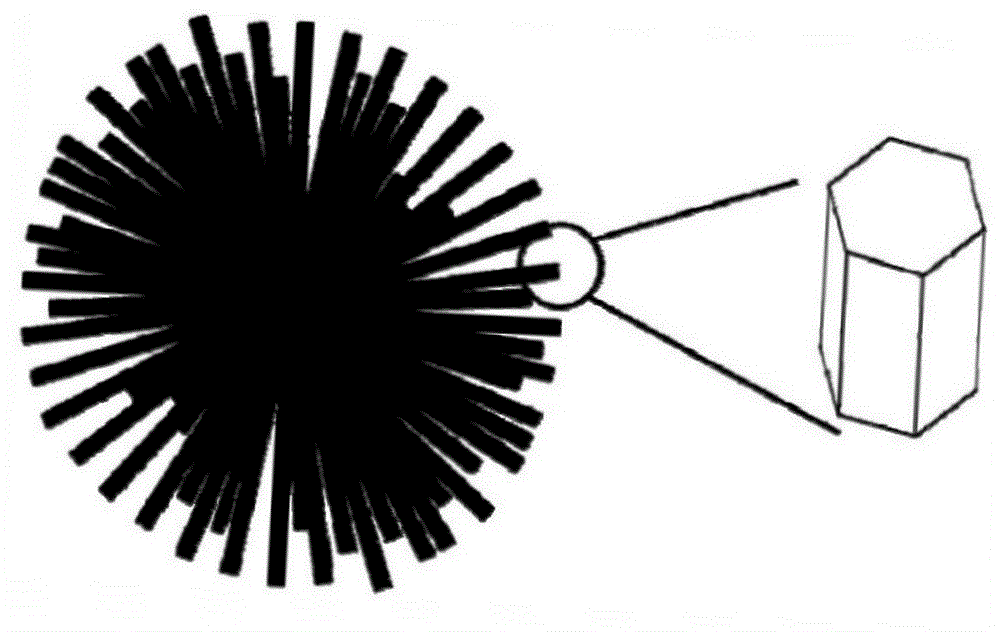

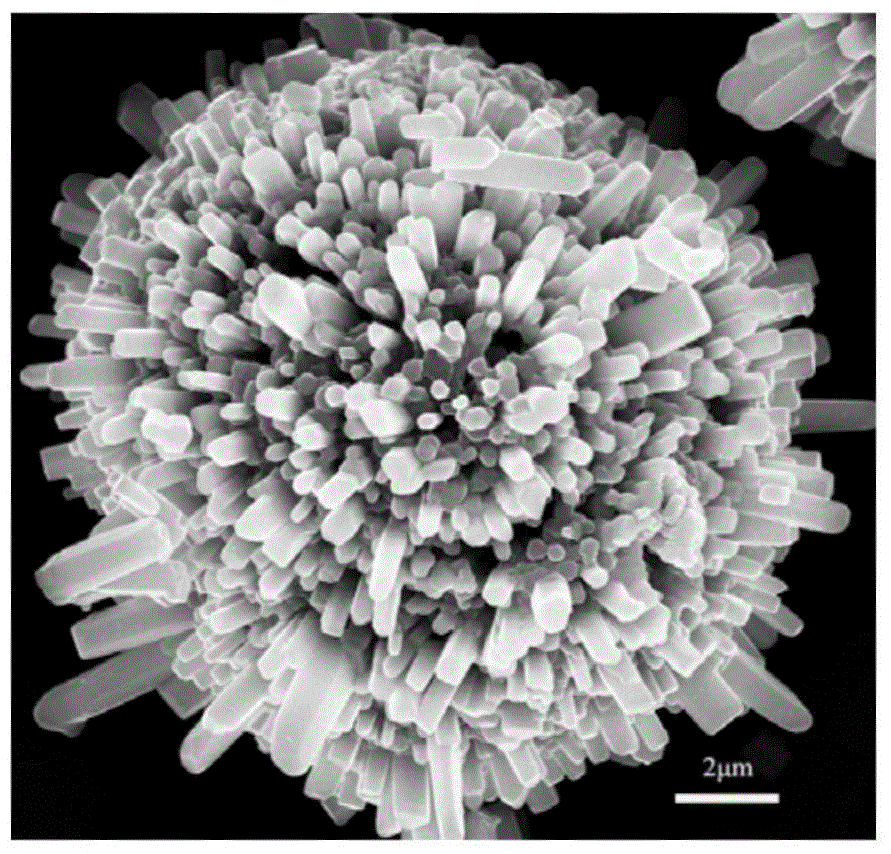

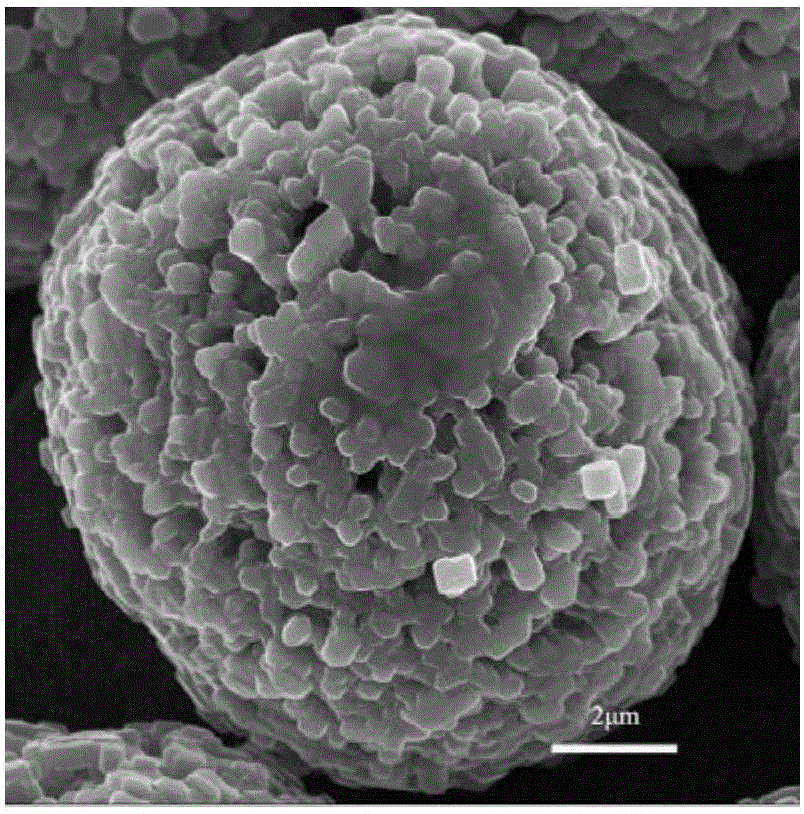

Urchin-like sodium-containing lithium-rich layered cathode material and preparation method thereof

A positive electrode material and sea urchin-shaped technology, which is applied in the field of lithium-ion battery electrode materials and its preparation, can solve the problems of poor film formation, low tap density and compacted density, and achieve improved tap density and compacted density, reduced The effect of small transmission distance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) 110g MnSO 4 ·H 2 O, 41.22g NiSO 4 ·7H 2 O and 44.07gCoSO 4 ·7H 2 O was dissolved in 650mL deionized water to obtain a transparent solution 1; 102.23g Na 2 CO 3 and 12.71 g NH 4 HCO 3 Dissolve in 650 mL deionized water to obtain colorless and transparent solution 2. Under the conditions of water bath temperature of 45°C and mechanical stirring speed of 800rpm, solution 1 and solution 2 were simultaneously added dropwise to the reaction kettle with a peristaltic pump at a rate of 5mL / min. Wash with deionized water several times to remove unreacted impurity ions, and dry in an oven at 55 °C for 12 h to obtain a transition metal composite carbonate precursor.

[0031] (2) Put the transition metal composite carbonate precursor obtained in step (1) into a porcelain boat, then place it in a muffle furnace with an oxygen atmosphere, and heat it to 500°C at a heating rate of 4°C / min after 30min And keep it warm for 6 hours, then slowly cool down to room temperature...

Embodiment 2

