Patents

Literature

266 results about "Particle contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Particle contamination is a common problem with airguns. It's one of the primary causes of valve leaks. It can also cause regulators to fail. Components should be checked before installation to make sure they're free of potentially damaging particles.

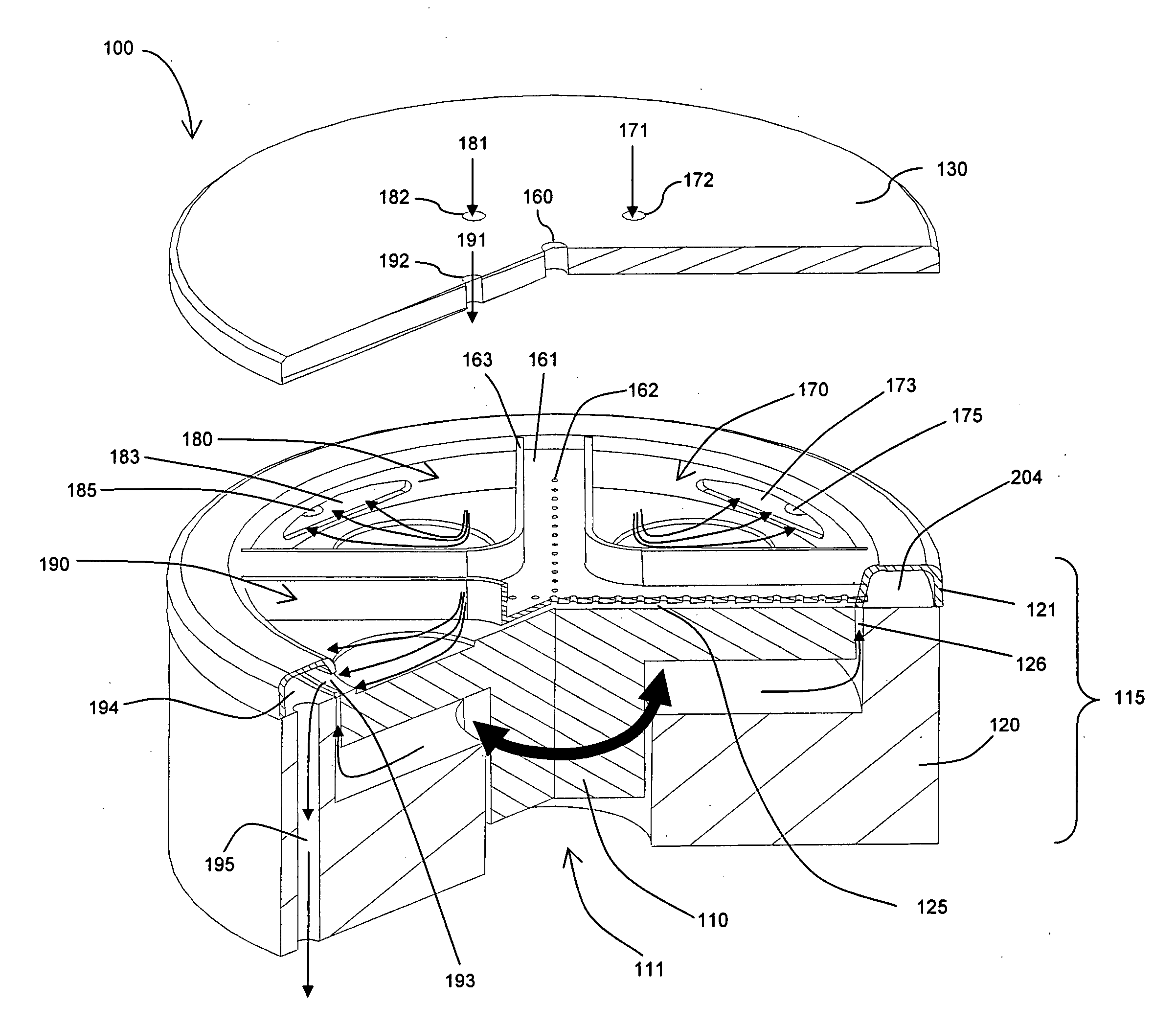

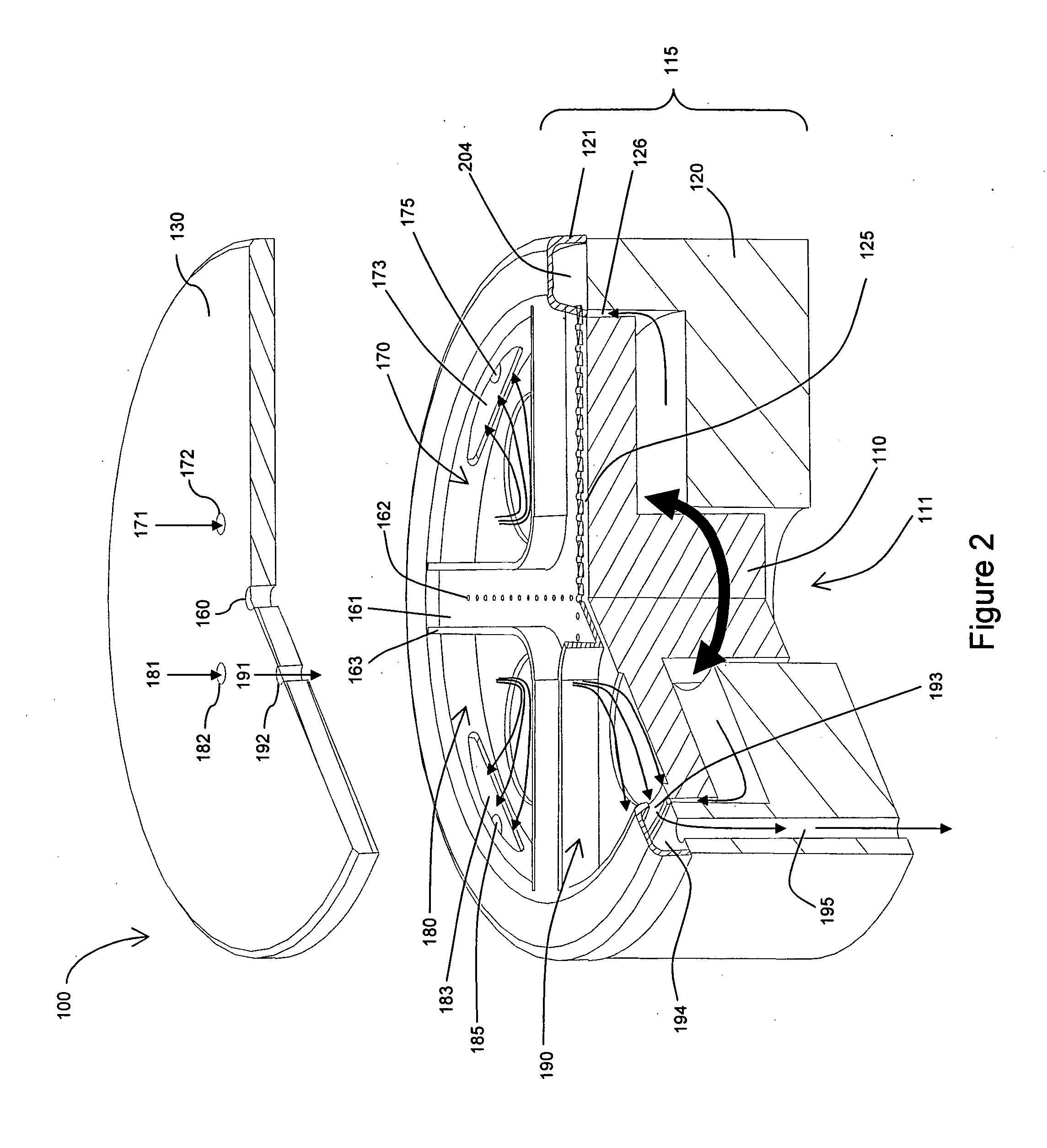

Exhaust apparatus configured to reduce particle contamination in a deposition system

InactiveUS7740705B2Reduce pollutionUniform processingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseEngineering

Owner:TOKYO ELECTRON LTD

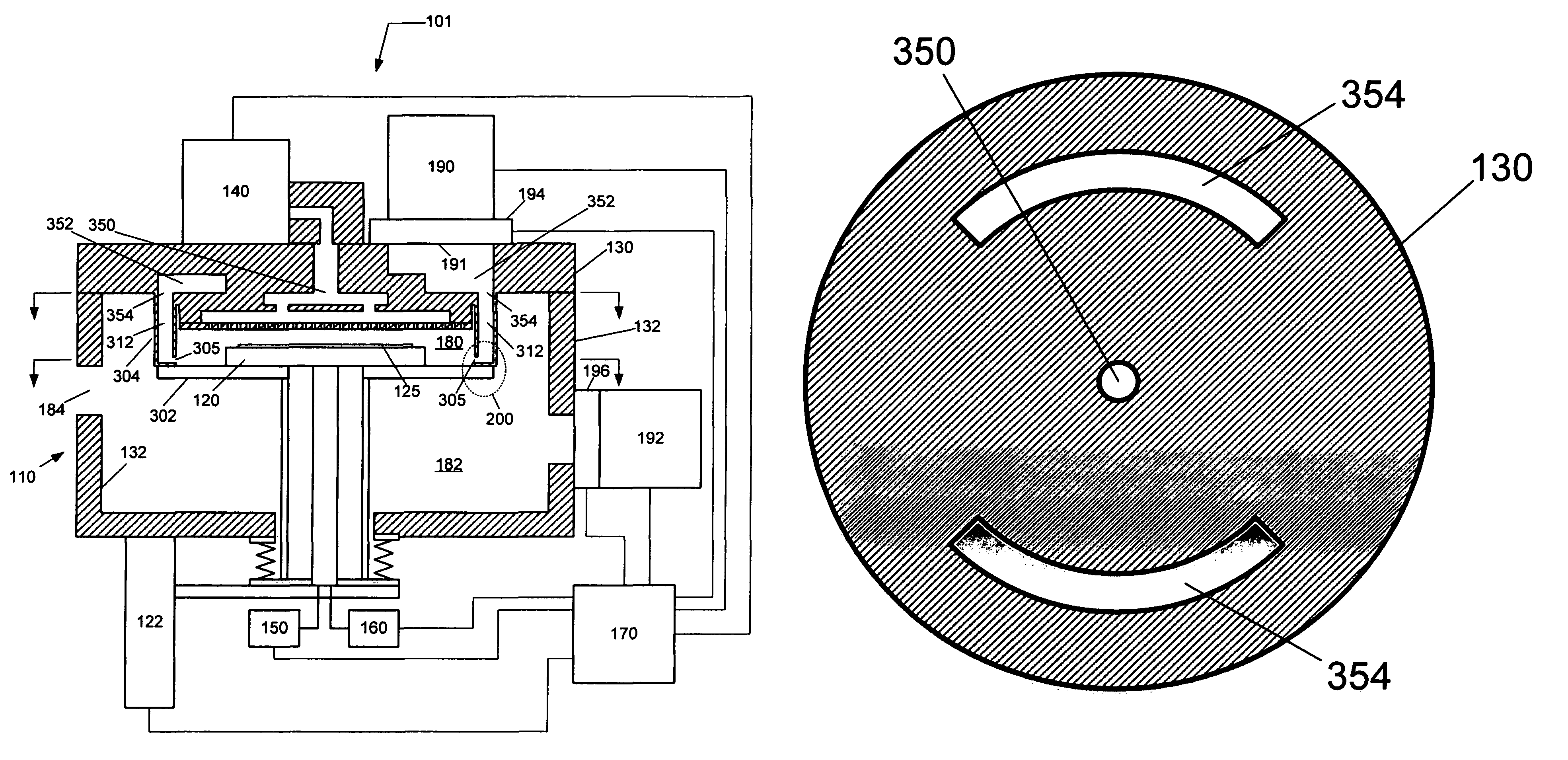

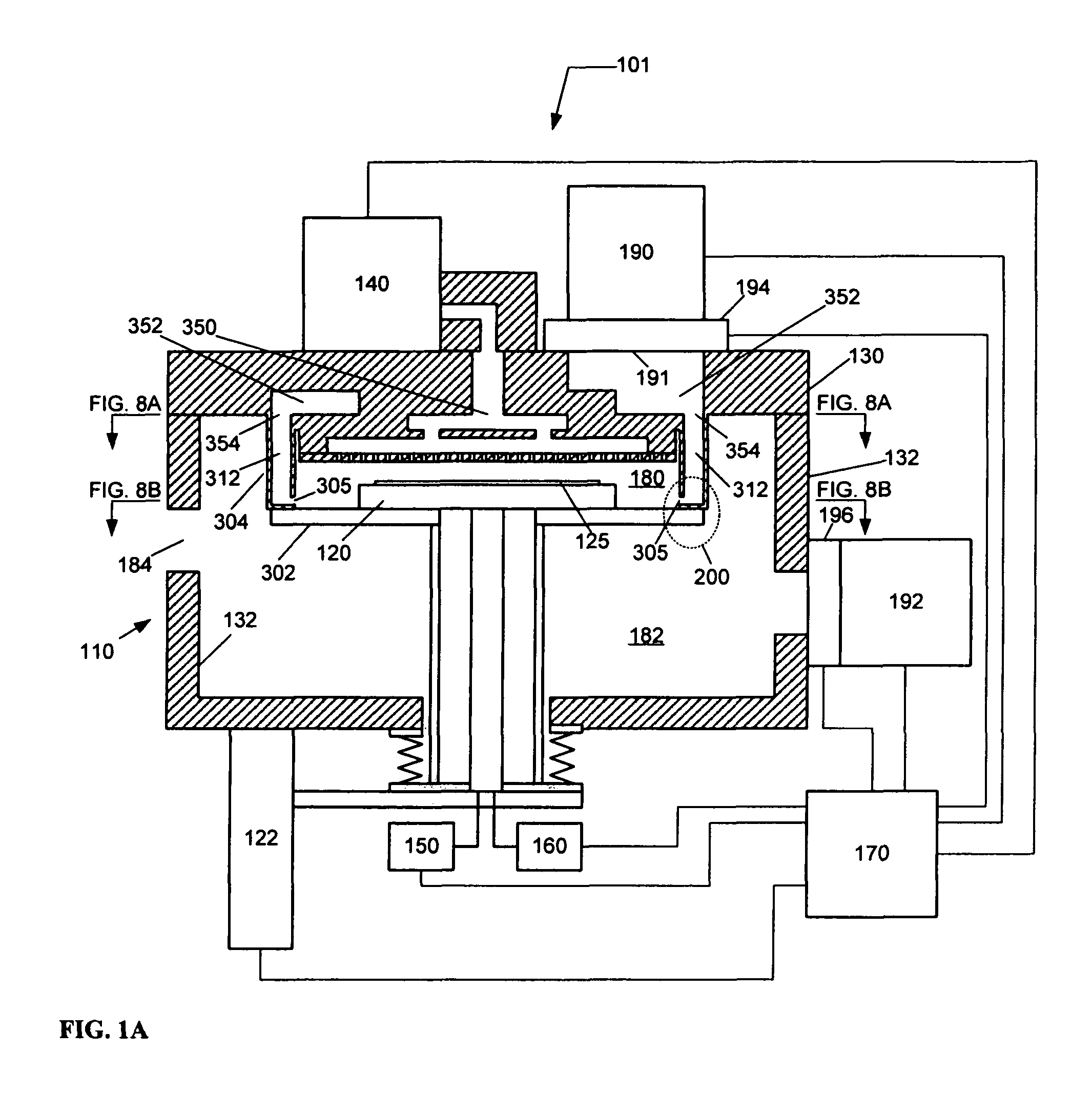

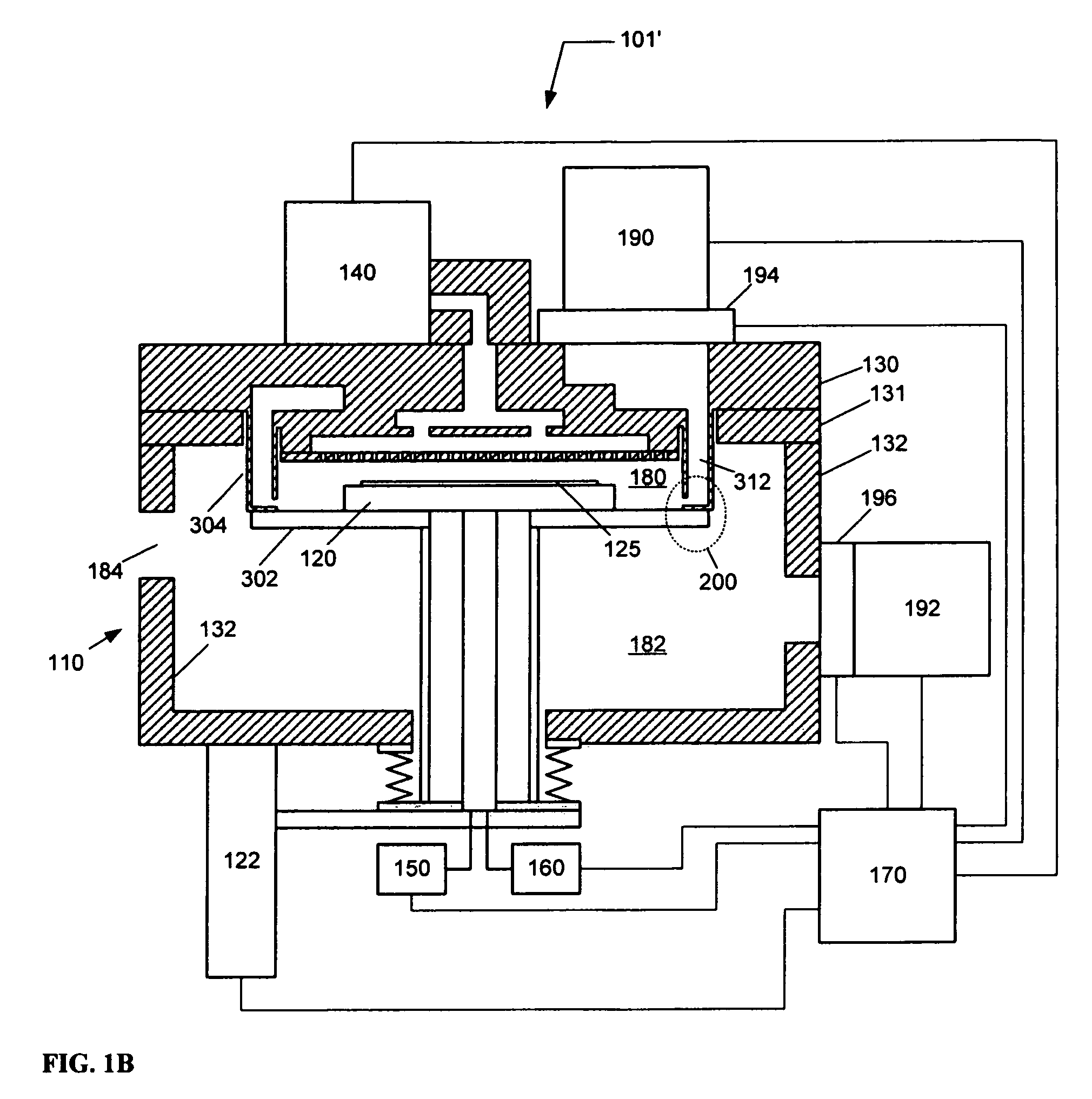

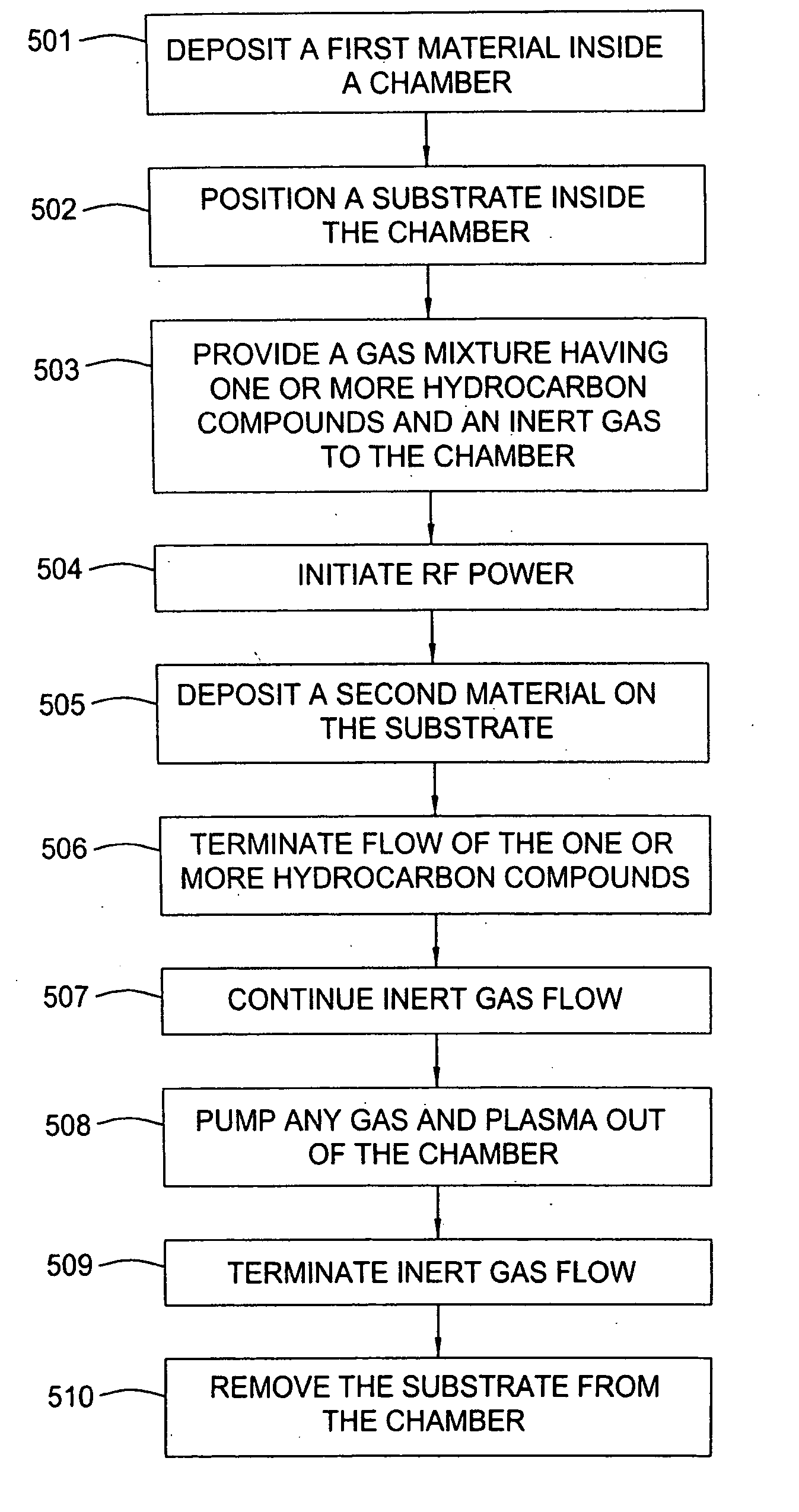

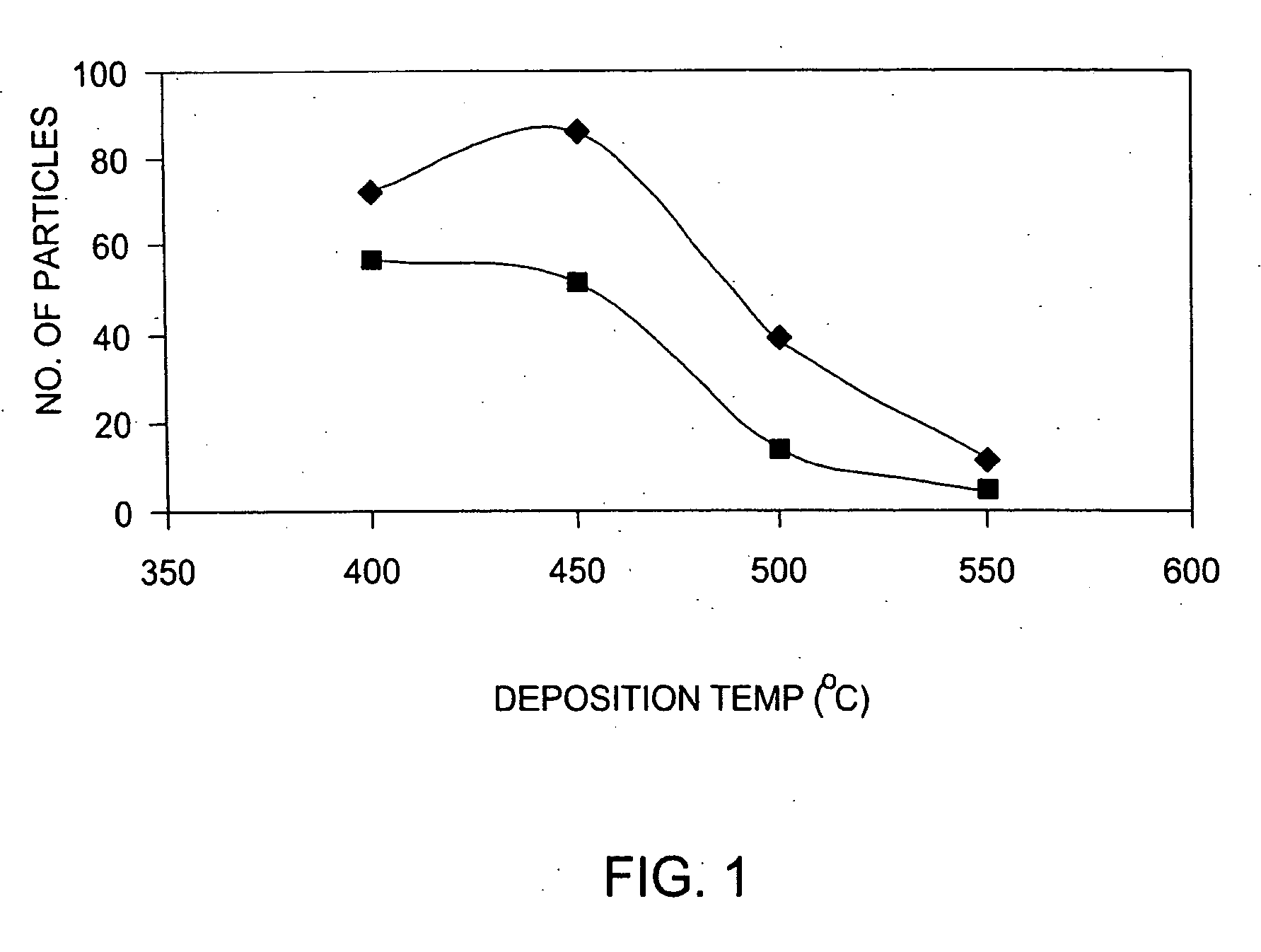

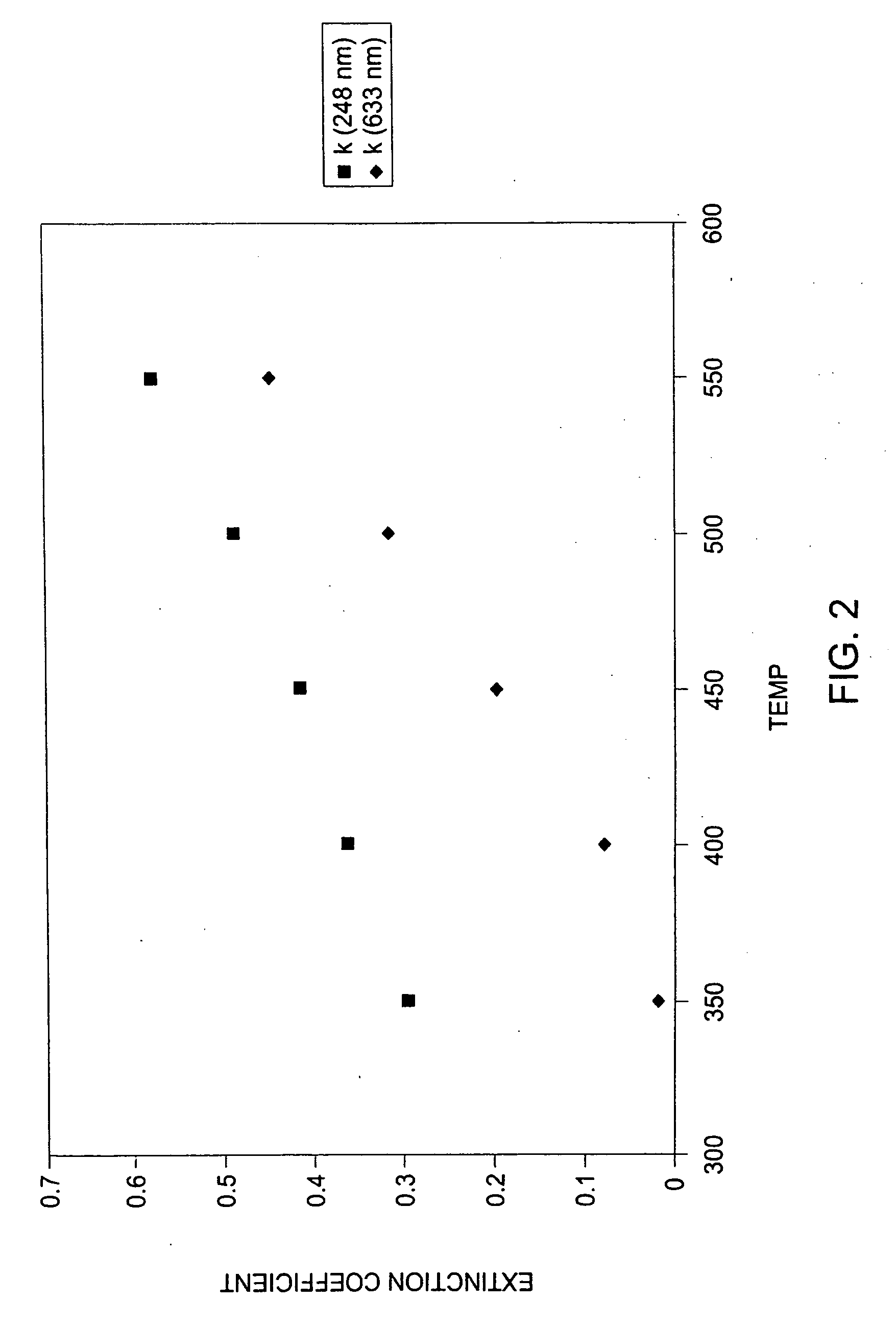

Methods for the reduction and elimination of particulate contamination with CVD of amorphous carbon

InactiveUS20060014397A1Minimal defect formationReduce particle pollutionSemiconductor/solid-state device manufacturingSpecial surfacesVariable thicknessMicroparticle

A method is provided for forming an amorphous carbon layer, deposited on a dielectric material such as oxide, nitride, silicon carbide, carbon doped oxide, etc., or a metal layer such as tungsten, aluminum or poly-silicon. The method includes the use of chamber seasoning, variable thickness of seasoning film, wider spacing, variable process gas flows, post-deposition purge with inert gas, and post-deposition plasma purge, among others, to make the deposition of an amorphous carbon film at low deposition temperatures possible without any defects or particle contamination.

