Patents

Literature

53results about How to "Determine the quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

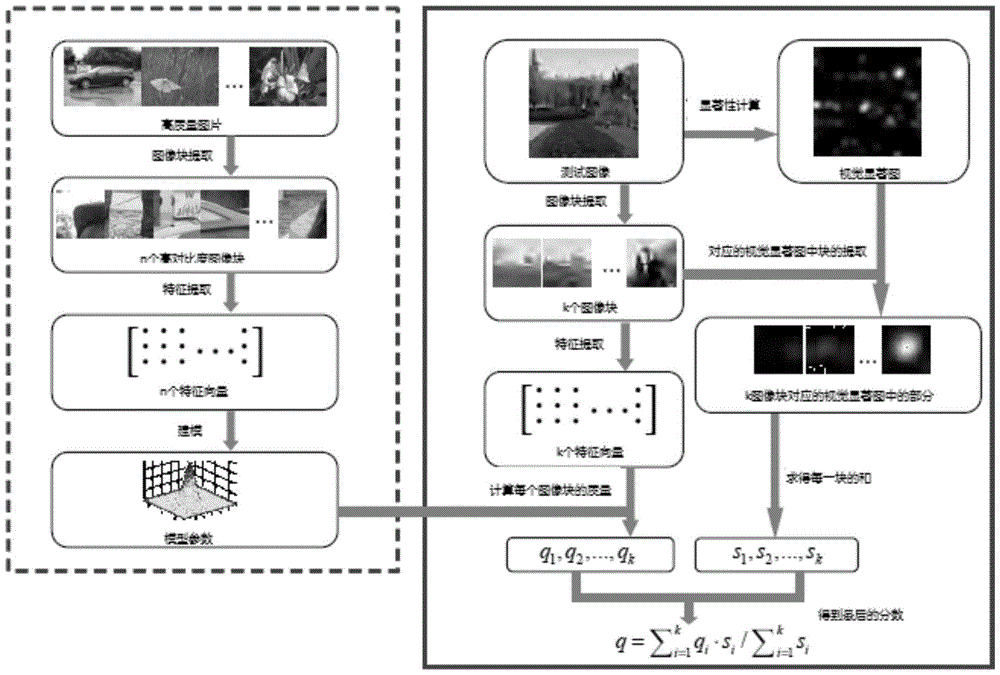

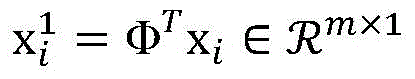

Non-reference image quality evaluation method based on high-quality natural image statistical magnitude model

ActiveCN103996192ADetermine the qualityOvercoming the problem of weak generalization abilityImage analysisCharacter and pattern recognitionImaging qualityVisual saliency

The invention discloses a non-reference image quality evaluation method based on a high-quality natural image statistical magnitude model. The method includes the steps that firstly, parameters corresponding to a multi-element Gaussian model are learnt from first image blocks of a high-quality natural image; a test image is divided into second image blocks which are the same in size, and a multi-element Gaussian model of each second image block is extracted; the distances between the multi-element Gaussian models are determined through a bhattacharyya distance, and then the quality of distorted image quality blocks is determined; the quality of all the distorted image blocks are linearly weighted through visual saliency, finally the objective evaluation grade of the test image is acquired, the problem that an existing evaluation method is low in generalization ability can be well solved, and the requirements of actual application for the non-reference image quality evaluation method are met.

Owner:TONGJI UNIV

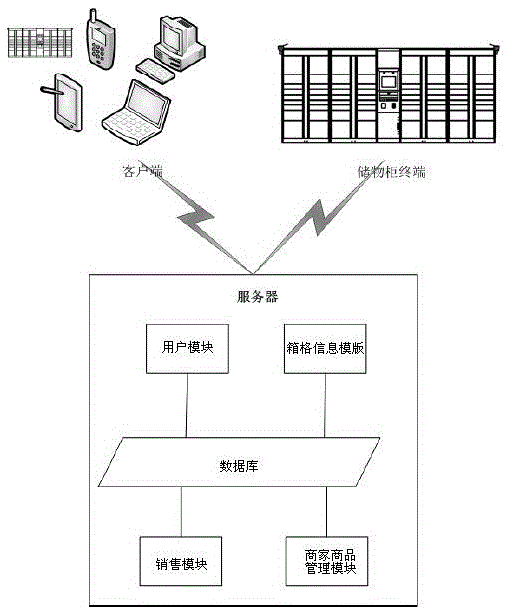

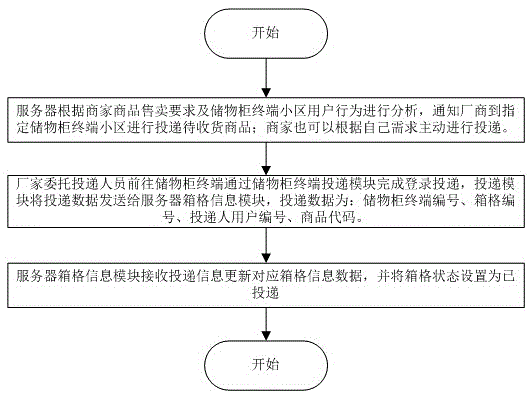

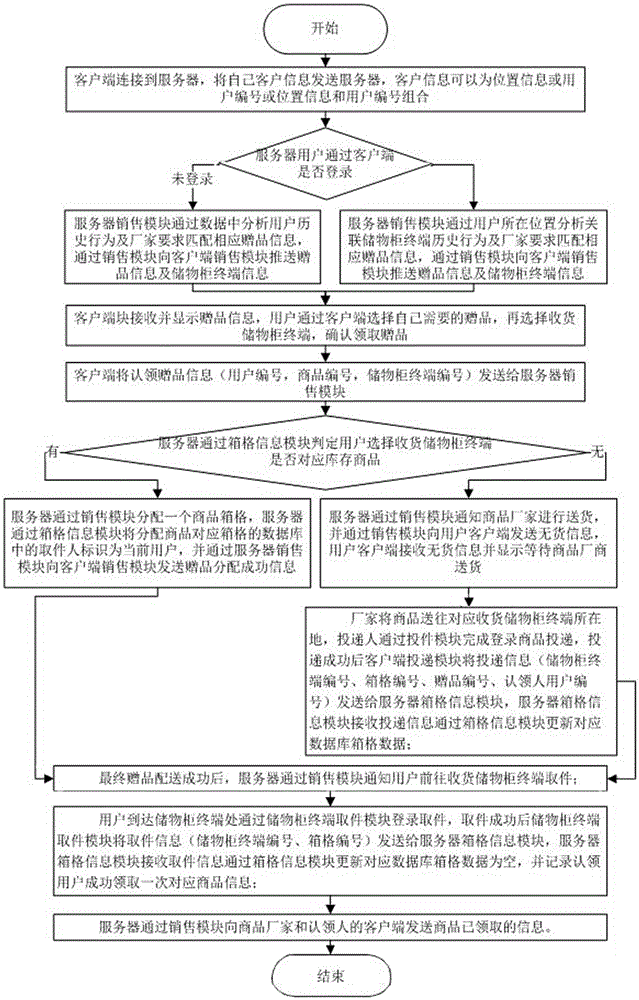

Locker system for directional giving and selling and method thereof

InactiveCN105631723AIncrease the use of functionsQuick selectionDiscounts/incentivesApparatus for meter-controlled dispensingDirect PaymentsPurchasing process

The invention discloses a locker system for directional giving and selling and a method thereof. A merchant delivers a to-be-taken present or a to-be-sold goods to a locker terminal; a corresponding to-be-taken present or a corresponding to-be-sold goods is directionally pushed to a client trough a server; the user confirms taking or buying through the client, the user selects a corresponding locker terminal for getting the goods, and taking or buying is completed. During the series of process, the system greatly expands the use function of the existing locker terminal; precise goods pushing and a goods getting-while-buying function are completed through the locker terminal, the use is quick and convenient, the user can directly get the goods while seeing the goods, if the goods needs to be paid, direct payment can be carried out through the locker terminal to complete the buying process, if the goods is given as a present, payment is not needed, and if the goods is pre-stored, goods payment can be completed in a real time mode.

Owner:CHENGDU WOLAILA GRID INFORMATION TECH

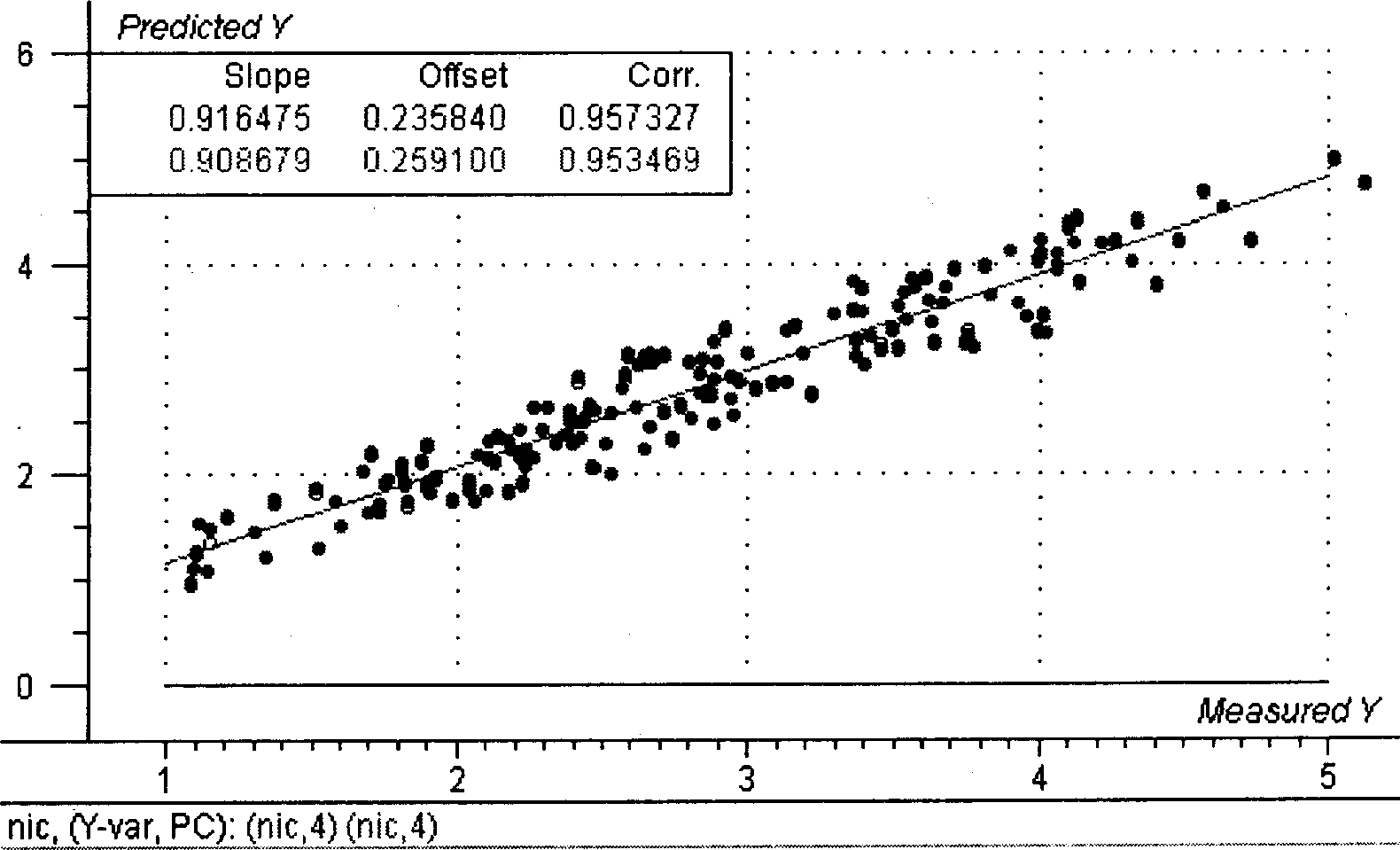

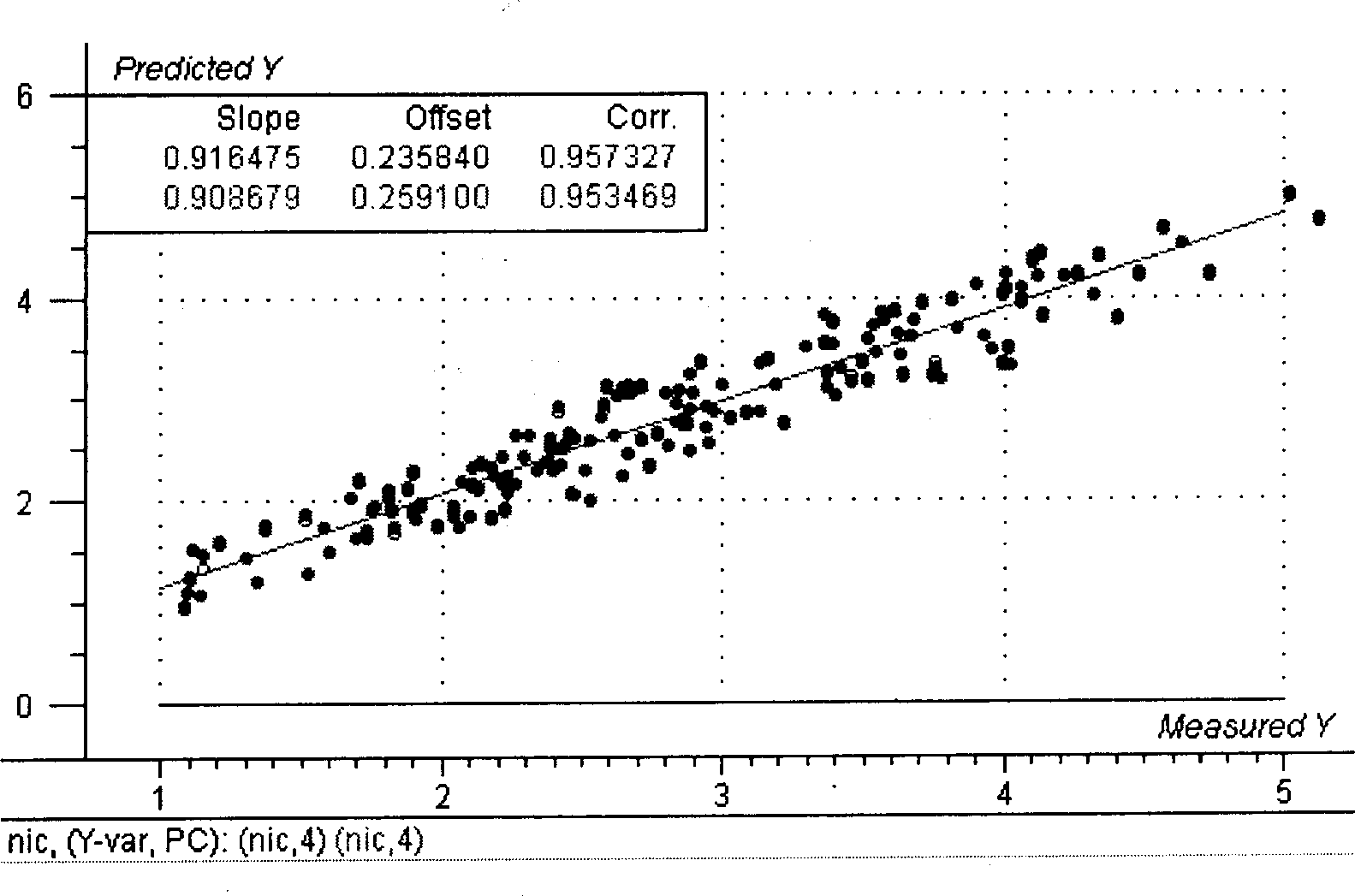

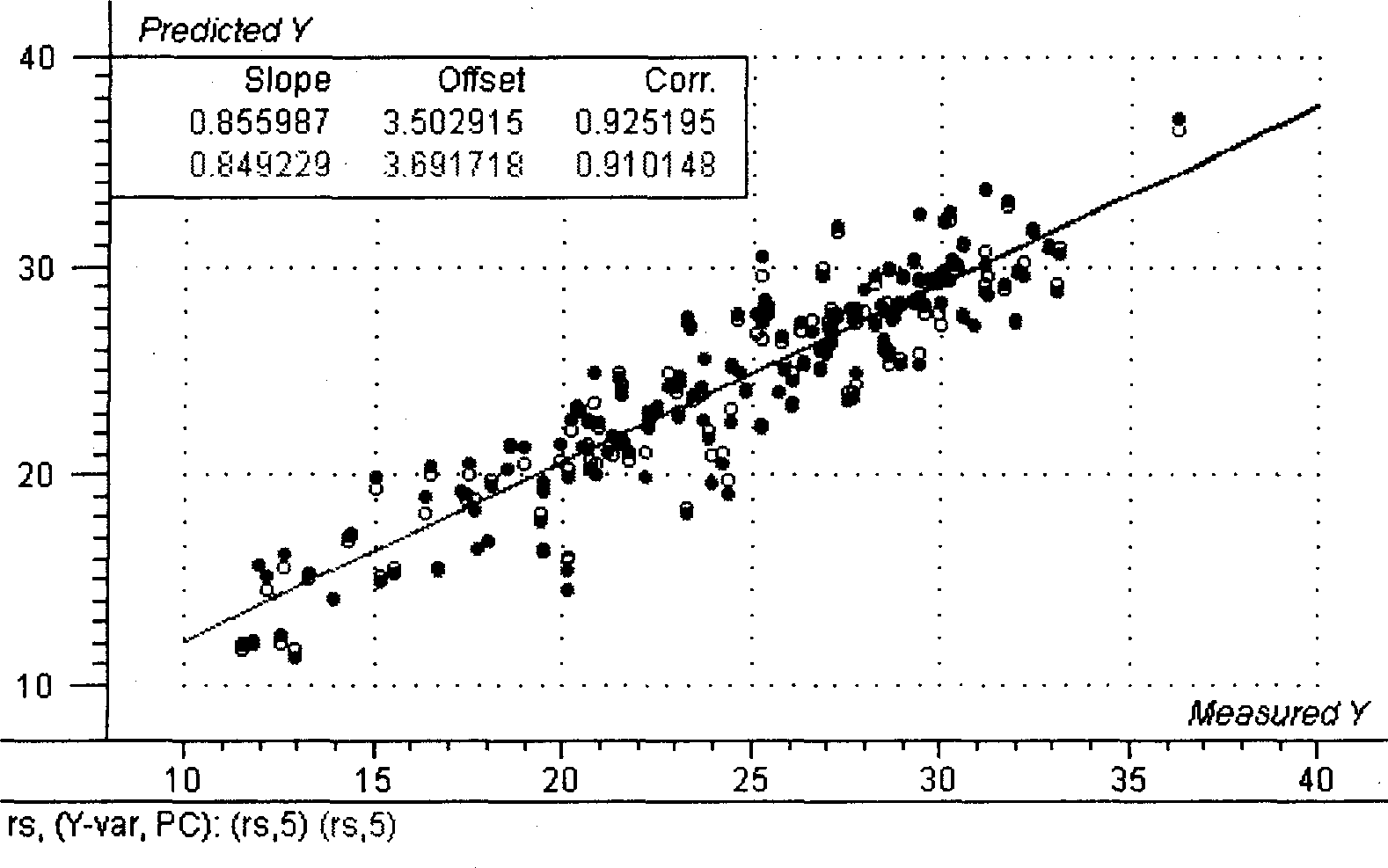

Method for detecting tobacco leaf chemical ingredient adopting near infrared light

ActiveCN1828272ADetermine the qualityAccurate analysisColor/spectral properties measurementsChemical compositionMathematical model

Owner:CHINA TOBACCO SHANDONG IND

Method for detecting chemical ingredient of tobacco adopting near infrared light

ActiveCN1828271ADetermine the qualityAccurate analysisColor/spectral properties measurementsChemical compositionEngineering

Owner:CHINA TOBACCO SHANDONG IND

Device and method for identifying obstacles for rail vehicles

ActiveCN106068217AIncrease exerciseImprove robustnessPedestrian/occupant safety arrangementApparatus for force/torque/work measurementIntegratorEngineering