[0035] (1) 142.41g manganese acetate tetrahydrate, 34.84g cobalt acetate tetrahydrate and 34.81g nickel acetate tetrahydrate were dissolved in 650mL deionized water to obtain transparent solution 1; 91.24g Na 2 CO 3 and 11.32 g NH 4 HCO 3 Dissolve in 650 mL deionized water to obtain colorless and transparent solution 2. Under the conditions of water bath temperature of 55°C and mechanical stirring speed of 700rpm, solution 1 and solution 2 were simultaneously added dropwise to the reaction kettle with a peristaltic pump at a rate of 8mL / min. After the dropwise addition, aged for 6h, suction filtered, Wash with deionized water several times to remove unreacted impurity ions, and dry in an oven at 55 °C for 6 h to obtain a transition metal composite carbonate precursor.

[0036] (2) Put the transition metal composite carbonate precursor obtained in step (1) into a porcelain boat, then place it in a muffle furnace with an oxygen atmosphere, and heat it to 450°C at a heating ra...

Embodiment 3

[0039] (1) 207.95g mass concentration of 50% Mn(NO 3 ) 2 Aqueous solution, 40.68g Ni(NO 3 ) 2 ·6H 2 O and 40.71g Co(NO 3 ) 2 ·6H 2 O was dissolved in 450mL deionized water to obtain a transparent solution 1; 91.24g Na 2 CO 3 and 6.90g (NH 4 ) 2 CO 3 Dissolve in 450 mL deionized water to obtain colorless and transparent solution 2. Under the conditions of water bath temperature of 60°C and mechanical stirring speed of 600rpm, solution 1 and solution 2 were added dropwise to the reaction kettle at the same time at a rate of 10mL / min. Washing several times to remove unreacted impurity ions, drying in a 55 °C oven for 10 h, to obtain a transition metal composite carbonate precursor.

[0040] (2) Put the transition metal composite carbonate precursor obtained in step (1) into a porcelain boat, then place it in a muffle furnace with an oxygen atmosphere, and heat it to 550°C at a heating rate of 8°C / min after 30min And keep it warm for 8 hours; then slowly cool down to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com