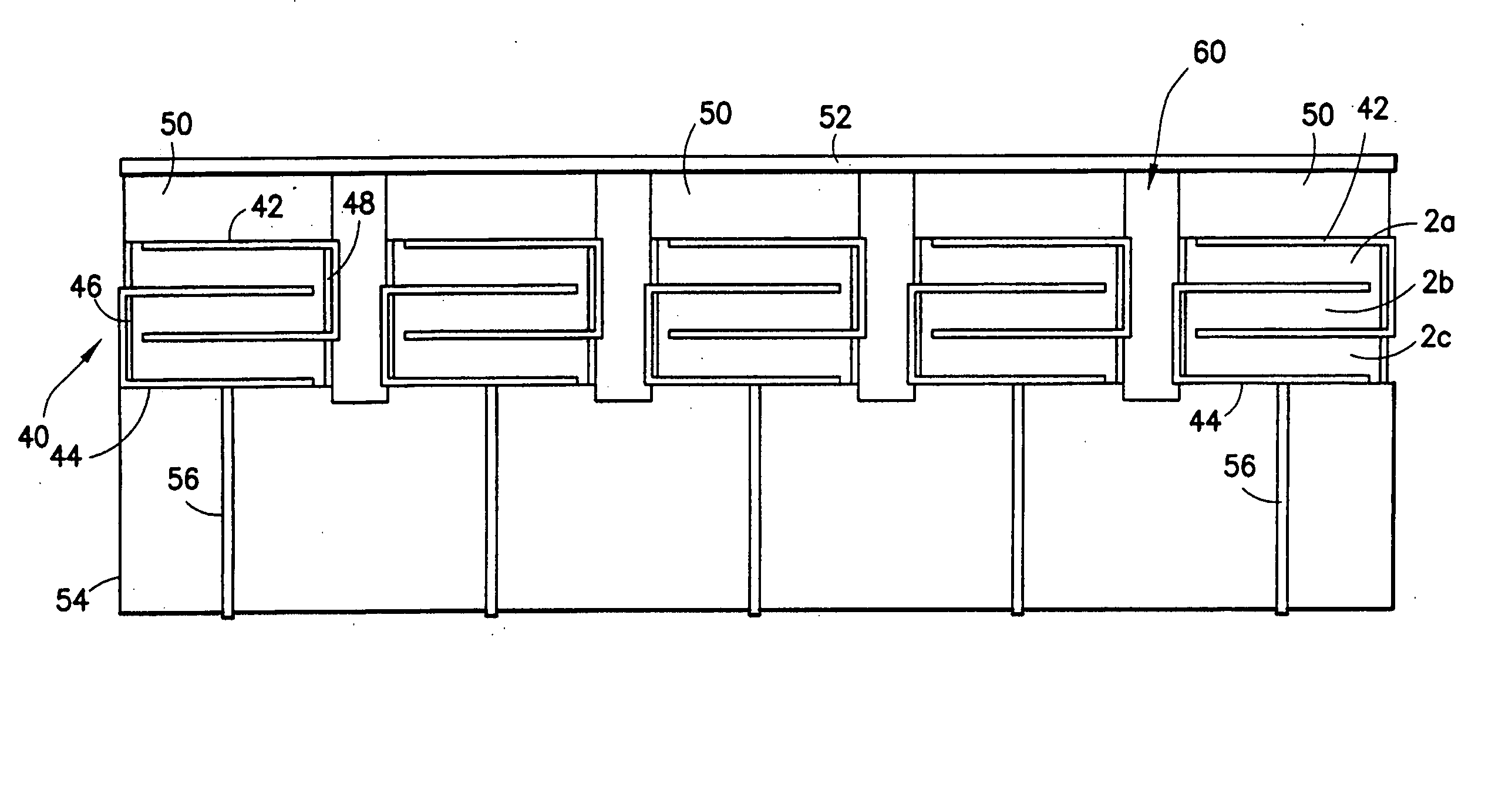

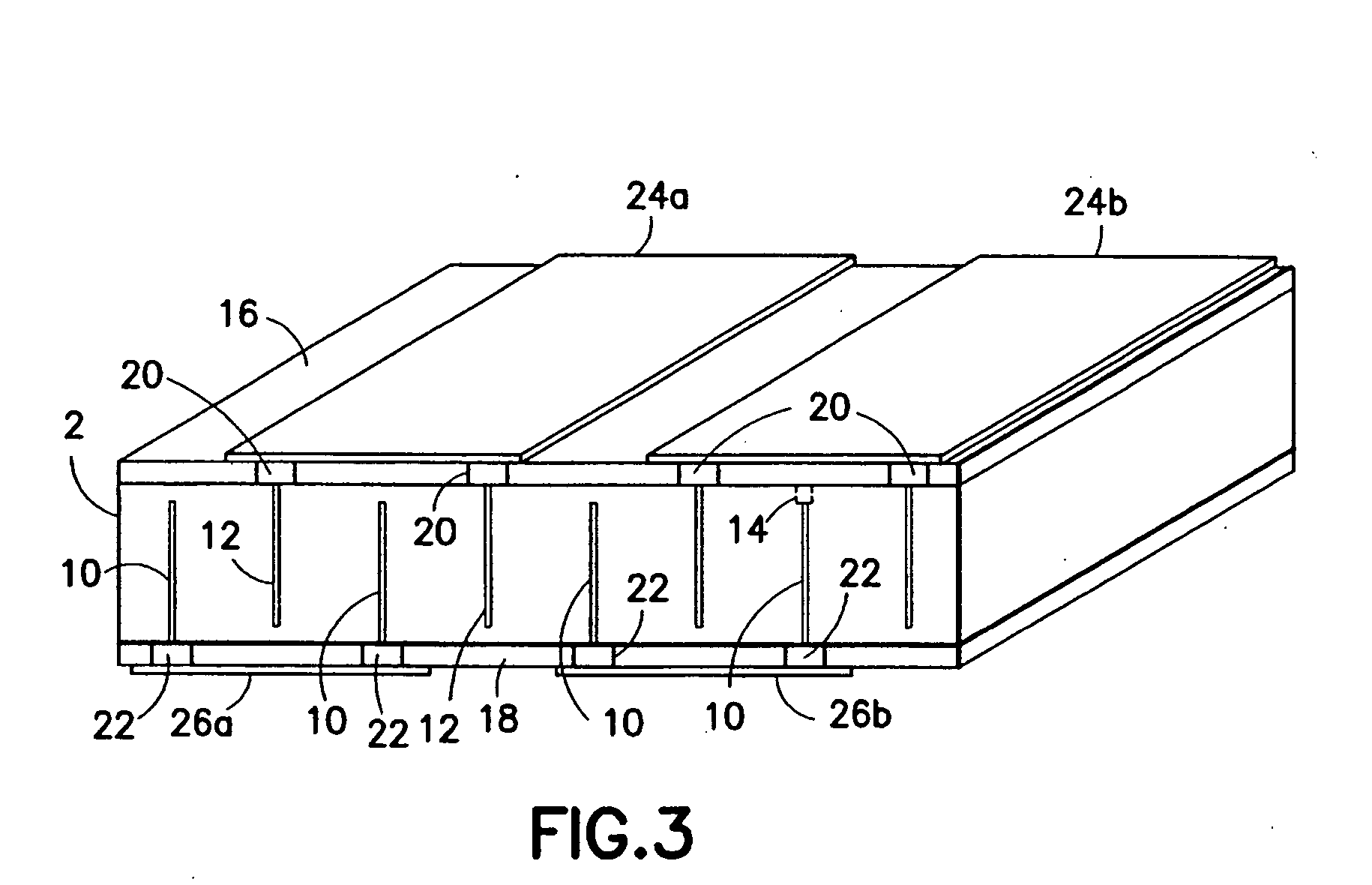

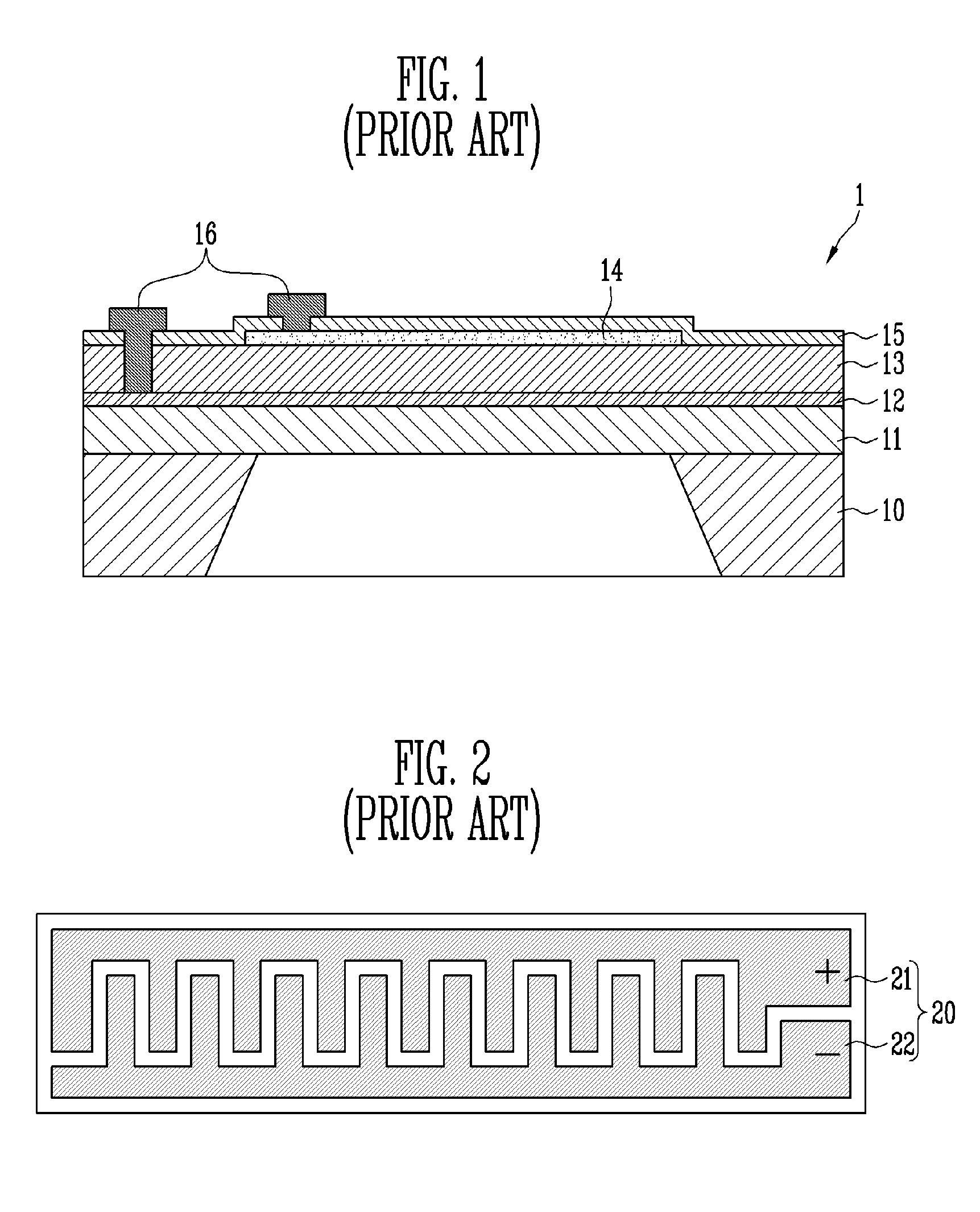

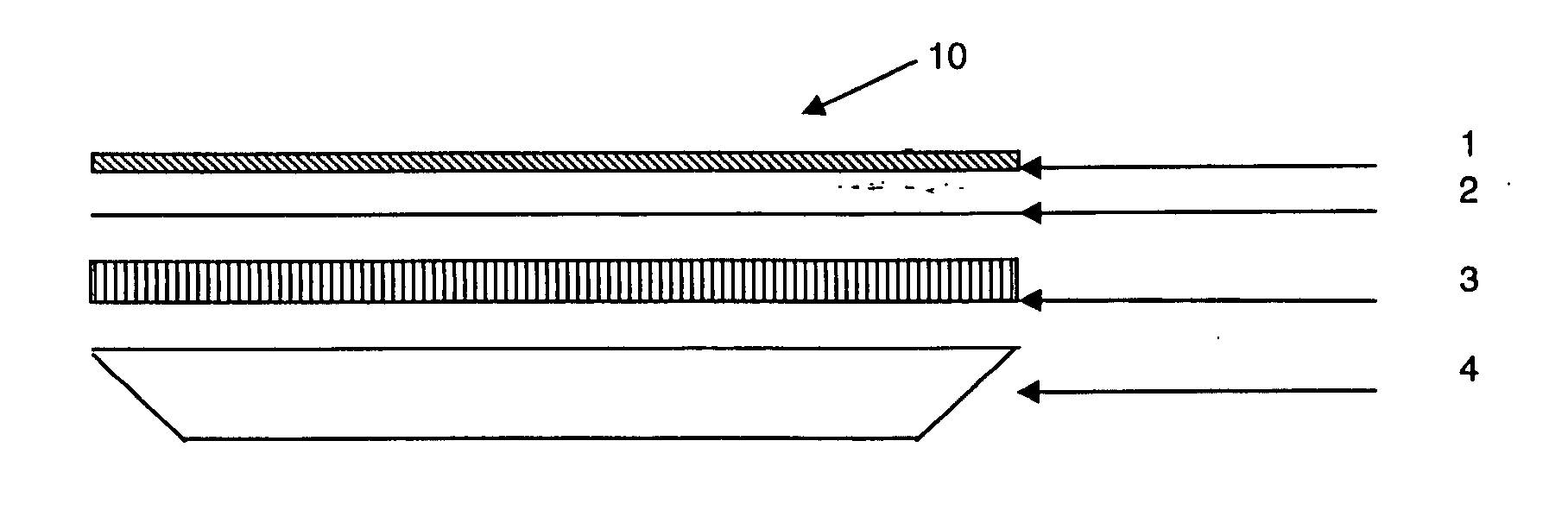

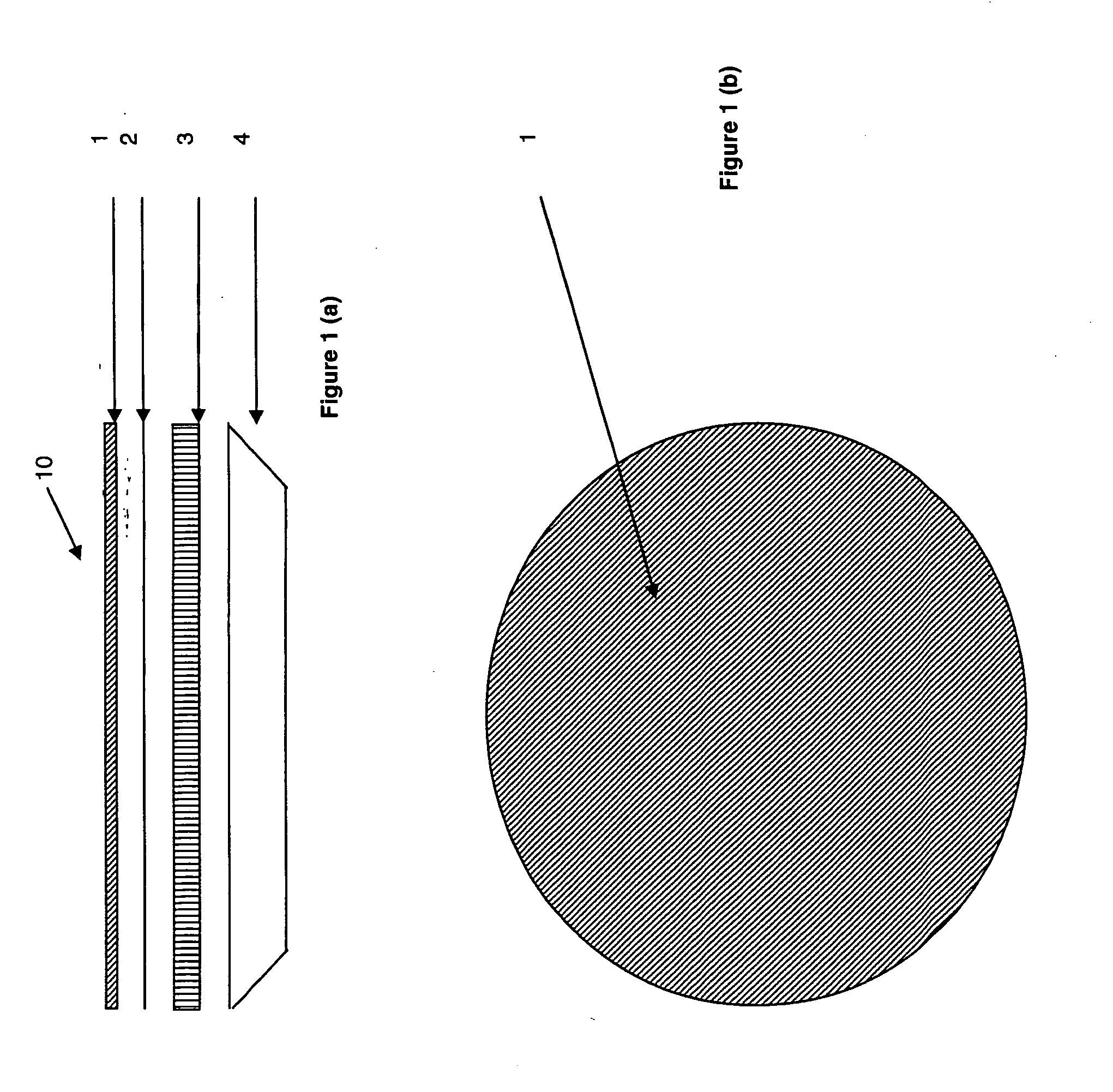

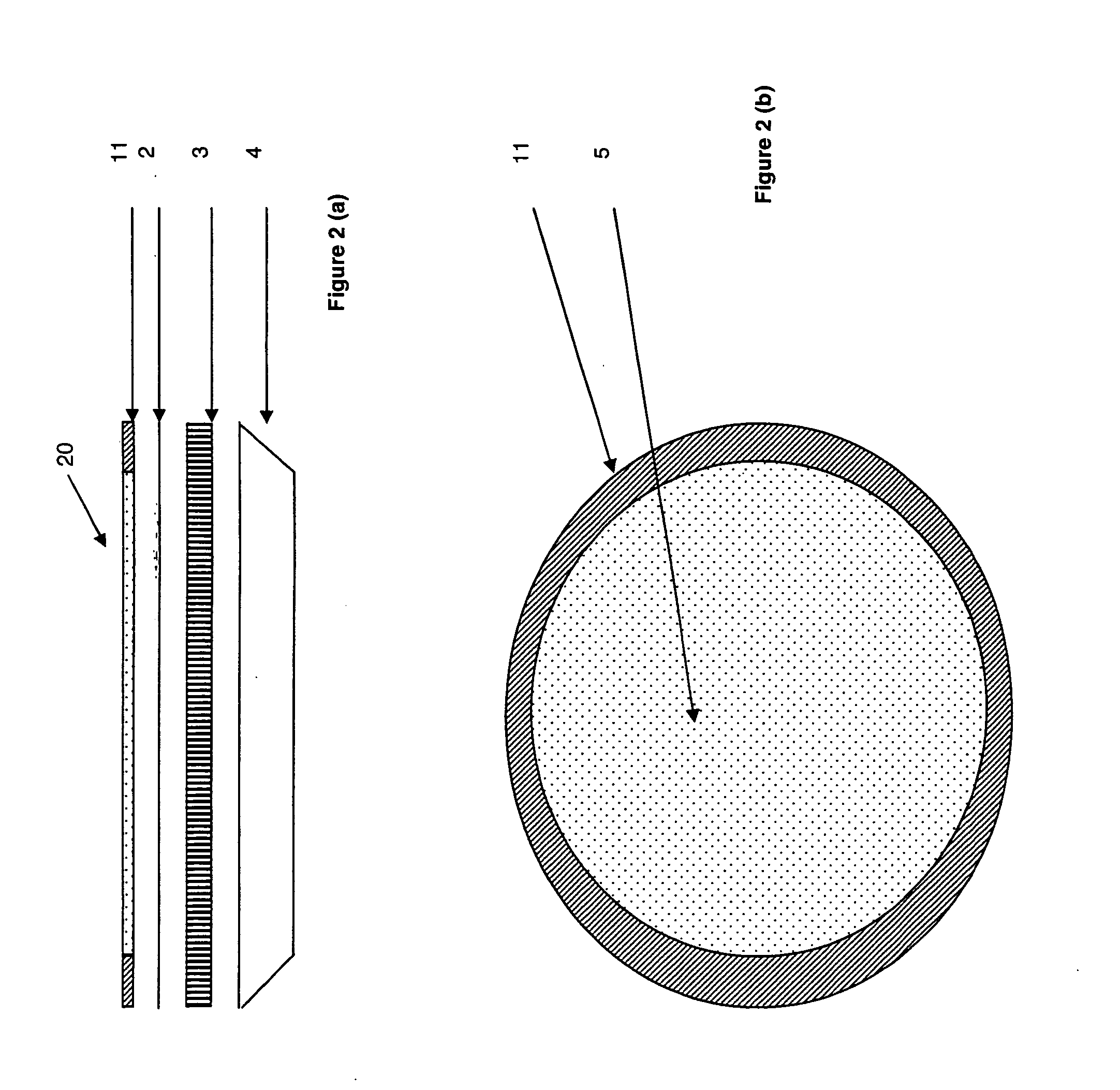

The present invention provides a highly sensitive biosensor capable of yielding good response even when the amount of a sample is extremely small. The biosensor of the present invention includes: a first insulating base plate which has a working electrode comprising a plurality of branches and a first counter electrode comprising a plurality of branches, the branches of the working electrode and the first counter electrode being arranged alternately; a second insulating base plate which has a second counter electrode and which is disposed at a position opposite to the first insulating base plate; a reagent system comprising an oxidoreductase; and a sample supply pathway formed between the first and second insulating base plates, wherein the branches of the working electrode and the first counter electrode that are arranged alternately, the second counter electrode, and the reagent system are exposed in the sample supply pathway.

Owner:PHC HLDG CORP

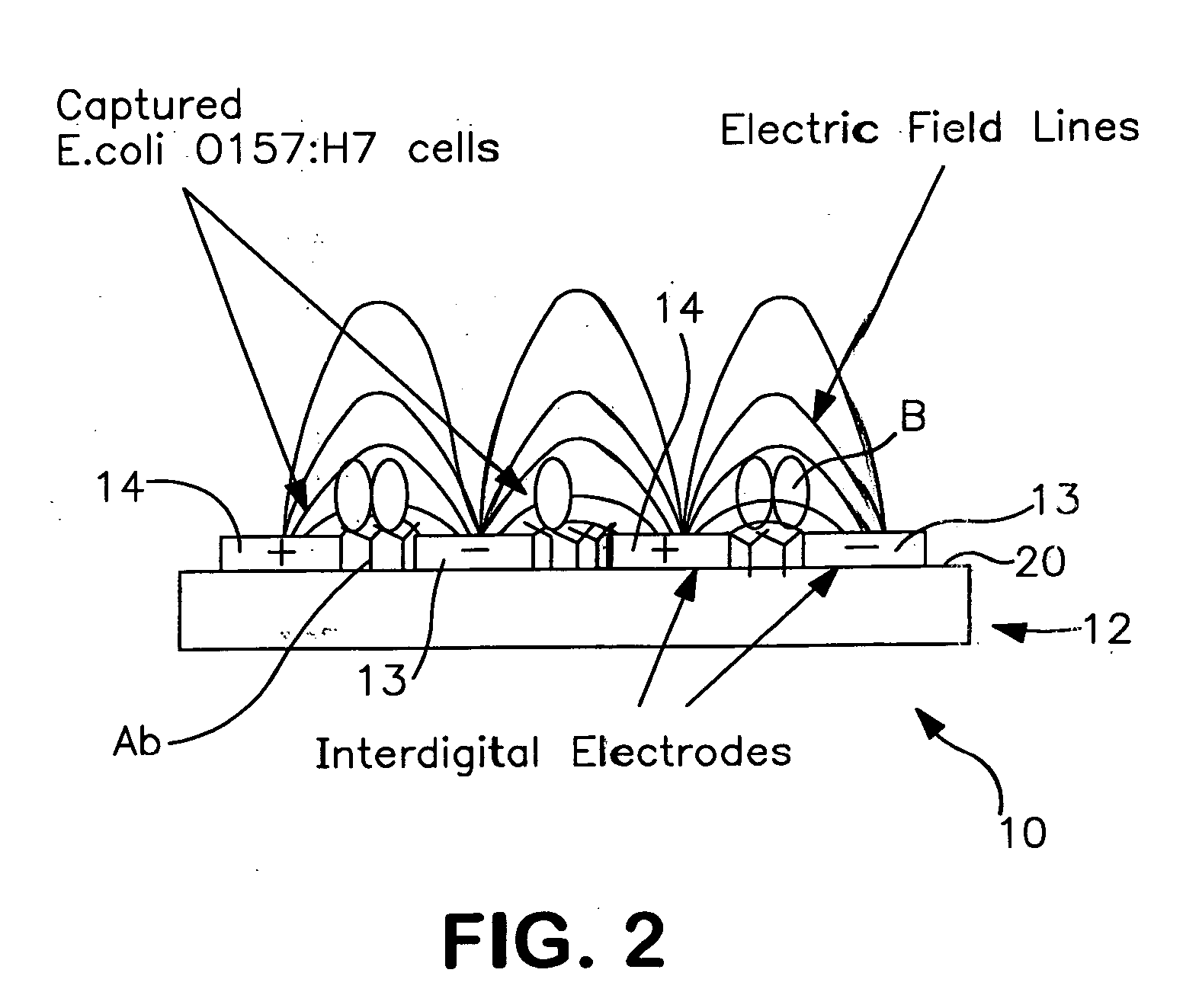

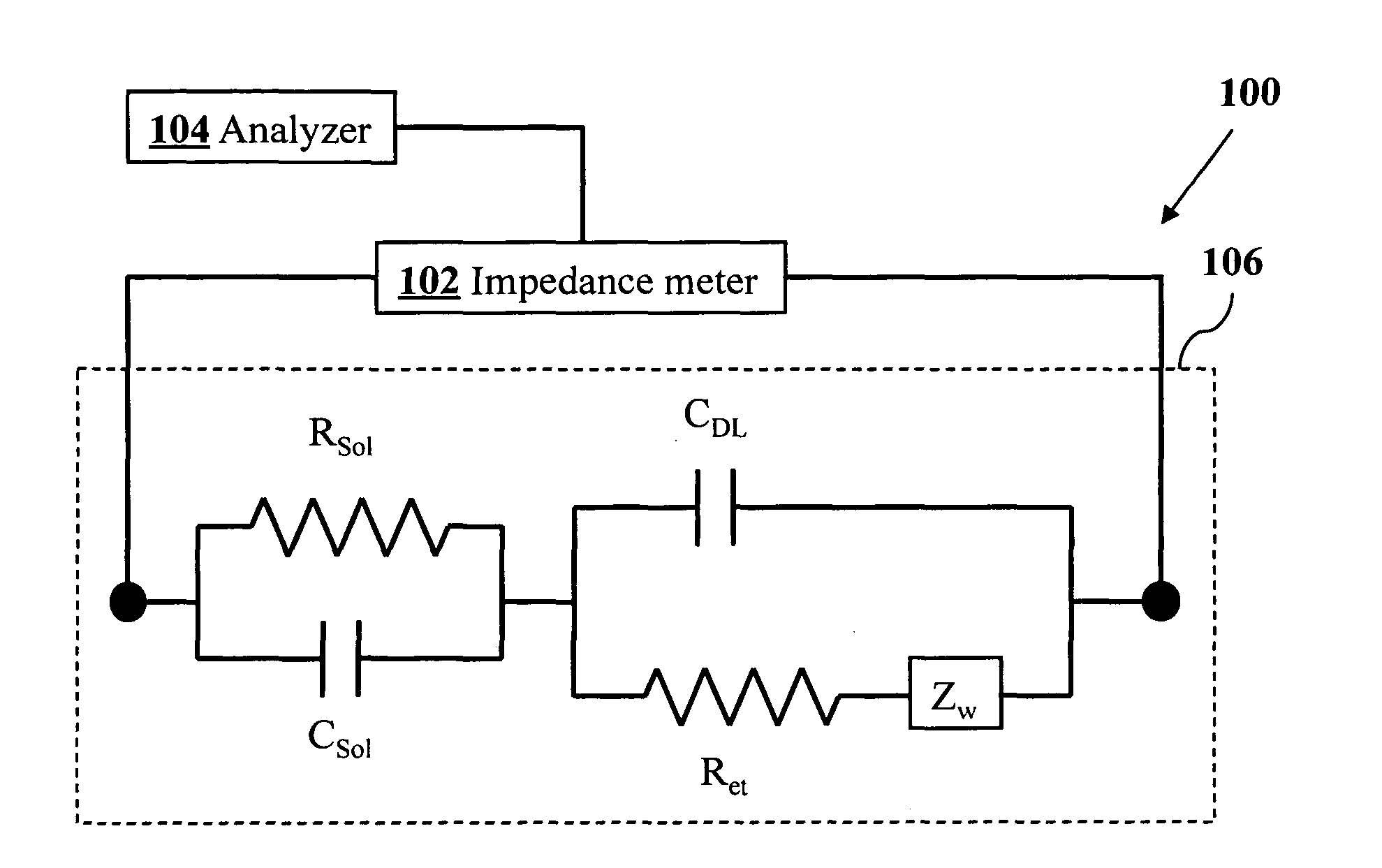

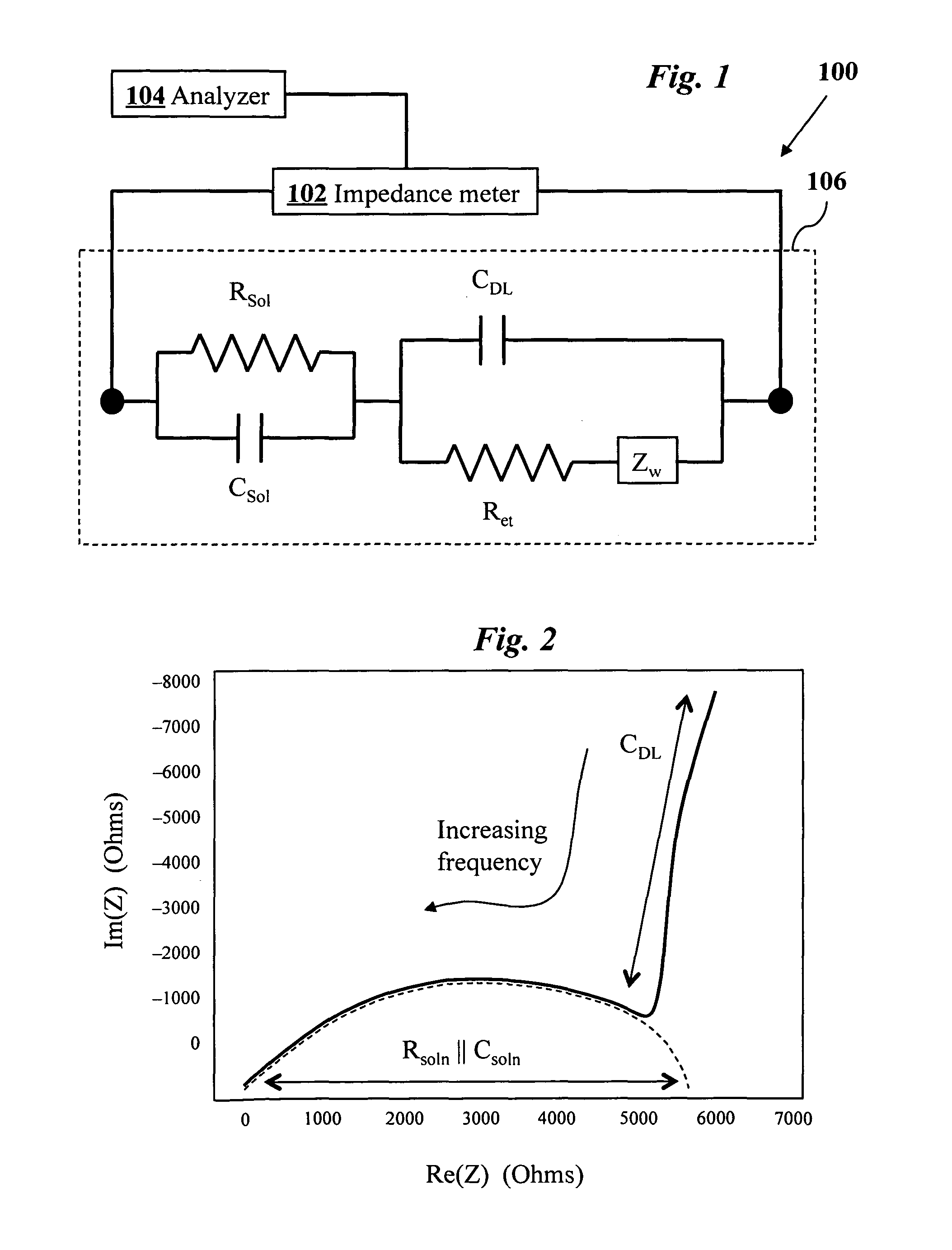

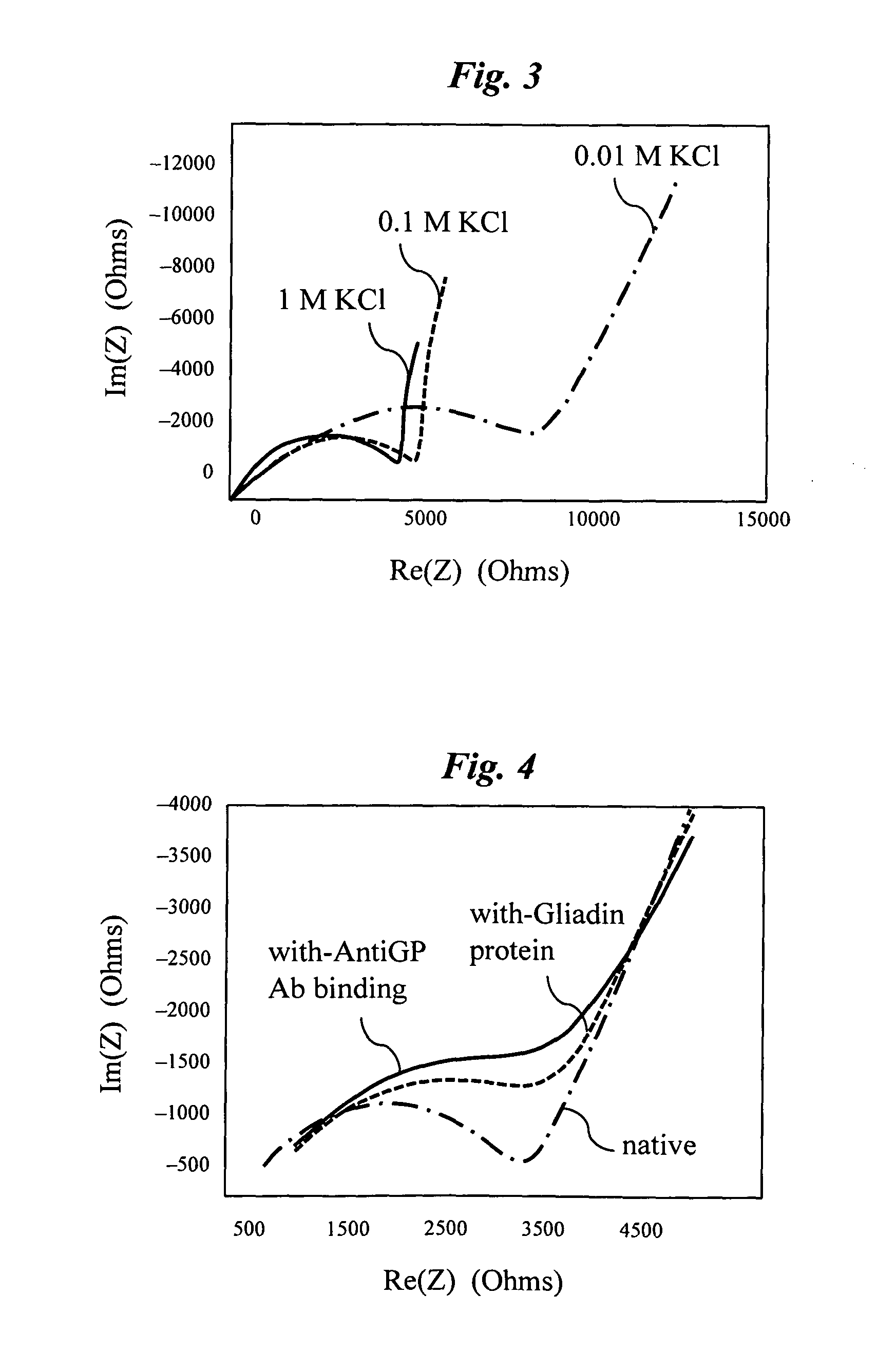

Impedimetric biosensor and its use for rapid detection of bacterial pathogens in solution