Owner:APPLIED MATERIALS INC +1

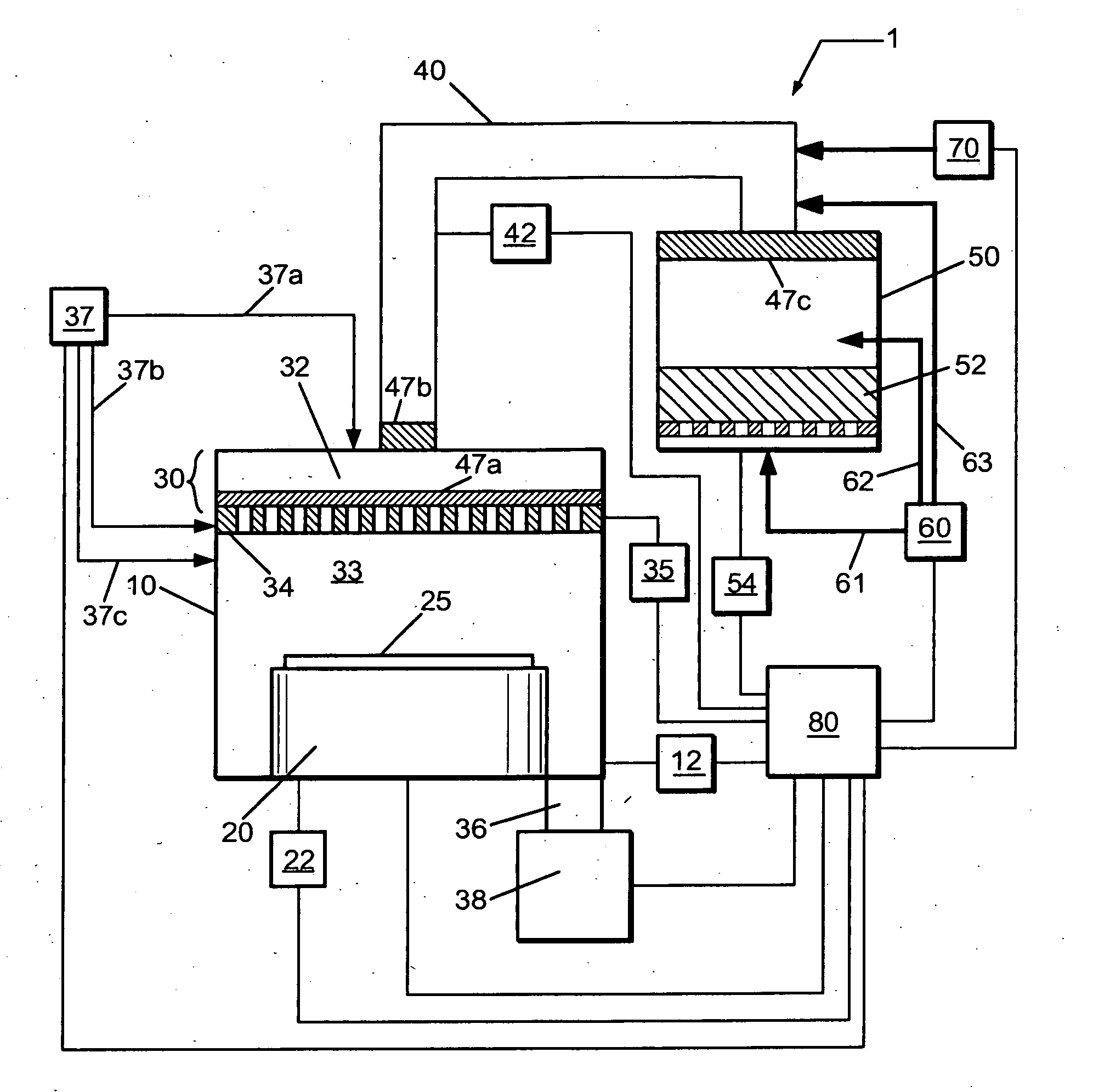

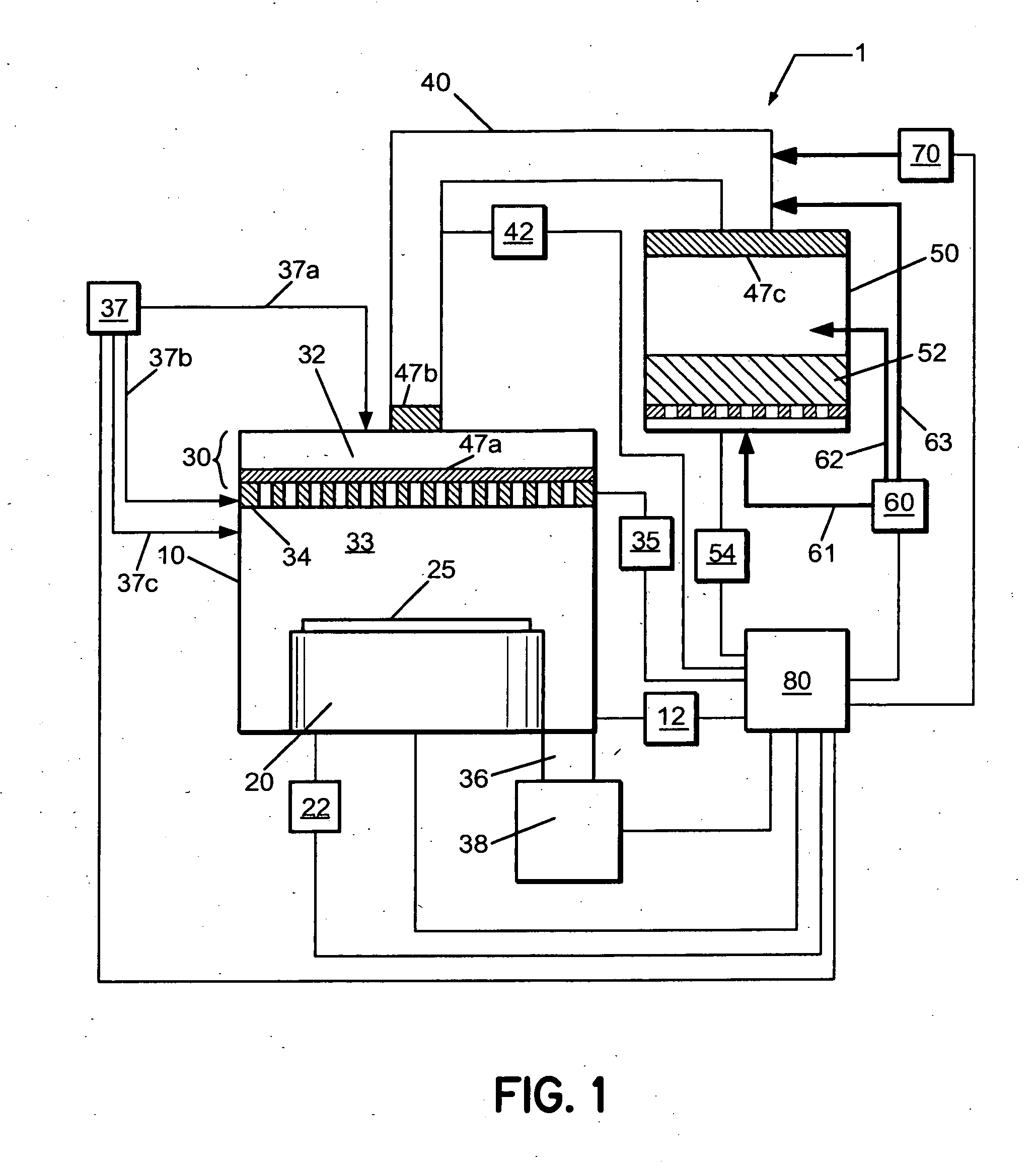

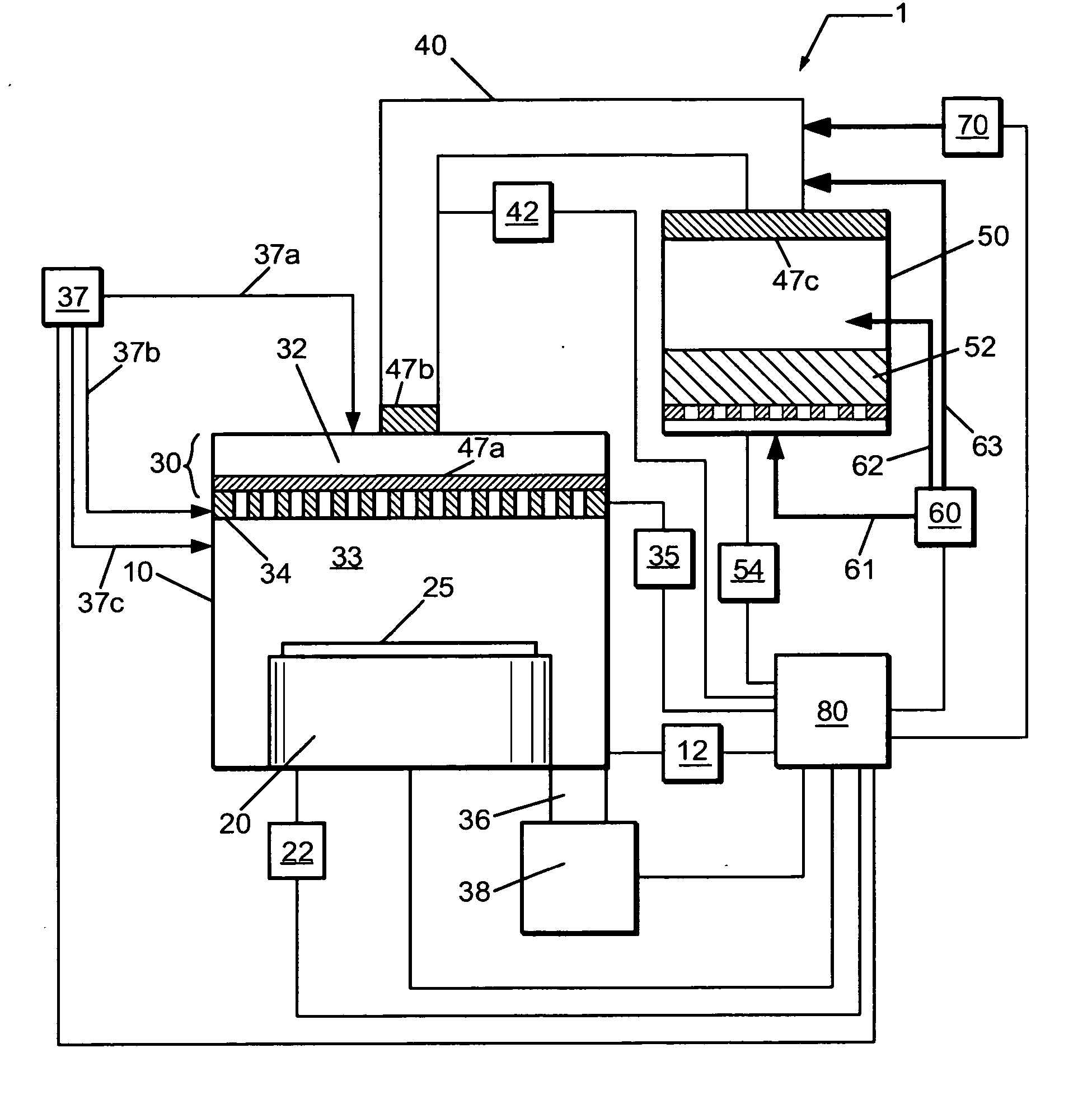

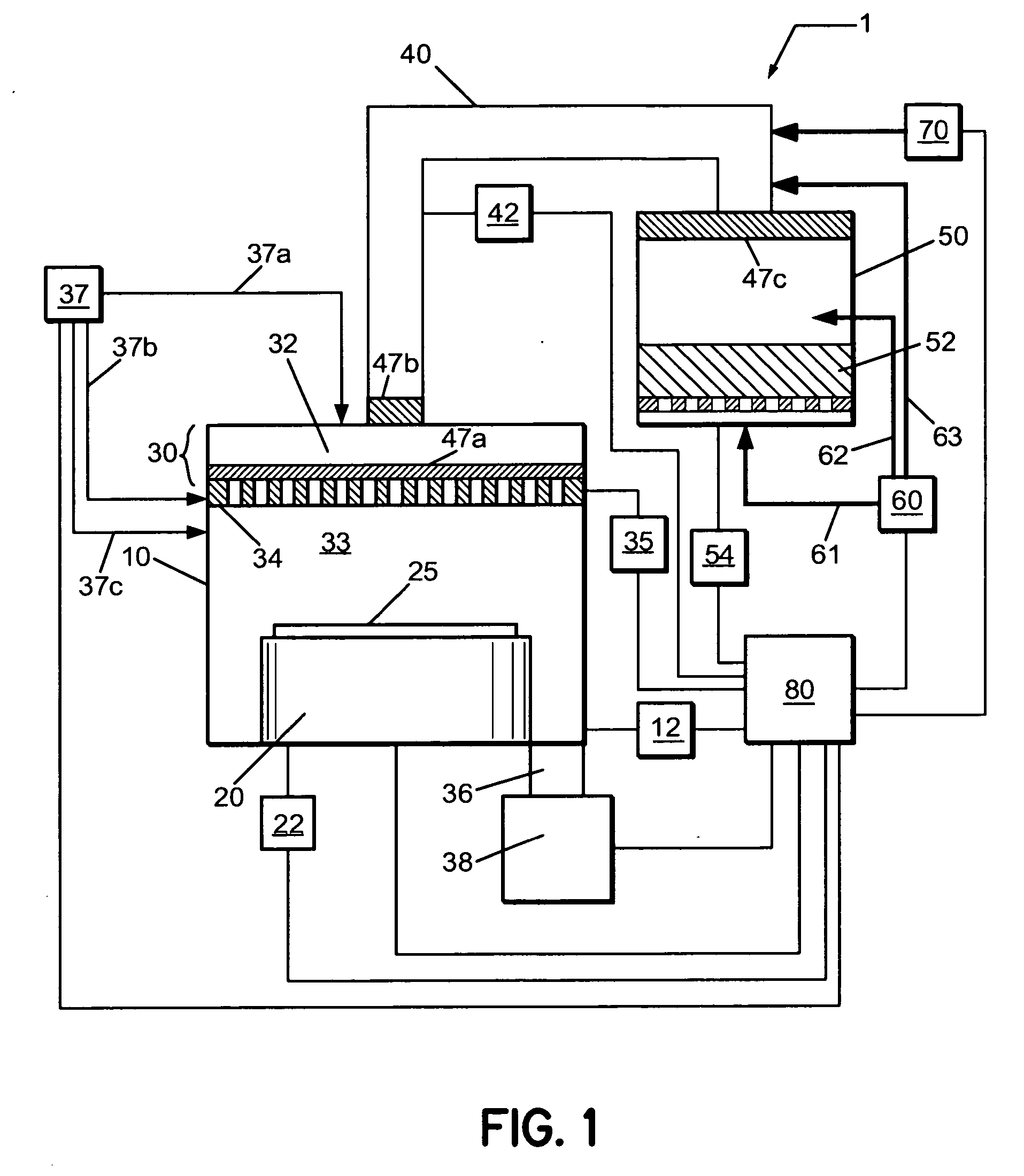

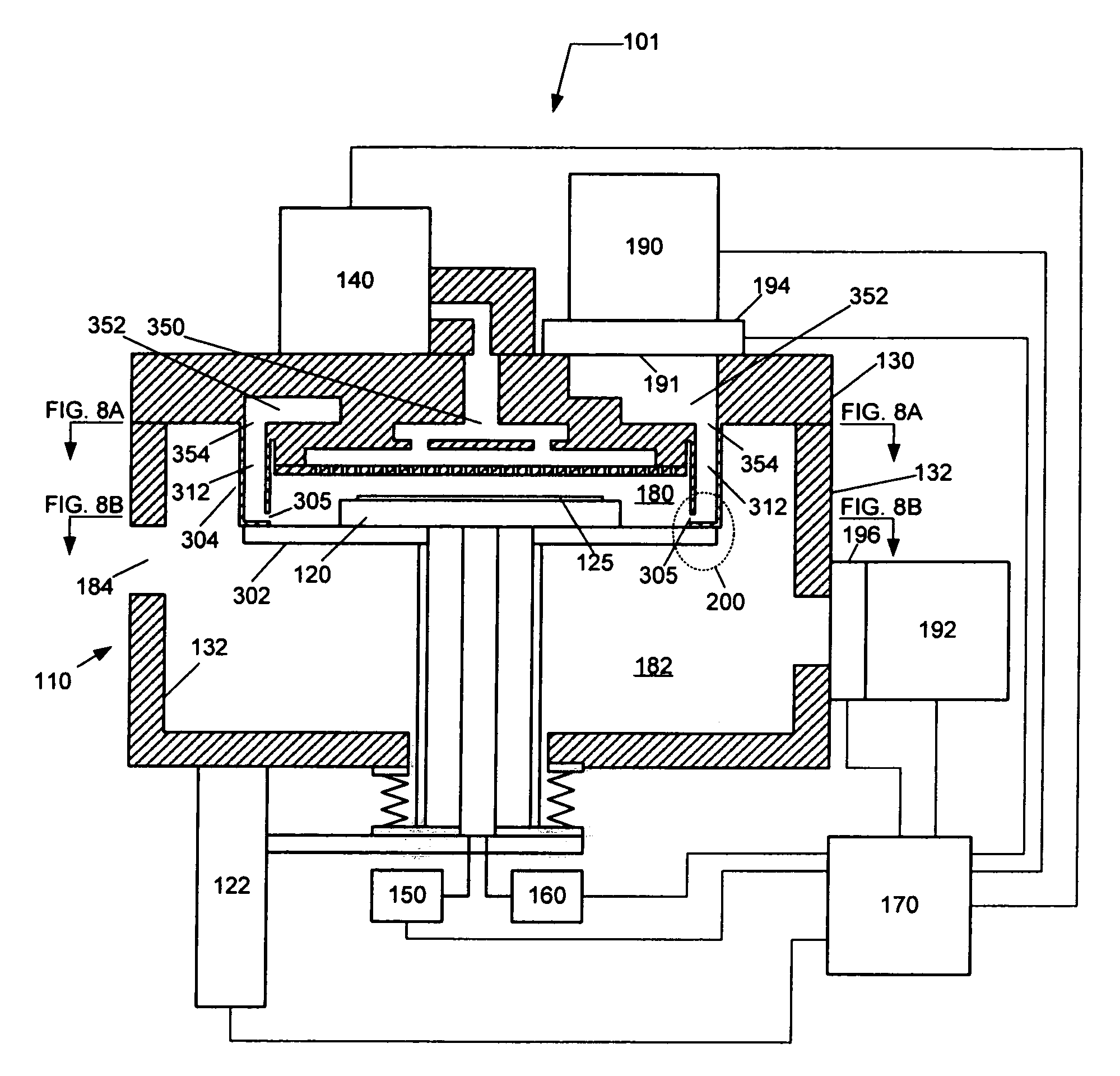

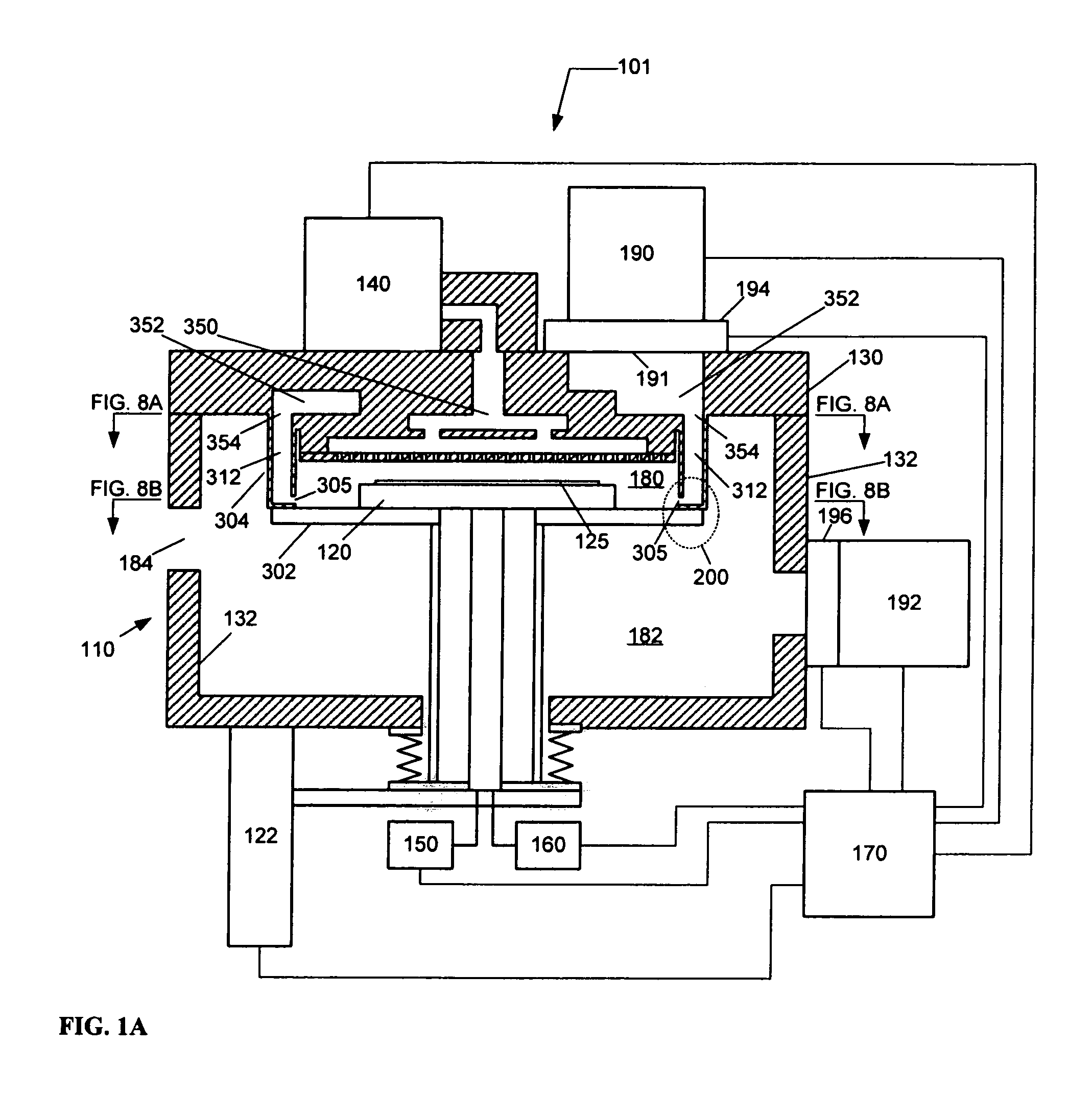

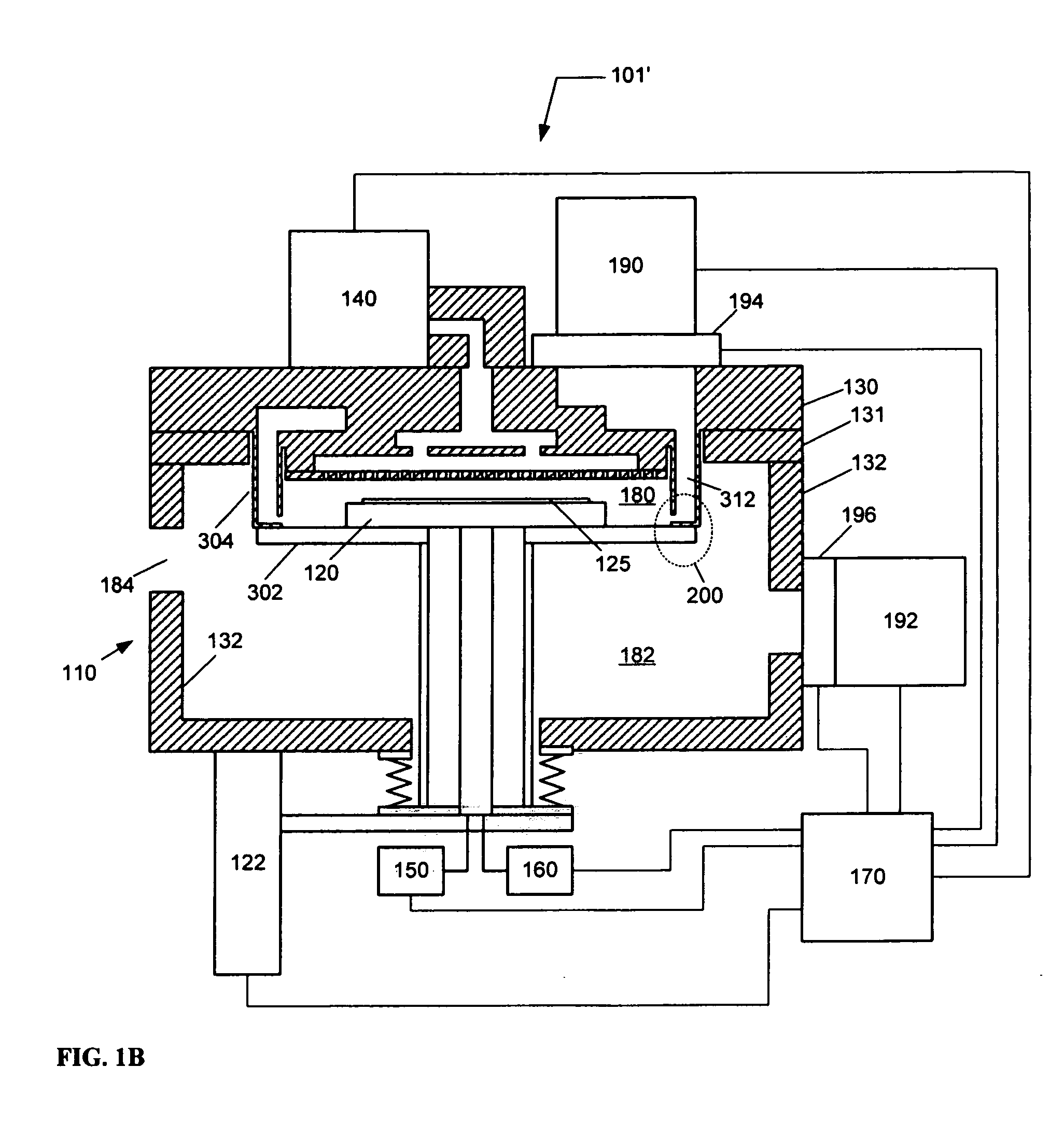

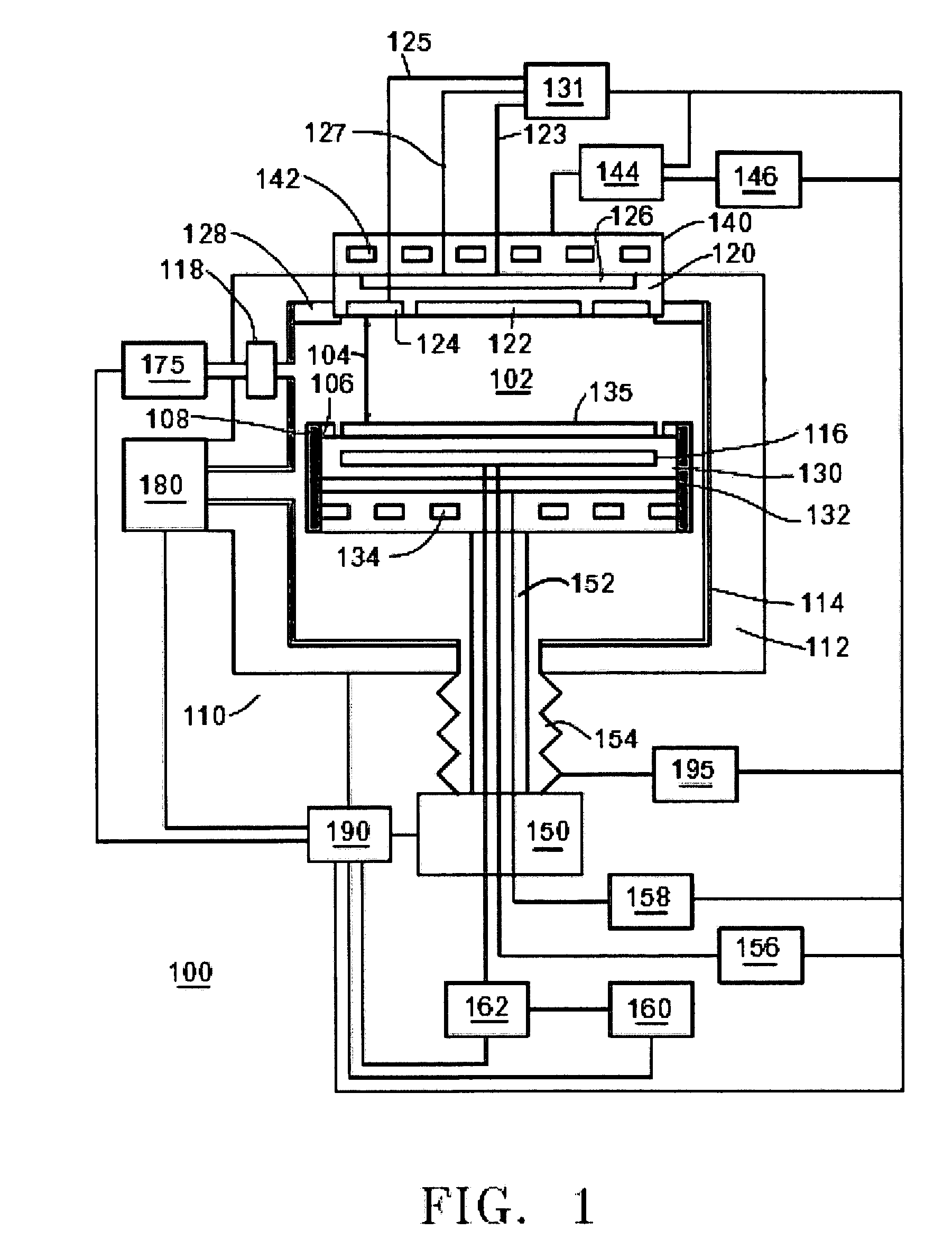

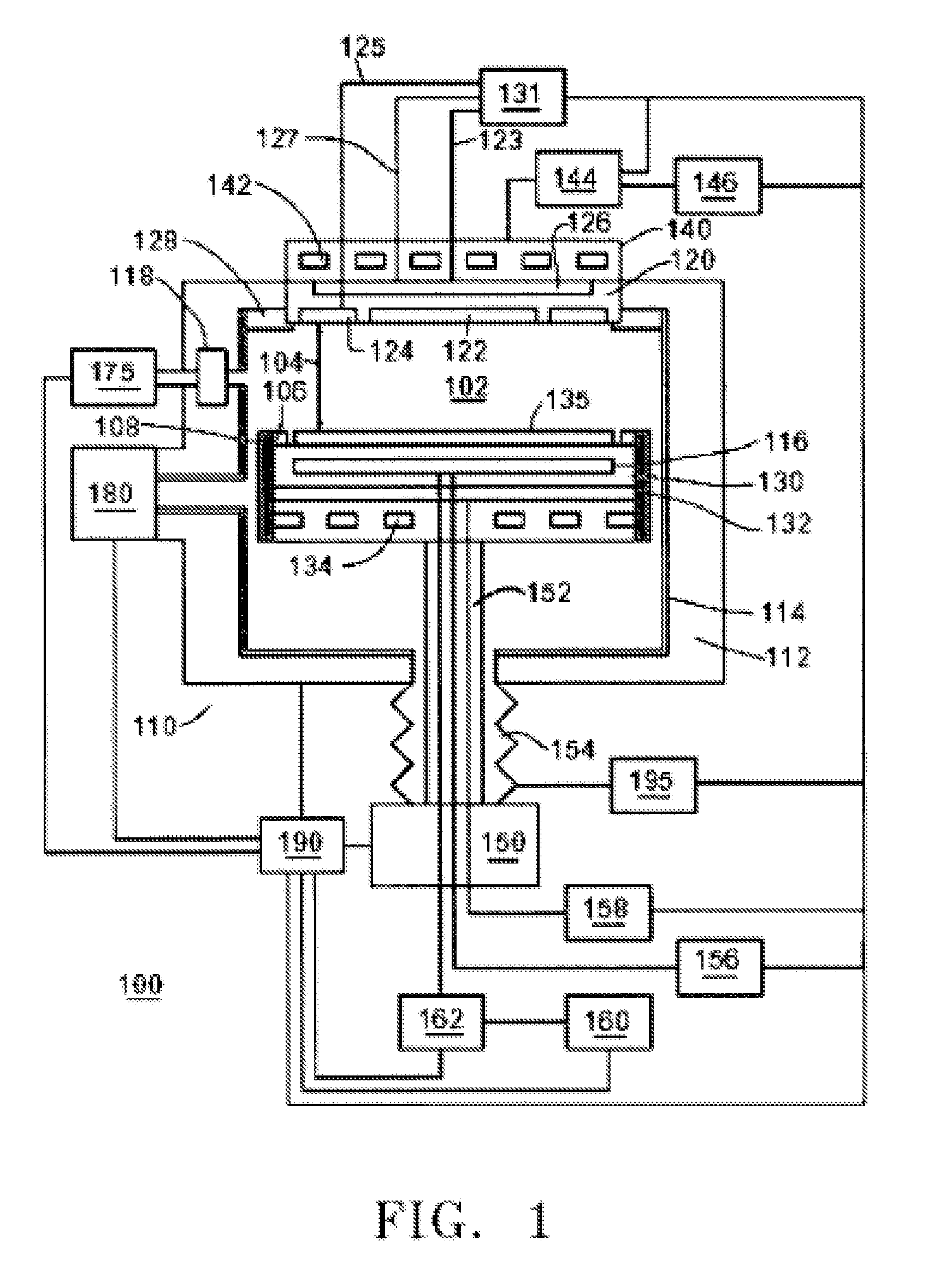

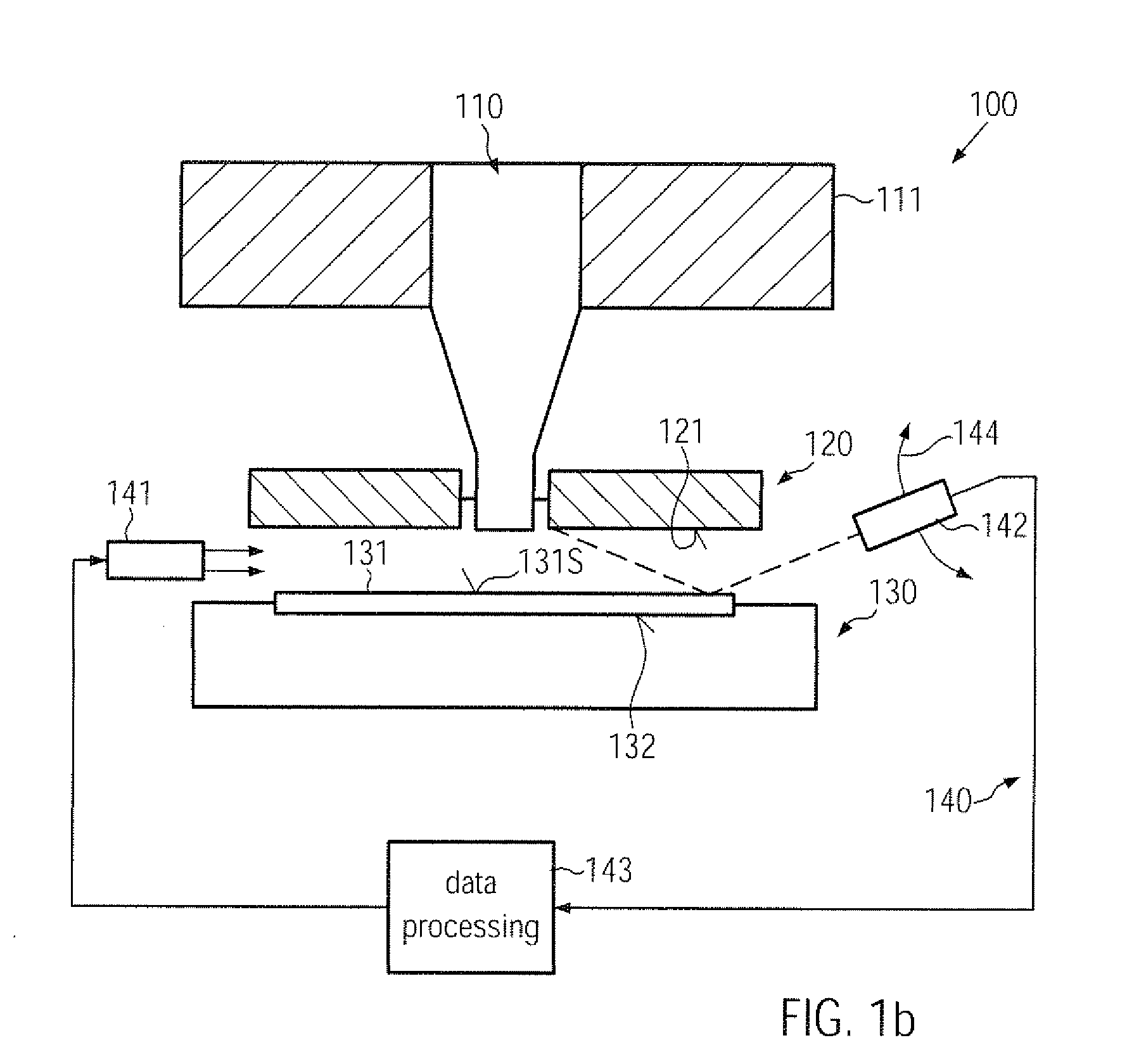

Method and apparatus for reducing particle contamination in a deposition system

ActiveUS20070215048A1Reduce particle pollutionChemical vapor deposition coatingDistribution systemEvaporation

A method and system is described for reducing particle contamination of a substrate in a deposition system. The deposition system comprises one or more particle diffusers disposed therein and configured to prevent or partially prevent the passage of film precursor particles, or break-up or partially break-up film precursor particles. The particle diffuser may be installed in the film precursor evaporation system, or the vapor delivery system, or the vapor distribution system, or two or more thereof.

Owner:TOKYO ELECTRON LTD

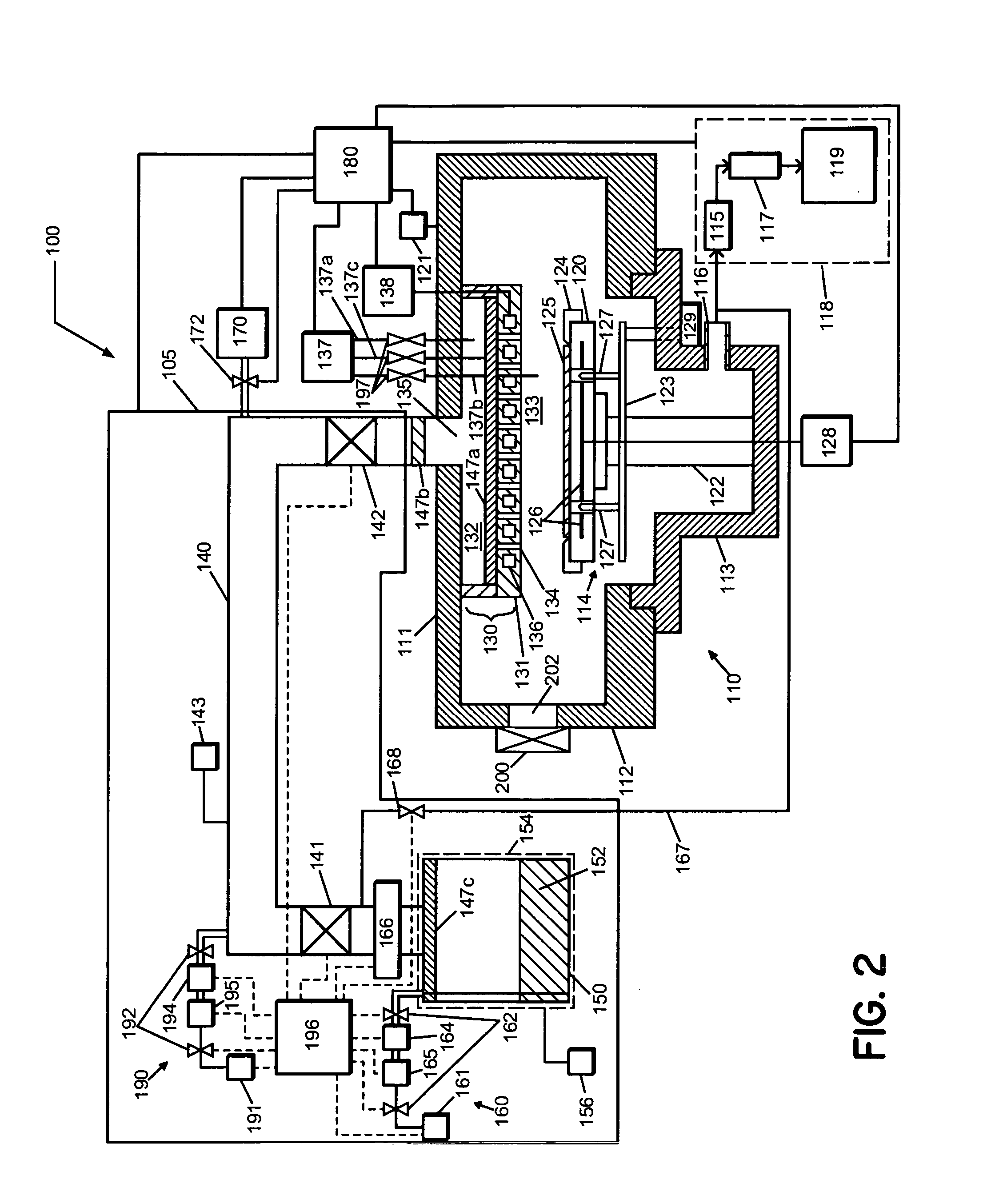

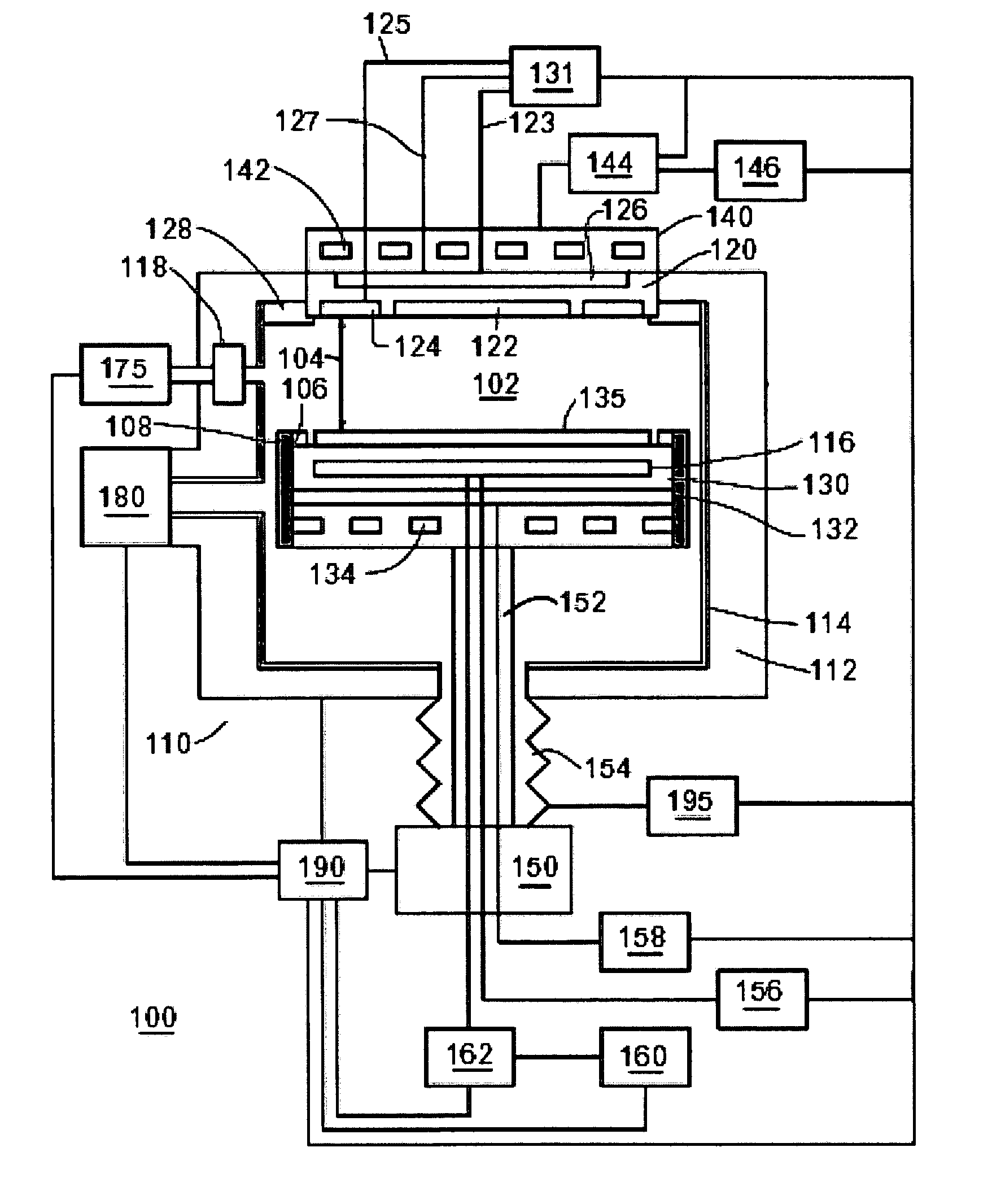

Method and apparatus for reducing particle formation in a vapor distribution system

InactiveUS20070218200A1Reduce particle pollutionChemical vapor deposition coatingDistribution systemEvaporation

A method and system is described for reducing particle contamination in a vapor distribution system. The vapor distribution system comprises a housing and a vapor distribution head comprising a plurality of openings configured to introduce a film precursor vapor to a deposition system. The housing and vapor distribution head define a plenum coupled to a film precursor evaporation system, and configured to receive the film precursor vapor from the evaporation system and distribute the film precursor vapor within the deposition system through the plurality of openings. In order to reduce particle contamination, the vapor distribution system is designed to reduce the difference, or ratio, between the pressure in the plenum and the pressure in the deposition system. For example, the plenum pressure can be less than twice the pressure in the process space, or can be less than 50 mTorr, 30 mTorr or even 20 mTorr than the pressure in the process space.