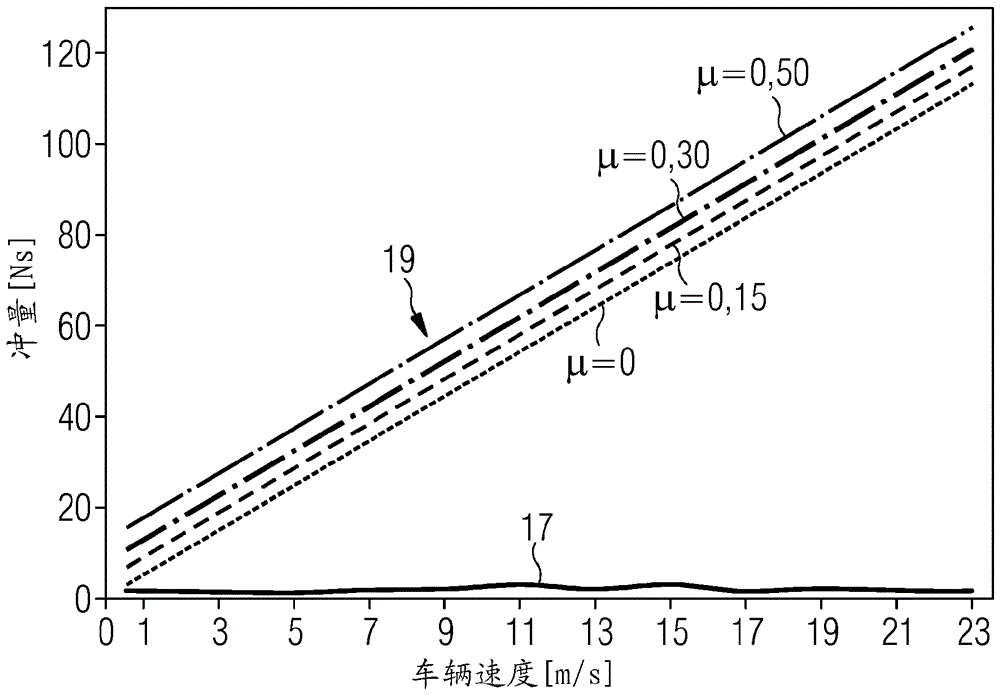

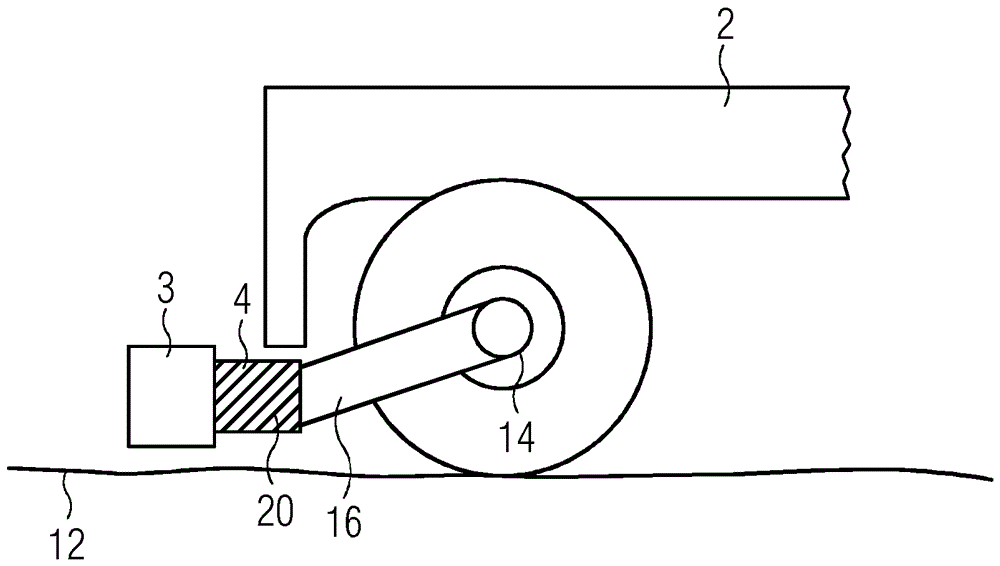

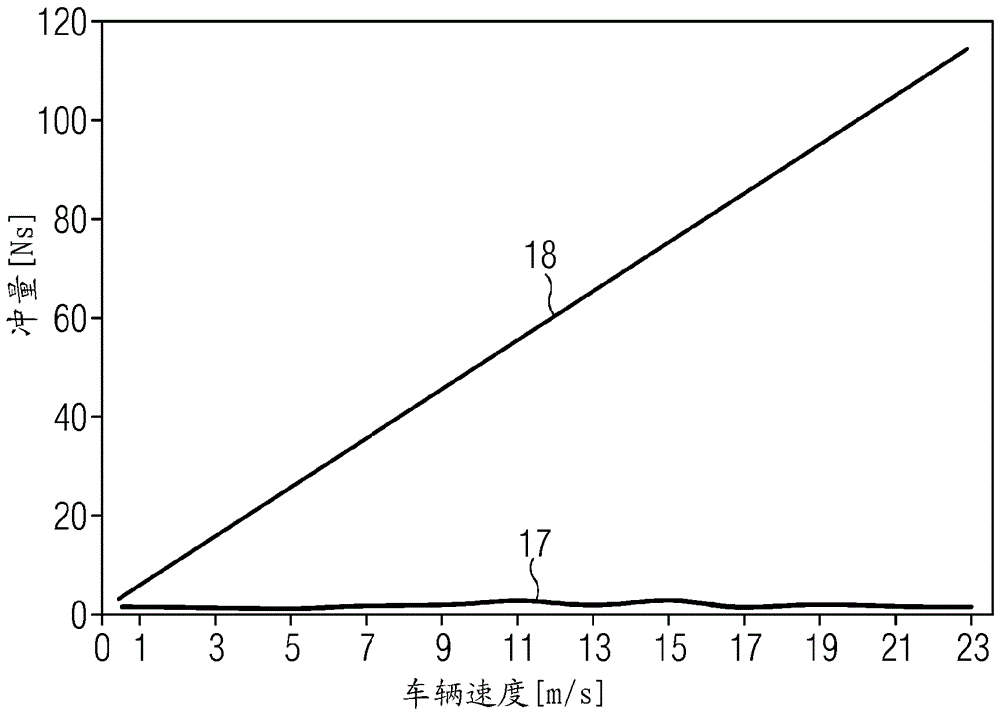

The invention relates to a device for identifying obstacles for rail vehicles (1), comprising a force measuring device (4) which generates a collision force measuring signal (5) in the event of a collision between a collision beam (3) of the rail vehicle (1) and a mass (m) of the collision object (11). Said collision force measuring signal (5) is directed to an evaluation device (7) together with a rail vehicle speed signal (6) and the evaluation device (7) is designed to integrate the collision force measuring signal (5) by means of an integrator (13) and by using the rail vehicle speed signal (6), to determine the mass (m) of the collision object (11).

Owner:SIEMENS MOBILITY AUSTRIA GMBH

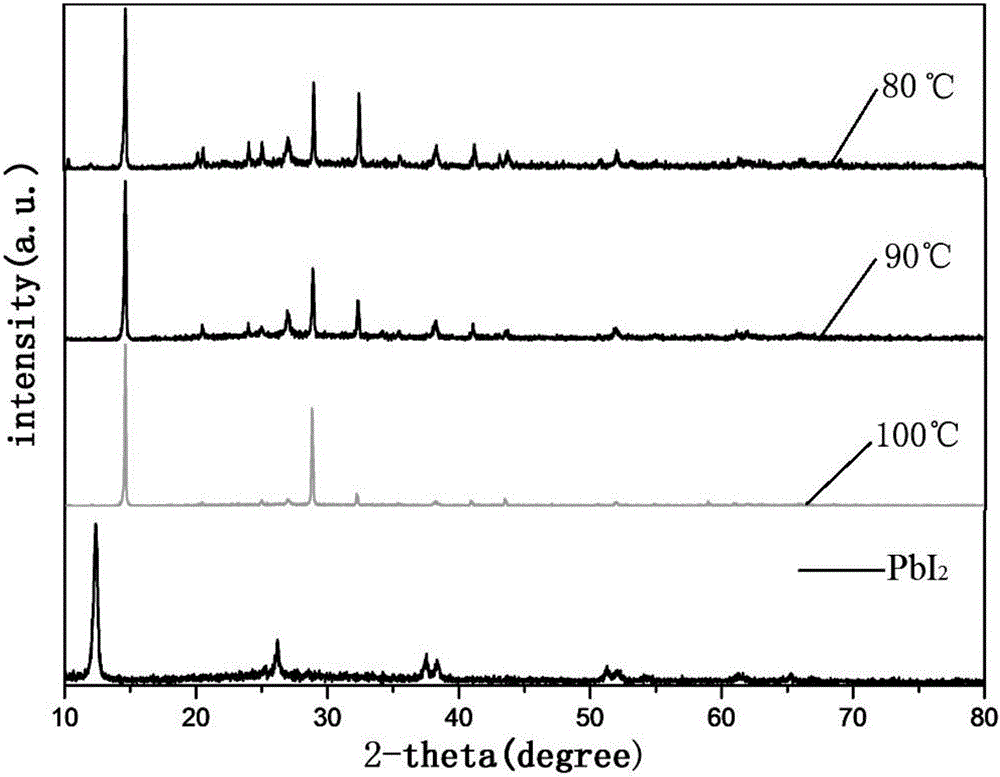

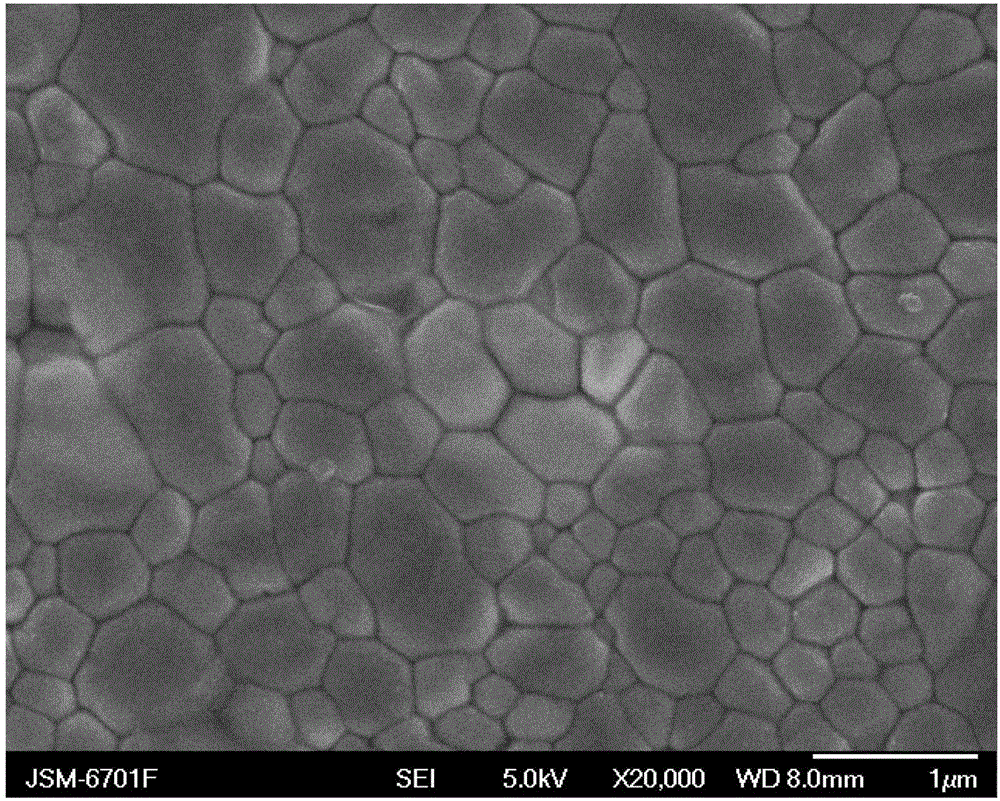

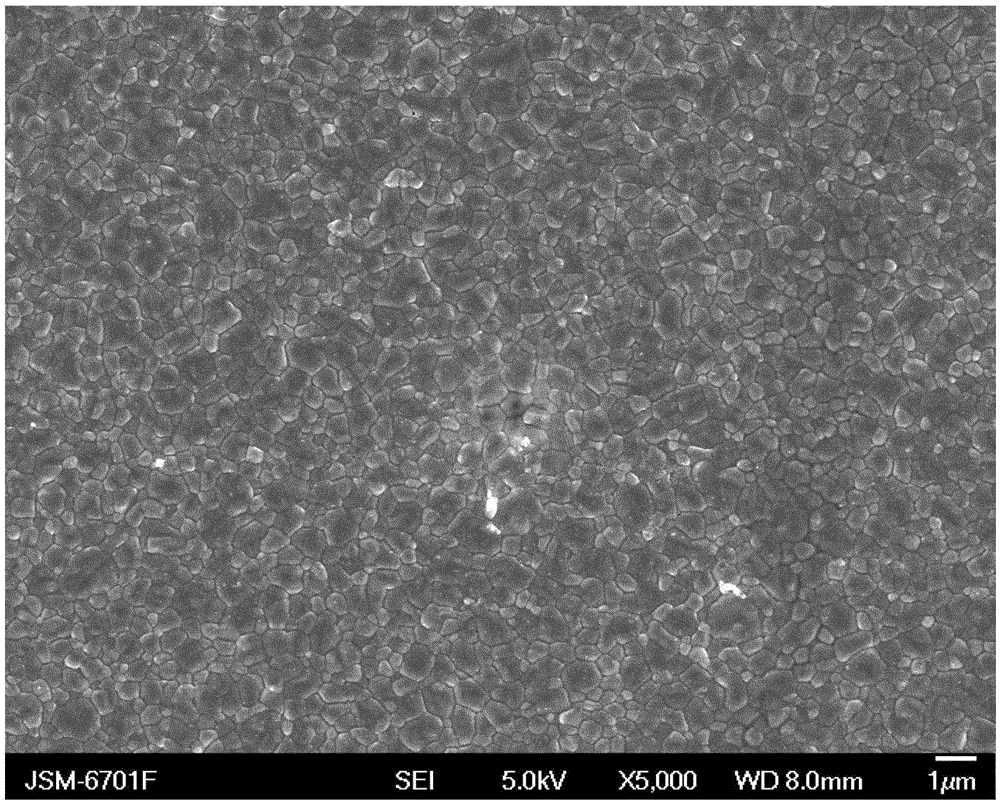

Powder covering substrate heating CH3NH3PbI3 perovskite film preparation method

ActiveCN106340591ASimple film forming processGood absorptionSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellMicrometer

The invention provides a powder covering substrate heating CH3NH3PbI3 perovskite film preparation method, belonging to the technical field of perovskite solar cell films. The process steps of the prior art are complex, and the requirement of process conditions is high. According to the method, a PbI2 film is prepared on a substrate firstly, and a CH3NH3PbI3 perovskite film is generated by the solid phase reaction of CH3NH3I and PbI2 in the PbI2 film. The method is characterized in that CH3NH3I crystal powders with the particle diameter of 10 to 50 micrometers are evenly spread at the surface of the PbI2 film, the heating is carried out from the substrate and 80 to 100 DEG C solid phase reaction temperature is provided for the CH3NH3I and the PbI2, and the solid phase reaction is completed through 8 to 10 minutes. The preparation method is simple, the process condition is loose, the product film is in a multi-crystalline state, the structure is compact, the crystallinity is high, the grain size reaches a micrometer level, the absorption is good in a visible light band, and the method can be used as a light absorbing material in the field of photovoltaic.

Owner:CHANGCHUN UNIV OF SCI & TECH

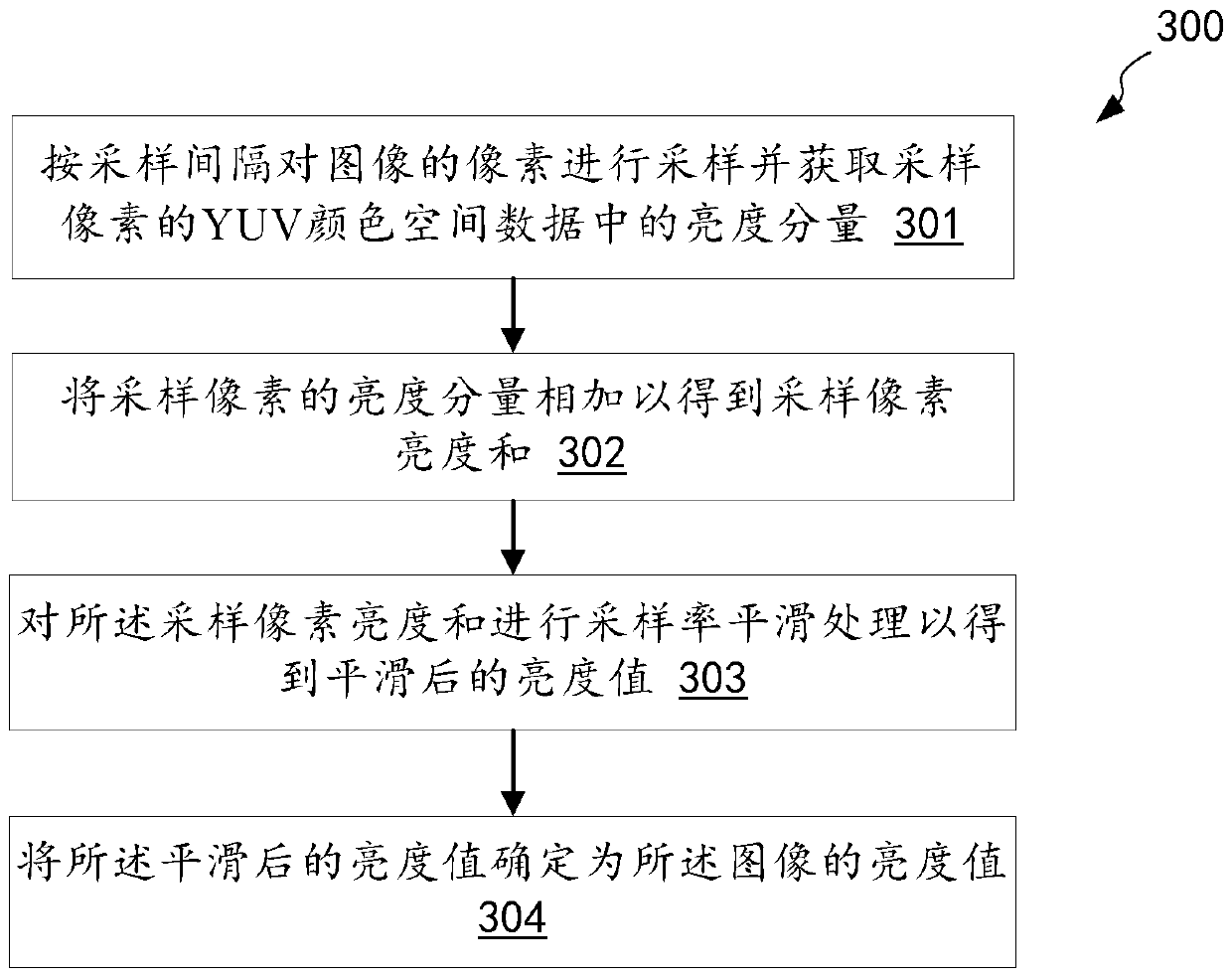

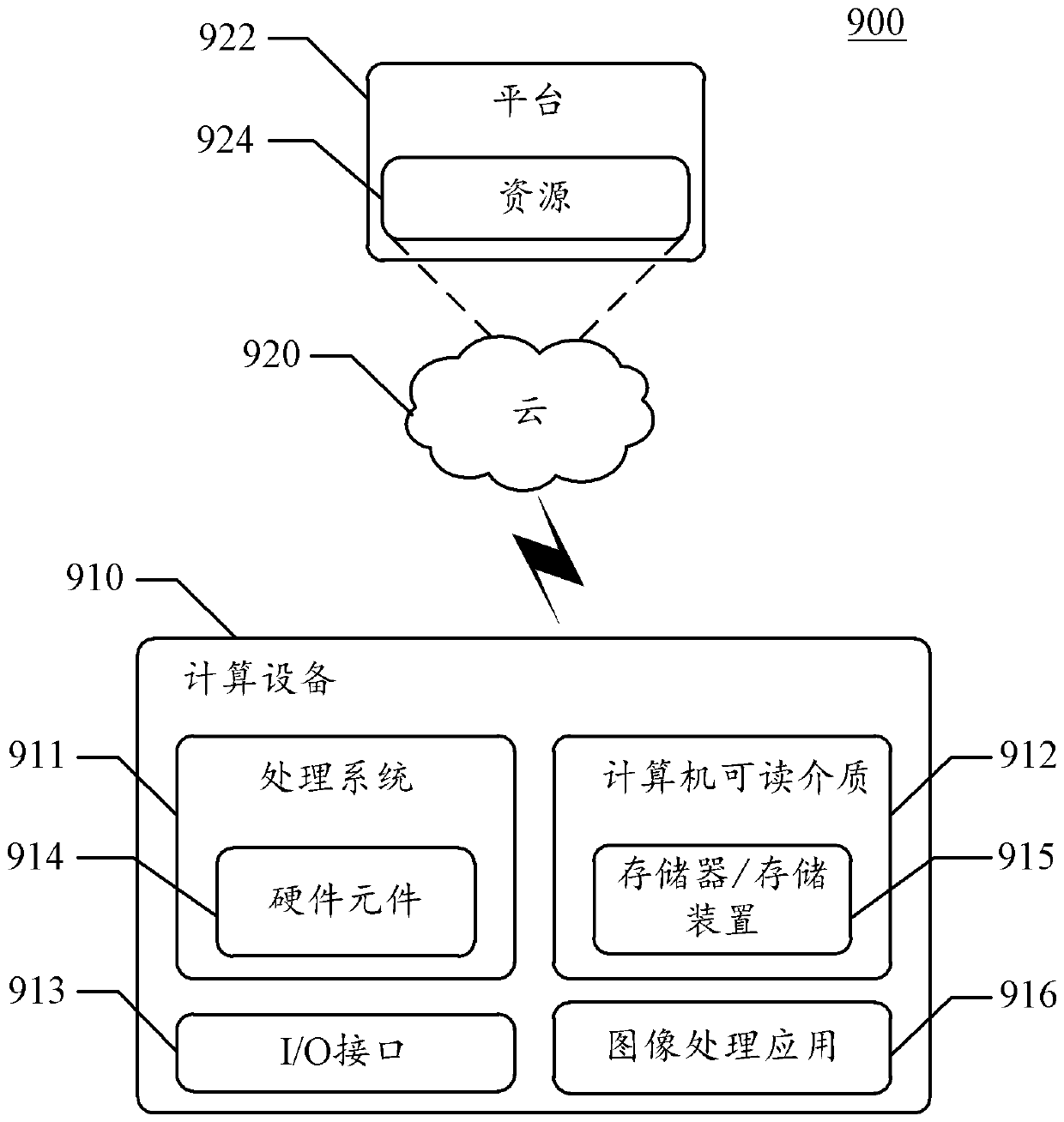

Image processing method and image processing device

ActiveCN110910333AIncrease brightnessDetermine the qualityImage enhancementImage analysisImaging processingRadiology

An image processing method and an image processing device are described herein. The method includes determining a luminance value of the image. In response to the fact that the brightness value of theimage is smaller than an image brightness threshold value, the brightness of the image is enhanced, and which comprises: determining each pixel of the image as a to-be-enhanced pixel; determining a brightness enhancement value of the to-be-enhanced pixel based on the brightness value of the image, the initial brightness value of the to-be-enhanced pixel and the initial brightness value of the adjacent pixel of the to-be-enhanced pixel; and enhancing the brightness of the to-be-enhanced pixel so as to take the brightness enhancement value as an enhanced brightness value of the to-be-enhanced pixel. By utilizing the method and the device, the resource occupancy rate in the image processing process can be greatly reduced.