InactiveUS20050059105A1Cheap constructionReliable and reliableBioreactor/fermenter combinationsBiological substance pretreatmentsBacteroidesMicroorganism

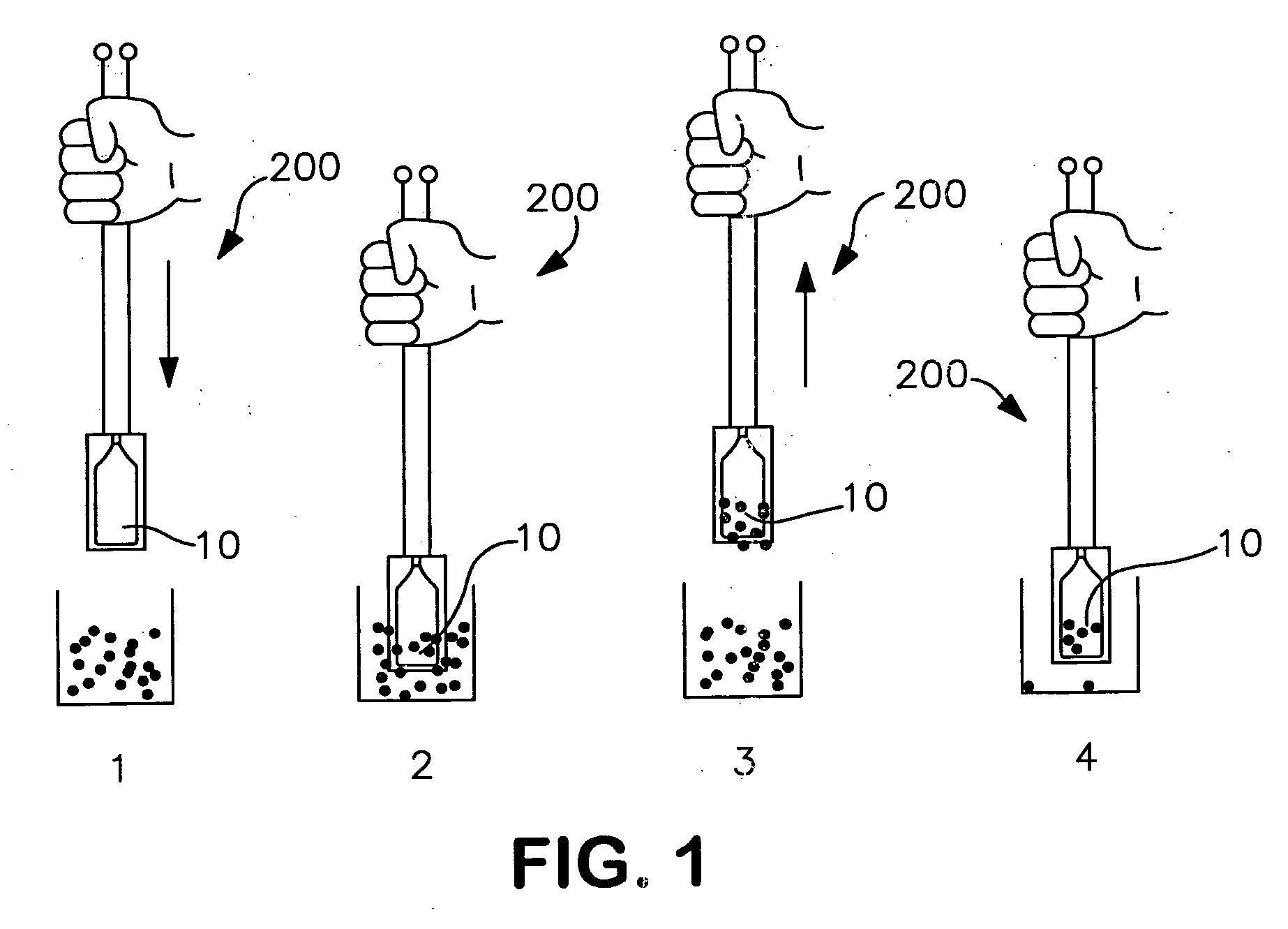

A method and device for the rapid detection of microorganisms by detection of a change of impedance as a result of the microorganism being bound between interdigitated electrodes is described. In particular, the present invention relates to a handheld device to be used for the detection and, in many instances, the identification of the microorganism.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

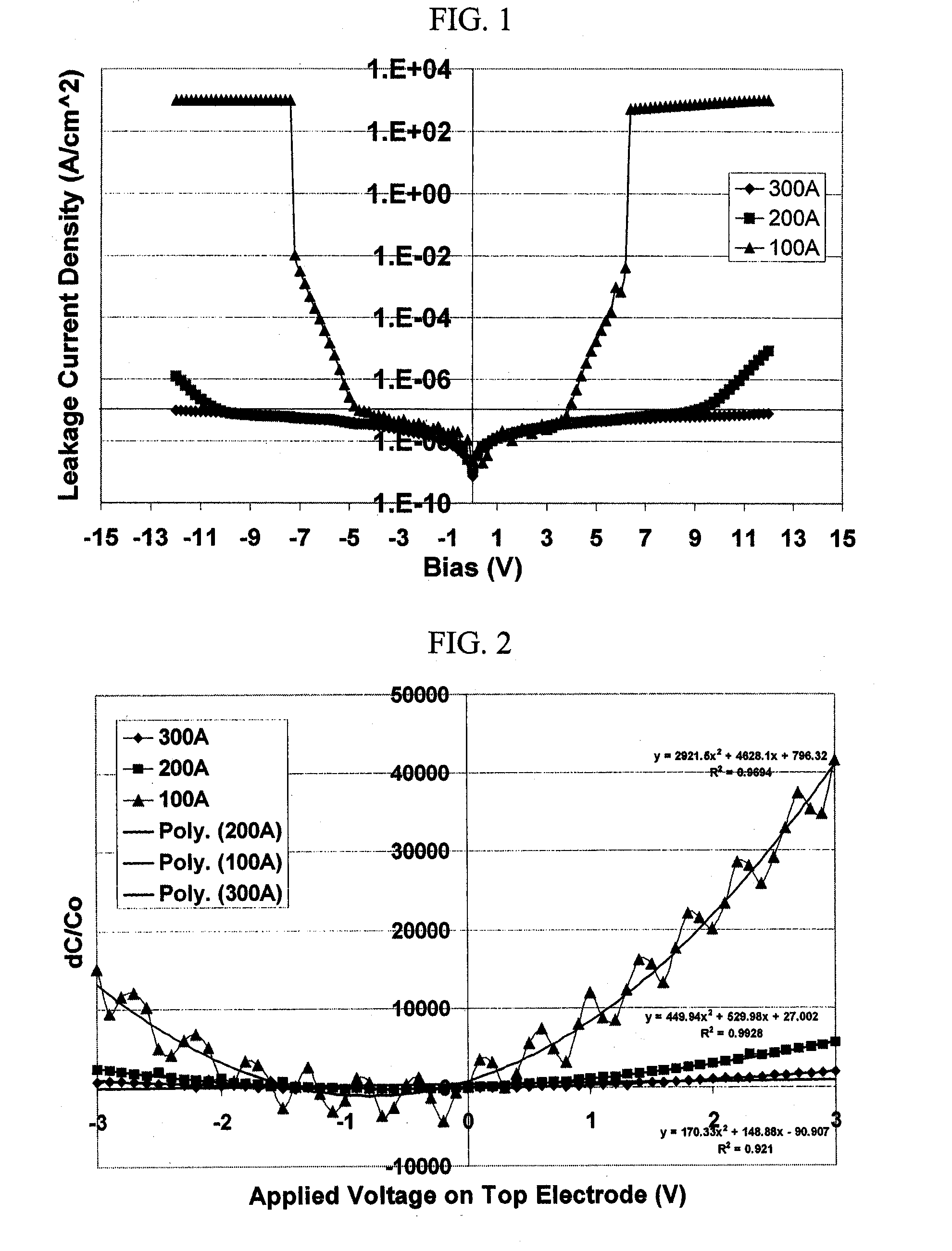

Breakdown-resistant thin film capacitor with interdigitated structure

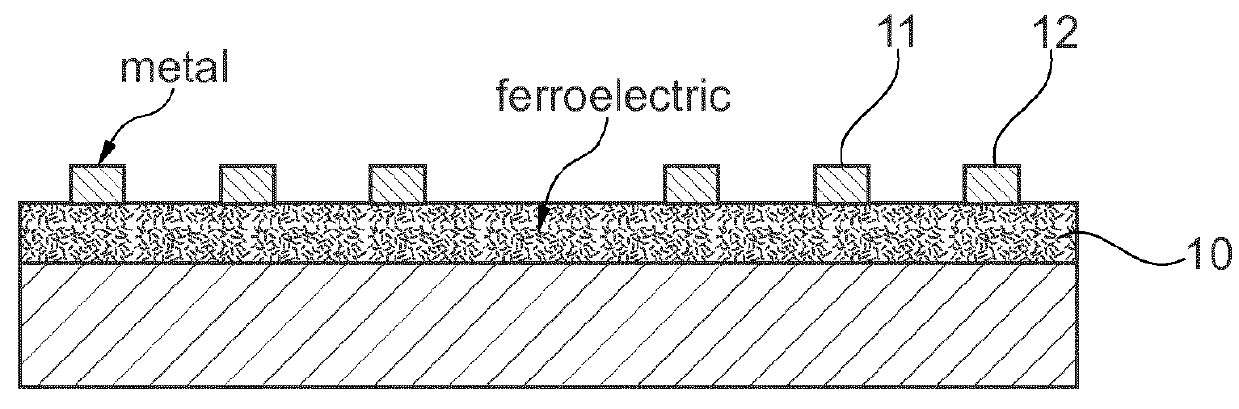

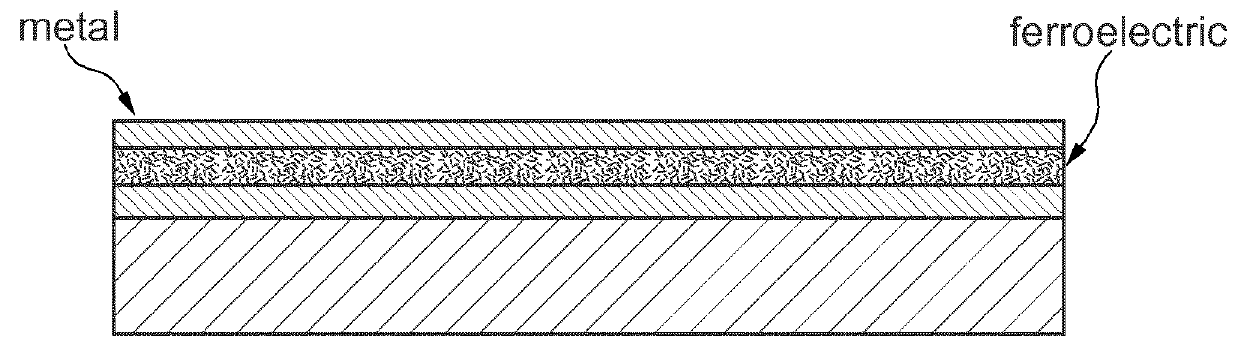

InactiveUS6999297B1High breakdown resistanceIncrease capacitanceThin/thick film capacitorFixed capacitor electrodesDielectricEngineering

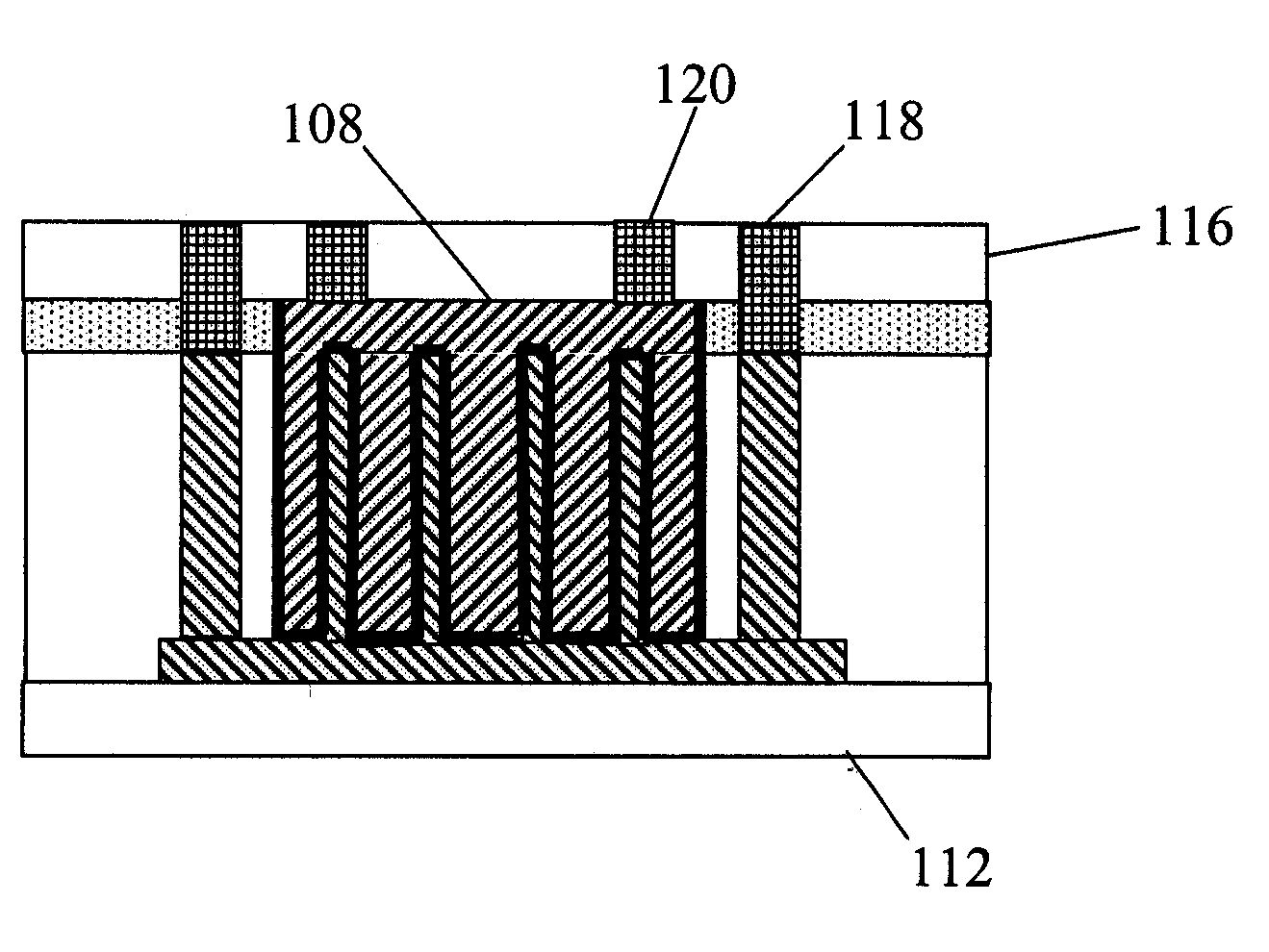

The invention relates to a thin film capacitor with a carrier substrate, at least two interdigitated electrodes, and a dielectric. A staggered arrangement of at least one interdigitated electrode below the dielectric with respect to an interdigitated electrode above the dielectric results in a breakdown-resistant thin film capacitor which can be manufactured in the same production process as a standard monolayer capacitor.

