A freestyle miniature supercapacitor based on laser graphics and a manufacturing method thereof

A technology for supercapacitors and manufacturing methods, which is applied in the manufacture of hybrid/electric double layer capacitors, electrodes for hybrid capacitors, nanotechnology for materials and surface science, etc. The problem of large capacitor thickness, etc., can reduce the thickness of the device, simplify the preparation process, and improve the effective working voltage and current density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

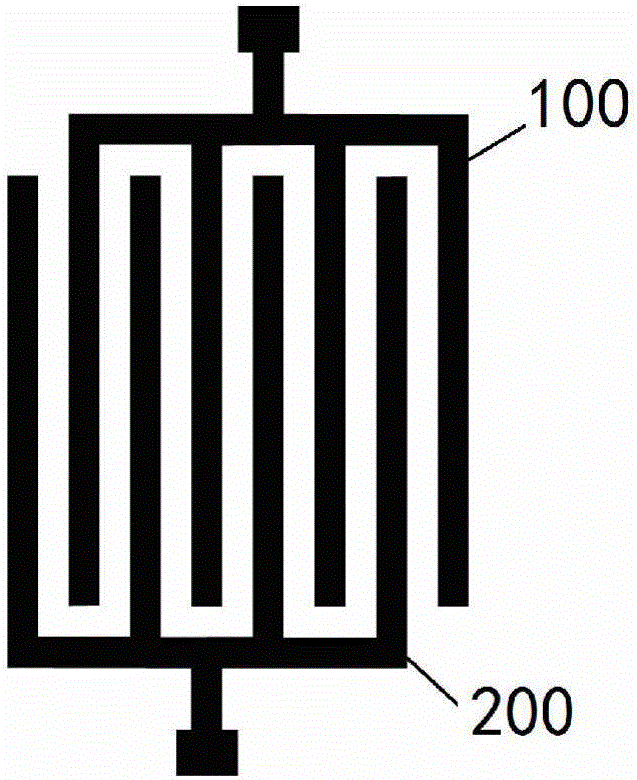

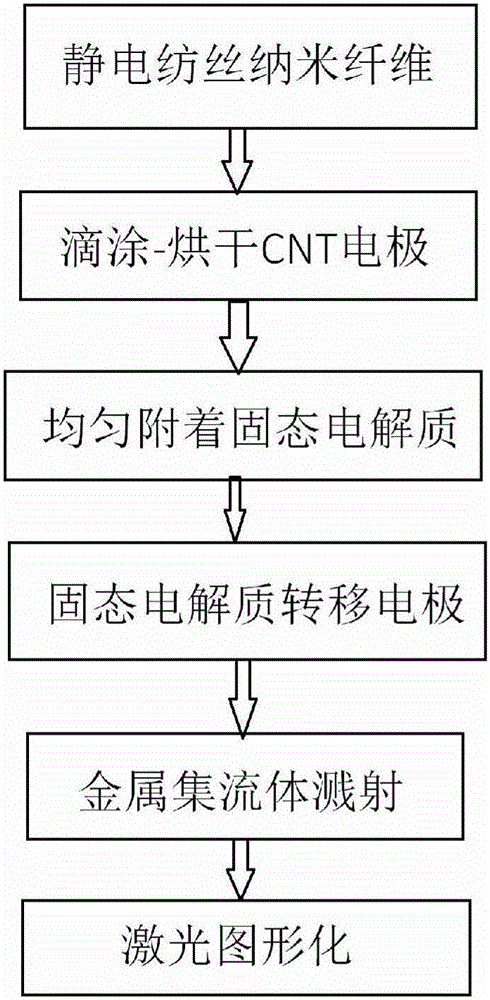

[0050] Example 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 shown,

[0051] A free-form micro supercapacitor based on laser patterning, the device includes: electrospun nanofibers, flexible electrodes, solid electrolytes, and metal current collectors. The electrospun nanofibers are prepared by electrospinning, such as polyvinylidene fluoride (PVDF), polyurethane (PU), etc.; the flexible electrodes are attached with multi-walled carbon nanofibers. tube (carbon nanotube, CNT) or other electrodes with flexible characteristics; the solid electrolyte is a gel polymer, including polyvinyl alcohol (PVA) and phosphoric acid (H 3 PO 4 ), sulfuric acid (H 2 SO 4 ), lithium chloride (LiCl), etc.; the metal current collector is a metal with good electrical conductivity, such as gold (Au), copper (Cu) and the like.

[0052] A free-form micro-supercapacitor based on laser patterning, through the las...

Embodiment 2

[0075] Example 2: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a laser-patterning-based free-form micro supercapacitor and a manufacturing method, comprising the following steps;

[0076] Step 1: Obtain PVDF powder, acetone and DMF organic solvent by weighing, mix the three evenly, and completely dissolve the PVDF powder by magnetic stirring to obtain a uniformly dispersed PVDF solution;

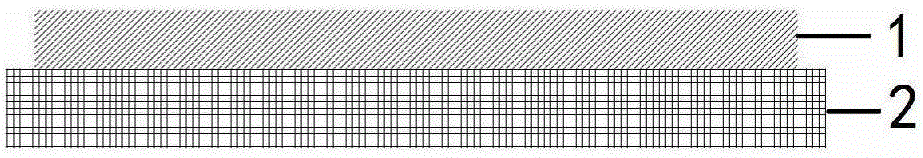

[0077] Step 2: through the process of electrospinning, the PVDF solution is deposited on the metal electrode 1 in a disorderly order by means of high voltage to obtain PVDF nanofibers 2;

[0078] Step 3: Obtain CNT and SDBS powder by weighing, mix the two evenly and add them into deionized water, and ultrasonicate the obtained solution at room temperature by means of water bath ultrasound, so that CNT and SDBS are fully contacted and completely dissolved in deionized water. In water, a uniformly d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com