Owner:TOKYO ELECTRON LTD

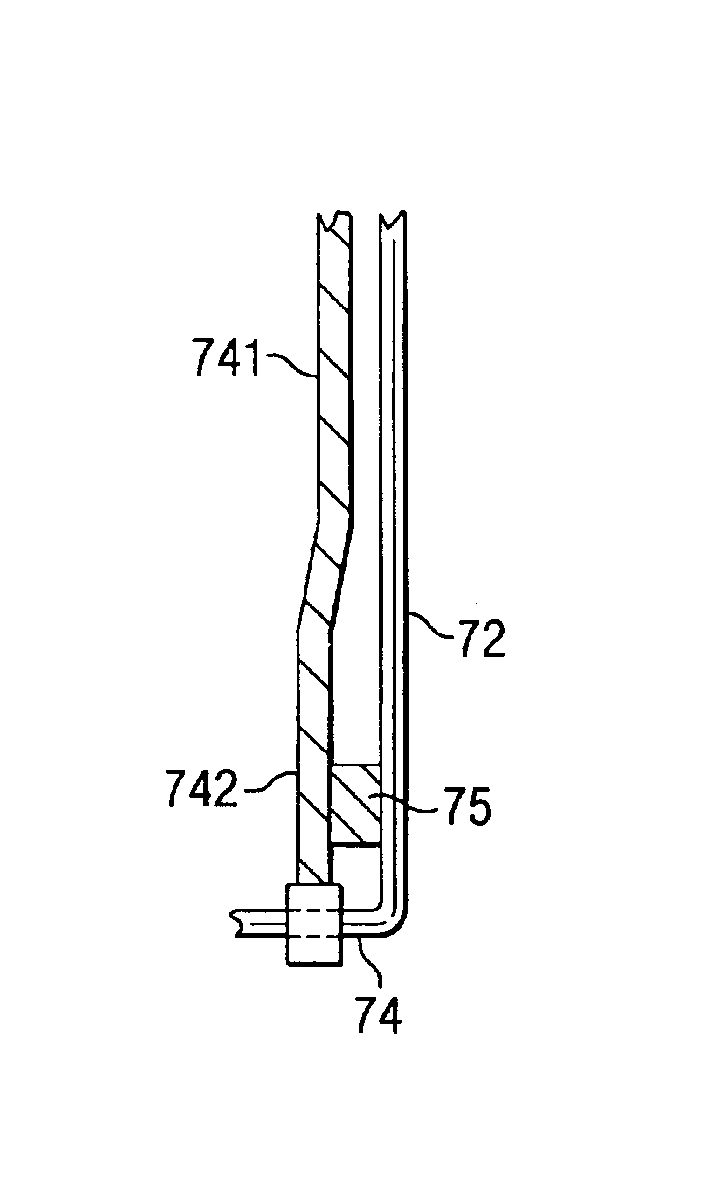

Gas injectors for a vertical furnace used in semiconductor processing

InactiveUS6929699B2Simple designStable positionChemical vapor deposition coatingEngineeringProduct gas

Improved long gas injectors for a vertical furnace used in semiconductor wafer processing are useful to minimize particulate contamination in the wafer processing area of the furnace, and minimize distortion of the long injectors during thermal excursions. The improved injectors are fabricated with a stabilizing quartz standoff positioned near the onset of the vertical portion of the injector tube which adds support to the long tube. Thickness of the standoff is calculated to define and enforce a specified separation distance between liner and injector, as well as to provide dual alignment points at the base of the liner and at the tip of the injector.

Owner:TEXAS INSTR INC

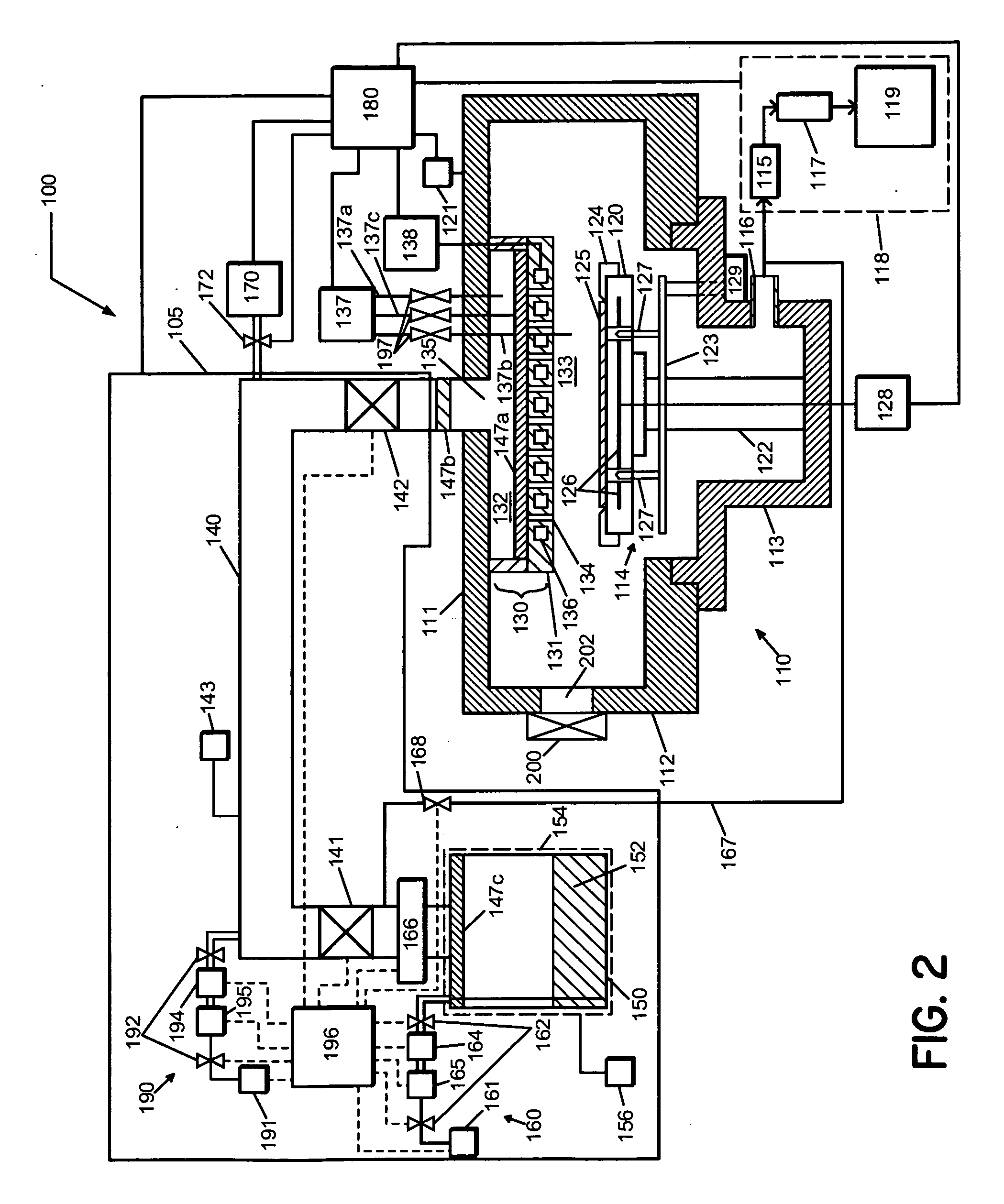

Exhaust apparatus configured to reduce particle contamination in a deposition system

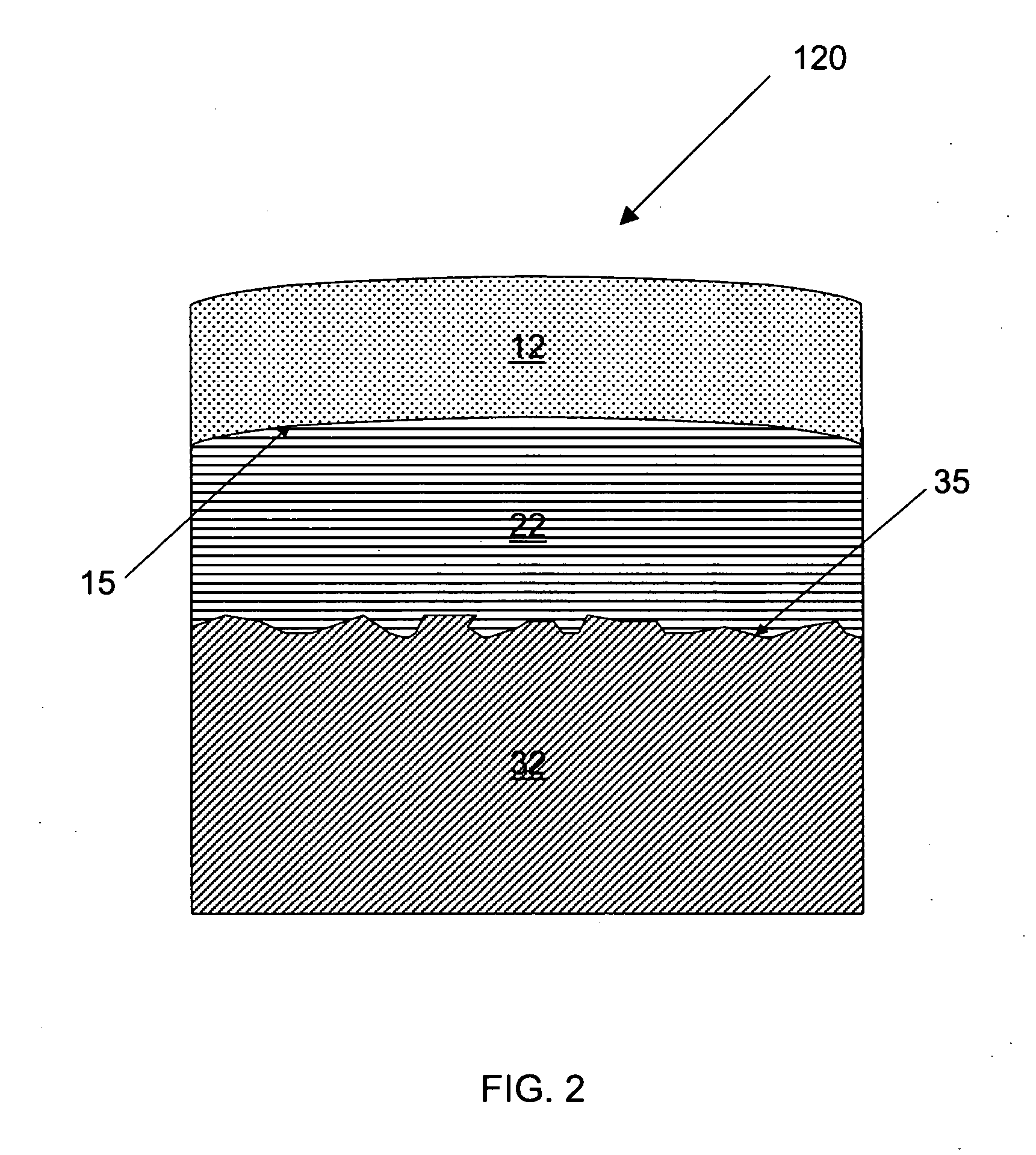

InactiveUS20070212484A1Reduce pollutionUniform processingPretreated surfacesSemiconductor/solid-state device manufacturingGas phaseEngineering

A method and system for vapor deposition on a substrate that disposes a substrate in a process space of a processing system that is isolated from a transfer space of the processing system, processes the substrate at either of a first position or a second position in the process space while maintaining isolation from the transfer space, and deposits a material on said substrate at either the first position or the second position. Furthermore, the system includes a high conductance exhaust apparatus configured to be coupled to the process space, whereby particle contamination of the substrate processed in the deposition system is minimized. The exhaust apparatus comprises a pumping system located above the substrate and an evacuation duct, wherein the evacuation duct has an inlet located below the substrate plane.

Owner:TOKYO ELECTRON LTD

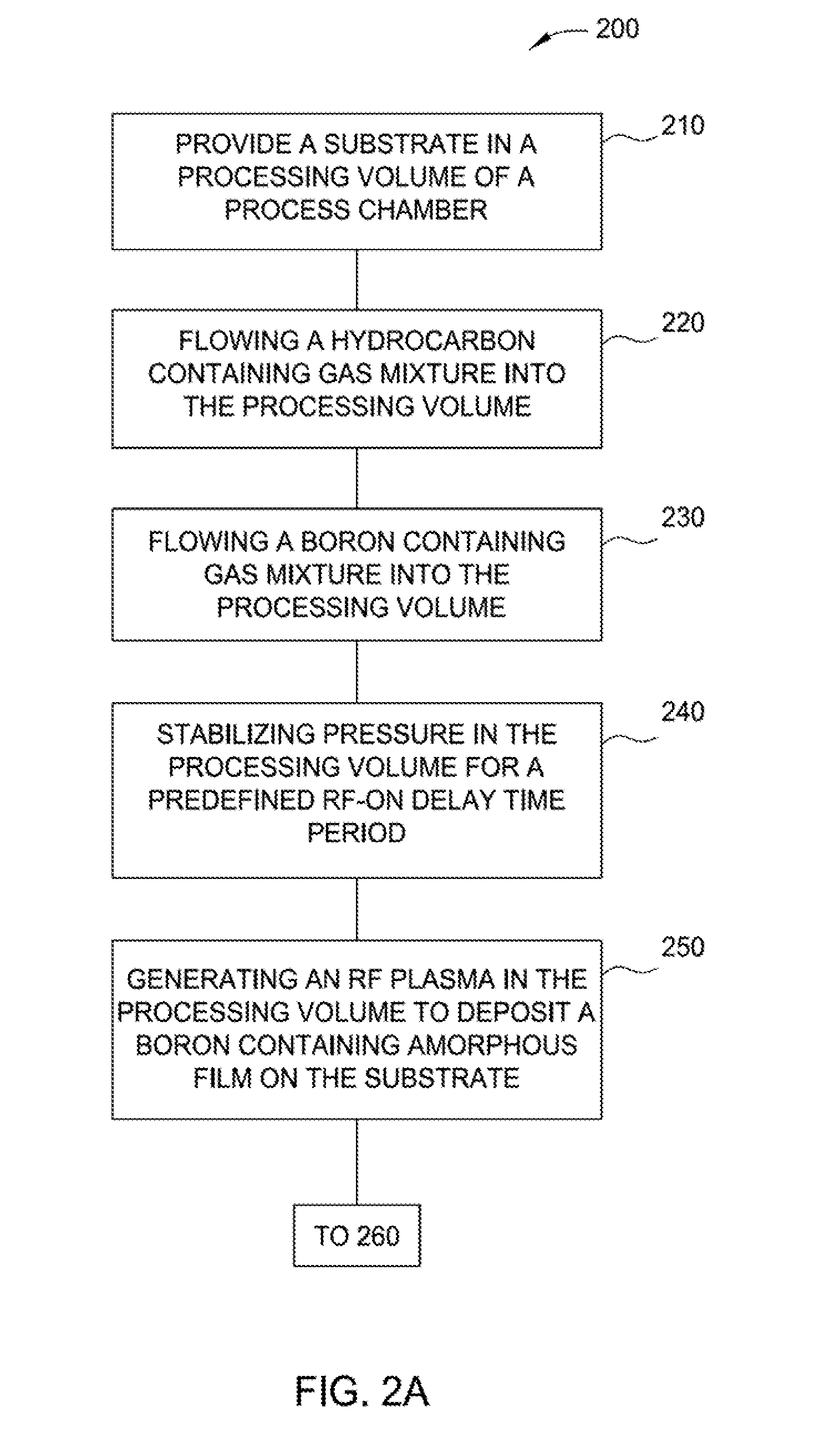

Methods to improve in-film particle performance of amorphous boron-carbon hardmask process in pecvd system

ActiveUS20170062218A1Reduce particle pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingBoron containingDelayed time

Implementations of the present disclosure generally relate to the fabrication of integrated circuits. More particularly, the implementations described herein provide techniques for deposition of boron-containing amorphous carbon films on a substrate with reduced particle contamination. In one implementation, the method comprises flowing a hydrocarbon-containing gas mixture into a processing volume having a substrate positioned therein, flowing a boron-containing gas mixture into the processing volume, stabilizing the pressure in the processing volume for a predefined RF-on delay time period, generating an RF plasma in the processing volume after the predefined RF-on delay time period expires to deposit a boron-containing amorphous film on the substrate, exposing the processing volume of the process chamber to a dry cleaning process and depositing an amorphous boron season layer over at least one surface in the processing volume of the process chamber.