Owner:NXP BV

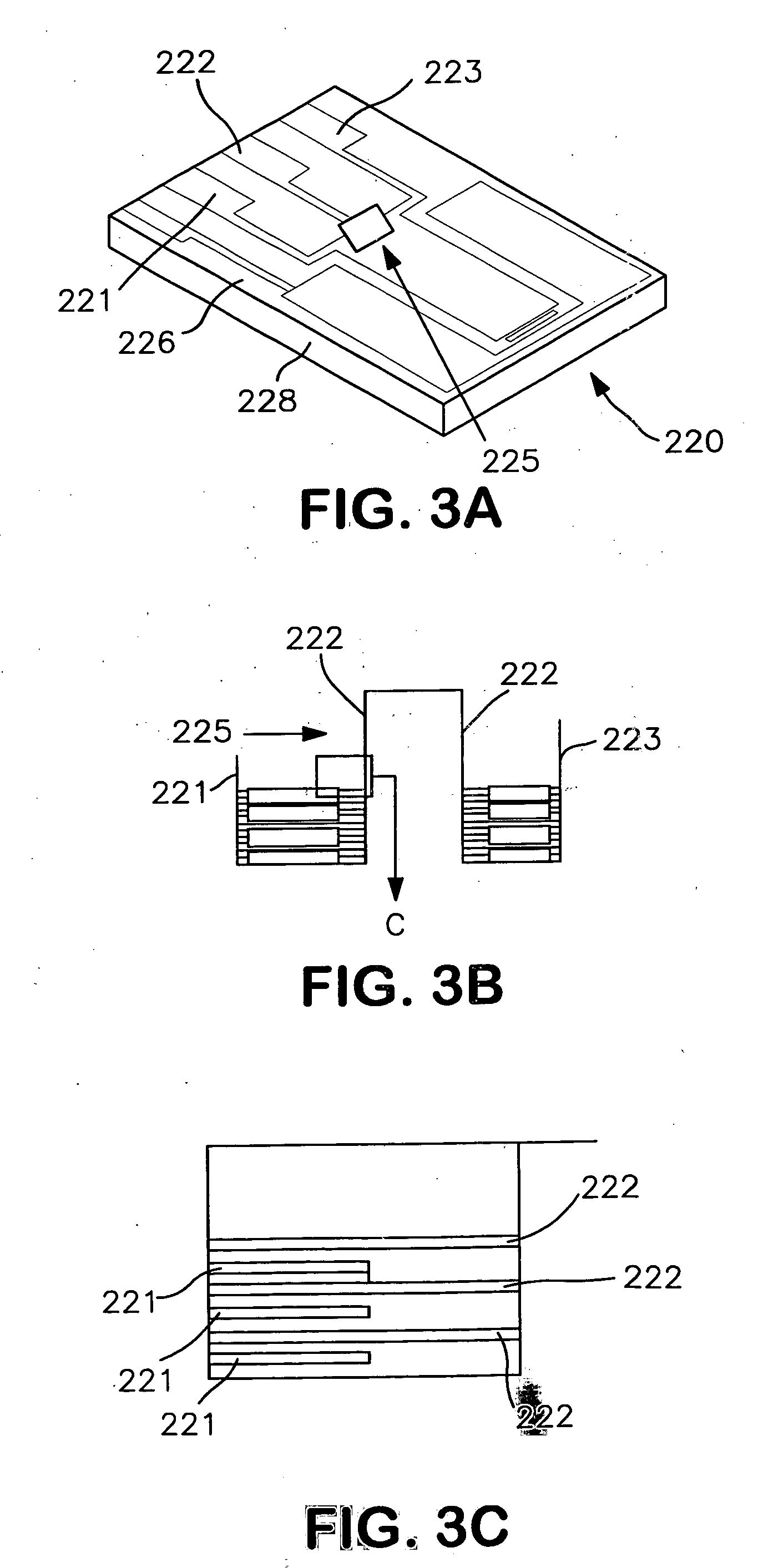

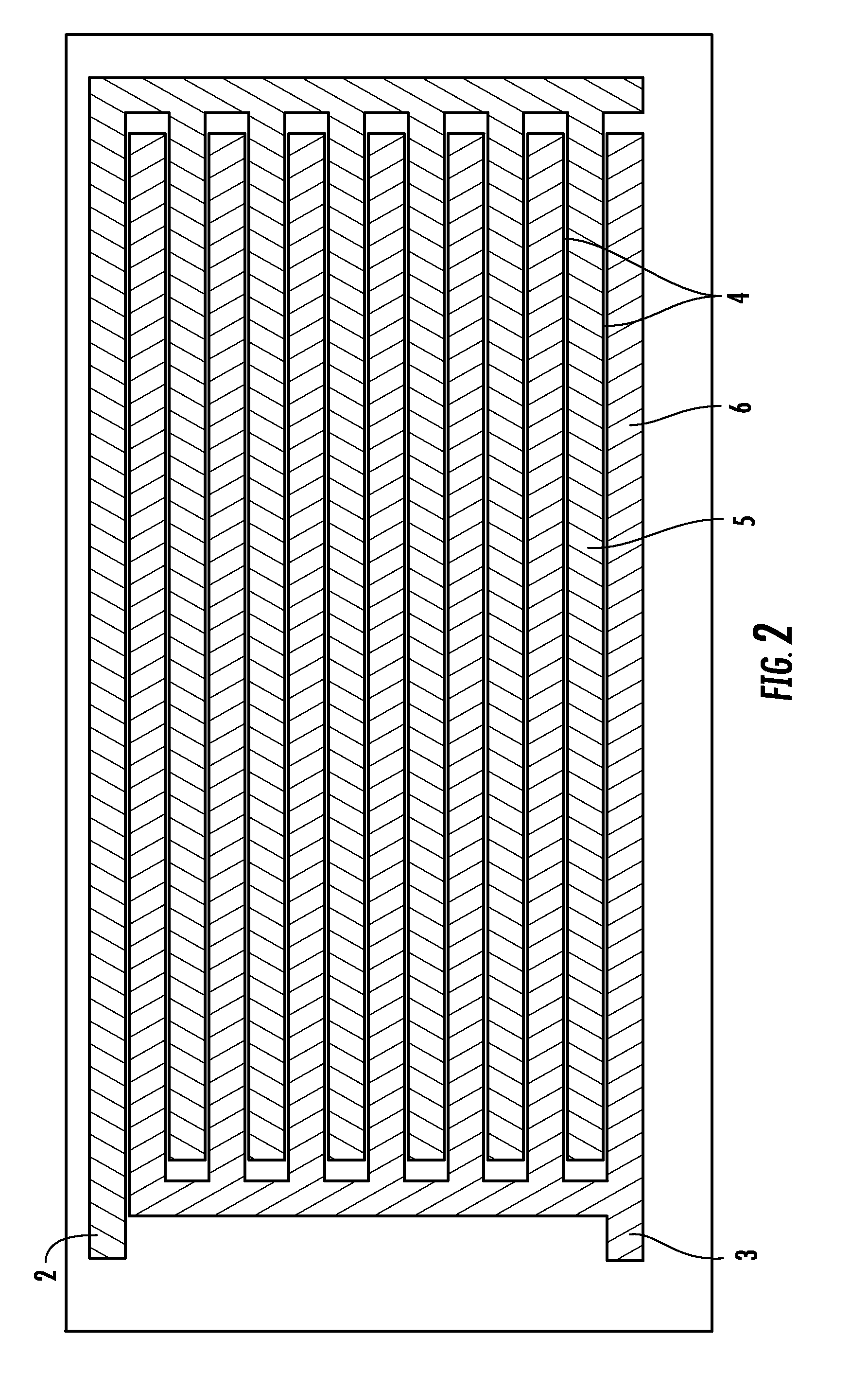

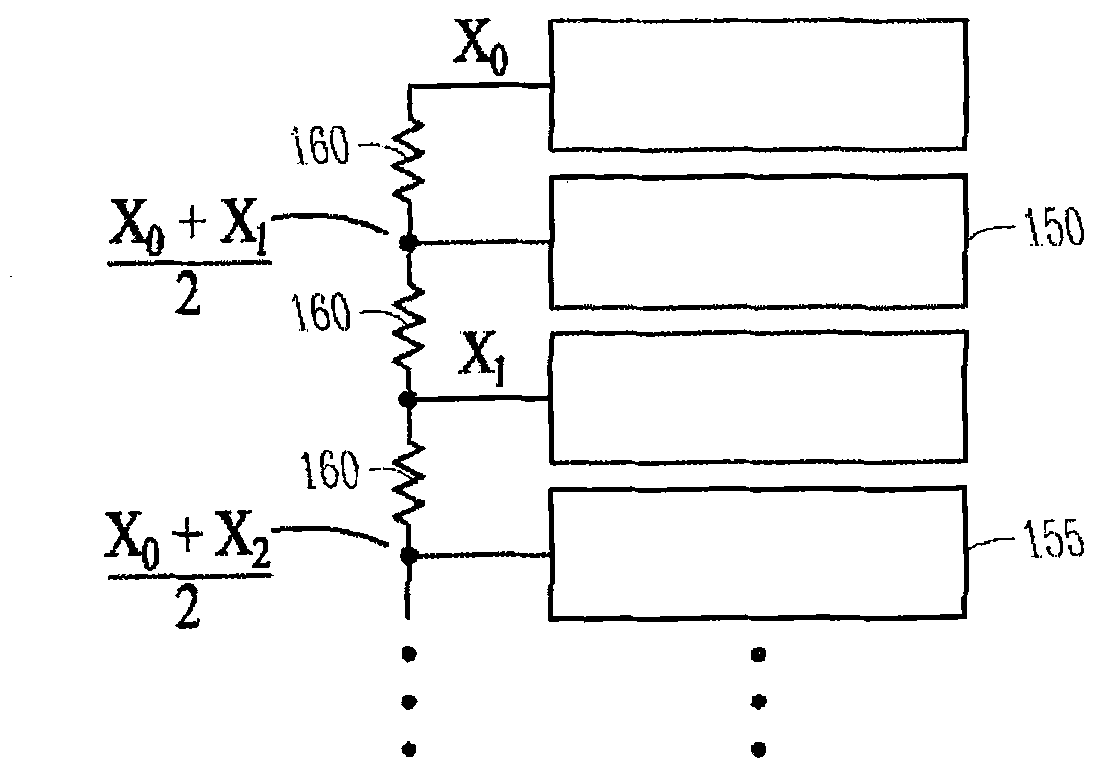

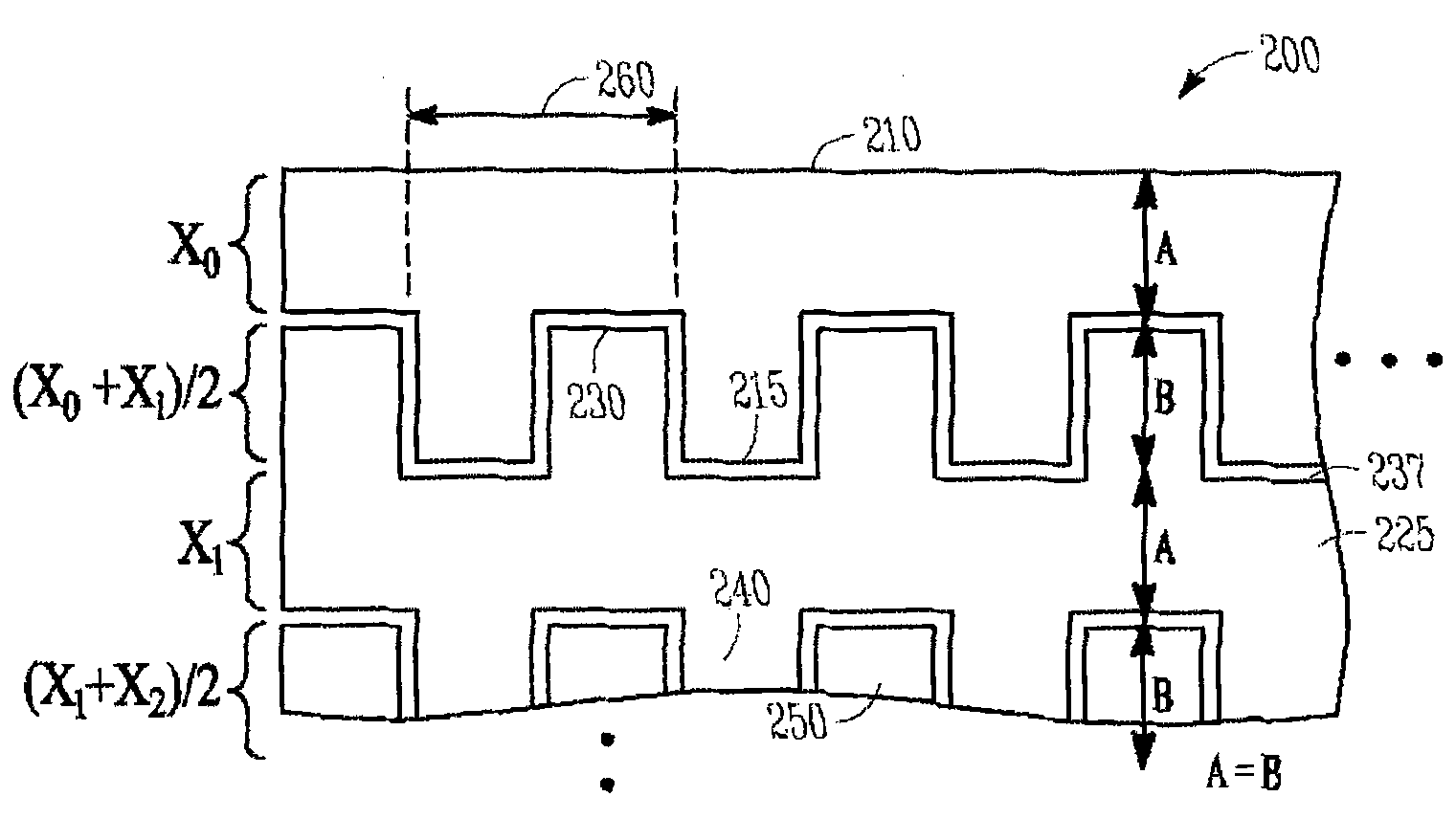

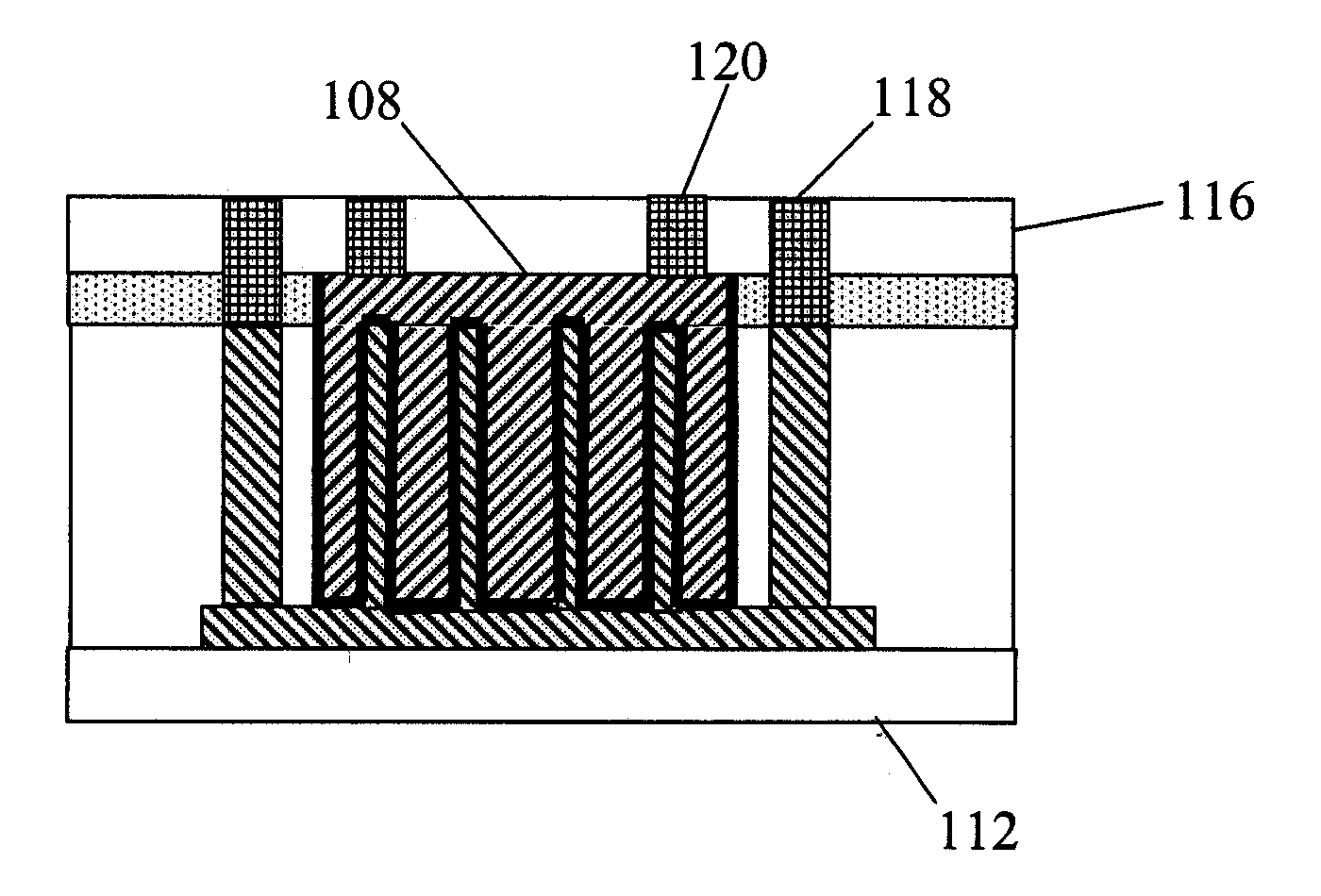

High density mimcap with a unit repeatable structure

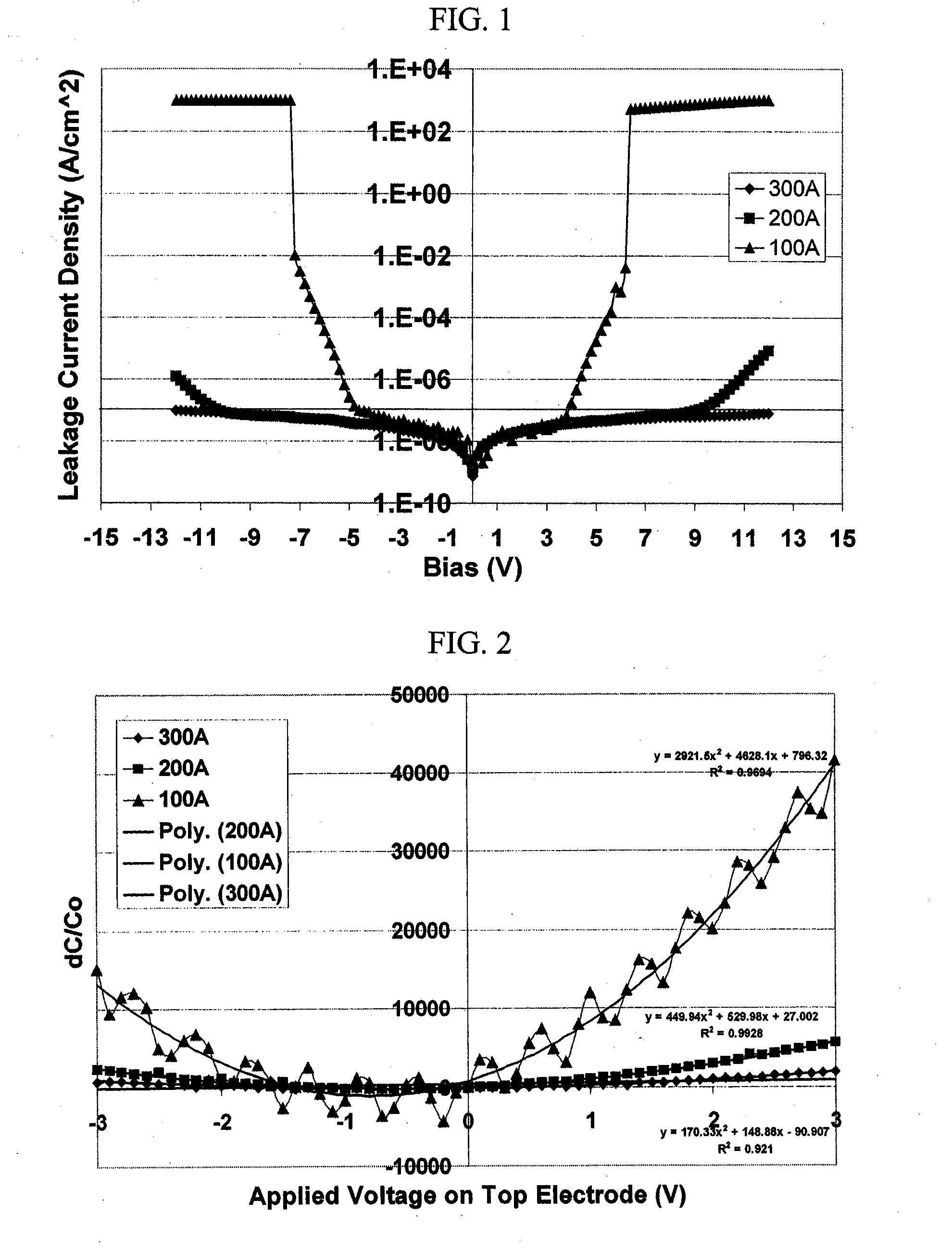

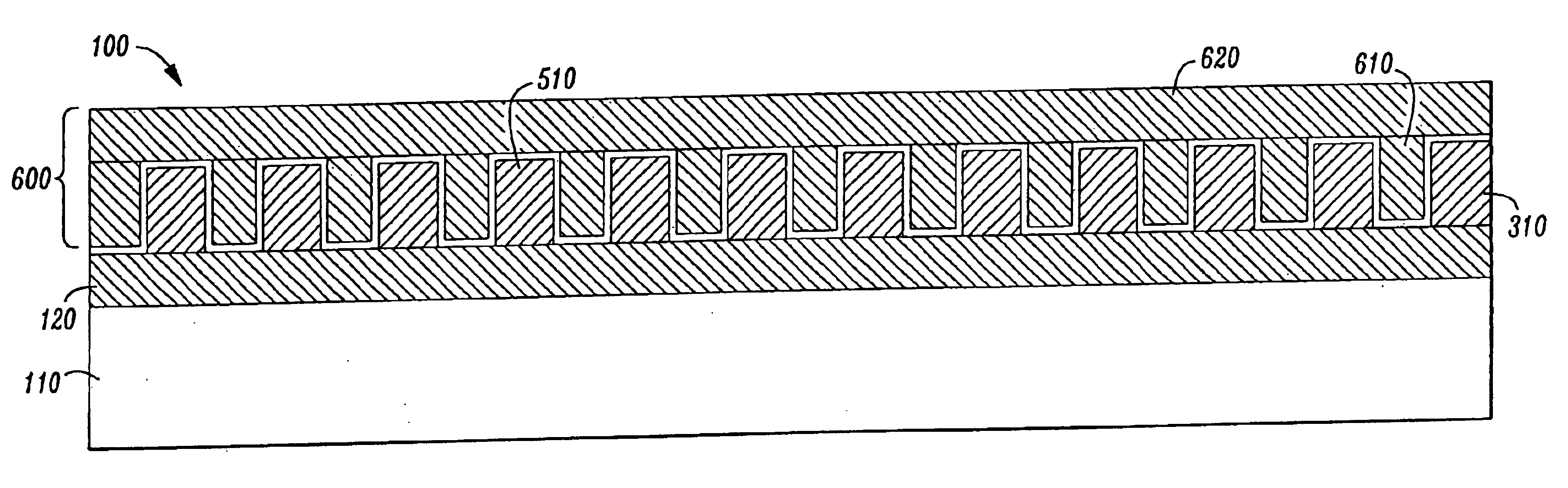

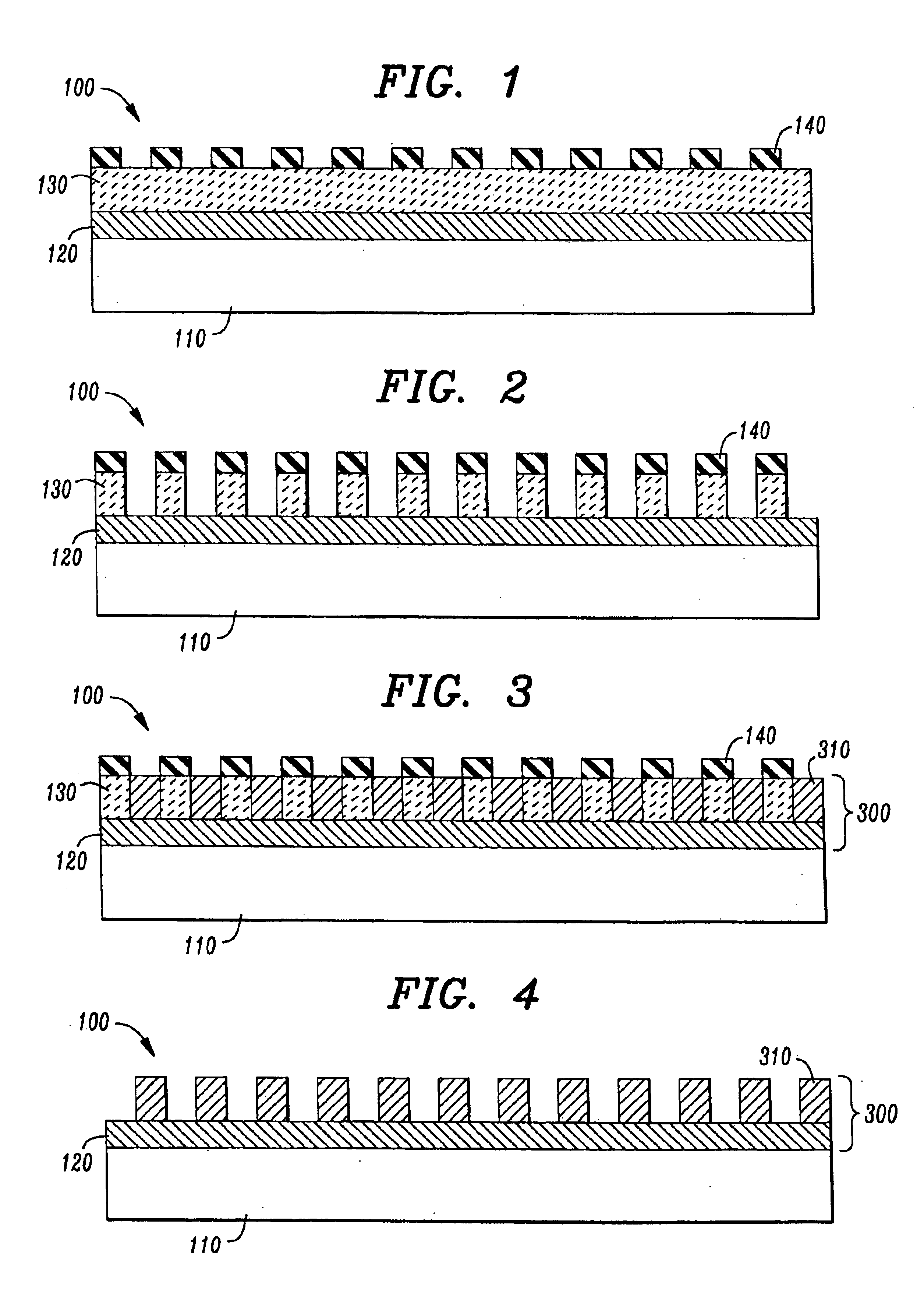

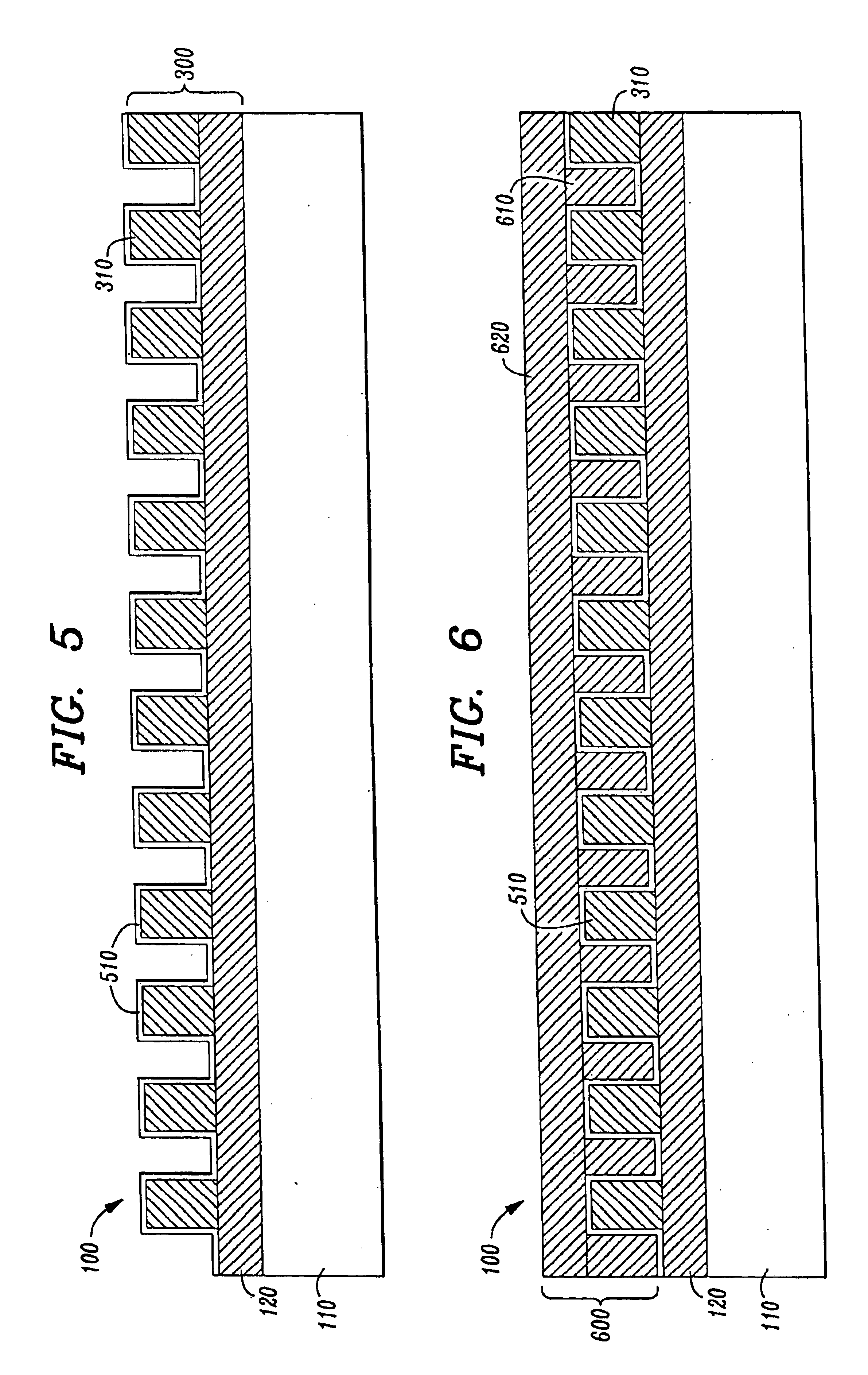

InactiveUS20050266652A1Increase surface areaSemiconductor/solid-state device detailsSolid-state devicesCapacitanceHigh density

A structure, apparatus and method for utilizing vertically interdigitated electrodes serves to increase the capacitor area surface while maintaining a minimal horizontal foot print. Since capacitance is proportional to the surface area the structure enables continual use of current dielectric materials such as Si3N4 at current thicknesses. In a second embodiment of the interdigitated MIMCAP structure the electrodes are formed in a spiral fashion which serves to increase the physical strength of the MIMCAP. Also included is a spiral shaped capacitor electrode which lends itself to modular design by offering a wide range of discrete capacitive values easily specified by the circuit designer.

Owner:IBM CORP

Ferroic transducer

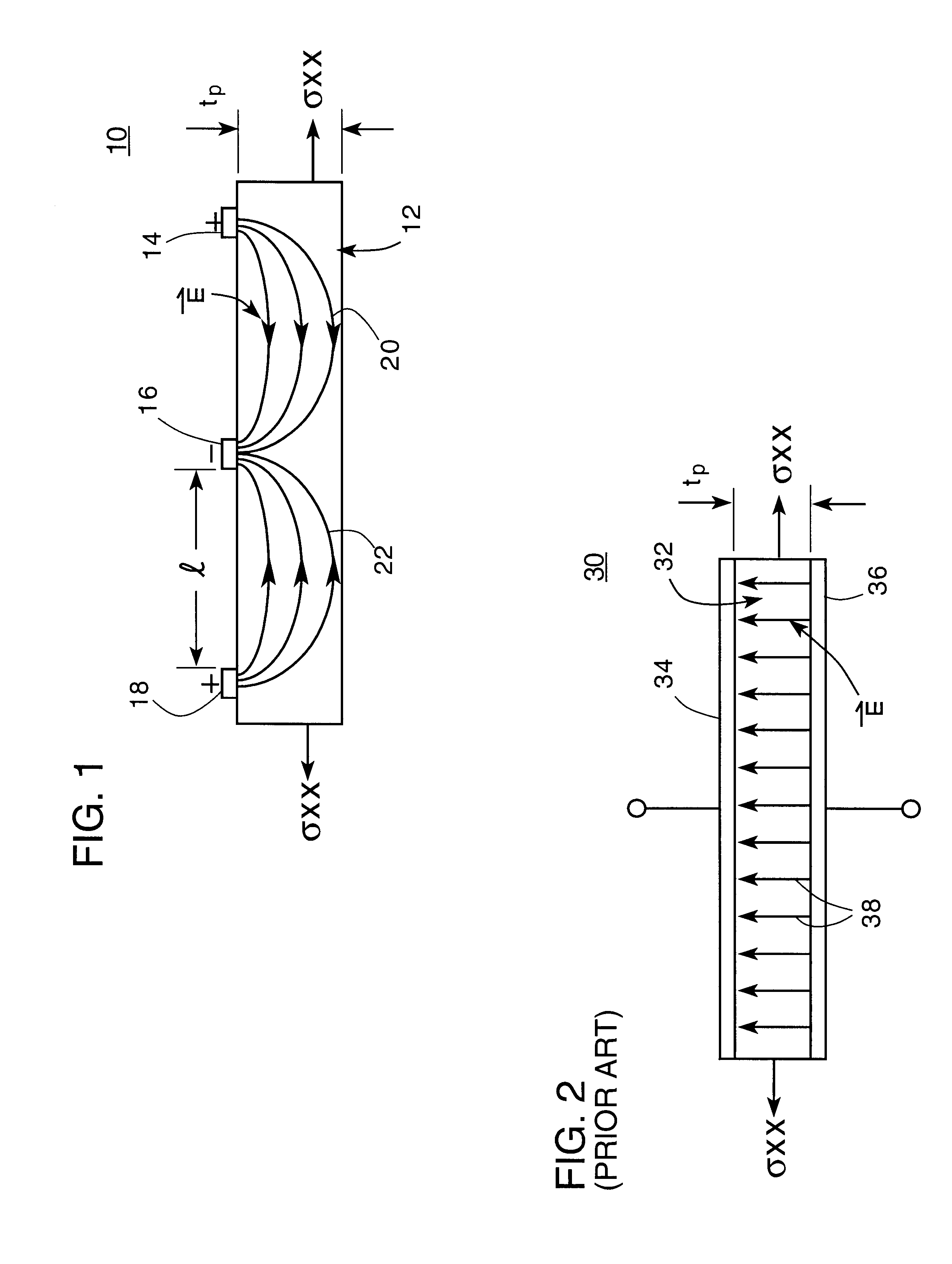

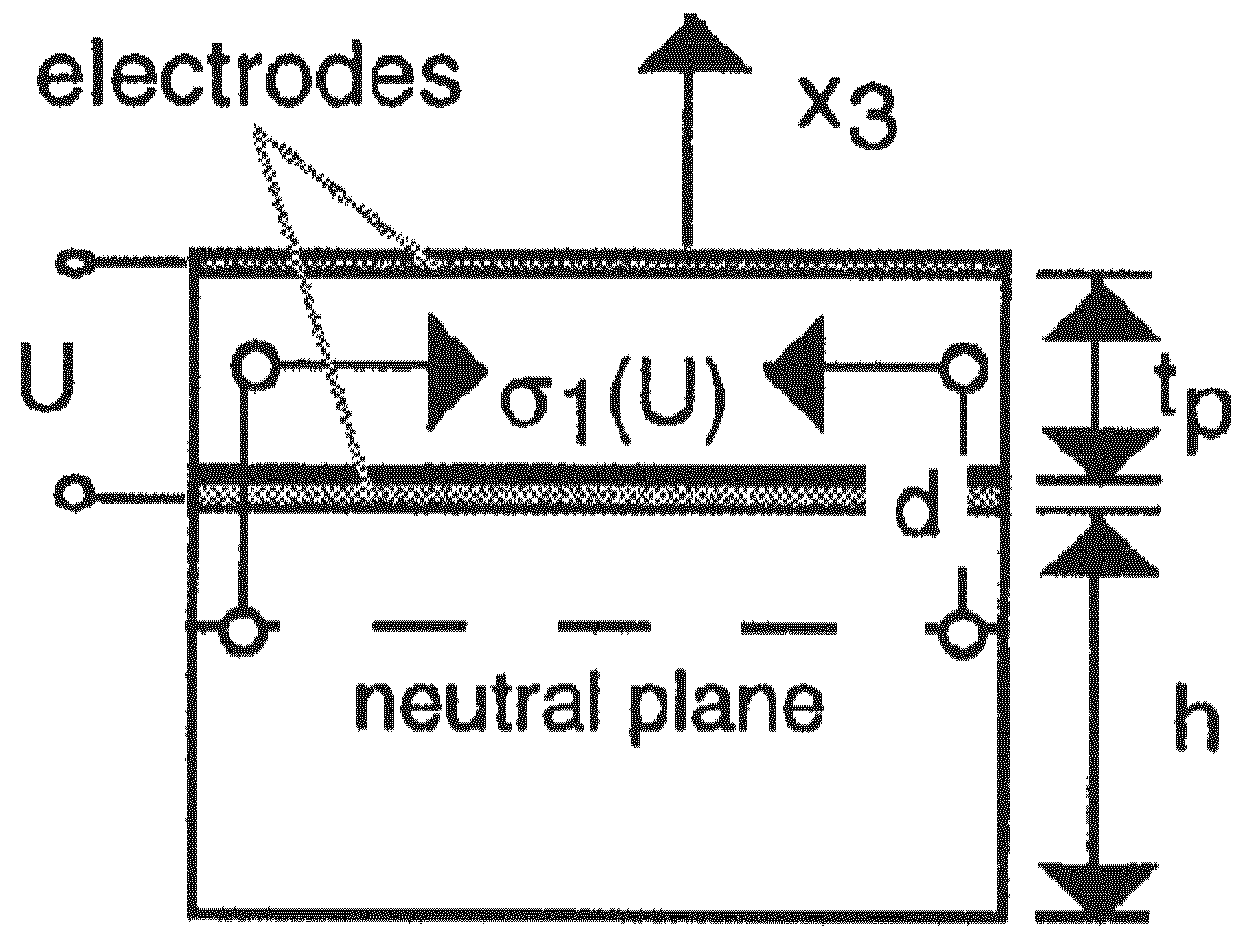

InactiveUS6323580B1High sensitivityIncrease spacingThermoelectric device with dielectric constant thermal changePiezoelectric/electrostriction/magnetostriction machinesTransducerInterdigitated electrode

An interdigitated electrode ferroic transducer includes a film of ferroic material electrically polarized substantially in the plane of the film; and a set of interdigitated electrodes including at least two electrodes spaced from one another on the same side of the film and disposed at the termini of the polarization field.

Owner:CHARLES TARK DRAPER LAB INC THE

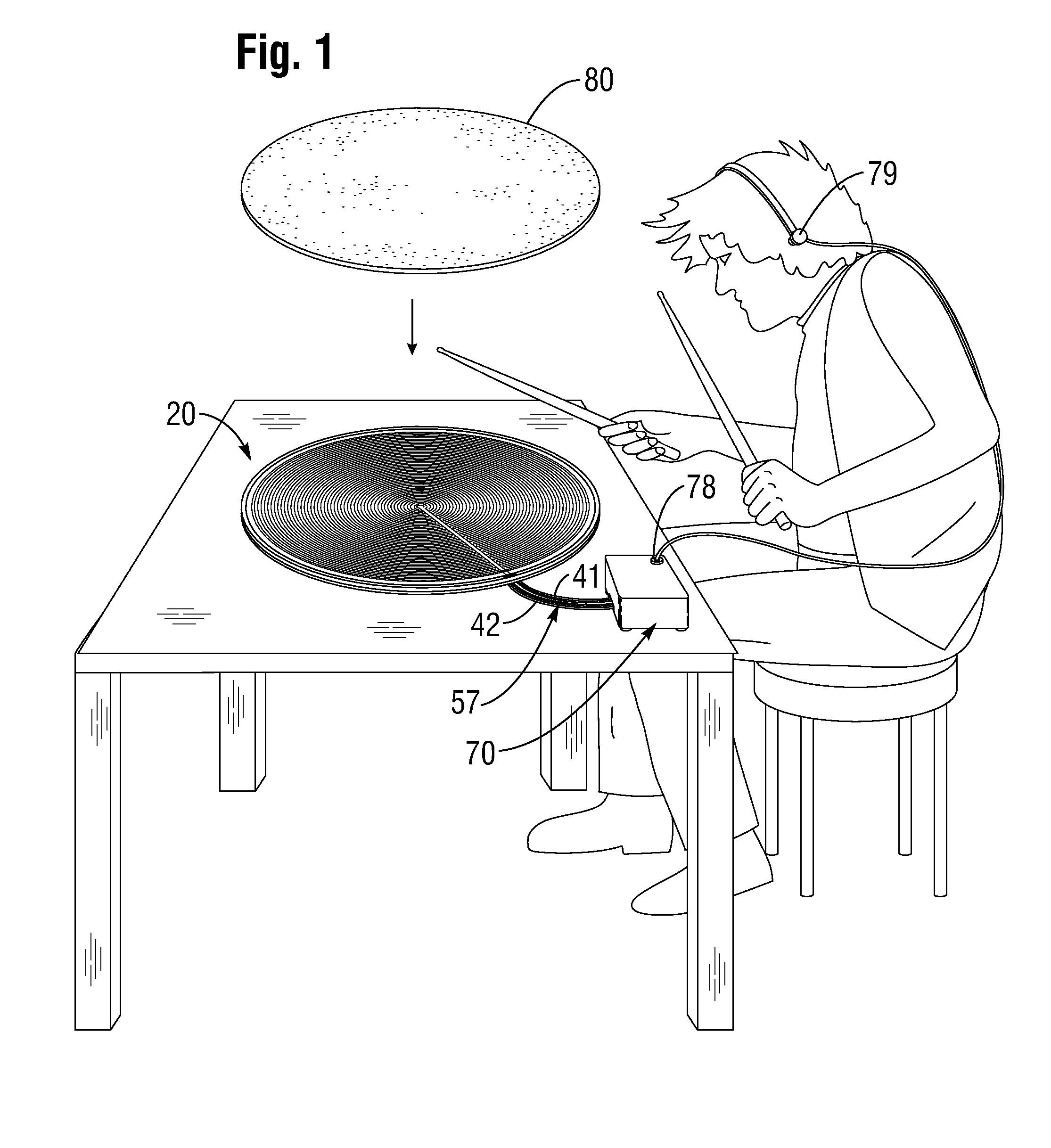

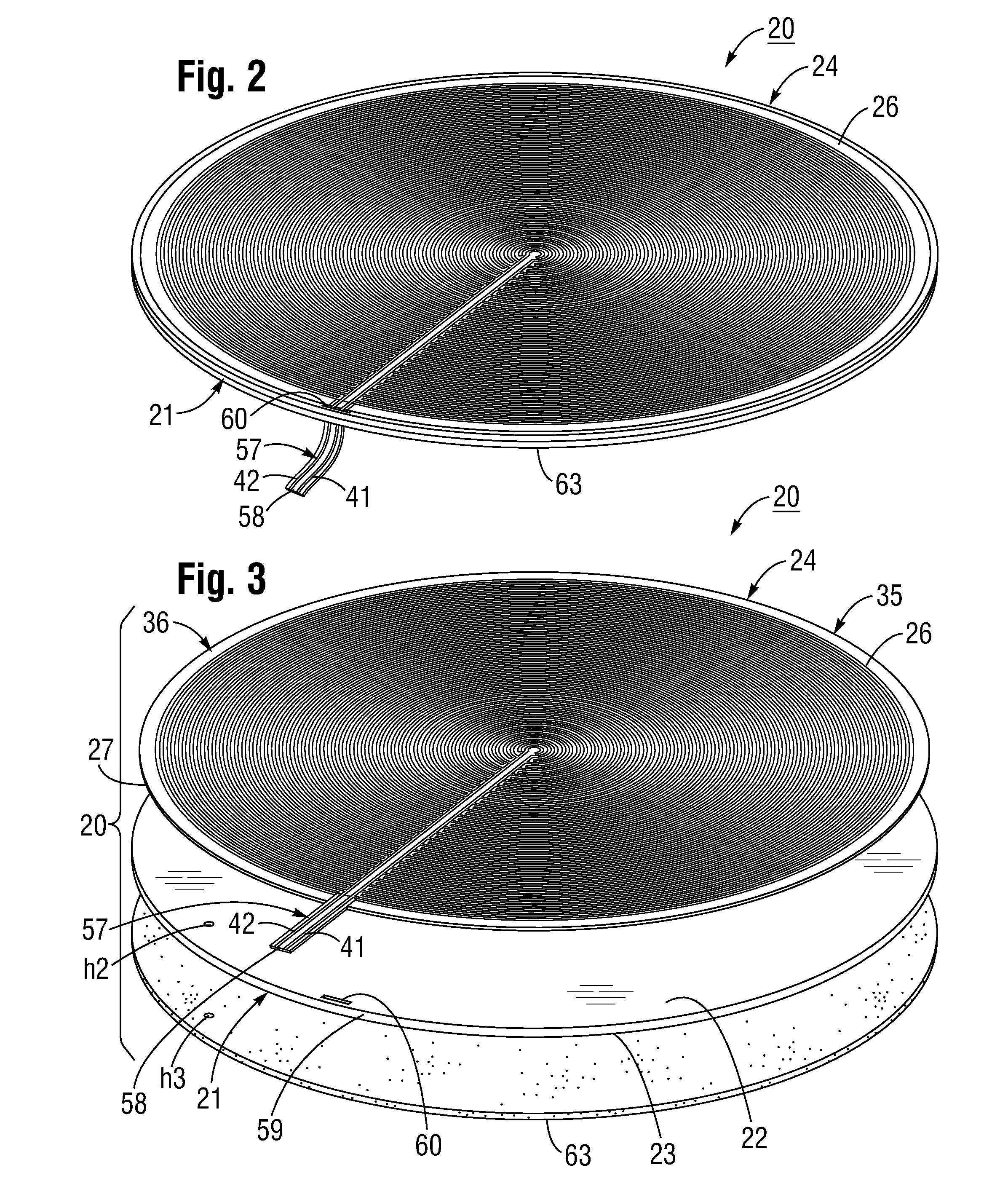

Impact Responsive Portable Electronic Drumhead

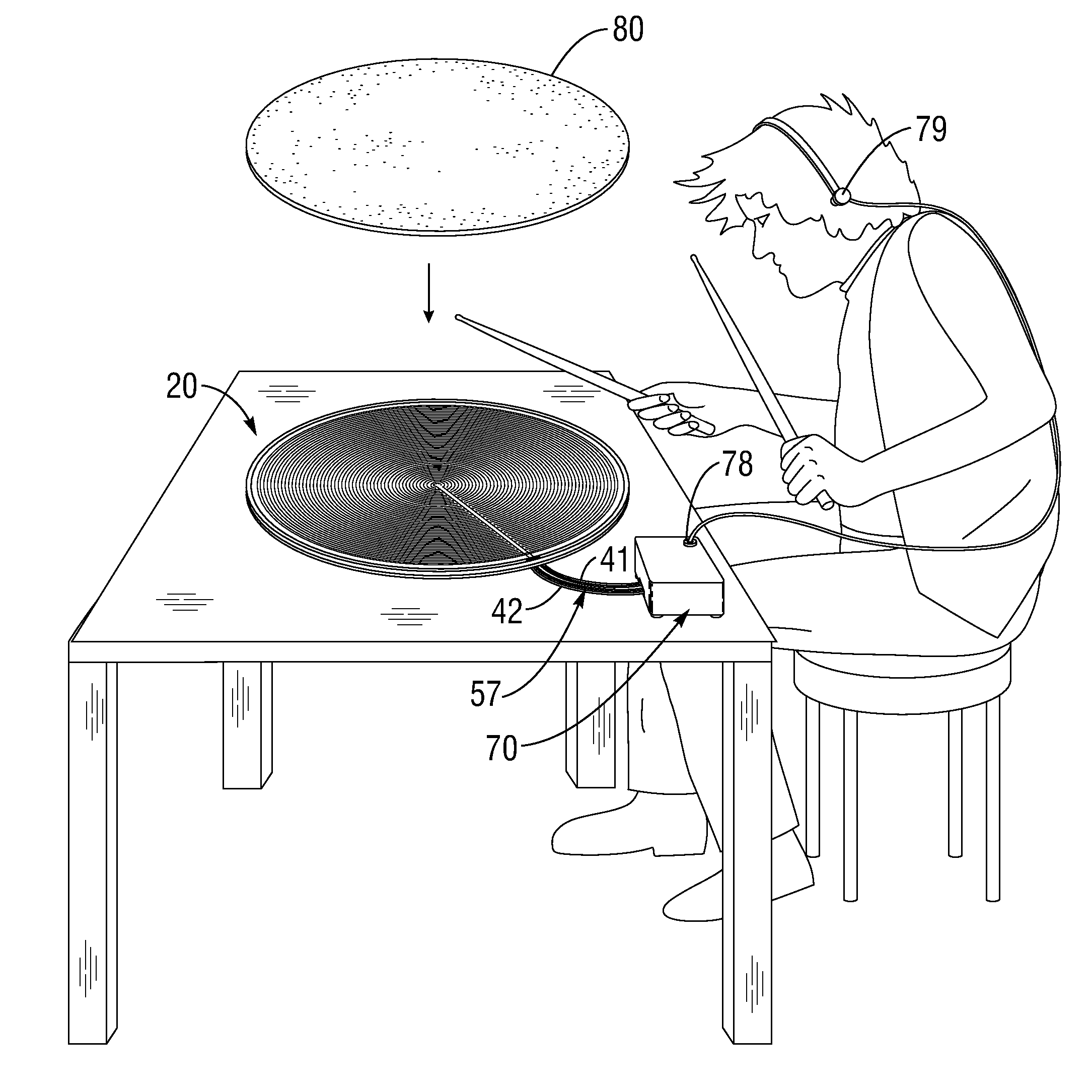

InactiveUS20130340598A1Lower resistanceElectrophonic musical instrumentsPercussion musical instrumentsElectrical resistance and conductanceForce-sensing resistor

A portable electronic drumhead includes a sensor responsive to drumstick impacts in producing electrical signal pulses input to headphones to thereby simulate sounds of an acoustic drumhead. The sensor includes a Force Sensing Resistor (FSR) lamination coated with an electrically conductive polymer ink, a spacer lamination, and a flexible electrode lamination having on an inner surface thereof a pair of interdigitated electrodes, the electrode lamination elastically contacting the FSR lamination in response to drumstick impacts on the outer surface of the electrode lamination or FSR lamination to thus momentarily reduce electrical resistance between the electrodes. Resilient batter pads overlying the laminations muffle sounds produced by drumstick impacts. Optionally, the sensor may have an annular ring shape which may be placed concentrically on the head of an acoustic drum, the sensor having an upwardly protruding resilient bumper strikable to produce electronically synthesized rim shot sounds.

Owner:AQUARIAN COATINGS CORP A CORP OF CA +1

Micro electro-mechanical variable capacitor

InactiveUS6906905B1Increase capacitanceHigh quality factorMechanically variable capacitor detailsCapacitor with electrode area variationDielectricCapacitance

A three-dimensional micro electro-mechanical (MEMS) variable capacitor is described wherein movable comb electrodes of opposing polarity are fabricated simultaneously on the same substrate are independently actuated. These electrodes are formed in an interdigitated fashion to maximize the capacitance of the device. The electrodes are jointly or individually actuated. A separate actuation electrode and a ground plane electrode actuate the movable electrodes. The voltage potential between the two electrodes provides a primary mode of operation of the device. The variation of the sidewall overlap area between the interdigitated fingers provides the expected capacitance tuning of the device. The interdigitated electrodes can also be attached on both ends to form fixed-fixed beams. The stiffness of the electrodes is reduced by utilizing thin support structures at the ends of the electrodes. The three dimensional aspect of the device avails large surface area. Large capacitance variation and tuning ranges are obtained by independent actuation of the electrode fingers. A plurality of modes of operation of the device provides wide flexibility and greater performance advantage for the device. Upon fabrication of the device, a separate substrate with etched dielectric is used to encapsulated the device. The MEMS device is then completely encapsulated, requiring no additional packaging of the device. Further, since alignment and bonding can be done on a wafer scale, an improved device yield is obtained at a lower cost.

Owner:GLOBALFOUNDRIES INC

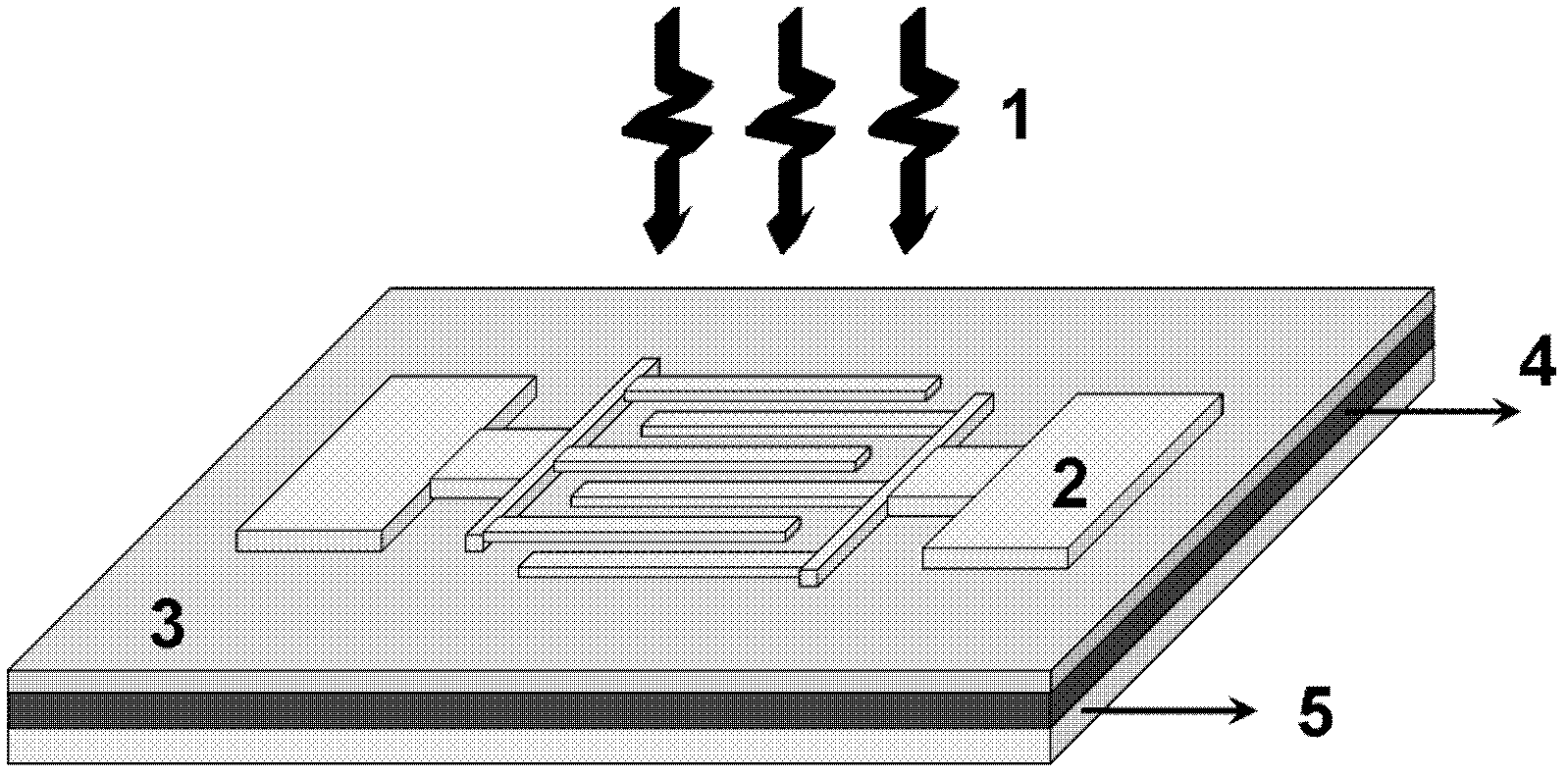

Modular interdigitated back contact photovoltaic cell structure on opaque substrate and fabrication process

InactiveUS20100154876A1Low costHigh efficiency and low costFinal product manufactureSemiconductor/solid-state device manufacturingDielectric surfaceInterdigitated electrode

A back contact integrated photovoltaic cell includes a substrate having a dielectric surface and a patterned metal layer with parallel spaced alternately positive and negative electrode fingers forming an interdigitated two-terminal structure over the dielectric surface of the substrate. A dielectric filler may be in the interstices of separation between adjacent spaced parts of the patterned metal layer. Parallel spaced strips, alternately of p+ doped polysilicon and of n+ doped polysilicon, may top the positive and negative interdigitated electrode fingers, respectively, and form doped p-type active regions and n-type active regions of the integrated photovoltaic cell, spaced and isolated by a strip of undoped or negligibly doped polysilicon. An n− or p− doped or intrinsic semiconducting layer of at least partly crystallized silicon, forming a semiconductor region of thickness adapted to maximize absorption of photonic energy when illuminated by sunlight, may cover the interdigitated active doped regions.

