Piezoresistive transducer probe based on electric conduction high molecule sensitivity membrane and preparation method thereof

A technology of conductive polymers and sensor probes, applied in the field of force sensors, can solve the problems of no quantitative accuracy and resolution, no practical application, etc., and achieve large range, improved repeatability, high force sensitivity accuracy and resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

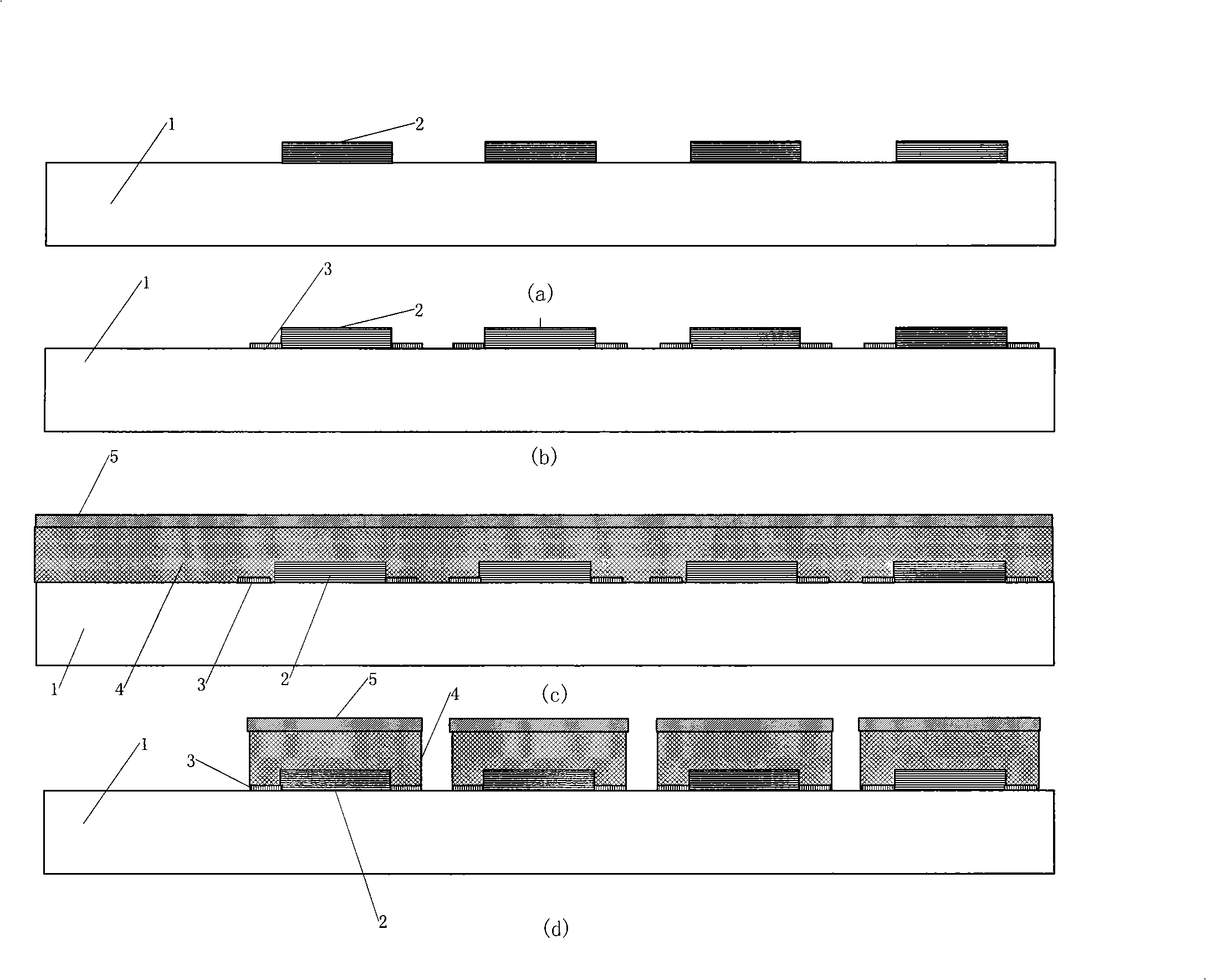

Method used

Image

Examples

Embodiment 1

[0047] a. Rinse the substrate printed with interdigitated electrodes successively in 95% methanol solution and deionized water to remove organic pollutants, and blow dry in dry air or nitrogen;

[0048] b. Spray the surface treatment agent SAD-5 special surface treatment agent for silicone rubber on both sides of the electrode area, and dry for 0.5 hours for later use;

[0049] c. Mix conductive carbon black powder with an average diameter of 0.02 μm, coupling agent vinyltriethoxysilane and liquid one-component room temperature vulcanized silicone rubber in n-hexane organic solvent; wherein, the mass ratio of each component is: Components RTV silicone rubber: conductive carbon black powder: coupling agent vinyltriethoxysilane: n-hexane organic solvent = 100:1:1:300;

[0050] d. Perform mechanical stirring under ultrasonic vibration, the temperature of the stirring environment is 30°C, and the stirring time is 2 hours to prepare a suspension of carbon black and room temperature...

Embodiment 2

[0057] a. Rinse the substrate printed with interdigitated electrodes successively in 95% methanol solution and deionized water to remove organic pollutants, and blow dry in dry air or nitrogen;

[0058] b. Spray the surface treatment agent on both sides of the electrode area and let it dry for 2 hours before use;

[0059] c. Mix conductive carbon black powder with an average diameter of 0.04 μm, coupling agent vinyltriethoxysilane and liquid one-component room temperature vulcanized silicone rubber in n-hexane organic solvent; wherein, the mass ratio of each component is: Components RTV silicone rubber: conductive carbon black powder: coupling agent vinyltriethoxysilane: n-hexane organic solvent = 100:5:2:400;

[0060] d. Perform mechanical stirring under ultrasonic vibration, the temperature of the stirring environment is 40°C, and the stirring time is 3 hours to prepare a suspension of carbon black and room temperature vulcanized silicone rubber, and ensure that the suspensi...

Embodiment 3

[0067] a. Rinse the substrate printed with interdigitated electrodes successively in 95% methanol solution and deionized water to remove organic pollutants, and blow dry in dry air or nitrogen;

[0068] b. Spray the surface treatment agent on both sides of the electrode area and let it dry for 1 hour for later use;

[0069] c. Mix conductive carbon black powder with an average diameter of 0.1 μm, coupling agent and liquid one-component room temperature vulcanized silicone rubber in n-hexane organic solvent; wherein, the mass ratio of each component is: one component room temperature vulcanized silicone rubber: Conductive carbon black powder: coupling agent vinyltriethoxysilane: n-hexane organic solvent=100:15:2:500;

[0070] d. Perform mechanical stirring under ultrasonic vibration, the temperature of the stirring environment is 60 ° C, and the stirring time is 4 hours to prepare a suspension of carbon black and room temperature vulcanized silicone rubber, and ensure that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com