Owner:APPLIED MATERIALS INC

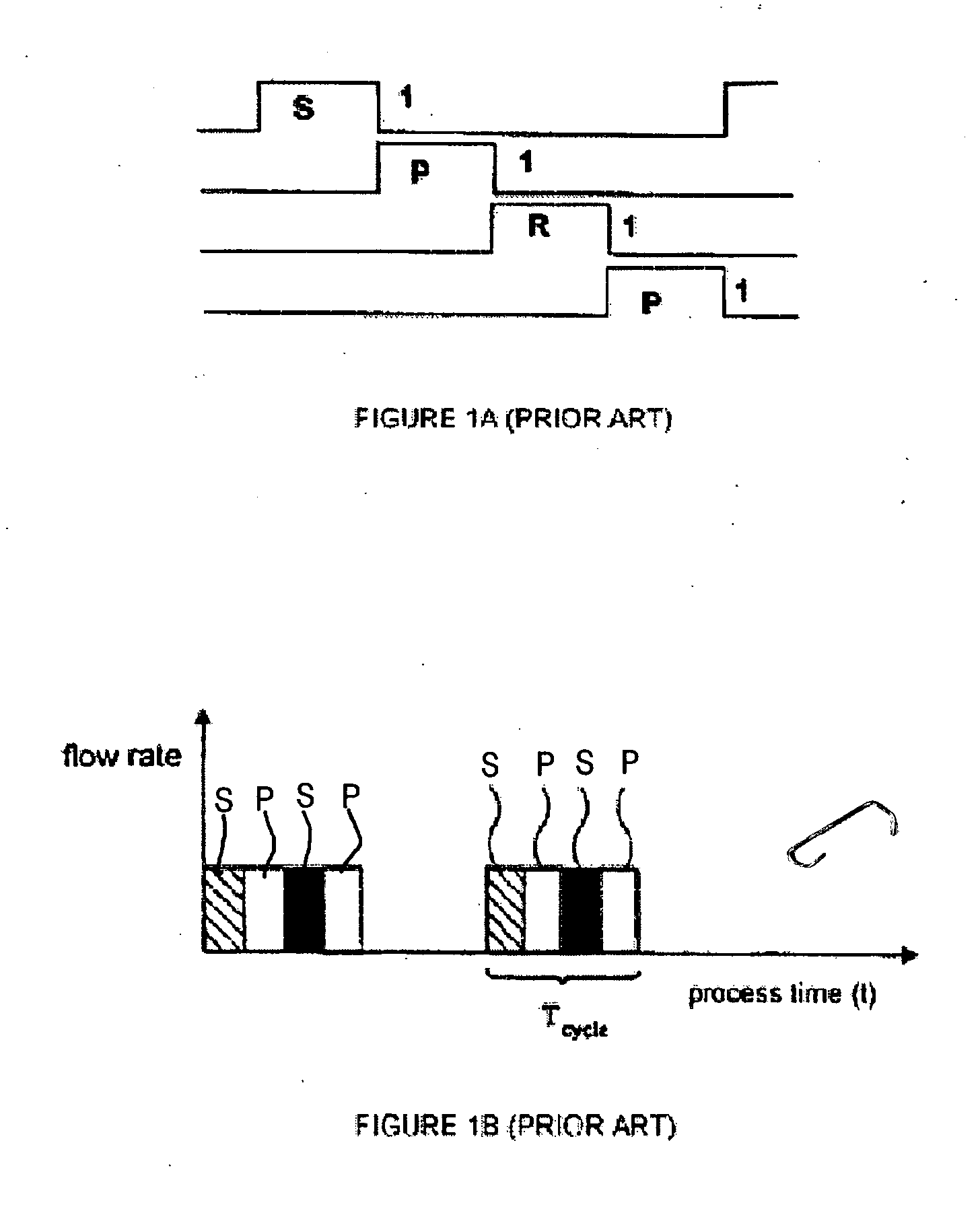

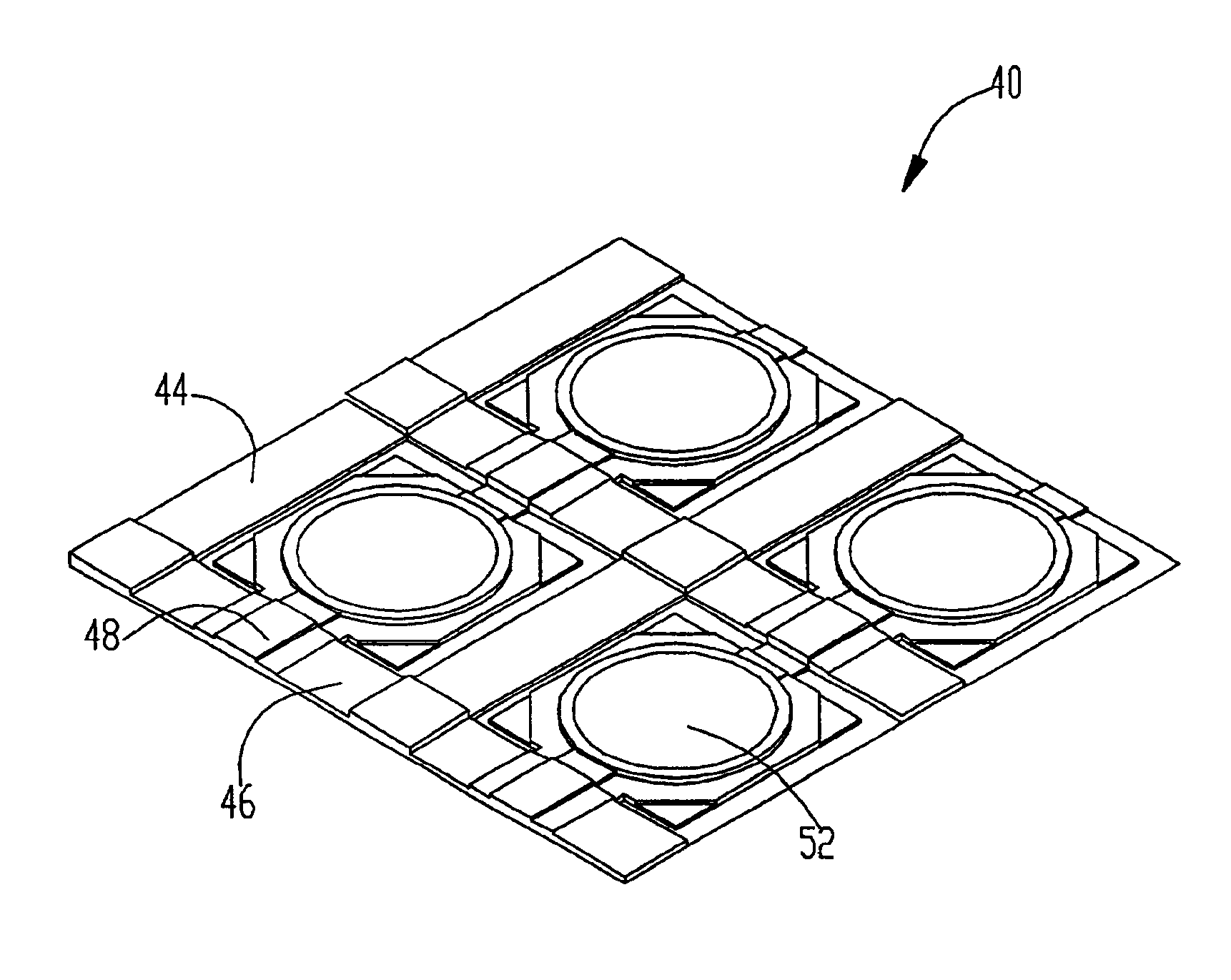

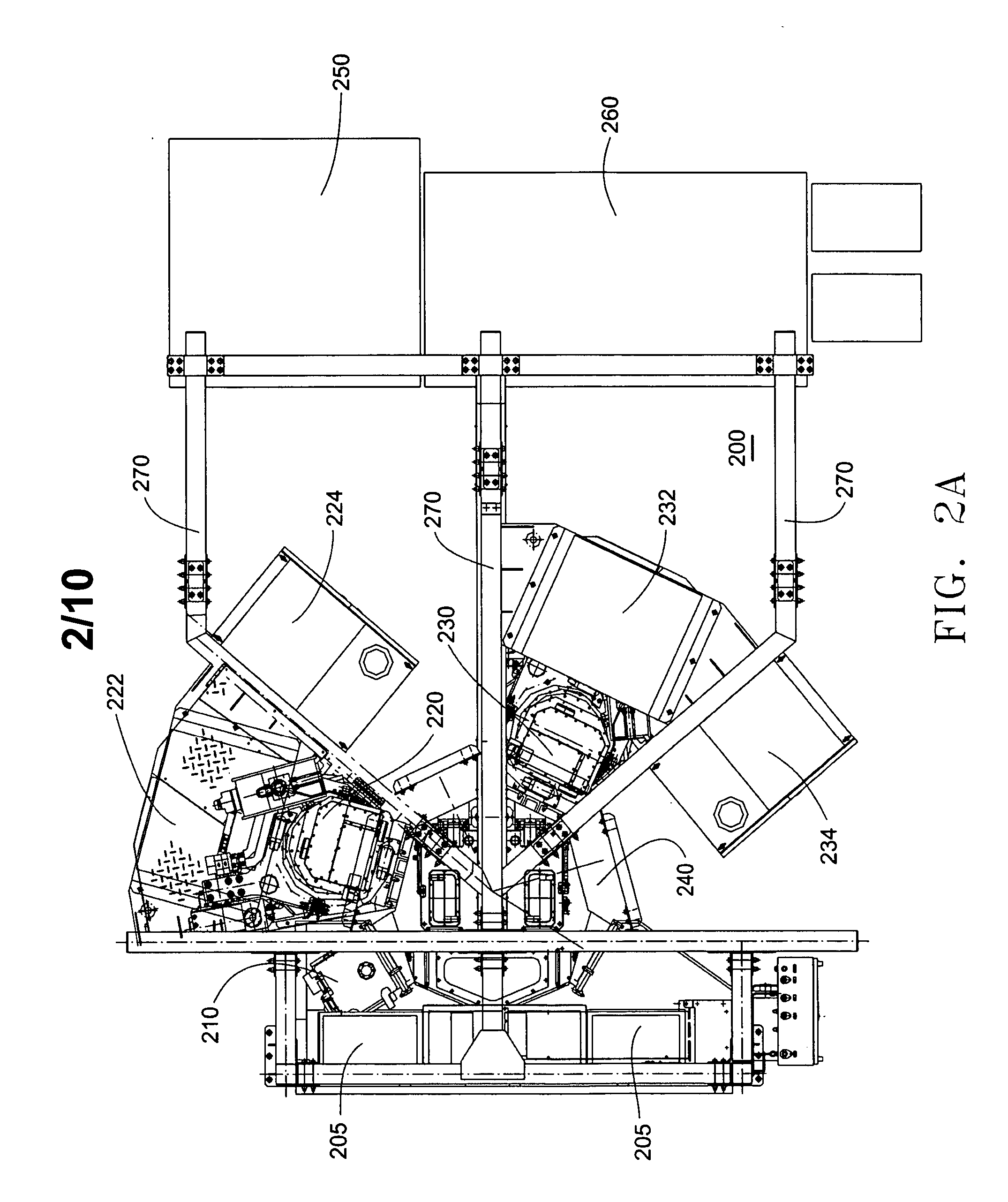

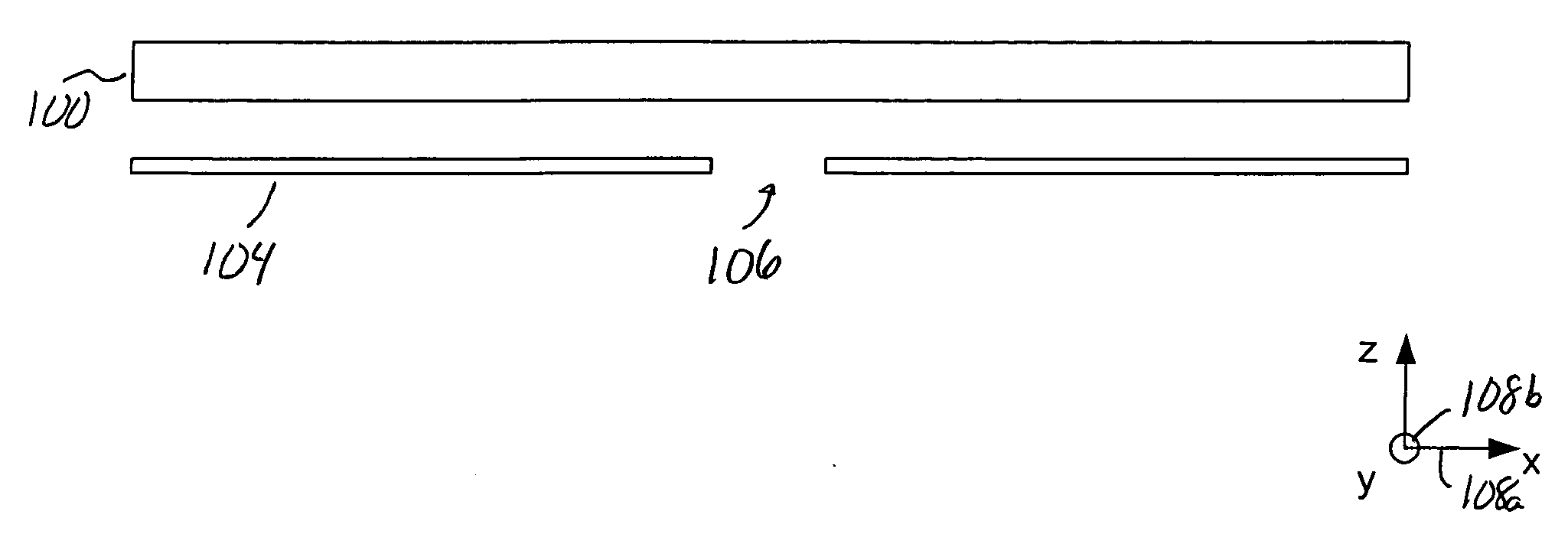

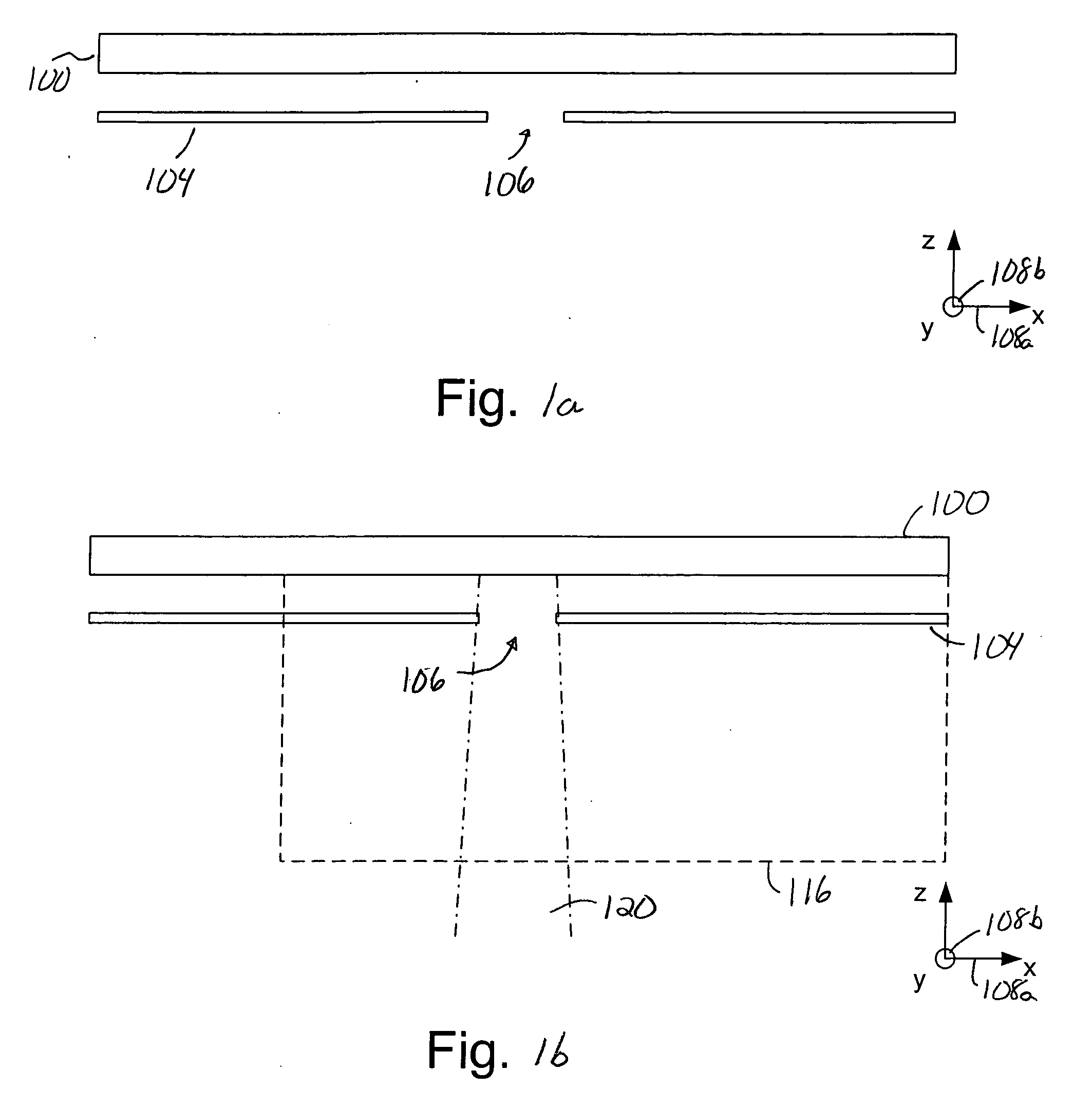

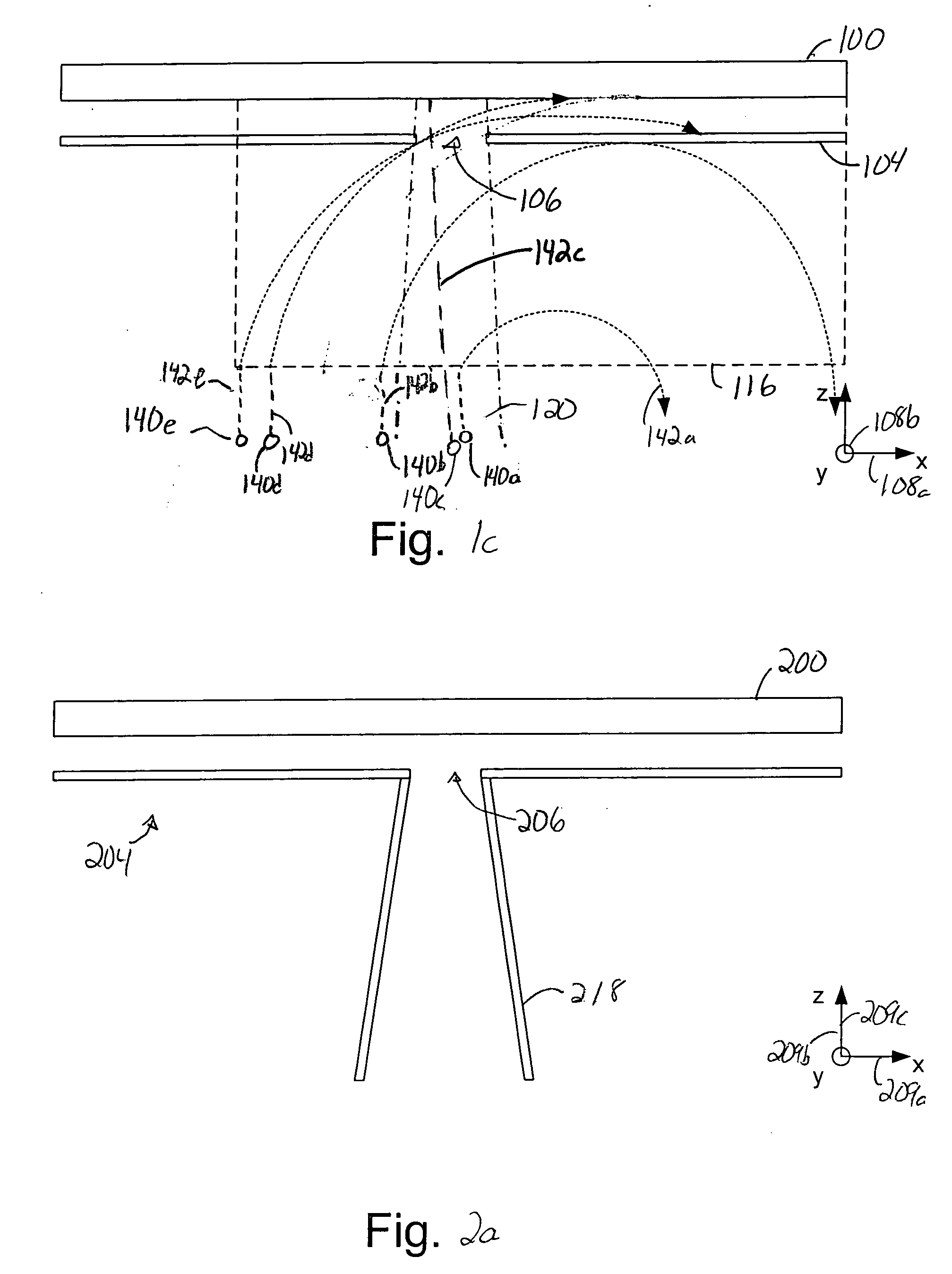

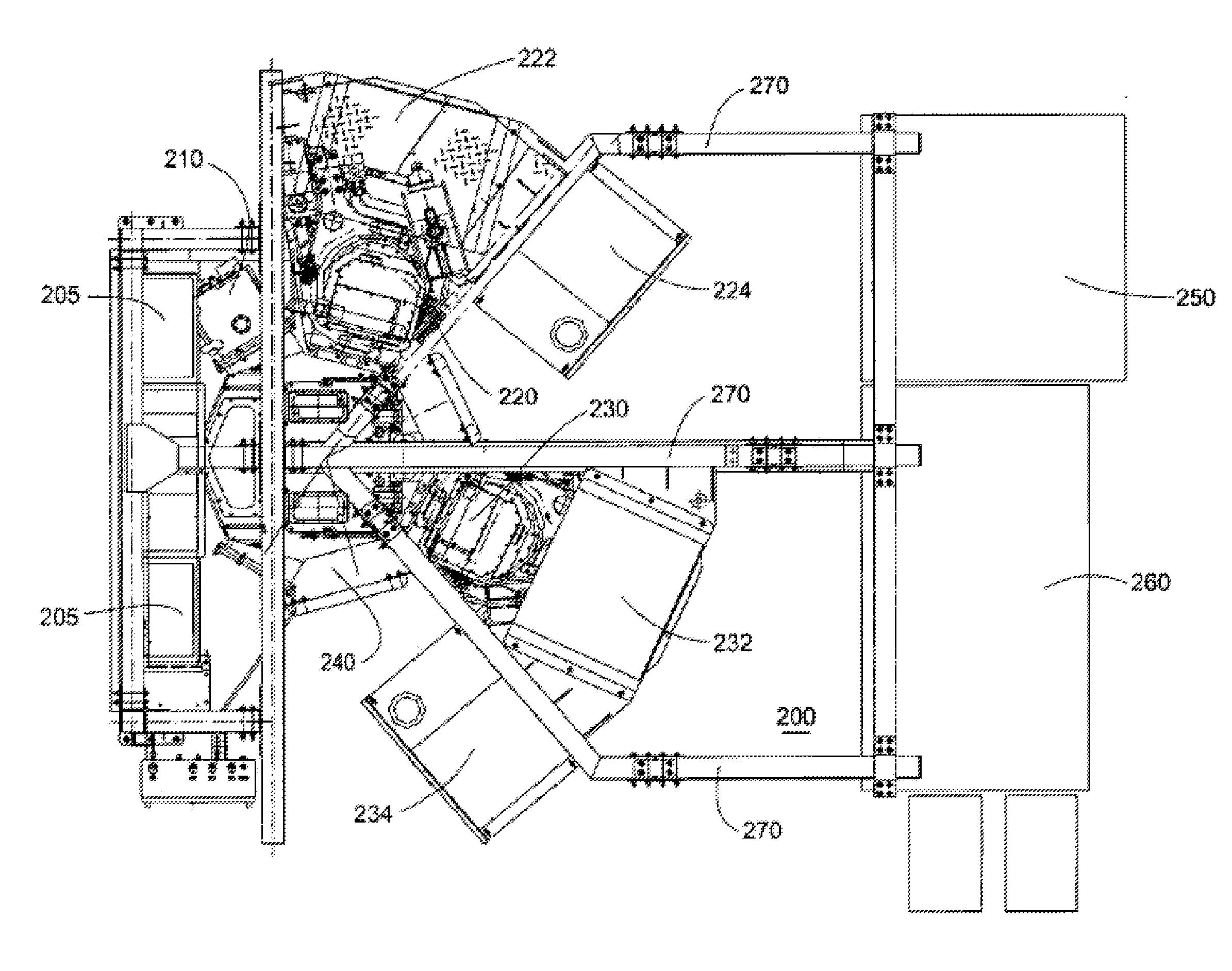

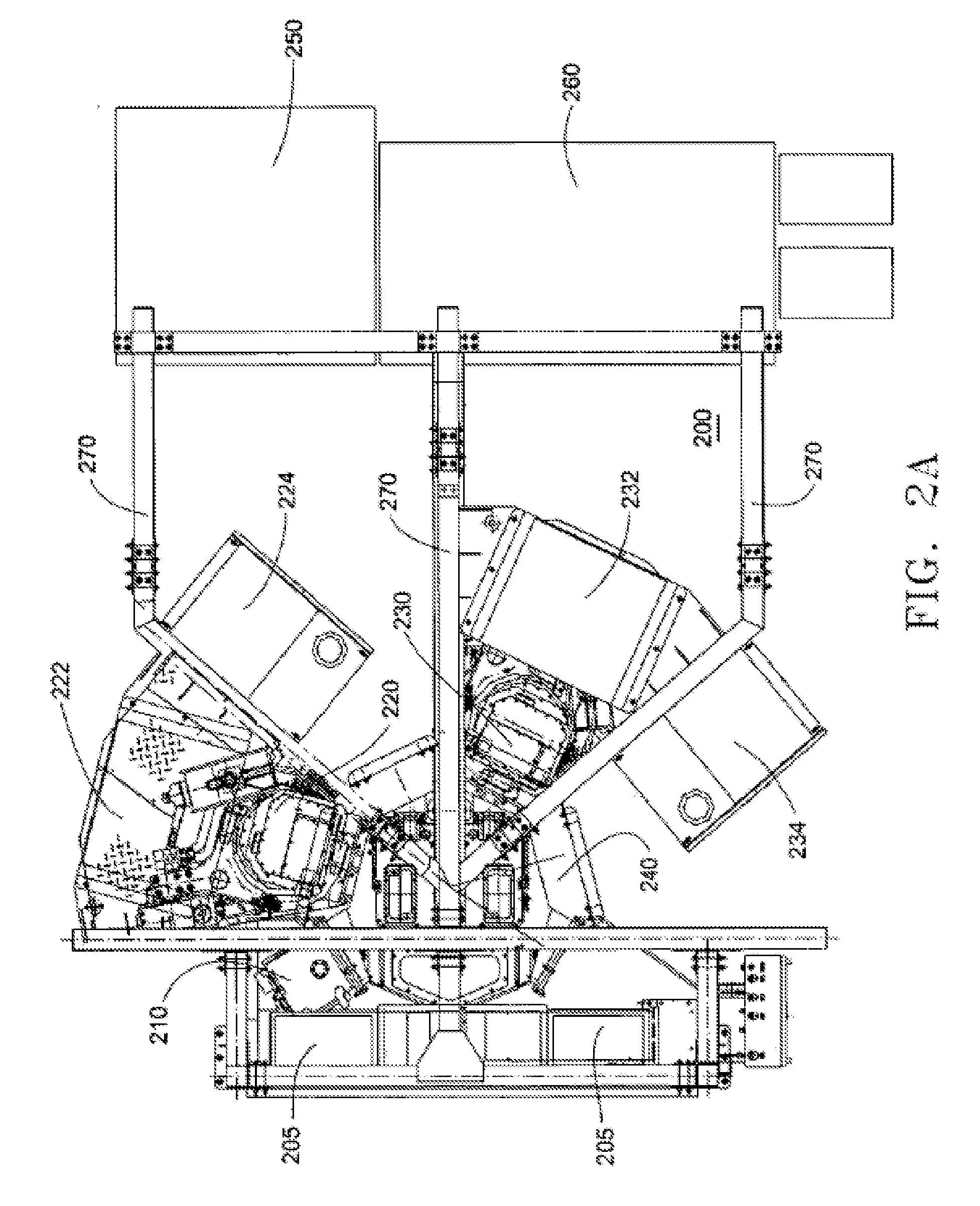

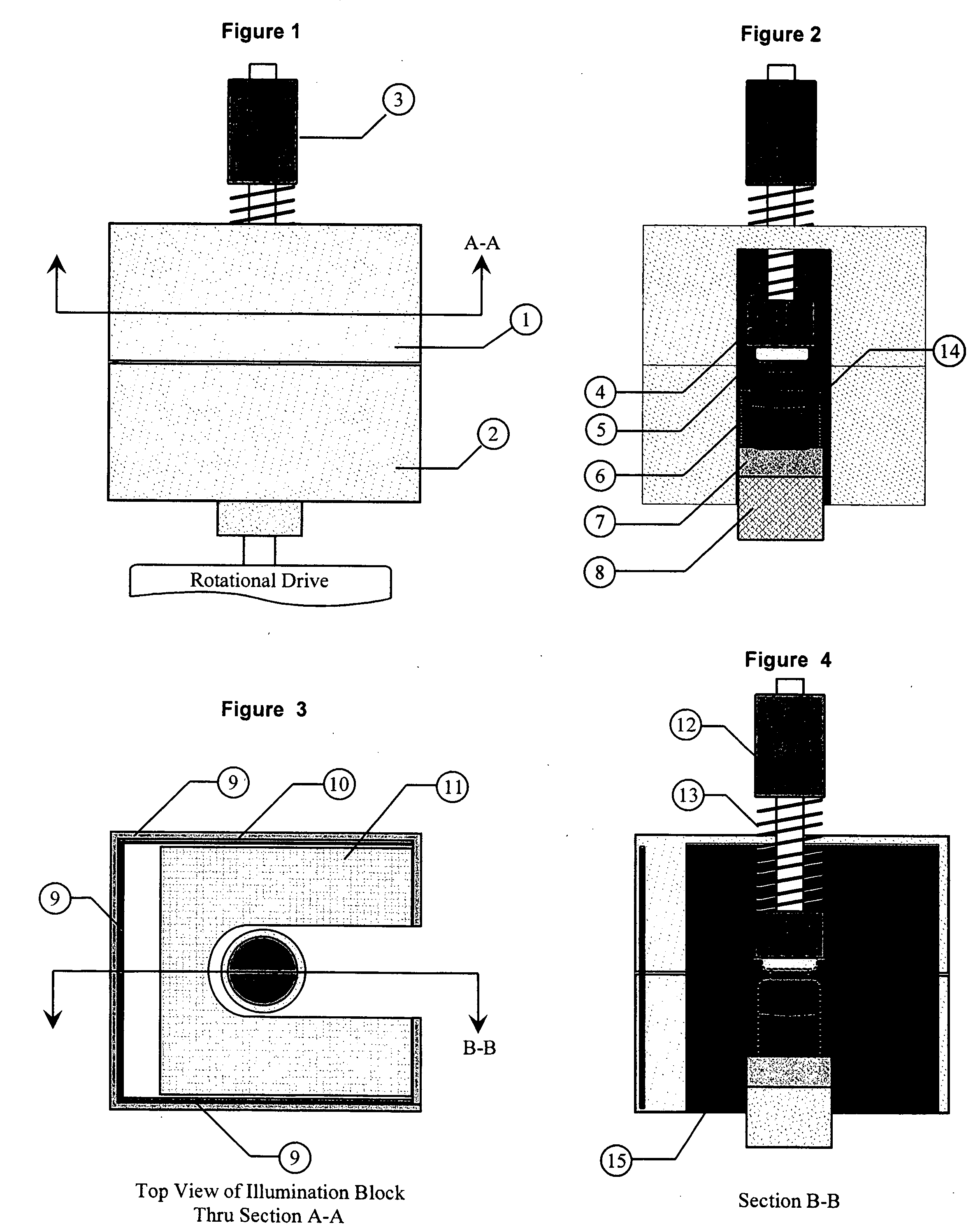

Method and apparatus of time and space co-divided atomic layer deposition

InactiveUS20070215036A1Polycrystalline material growthSemiconductor/solid-state device manufacturingEngineeringAtomic layer deposition

Space and time co-divided atomic layer deposition (ALD) apparatuses and methods are provided. Substrates are moved (e.g., rotated) among multiple reaction zones, each of which is exposed to only one ALD reactant. At the same time, reactants are pulsed in each reaction zone, with purging or other gas removal methods between pulses. Separate exhaust passages for each reactant and purging during wafer movement minimizes particle contamination. Additionally, preferred embodiments permit different pulsing times in each reaction space, thus permitting flexibility in pulsing.

Owner:ASM GENITECH KOREA

Conductive, plasma-resistant member

InactiveUS20070248832A1Improve corrosion resistanceSuppress particle contaminationMolten spray coatingNatural mineral layered productsDisplay deviceFlat panel display

An electrically conductive, plasma-resistant member adapted for exposure to a halogen-based gas plasma atmosphere includes a substrate having formed on at least part of a region thereof to be exposed to the plasma a thermal spray coating composed of yttrium metal or yttrium metal in admixture with yttrium oxide and / or yttrium fluoride so as to confer electrical conductivity. Because the member is conductive and has an improved erosion resistance to halogen-based corrosive gases or plasmas thereof, particle contamination due to plasma etching when used in semiconductor manufacturing equipment or flat panel display manufacturing equipment can be suppressed.

Owner:SHIN ETSU CHEM IND CO LTD

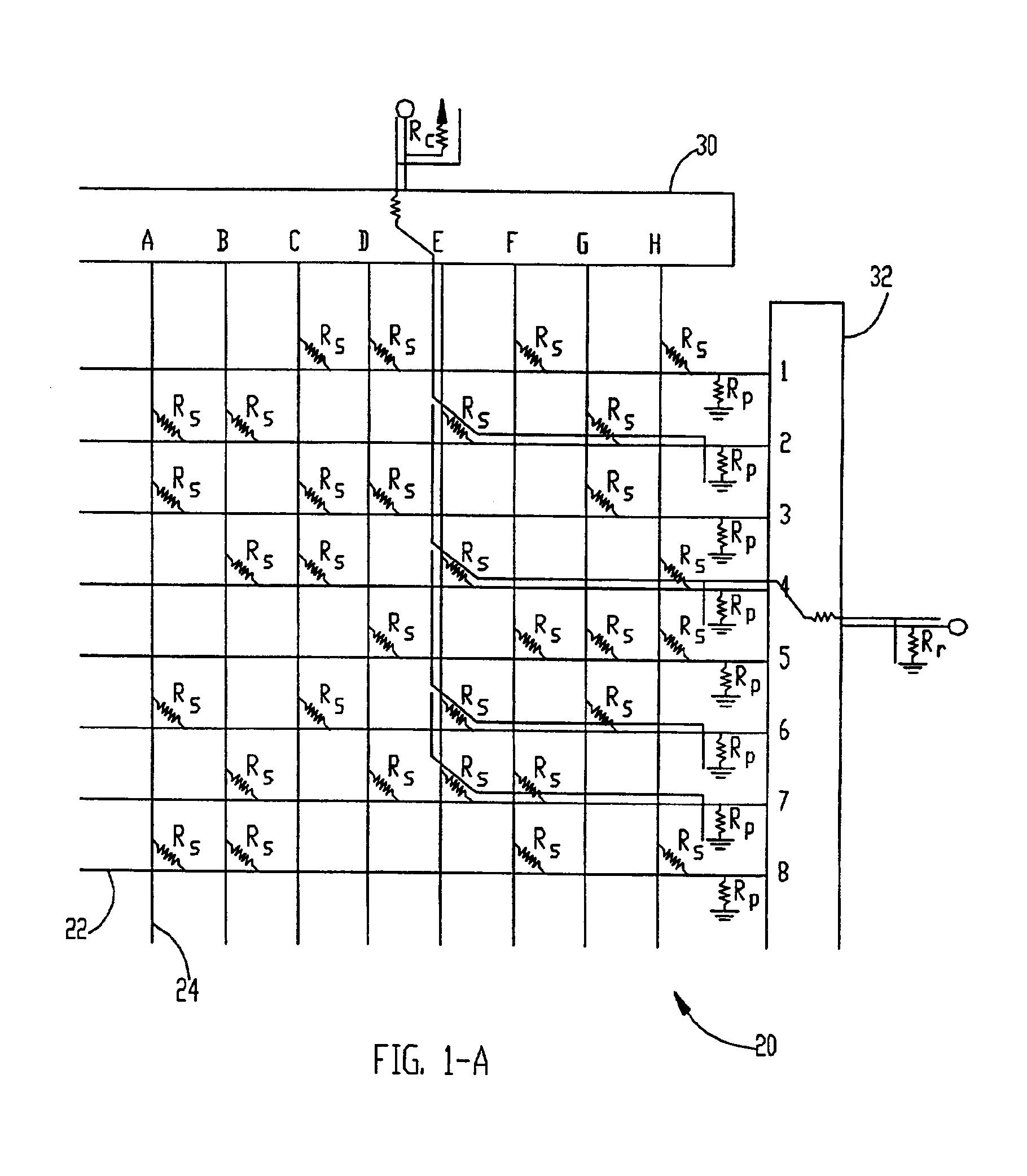

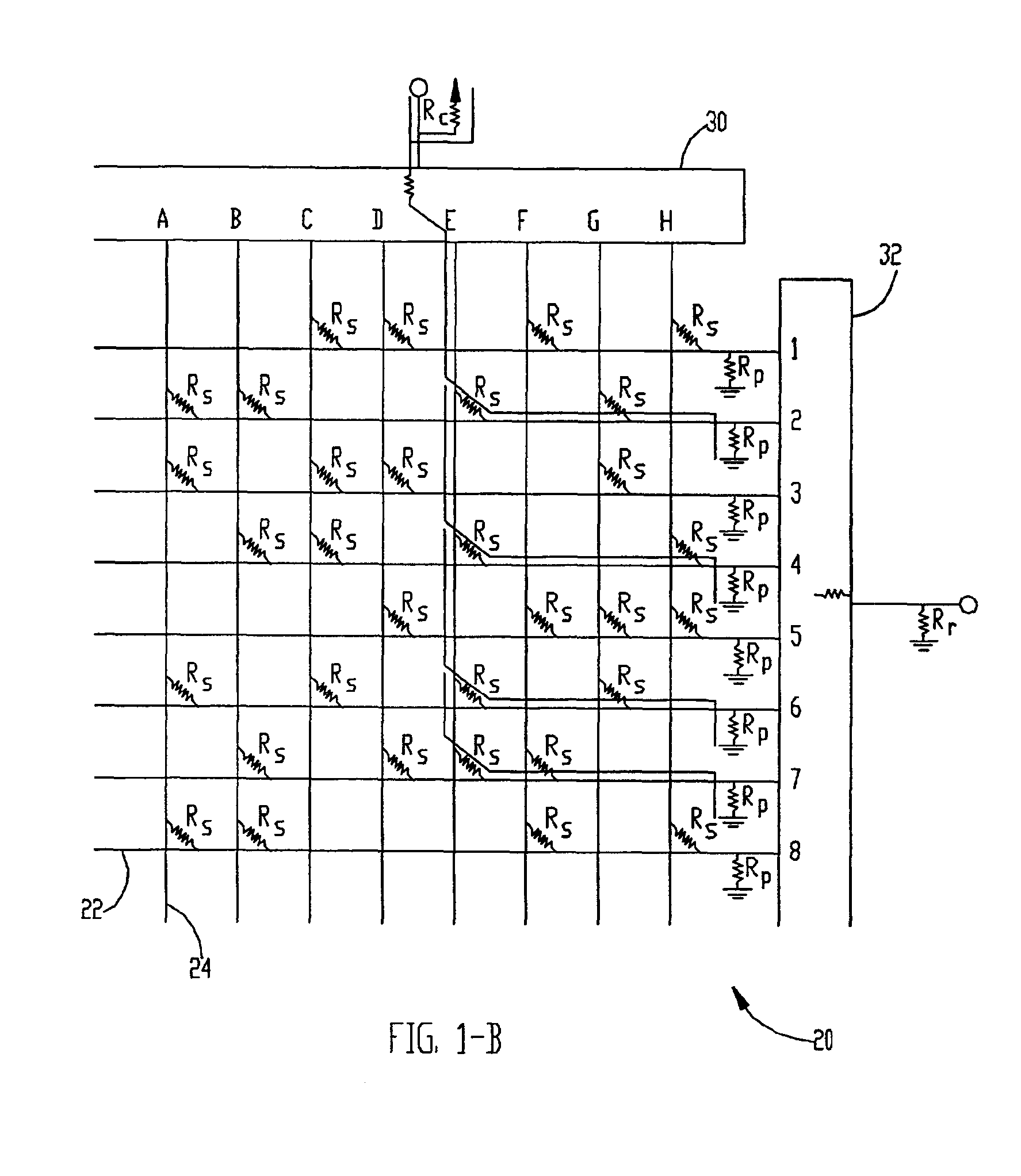

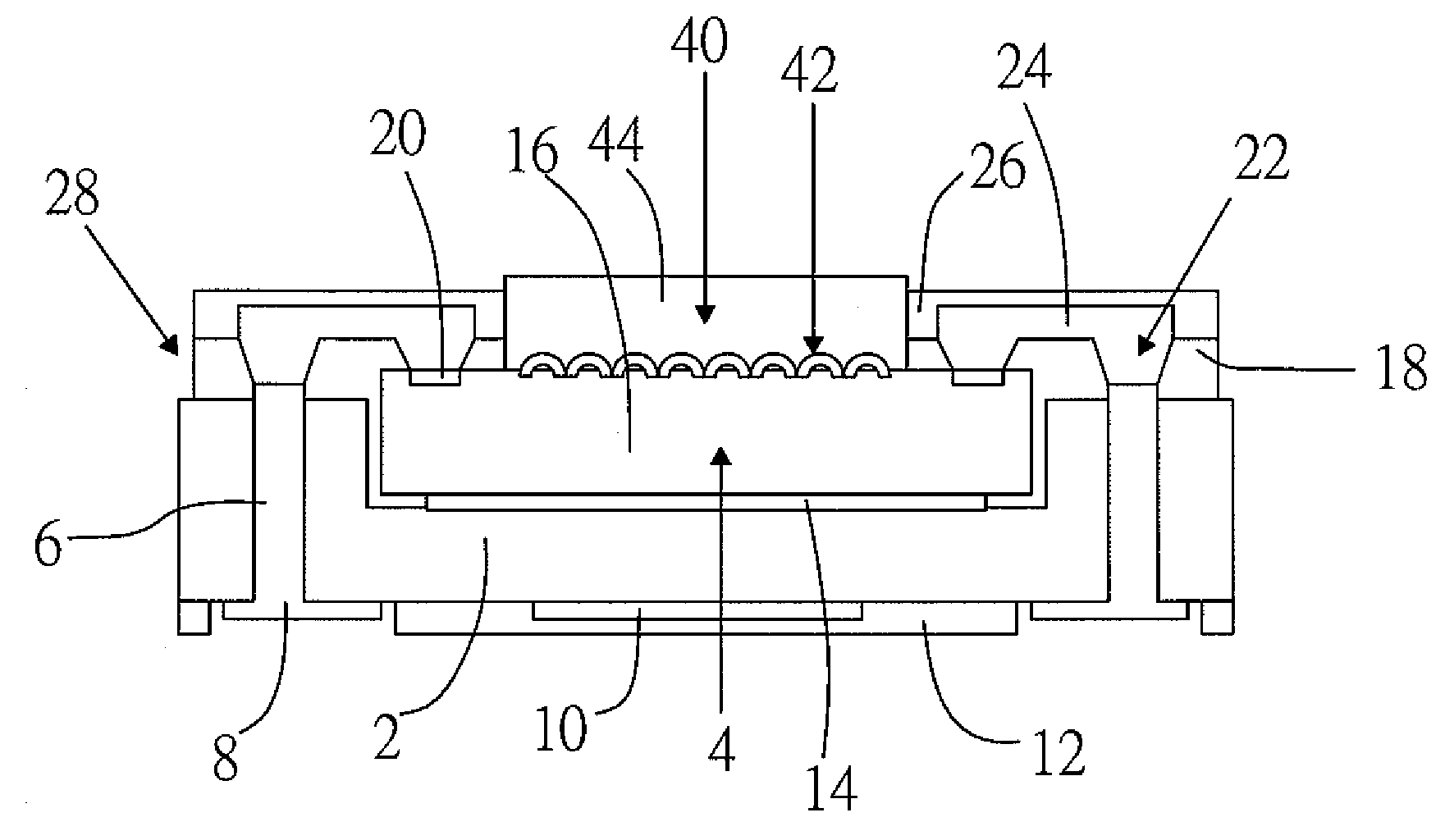

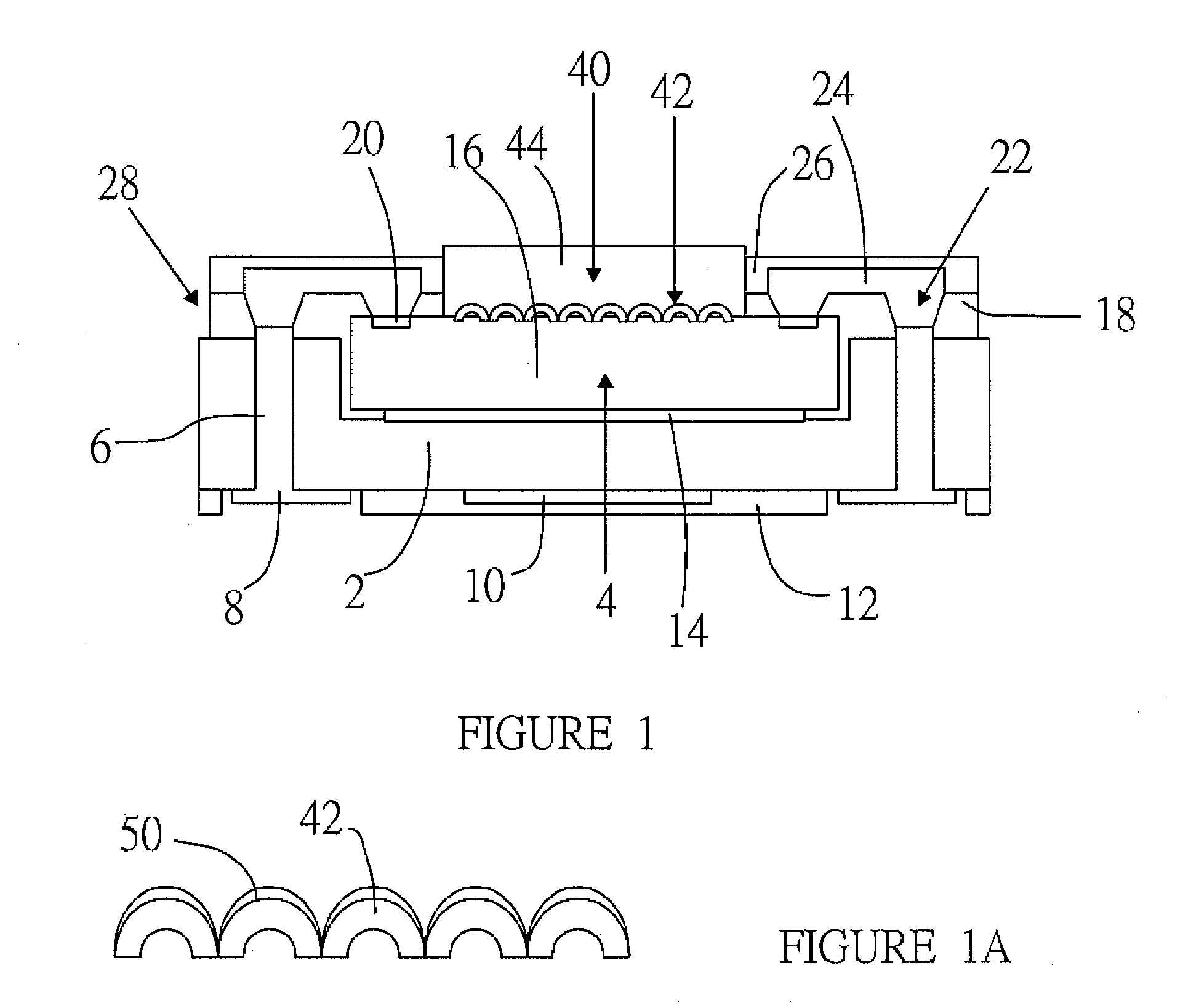

Fingerprint sensors using membrane switch arrays

InactiveUS6889565B2Electrostatic/electro-adhesion relaysResistance/reactance/impedenceMembrane switchEngineering

A sensor for identifying fingerprints or other skin textures includes an array of cells each including a membrane switch. Each switch includes a fixed lower electrode disposed on a chip substrate, and a flexible membrane disposed over the lower electrode and capable of flexing downward to establish electrical contact between the lower electrode and an upper electrode. The upper electrode can form the membrane itself or a layer of the membrane, or can be attached to other membrane layers. Switches situated underneath skin ridges change state (e.g. are closed) by the applied pressure, while switches underneath skin valleys remain in their quiescent state (e.g. open). Adjacent switch chambers are connected by fluid tunnels which allow the passage of air between the chambers. Each chamber is substantially closed to the exterior of the sensor, such that particles from the environment cannot contaminate the switch contact surface defined between the switch electrodes. The cells are preferably not hermetically sealed, such that the pressure within the chamber interiors can stay equal to the external (atmospheric) pressure in varying environmental conditions. The membrane design of the cells according to the preferred embodiment allows improved sensor robustness, enhanced resistance to impact forces, decreased vulnerability to particle contamination, and reduced inter-cell crosstalk.

Owner:LENOVO PC INT

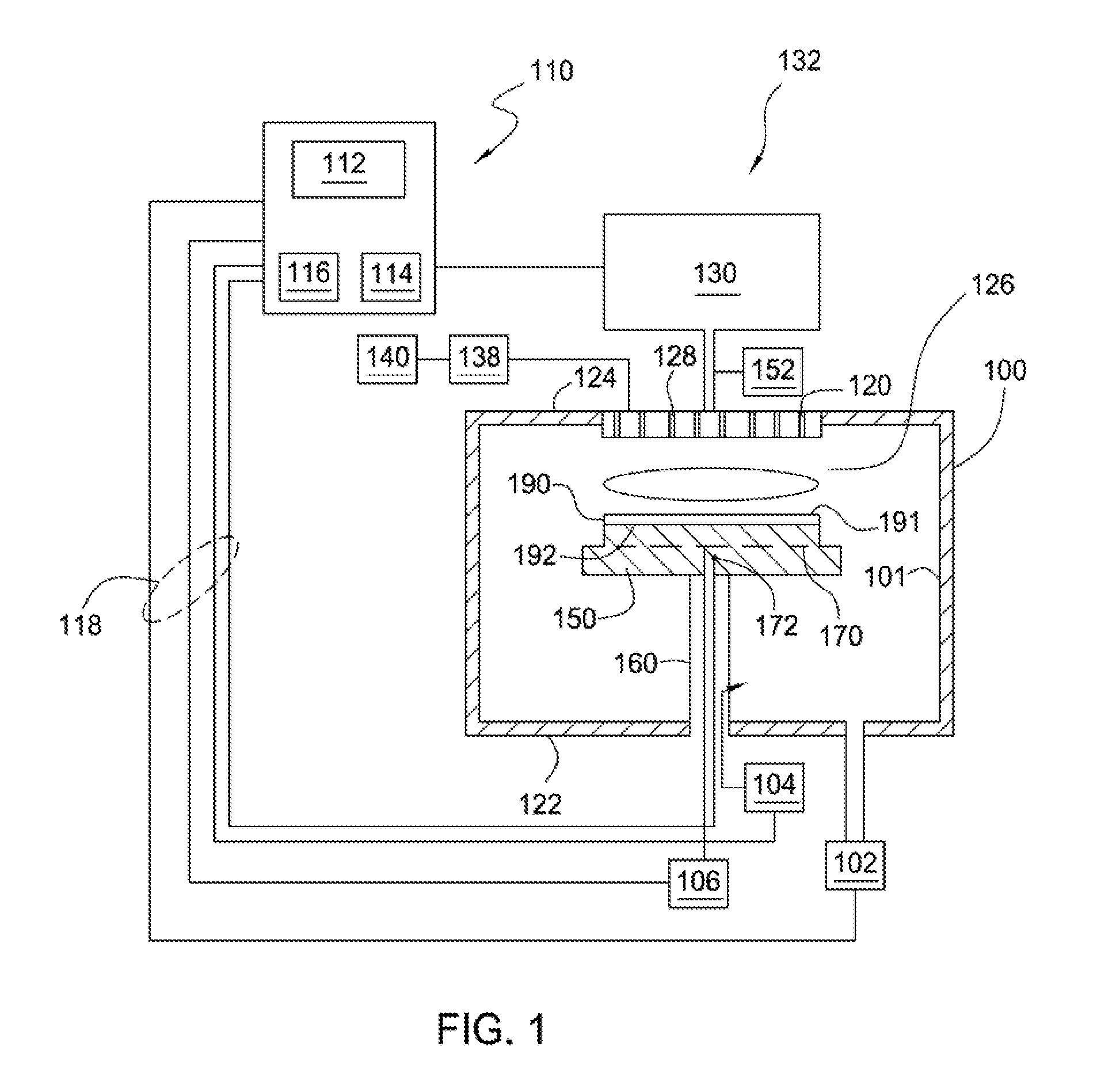

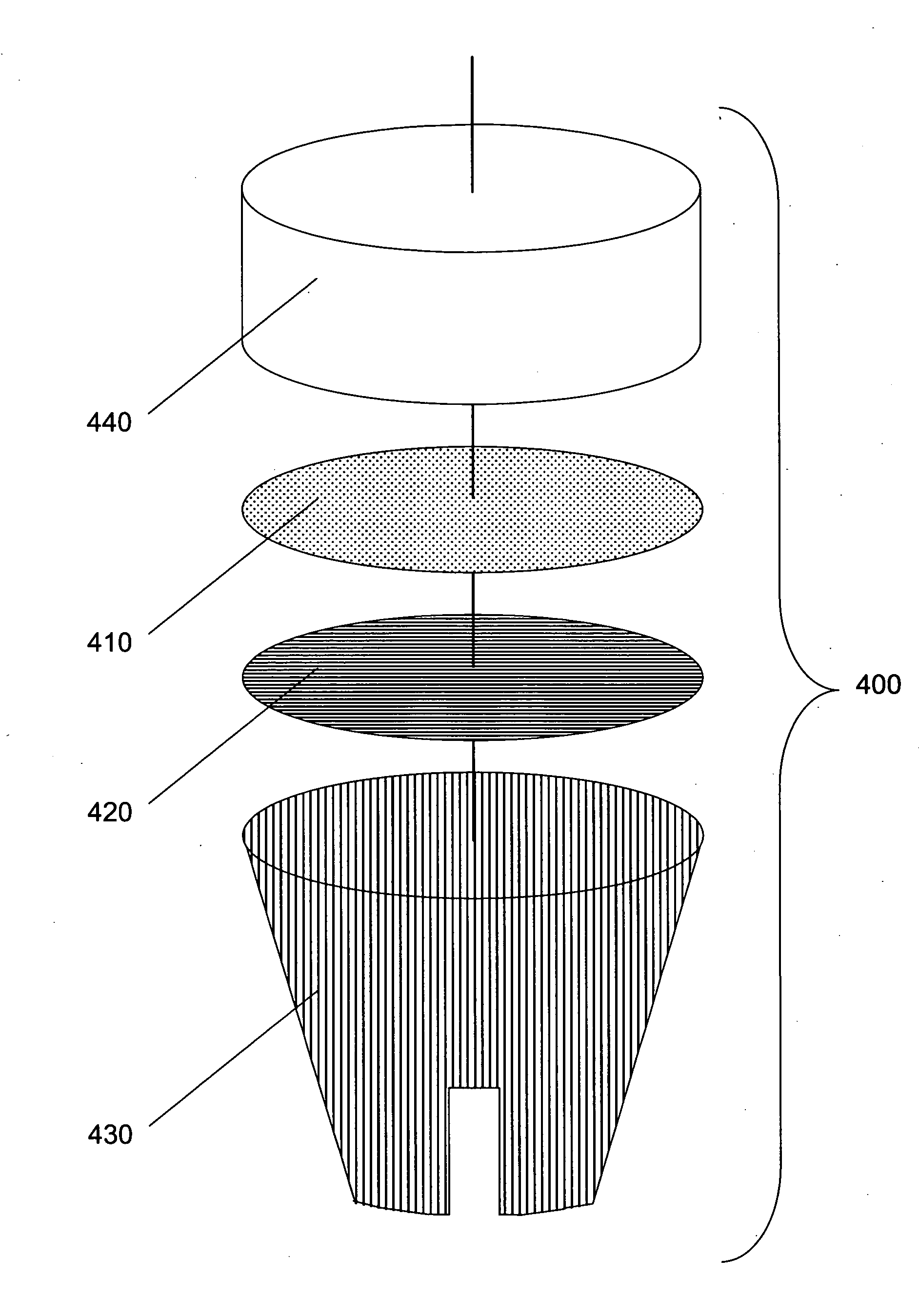

Method of improving the wafer to wafer uniformity and defectivity of a deposited dielectric film

InactiveUS20050221020A1Enhanced vapor depositionElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricEngineering

A method and apparatus are included that provide an improved deposition process for a Tunable Etch Resistant ARC (TERA) layer with improved wafer to wafer uniformity and reduced particle contamination. More specifically, the processing chamber is seasoned to reduce the number of contaminant particles generated in the chamber during the deposition of the TERA layer and improve wafer to wafer uniformity. The apparatus includes a chamber having an upper electrode at least one RF source, a substrate holder, and a showerhead for providing multiple precursors and process gasses.

Owner:TOKYO ELECTRON LTD

Water contaminant indicators

InactiveUS20050109683A1Detection of fluid at leakage pointMaterial analysis by observing effect on chemical indicatorWater treatment systemFiltration

A filtering device for a gravity-flow liquid treatment system includes a first filter component that can be either exposed or adjacent to a substantially transparent region in at least a portion of a filter housing. The first filter component is capable of providing a visual indication of exposure to at least one contaminant. The contaminants for which the first filter component can indicate exposure include particles, inorganic, and organic contamination. Particle contamination is indicated by a change in color of the first filter component through particle collection. Inorganic and organic contaminants are indicated by reaction with at least one agent capable of undergoing a color-change reaction in response to at least one contaminant. Water treatment systems and filtration devices that include at least one agent capable of undergoing a color-change reaction and thus give a visual indication of exposure to at least one contaminant for use in both gravity-driven and pressure-driven environments are also described.

Owner:THE CLOROX CO

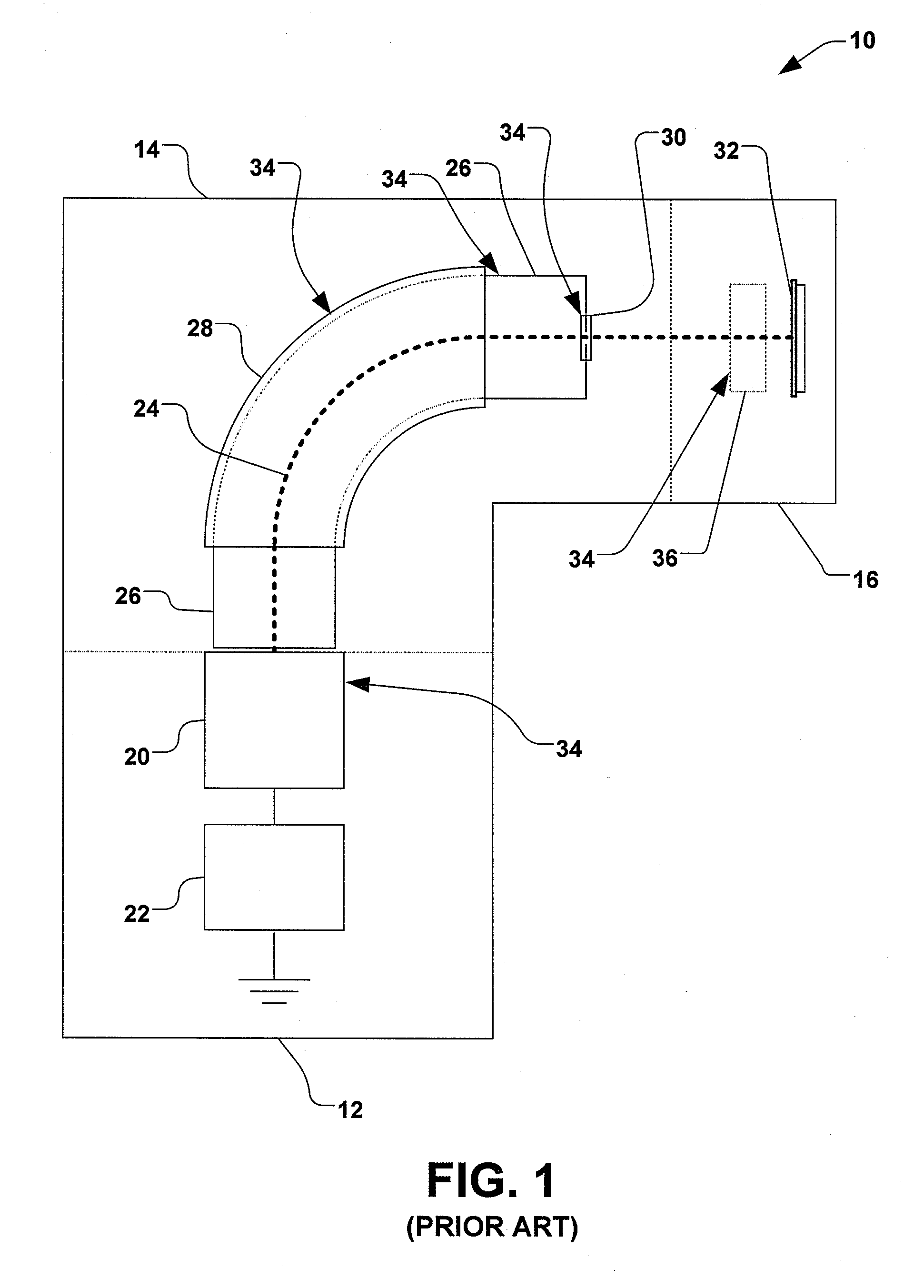

Method and apparatus for protecting an EUV reticle from particles

InactiveUS20050275835A1Reduce in quantityReduce the possibilityNanoinformaticsMaterial analysis by optical meansLithography processParticle method

Methods and apparatus for reducing particle contamination on a reticle used in an extreme ultraviolet (EUV) lithography process. According to one aspect of the present invention, an apparatus that protects a surface of an object includes a plate that is positioned in proximity to the surface and protects at least a first portion of the surface. An opening is defined within the plate, and is such that a second portion of the surface is exposed through the opening. The apparatus also includes at least one magnetic component which creates a static magnetic field that is arranged to deflect charged particles away from the opening and the surface of the object.