Owner:STMICROELECTRONICS SRL

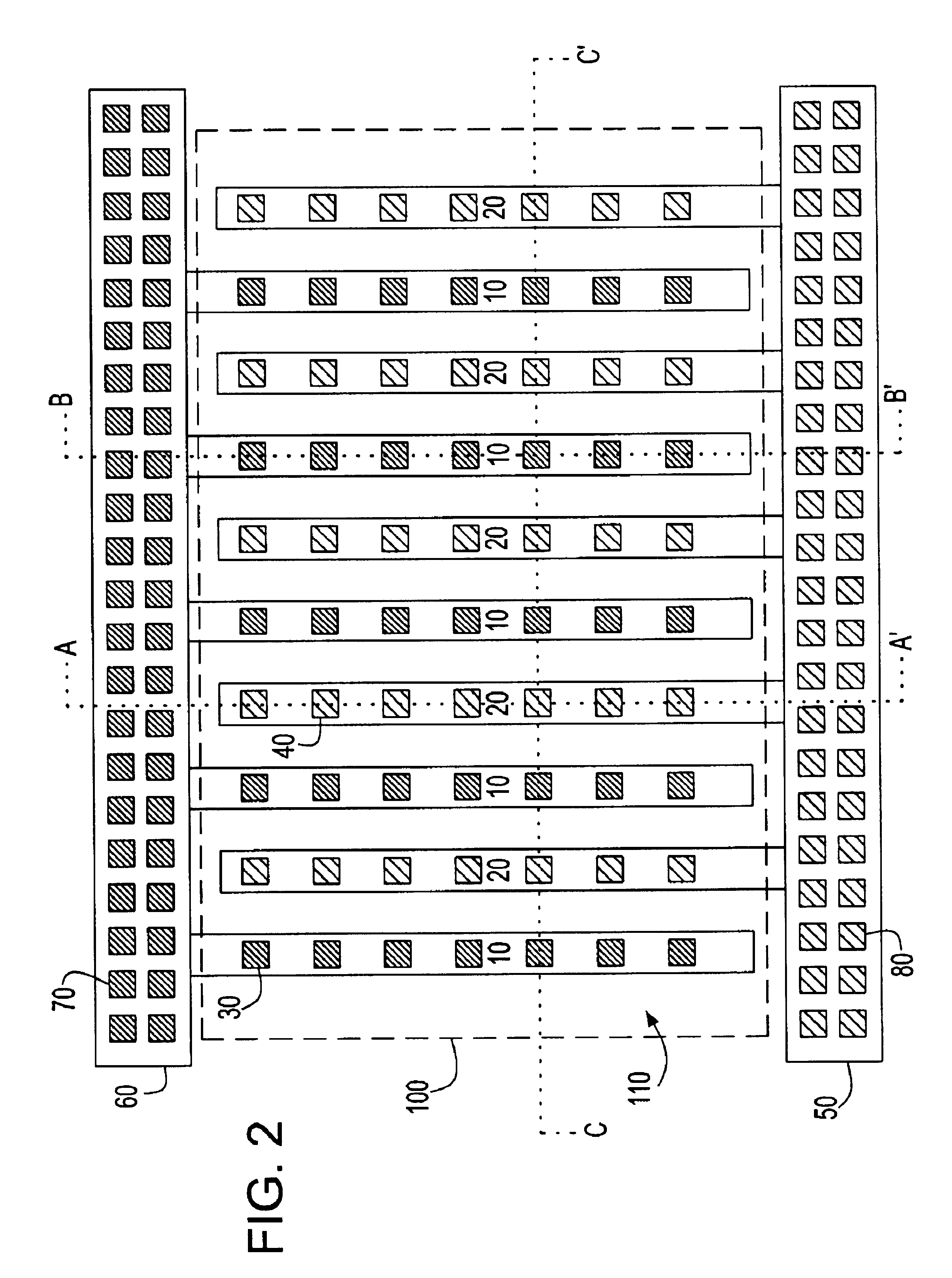

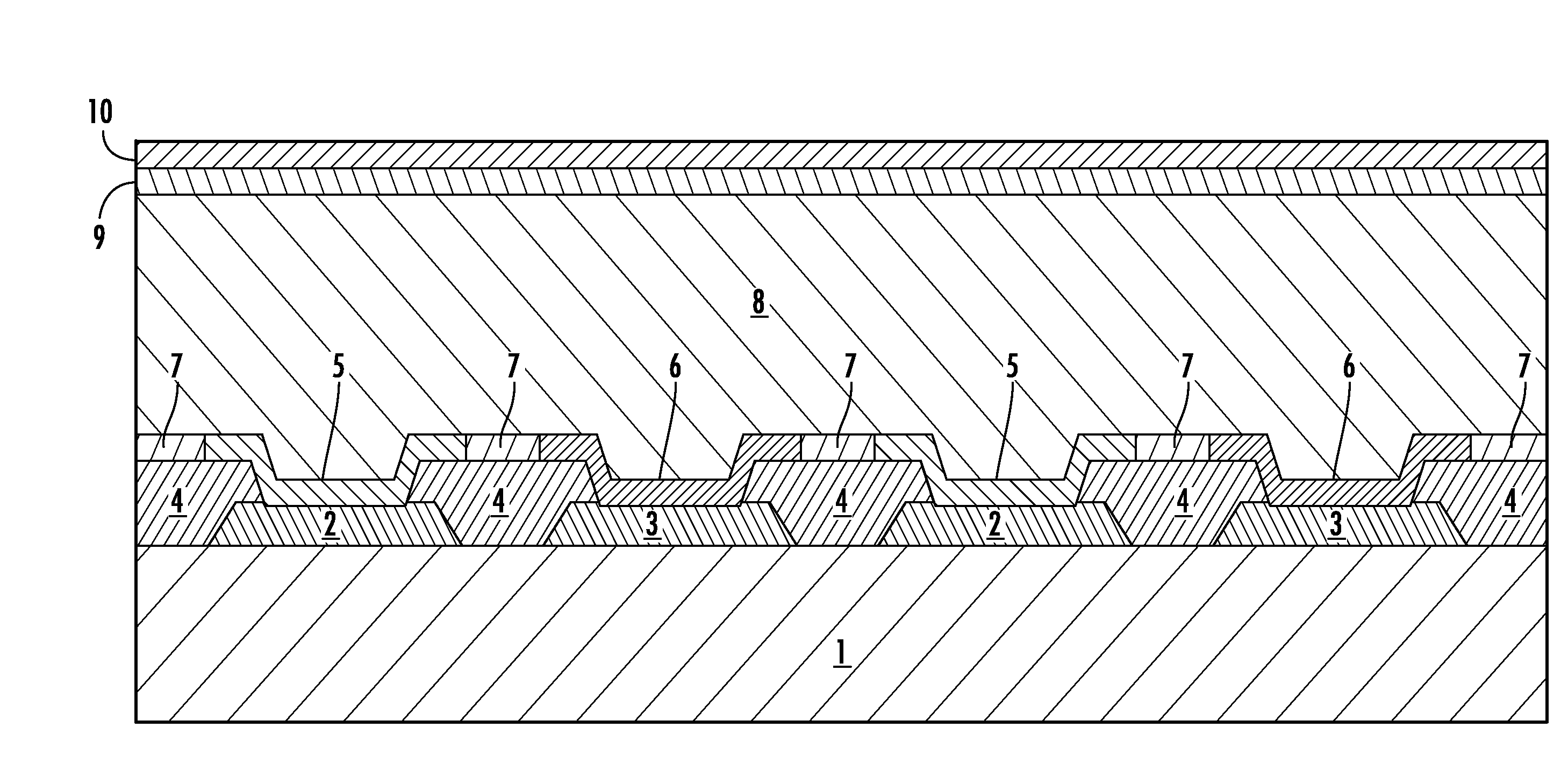

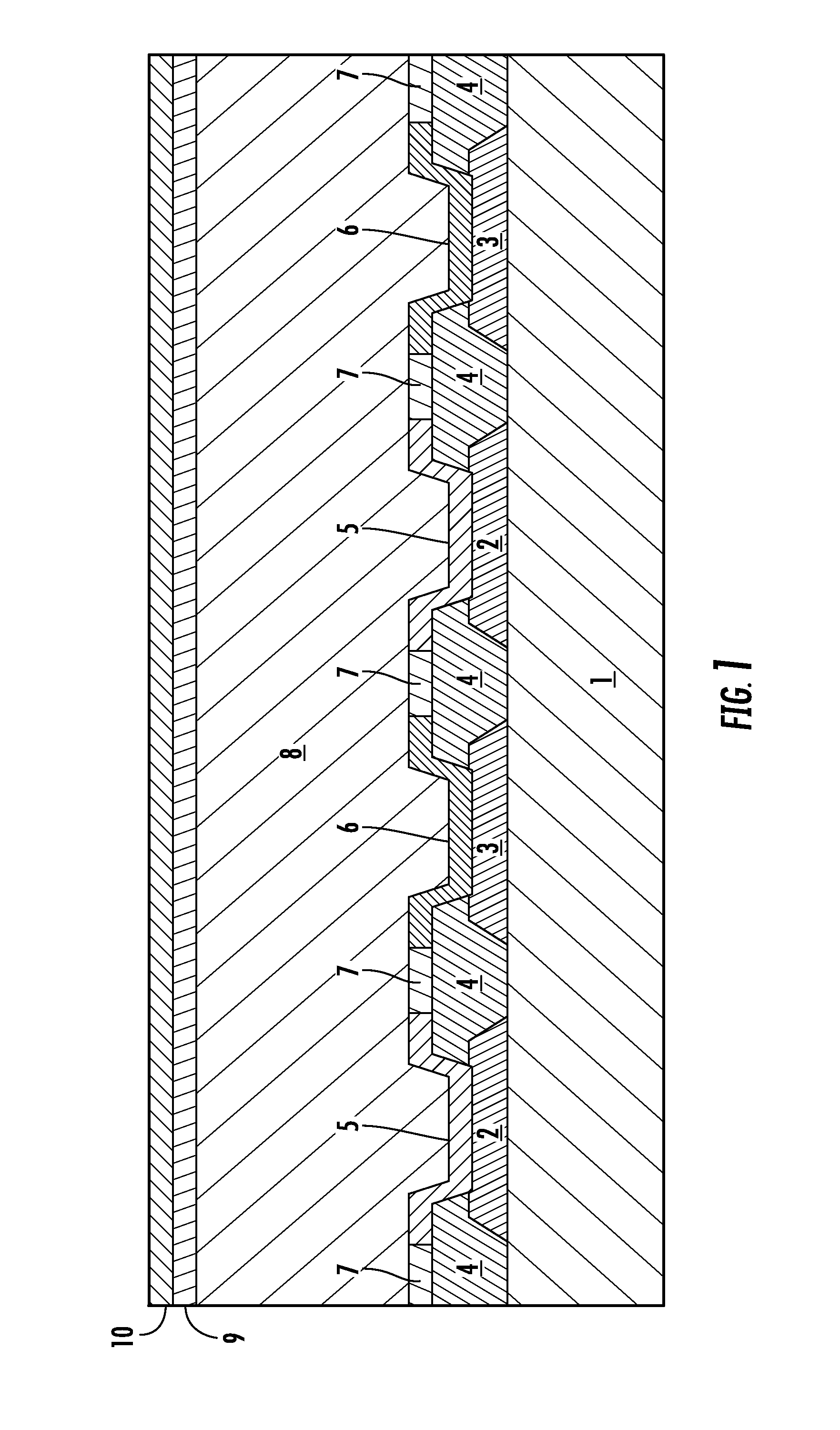

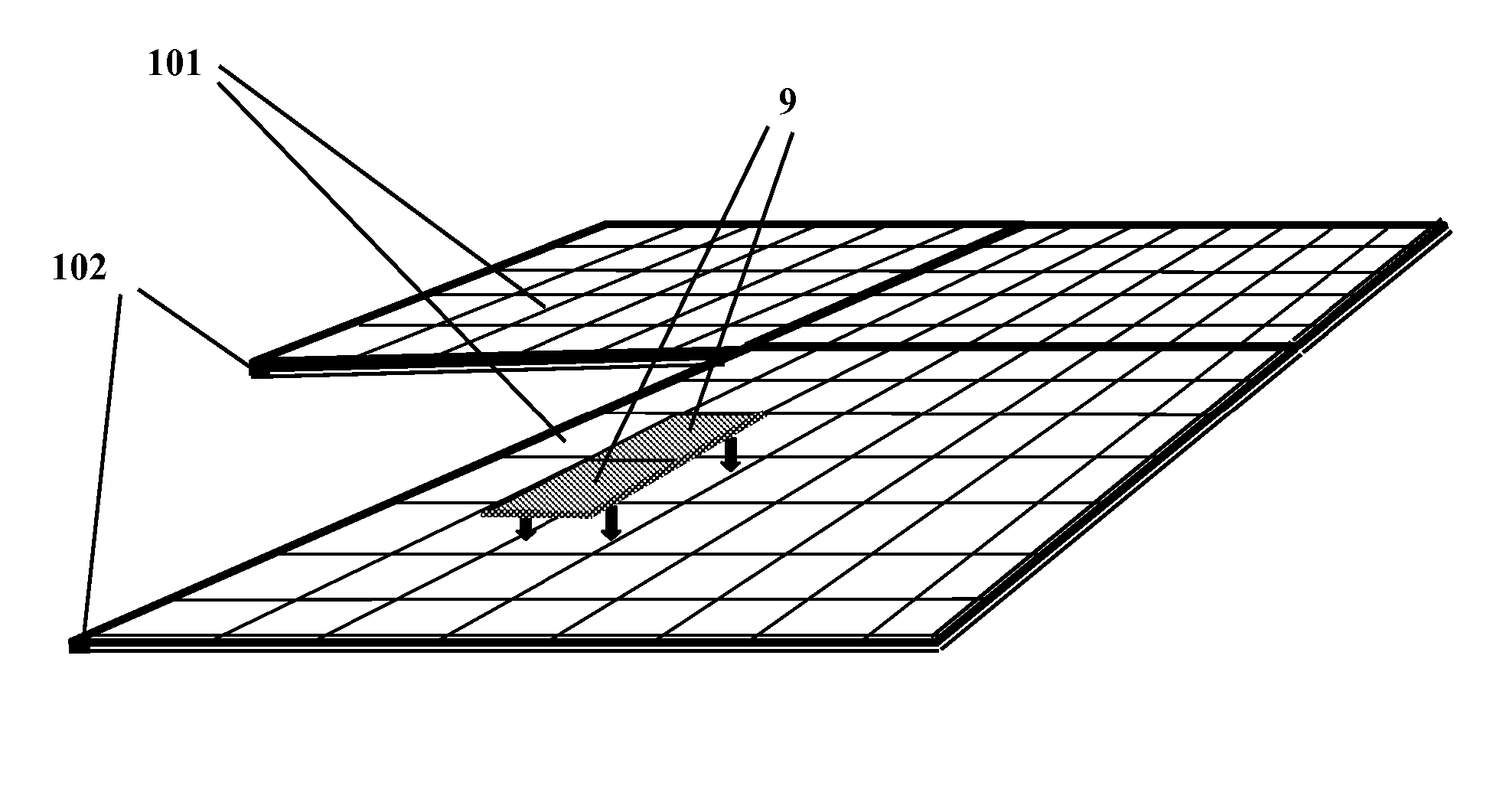

Digital flooring detection system

InactiveUS20070171058A1Reducing sensor resolutionLess finite resolution of location detectionBurglar alarm by pressureElectricityInterdigitated electrode

A flooring system comprising a plurality of electrode pairs in contact with a metaplastic composite material. The metaplastic material is such that it locally conducts electrical current in an area where any load is applied to the metaplastic. An electric potential is applied to one or more interdigitated electrodes located at a face of the metaplastic material in line with applied loads. Larger area coverage can be obtained either by pre-installing a subsurface layer comprising of an array of interdigitated electrodes and their trace line outputs and then covering this layer with a tiling of metaplastic material sheets that is in direct contact with the array of interdigitated electrodes, or, by directly attaching one or more interdigitated electrodes and their output trace lines to an individual sections of metaplastic material and electrically interconnecting their outputs. By applying a sufficient number of interdigitated electrodes and sheets of the metaplastic material and monitoring the electrical current flowing in each interdigitated electrode so placed, it can be determined whether and where loads are being applied to the PCC flooring material and the approximate size and shape of the load.

Owner:LATITUDE BROADBAND

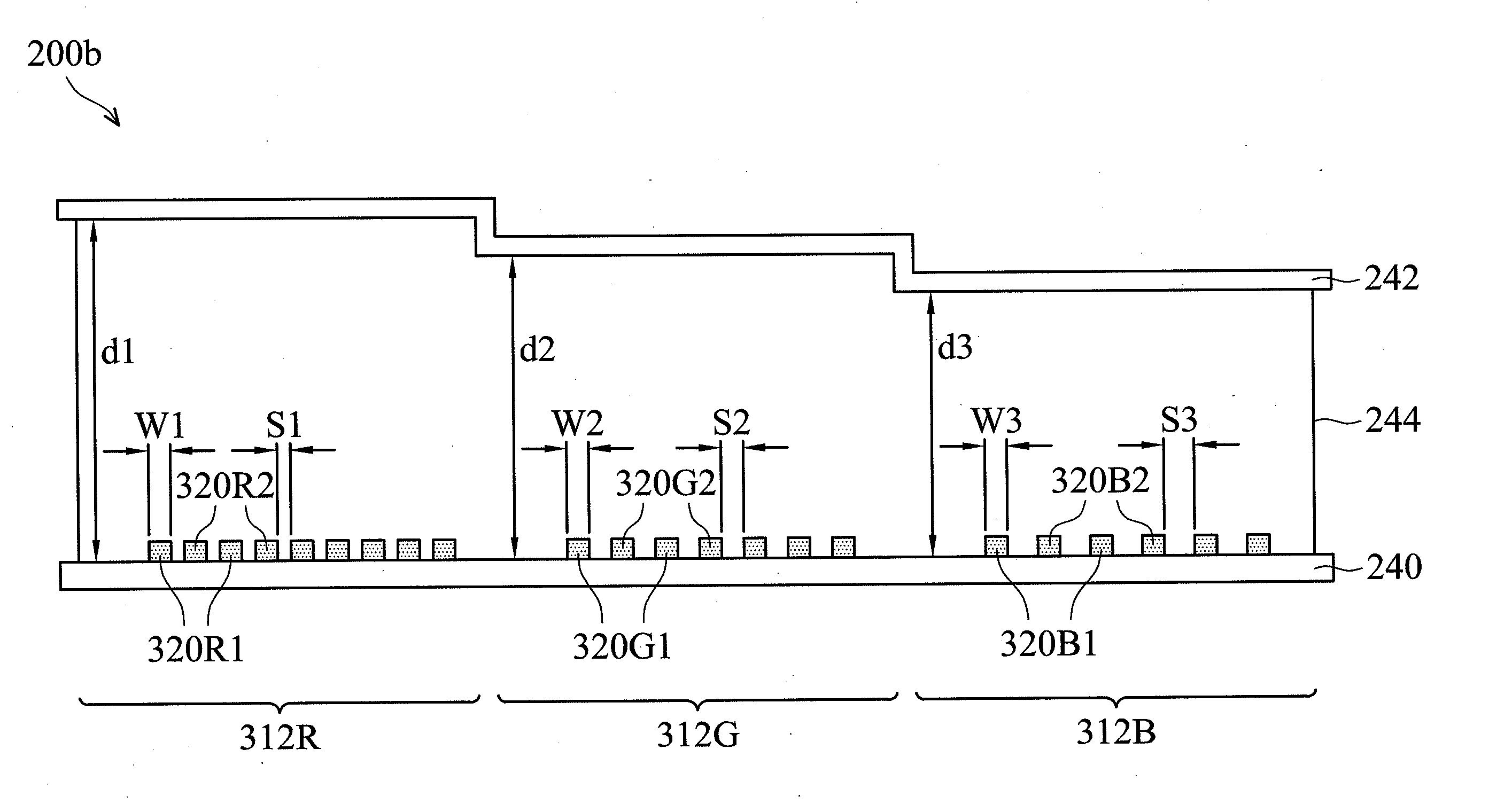

Display device and electronic device

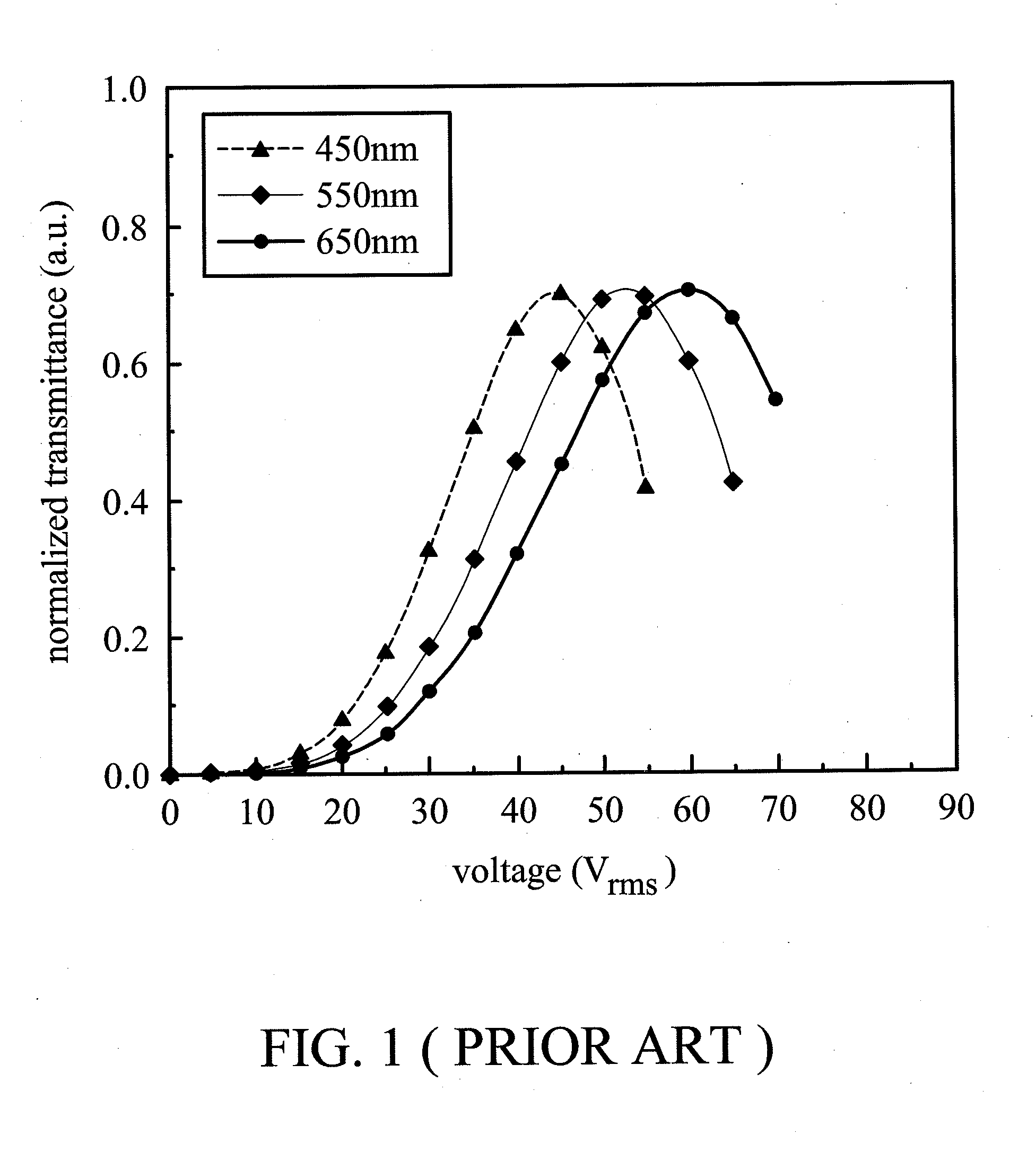

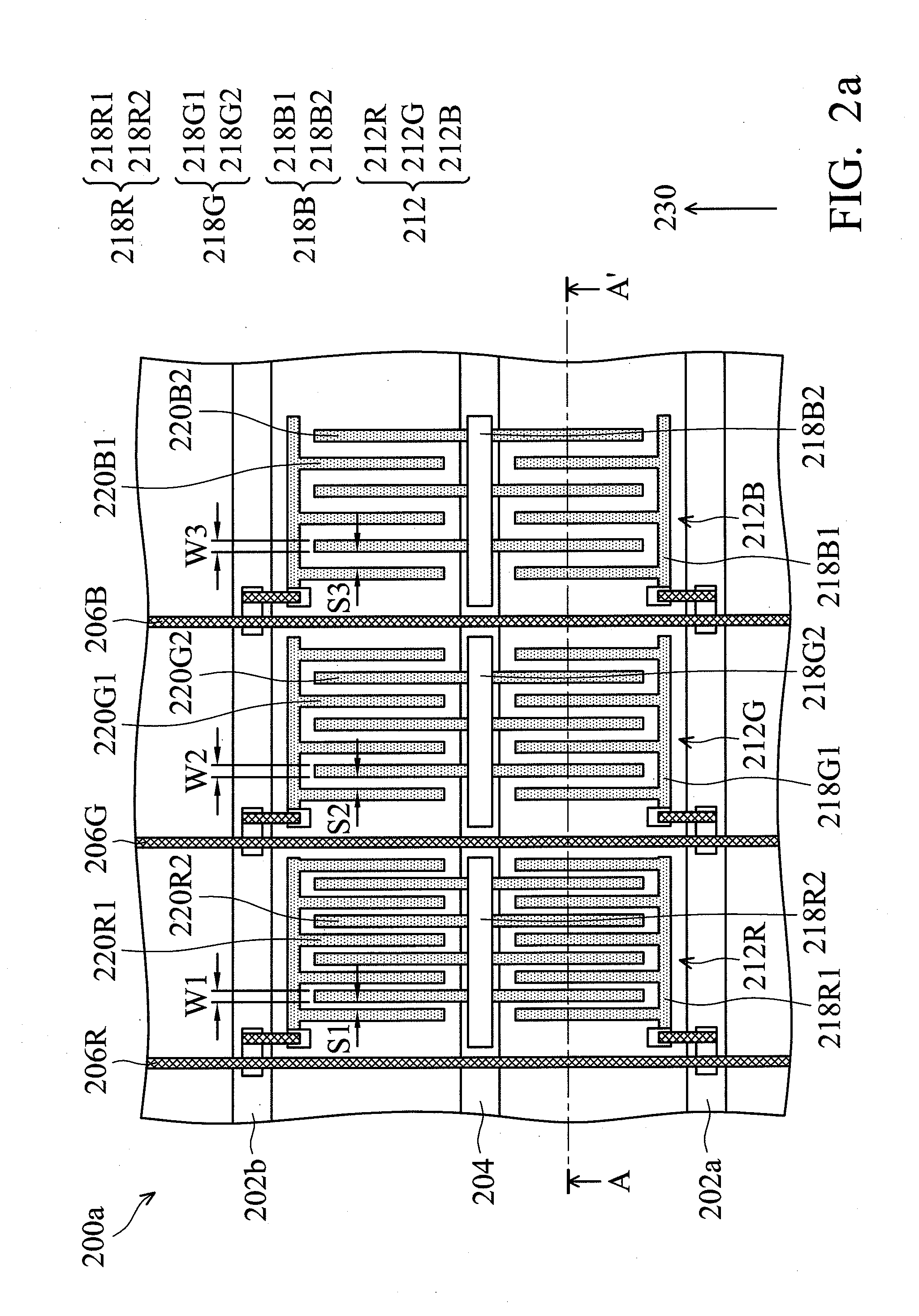

A display device includes a first, second and third sub-pixel areas allowing light of a first, second and third main wavelengths transmitting therethrough, respectively. The first, second and third sub-pixel areas have first, second and third ratios of first, second and third electrode widths to first, second and third electrode slits of first, second and third interdigitated electrodes, respectively. When the first main wavelength is larger than the second main wavelength and the second main wavelength is larger than the third main wavelength, a difference between any two of the first, second and third ratios is less than 0.2. A first electrode slit of the first interdigitated electrode is smaller than the second electrode slit of the second interdigitated electrode, and the second electrode slit of the second interdigitated electrode is smaller than the third electrode slit of the third interdigitated electrode.

Owner:INNOCOM TECH SHENZHEN +1

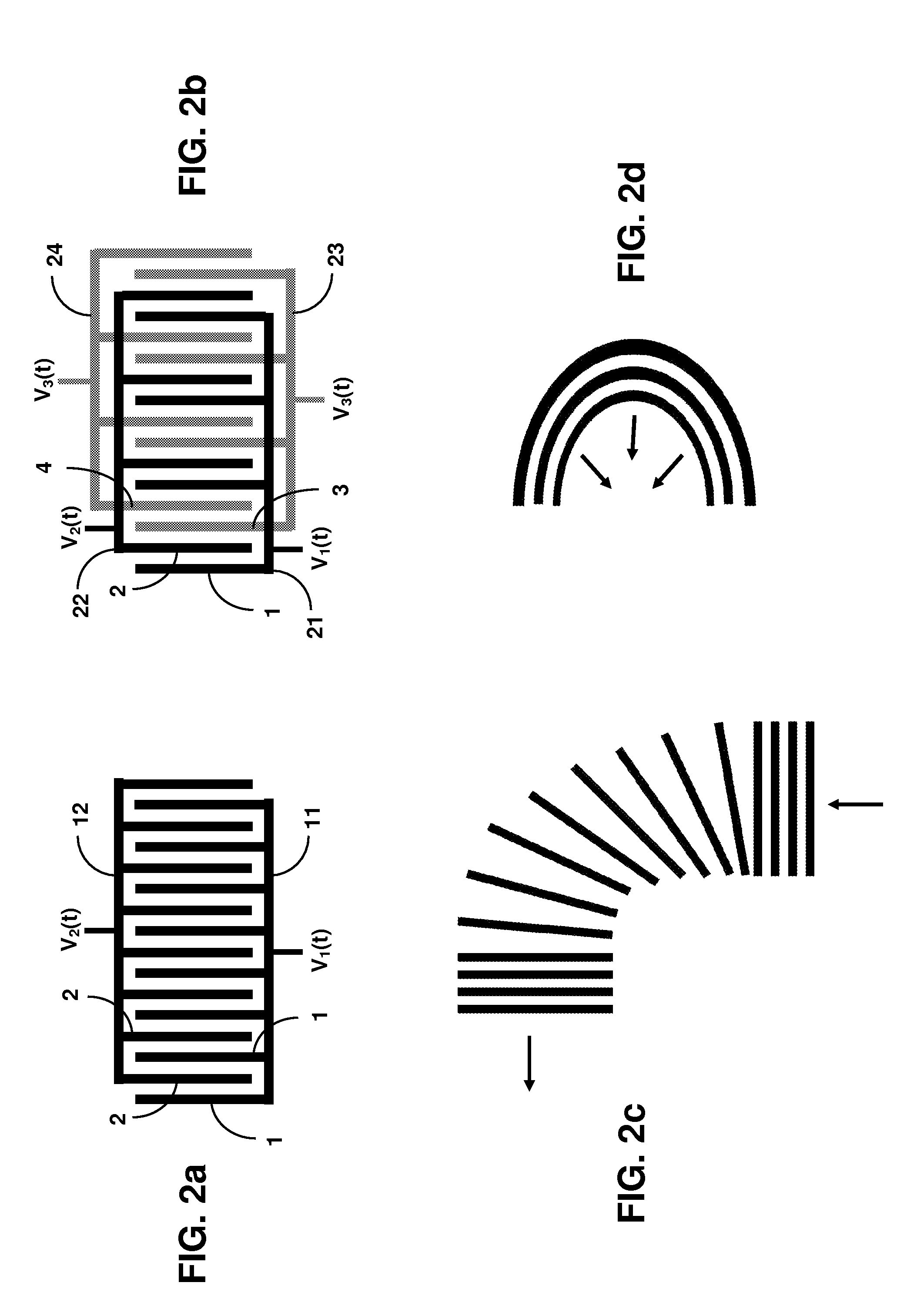

Method for optimizing a piezoelectric actuator structure for a deformable lens

ActiveUS9964672B2Projector focusing arrangementCamera focusing arrangementOptical propertyPiezoelectric actuators

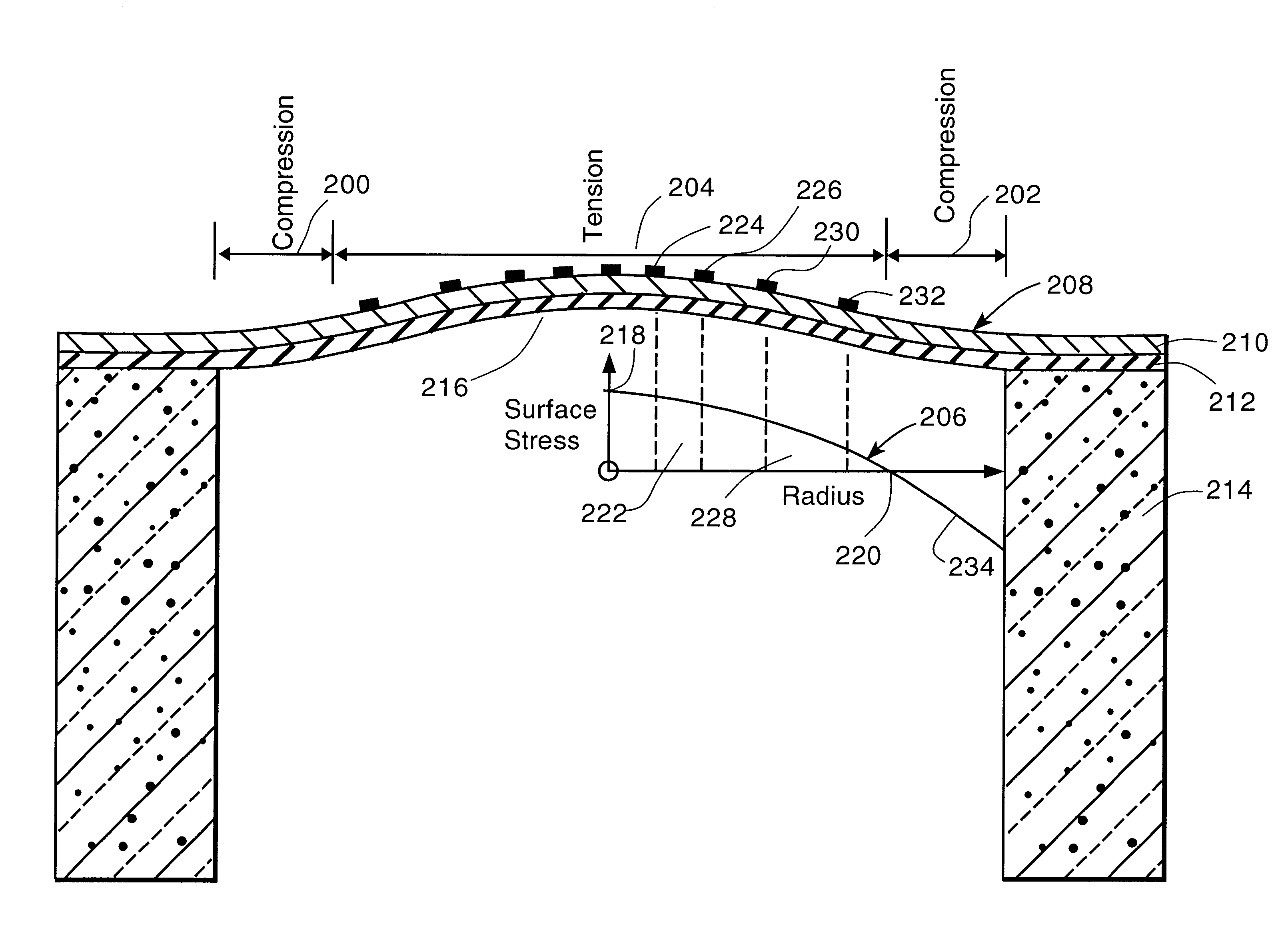

The present invention comprises a system and a method thereof for identifying a specific Interdigitated Electrode pattern arrangement for piezoelectric actuators located around an aperture of a flexible lens body, wherein the Interdigitated Electrode configuration is configurable, when activated, to provide a specific definable bending force distribution, thereby providing a specific definable shaping of the flexible lens body, thereby providing specific definable optical characteristics of the flexible lens body.

