Preparation method of polyvinyl chitosan mixed film

A technology of polyvinyl alcohol and chitosan, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of increased investment, poor safety, difficult operation, etc., and achieve high mechanical strength and good separation Excellent performance and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

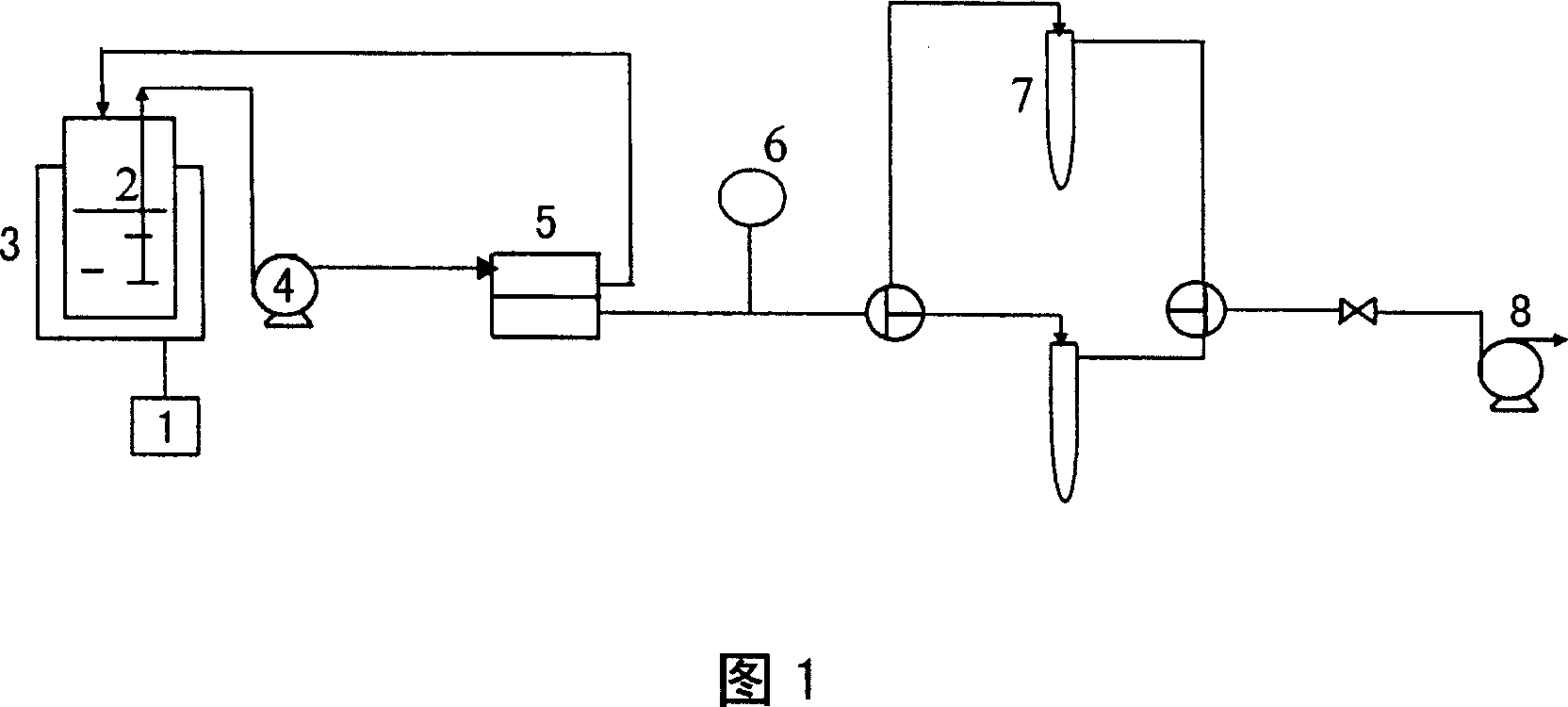

Method used

Image

Examples

Embodiment 1

[0047] Accurately weigh 5g of PVA (degree of alcoholysis: 99.8%-100%), dissolve it in 95g of deionized water at 90°C, and stir evenly for 4h. After the PVA is completely dissolved, filter the solution to remove some undissolved impurities. Set aside. Dissolve 1.5g of CS (low molecular weight, deacetylation degree 75%-85%) in 2% acetic acid aqueous solution at 25°C, stir evenly, make 1wt% CS solution, filter to remove some undissolved Impurities. Weigh 3.2g of 5wt% PVA solution and 8g of 1wt% CS solution respectively, mix them at room temperature, and stir evenly for 3 hours. on the glass plate (the glass plate should be horizontal), the temperature of the glass plate is kept at 40°C, the solvent is volatilized for 12 hours, the film is peeled off from the glass plate, and heat treated in a vacuum oven at 120°C for 4 hours to obtain PVA:CS=2:1 blend film.

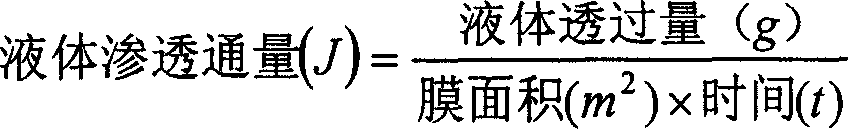

[0048] The membrane is pervaporated to separate methanol / DMC azeotrope (methanol 70wt%, DMC30wt%), the raw material sid...

Embodiment 2

[0050] Weigh 2.4g of 5wt% PVA solution and 12g of 1wt% CS solution respectively, mix at room temperature, stir evenly for 2 hours, after the solution is uniformly clarified, perform vacuum degassing for 4 hours, and then pour the casting solution into a clean glass plate (the glass plate should be horizontal), the temperature of the glass plate is kept at 40°C, the solvent is volatilized for 14 hours, the film is peeled off from the glass plate, and heat treated in a vacuum oven at 140°C for 2 hours to obtain PVA:CS=1:1 blend film.

[0051] The membrane is pervaporated to separate methanol / DMC azeotrope (methanol 70wt%, DMC30wt%), the raw material side maintains normal pressure, the permeate side is vacuumed, the downstream pressure is 2 h), separation factor 4.1, pervaporation separation index (PSI value) 324.6g / (m 2 h).

Embodiment 3

[0053] Weigh 16g of 1wt% CS solution and 1.6g of 5wt% PVA solution respectively, mix them at room temperature, and stir evenly for 2 hours. plate (the glass plate should be horizontal), the temperature of the glass plate is kept at 40°C, the solvent is volatilized for 12 hours, the film is peeled off from the glass plate, and heat treated in a vacuum oven at 120°C for 2 hours to obtain PVA:CS=1:2 blend film.

[0054] The membrane is pervaporated to separate methanol / DMC azeotrope (methanol 70wt%, DMC30wt%), the raw material side maintains normal pressure, the permeate side is vacuumed, the downstream pressure is 2 h), separation factor 5.0, pervaporation separation index (PSI value) 660.8g / (m 2 h).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com