Owner:TENCENT TECH (SHENZHEN) CO LTD

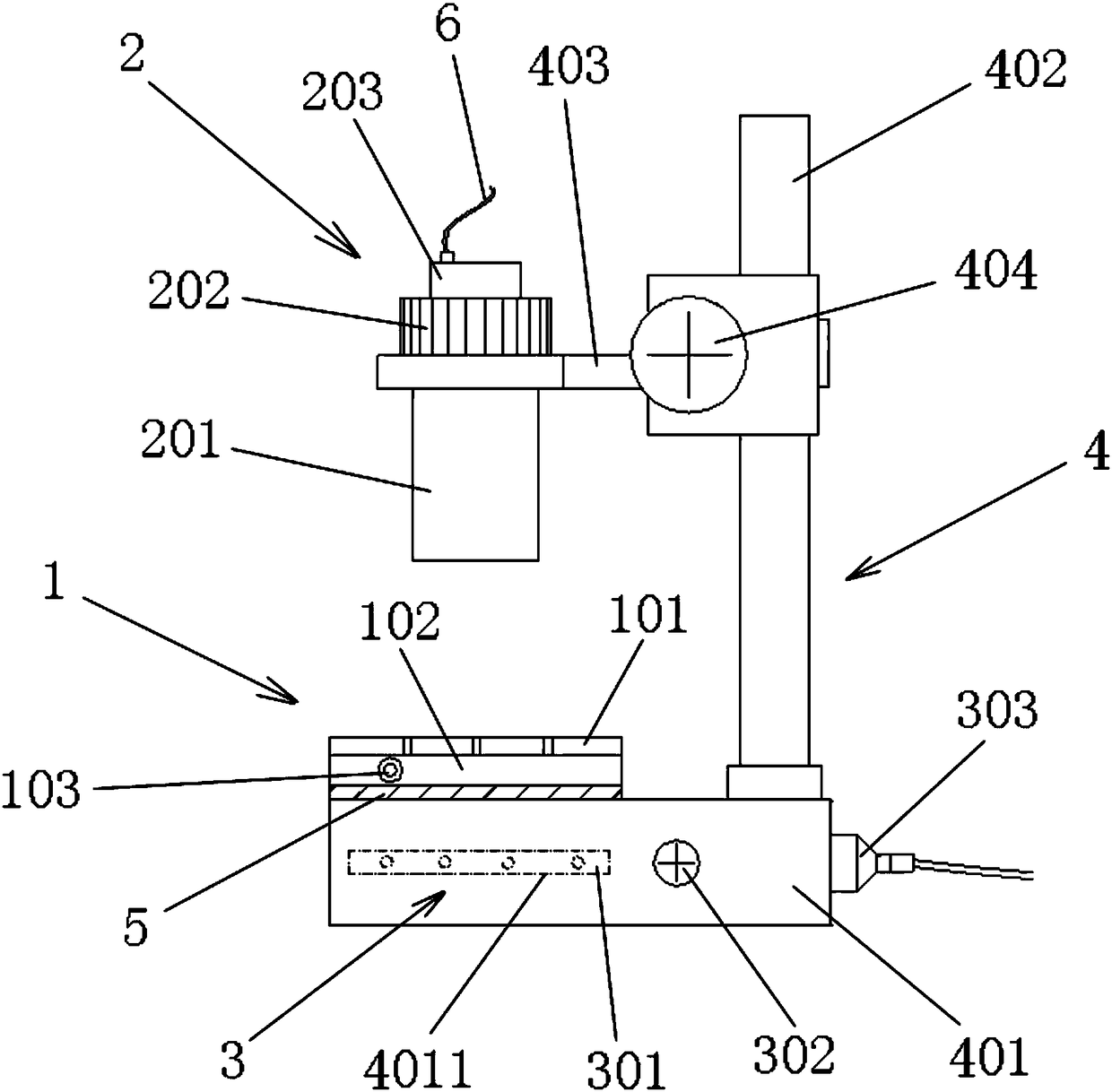

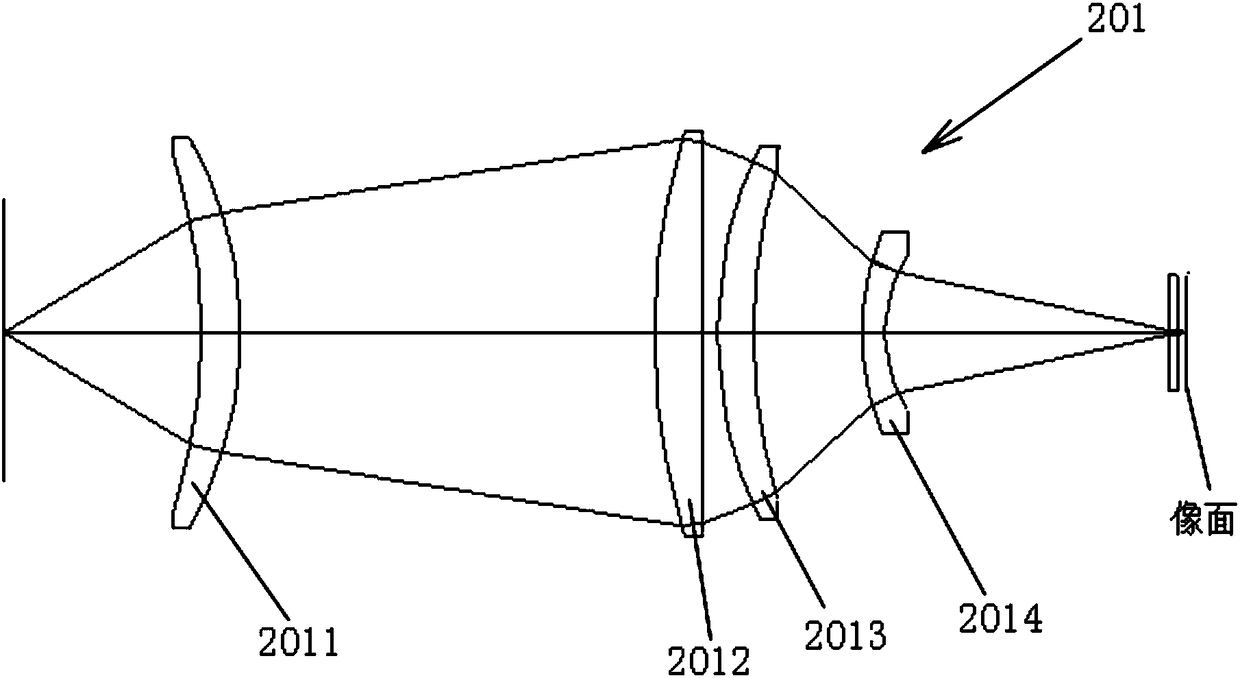

Infrared optical material microdefect detection device and far infrared microscope lens

PendingCN108375584ADetermine the qualitySimple structureOptically investigating flaws/contaminationInfraredOptical axis

The invention relates to an infrared optical material microdefect detection device, a far infrared microscope lens applied to the device, and a detection method of the detection device. The far infrared microscope lens comprises a first lens, a second lens, a third lens and a fourth lens sequentially arranged along an optical axis from an object side to an image side; the first lens, the third lens and the fourth lens are made of germanium glass; the second lens is made of chalcogenide glass; object side surfaces of the first lens and the third lens are spherical surfaces; image side surfacesof the first lens and the third lens are aspheric surfaces; the aspheric surface of the third lens is provided with a diffraction ring zone; the object side surfaces and the image side surfaces of thesecond lens and the fourth lens are spherical surfaces. The far infrared microscope lens provided by the invention can be used for observing microdefects far-infrared transmitted and unobserved by naked eyes inside infrared optical materials (silicon, germanium or chalcogenide glass and the like), so that different types of defects such as air bubbles, impurities and / or cracks can be clearly observed.

Owner:NINGBO SUNNY INFRARED TECH COMPANY

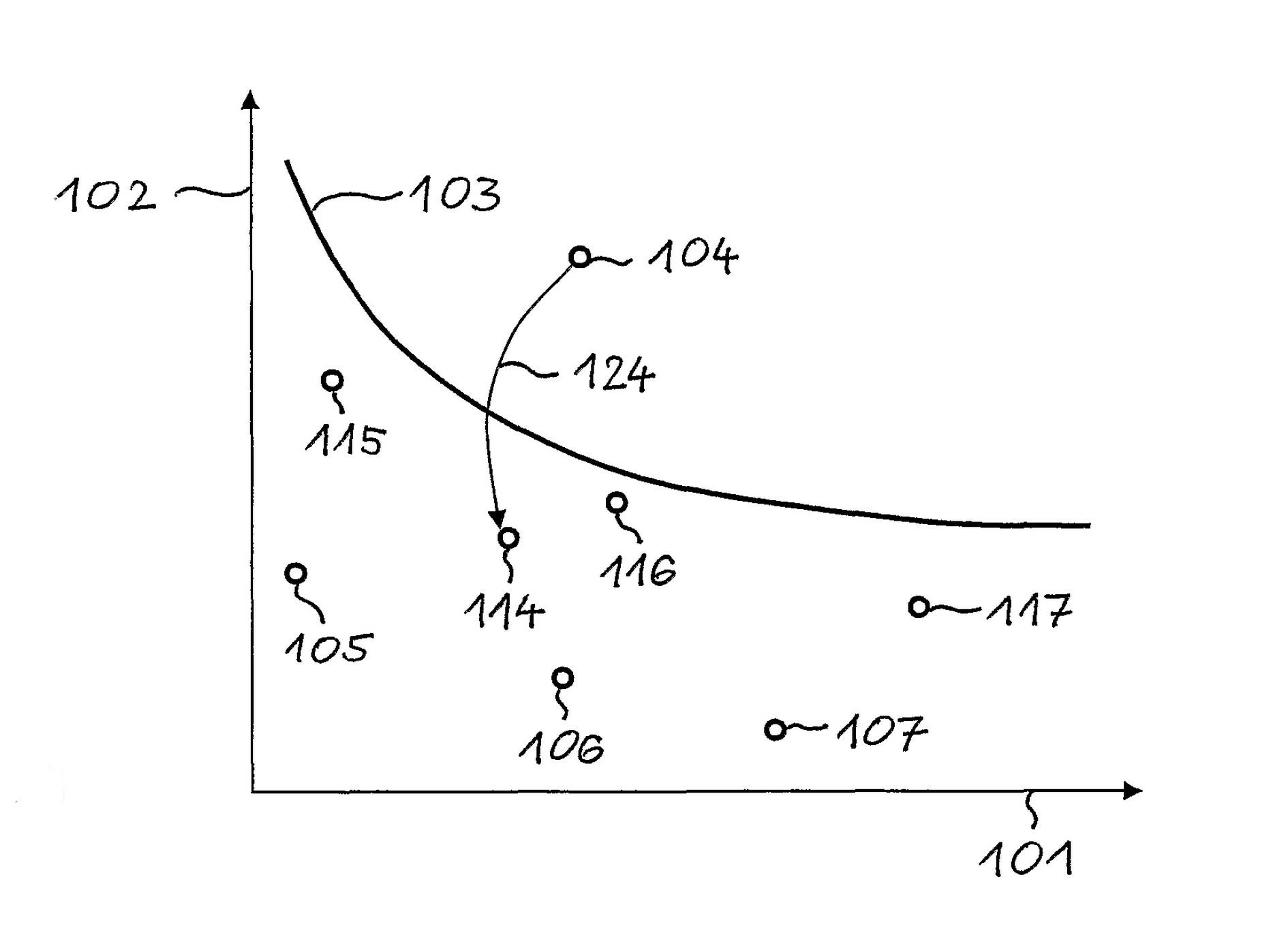

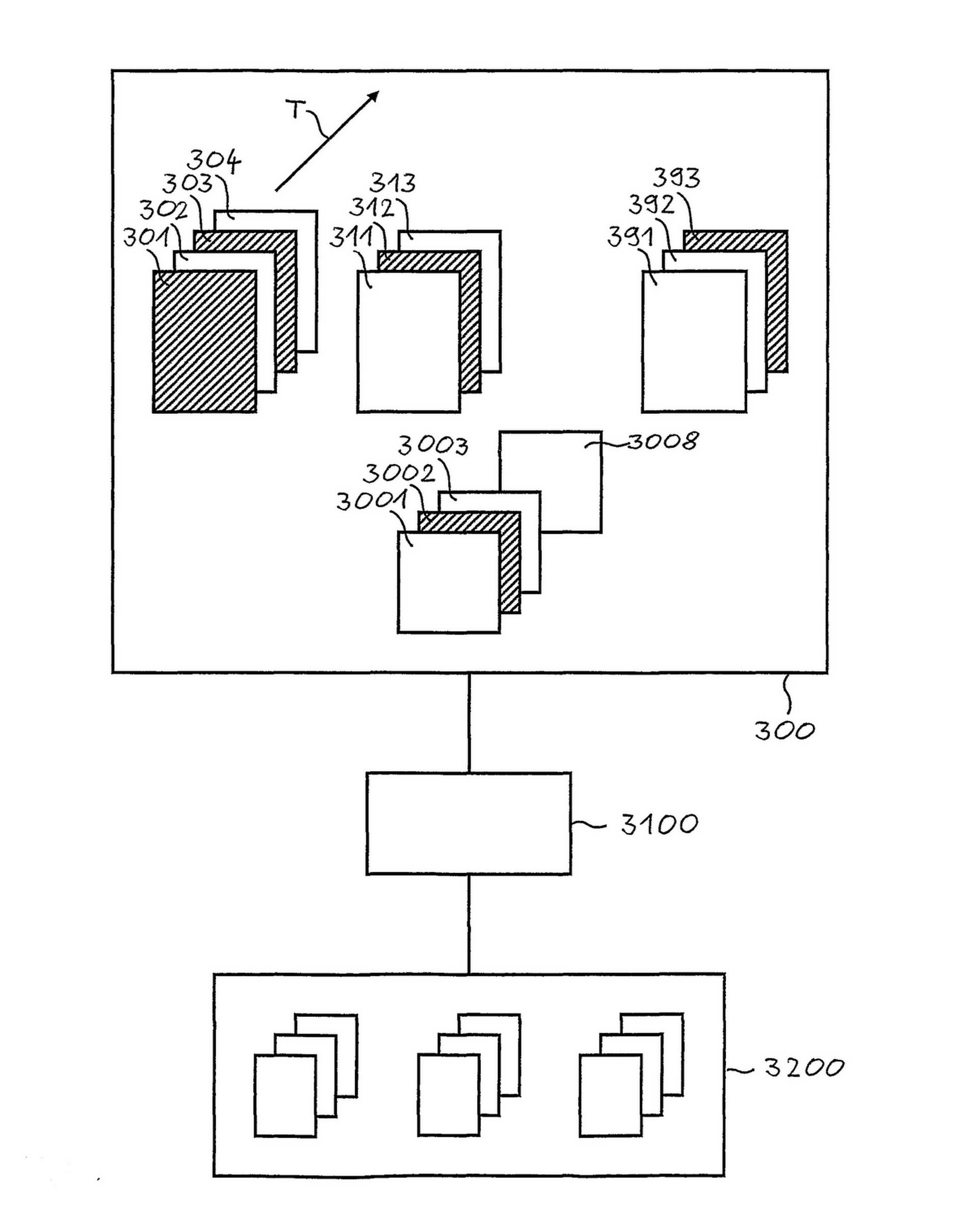

A method for monitoring a manufacturing process in a textile plant

ActiveCN102216503ADetermine the qualityDetermine production capacityContinuous processingYarnRaw material

The invention discloses a method for optimizing the manufacturing process of quality, capacity and / or profitability in a textile plant is applied when raw material is processed in the manufacturing process in several processing steps into intermediate products and an end product is produced. Parameters (301, 303, 312, 393) of the raw material, the intermediate products and / or the end product are measured in at least two different processing steps, stored in a database (300) and linked in an index file (3002). Thus the employed qualities of a lot are as close as possible to the quality of a lot which can also be designated as necessary quality of a lot in order to offer the yarn quality provided for a delivery agreement.

Owner:USTER TECHNOLOGIES

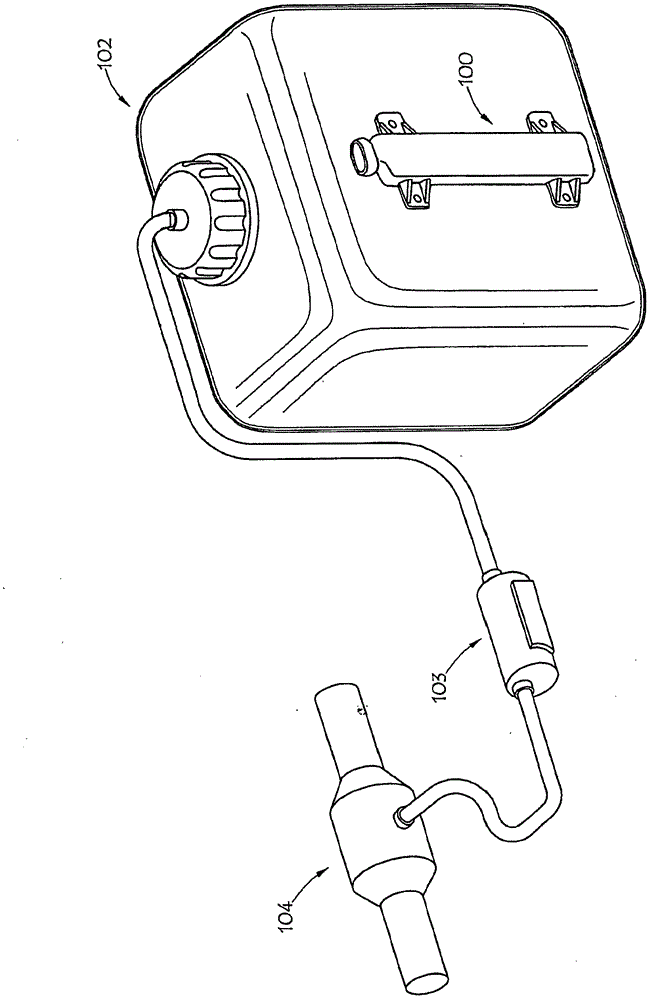

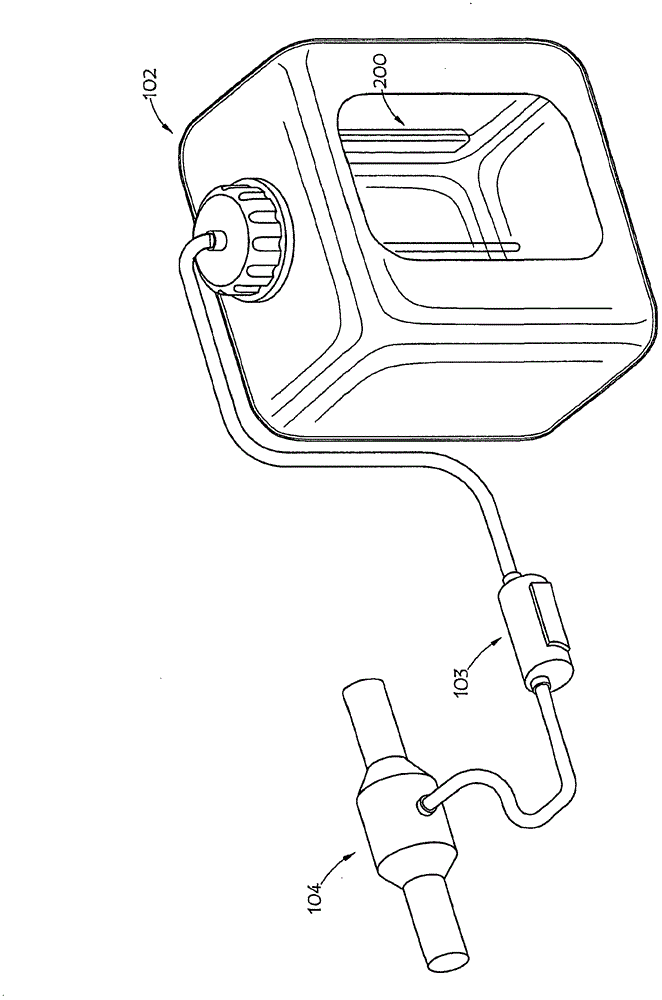

Liquid level and quality sensing apparatus, systems and methods using emf wave propagation

InactiveCN102803910AChanging impedanceDetermine the qualityInternal combustion piston enginesResistance/reactance/impedenceResonanceRefractive index

A liquid level, composition and contamination sensor generates an RF signal across a resonant circuit that includes a variable inductor and capacitor. The resulting electromagnetic radiation is propagated into the liquid and changes in impedance and resonance of the resonant circuit that result from changes in the conductivity and dielectric properties of the liquid, which are proportional to liquid content and volume, are detected. The conductivity and dielectric properties of the liquid are measured, based on the changed impedance and resonance of the resonant circuit, and are compared to determine aging and contamination of the urea solution by other liquids. Also, an optical sensor may be submerged in the liquid to determine the refractive index of the liquid. The refractive index of the liquid may be used to determine: if the liquid is water or a urea solution; the concentration of a urea solution.