Owner:NIKON CORP

System for improving the wafer to wafer uniformity and defectivity of a deposited dielectric film

A method and apparatus are included that provide an improved deposition process for a Tunable Etch Resistant ARC (TERA) layer with improved wafer to wafer uniformity and reduced particle contamination. More specifically, the processing chamber is seasoned to reduce the number of contaminant particles generated in the chamber during the deposition of the TERA layer and improve wafer to wafer uniformity. The apparatus includes a chamber having an upper electrode at least one RF source, a substrate holder, and a showerhead for providing multiple precursors and process gasses.

Owner:TOKYO ELECTRON LTD

Cleaning solution for substrate for semiconductor device and cleaning method

InactiveUS20060270573A1Good water rinsabilityEasy to cleanOrganic detergent compounding agentsDetergent mixture composition preparationDevice materialOrganic base

To provide a cleaning solution for a substrate for a semiconductor device capable of removing particle contamination, organic contamination and metal contamination at the same time without corroding the substrate surface, and further having good water rinsability and capable of making the substrate surface highly clean in a short time, and a cleaning method. A cleaning solution for a substrate for a semiconductor device, which comprises an organic acid as component (a), an organic alkaline component as component (b), a surfactant as component (c) and water as component (d) and which has a pH of at least 1.5 and less than 6.5. A method for cleaning a substrate for a semiconductor device, which comprises cleaning a substrate for a semiconductor device having a Cu film and a low dielectric constant insulating film on its surface and having CMP treatment applied thereto, by means of the above cleaning solution for a substrate for a semiconductor device.