Owner:POLIGHT

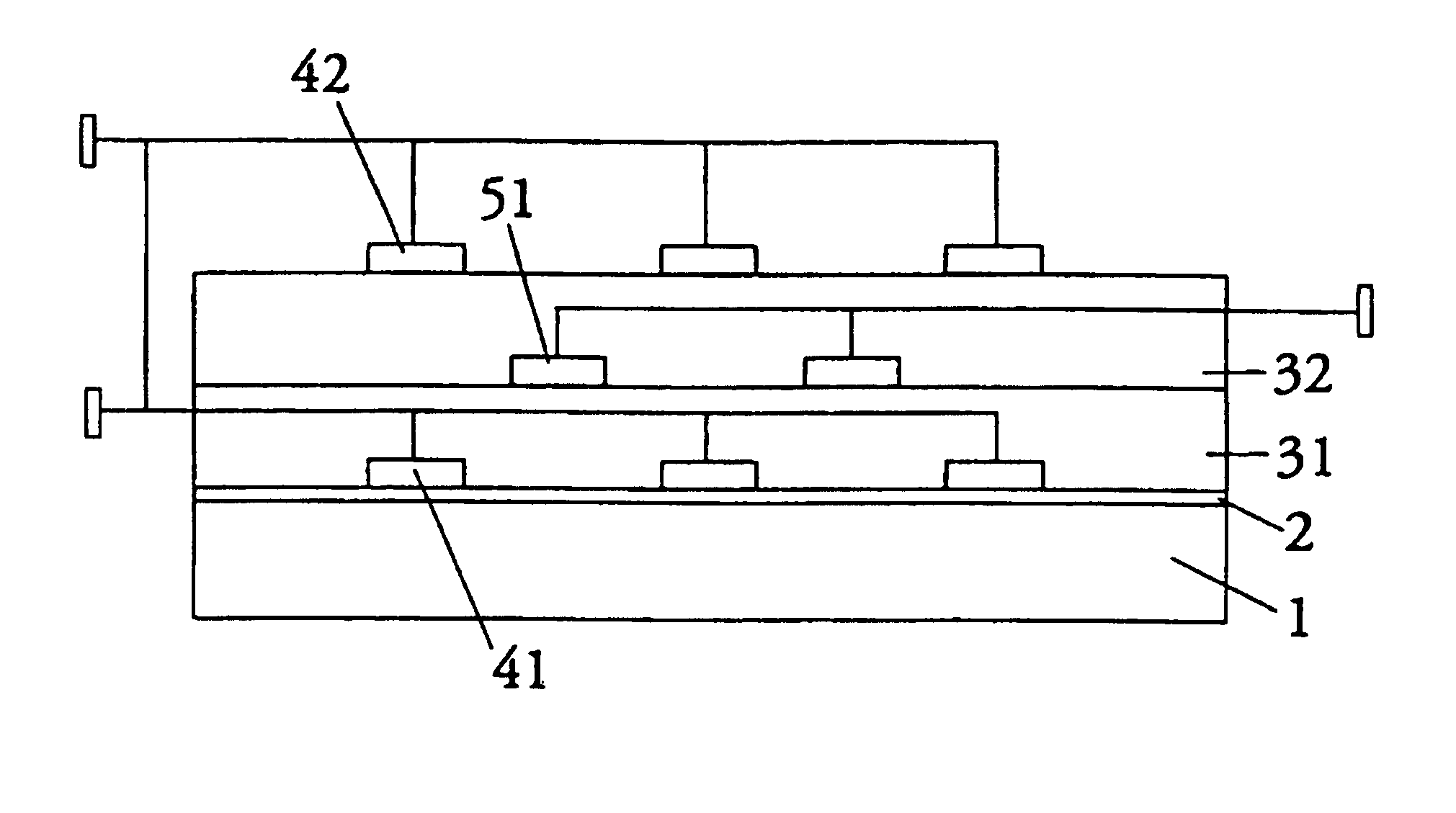

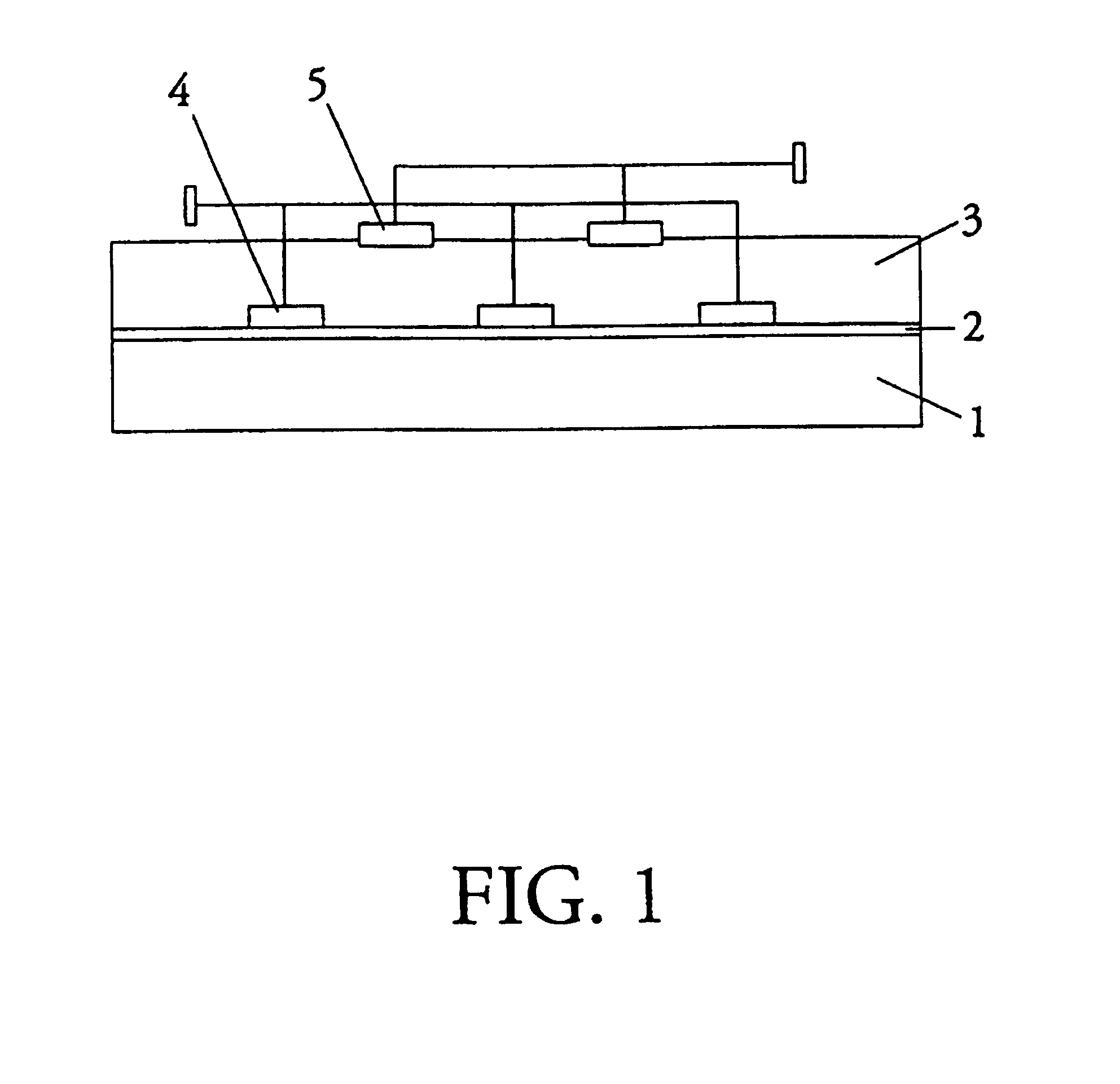

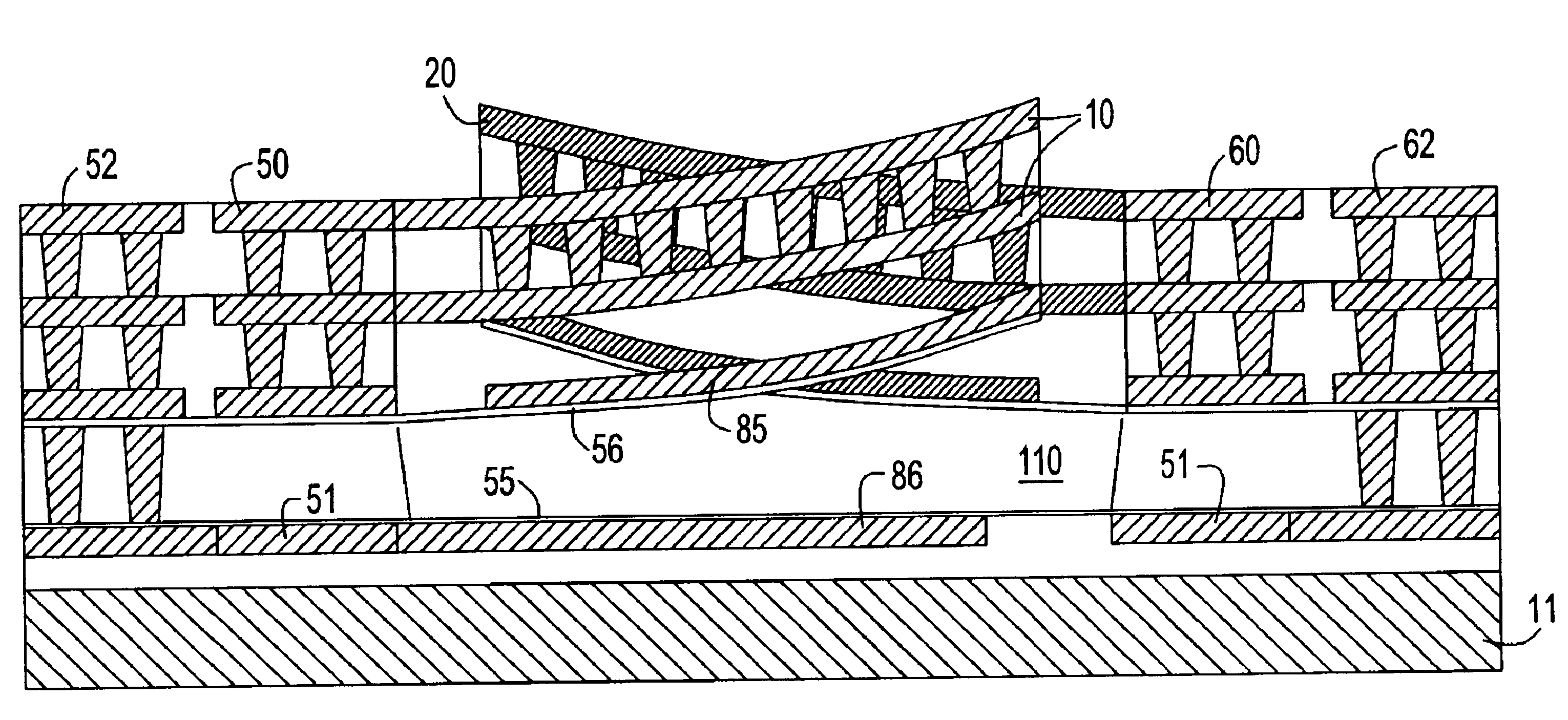

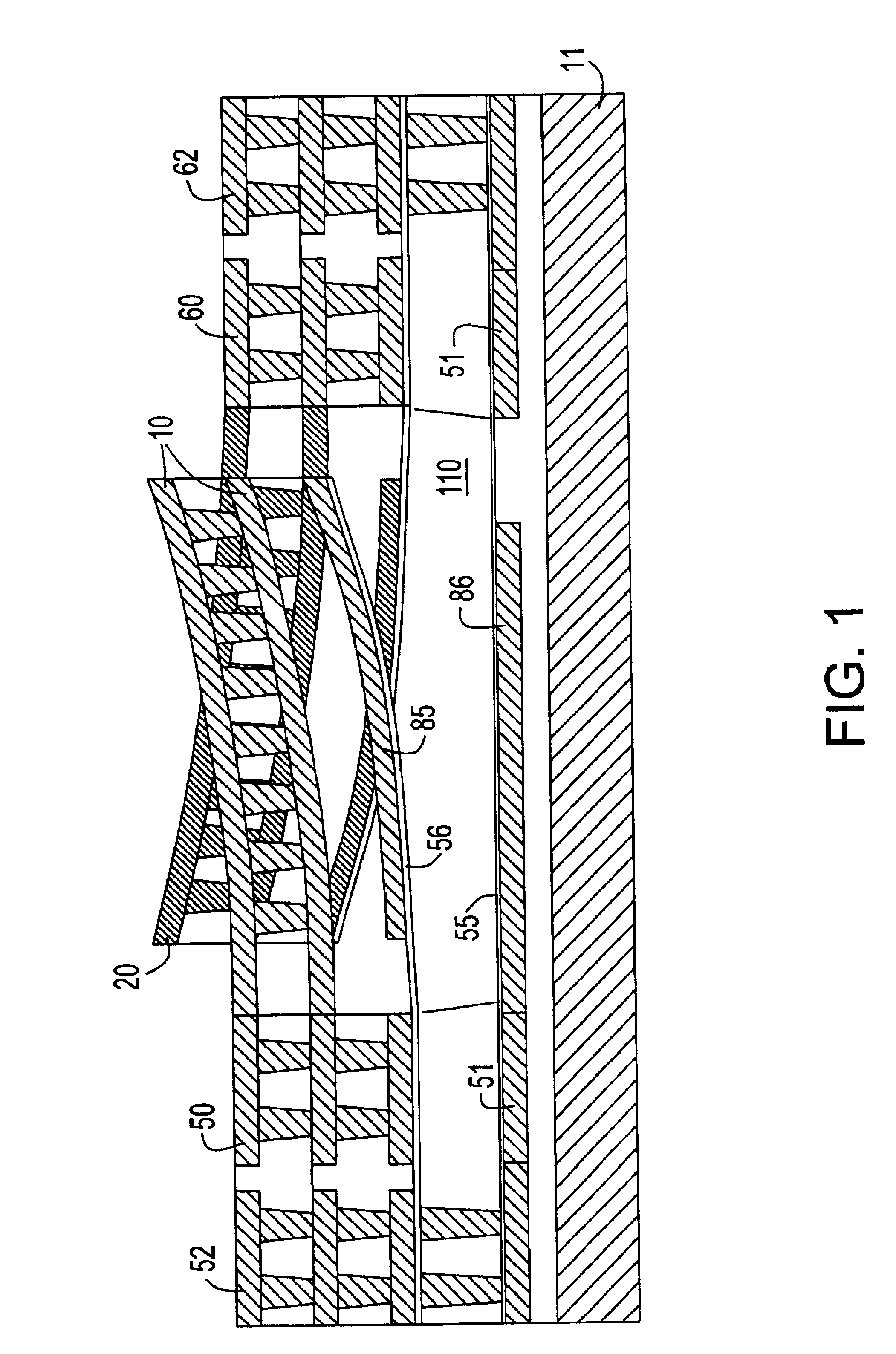

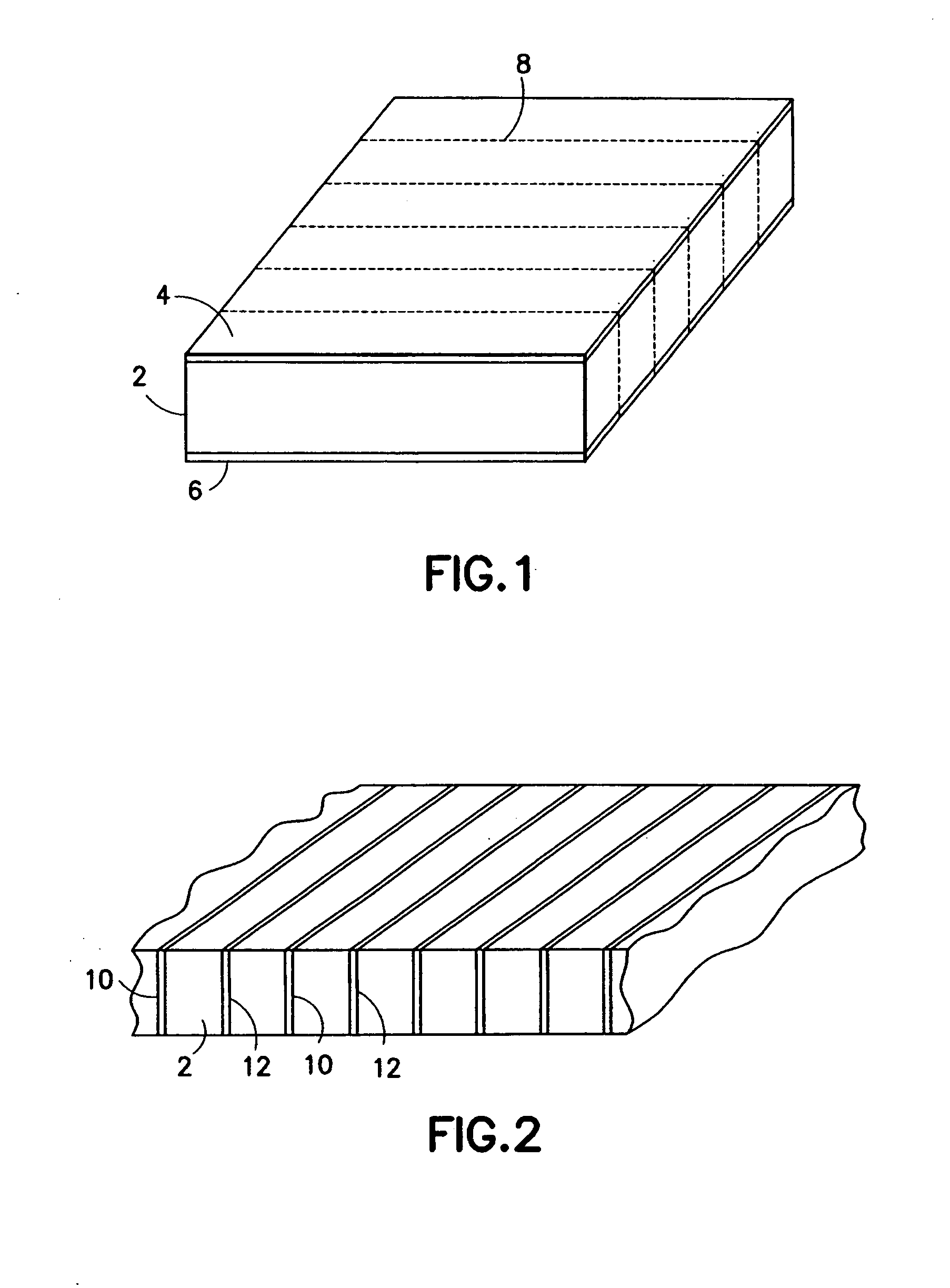

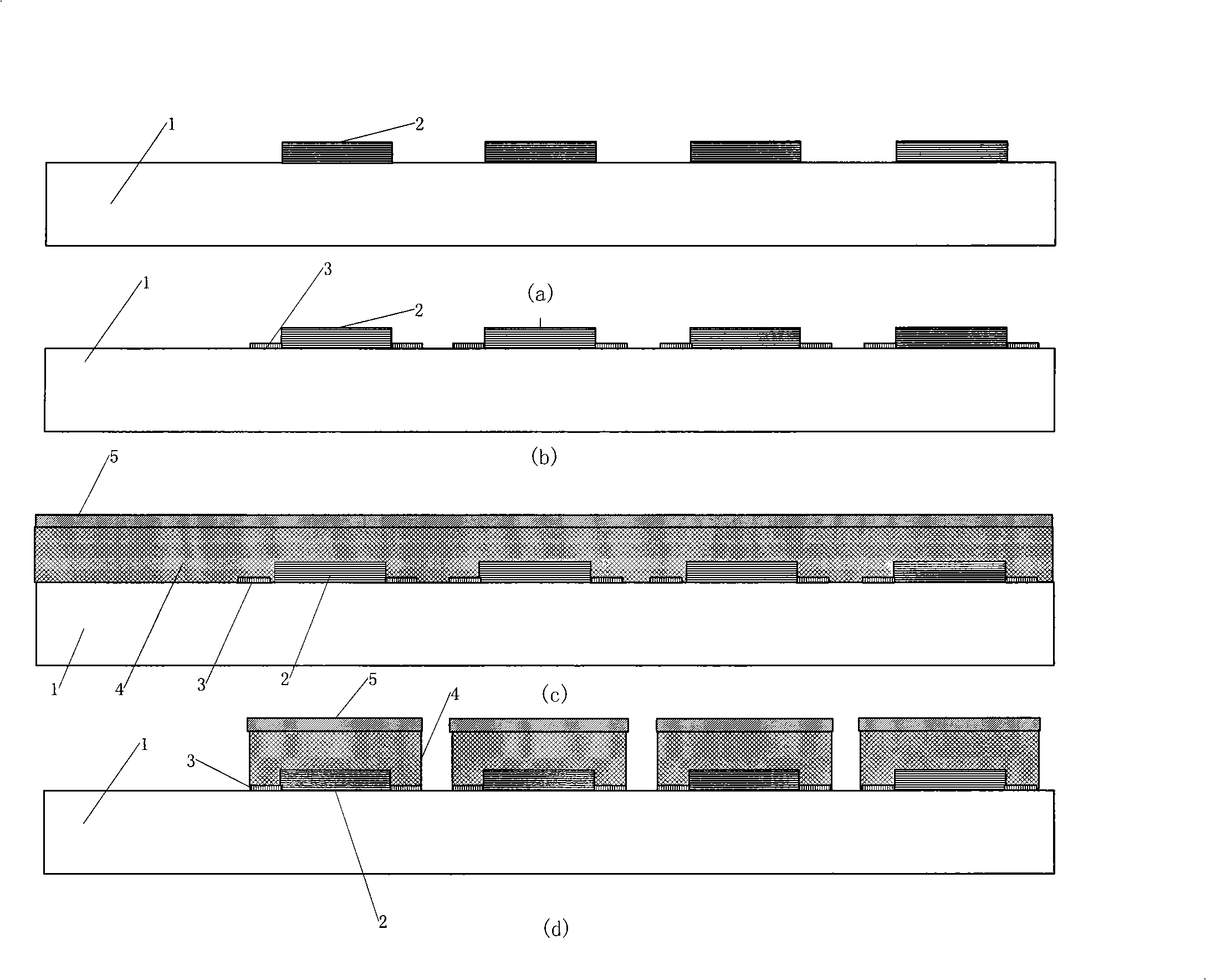

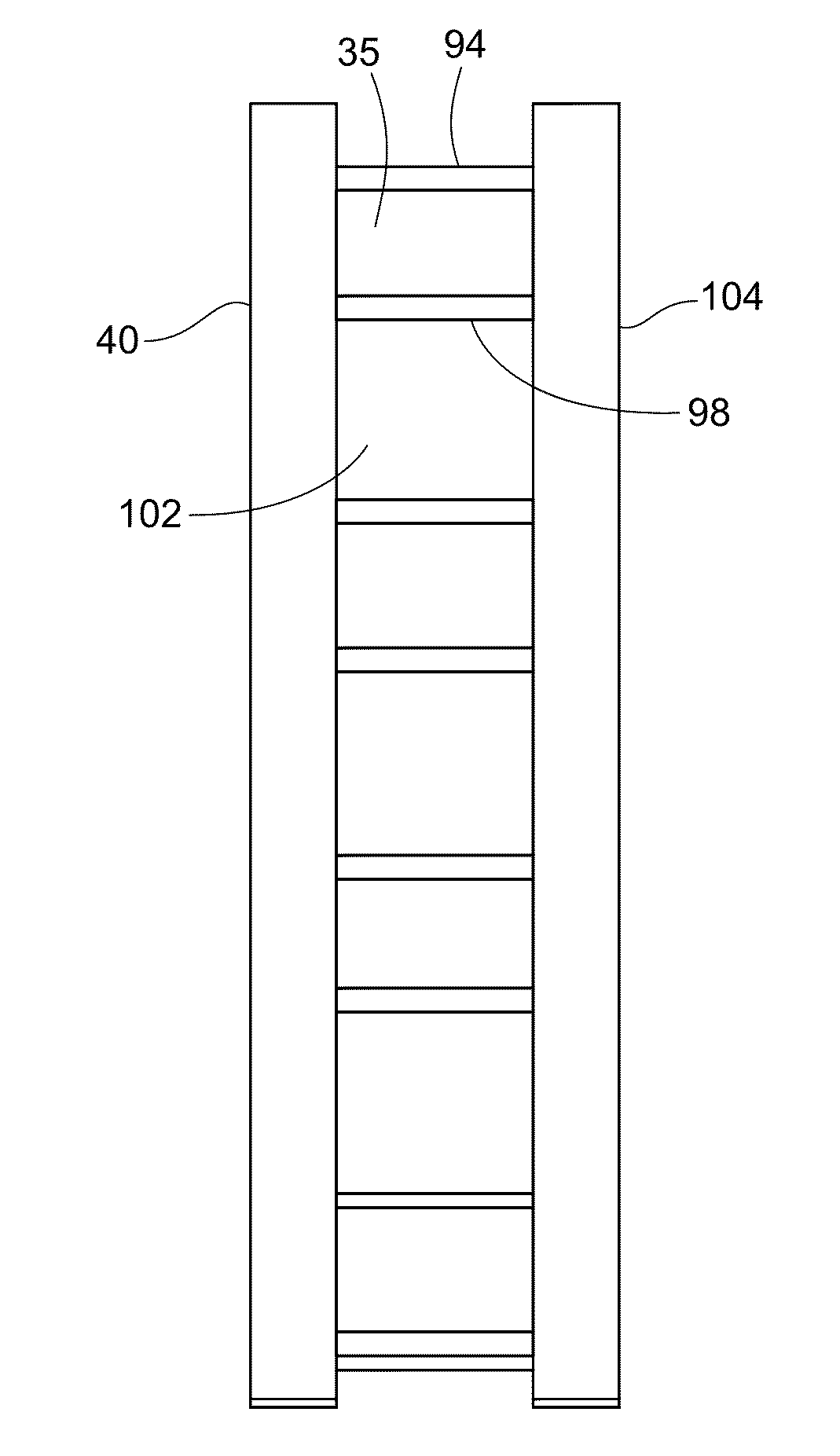

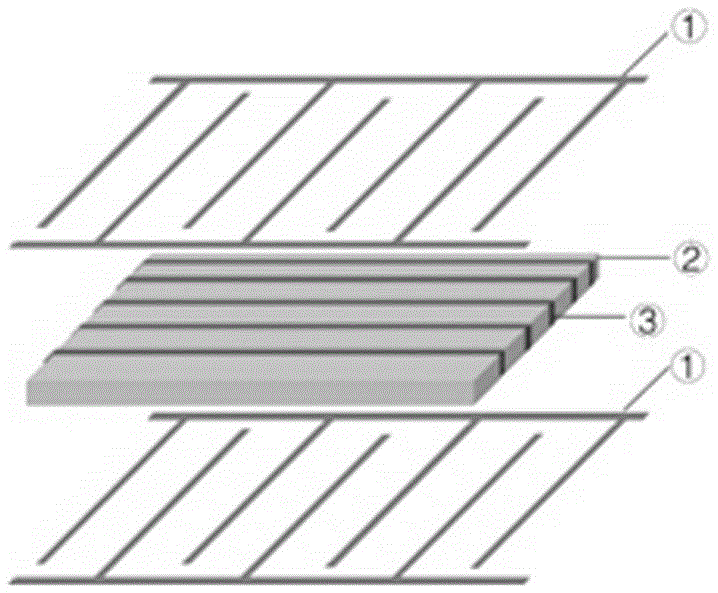

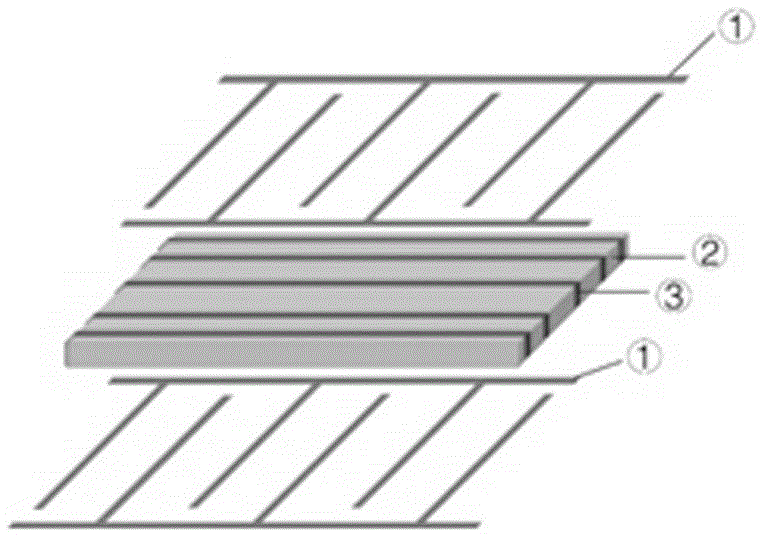

Method for making multi-layer ceramic acoustic transducer

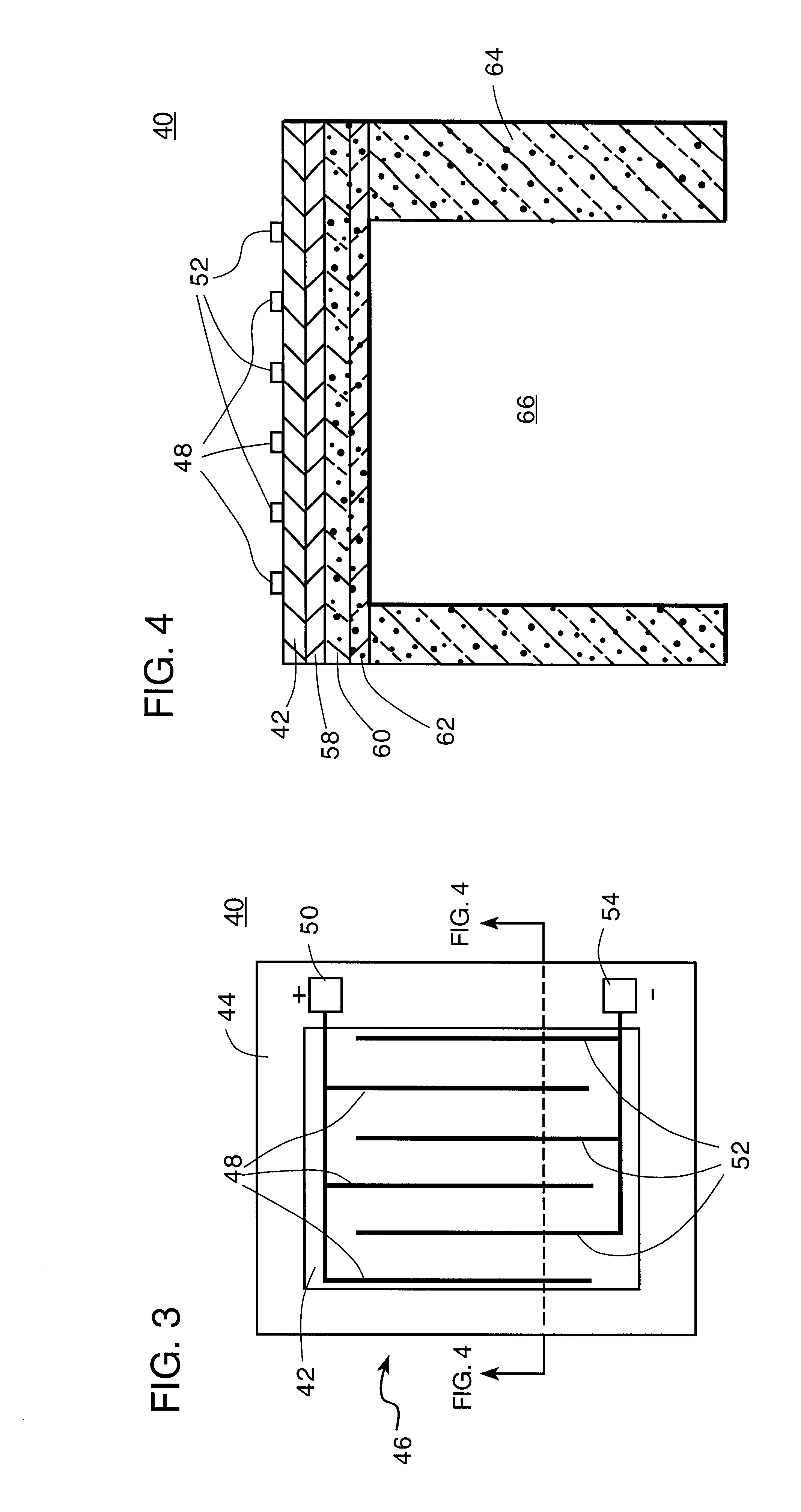

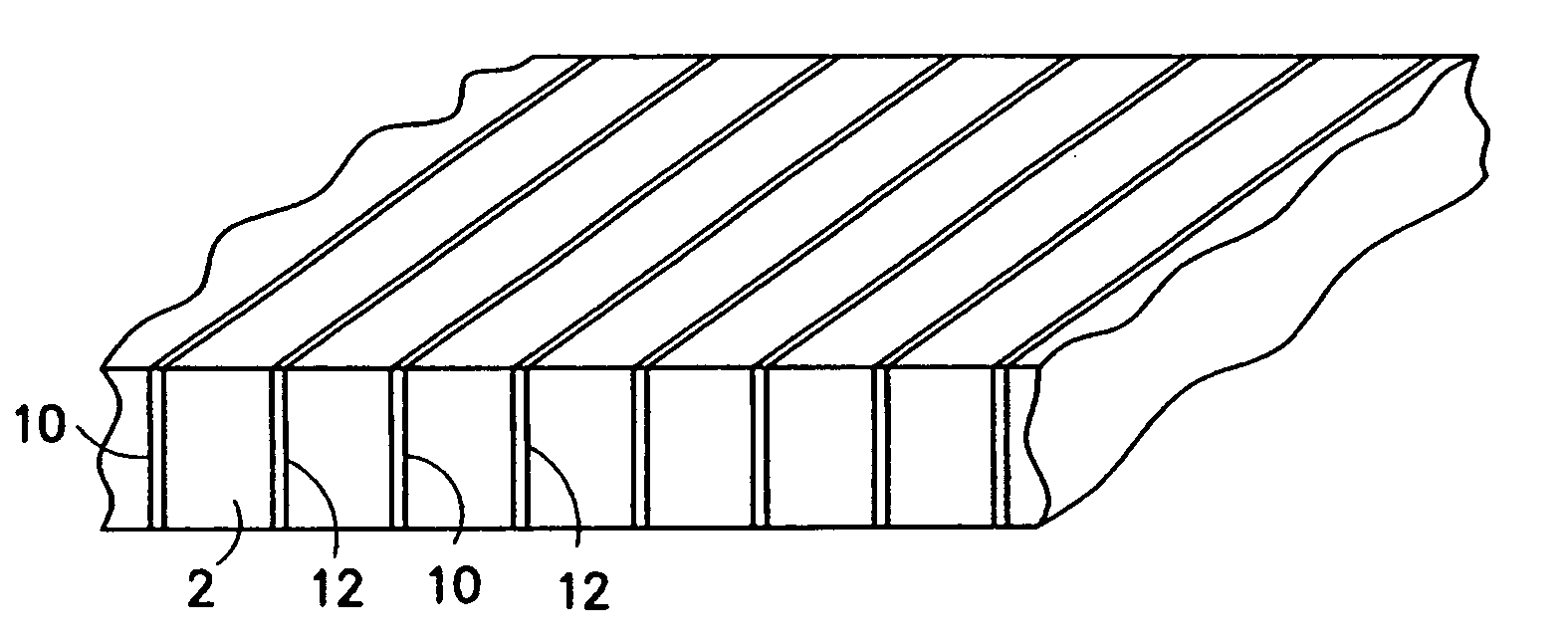

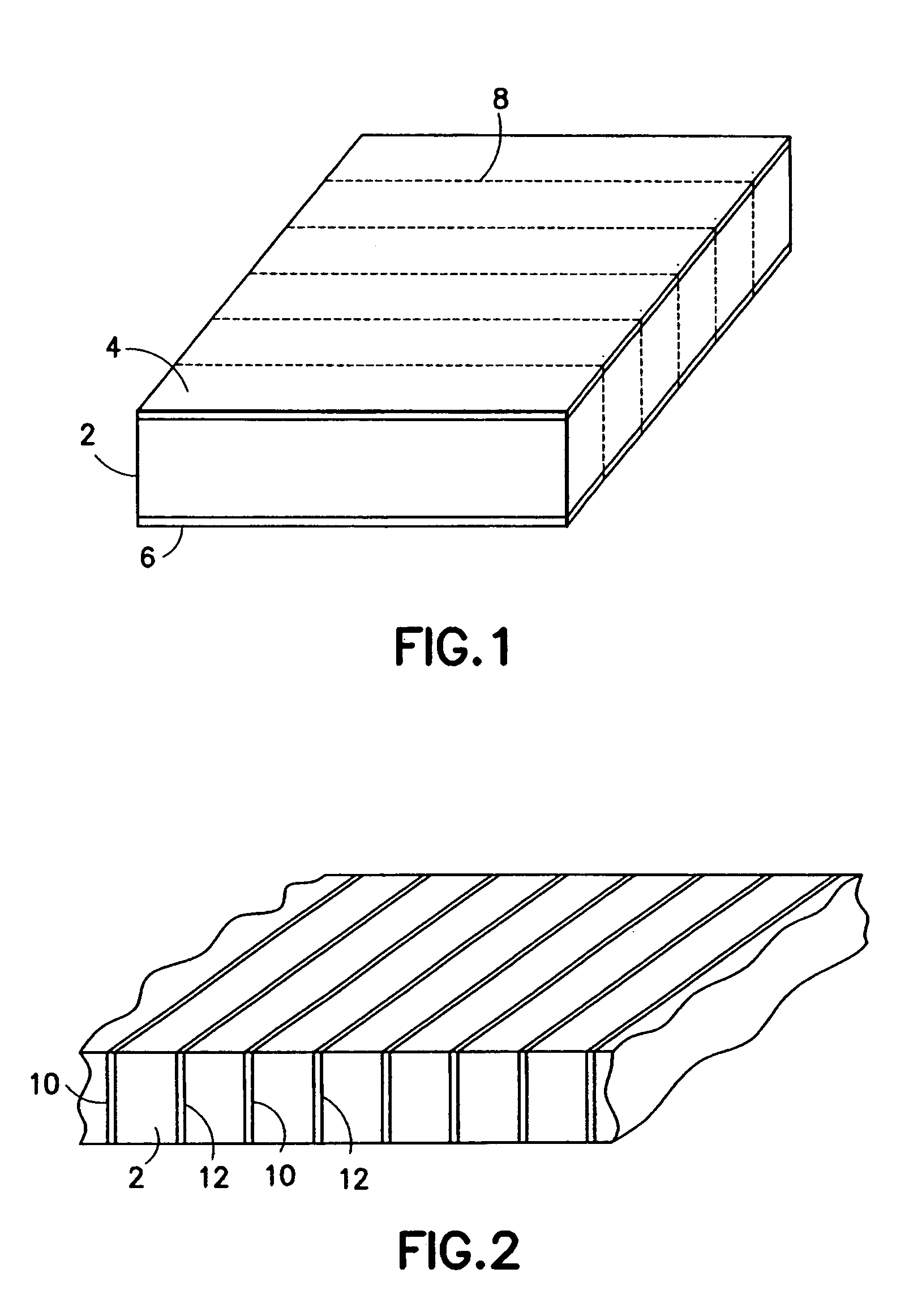

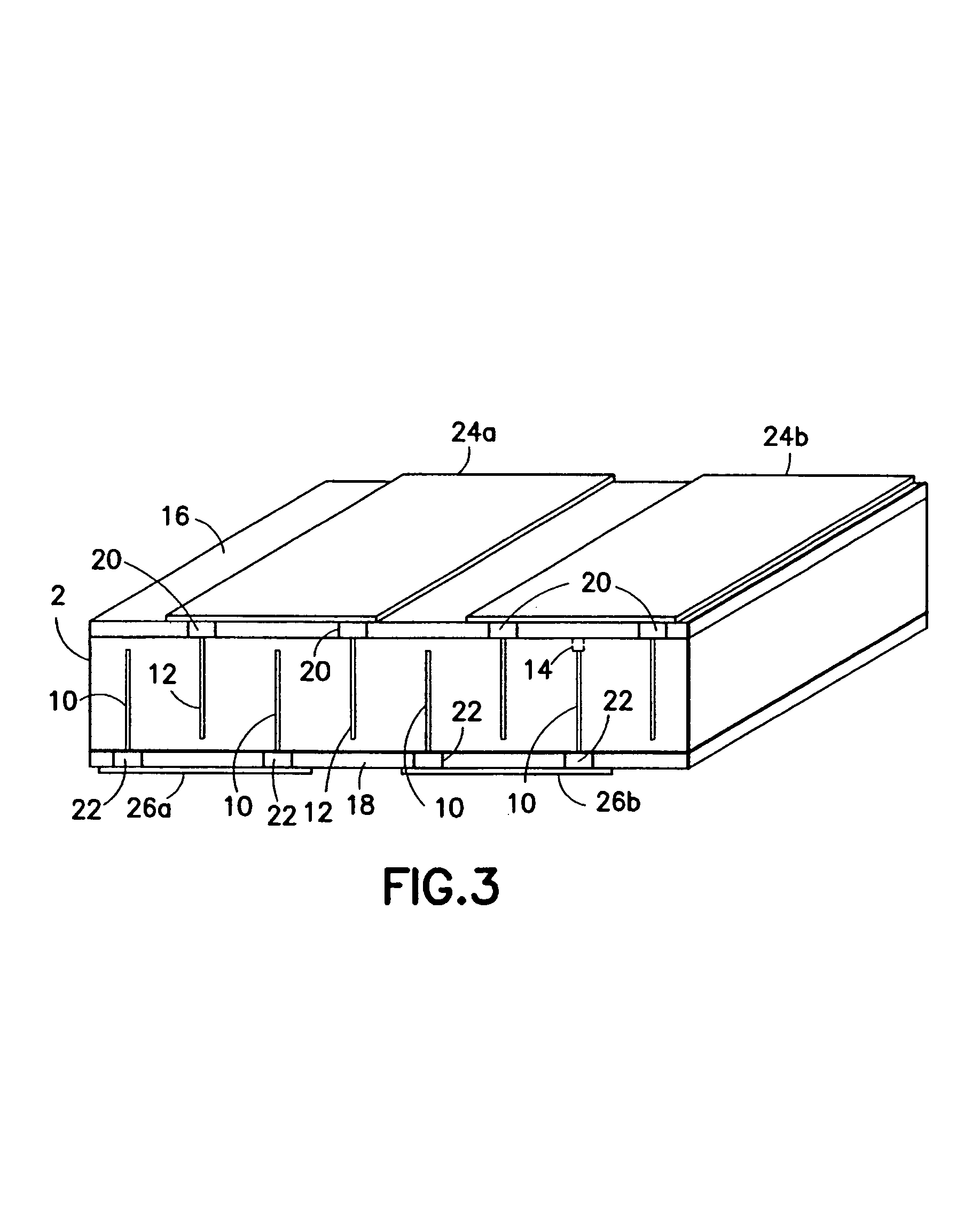

InactiveUS7156938B2Reduce electrical impedanceImprove matchPiezoelectric/electrostrictive device manufacture/assemblyLamination ancillary operationsElectricityElectrical resistance and conductance

Methods for preparing a multi-layer acoustic transducer with reduced total electrical impedance. The methods are based on the stacking of individual piezoelectric layers with metallized surfaces to form a plate in which the metal layers are electrically connected to form interdigitated electrodes. The total electrical impedance of a multi-layer stack comprised of piezoelectric layers connected in this manner is inversely related to the square of the number of layers in the stack. This provides for better matching of the acoustic stack impedance to that of the electrical cable and improved acoustic element sensitivity.

Owner:GENERAL ELECTRIC CO

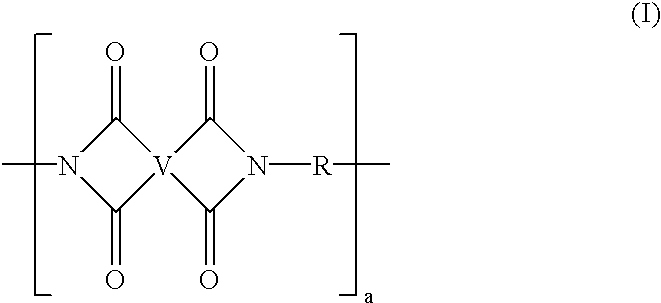

Impedimetric sensors using dielectric nanoparticles

InactiveUS20120037515A1High sensitivityMaterial nanotechnologyWeather/light/corrosion resistanceFunctionalized nanoparticlesSpectroscopy

A method for electrochemical impedance spectroscopy uses interdigitated electrodes functionalized with a first species and nanoparticles functionalized with a second species that preferentially attaches to the first species. The nanoparticles are composed of a material with a dielectric constant (k value) greater than 2. The chemically functionalized electrodes are then exposed to a solution containing the chemically functionalized nanoparticles which then become immobilized on the electrodes through the attachment of the first species to the second species. The impedance spectrum is measured and an amount of the first species is then determined from the measured spectrum. Because the high-k dielectric nanoparticles increase the double-layer capacitive impedance, the sensitivity of determining the amount of the first species attached to the second species is enhanced.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE STATE BOARD OF HIGHER EDUCATION ON BEHALF OF THE PORTLAND STATE UNIV

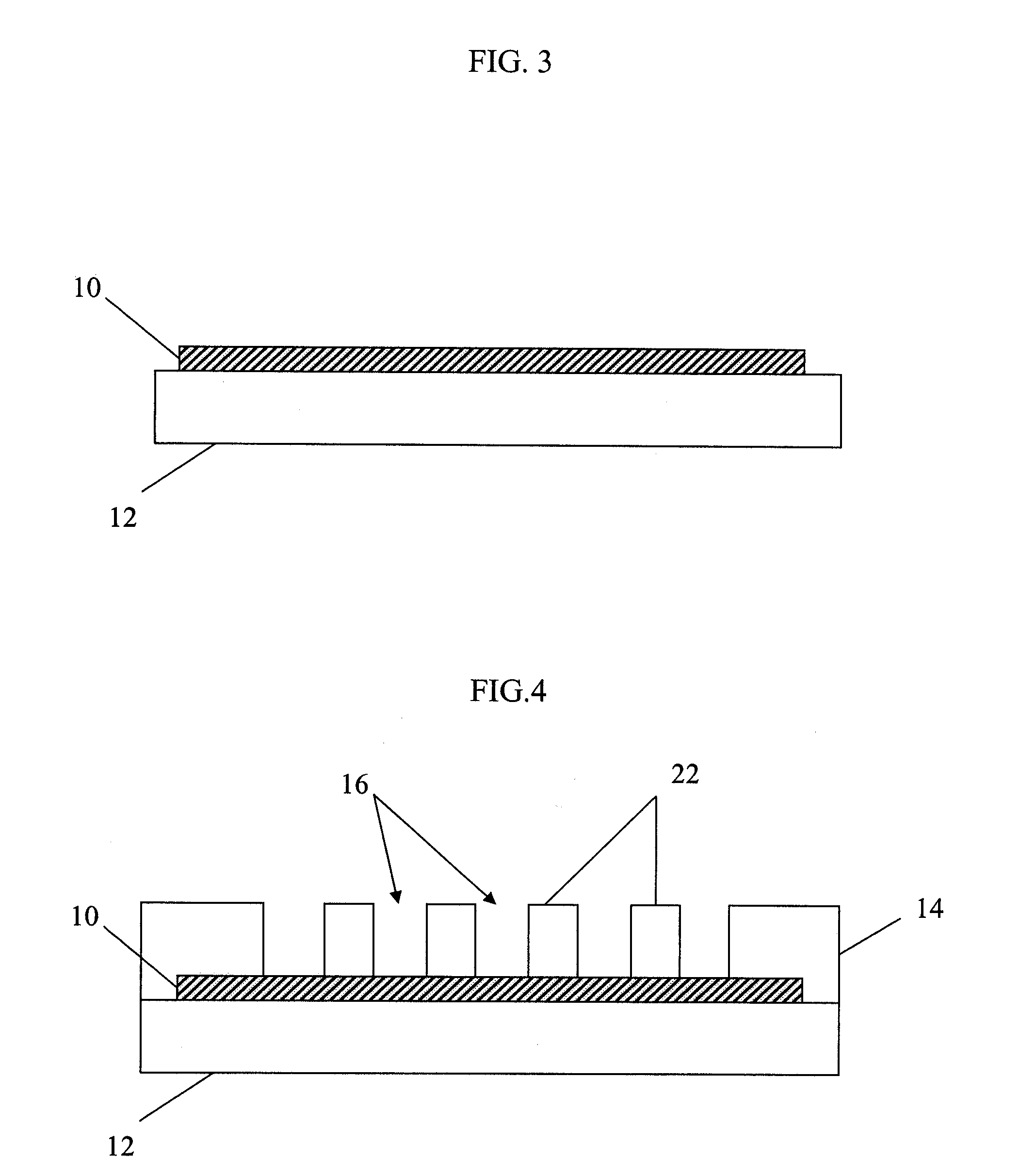

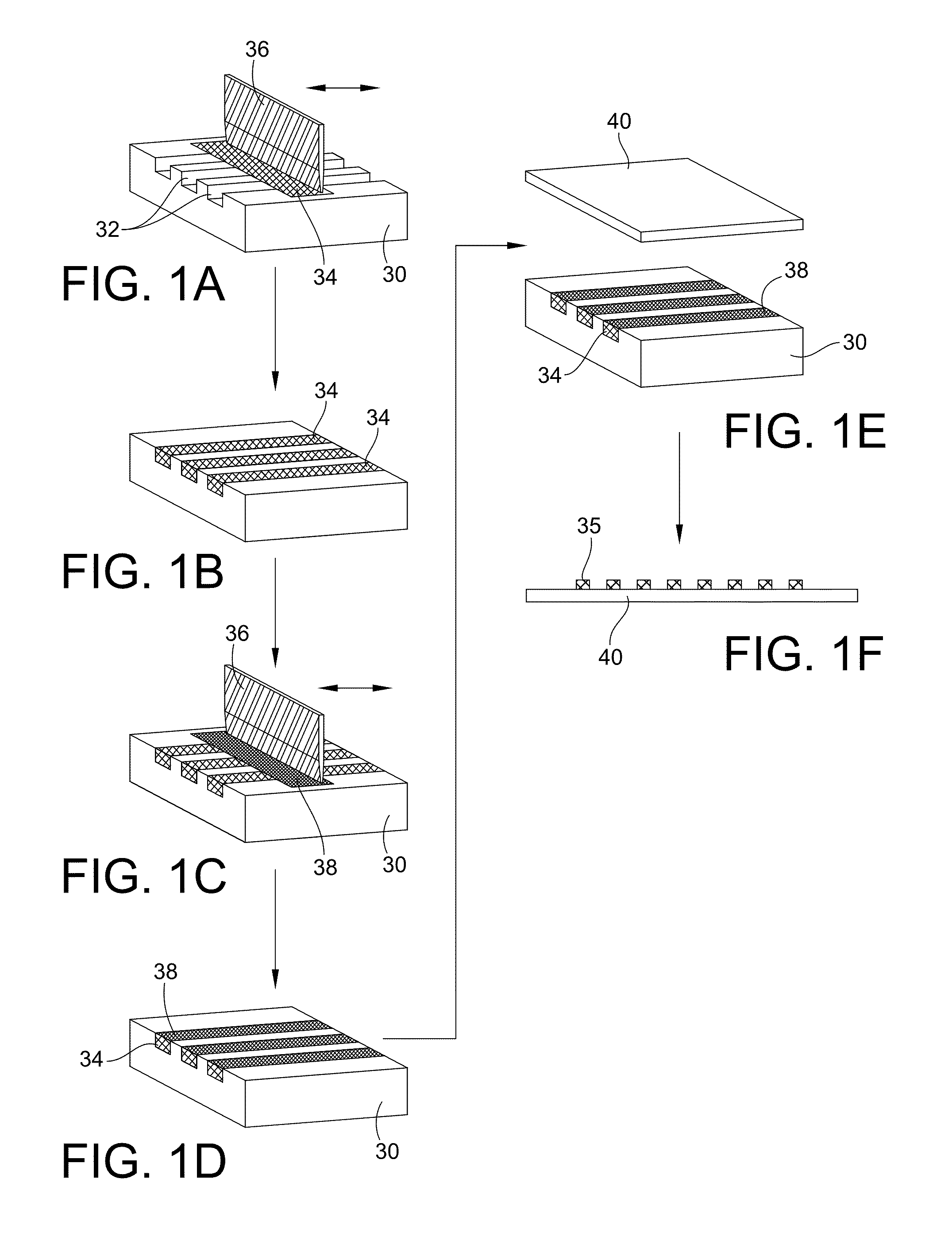