Owner:SCHRADER ELECTRONICS LTD

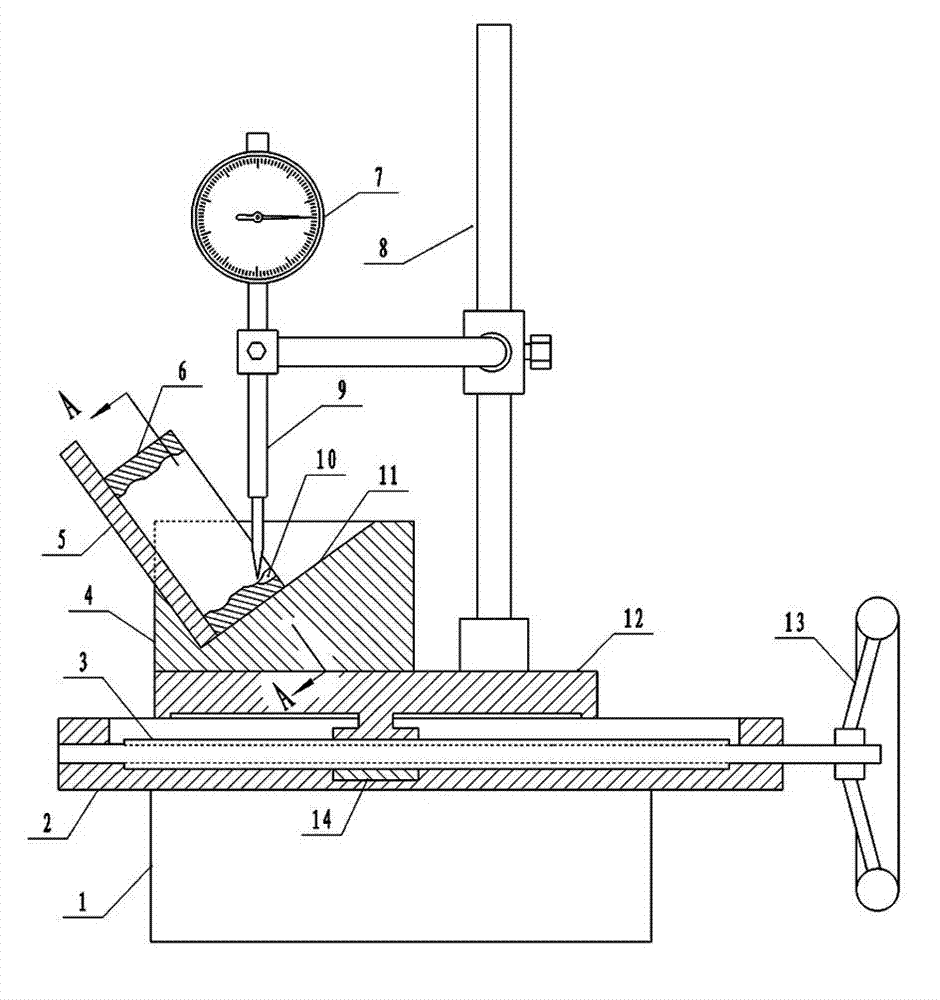

Bearing ball installing groove detector

InactiveCN103206908AMake sure to point toEnsure normative standardsMechanical depth measurementsEngineeringNotching

Provided is a bearing ball installing groove detector. A fixed plate is installed on a base, a lead screw is installed in the middle of the fixed plate, one end of the lead screw is provided with a handle, a movable plate is installed on the surface of the fixed plate, a nut is fixed under the movable plate and is sleeved on the lead screw, and a positioning block is installed on the movable plate. A V-shaped chute is designed on the positioning block, a blocking plate is installed at one end of the chute, and the chute bottom of the chute and the axial direction of the lead screw are consistent. An included angle is in a range from 300 to 450, a fixed column is installed beside the positioning block, a dial indicator is installed on the fixed column, and a probe of the dial indicator right faces the groove bottom of a ball installing groove on a bearing excircle. When the bearing ball installing groove detector is used, an operator turns the excircle to ensure the probe to right face the lowest point of the installing groove and turns the handle on the lead screw, the excircle performs horizontal movement, the dial indicator measures a height numerical value of a protruding edge in the installing groove and a low point of a bearing arc-shaped groove, and the accuracy of a notching position of the installing groove can be detected.