Owner:MITSUBISHI CHEM CORP

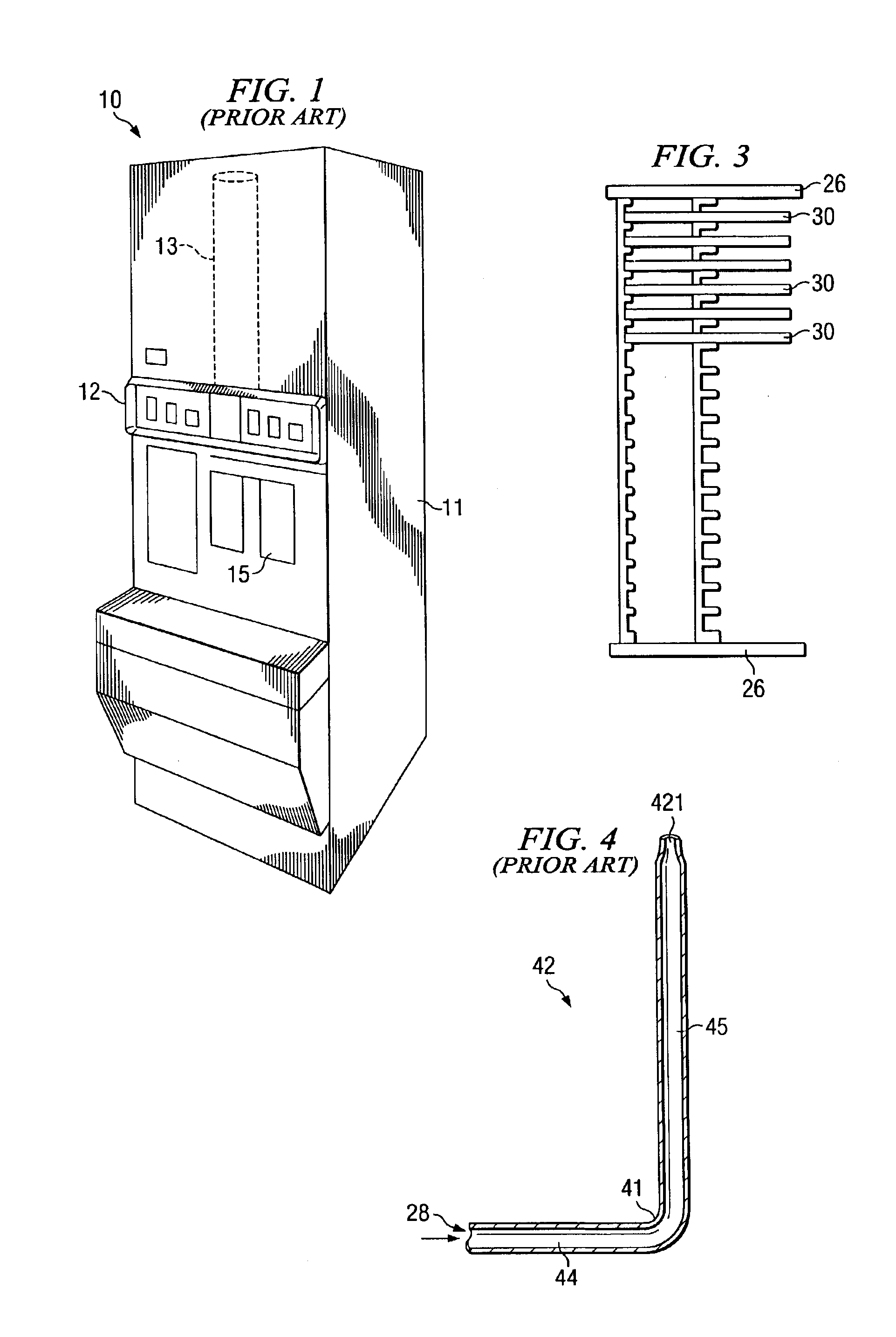

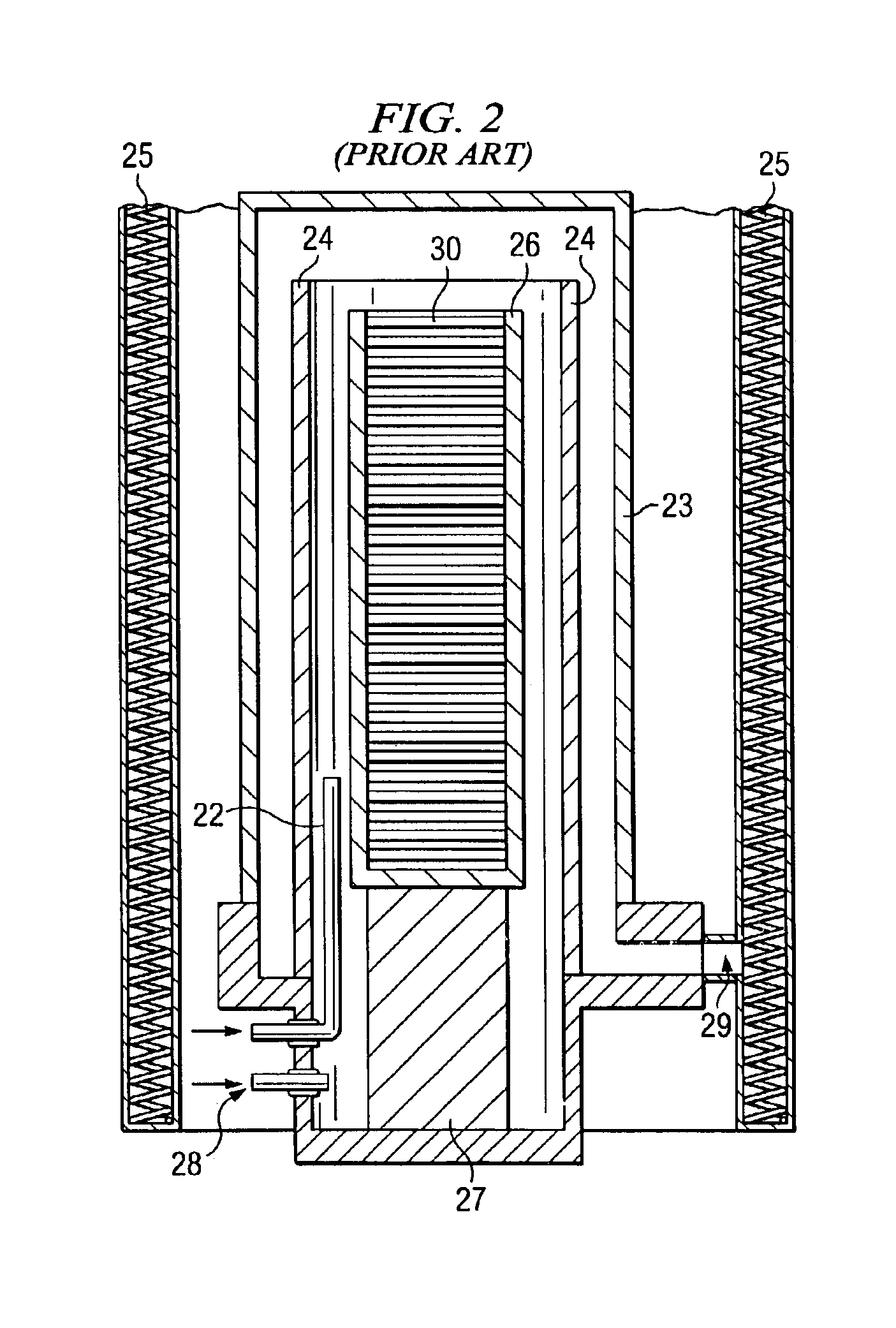

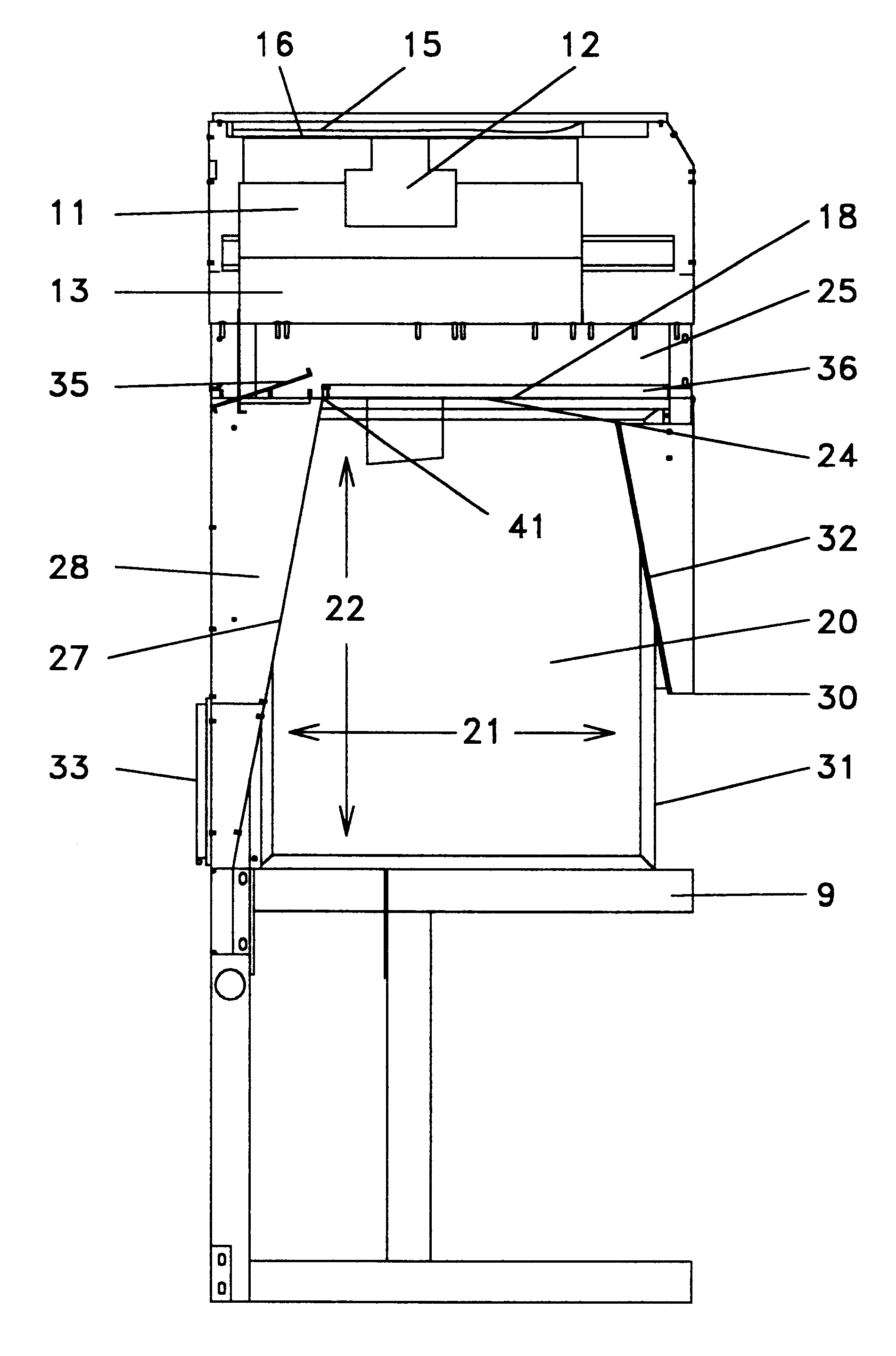

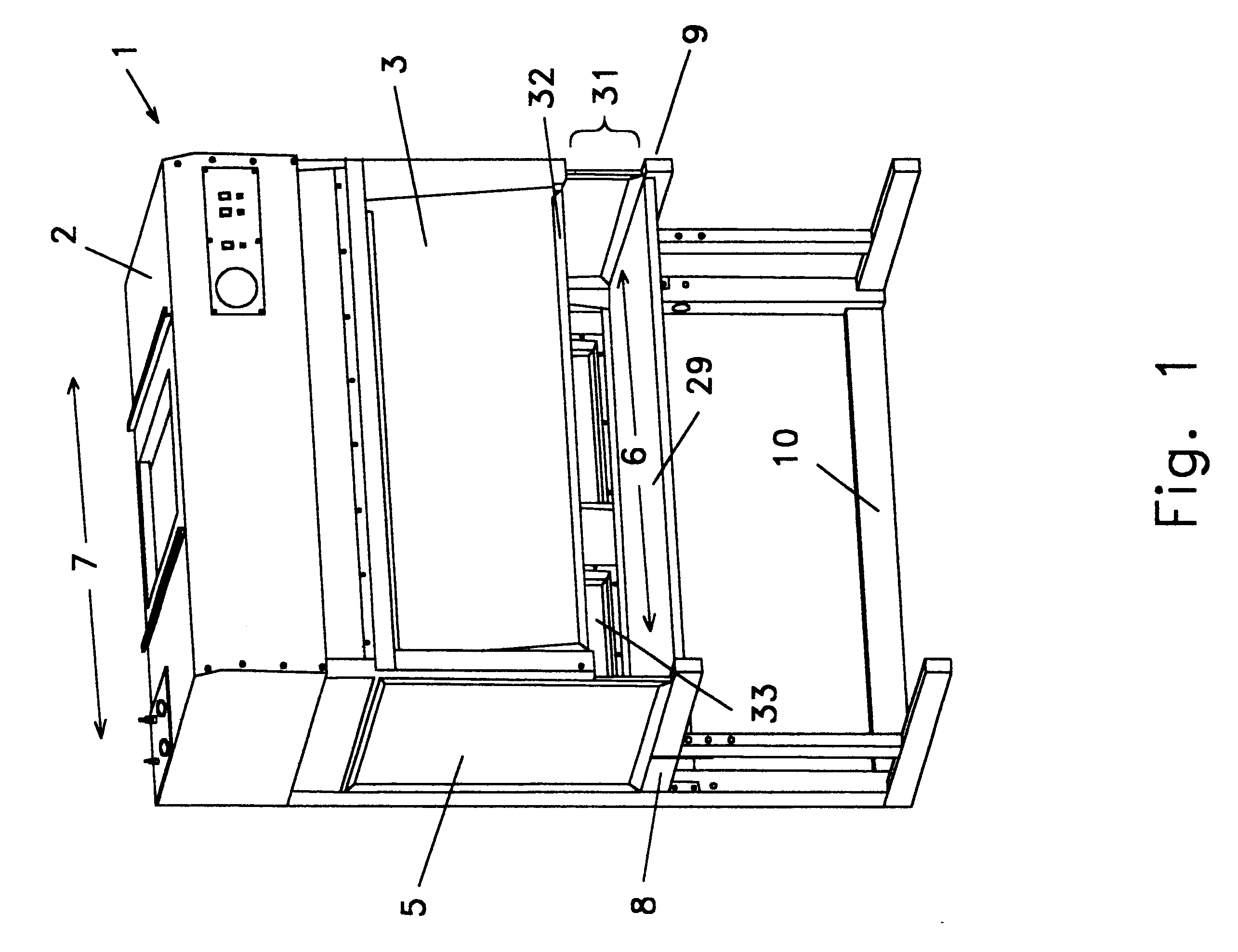

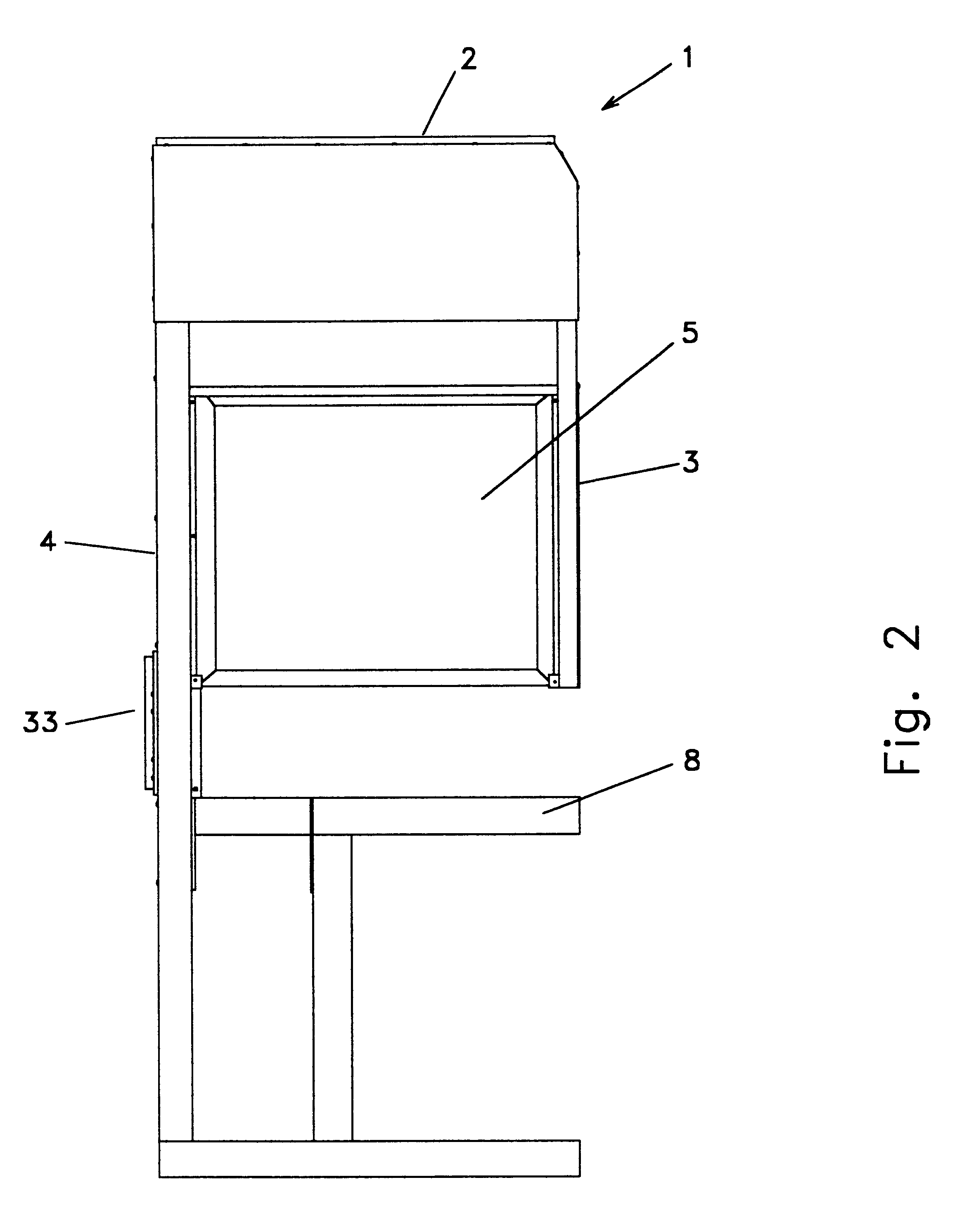

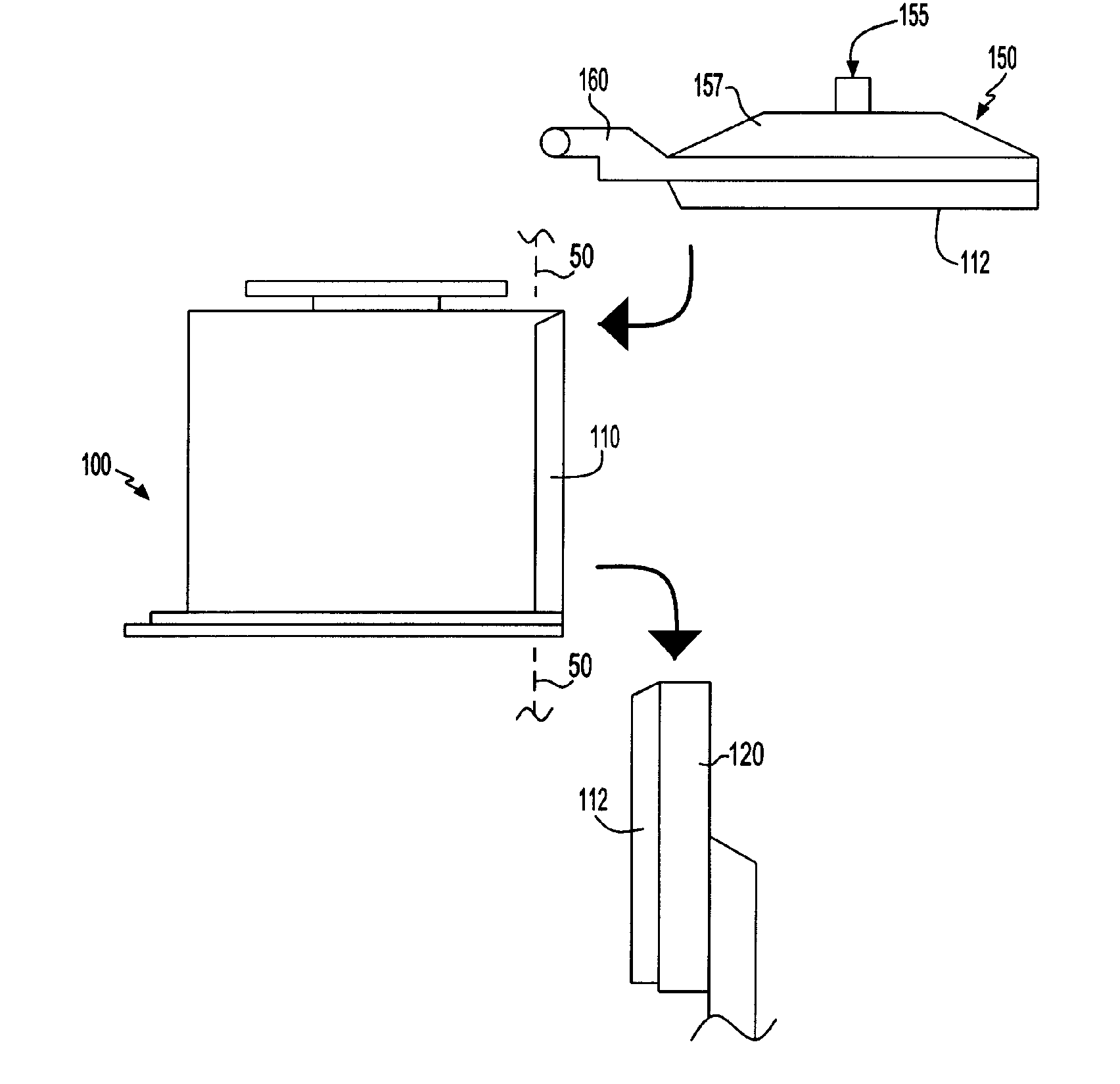

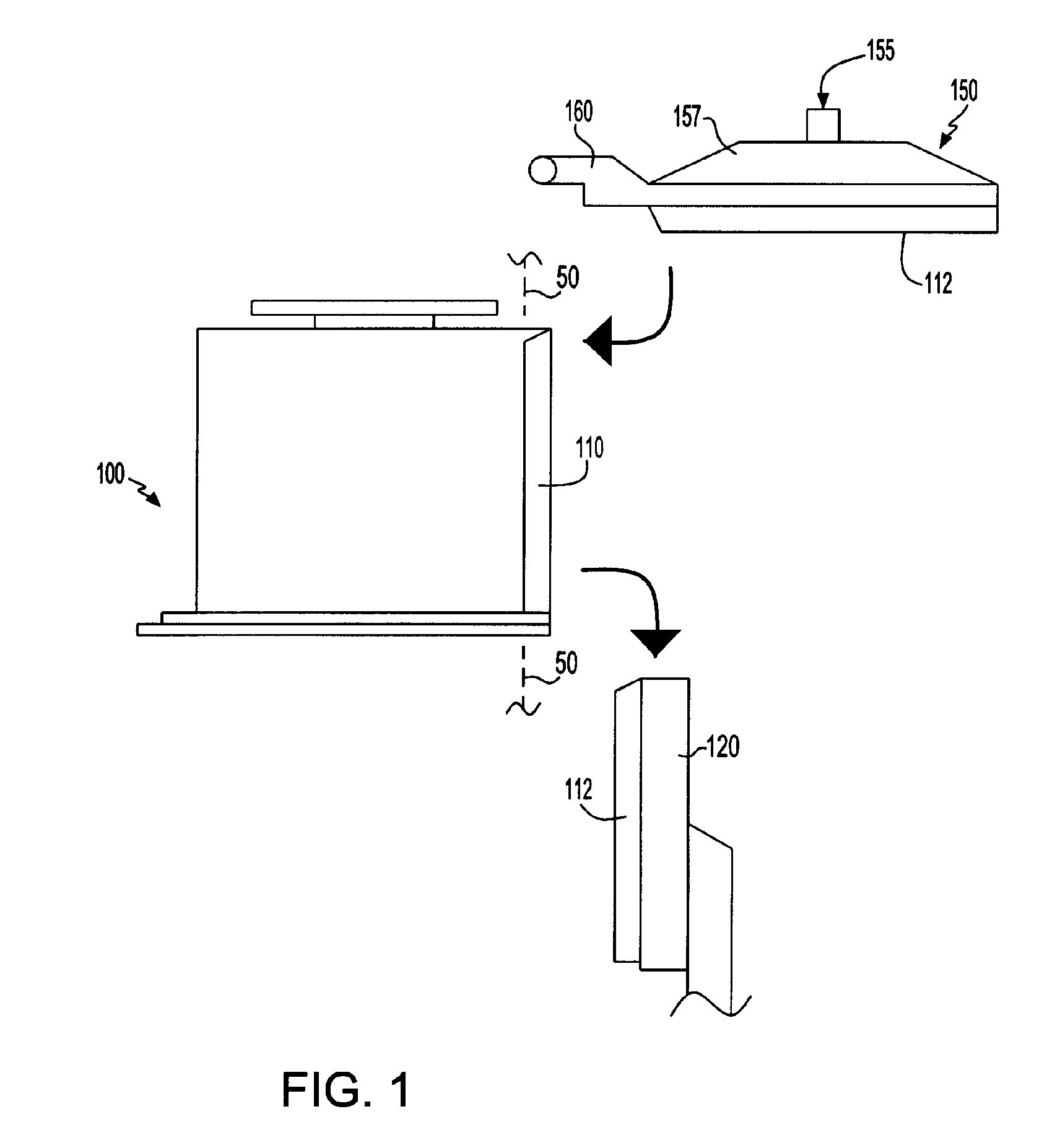

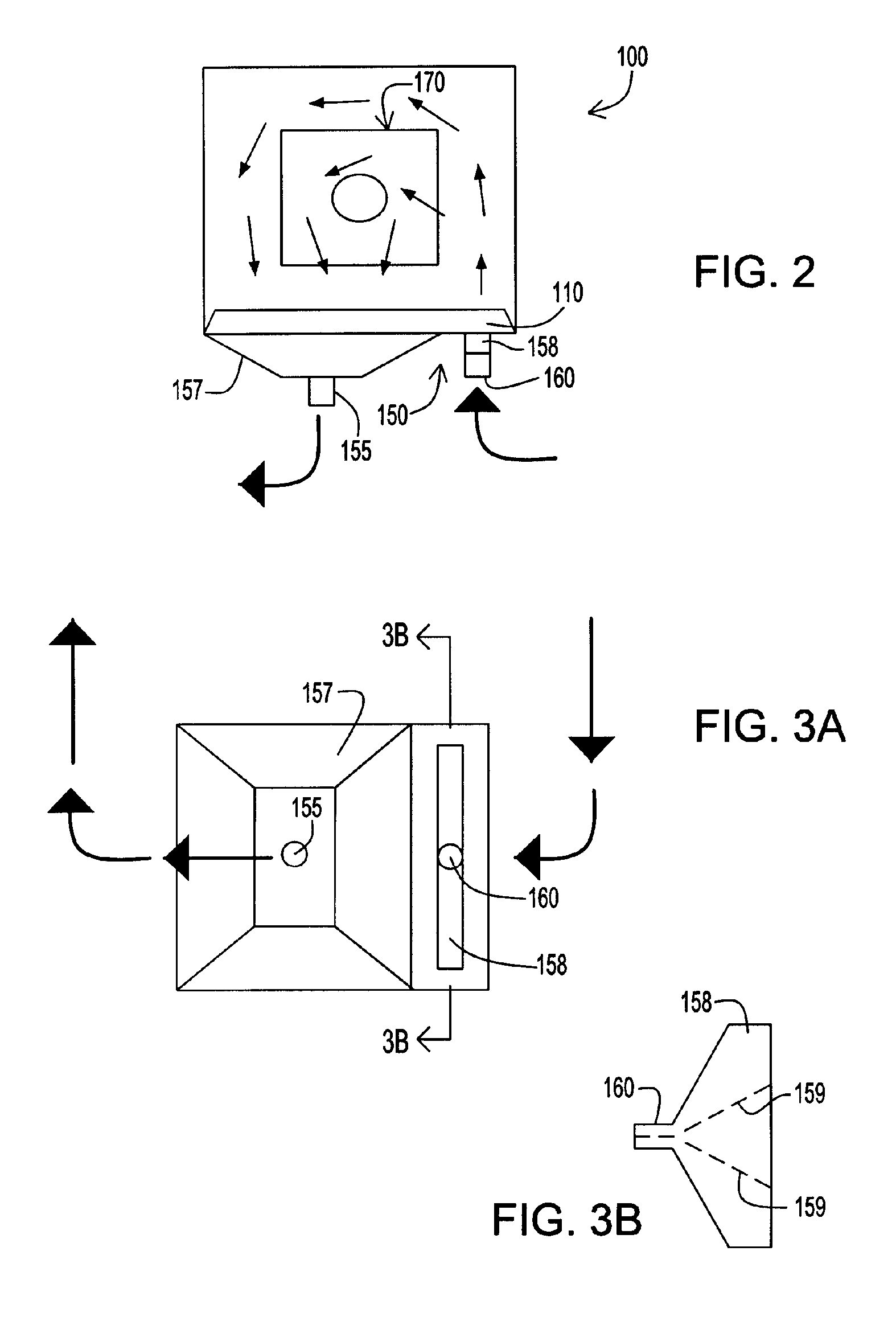

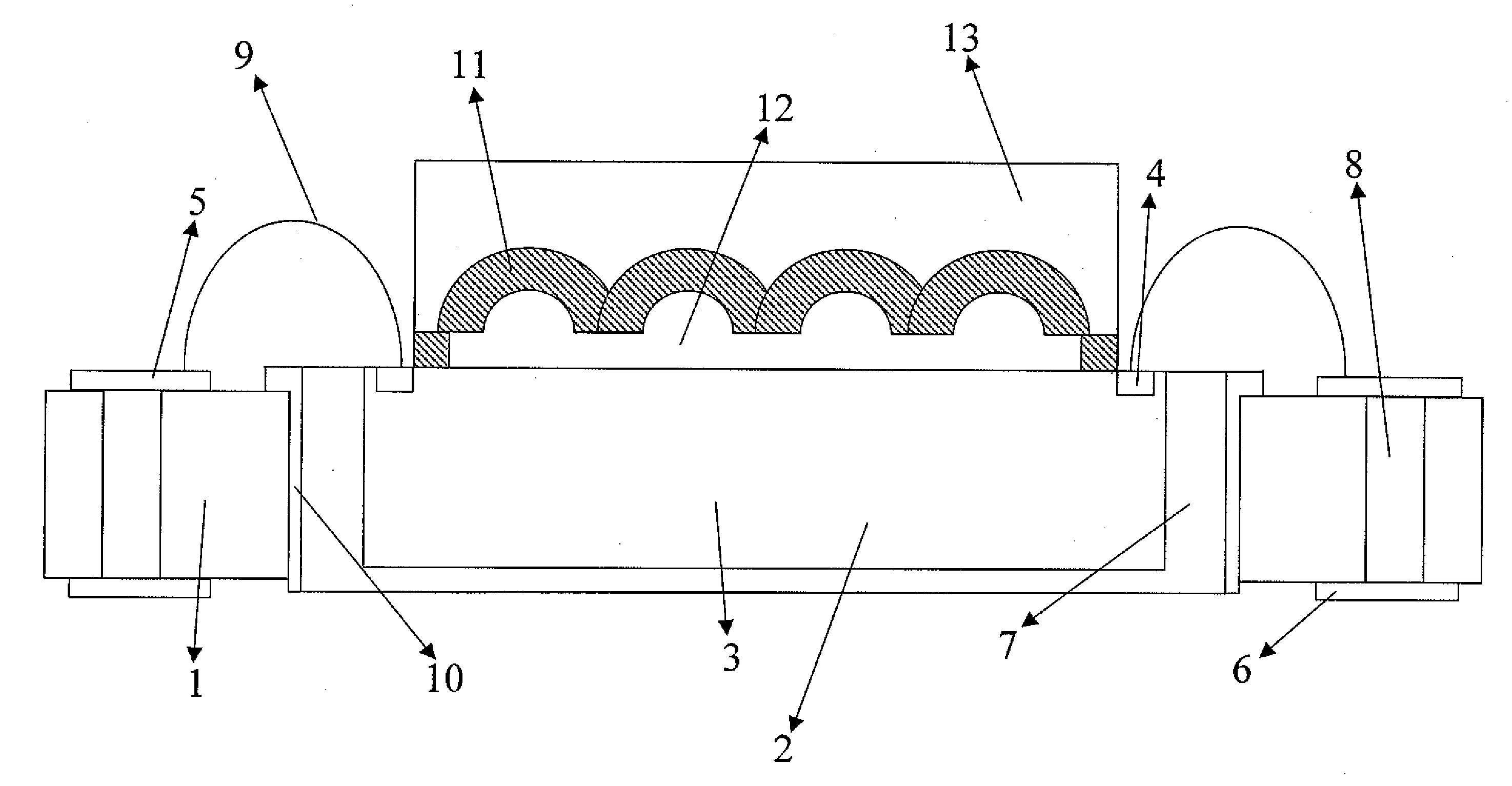

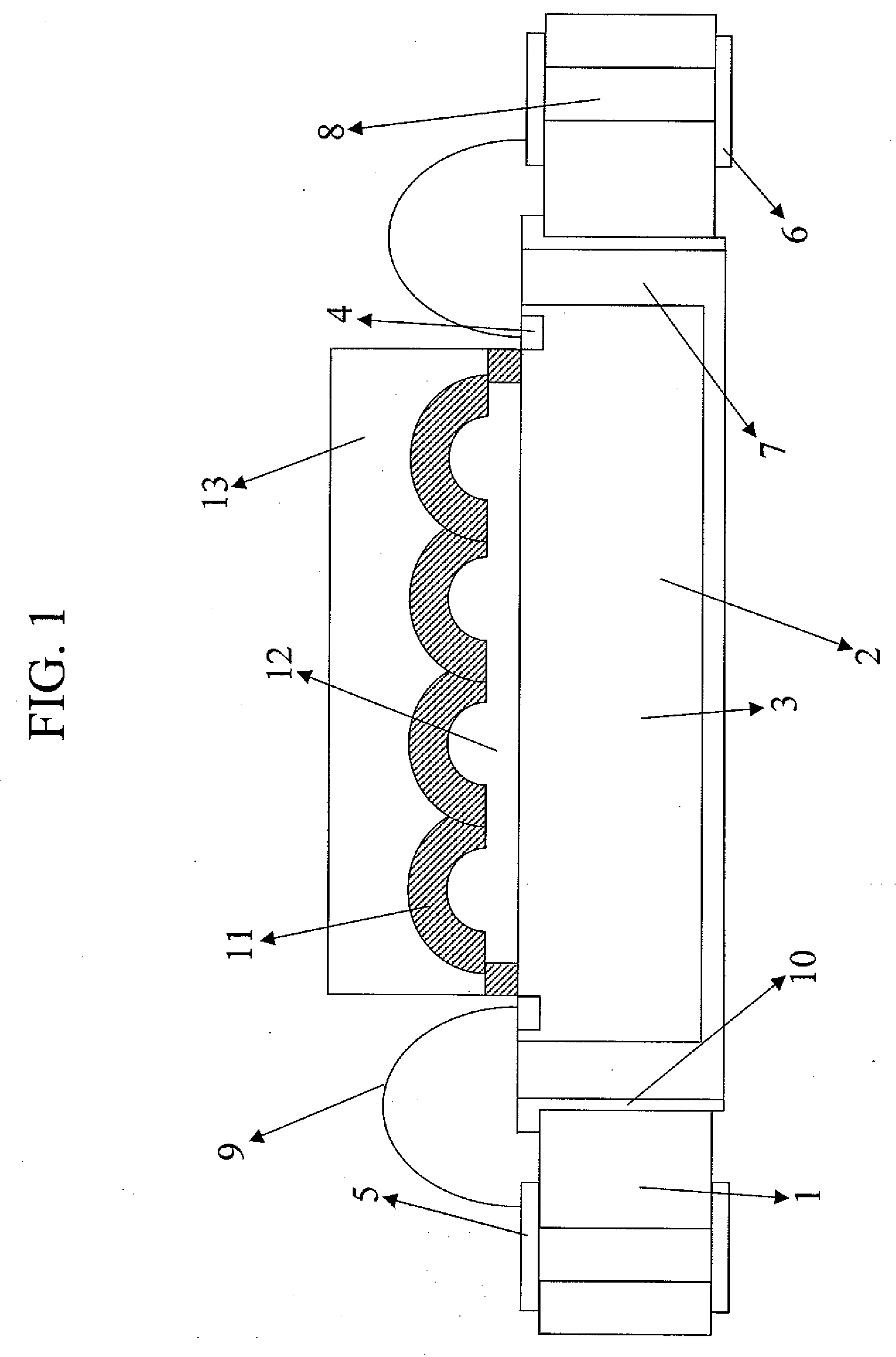

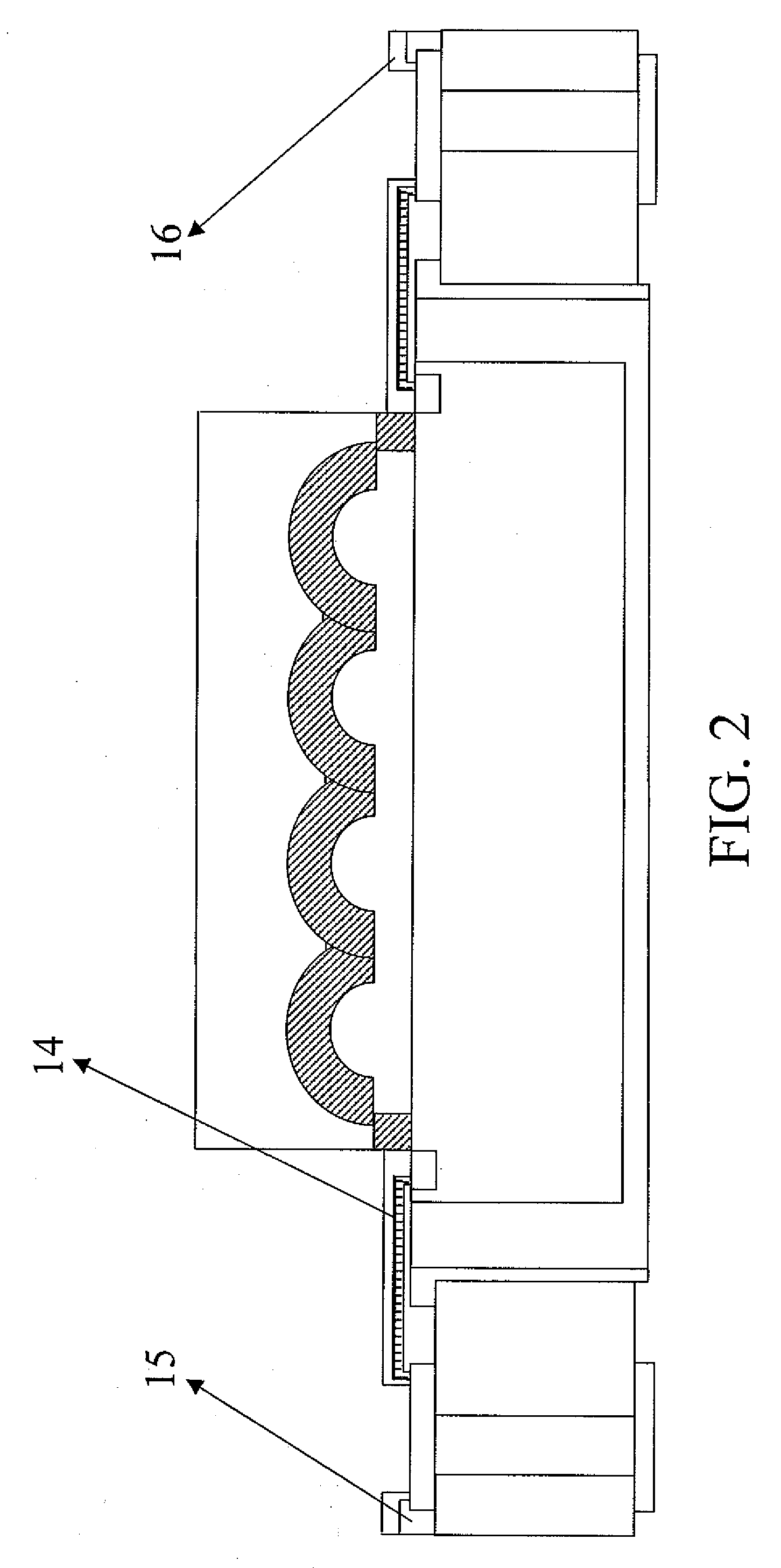

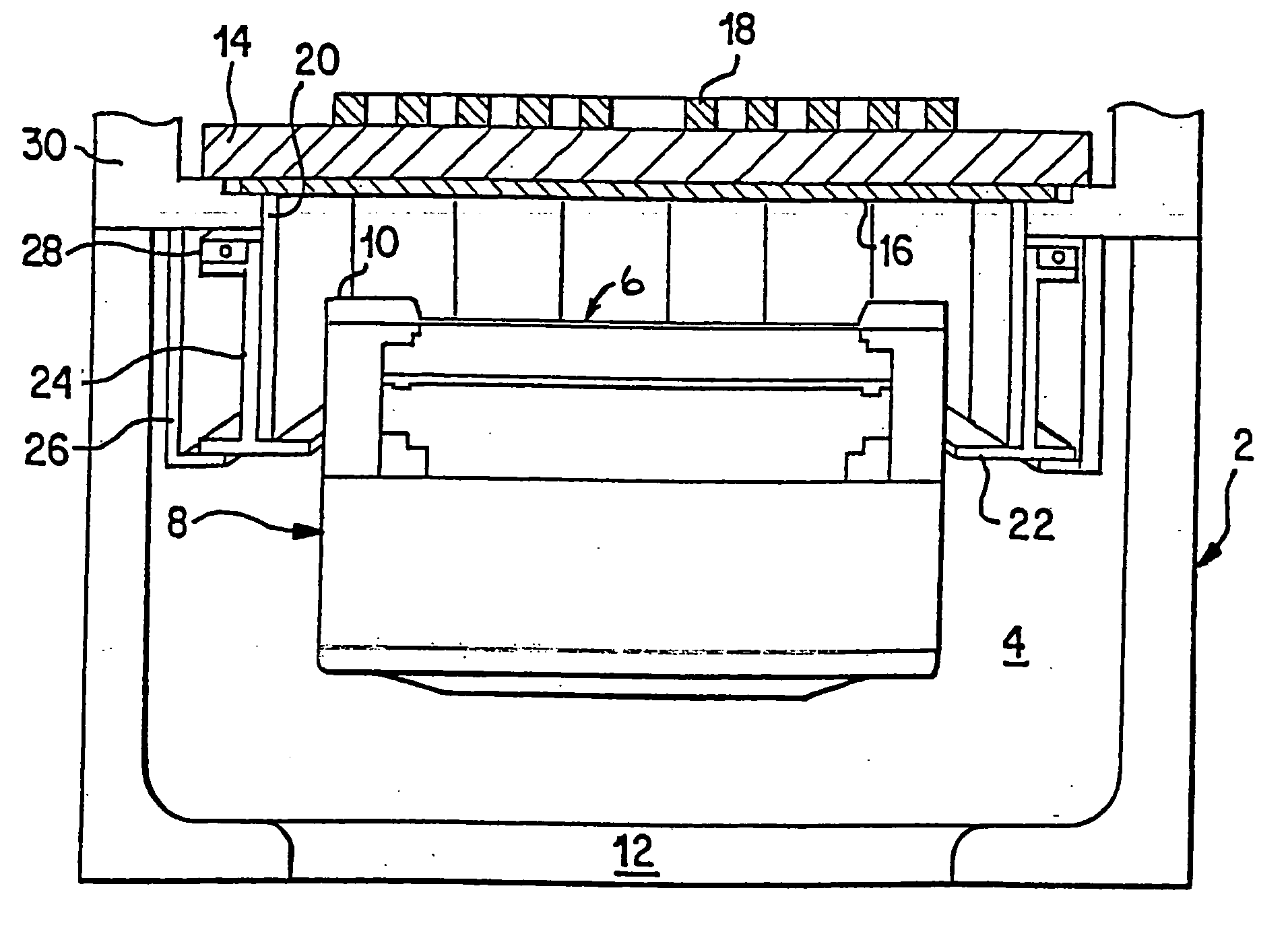

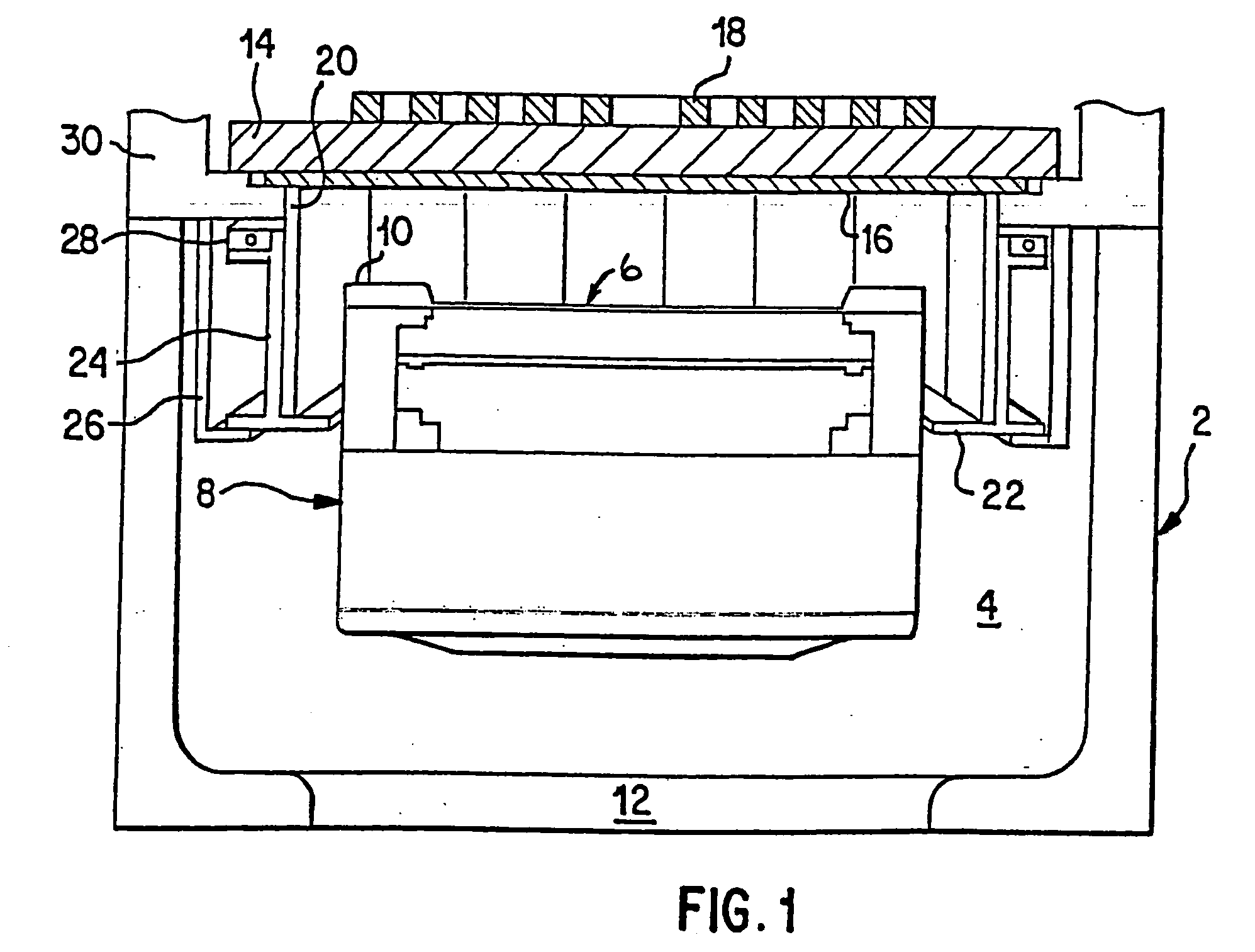

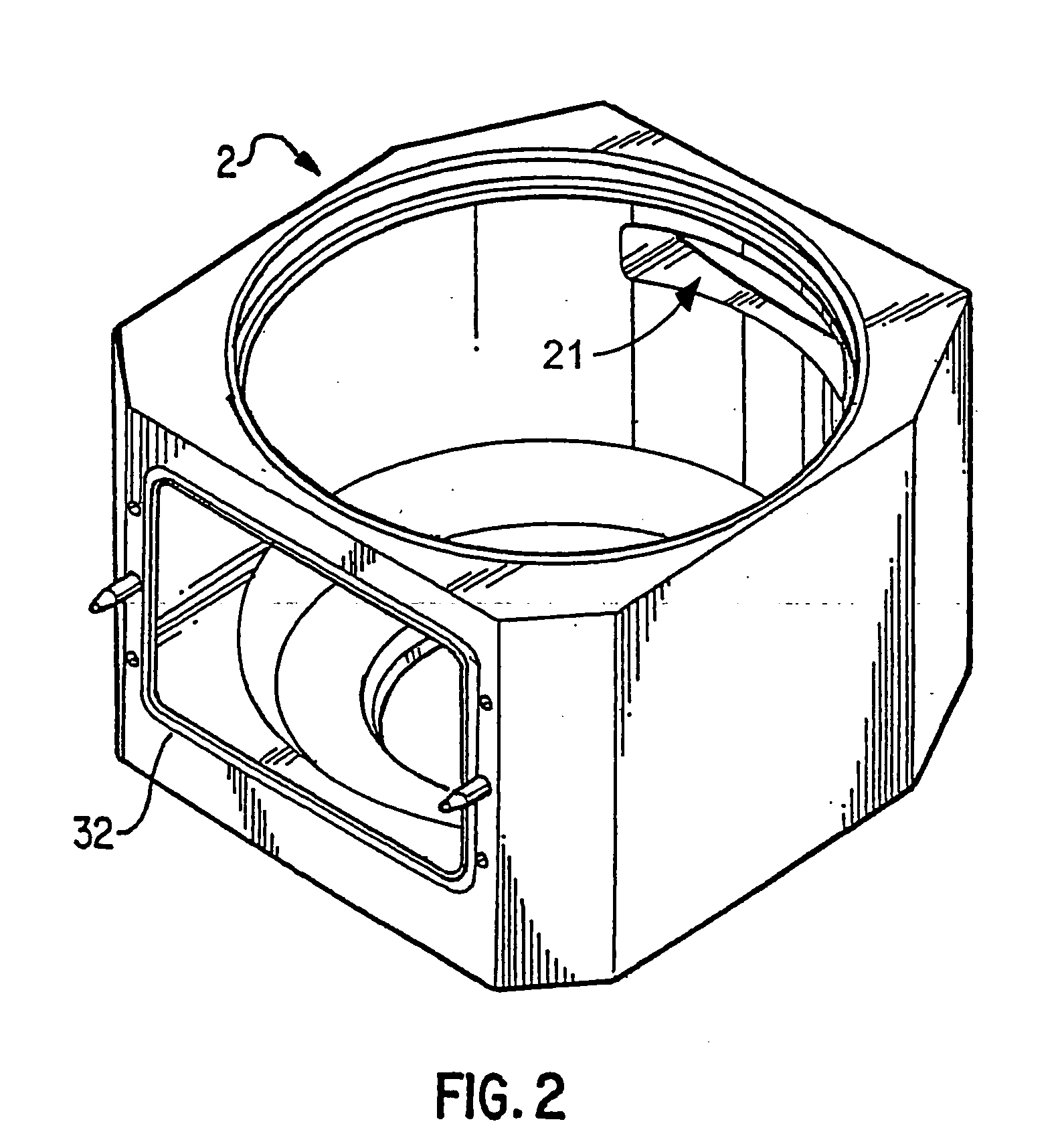

Adjustable clean-air flow environment

InactiveUS6632260B1Free from pollutionMany of constraintCombination devicesDomestic stoves or rangesEngineeringSmall footprint

Enclosures having adjustable clean gas flow environments and methods of enclosed pressure differential distribution technology. Specifically, clean gas flow enclosures, which provide for the isolation of materials from airborne micro-particulate contamination. An embodiment of the invention utilizes a small footprint, modular, selectable, clean-gas flow environment for handling and isolating materials. The environment can be a clean room class environment by providing filtered gas from a gas flow generator (12) through a gas filter (13) to a filtered gas flow space (20). An embodiment of the invention provides a first plenum (23) and a second plenum (26) so that both a horizontal filtered gas flow and vertical filtered gas flow may be used separately or in combination within the same filtered gas flow space (20).

Owner:STRATOTECH CORP

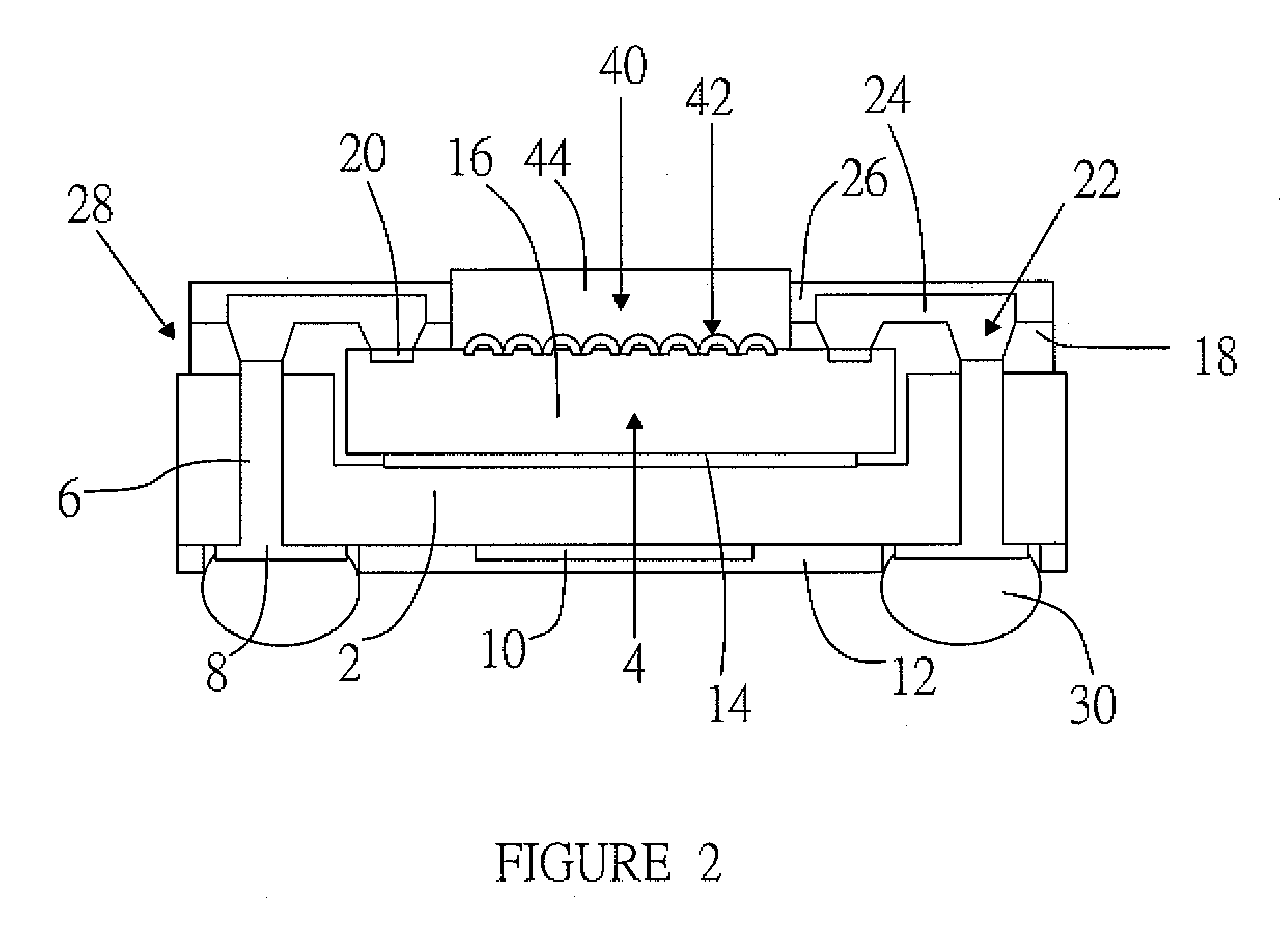

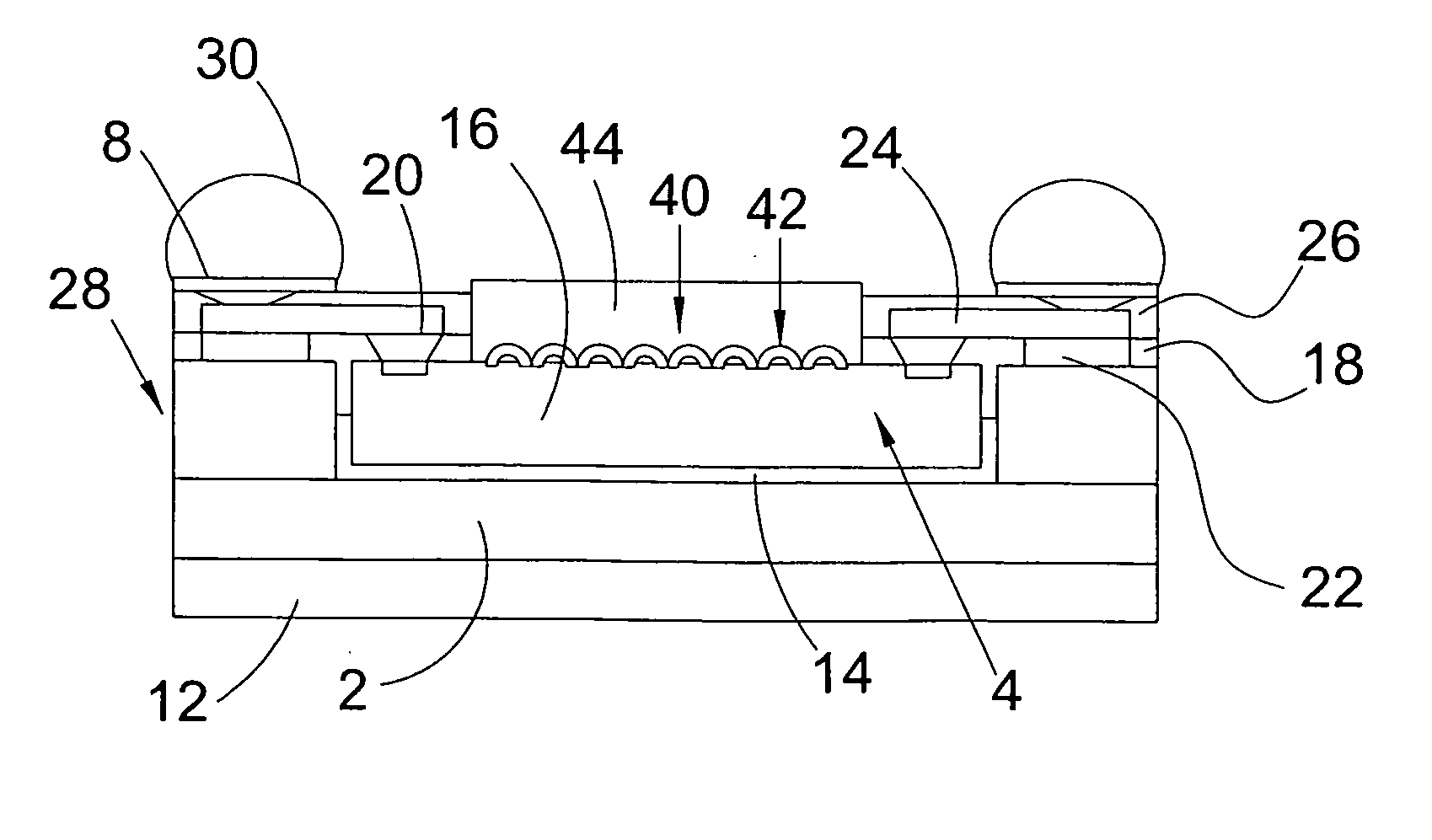

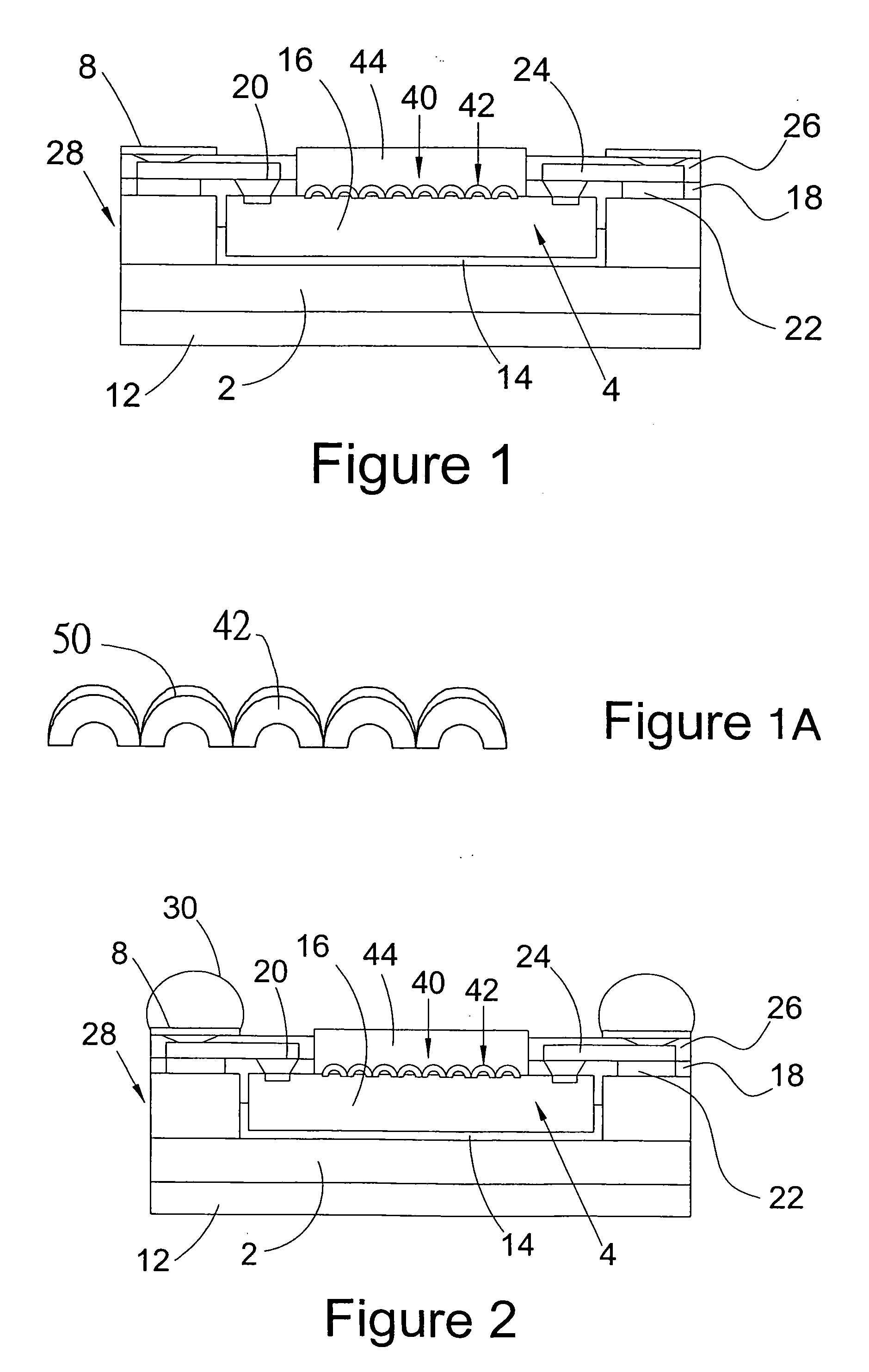

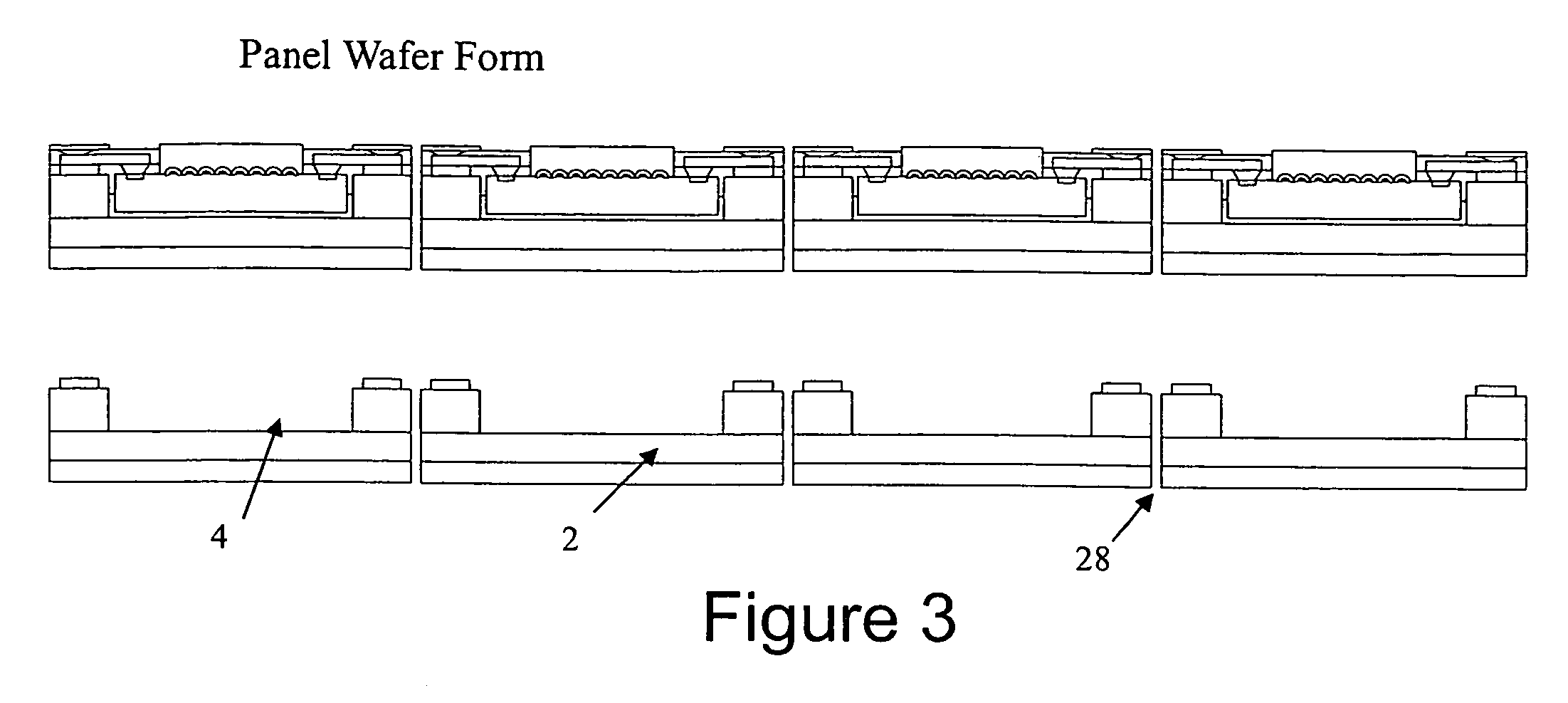

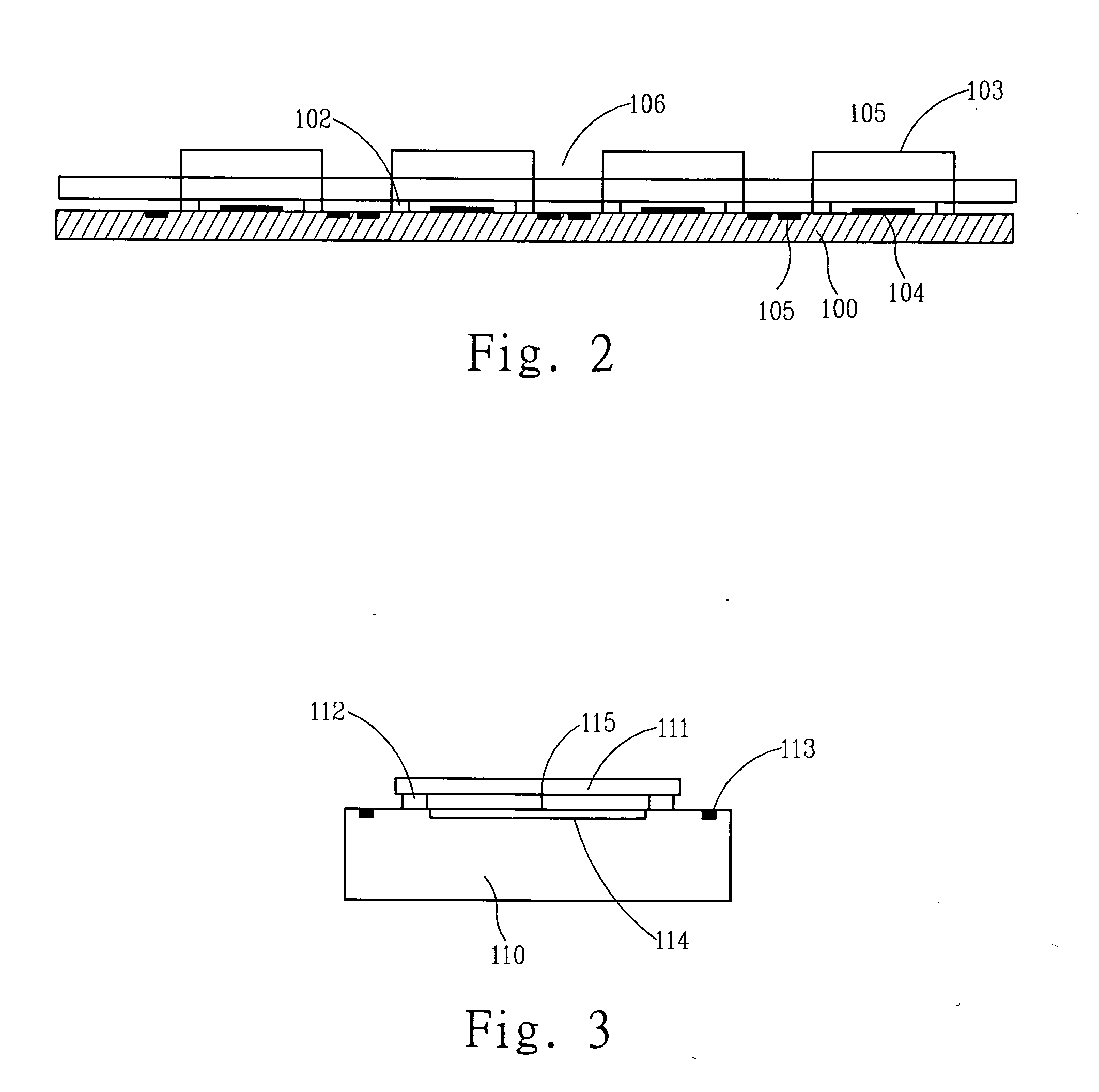

Wafer level image sensor package with die receiving cavity and method of the same

InactiveUS20080191297A1Avoid Particle ContaminationSemiconductor/solid-state device detailsSolid-state devicesEngineeringProtection layer

The present invention provides a structure of package comprising a substrate with a die receiving cavity formed within an upper surface of the substrate and a through holes structure formed there through, wherein a terminal pads are formed under the through holes structure and the substrate includes a conductive trace formed on a lower surface of the substrate. A die is disposed within the die receiving cavity by adhesion and a dielectric layer formed on the die and the substrate. A re-distribution metal layer (RDL) is formed on the dielectric layer and coupled to the die and the through holes structure. Conductive bumps are coupled to the terminal pads. An opening is formed within the dielectric layer and a top protection layer to expose the micro lens area of the die for Image Sensor chip. A protection layer (film) be coated on the micro lens area with water repellent and oil repellent to away the particle contamination. A transparent cover with coated IR filter is optionally formed over the micron lens area for protection.

Owner:ADVANCED CHIP ENG TECH

Method And Apparatus For Testing Particulate Contamination In Wafer Carriers

InactiveUS20070062561A1Avoid pollutionReduce impactSamplingHollow article cleaningProduct gasParticulate contamination

Wafer carriers in an integrated circuit fab are tested for residual particle contamination by replacing the standard carrier door by a test cover having a gas inlet and outlet, counting the number of FM particles exiting the carrier during a flush cycle with a test gas having a known concentration of FM particles and either continuing processing if the number of FM particles is below a threshold, performing a purge with the test gas if the contamination is in a purge range, or sending the carrier out for cleaning if the number of FM particles is above the purge range.