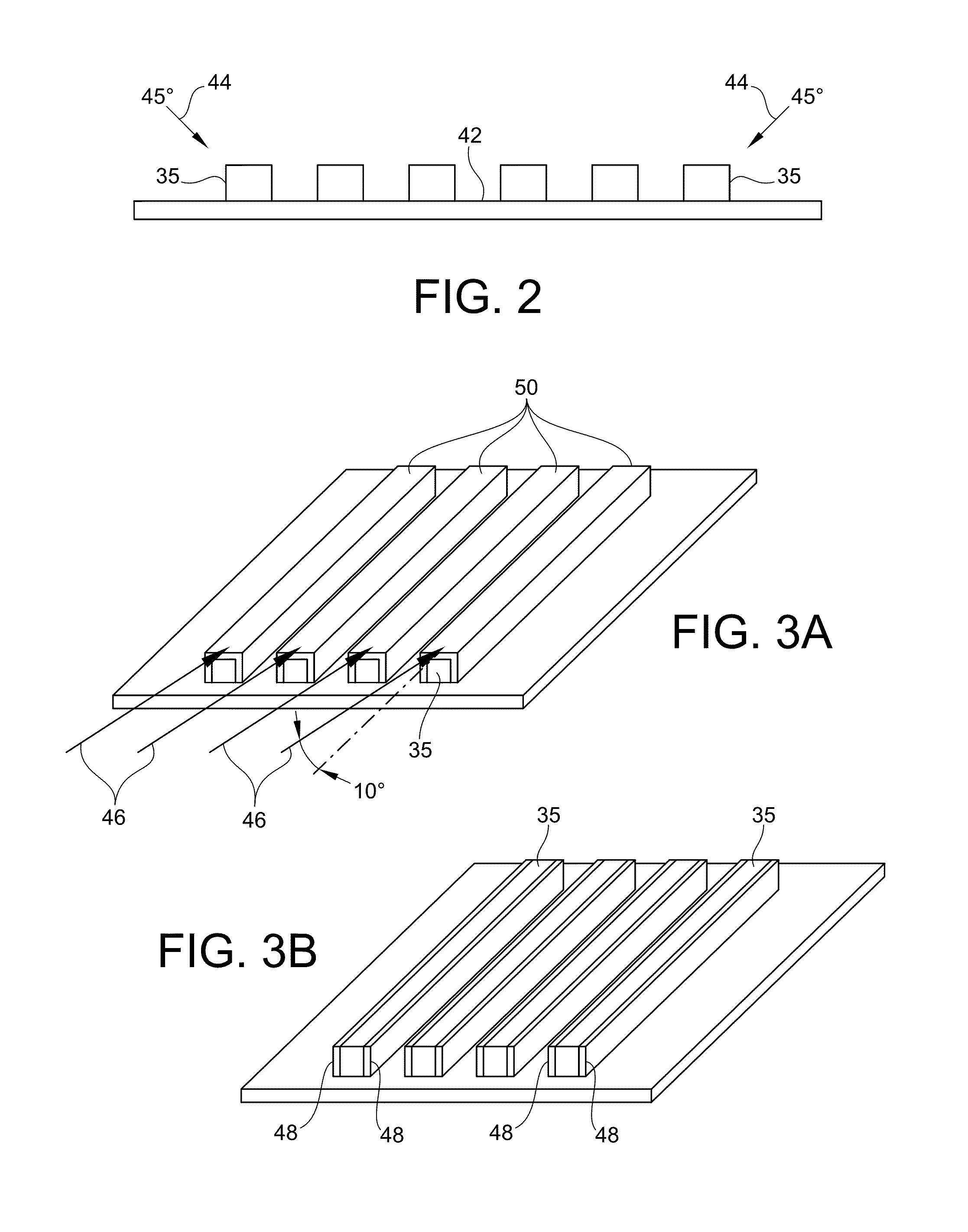

Methods for embossing and embossed articles formed therby

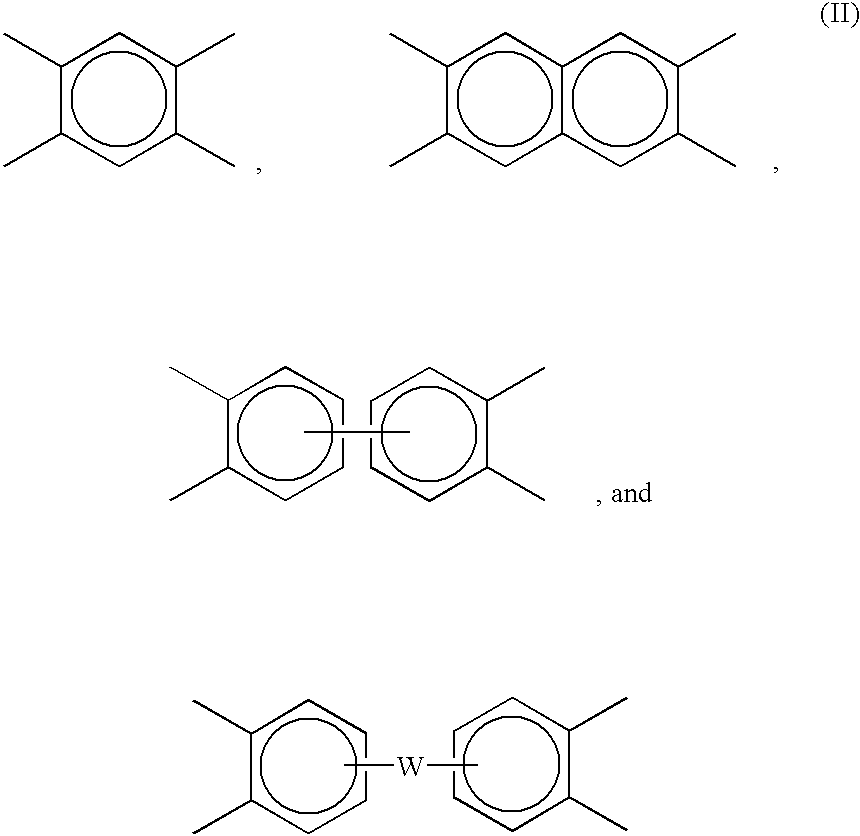

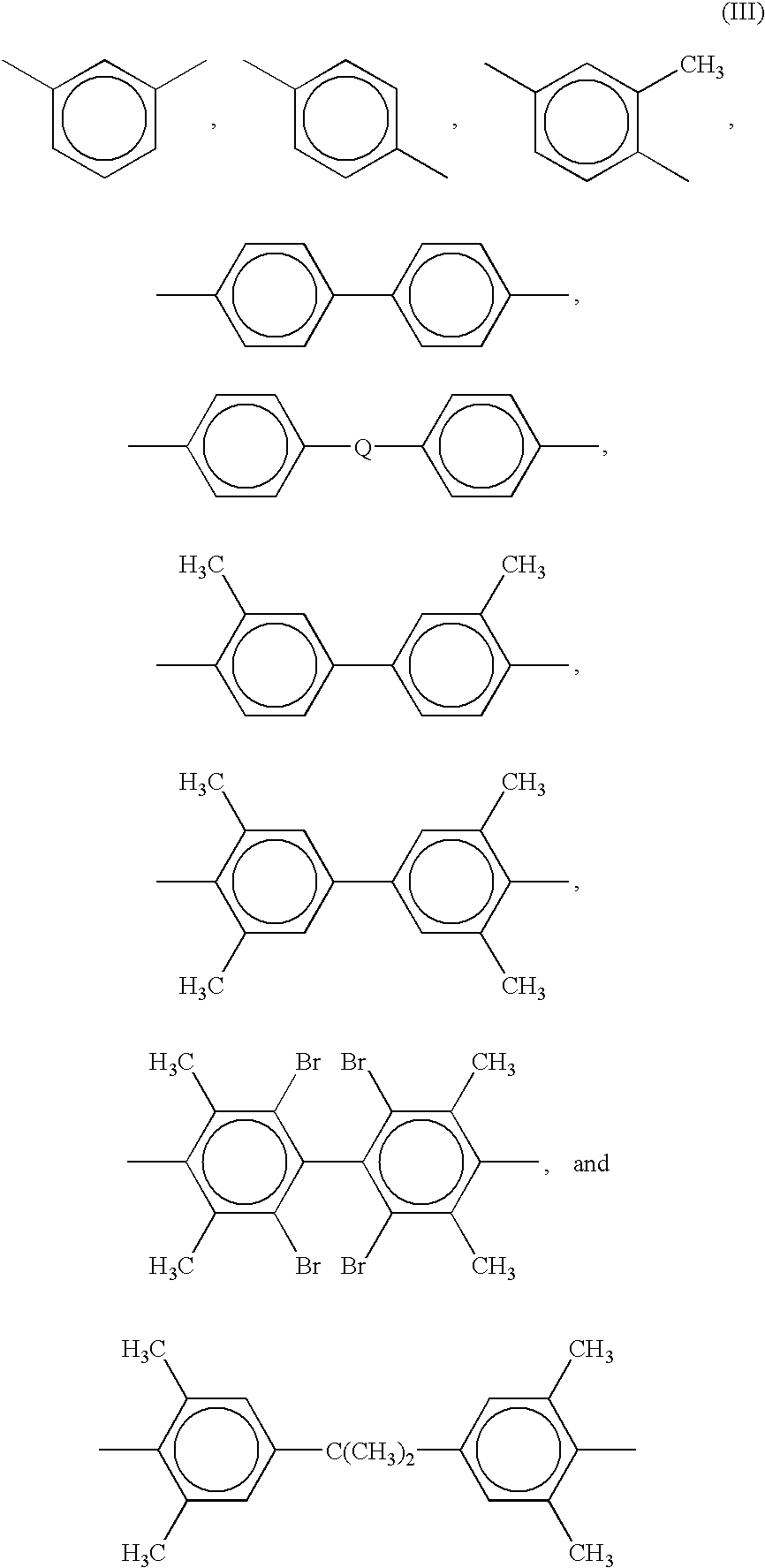

InactiveUS20030057601A1Facilitated releaseImprove adhesionDifferent record carrier formsPlastic/resin/waxes insulatorsPolymeric surfacePolymer science

A method for manufacturing an embossed surface comprising a polymer with a first glass transition temperature Tg1 comprises embossing the surface a temperature Temb; and raising the first glass transition temperature Tg1 of the embossed polymeric surface to a second glass transition temperature Tg2 such that Tg2>Temb. In another embodiment, a method for improving the release of a polymeric surface from an embossing tool comprises incorporating of one or more of fluorine atoms, silicon atoms, or siloxane segments into the backbone of polymer. The methods are particular suited for direct patterning of photoresists, fabrication of interdigitated electrodes, and fabrication of data storage media.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Method for making multi-layer ceramic acoustic transducer

ActiveUS20050099097A1Reduce electrical impedanceImprove matchPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical resistance and conductanceElectricity

Methods for preparing a multi-layer acoustic transducer with reduced total electrical impedance. The methods are based on the stacking of individual piezoelectric layers with metallized surfaces to form a plate in which the metal layers are electrically connected to form interdigitated electrodes. The total electrical impedance of a multi-layer stack comprised of piezoelectric layers connected in this manner is inversely related to the square of the number of layers in the stack. This provides for better matching of the acoustic stack impedance to that of the electrical cable and improved acoustic element sensitivity.

Owner:GENERAL ELECTRIC CO

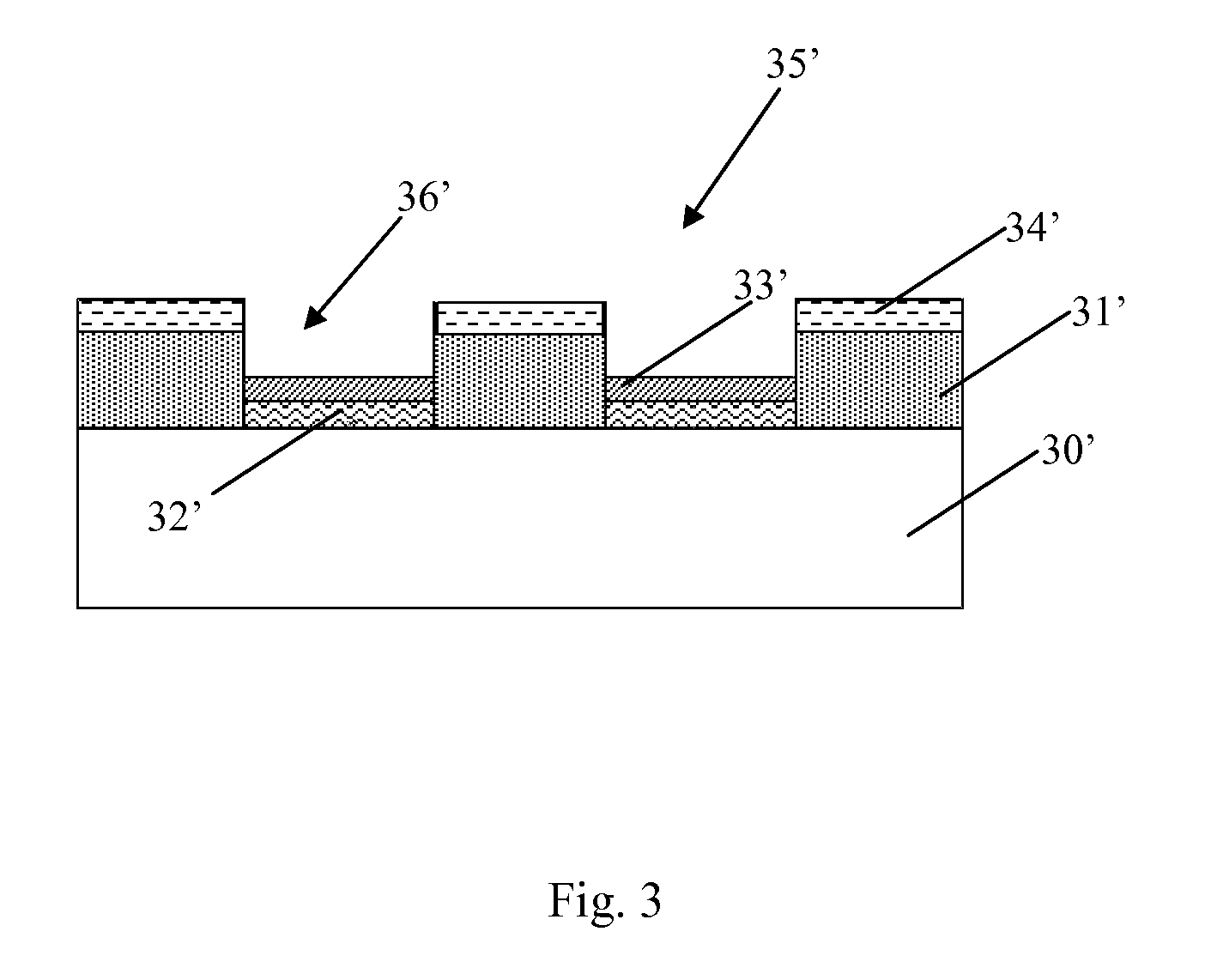

Interdigitated capacitor and method of manufacturing thereof

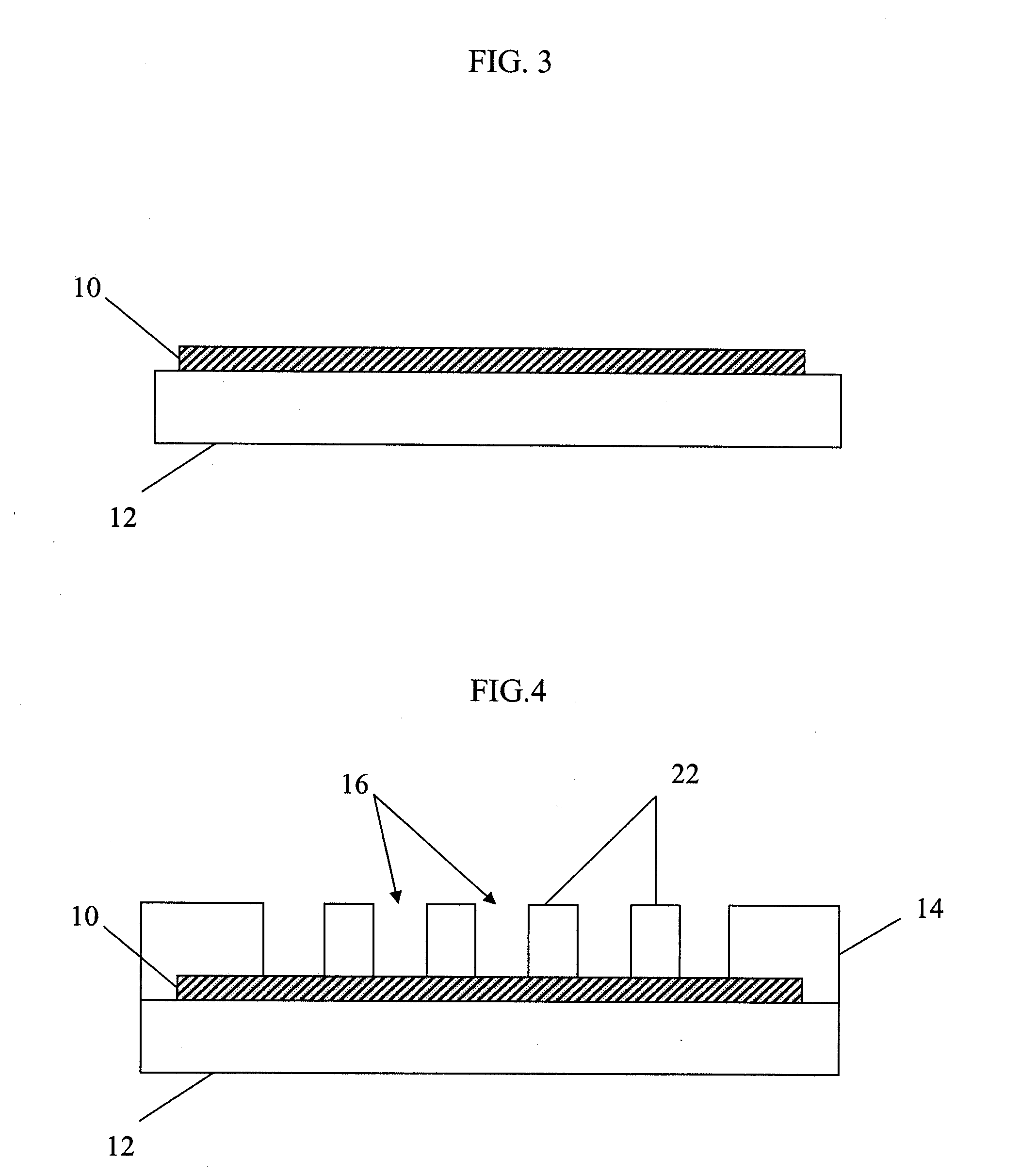

InactiveUS6927125B2Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectrode Contact

The present invention provides a method of manufacturing an interdigitated semiconductor device. In one embodiment, the method comprises simultaneously forming first electrodes adjacent each other on a substrate, forming a dielectric layer between the first electrodes, and creating a second electrode between the first electrodes, the second electrode contacting the dielectric layer between the first electrodes to thereby form adjacent interdigitated electrodes. An interdigitated capacitor and a method of manufacturing an integrated circuit having an interdigitated capacitor are also disclosed.