Owner:TONGHAI DAYU BEARING

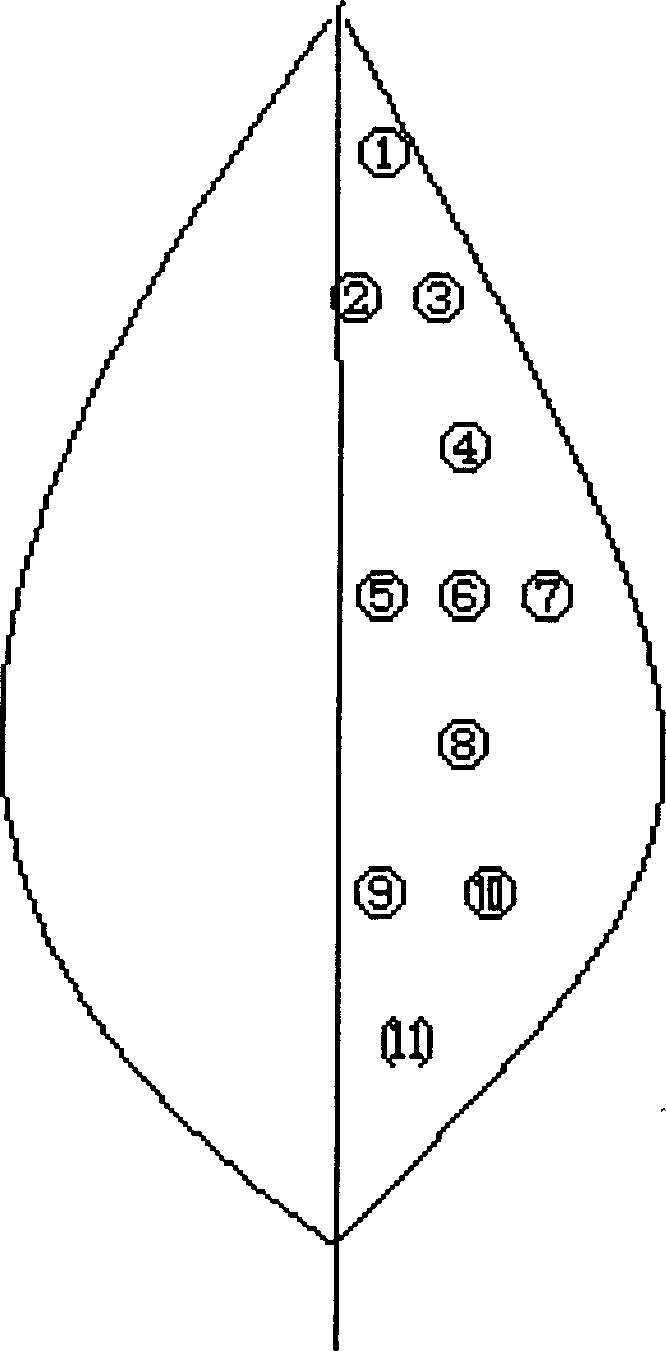

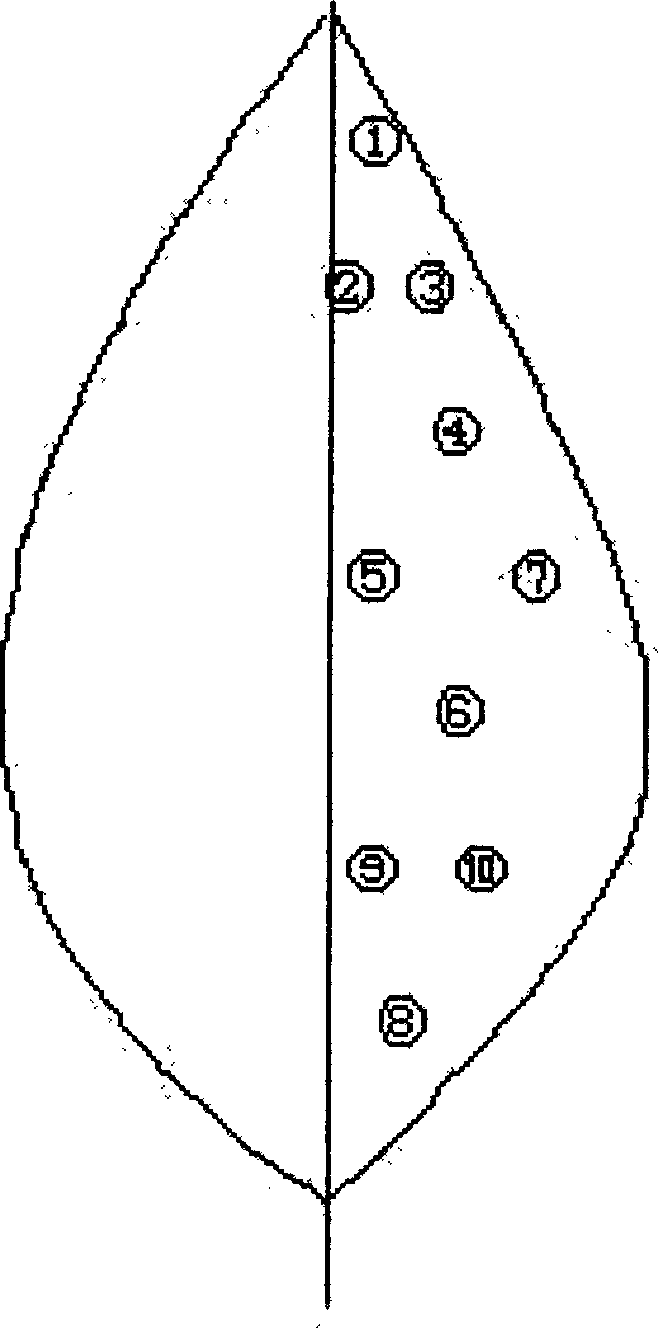

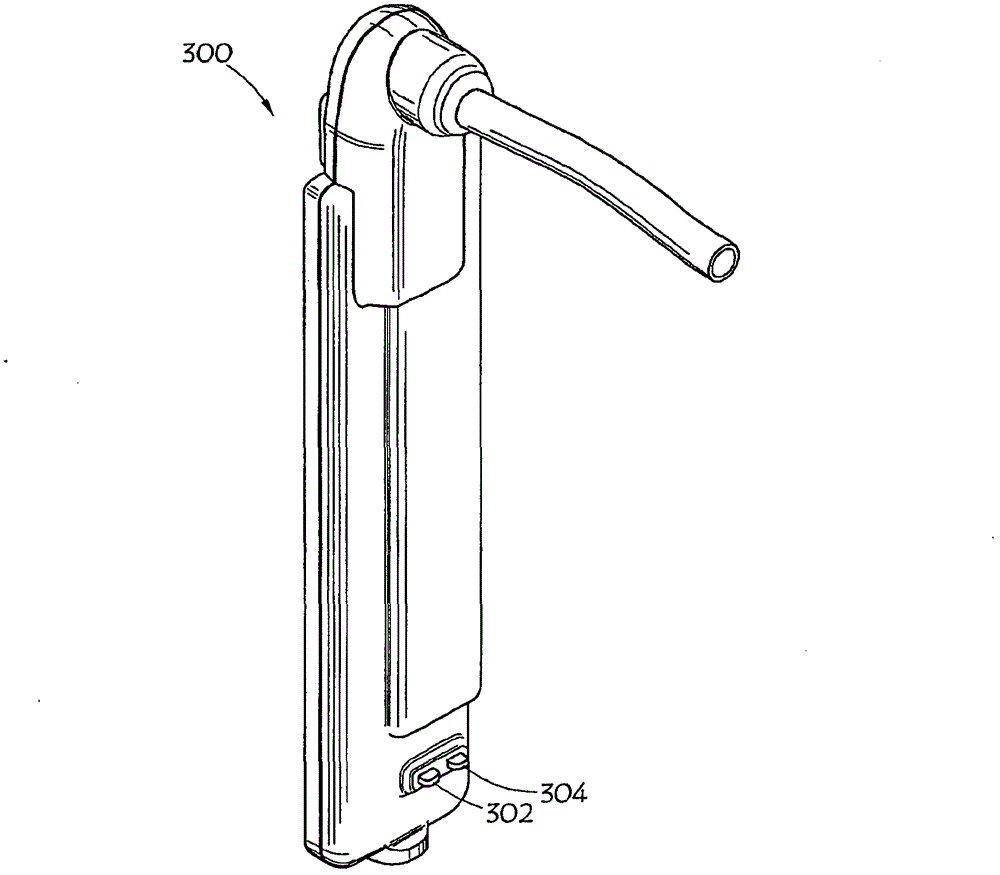

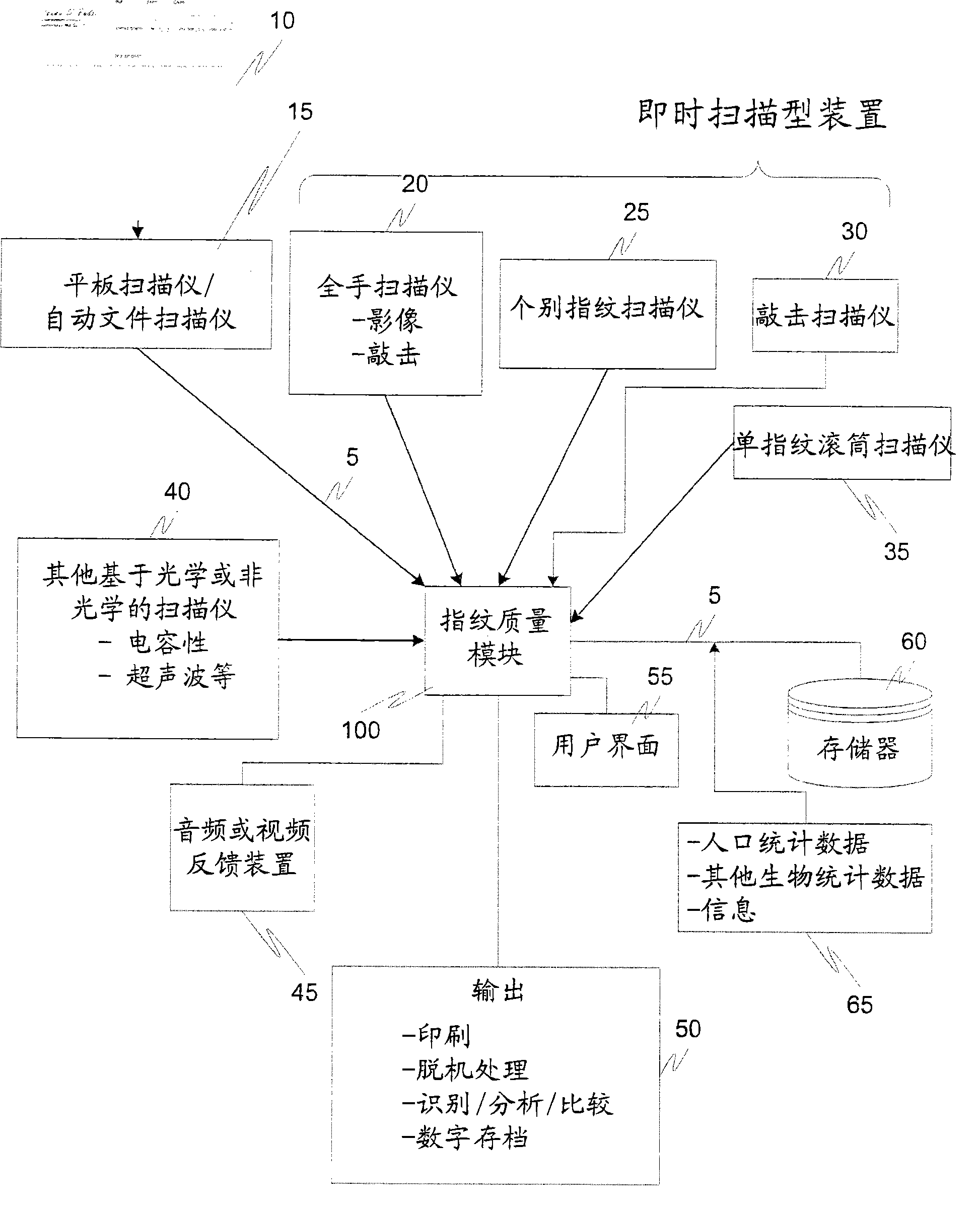

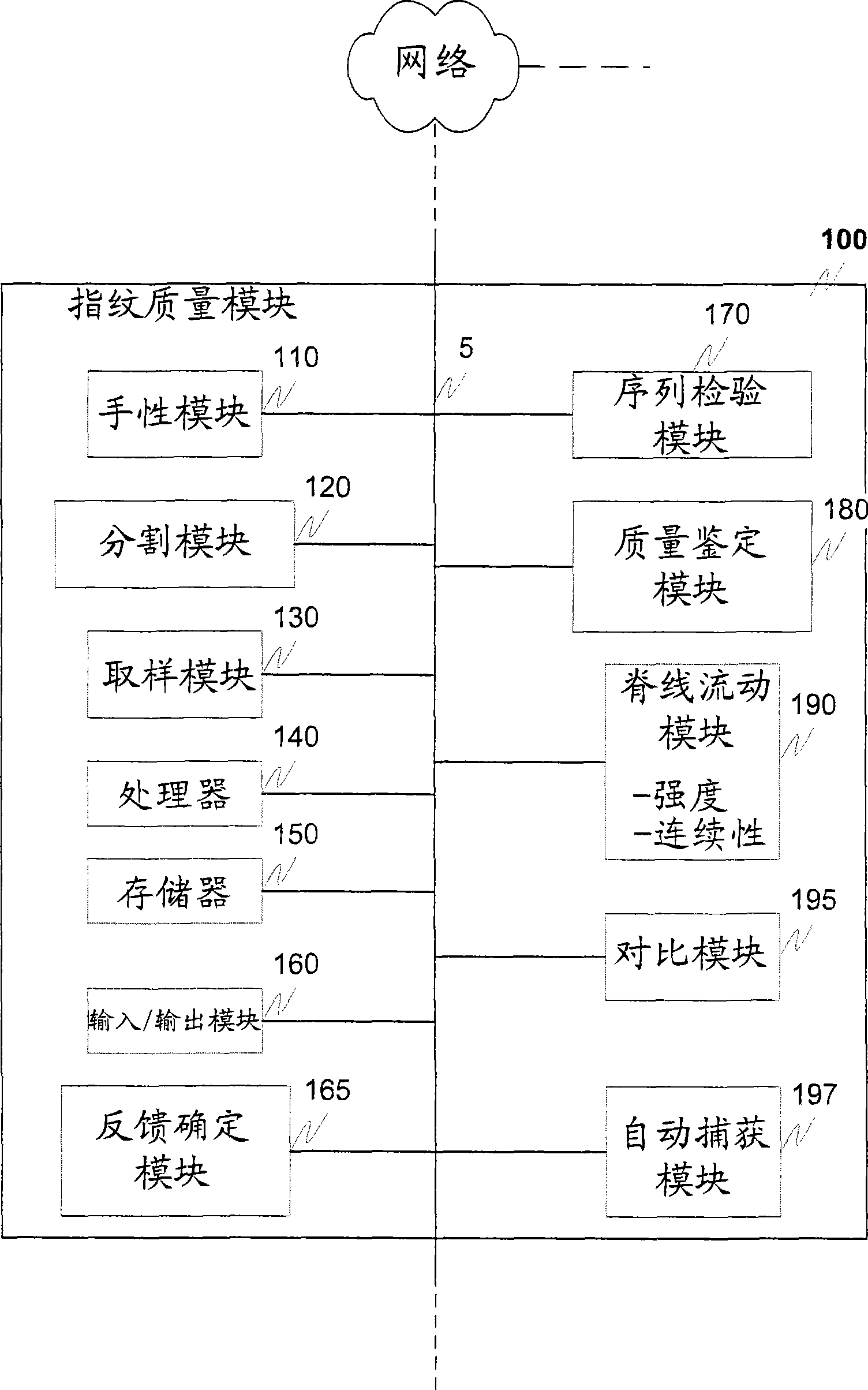

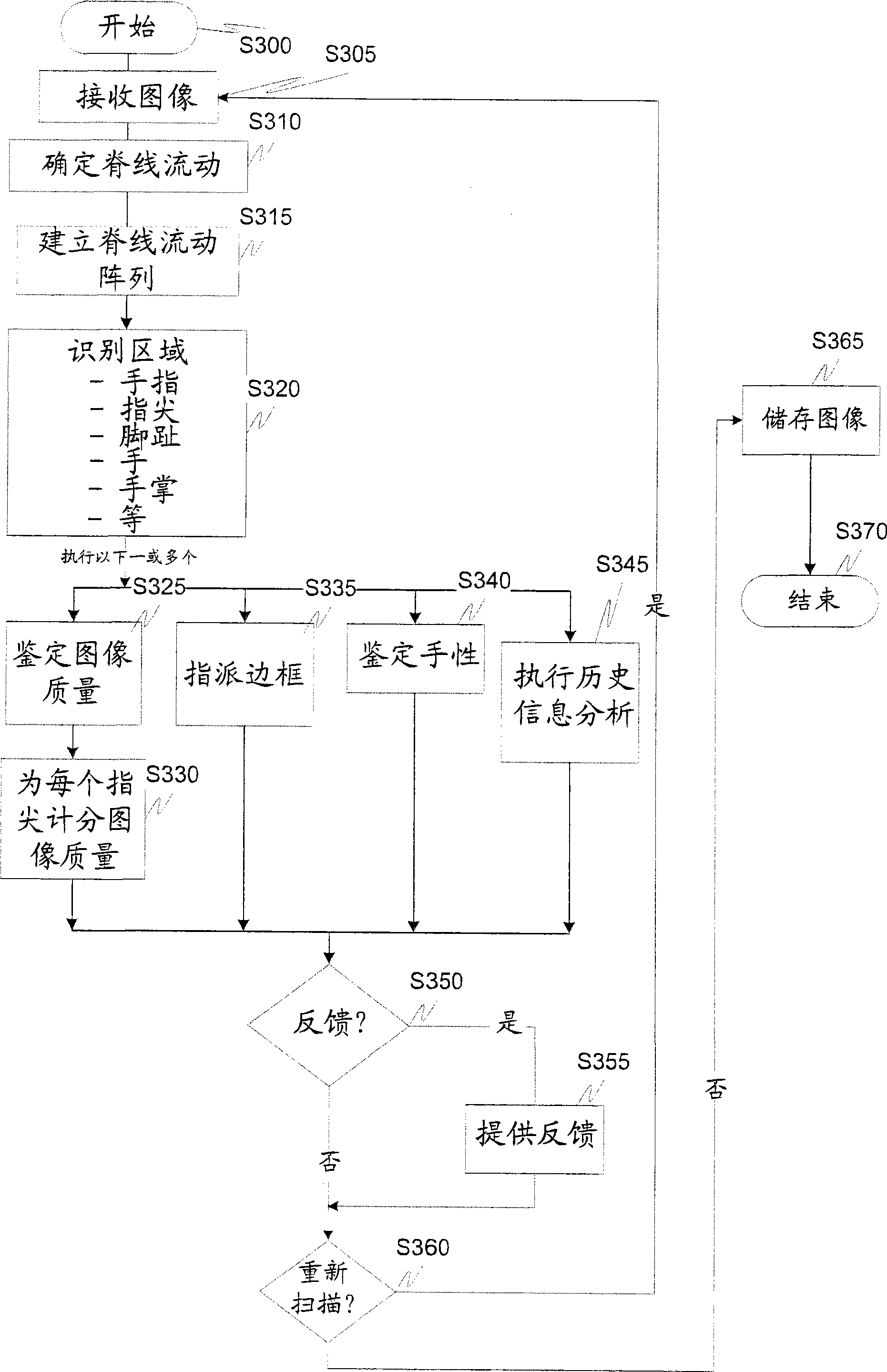

Fingerprint preview quality and segmentation

InactiveCN101443784AInvolves determining the qualityDetermine the qualityImage enhancementImage analysisPattern recognitionInformation analysis

A ridge flow based fingerprint image quality determination can be achieved independent of image resolution, can be processed in real-time and includes segmentation, such as fingertip segmentation, therefore providing image quality assessment for individual fingertips within a four finger flat, dual thumb, or whole hand image. A fingerprint quality module receives from one or more scan devices ridge-flow-containing imagery which can then be assessed for one or more of quality, handedness, historical information analysis and the assignment of bounding boxes.

Owner:阿瓦尔有限公司

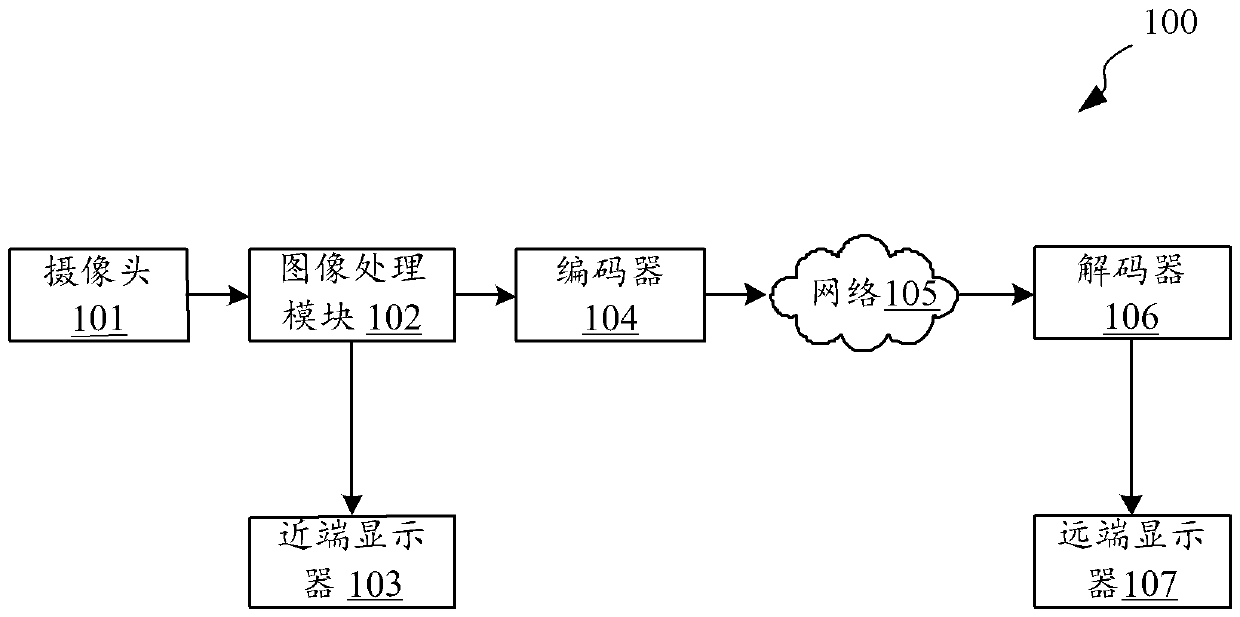

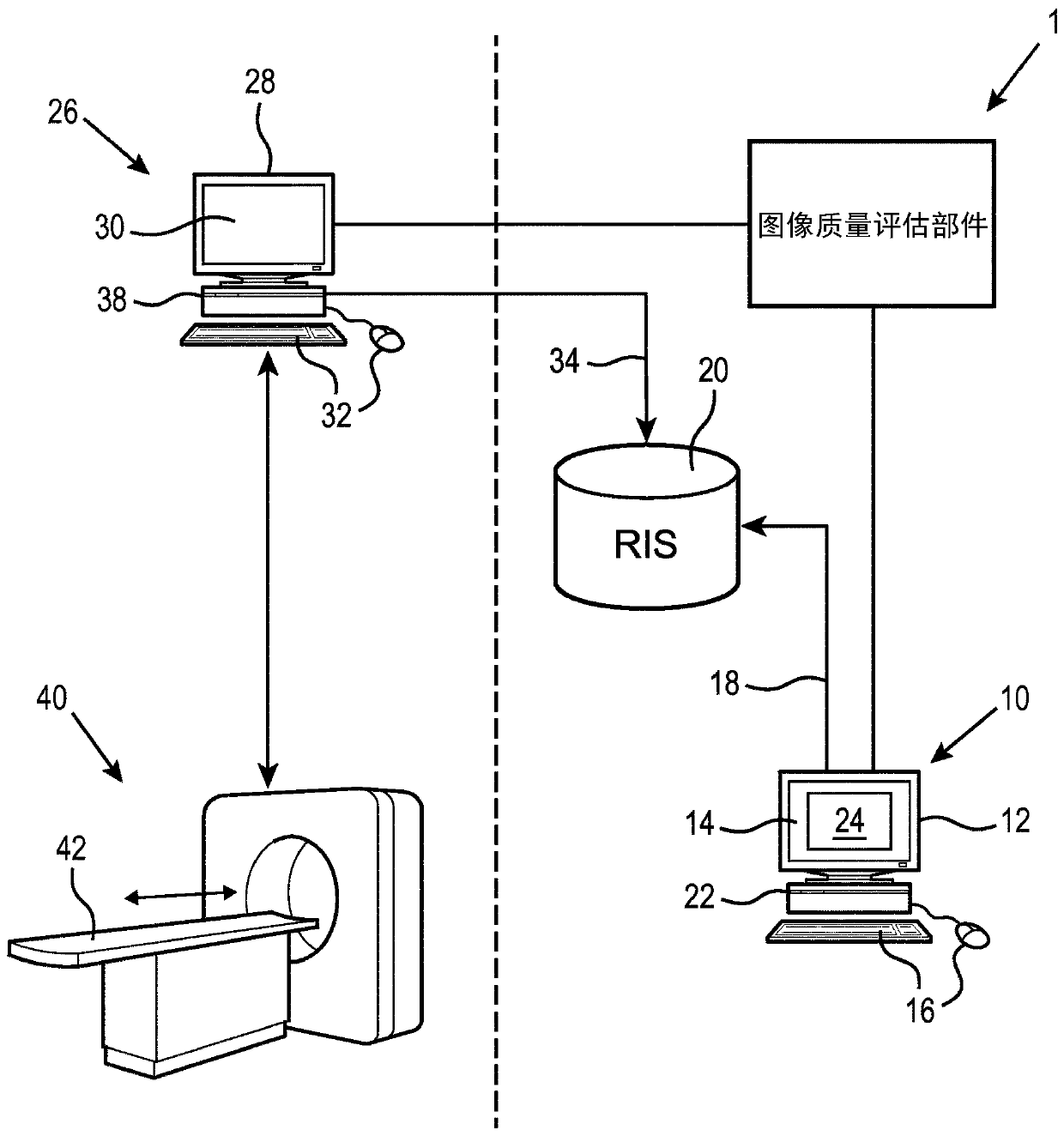

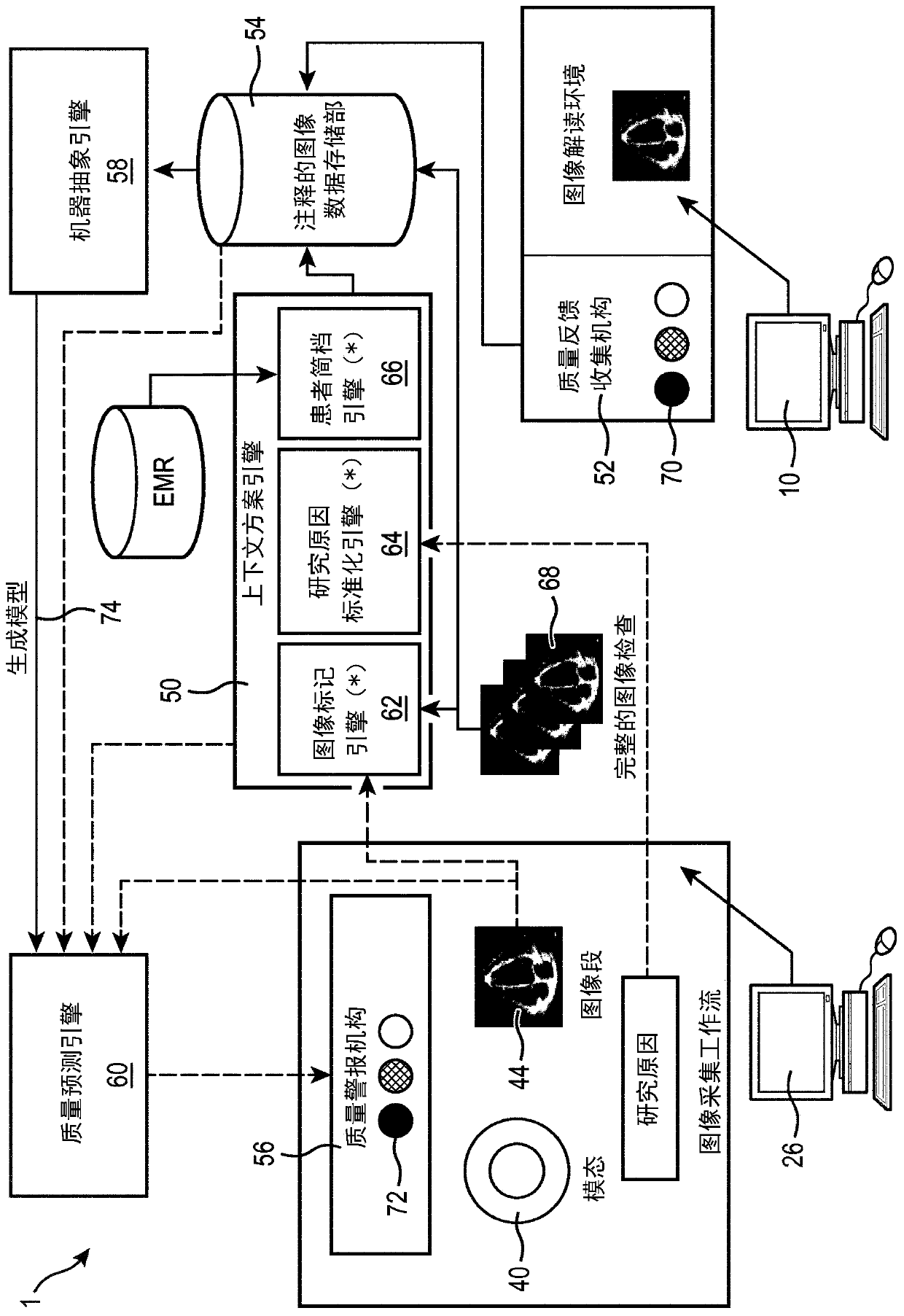

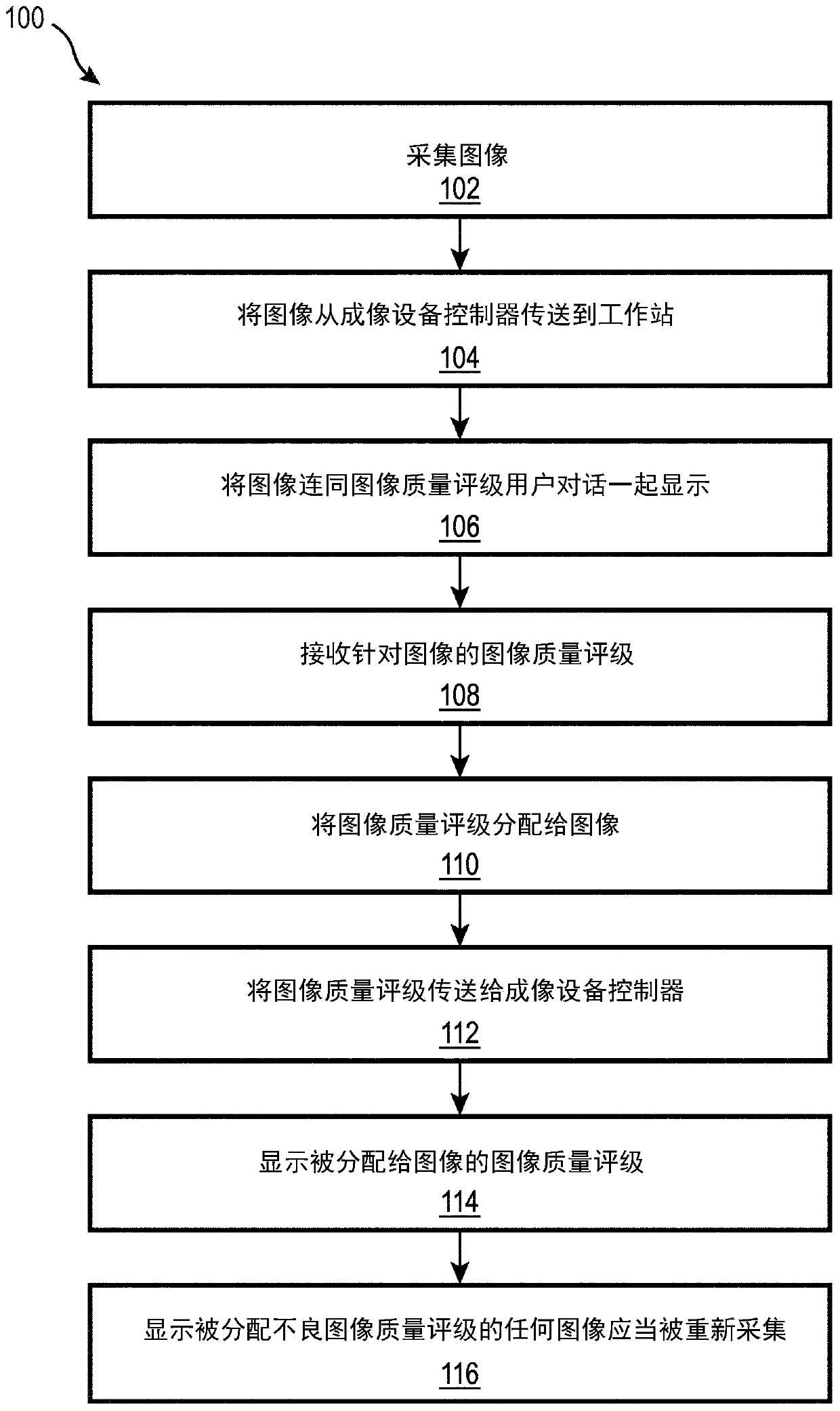

A closed-loop system for contextually-aware image-quality collection and feedback

ActiveCN110140178ADetermine the qualityImage enhancementData processing applicationsImaging qualityDisplay device

A medical imaging apparatus includes a radiology workstation (10) with a workstation display (14) and one or more workstation user input devices (16). A medical imaging device controller (26) includesa controller display (30) and one or more controller user input devices (32). The medical imaging device controller is connected to control a medical imaging device (40) to acquire medical images (44). One or more electronic processors (22, 38) are programmed to: operate the medical workstation to provide a graphical user interface (GUI) (24) that displays medical images stored in a radiology information system (RIS) (20), receives entry of medical examination reports, displays an image rating user dialog (70), and receives, via the image rating user dialog, image quality ratings for medicalimages displayed at the medical workstation; operate the medical imaging device controller to perform an imaging examination session including operating the medical imaging device controller to control the medical imaging device to acquire session medical images; while performing the imaging examination session, assign quality ratings to the session medical images based on image quality ratings received via the image quality rating user dialog displayed at the medical workstation; and while performing the imaging examination session, display quality ratings assigned to the session medical images.