Owner:IBM CORP

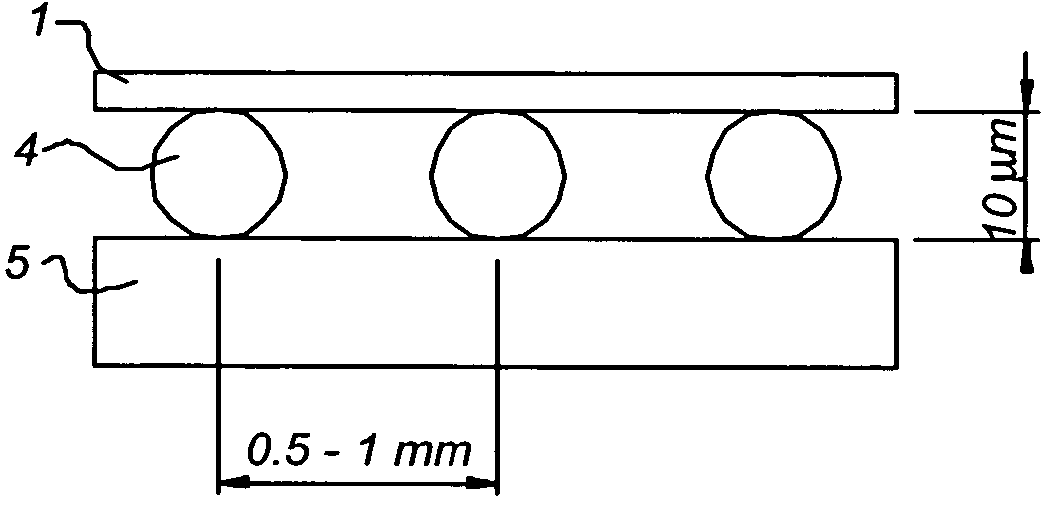

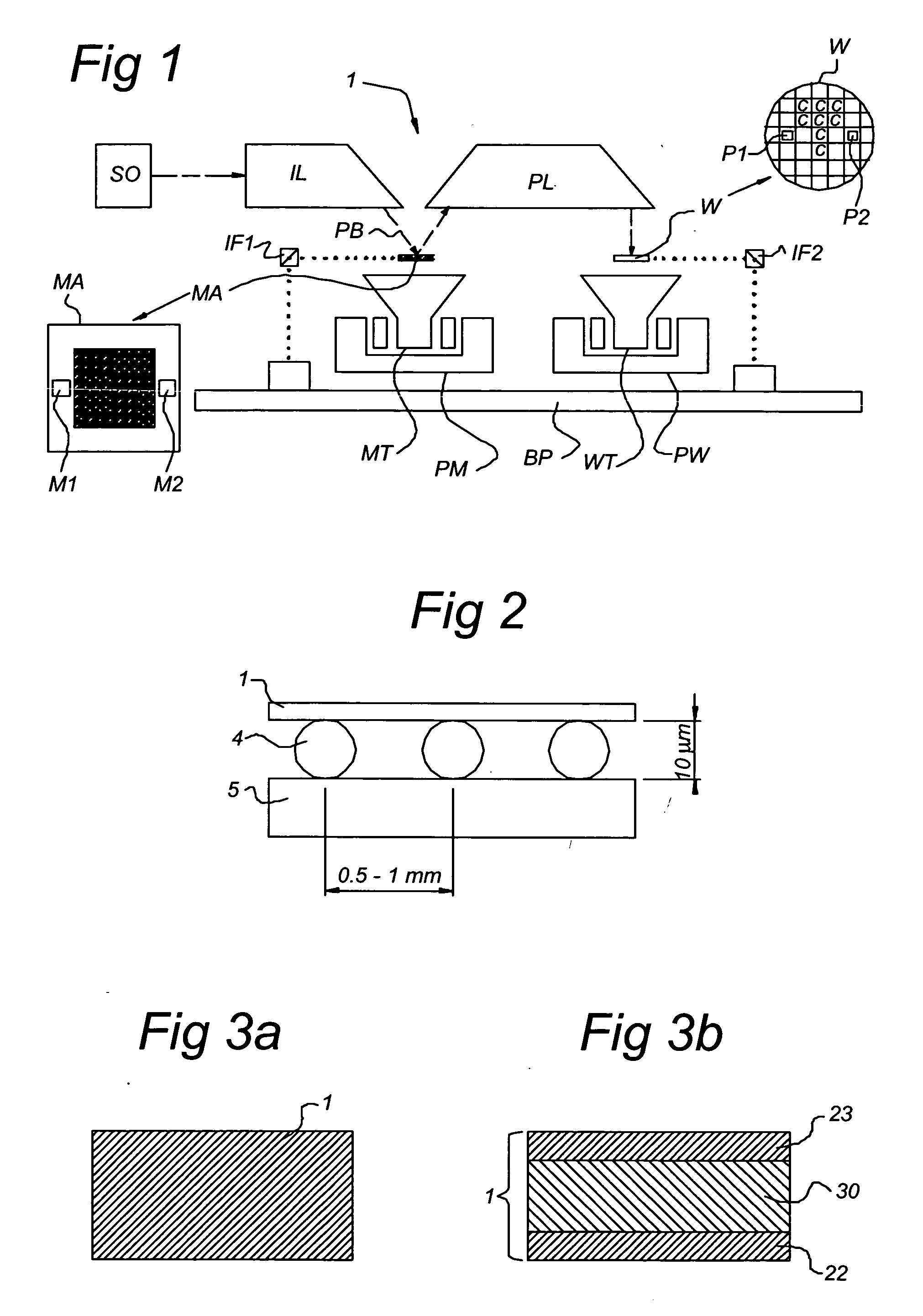

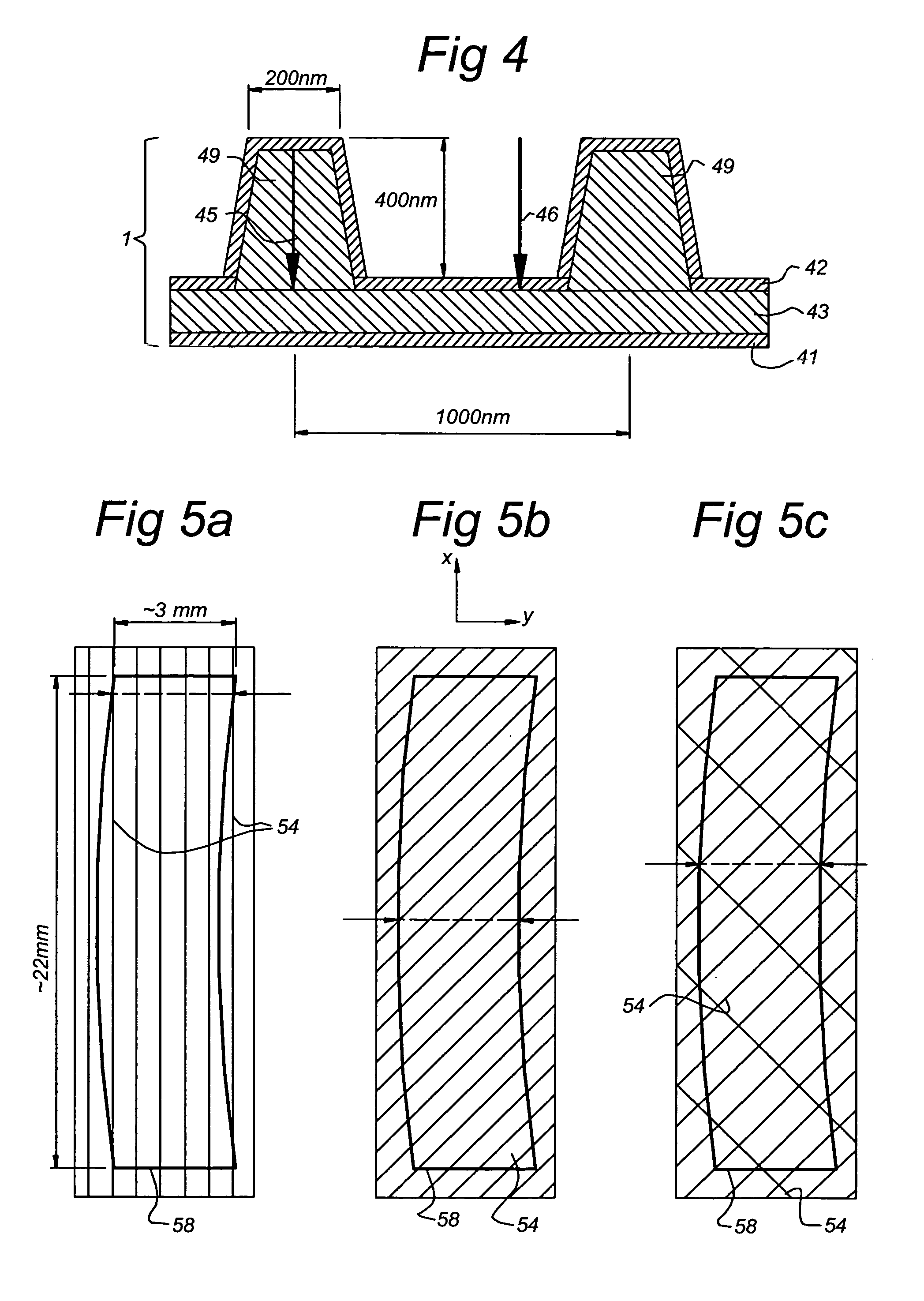

Filter window, lithographic projection apparatus, filter window manufacturing method, device manufacturing method and device manufactured thereby

InactiveUS20050040345A1Improve throughputIncrease the light areaRadiation/particle handlingNanoinformaticsProjection opticsLength wave

The invention relates to a filter window for EUV lithography comprising a pellicle, a wire structure for supporting the pellicle, characterized in that the pellicle comprises a first layer comprising at least one of AlN, Ru, Ir, Au, SiN, Rh, C. A pellicle with these materials has a very low EUV absorption in combination with a minimal oxidation rate. In a particular embodiment, the thickness of the pellicle is between 30 nm and 100 nm. It can be easily checked that absorption of EUV radiation of such a thin pellicle is equal to known filter windows, i.e. about 50% at a wavelength of 13.5 nm wavelength, but the oxidation of the pellicle according to the invention is much smaller. The filter window can for example be used to separate a Projection Optics box and a wafer compartment of the apparatus or to shield a reticle from particle contamination.

Owner:ASML NETHERLANDS BV

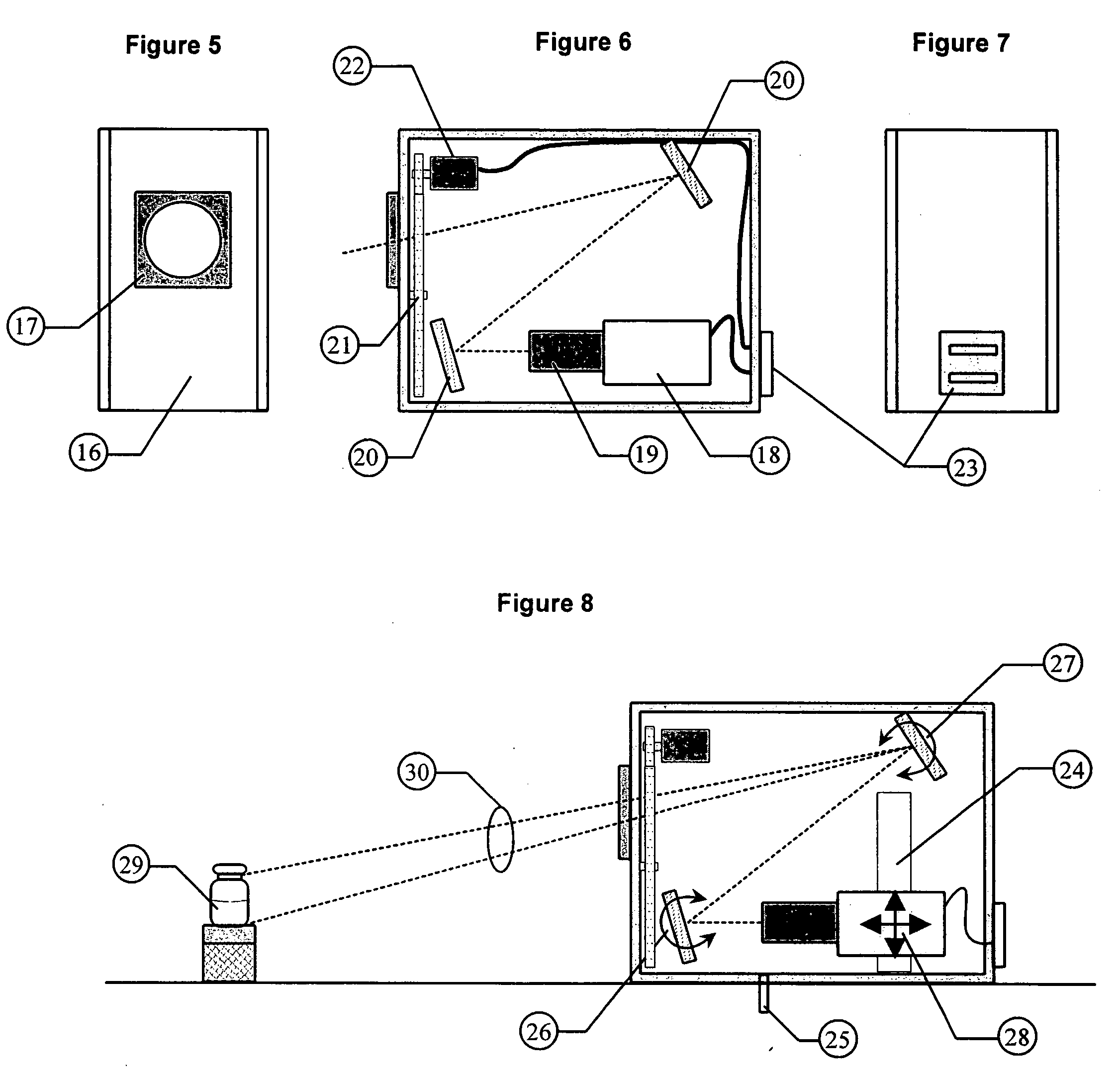

Automated visual inspection system for the detection of microbial growth in solutions

ActiveUS20060072111A1Easy to adjustLess optical densityOptically investigating flaws/contaminationParticle size analysisNon destructiveVisual inspection

Essential prerequisites for any injectable product are its sterility, its freedom from pathogens and its freedom from visible particle contamination . . . . These requirements must be satisfied prior to the release of an injectable product batch for sale and use. A major difficulty in responding to these assay requirements is the need for a size sensitivity difference of 100 or greater in determining the presence of viable pathogenic organisms and of non-viable random particle contaminants. The wide dynamic testing range cannot be satisfied in current art with a single non-destructive testing station. The present invention uses a special agitation procedure to generate separate liquid volumes containing the small viable and larger non-viable particle contaminants. This separation makes possible the introduction of sensing systems that have been optimized for each size range and that can operate in parallel without interference.

Owner:BUDD GERALD WALTER +1

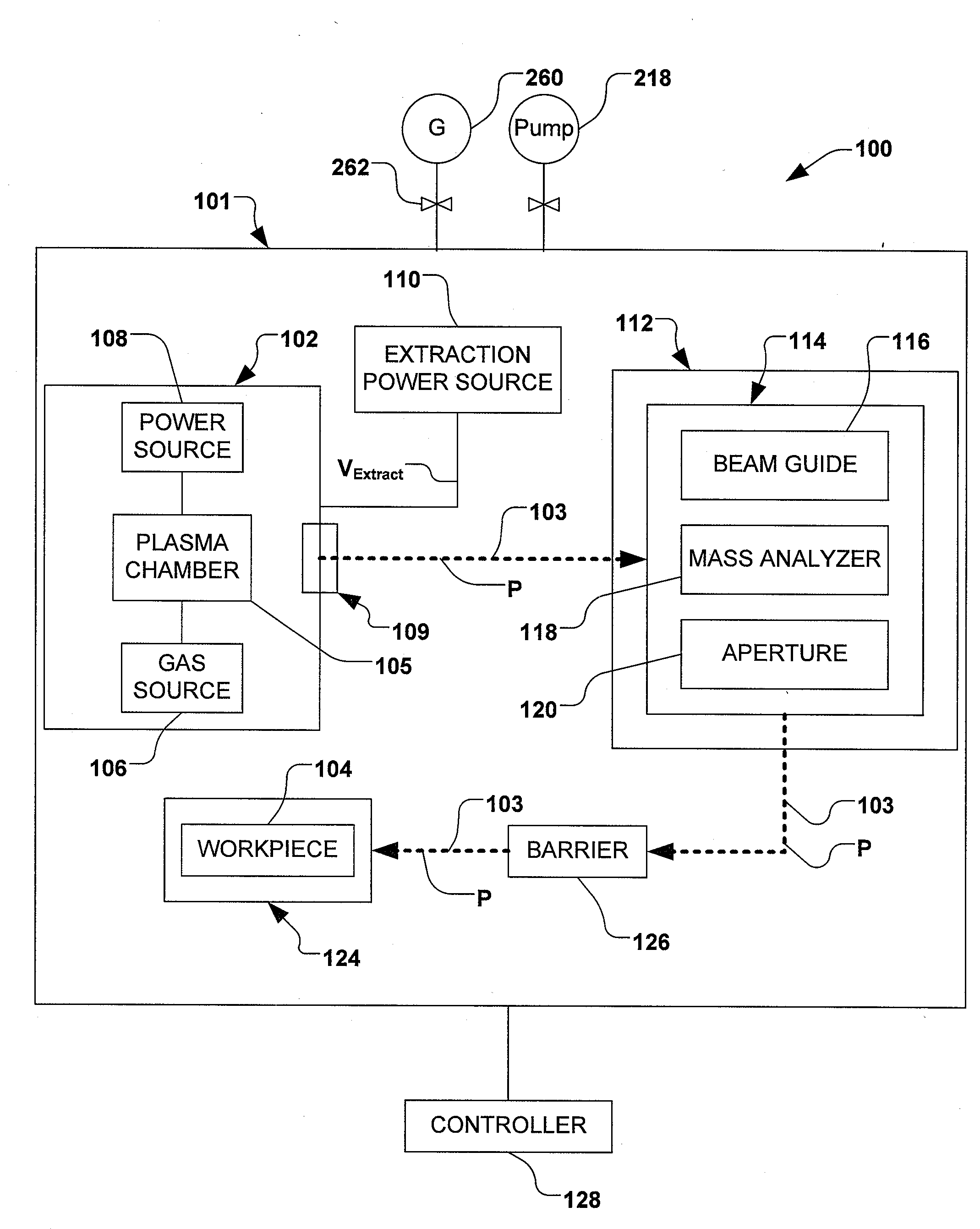

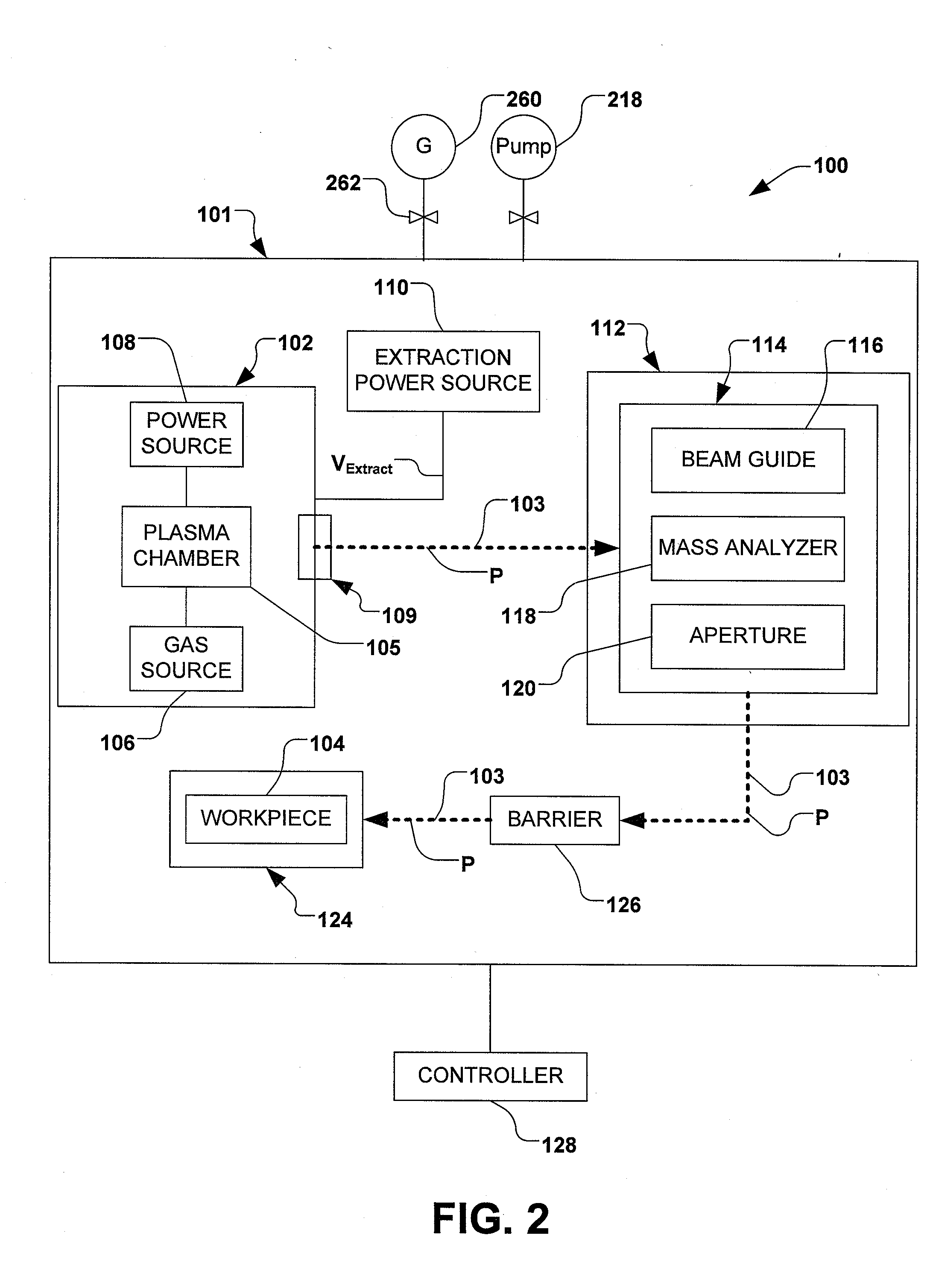

Control of particles on semiconductor wafers when implanting boron hydrides

ActiveUS20090294698A1Reduce particle pollutionElectric discharge tubesCleaning using gasesMulti pollutantIon beam

A method for reducing particle contamination during implantation of ions comprises providing an implantation system for implanting ions into a workpiece via an ion beam, wherein one or more components are under selective vacuum and have one or more contaminants in a first state disposed thereon. A gas is introduced to the implantation system, wherein the gas generally reacts with at least a portion of the one or more contaminants, therein transforming the at least a portion of the one or more contaminants into a second state The at least a portion of the one or more contaminants in the second state remain disposed on the one or more components, and wherein the at least a portion of the second state of the one or more contaminants generally does not produce particle contamination on the one or more workpieces.

Owner:AXCELIS TECHNOLOGIES

Image sensor package utilizing a removable protection film and method of making the same

InactiveUS20090008729A1Avoid Particle ContaminationStrip awaySemiconductor/solid-state device detailsSolid-state devicesTectorial membraneEngineering

The present invention discloses a structure of image sensor package utilizing a removable protection film. The structure comprises a substrate with a die receiving cavity and inter-connecting through holes. Terminal pads are formed under the inter-connecting through holes and metal pads are formed on an upper surface of the substrate. A die is disposed within the die receiving cavity by an adhesion material. Bonding pads are formed on the upper edge of the die. Bonding wires are coupled to the metal pads and the bonding pads. A protection layer is formed on the micro lens area to protect the micro lens from particle contamination. A removable protection film is formed over the protection layer to protect the micro lens from water, oil, dust or temporary impact during the packaging and assembling process.

Owner:ADVANCED CHIP ENG TECH

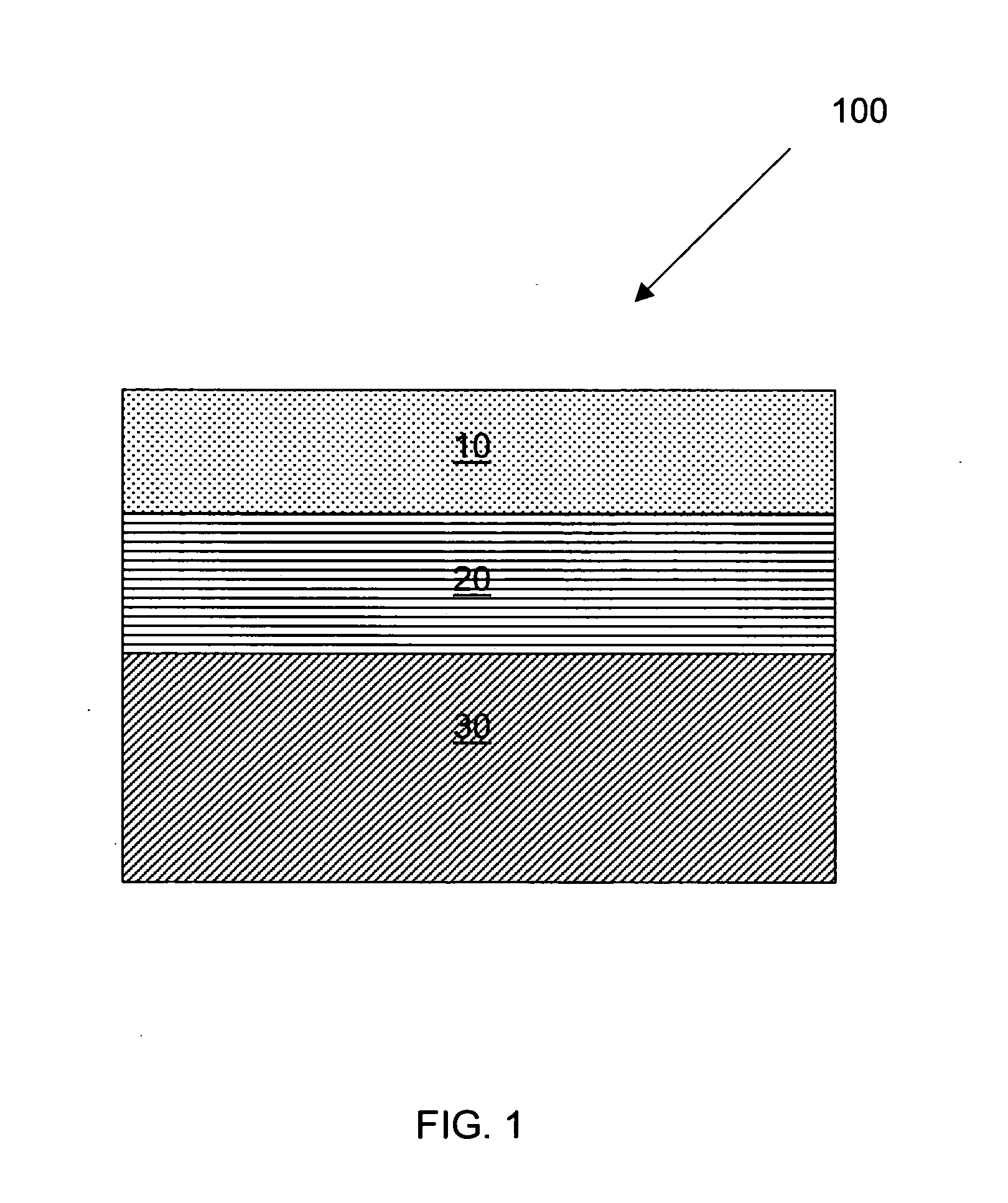

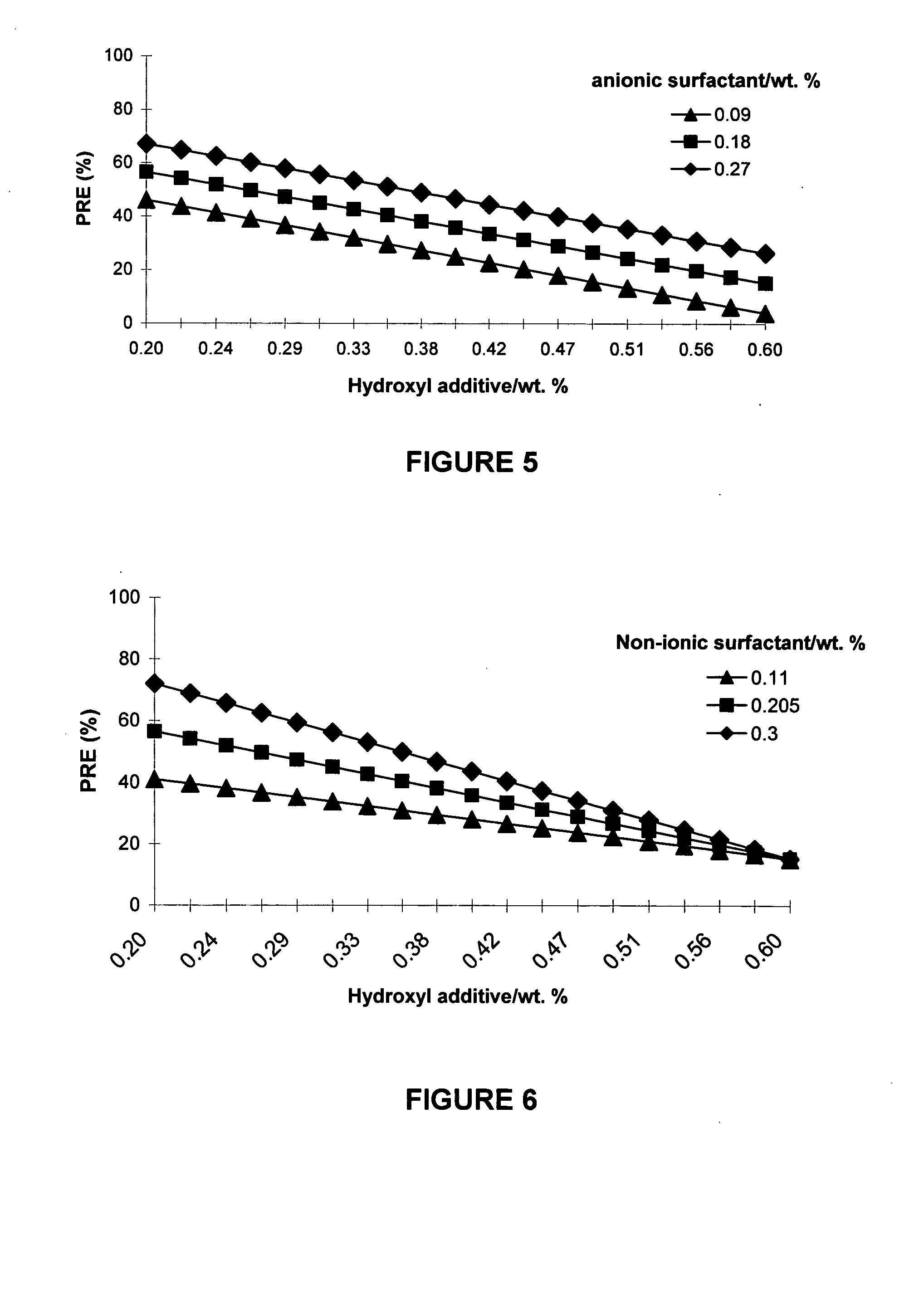

Removal of particle contamination on a patterned silicon/silicon dioxide using dense fluid/chemical formulations

InactiveUS20060019850A1Non-ionic surface-active compoundsNon-surface-active detergent compositionsOrganic compoundSilicon dioxide

A cleaning composition for cleaning particulate contamination from small dimensions on microelectronic device substrates. The cleaning composition contains dense CO2 (preferably supercritical CO2 (SCCO2)), alcohol, fluoride source, anionic surfactant source, non-ionic surfactant source, and optionally, hydroxyl additive. Such cleaning composition overcomes the intrinsic deficiency of SCCO2 as a cleaning reagent, viz., the non-polar character of SCCO2 and its associated inability to solubilize species such as inorganic salts and polar organic compounds that are present in particulate contamination on wafer substrates and that must be removed from the microelectronic device substrate for efficient cleaning. The cleaning composition enables damage-free, residue-free cleaning of substrates having particulate contamination on Si / SiO2 substrates.

Owner:ADVANCED TECH MATERIALS INC

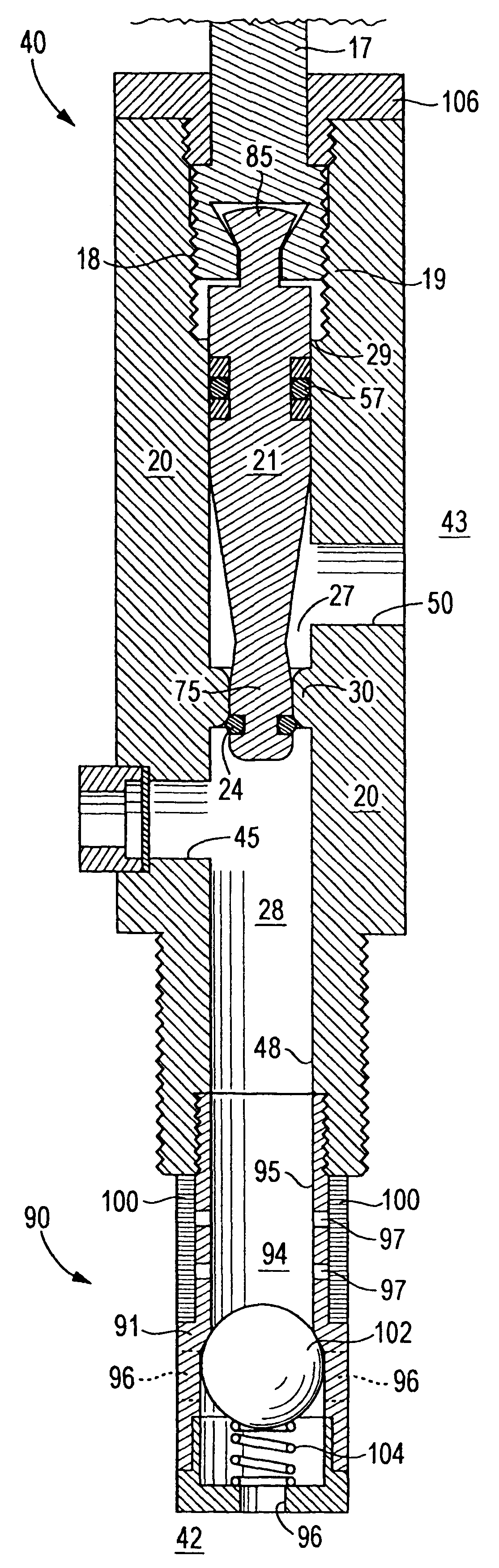

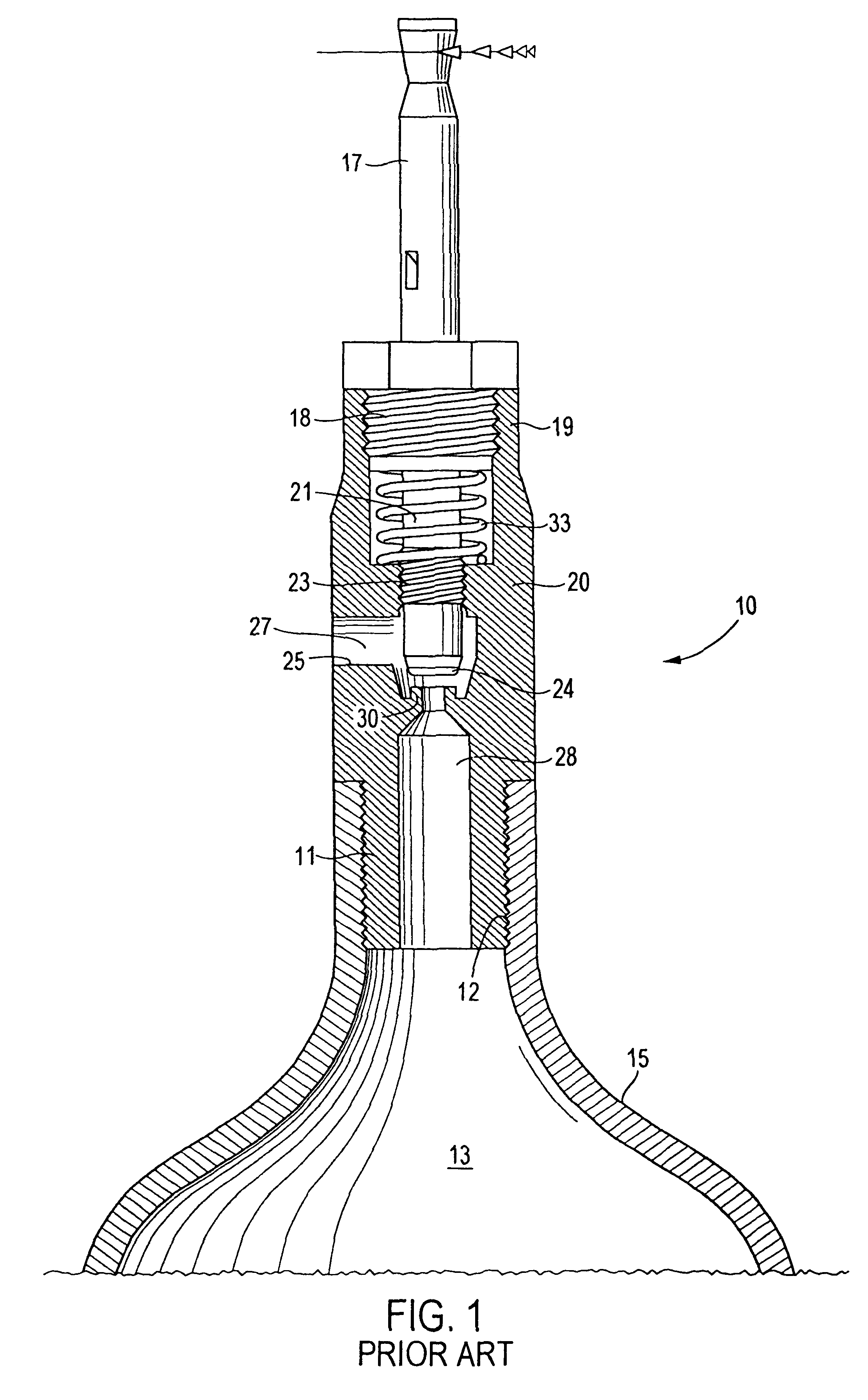

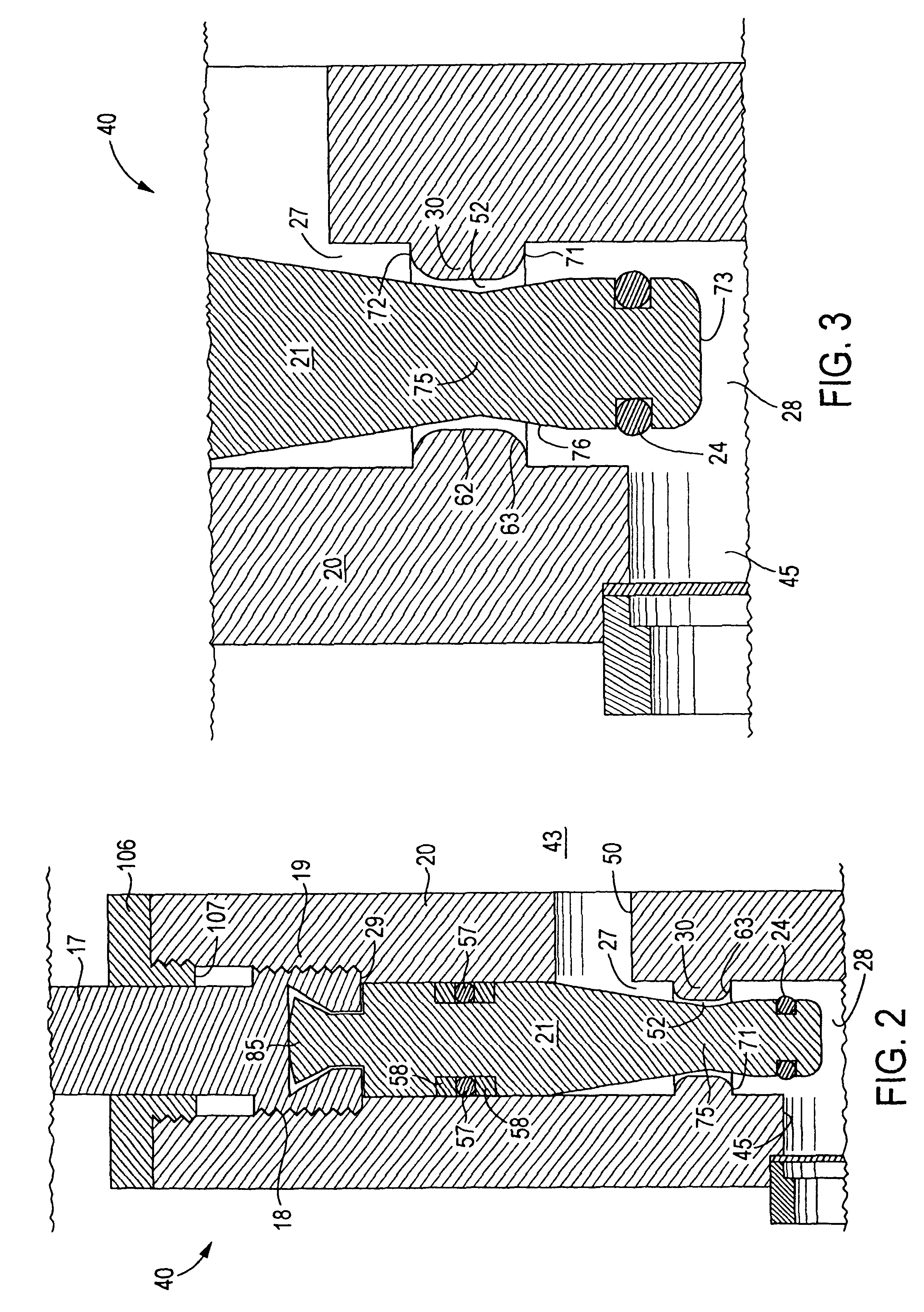

Cylinder valve and bayonet check-filter with excess-flow protection feature

InactiveUS6607007B1Reduce the risk of fireLower potentialFunctional valve typesContainer filling methodsOxygen systemHigh pressure oxygen

A valve apparatus especially well-suited for use in gaseous oxygen delivery systems. A valve apparatus is provided that substantially reduces the risk of fire in high-pressure oxygen systems. The apparatus is particularly well-suited for use as a plug valve on ordinary cylinder containers, but may be beneficially used in any pressurized gas system, particularly oxygen systems such as those encountered in many industrial facilities. The wetted portion of the valve is isolated from threaded portions to prevent particulate contamination of the gas stream. The valve seat is located to protect it from direct impact of high-velocity gas streams. The inventive valve, and its associated inventive check-filter and excess-flow prevention features, reduces the potential for hazardous combustion at valve points within oxygen delivery systems.