Owner:BELL SEMICON LLC

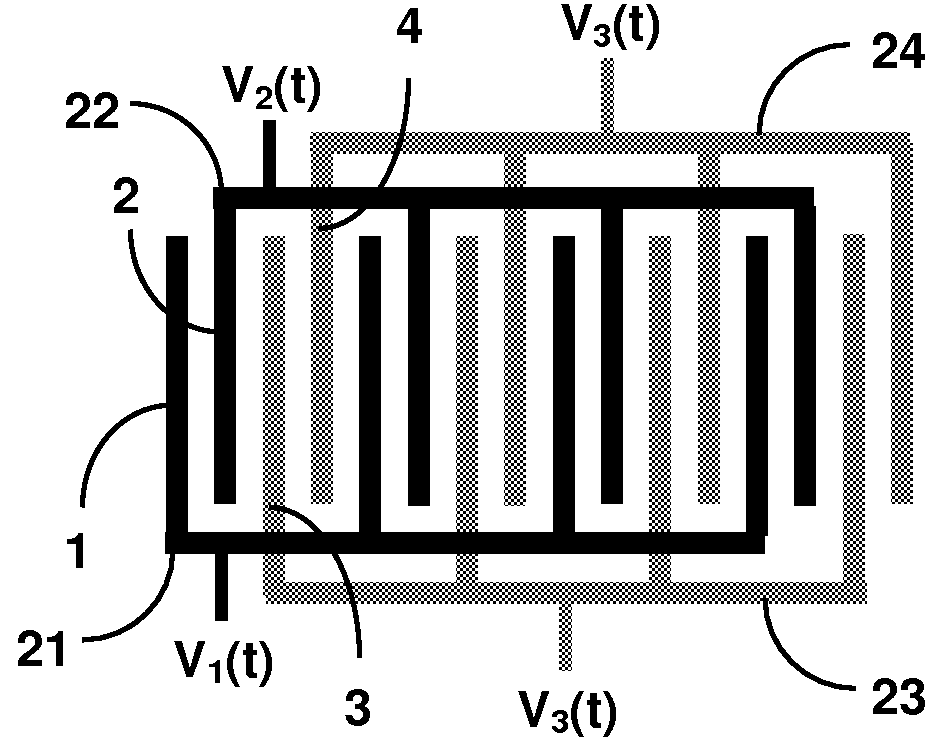

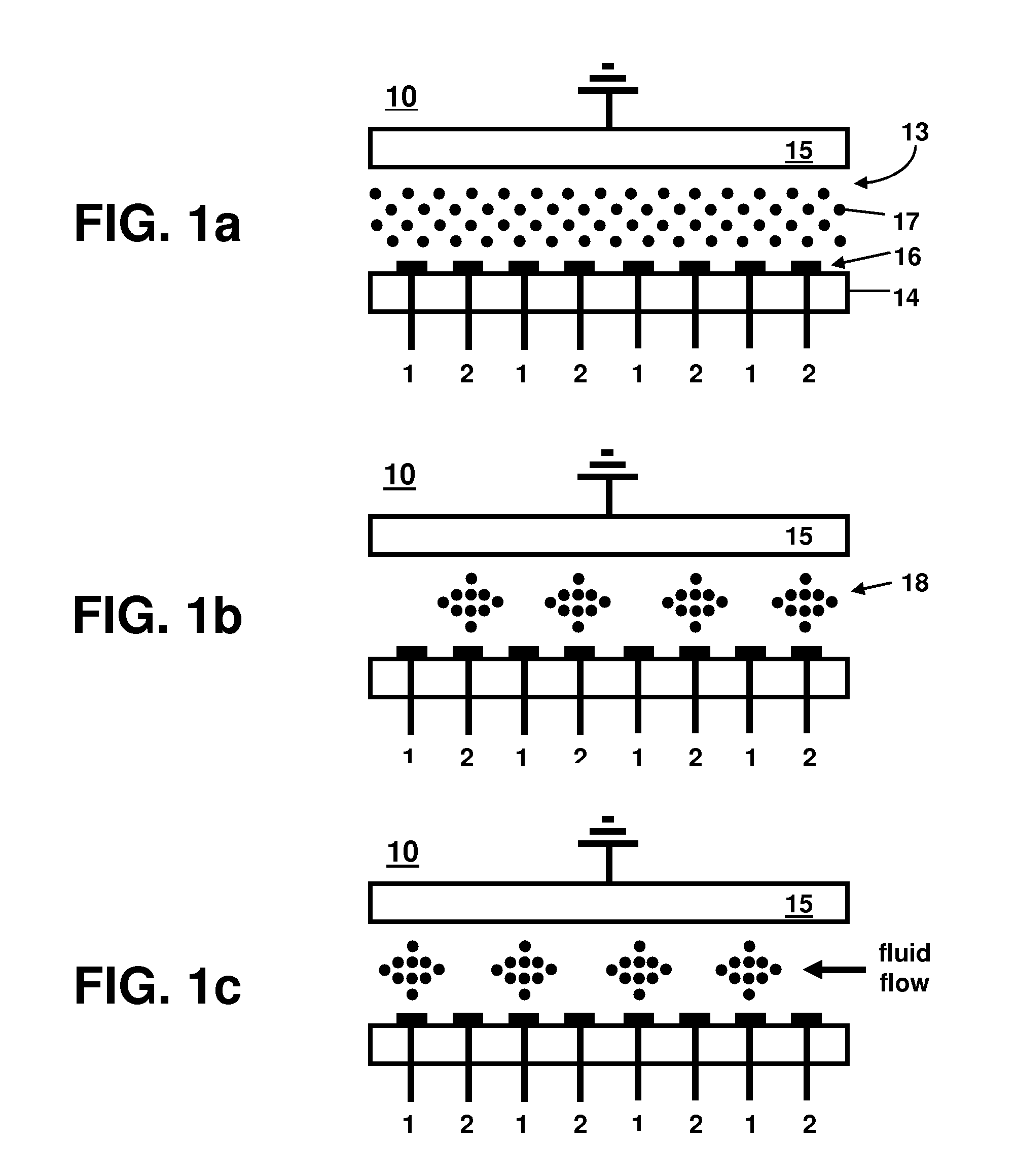

Microfluidic device for the assembly and transport of microparticles

ActiveUS7744737B1Reduce field strengthDielectrophoresisElectrostatic separatorsMicroparticleEngineering

A microfluidic device comprising independently addressable arrays of interdigitated electrodes can be used to assembly and transport large-scale microparticle structures. The device and method uses collective phenomena in a negatively polarized suspension exposed to a high-gradient strong ac electric field to assemble the particles into predetermined locations and then transport them collectively to a work area for final assembly by sequentially energizing the electrode arrays.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

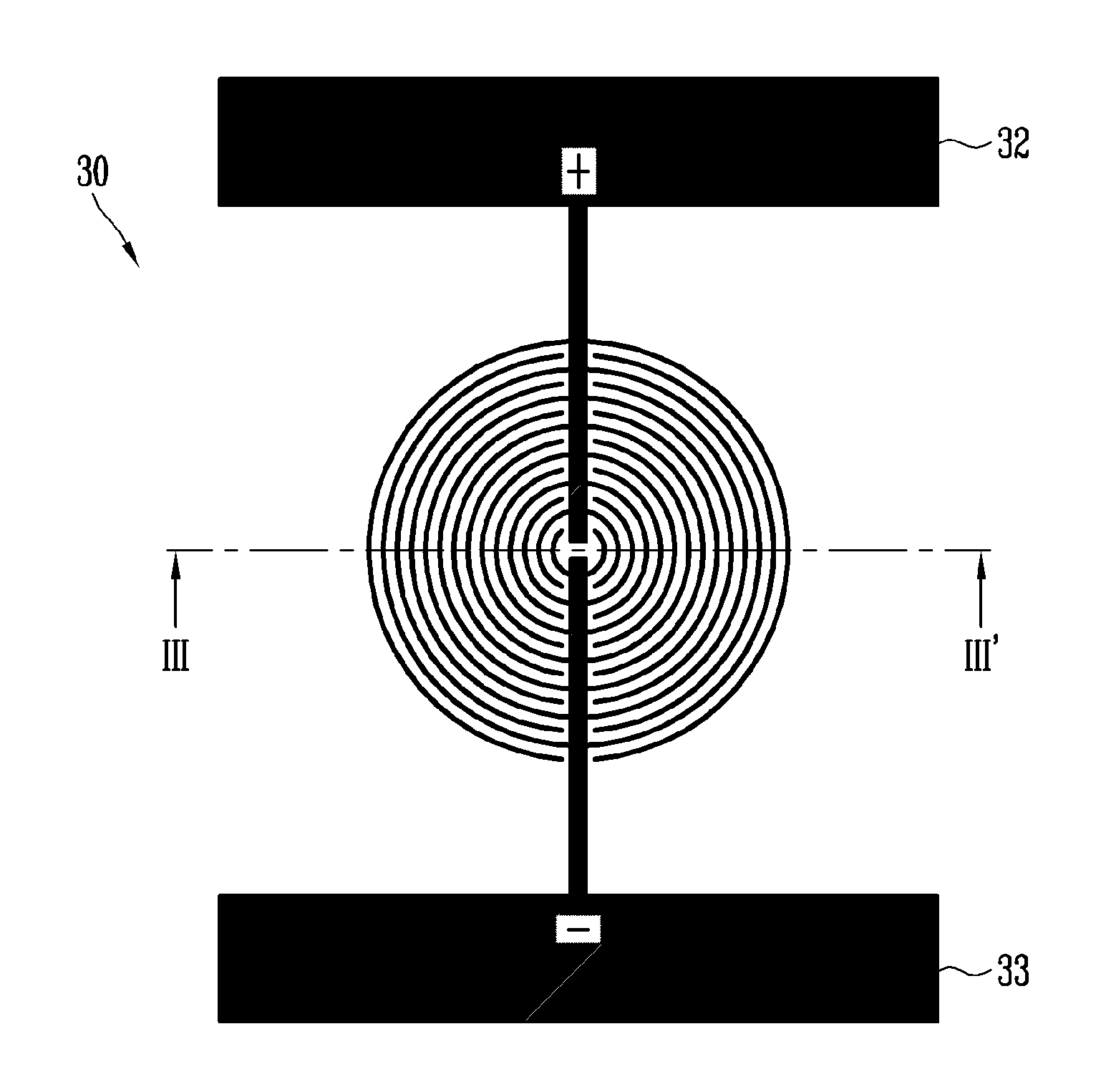

Interdigitated electrode for electronic device and electronic device using the same

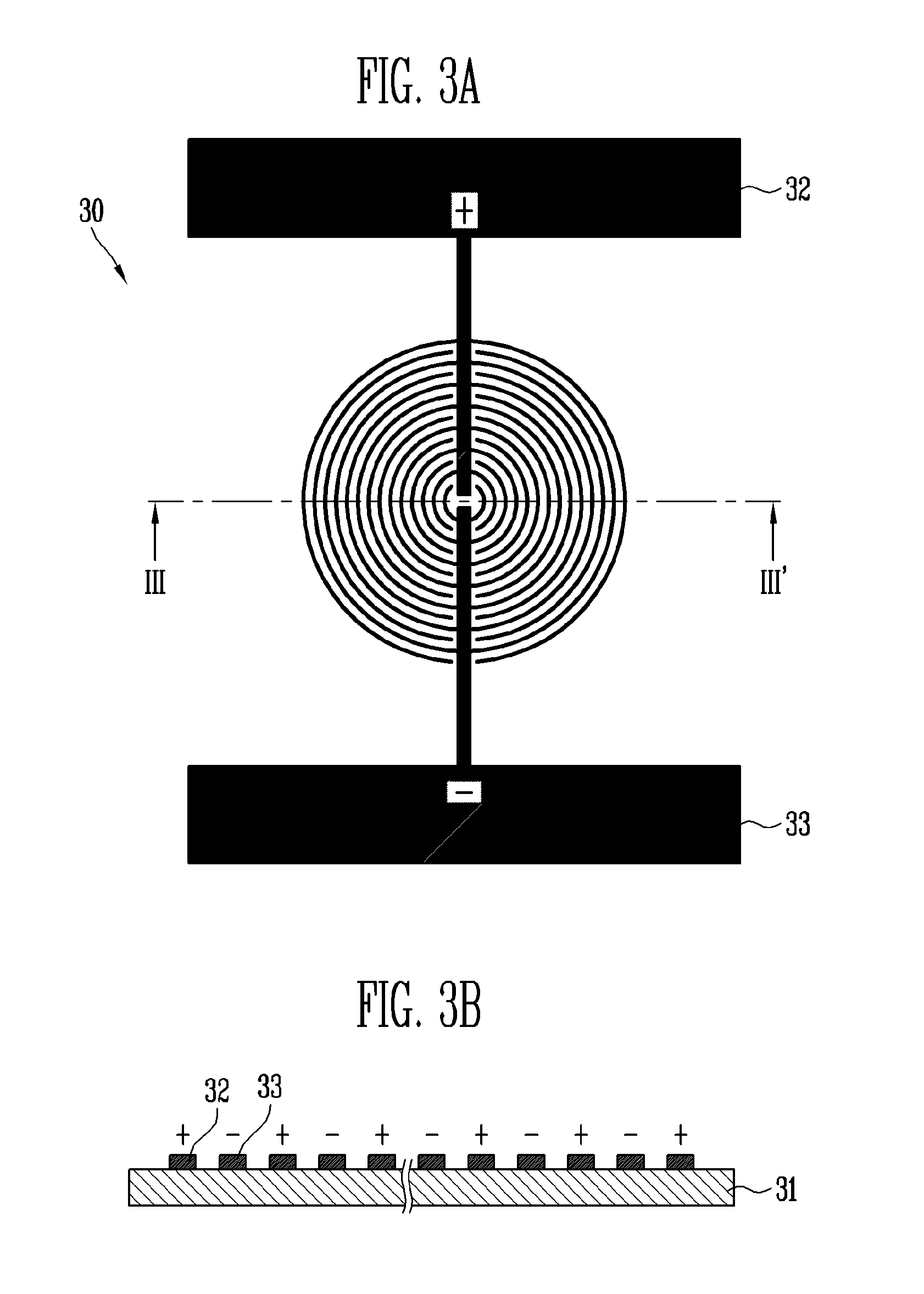

InactiveUS20080134792A1Vibration measurement in solidsVibration measurement in fluidManufacturing technologyEngineering

Provided are an interdigitated electrode (IDE) for an electronic device, which includes a plurality of anodes and a plurality of cathodes arranged radially in an alternating fashion for electrical insulation from one another, and an electronic device using the same. The IDE in which the anodes and the cathodes are arranged radially in an alternating fashion is fabricated and applied to the electronic device, so that the entire fabrication process can be simplified compared to that of a typical electronic device in which an upper electrode is different from a lower electrode. Also, circular or polygonal IDEs can be applied to systems that are driven or measure values on their central axes, thereby enhancing the performance and efficiency of the systems. Furthermore, the circular or polygonal IDEs can be employed in systems such as acoustic sensors, pressure sensors, micro-speakers, biological sensors, and acceleration sensors, so that the structure and operation of the systems can be simplified.

Owner:ELECTRONICS & TELECOMM RES INST

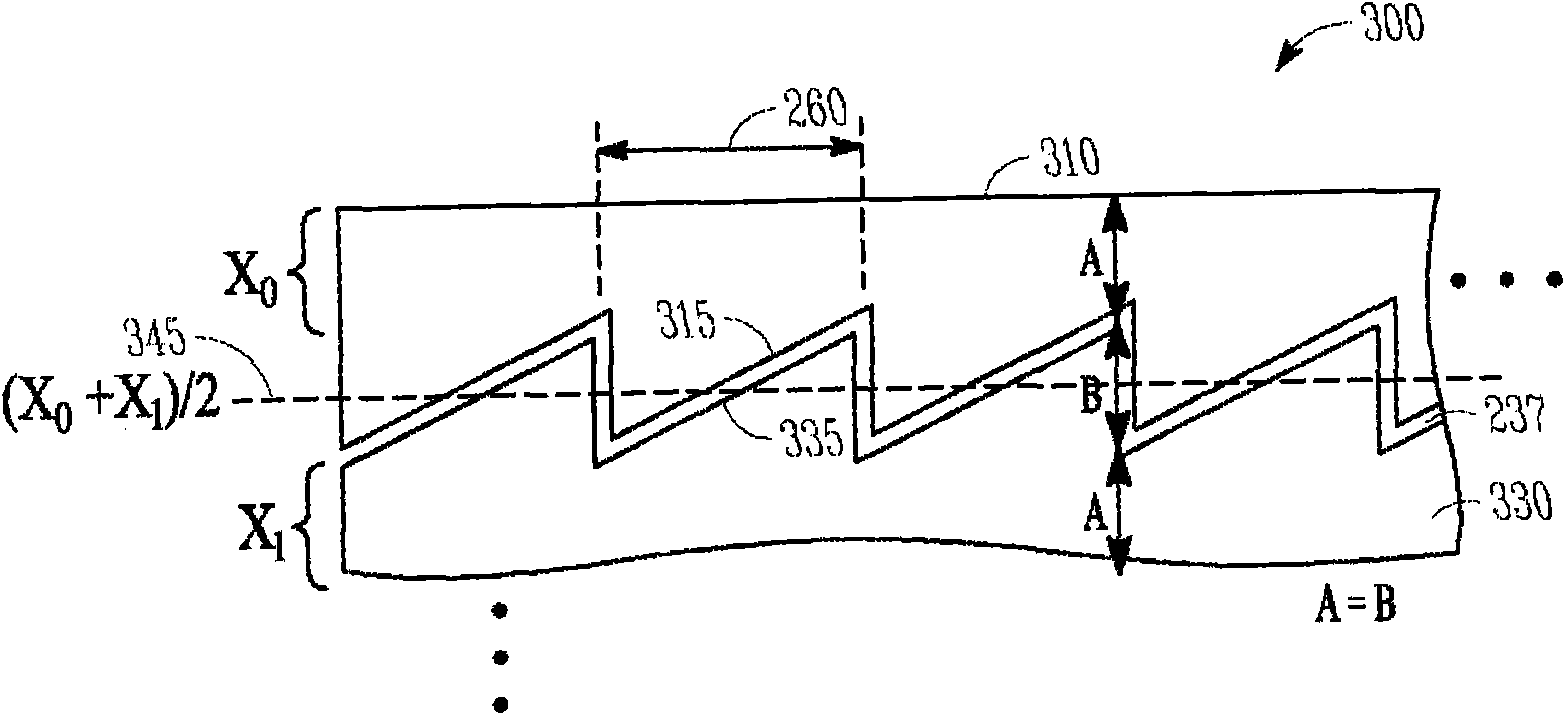

Interdigitated touchscreen electrodes

Interdigitated touchscreen electrodes. A device includes a plurality of adjacent electrodes for a touch sensitive device. The electrodes run generally in a first direction. Adjacent electrodes are interdigitated to provide one or more interpolation sections of the electrodes. Touch sensitive devices may utilize such interdigitated electrodes as drive electrodes, along with transverse sense electrodes formed over a display.

Owner:NEODRON LTD

High density MIMCAP with a unit repeatable structure

InactiveUS7186625B2Semiconductor/solid-state device detailsSolid-state devicesCapacitanceContinuous use

Owner:INT BUSINESS MASCH CORP

Clamp for use in processing semiconductor workpieces

ActiveUS20060171094A1Increase clamping forceReduce leakageSemiconductor/solid-state device manufacturingDielectricEngineering

An apparatus is provided to improve clamping of a work piece to a support surface. The apparatus includes a support base, an insulator layer disposed on the support base, an electrode layer disposed on the insulator layer, and a clamping layer comprising aluminum oxynitride disposed on the electrode layer wherein the workpiece is clamped to the surface of the clamping layer. The apparatus provides a higher clamping force for the workpiece while reducing gas leakage and particle levels in addition to maintaining a declamping time suitable for high throughput processing. The apparatus may further provide a raised surface geometry or embossments on the dielectric or a dielectric comprising an outer ring a center cavity for reducing particle contamination to the backside of the workpiece. Also, a thin wall sleeve may be provided between the base and the insulator and alternating current may be applied to opposite ones of interdigitated electrode pairs to reduce particle contamination and improve the implantation uniformity.

Owner:VARIAN SEMICON EQUIP ASSOC INC

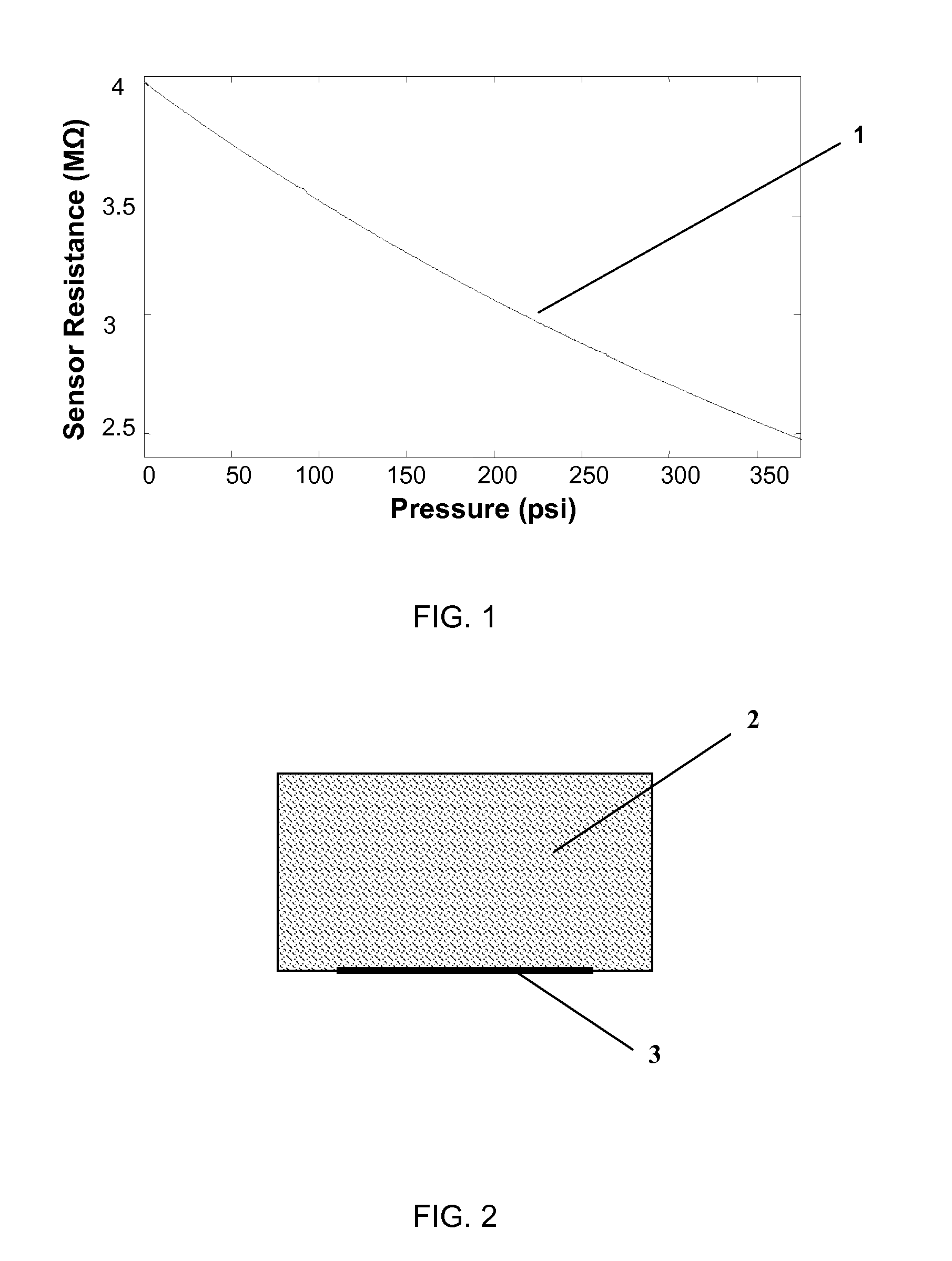

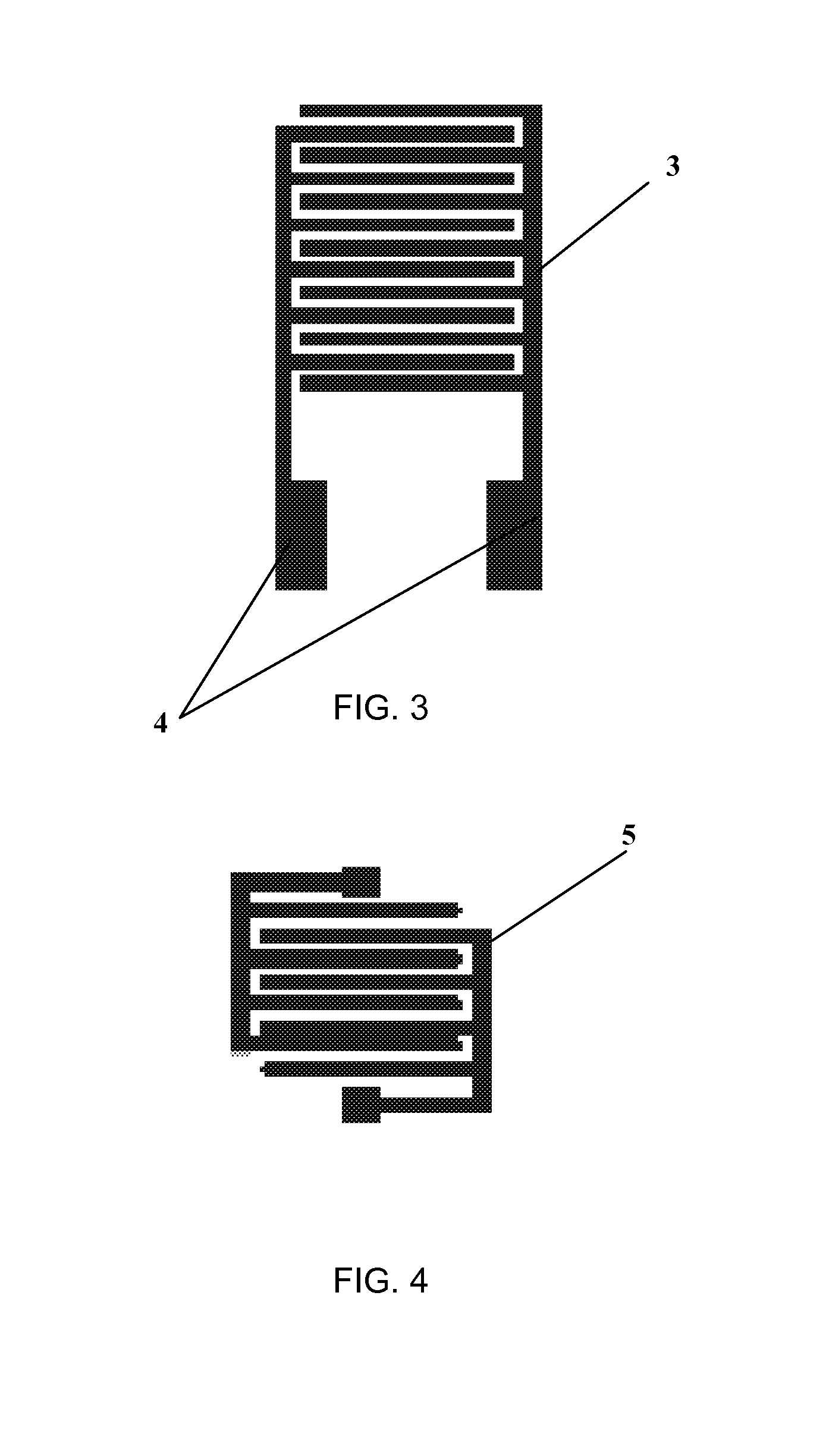

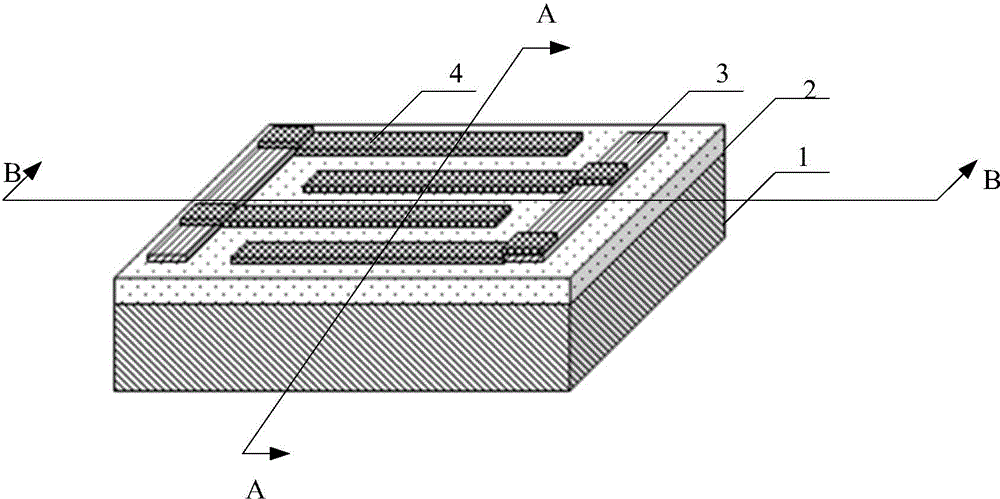

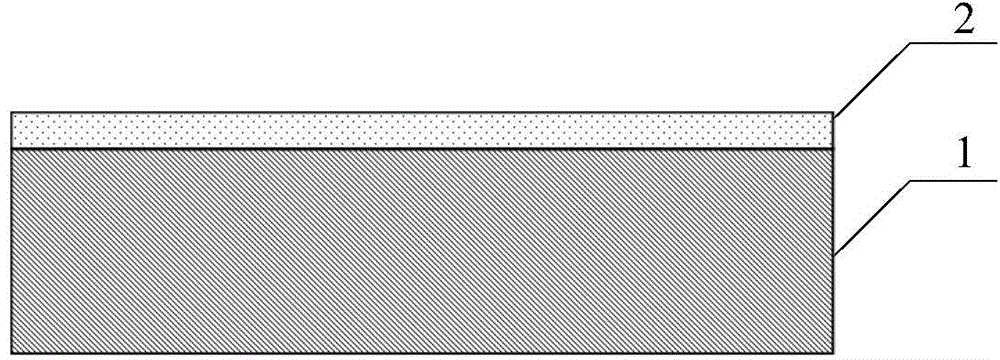

Piezoresistive transducer probe based on electric conduction high molecule sensitivity membrane and preparation method thereof

InactiveCN101354298AImprove adhesionReduce contact resistanceForce measurement using piezo-resistive materialsVulcanizationContact force

The invention relates to a piezoresistive sensor probe based on a conductive polymeric sensitive membrane and a preparation method thereof, pertaining to the technical field of a force sensor. The probe consists of a base, an interdigitated electrode printed on the base and the conductive polymeric sensitive membrane vulcanized on the electrode; the membrane is essentially composed of conductive carbon black as a conductive phase and single-pack room-temperature vulcanized silicone rubber as an insulation phase. The method comprises the steps that: powder of the conductive carbon black and the liquid single-pack room-temperature vulcanized silicone rubber are mixed in an ethane organic solvent; mechanical stirring is carried out in sonic oscillation, and carbon black suspending liquid with even dispersion and good liquidity is produced; a cascade spin coating method is used for coating the suspending liquid on the base provided with the interdigitated electrode to form a conductive polymeric membrane; then packaging and vulcanization are carried out, and the piezoresistive sensor probe is formed. By adopting the method of the invention, sensor probes with thin structure, good flexibility, wide measuring range and high precision can be manufactured and are especially applicable to the online monitoring of contact force and extrusion force between curved surfaces.