Owner:KONINKLJIJKE PHILIPS NV

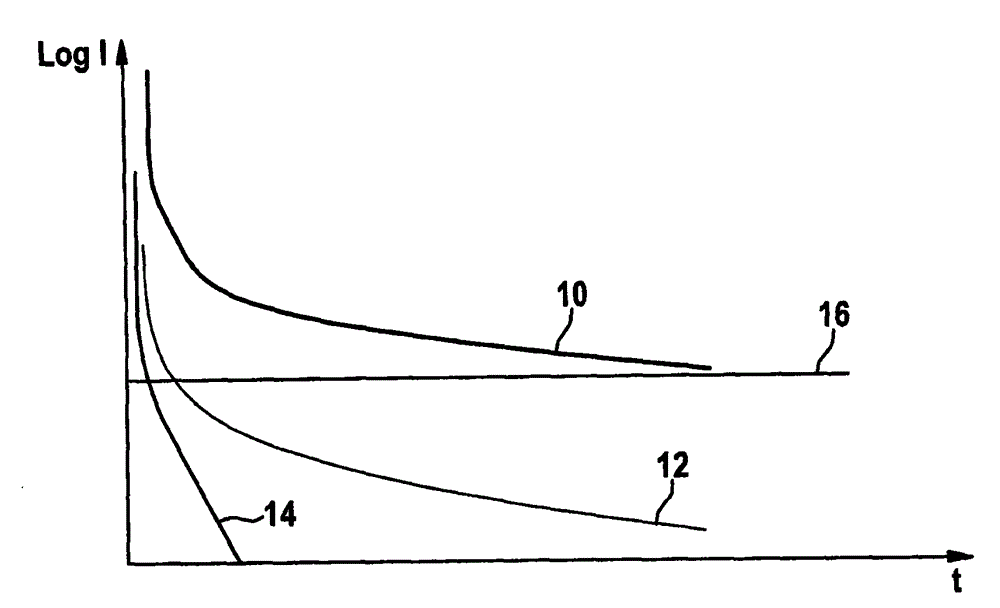

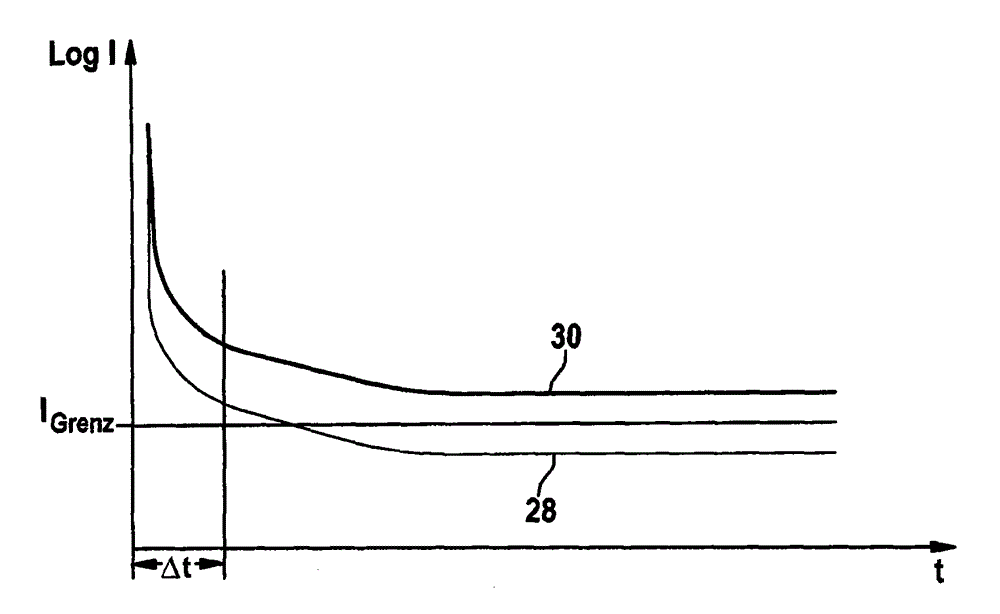

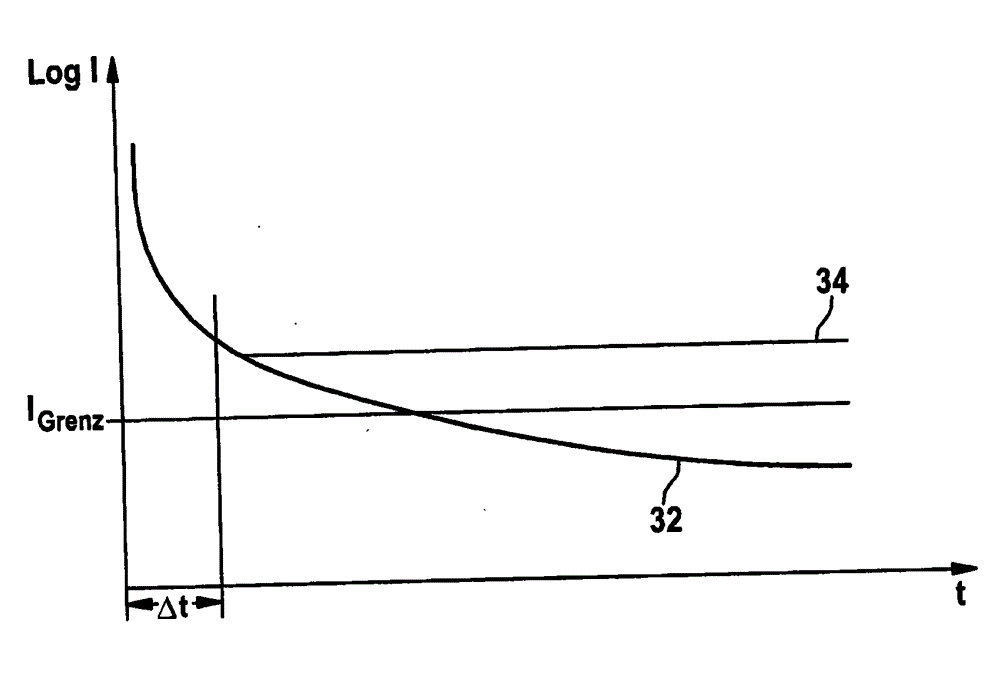

Method for detecting insulation device

ActiveCN104950175ADeterministic functionDetermine the qualityElectric devicesResistance/reactance/impedenceElectrical resistance and conductanceReference current

The present invention relates to a method for detecting insulation resistance of an insulation device of a battery. The method comprises the steps of applying a measuring voltage to the insulation device, measuring a total current changing process (28, 30) in a set measuring time interval ([delta]t), and comparing the total current changing process (28, 30) measured in the set measuring time interval ([delta]t) with a reference current changing process. In addition, the present invention also relates to a computer program and system for implementing the method.

Owner:ROBERT BOSCH GMBH

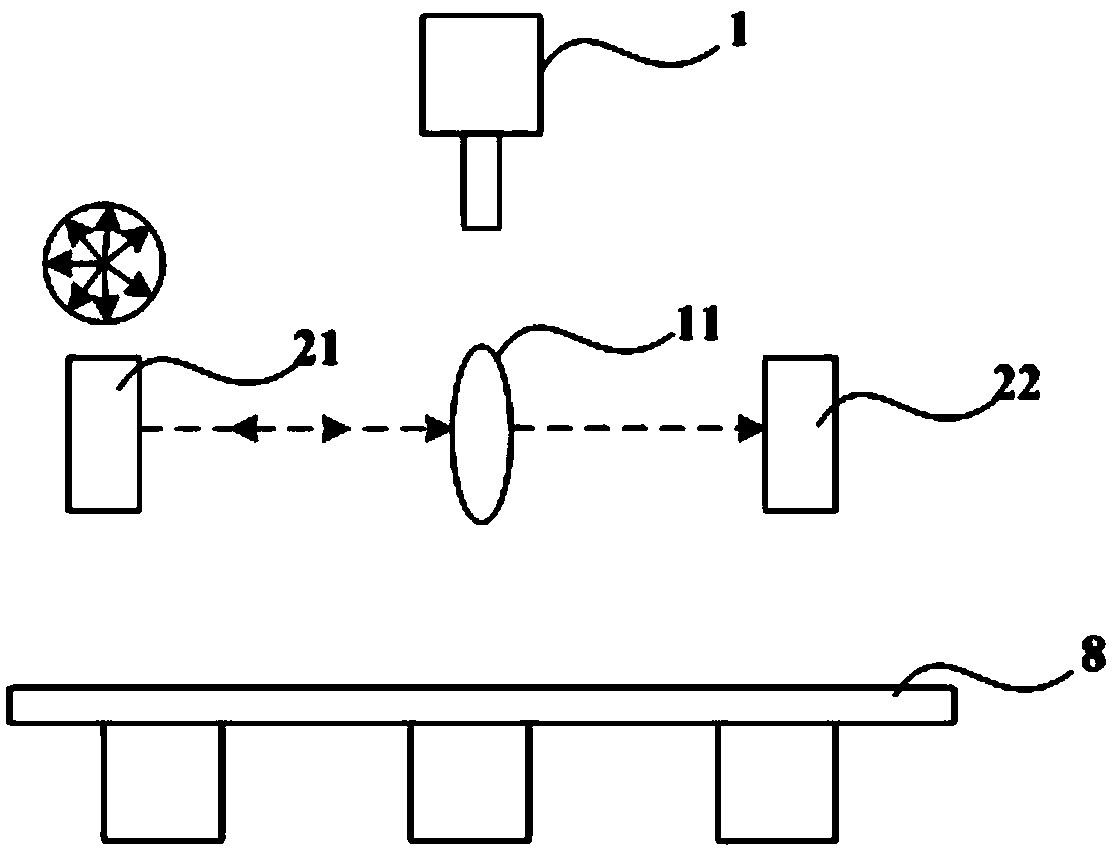

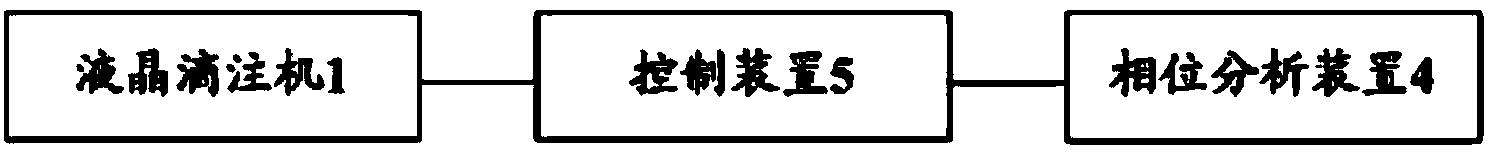

System, method and device for controlling liquid crystal dropping

InactiveCN103885254AImprove the display effectImprove display qualityNon-linear opticsLiquid-crystal displayControl system

The invention relates to the technical field of displaying, and discloses a system, method and device for controlling liquid crystal dropping. Precision of the liquid crystal filling capacity of a liquid crystal display panel is improved, the display quality of a liquid crystal display device is improved, and production efficiency of a product is improved. The system for controlling liquid crystal dropping comprises a liquid crystal dropping machine, a phase analysis device and a control device, the phase analysis device is used for collecting and calculating the current phase difference between ordinary light and extraordinary light which are formed by transmitting liquid crystal drops by incident light and recording the contact time of the liquid crystal drops and the incident light, and the control device is in signal connection with the phase analysis device and the liquid crystal dropping machine and is used for obtaining the volume of the liquid crystal drops according to the contact time of the liquid crystal drops and the incident light and the corresponding relation of the current phase difference and the volume of the liquid crystal drops. The quality of the liquid crystal drops is determined according to the volume of the liquid crystal drops. When the quality of the liquid crystal drops exceeds the allowable quality range of the liquid crystal drops, a dropping stop signal is output, and the liquid crystal dropping machine is controlled to stop dropping.

Owner:BOE TECH GRP CO LTD +1

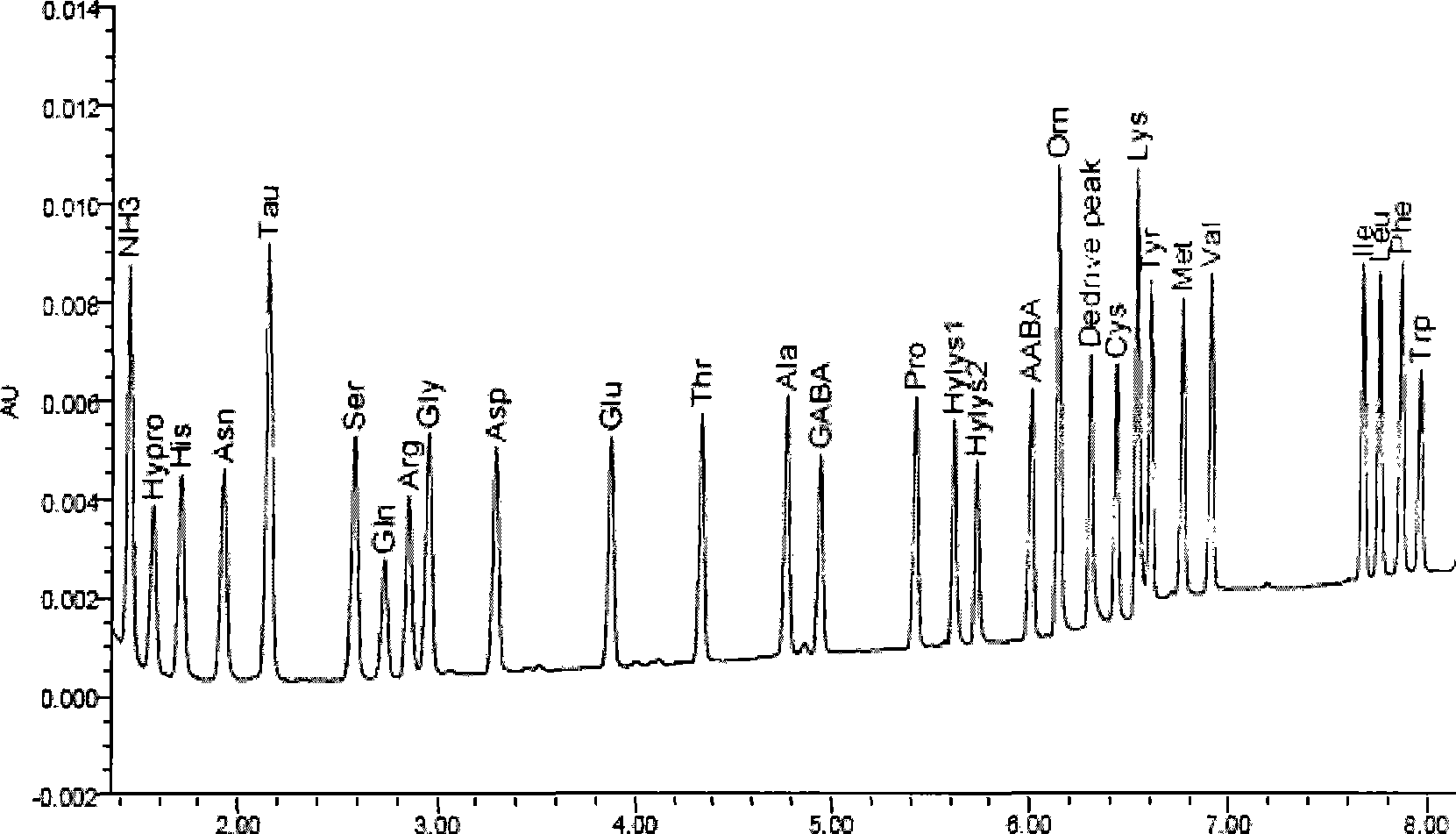

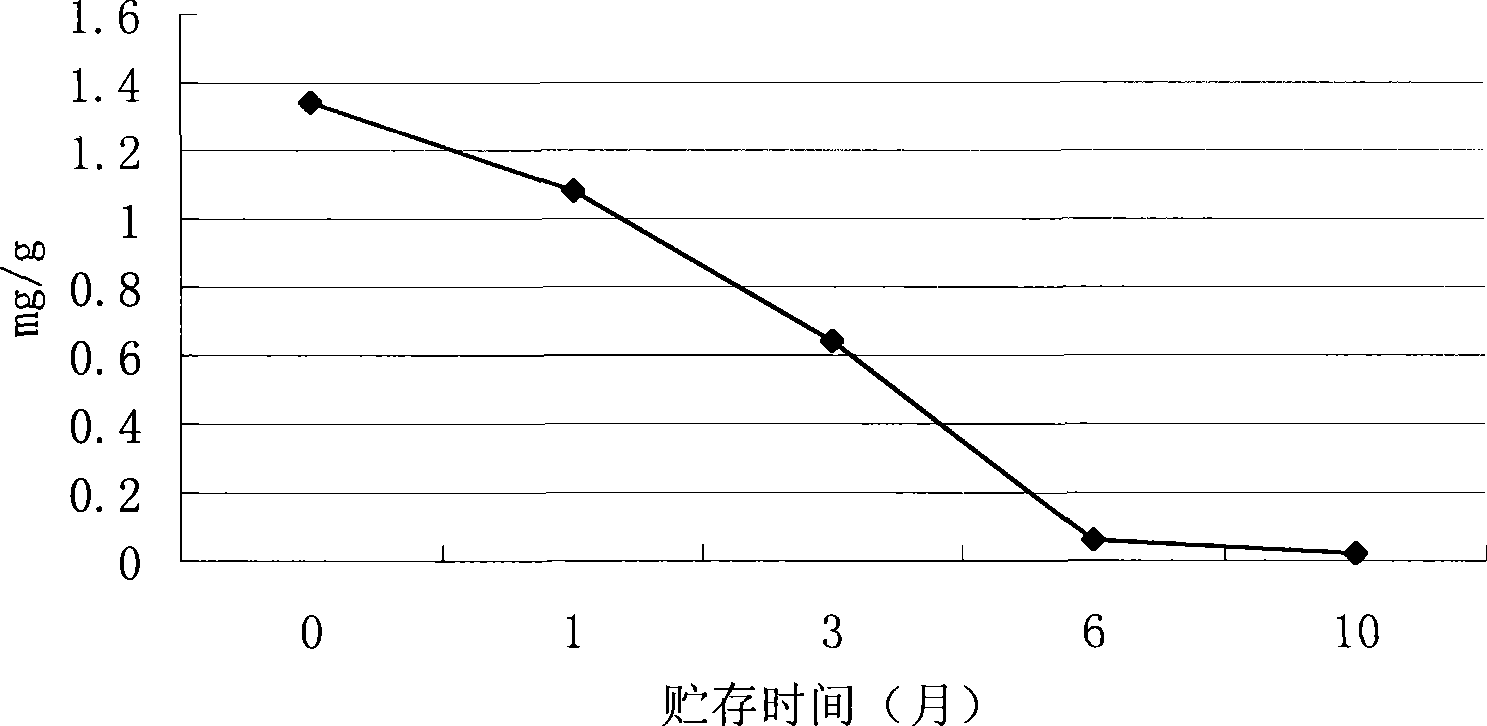

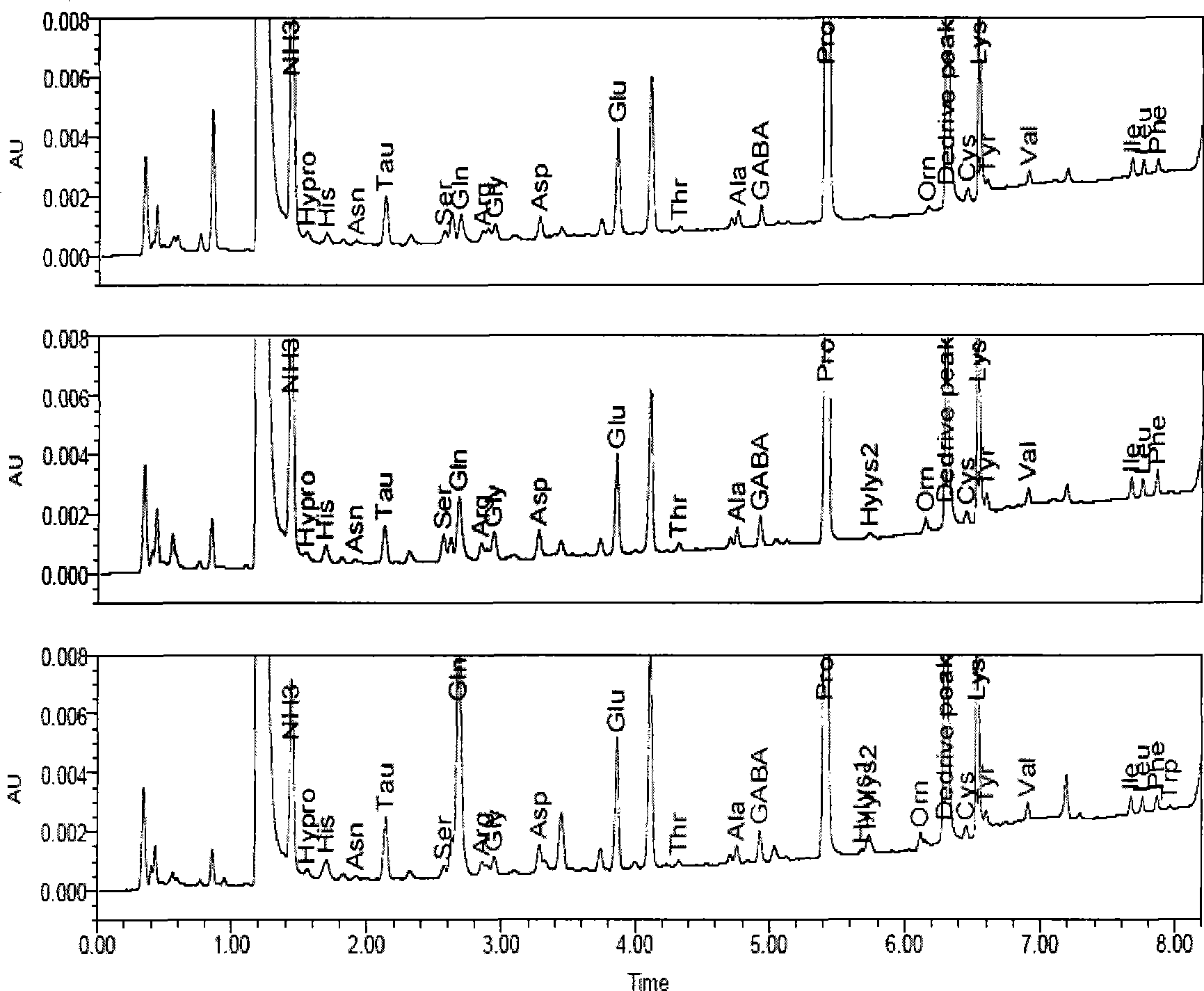

Method for estimating aptness of royal jelly storage condition

InactiveCN101363830ADetermine the qualityHigh sensitivityComponent separationBiological testingRoyal jellyChemistry