Owner:LUXFER INC

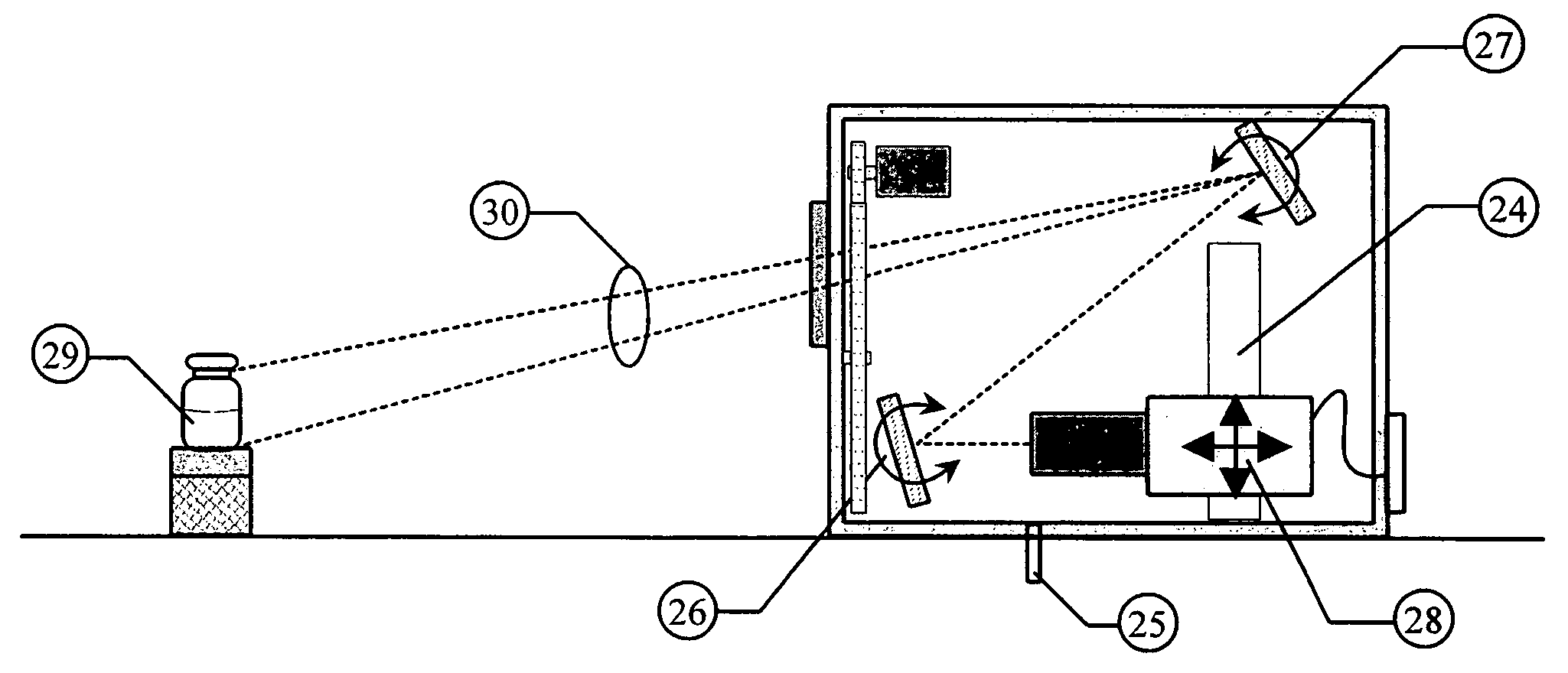

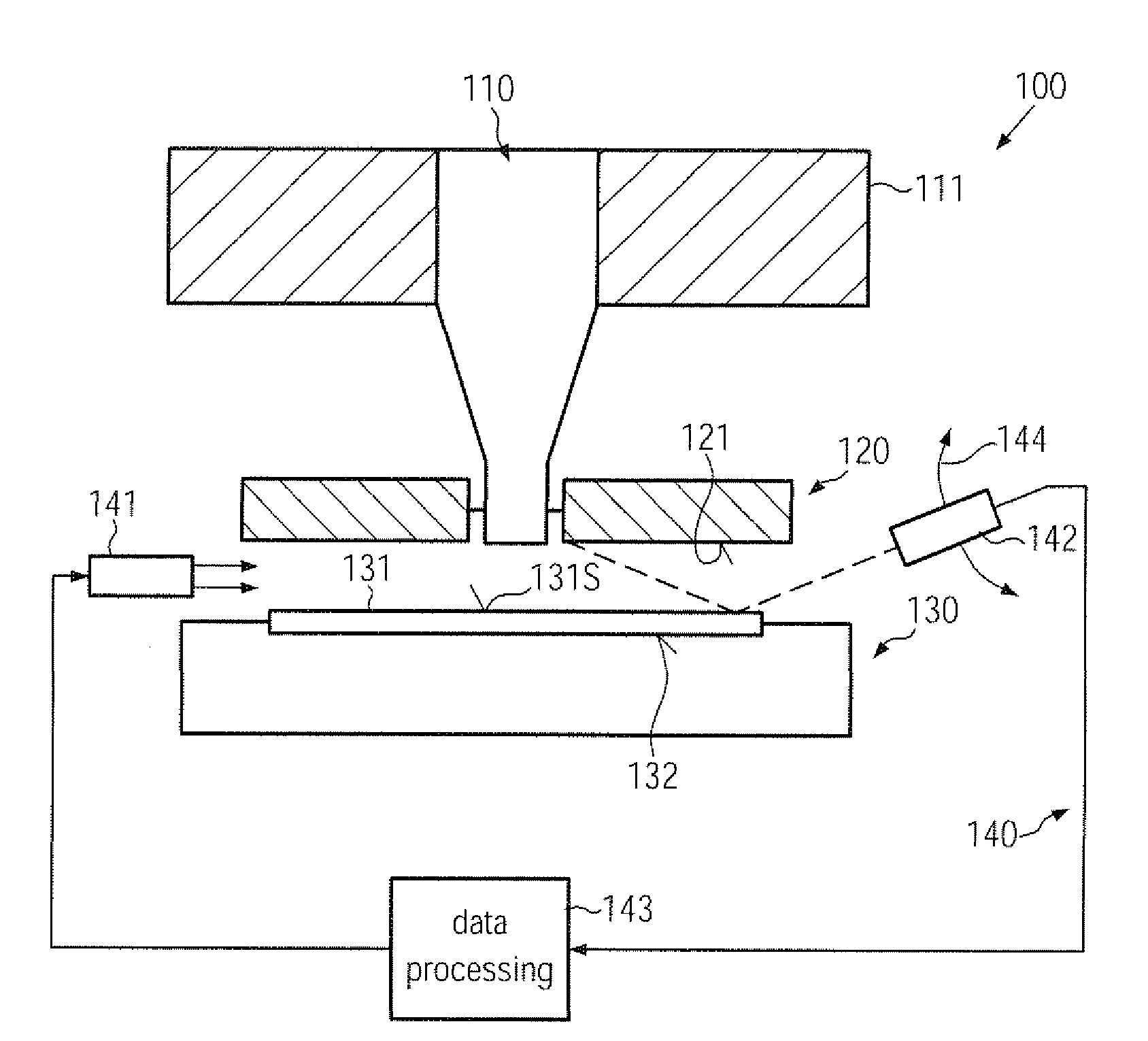

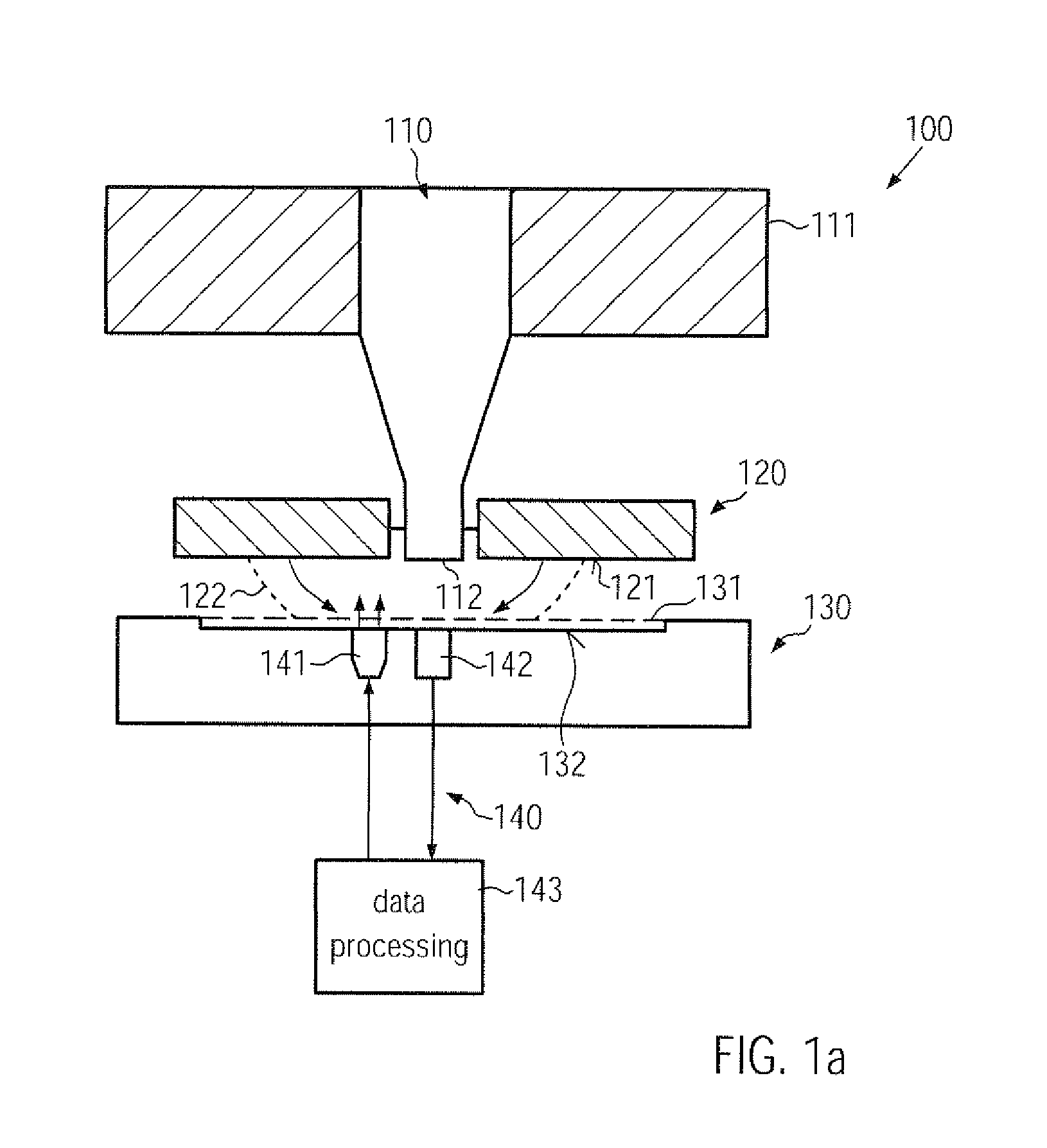

Method and system for detecting particle contamination in an immersion lithography tool

InactiveUS20100245790A1Easy to detectSignificant down timePhotomechanical apparatusPhotographic printingDigital imagingLithographic artist

In an immersion lithography tool, the status of the immersion hood surface may be estimated on the basis of an inline detection system that generates optical measurement data. For example, a digital imaging system may be implemented in order to obtain optical measurement data without requiring exposure of the interior of the lithography tool to ambient air. In other cases, other optical measurement techniques, such as FTIR and the like, may be applied.

Owner:GLOBALFOUNDRIES US INC

Semiconductor processing equipment having improved process drift control

InactiveUS20050145176A1Reduce contaminationReduce processElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricInterior space

A plasma processing chamber including a slip cast part having a surface thereof exposed to the interior space of the chamber. The slip cast part includes free silicon contained therein and a protective layer on the surface which protects the silicon from being attacked by plasma in the interior space of the chamber. The slip cast part can be made of slip cast silicon carbide- coated with CVD silicon carbide. The slip cast part can comprise one or more parts of the chamber such as a wafer passage insert, a monolithic or tiled liner, a plasma screen, a showerhead, dielectric member, or the like. The slip cast part reduces particle contamination and reduces process drift in plasma processes such as plasma etching of dielectric materials such as silicon oxide.

Owner:LAM RES CORP

Wafer level image sensor package with die receiving cavity and method of making the same

InactiveUS20080274579A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringProtection layer

The present invention provides a structure of package comprising a substrate with a die receiving cavity formed within an upper layer of the substrate, wherein terminal pads are formed on the upper surface of the substrate, the same plain as the micro lens. A die is disposed within the die receiving cavity by adhesion and a dielectric layer formed on the die and the substrate. A re-distribution metal layer (RDL) is formed on the dielectric layer and coupled to the die. An opening is formed within the dielectric layer and a top protection layer to expose the micro lens area of the die for Image Sensor chip. A protection layer (film) be coated on the micro lens area with water repellent and oil repellent to away the particle contamination. A transparent cover with coated IR filter is optionally formed over the micron lens area for protection.

Owner:ADVANCED CHIP ENG TECH INC

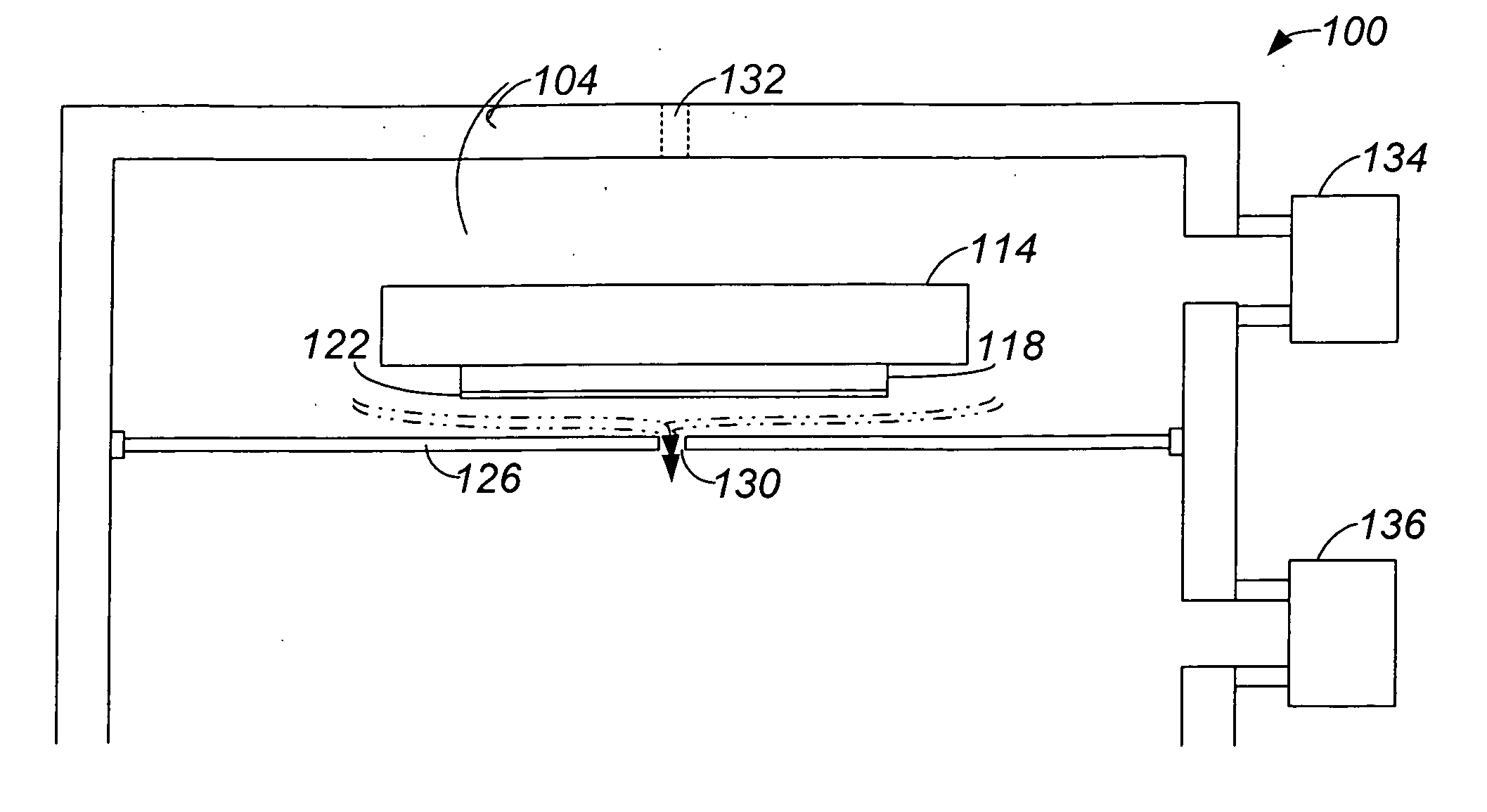

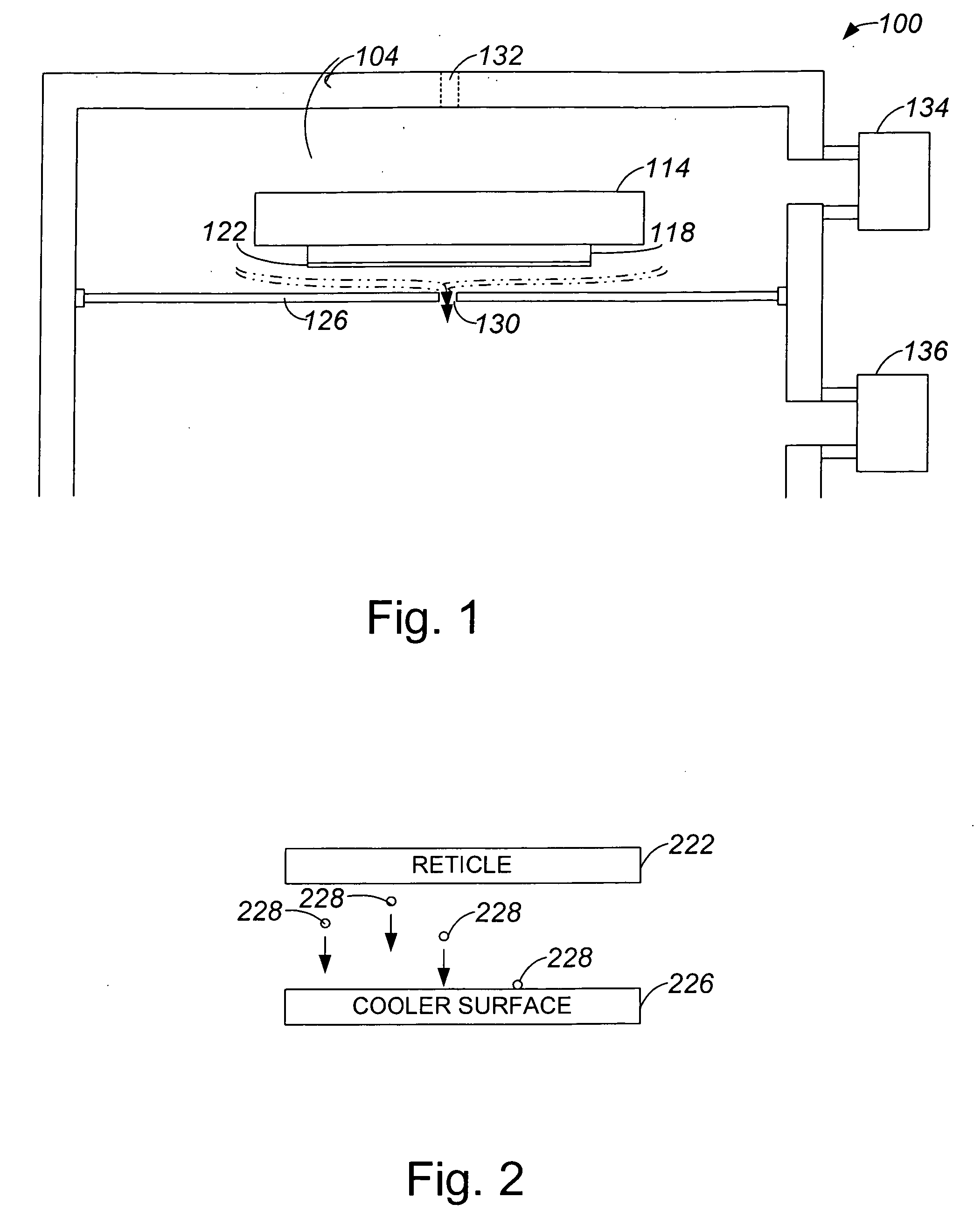

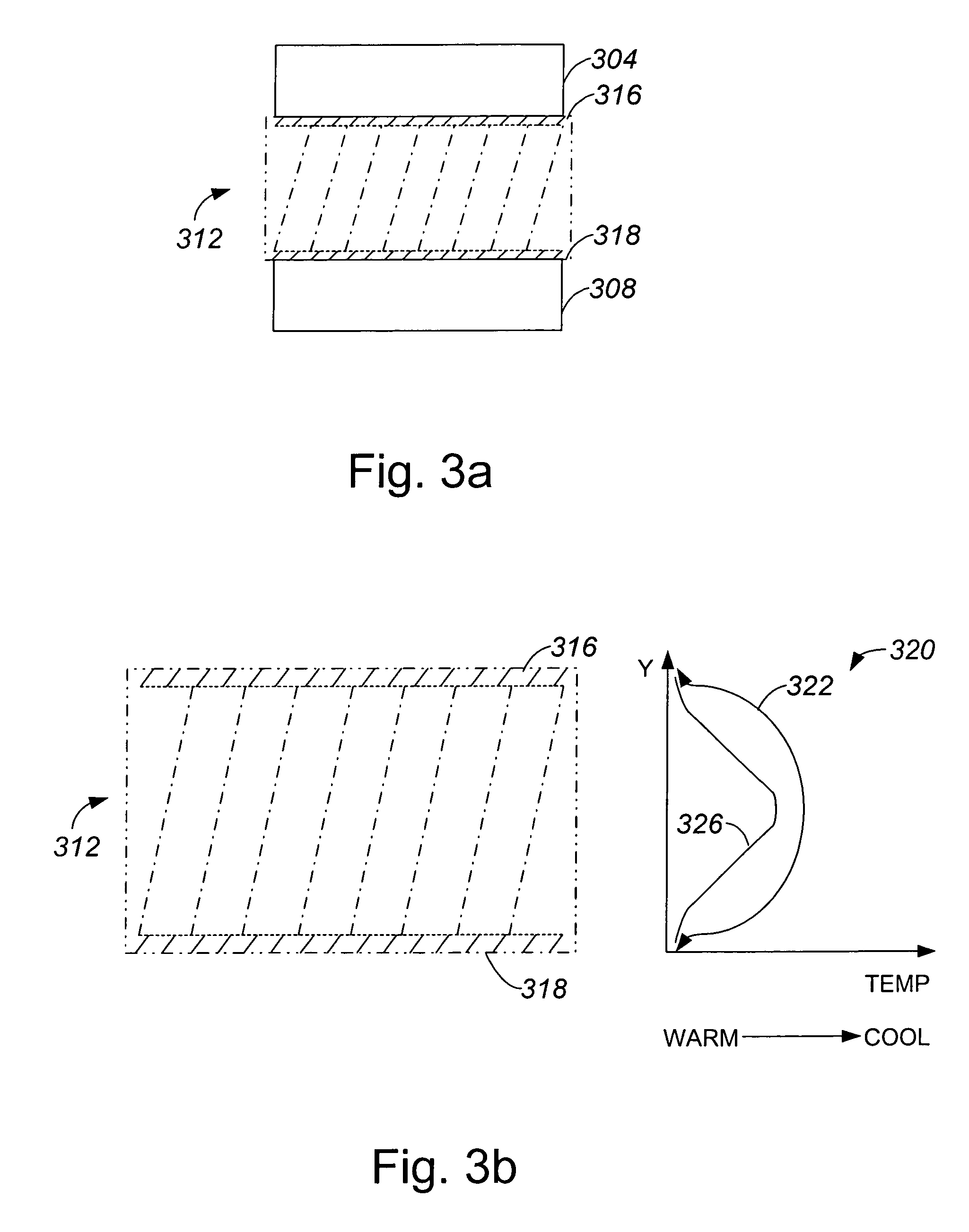

Extreme ultraviolet reticle protection using gas flow thermophoresis

InactiveUS20060017895A1Reduce particle pollutionDrying solid materials without heatPhotomechanical apparatusUltravioletEngineering

Methods and apparatus for using a flow of a relatively cool gas to establish a temperature gradient between a reticle and a reticle shield to reduce particle contamination on the reticle are disclosed. According to one aspect of the present invention, an apparatus that reduces particle contamination on a surface of an object includes a plate and a gas supply. The plate is positioned in proximity to the object such that the plate, which has a second temperature, and the object, which has a first temperature, are substantially separated by a space. The gas supply supplies a gas flow into the space. The gas has a third temperature that is lower than both the first temperature and the second temperature. The gas cooperates with the plate and the object to create a temperature gradient and, hence, a thermophoretic force that conveys particles in the space away from the object.

Owner:NIKON CORP

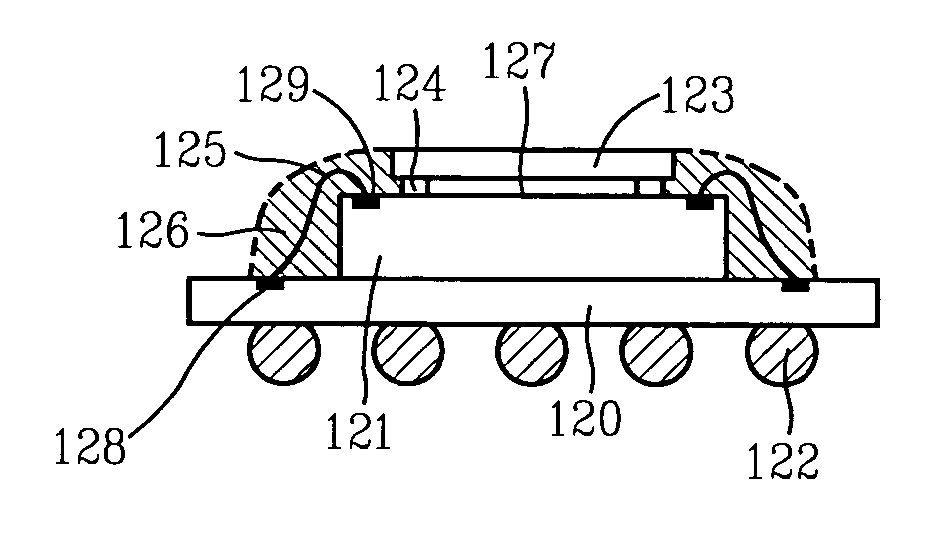

FBGA and COB package structure for image sensor

ActiveUS20060145325A1Avoid Particle ContaminationSemiconductor/solid-state device detailsSolid-state devicesEngineeringPrinted circuit board

A structure of package comprises a die placed on printed circuit board. A glass substrate is adhered on an adhesive film pattern to form an air gap area between the glass substrate and the chip. Micro lens are disposed on the chip. A lens holder is fixed on printed circuit board. The glass substrate can prevent the micro lens from particle contamination.

Owner:ADVANCED CHIP ENG TECH

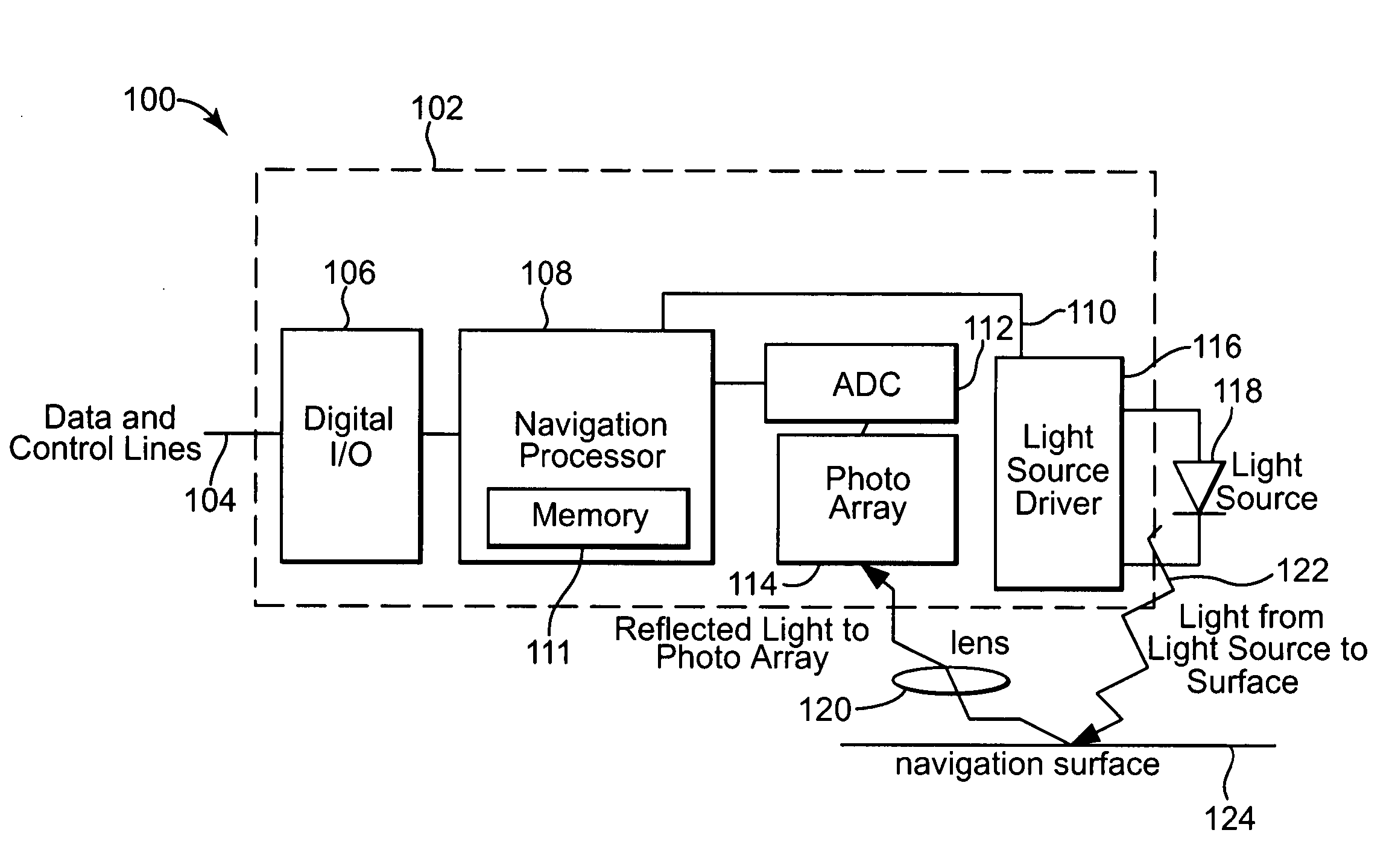

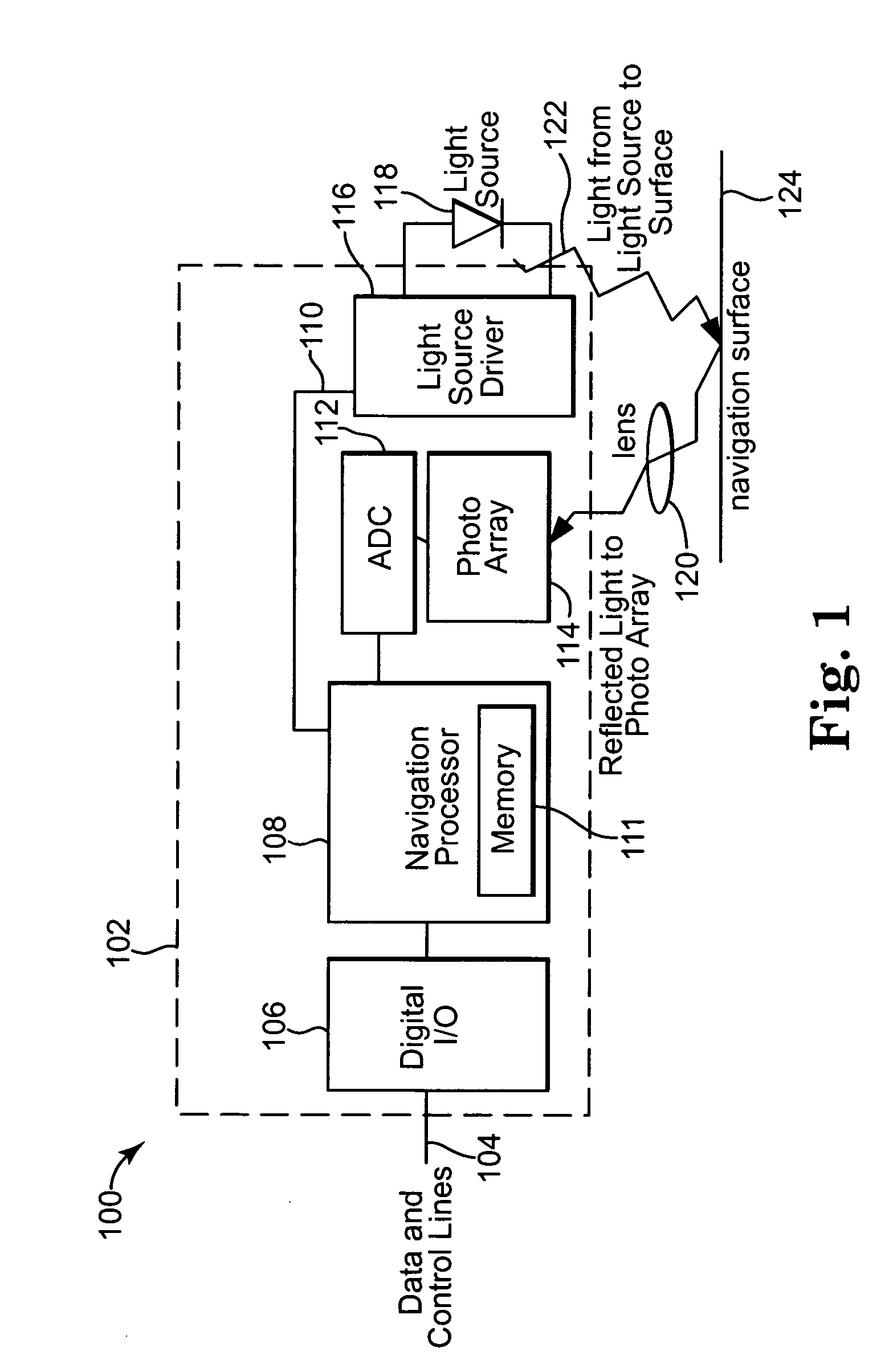

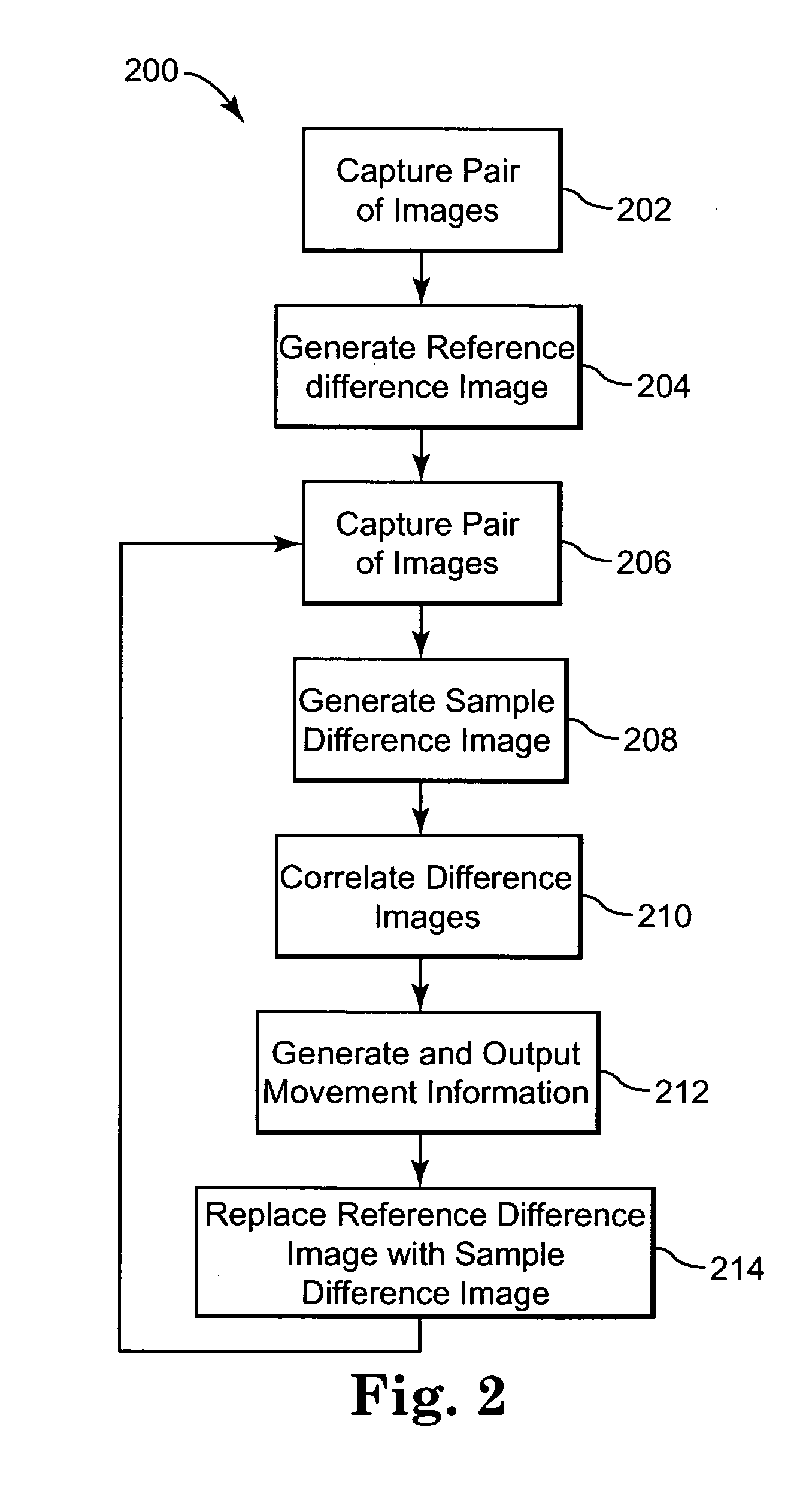

Apparatus for controlling the position of a screen pointer with low sensitivity to particle contamination

ActiveUS20050206614A1Low sensitivity to effectInput/output for user-computer interactionCathode-ray tube indicatorsRelative motionComputer vision

An apparatus for controlling the position of a screen pointer includes an at least partially coherent light source for illuminating an imaging surface, thereby generating reflected images. The apparatus includes a navigation sensor for generating digital images based on the reflected images, performing a movement computation based on the digital images, generating movement data based on the movement computation that is indicative of relative motion between the imaging surface and the apparatus, wherein the movement computation has a low sensitivity to effects in the digital images caused by particle contamination.

Owner:PIXART IMAGING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com