Semiconductor processing equipment having improved process drift control

a technology of process drift and processing equipment, applied in the direction of electrical equipment, chemical vapor deposition coating, coating, etc., can solve the problems of coating cracking, and achieve the effect of reducing particle contamination and/or process dri

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

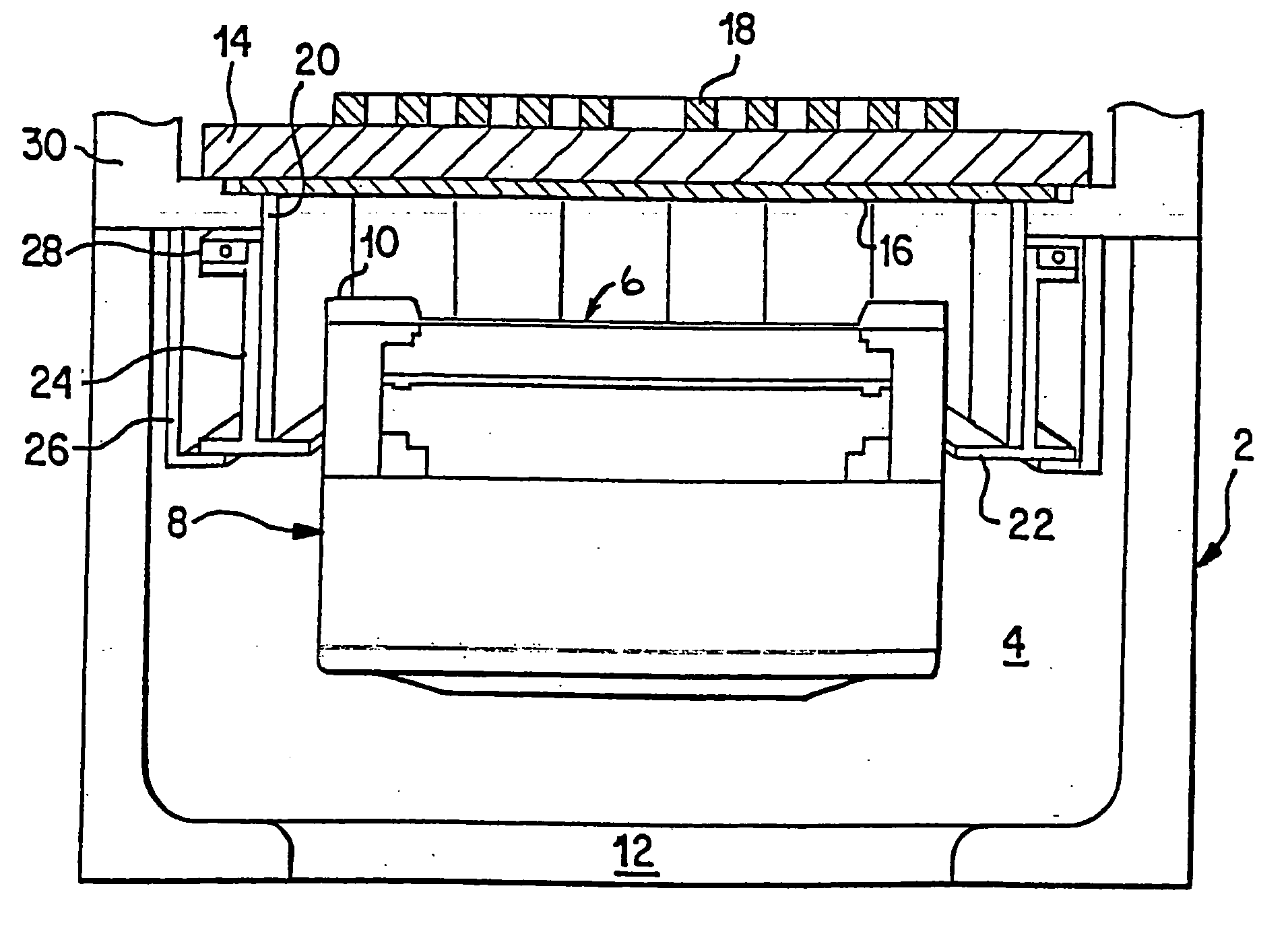

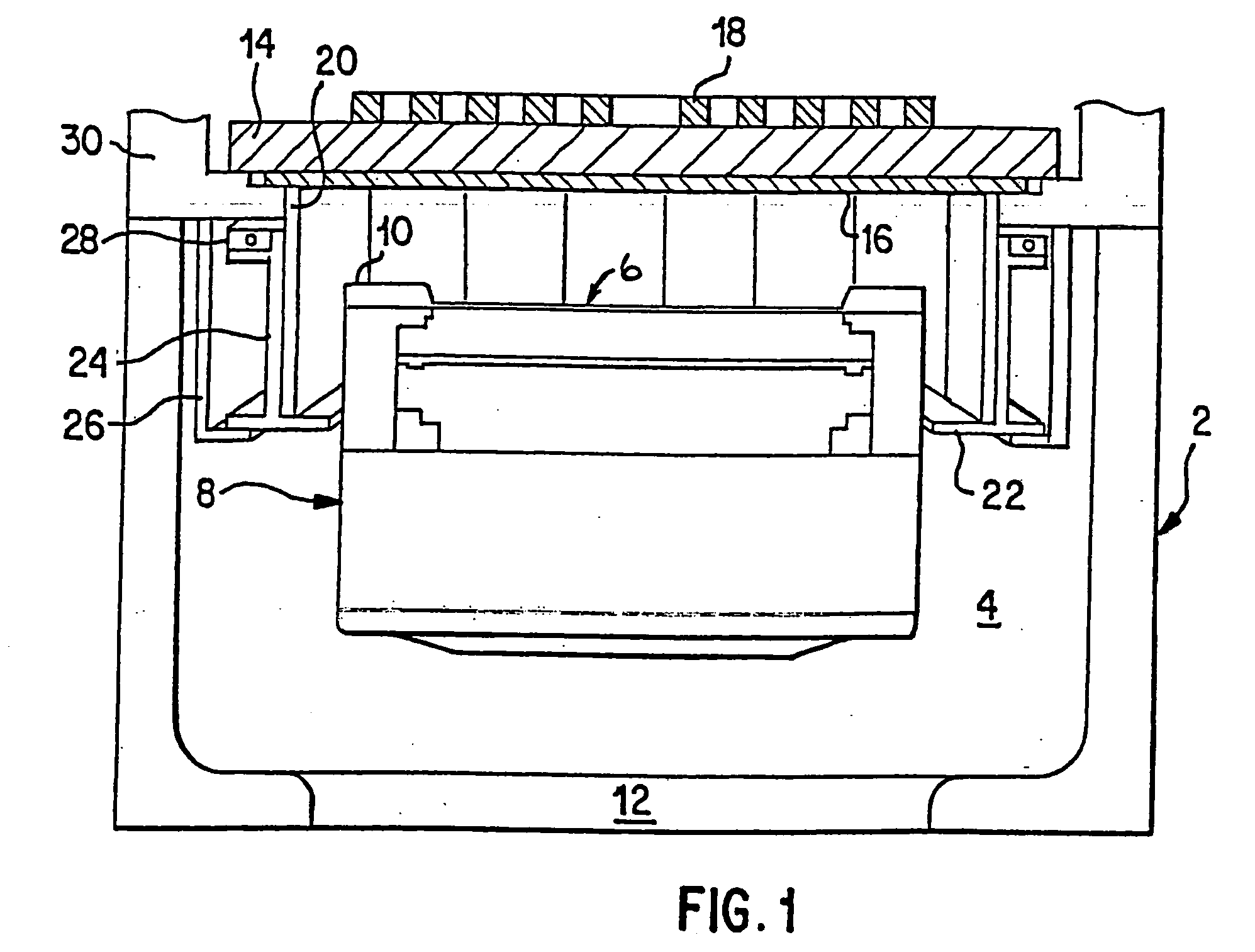

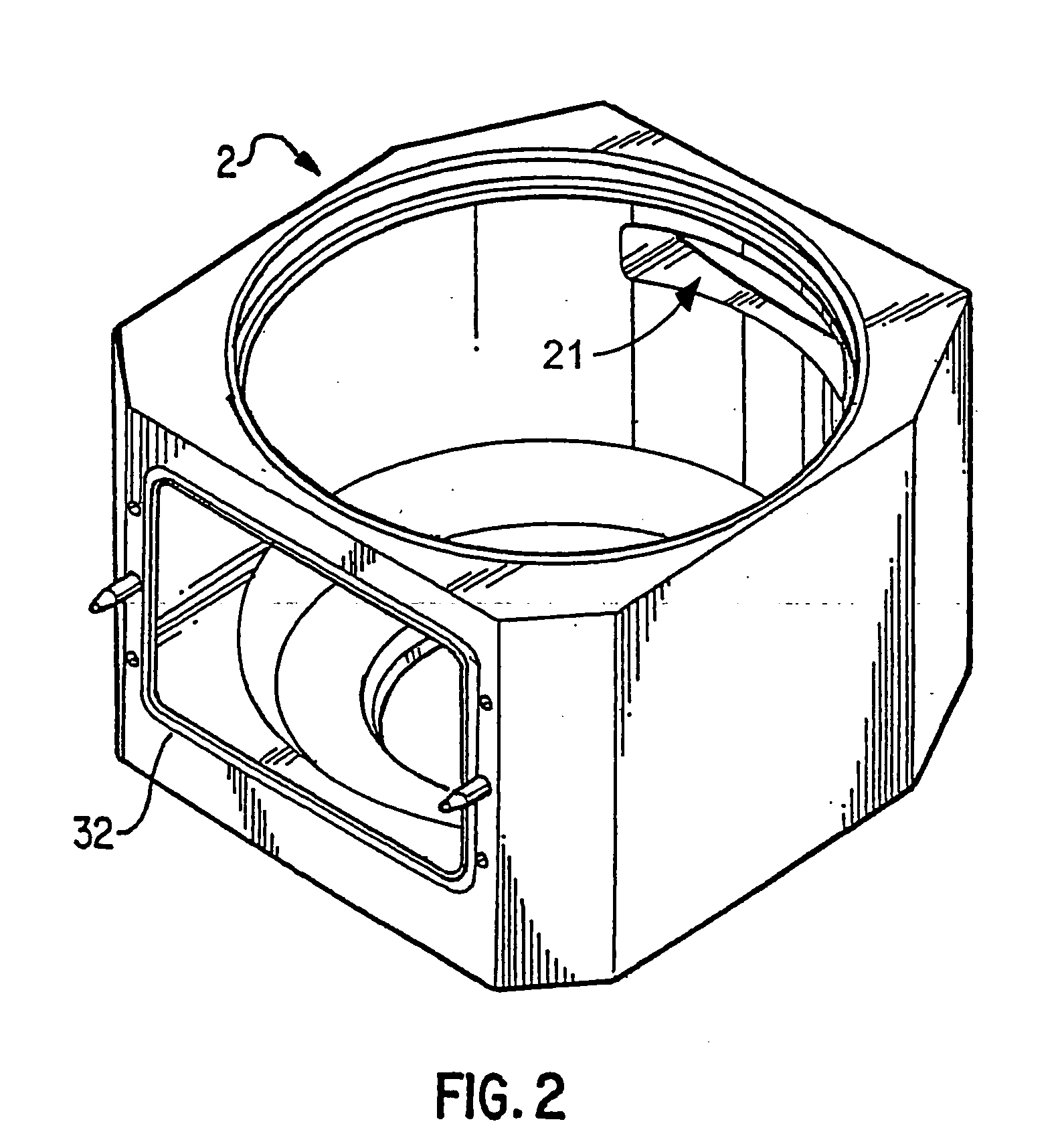

[0029] According to the invention, a plasma processing chamber having improved process drift control is provided. The improved process drift control is achieved by use of one or more parts in the chamber of a part having a surface thereof exposed to the interior space, the part having free silicon contained therein and a protective layer on the surface which protects the silicon from being attacked by the plasma in the interior. The free silicon can be silicon impregnated into a porous SiC body, the silicon filling the porosity to minimize undesirable process effects and increase electrical conductivity which is useful for lowering the RF impedance of the part.

[0030] The part can have any desired configuration such as that of a wafer passage insert, a chamber wall, a substrate support, an electrode, a showerhead, etc. According to a preferred embodiment, the part comprises a slip cast silicon carbide part which has been backfilled or impregnated with silicon and the protective coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com