The invention provides an evaluation method for the suitability of the storage condition of royal jelly. The suitability of the storage condition of royal jelly is judged by detecting the content of free Gln in the royal jelly and according to the content of free Gln in the royal jelly, and the quality of the royal jelly can be further judged. The storage condition of the royal jelly can be sensitively judged, so as to provide a basis for the manufacturers and the consumers to accurately judge the quality of the royal jelly, and the present royal jelly quality specification can also be completed, in order to effectively monitor the quality of the royal jelly.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

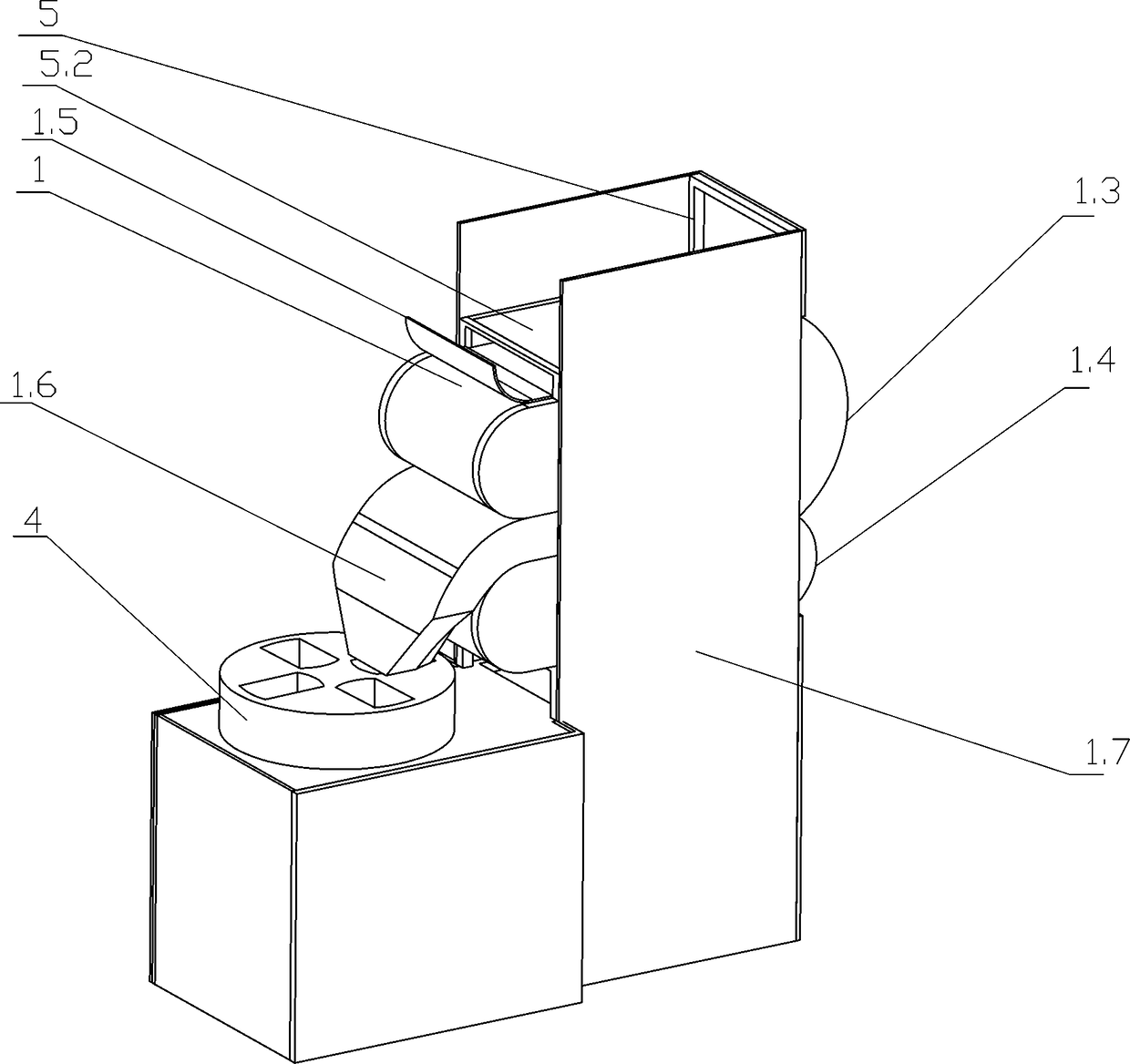

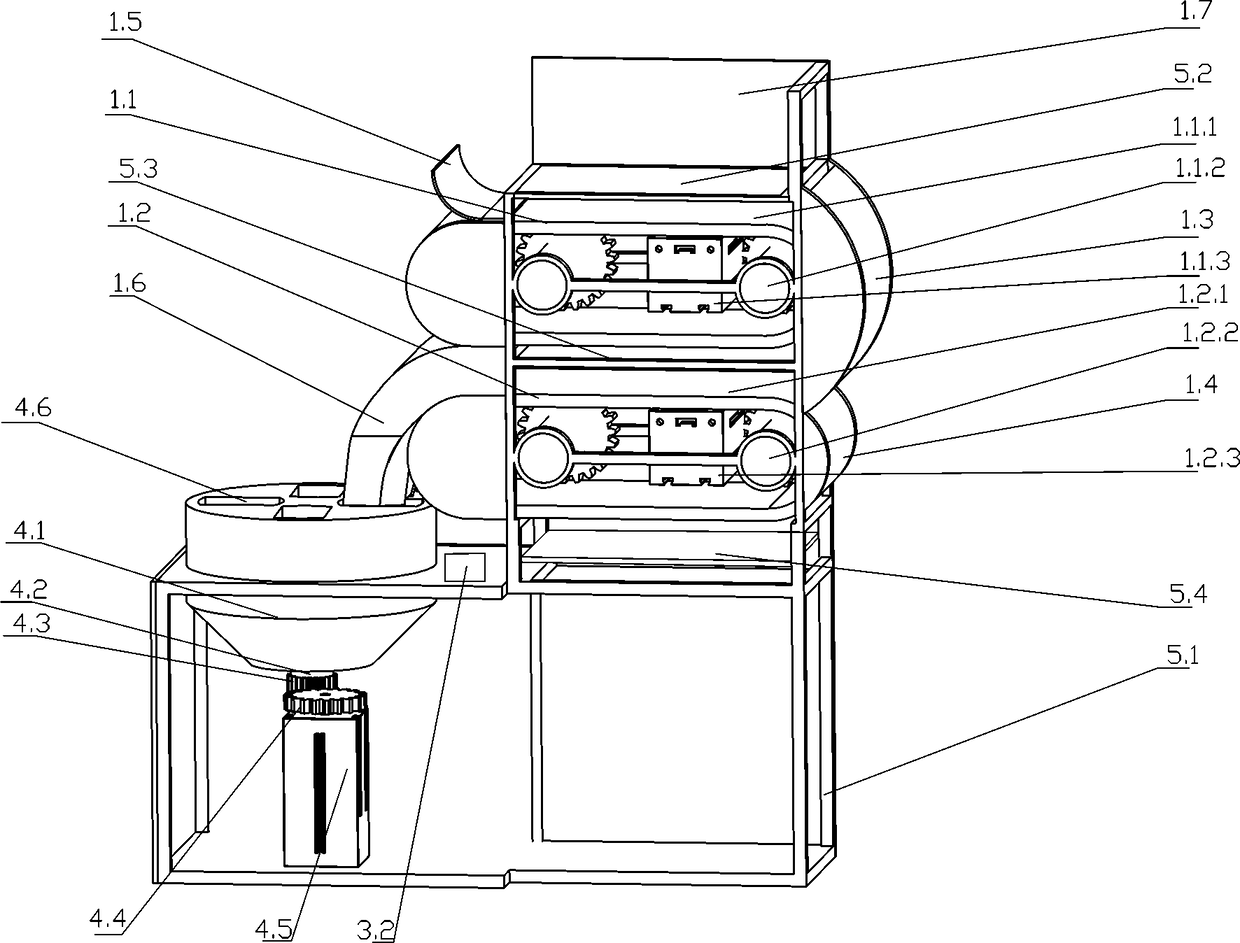

Automatic reed leaf sorting unit

The invention discloses an automatic reed leaf sorting unit which comprises the following parts including a conveying mechanism used for conveying reed leaves and overturning the reed leaves, a visualmodule used for shooting and capturing images on the front and back faces of the reed leaves, a control module used for receiving image information collected by the visual module and controlling a driving device of the conveying mechanism and a storing mechanism, and the storing mechanism used for storing the reed leaves into different zones according to the different qualities of the reed leaves. By means of the sorting unit, the different reed leaves can be sorted according to the qualities of the reed leaves, manpower and time cost needed by manual reed leaf sorting are reduced, and the damage to the reed leaves is reduced, and the production and machining efficiency of the reed leaves are improved.

Owner:CHINA THREE GORGES UNIV

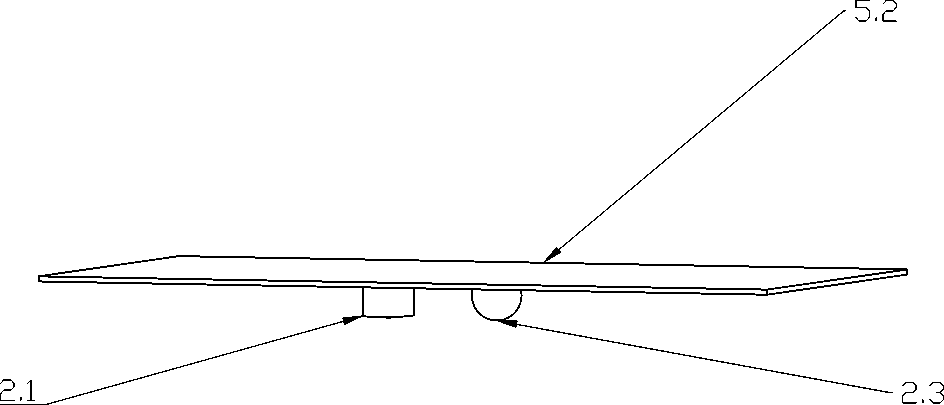

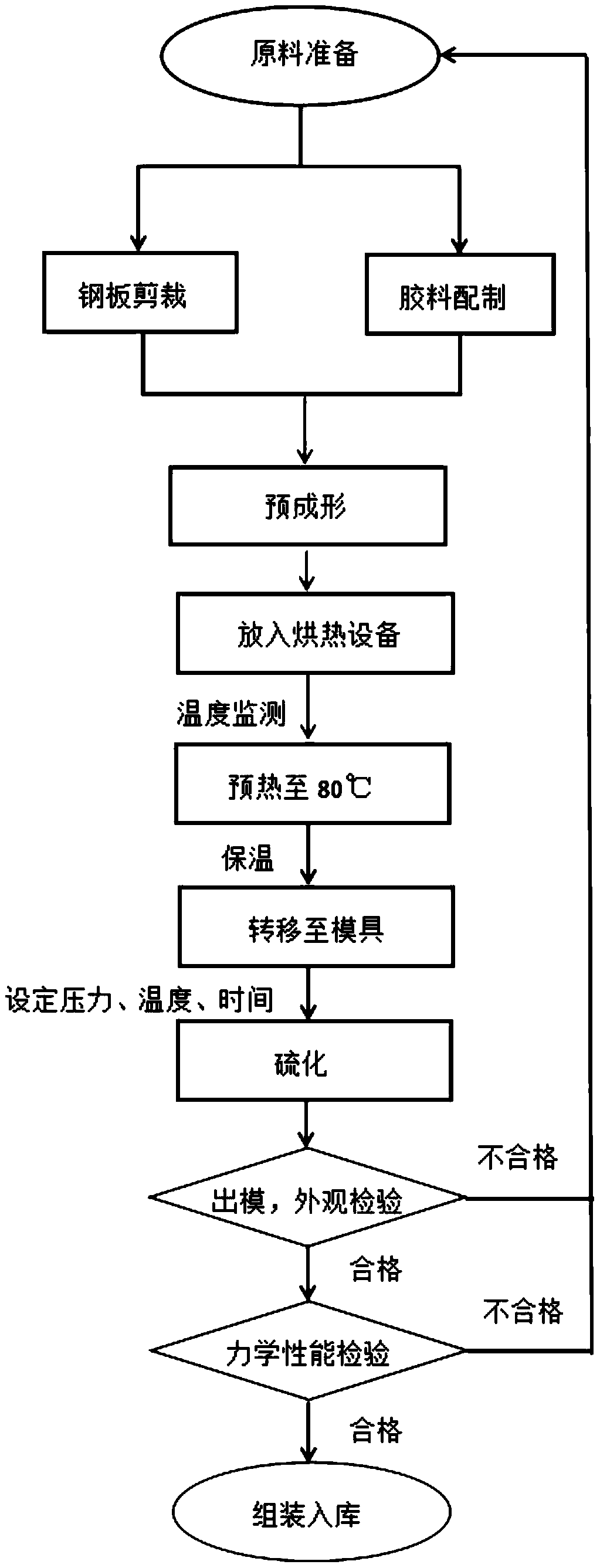

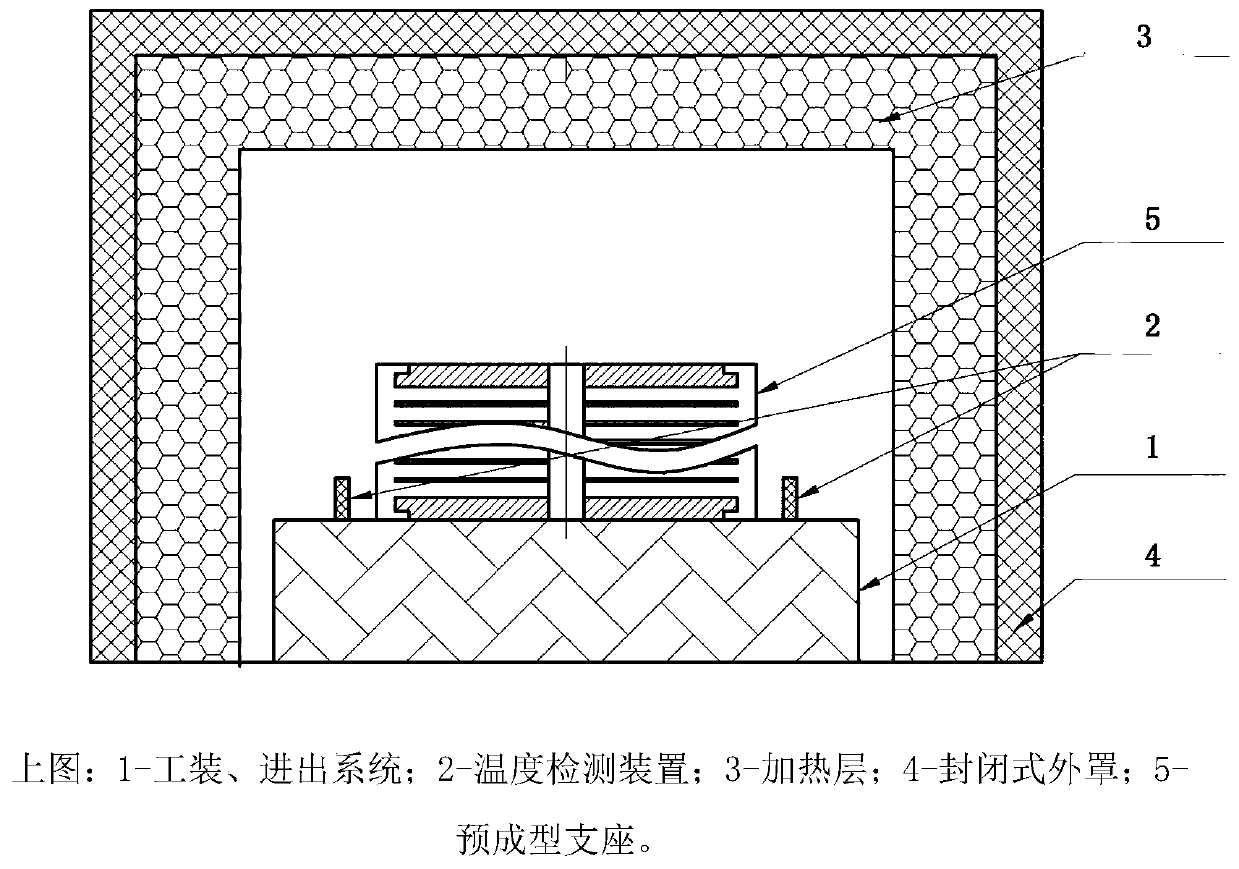

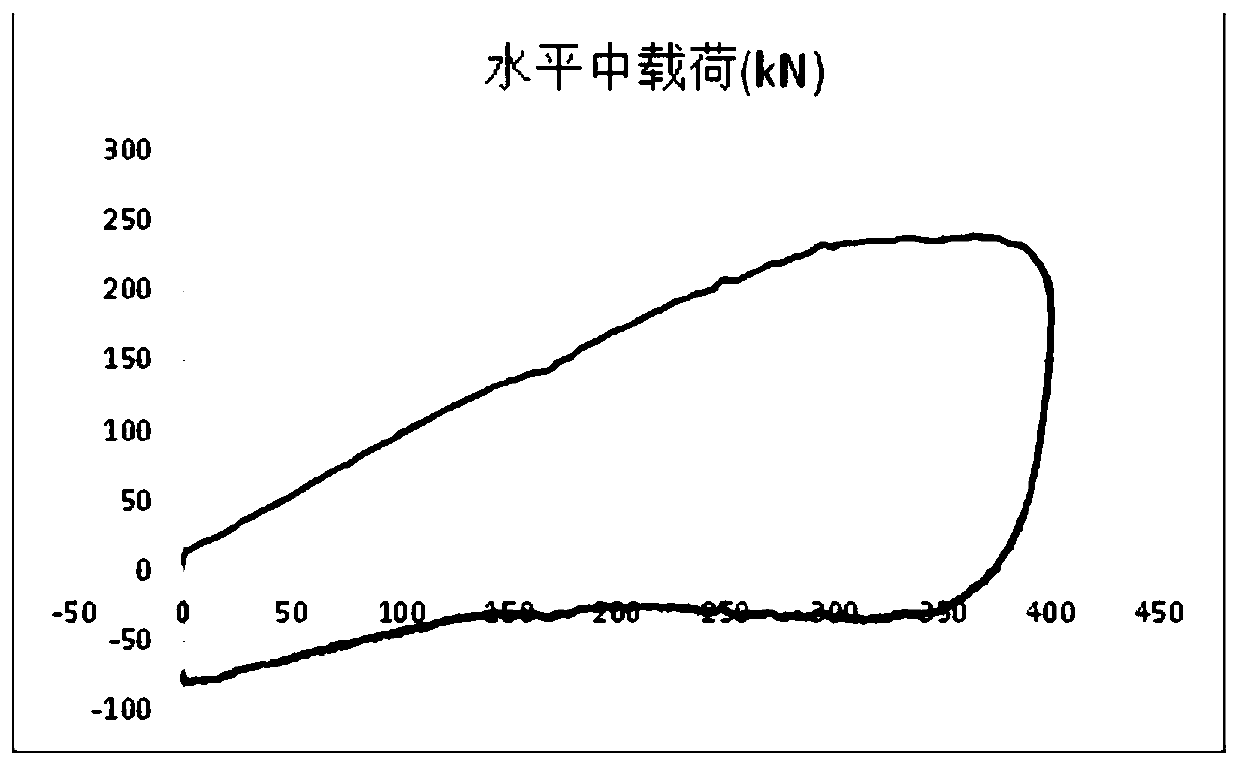

Preparation method of building shock insulation rubber support and building shock insulation rubber support prepared by applying same

ActiveCN111070531AIncrease profitReduce consumptionProtective buildings/sheltersShock proofingVulcanizationMold filling

The invention provides a preparation method of a building shock insulation rubber support and the building shock insulation rubber support product prepared by applying the same. The preparation methodcomprises the following steps that firstly, a rubber compound material is prepared, a steel plate is cut, and laminating and forming are carried out on the rubber compound material and the cut steelplate subjected to shot blasting to obtain a semi-finished product to be subjected to mold filling; the semi-finished product to be subjected to mold filling is placed into a heating device for preheating, and after the temperature rises to 75-85 DEG C at the speed of 5 DEG C / min in the preheating process, the temperature is kept for more than 4 hours; mold filling and vulcanizing are carried outon the preheated semi-finished product; and demolding and trimming are carried out to obtain the building shock insulation rubber support. By adding the preheating step, adjusting the formula and improving the process, the vulcanization uniformity and the vulcanization efficiency of the building shock insulation rubber support are effectively improved.