Owner:TSINGHUA UNIV

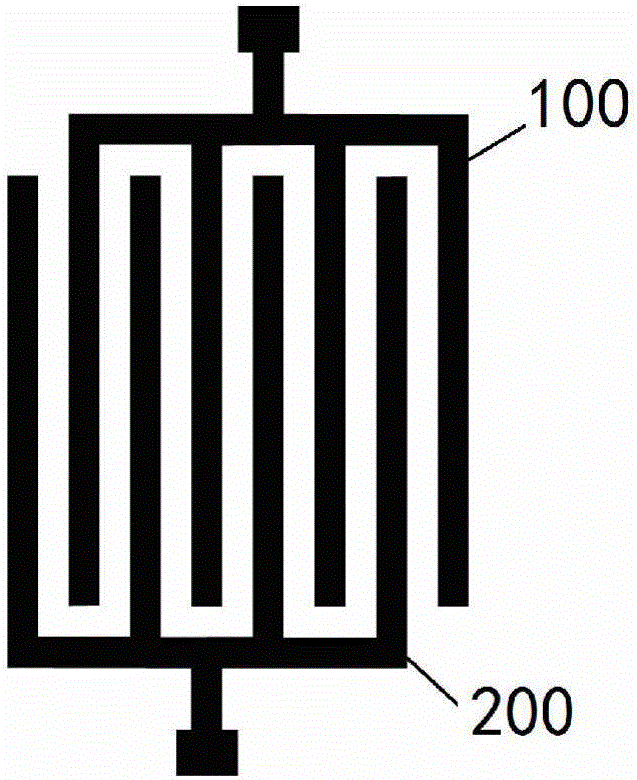

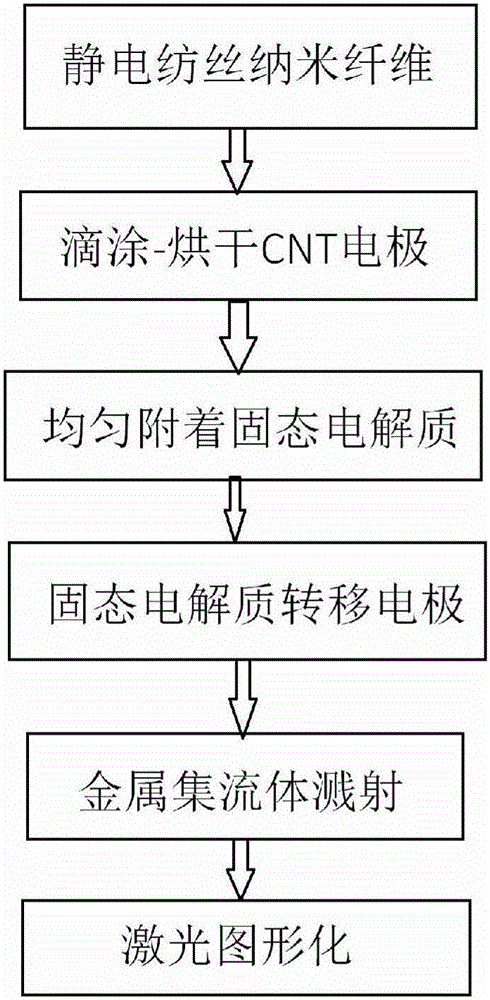

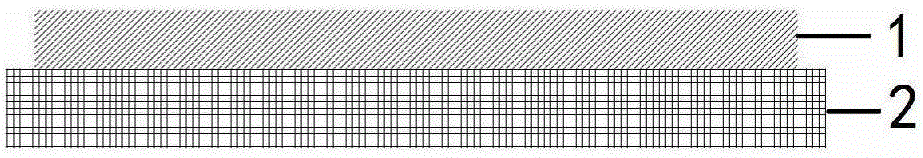

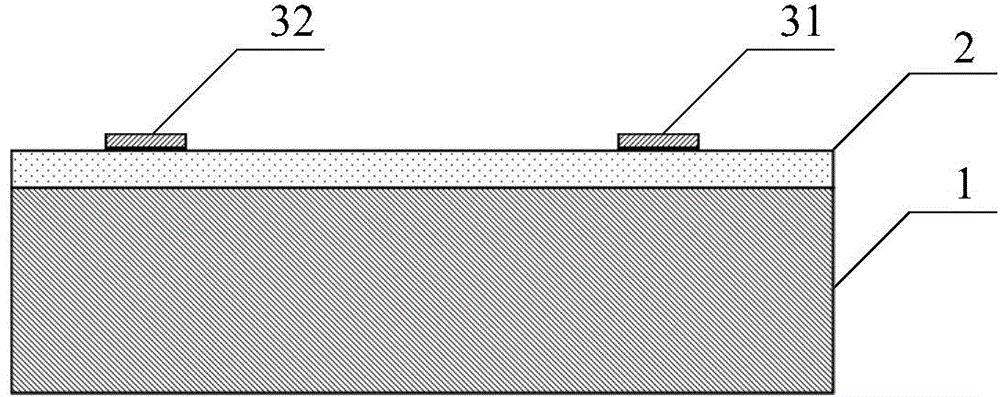

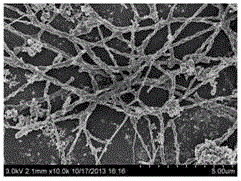

A freestyle miniature supercapacitor based on laser graphics and a manufacturing method thereof

ActiveCN106449134AReduce thicknessSimple structureMaterial nanotechnologyHybrid capacitor electrodesSolid state electrolyteElectrospun nanofiber

A freestyle miniature supercapacitor based on laser graphics and a manufacturing method thereof belong to the technical field of micro-power energy storage. The structure is composed of a solid electrolyte, a flexible electrode and a metal current collector from the bottom up. Carbon nanotubes are dispensed on electrospun nanofibers to obtain the flexible electrode. The present invention proposes the freestyle miniature supercapacitor which uses a planar interdigitated electrode. Compared with a conventional supercapacitor in a sandwich structure, the freestyle miniature supercapacitor has a much lower device thickness, higher device flexibility, and can be better integrated with flexibly electronic devices. Meanwhile, through use of the advantages of the high specific surface area and high conductivity of the electrospun nanofibers and the carbon nanotubess, the light and stable flexible electrode is manufactured to further improve the energy and power density. Compared with other miniature supercapacitors, the freestyle miniature supercapacitor of the invention has the much lower device thickness in a novel electrolyte transfer mode without any additional substrate, and the damage which may be brought for complex transfer technology can be avoided.

Owner:PEKING UNIV

Nanoscale High-Aspect-Ratio Metallic Structure and Method of Manufacturing Same

InactiveUS20110203656A1Improve performanceOvercome problemsSemiconductor/solid-state device detailsSolid-state devicesNanowireGrating

Nanoscale high-aspect-ratio metallic structures and methods are presented. Such structures may form transparent electrode to enhance the performance of solar cells and light-emitting diodes. These structures can be used as infrared control filters because they reflect high amounts of infrared radiation. A grating structure of polymeric bars affixed to a transparent substrate is used. The sides of the bars are coated with metal forming nanowires. Electrodes may be configured to couple to a subset of the rails forming interdigitated electrodes. Encapsulation is used to improve transparency and transparency at high angles. The structure may be inverted to facilitate fabrication of a solar cell or other device on the back-side of the structure. Multiple layered electrodes having an active layer sandwiched between two conductive layers may be used. Layered electro-active layers may be used to form a smart window where the structure is encapsulated between glass to modify the incoming light.

Owner:IOWA STATE UNIV RES FOUND

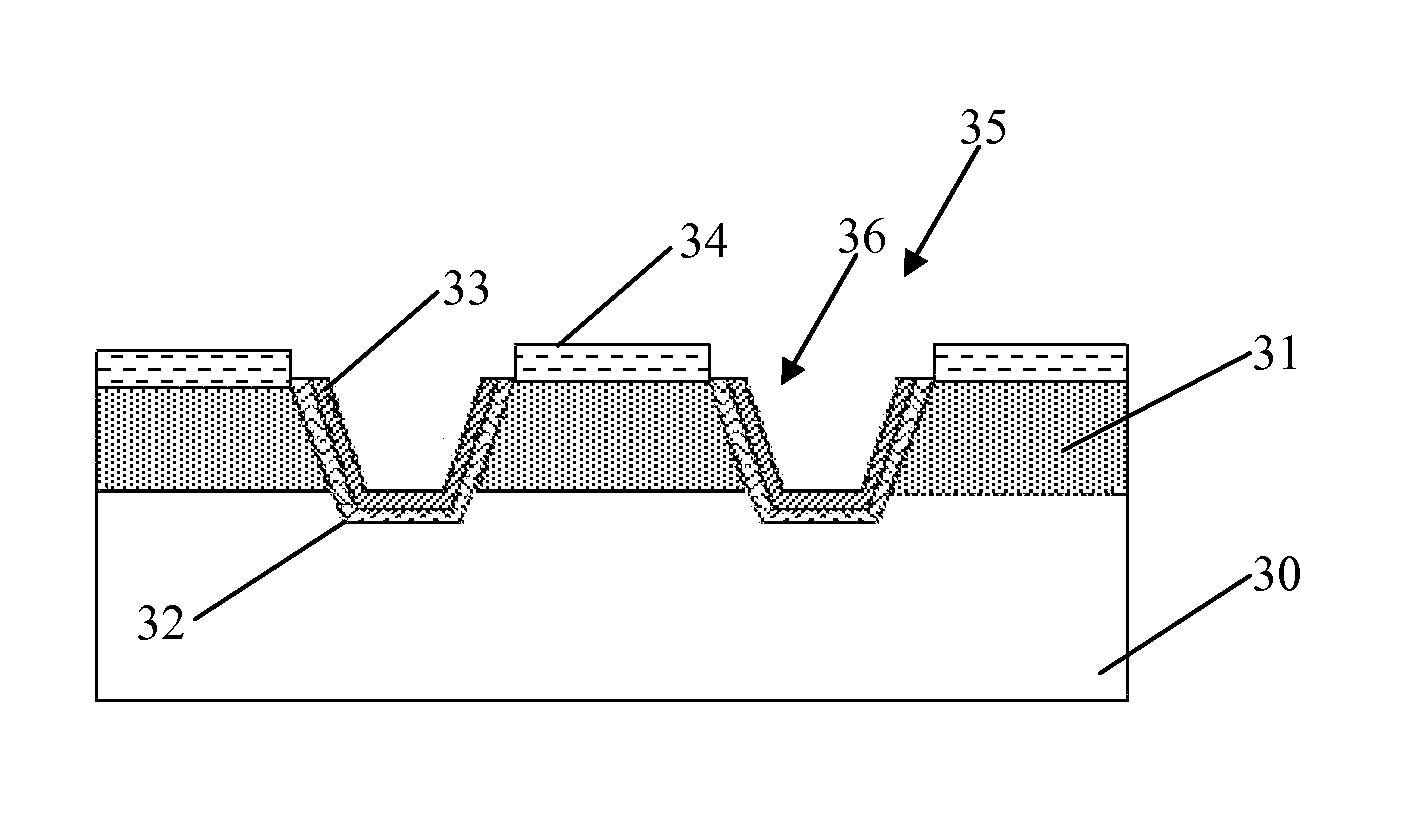

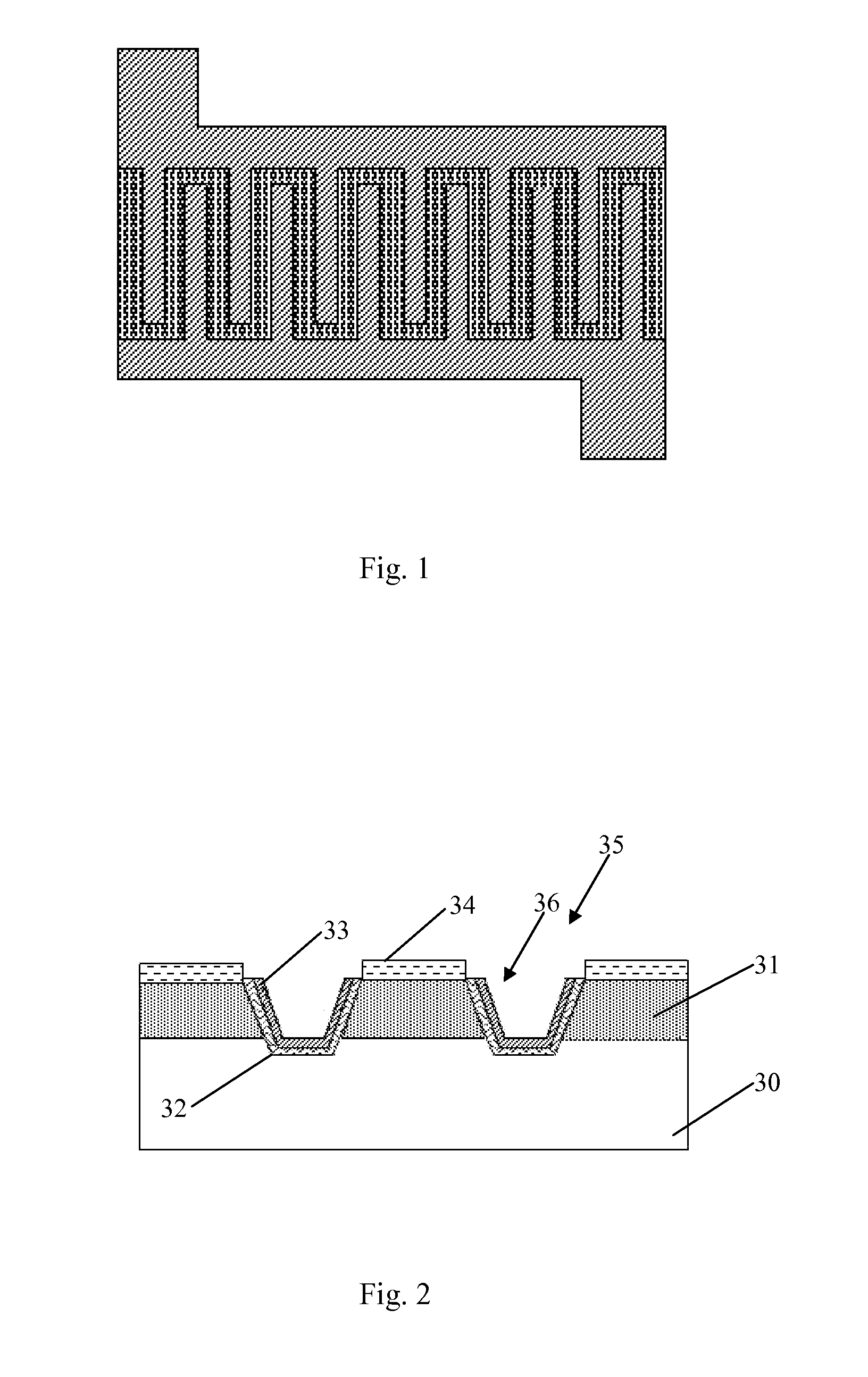

Photoconductive ultraviolet detector and manufacturing method thereof

ActiveCN104810411AIncrease the effective light-receiving areaImprove performanceSemiconductor devicesSilicon oxideInterdigitated electrode

The invention provides a photoconductive ultraviolet detector and a manufacturing method thereof. The photoconductive ultraviolet detector is composed of an insulating substrate, an ultraviolet sensitive film, metal electrodes and graphene transparent interdigitated electrodes sequentially from bottom to top. The insulating substrate can be a quartz glass sheet or a silicon wafer, wherein an insulating medium such as silicon oxide or silicon nitride is grown or deposited on the surface of the silicon wafer. The ultraviolet sensitive film is made of a film material chosen from gallium nitride, aluminum-doped gallium nitride, zinc oxide, magnesium-doped zinc oxide, silicon carbide and diamond. The strip-shaped metal electrodes are made of gold or platinum. The graphene transparent interdigitated electrodes cover the ultraviolet sensitive film and the metal electrodes. By adopting the graphene transparent interdigitated electrodes instead of metal interdigitated electrodes, the ultraviolet radiation transmittance of the detector is high, and the performance of the device is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

An ethanol sensor based on a zinc oxide nanometer structure and a preparing method thereof

ActiveCN104698041AHigh sensitivityShort response timeMaterial resistanceEthanol absorptionResponsivity

An ethanol sensor based on a zinc oxide nanometer structure and a preparing method thereof are provided. The ethanol sensor comprises two electrode groups forming an interdigitated electrode and a zinc oxide nanometer film on at least one side surface of the interdigitated electrode. The zinc oxide nanometer film is formed by zinc oxide nanowires having a hexagonal wurtzite crystal phase. The two electrode groups of the interdigitated electrode are not conducted and form signal output ends of the ethanol sensor. The ethanol sensor can sense resistance reduction on the zinc oxide surface caused by ethanol absorption. The responsivity of the ethanol sensor is in approximate linear variation with the concentration of added ethanol gas in the environment.

Owner:纳米新能源生命科技(唐山)有限责任公司

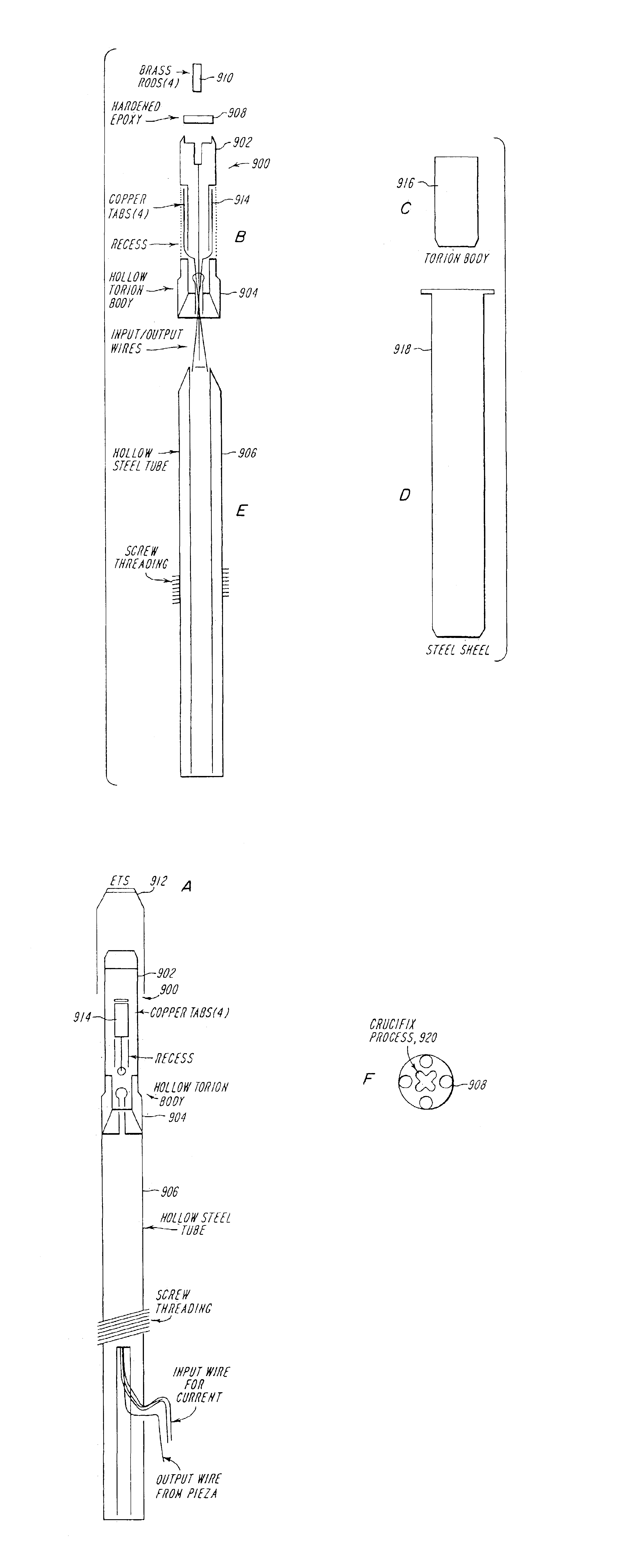

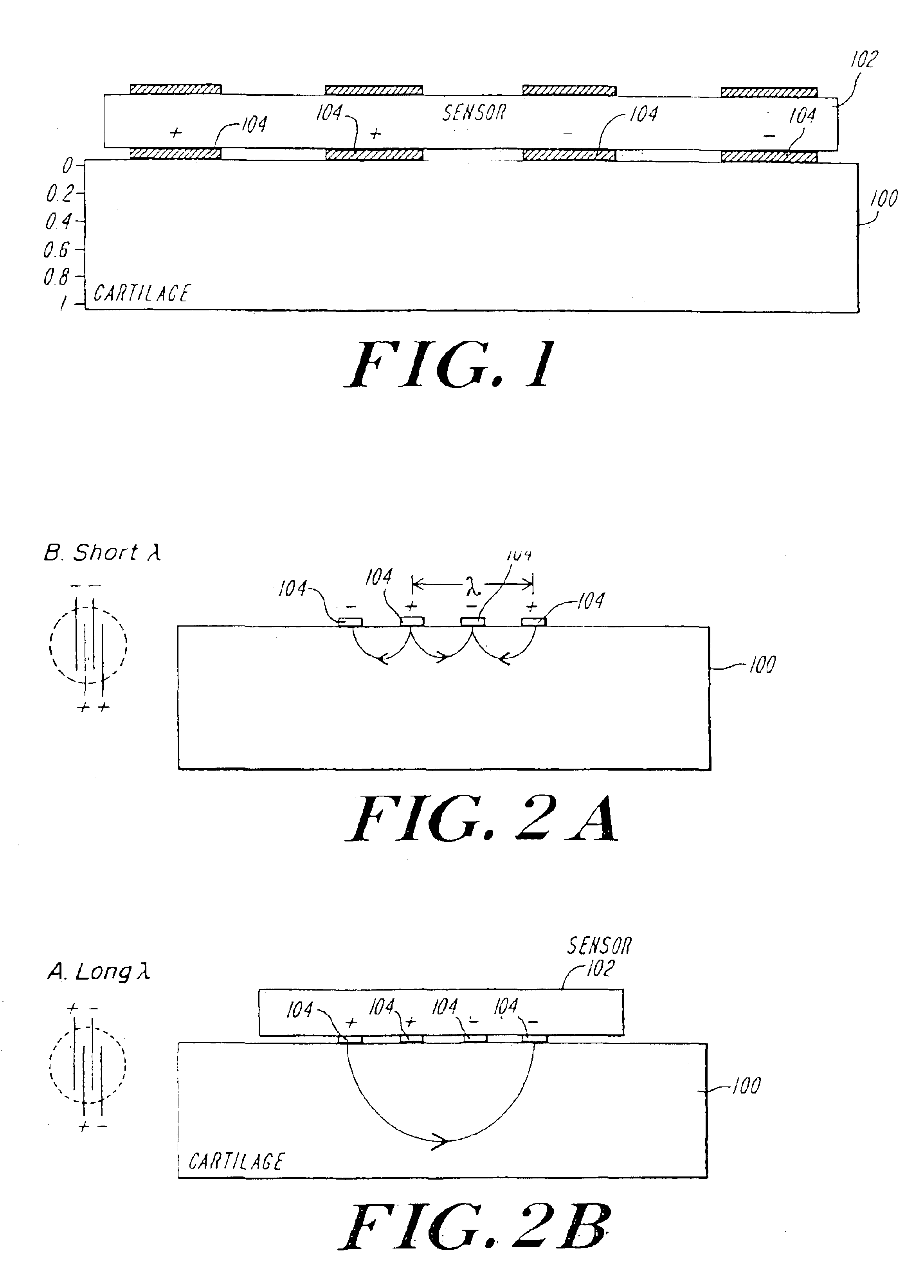

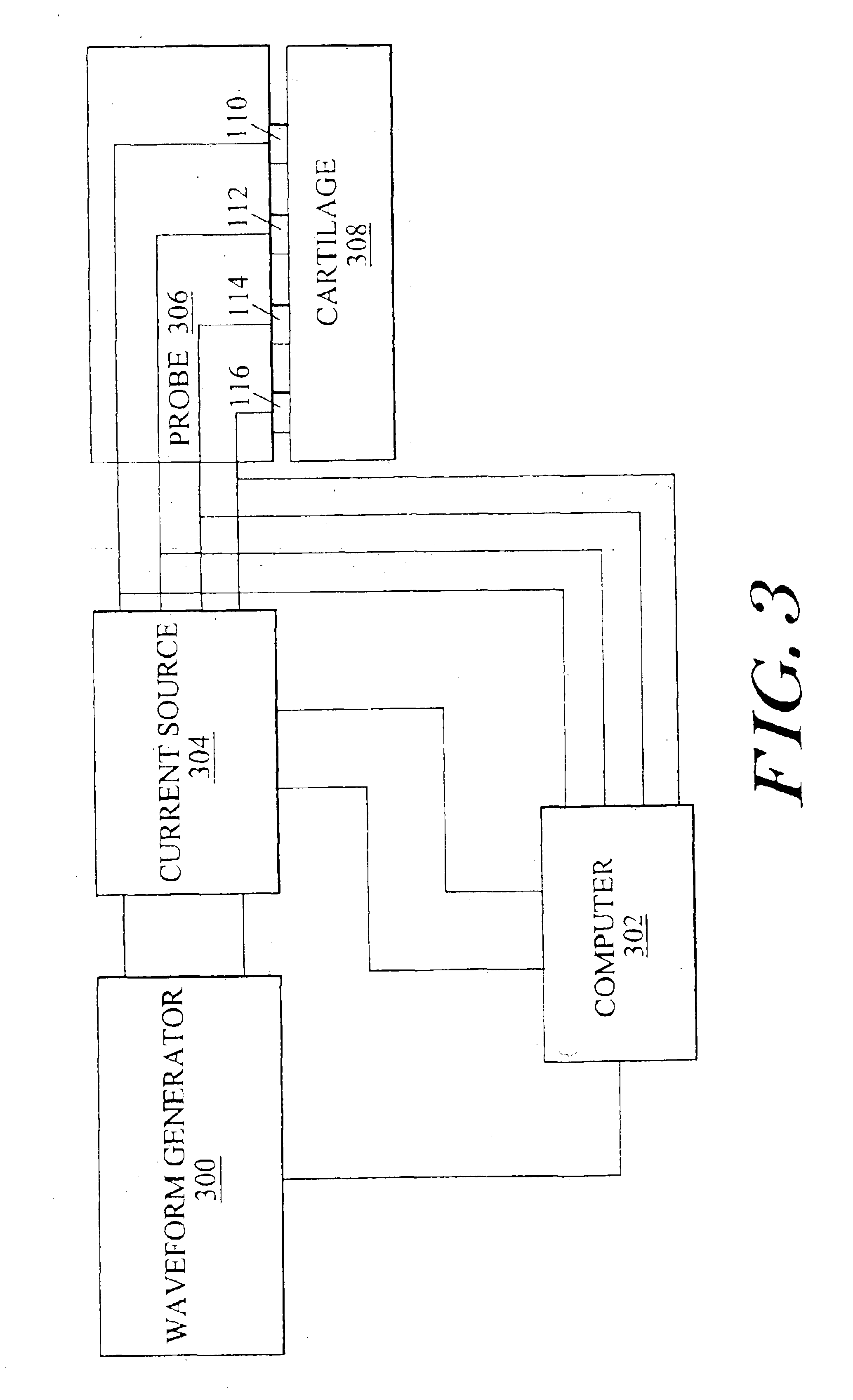

Arthroscopic impedance probe to detect cartilage degeneration

InactiveUS6856834B2Modulus is reducedHigh inflation pressureStrain gaugePerson identificationCell-Extracellular MatrixECM Protein

The change in tissue impedance due to the change in the extracellular matrix that results from the degradation of cartilage is utilized to detect degradation of articular cartilage. A probe comprising electrodes is applies a current to the articular cartilage which results in a current distribution and electric field within the cartilage, along with an associated voltage drop across the electrodes. The amplitude of this voltage drop is then measured and divided by the current applied to determine the tissue impedance. By measuring the impedance of patient tissue and comparing the detected patient impedance to a normal value for the tissue from clinically normal tissue, a determination of whether the patient tissue is degraded and the extent of degradation is possible. Preferably, the impedance is measured using a probe with interdigitated electrodes. By changing which electrodes are utilized, the wavelength of the current distribution changes, allowing the probe to image depth dependent focal lesions.

Owner:MASSACHUSETTS INST OF TECH

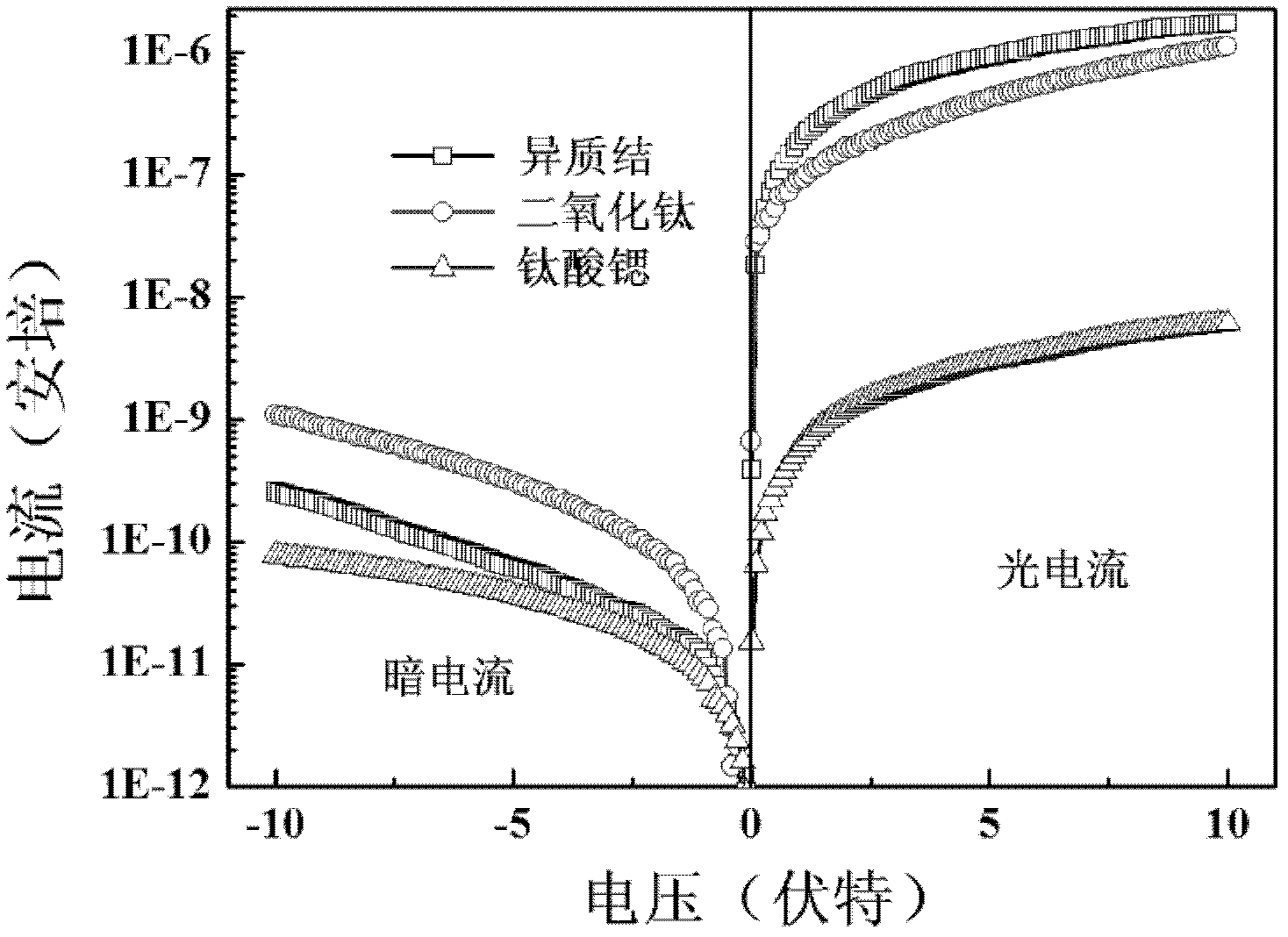

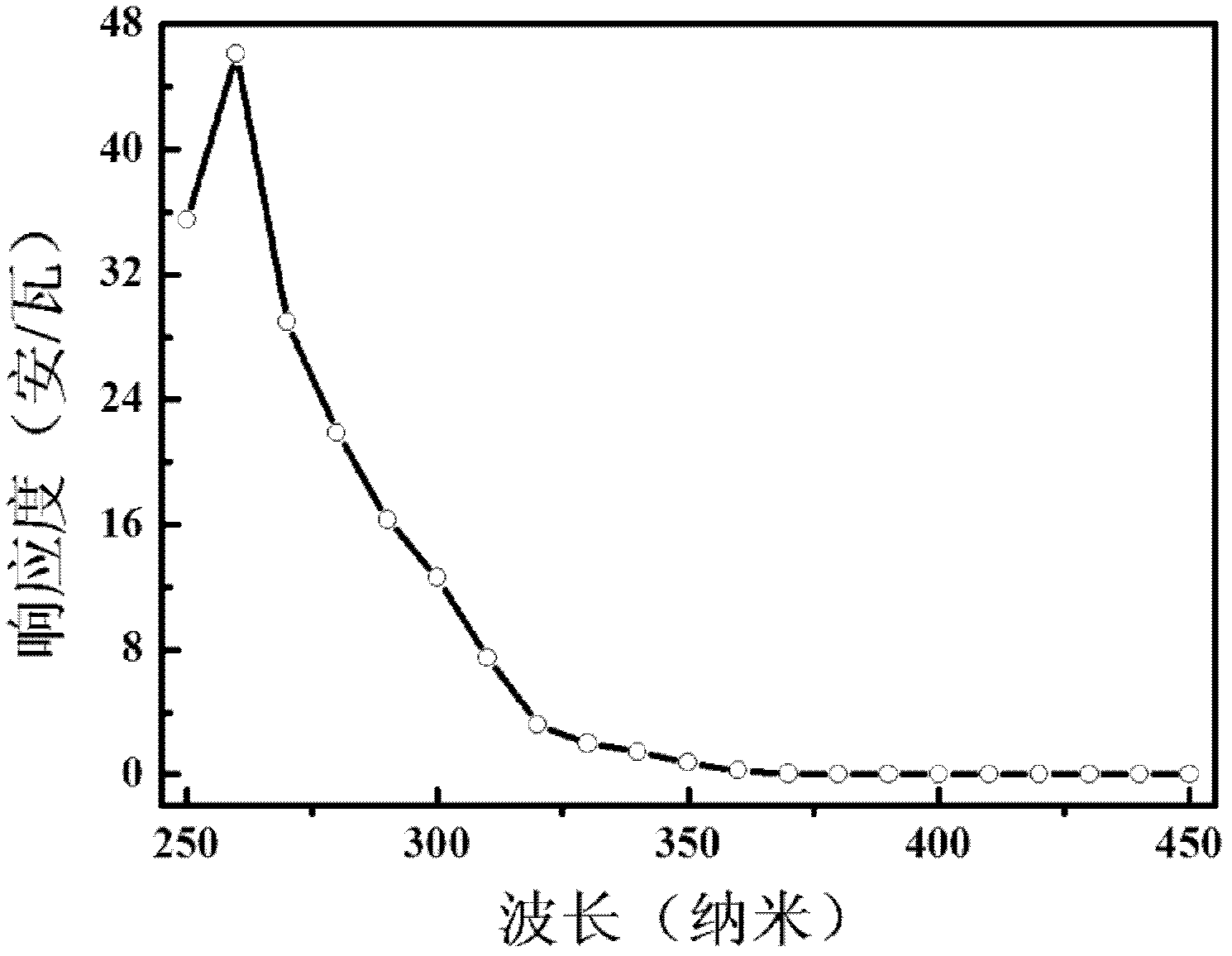

Ultraviolet detector based on titanium dioxide/strontium titanate heterojunction and preparation method

InactiveCN102509743AFree yourself from the lack of suitable substratesSimple processFinal product manufactureSemiconductor devicesHeterojunctionHYDROSOL

The invention particularly relates to a high-performance semiconductor ultraviolet photoelectric detector and a preparation method thereof, wherein for the high-performance semiconductor ultraviolet photoelectric detector, an ultra-thin silicon chip is used as a substrate, a nano TiO2 / SrTiO3 heterojunction active layer is used as a base material, and Au is used as a metal interdigitated electrode. The preparation method comprises the following steps of: preparing a TiO2 and SrTiO3 sol by adopting a sol-gel technology, and growing a compact nano SrTiO3 film and a compact TiO2 film in order on the ultra-thin silicon substrate; and preparing the Au interdigitated electrode with a certain shape on the surface of the films through adoption of a magnetron sputtering technology and a standard photoetching and stripping technology. The TiO2 / SrTiO3 heterojunction metal-semiconductor-metal ultraviolet detector prepared with the preparation method disclosed by the invention has the characteristics of simple preparation method, low cost and potentiality in large-scale production, and has a good detection performance for detecting ultraviolet rays of which the wavelength is 250-350 nm.

Owner:JILIN UNIV

Black silicon based metal-semiconductor-metal photodetector

ActiveUS20120012967A1Design complexProcess complexFinal product manufactureSemiconductor/solid-state device manufacturingPhotodetectorInterdigitated electrode

A black silicon based metal-semiconductor-metal photodetector includes a silicon substrate and a black silicon layer formed on the silicon substrate. An interdigitated electrode pattern structure is formed on the black silicon layer, which can be a planar or U-shaped structure. A thin potential barrier layer is deposited at the interdigitated electrode pattern structure. An Al or transparent conductive ITO thin film is deposited on the thin potential barrier layer. A passivation layer is provided on the black silicon layer. In the black silicon based metal-semiconductor-metal photodetector, the black silicon layer, as a light-sensitive area, can respond to ultraviolet, visible and near infrared light.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Gradient piezoelectric fiber composite material and preparation method thereof

ActiveCN105405963AGood flexibilityExcellent piezoelectric driving characteristicsPiezoelectric/electrostrictive device manufacture/assemblyFiberPliability

The invention discloses a gradient piezoelectric fiber composite material, which comprises two interdigitated electrodes, piezoelectric fibers and a high-molecular polymer, wherein the volume percent of the piezoelectric fibers is 45%-90%; and the volume percent of the high-molecular polymer is 10%-55%; the piezoelectric fibers and the high-molecular polymer are alternately arranged; and the volume fraction of the single piezoelectric fiber is in a continuous gradient change along with the transverse direction of the gradient piezoelectric fiber composite material. The gradient piezoelectric fiber composite material disclosed by the invention has high flexibility and excellent piezoelectric drive characteristic; the continuously changing drive deformation capacity can be provided in the transverse direction of the composite material; and the gradient piezoelectric fiber composite material integrates the piezoelectric fibers, the polymer and the interdigitated electrodes into a whole, and is high in integration level and convenient to operate and use. In addition, the gradient piezoelectric fiber composite material is prepared by a cutting-filling method, and is simple in process, low in cost, short in production cycle and stable in product performance.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com