Owner:SINO RUBBER TECH CO LTD

Process for preparation of large-particle-size zinc sulfate

The invention relates to a process for preparation of large-particle-size zinc sulfate, wherein the process comprises the following steps: (1) placing a concentrated zinc sulfate sample solution withthe Baume degree of 54 Be into a crystallizer, and starting to slowly cool the solution temperature of 50 DEG C to 30-34 DEG C, wherein fine crystals begin to appear; (2) then rapidly heating the solution to 45-48 DEG C until the crystals are completely dissolved, wherein the stirring rate is 70 RPM; and (3) slowly cooling the solution to 39.5 DEG C-40 DEG C, adding 3-4 g of a crystal seed, rapidly cooling the solution to 25-29 DEG C with the cooling rate of 1 DEG C / min, then making the temperature of the solution constant for 6 h-7 h, adjusting the stirring rotating speed to 100 RPM, and allowing the large-particle-size zinc sulfate crystals to appear. The large-particle-size zinc sulfate can be obtained, the crystallization time is shortened and the production efficiency is improved.

Owner:侯马高知新生物科技有限公司

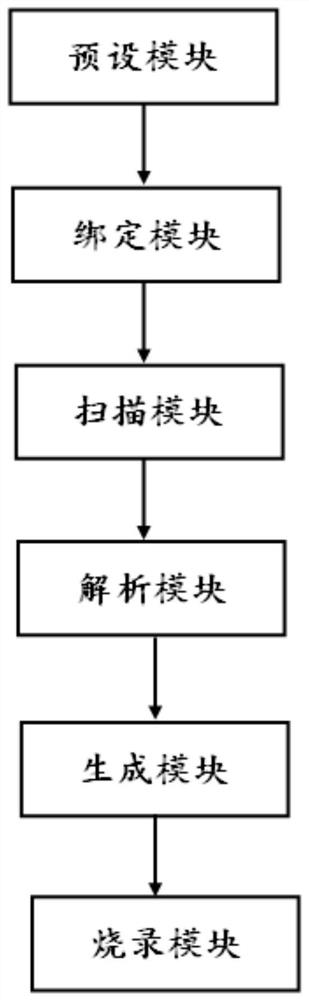

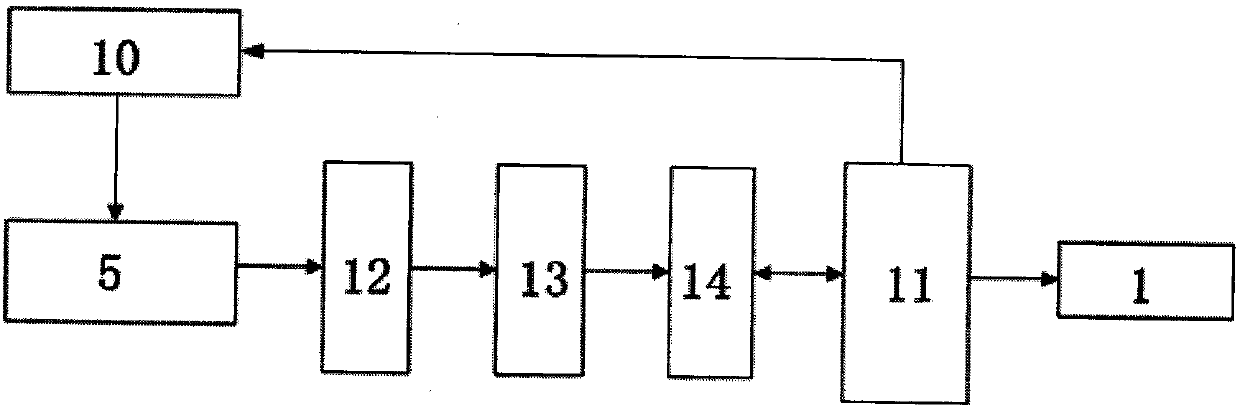

Camera module burning system based on turntable

PendingCN111913724AReduce capacityHigh coding densityTelevision system detailsColor television detailsDatasheetEngineering

The invention relates to the technical field of cameras, and relates to a camera module burning system based on turntable, which comprises a preset module for presetting an identification code for recording identification information of a camera module on the camera module; a binding module used for binding the corresponding data of the camera module with the identification code; a scanning moduleused for scanning the identification code on the camera module; an analysis module used for analyzing the identification code information and obtaining identity data in the identification code information; a generation module used for generating a target feature data table according to the configuration information of an intelligent terminal; and a burning module used for matching the identity data with the target feature data table and burning the identity data and the data bound with the identification code into a memory of the intelligent terminal in batches. According to the invention, the problems of easy crash and low efficiency during identity data burning in the prior art are solved.

Owner:SHINE OPTICS TECH CO LTD

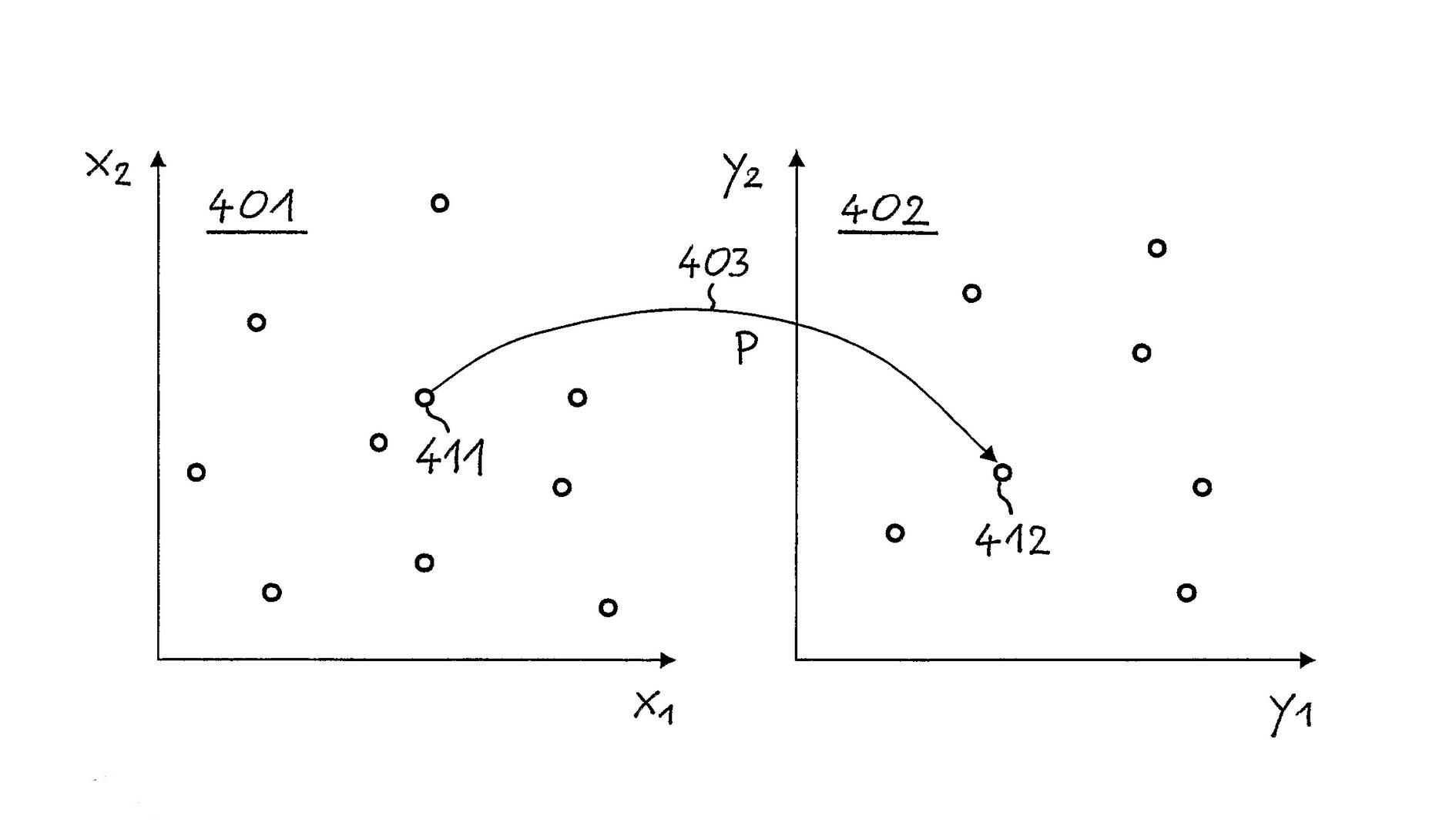

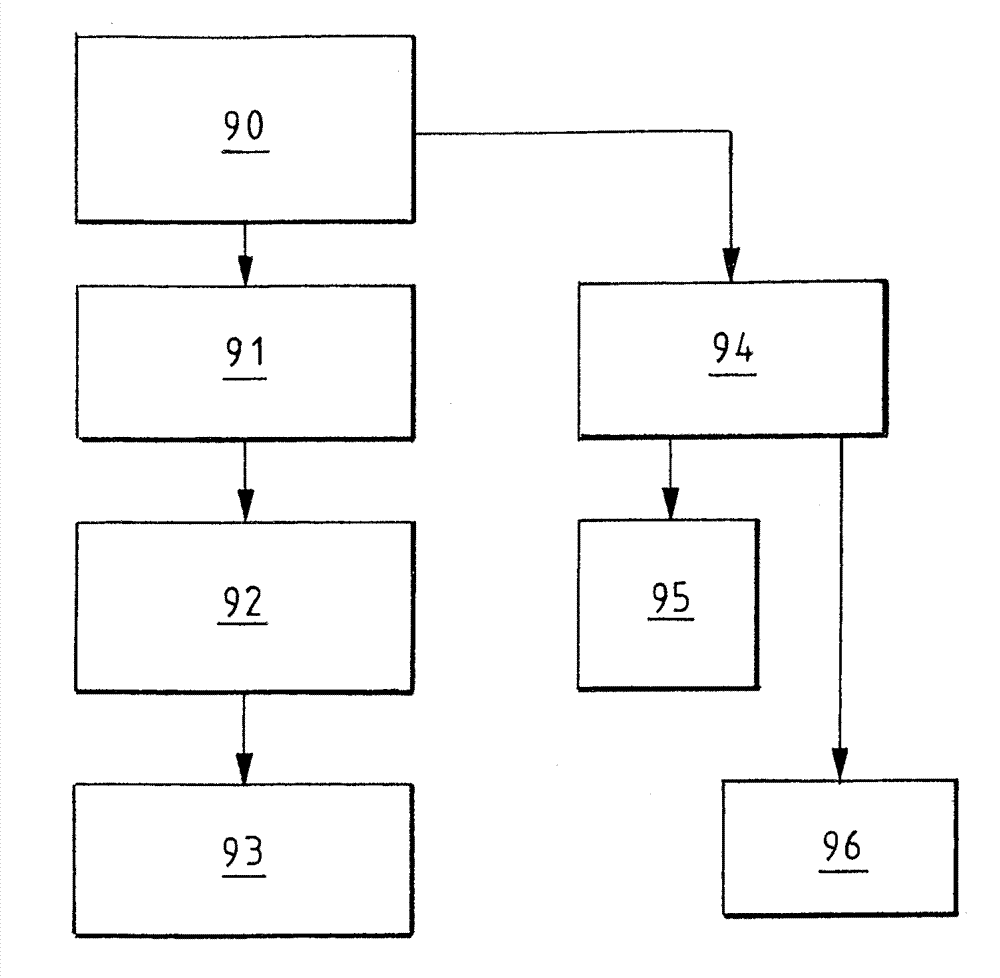

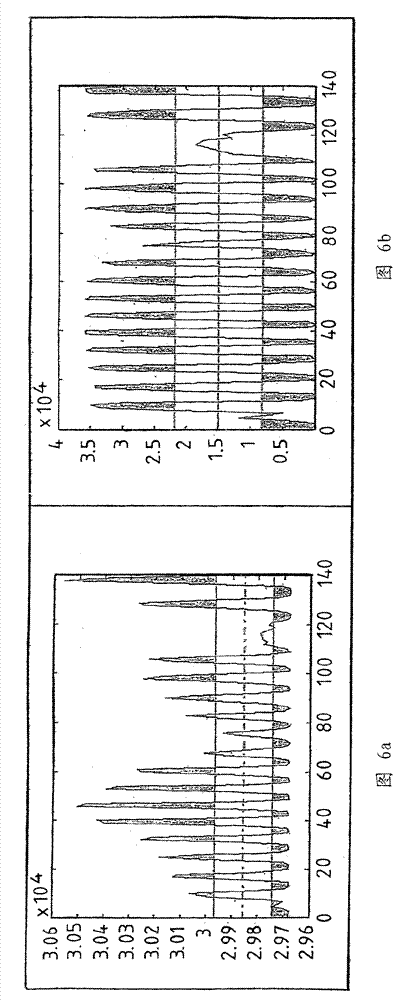

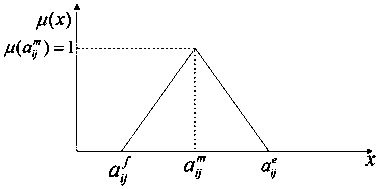

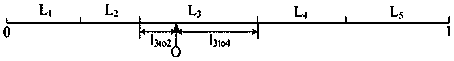

No-reference image quality assessment method based on high-quality natural image statistical model

ActiveCN103996192BDetermine the qualityOvercoming the problem of weak generalization abilityImage analysisCharacter and pattern recognitionImaging qualityVisual saliency

The invention discloses a non-reference image quality evaluation method based on a high-quality natural image statistical magnitude model. The method includes the steps that firstly, parameters corresponding to a multi-element Gaussian model are learnt from first image blocks of a high-quality natural image; a test image is divided into second image blocks which are the same in size, and a multi-element Gaussian model of each second image block is extracted; the distances between the multi-element Gaussian models are determined through a bhattacharyya distance, and then the quality of distorted image quality blocks is determined; the quality of all the distorted image blocks are linearly weighted through visual saliency, finally the objective evaluation grade of the test image is acquired, the problem that an existing evaluation method is low in generalization ability can be well solved, and the requirements of actual application for the non-reference image quality evaluation method are met.

Owner:TONGJI UNIV

Detection method of FPC (flexible printed circuit) high-Tg glued substrate

InactiveCN105259068AHeat resistantElectrical performance degradationWeather/light/corrosion resistanceStrength propertiesImpact testAging test

The invention relates to the field of substrate detection, in particular to a detection method of an FPC (flexible printed circuit) high-Tg glued substrate applied to vehicle-mounted LED (light emitting diode) lamp products. The method mainly comprises the following steps of (1) performing aging test on the FPC high-Tg glued substrate; (2) respectively performing a cold and hot impact test, a constant-temperature and constant-humidity test and a high-temperature storage test on the FPC high-Tg glued substrate. The method provided by the invention can be used for detecting whether the FPC high-Tg glued substrate has the heat-resistant performance and the environment-resistant performance or not and whether the dimension stability and the mechanical intensity can be maintained at high temperature or not, so that whether the electric performance of the substrate is reduced or not and whether the service life of a product can be influenced or not are determined, and the quality of the substrate is further determined.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

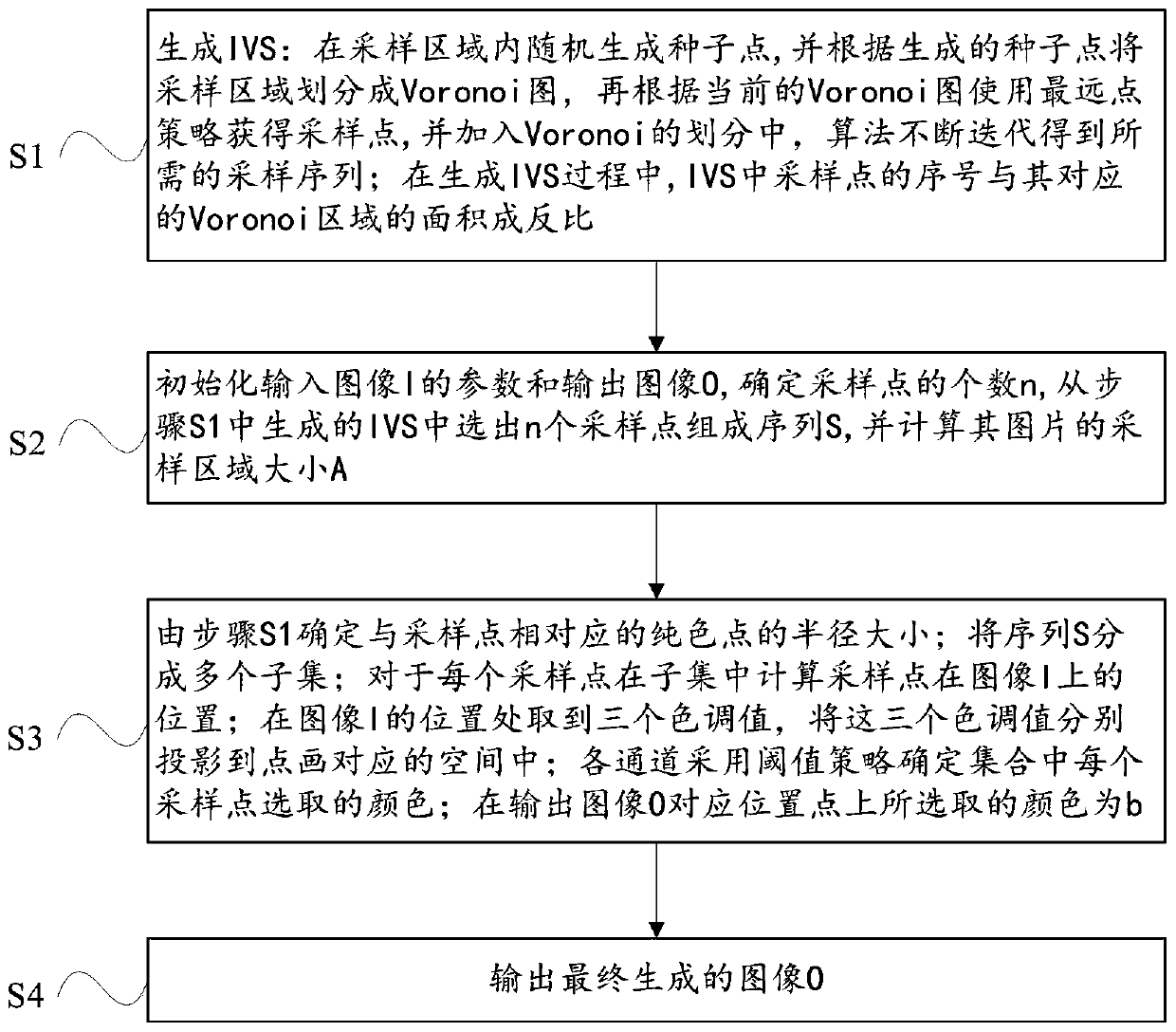

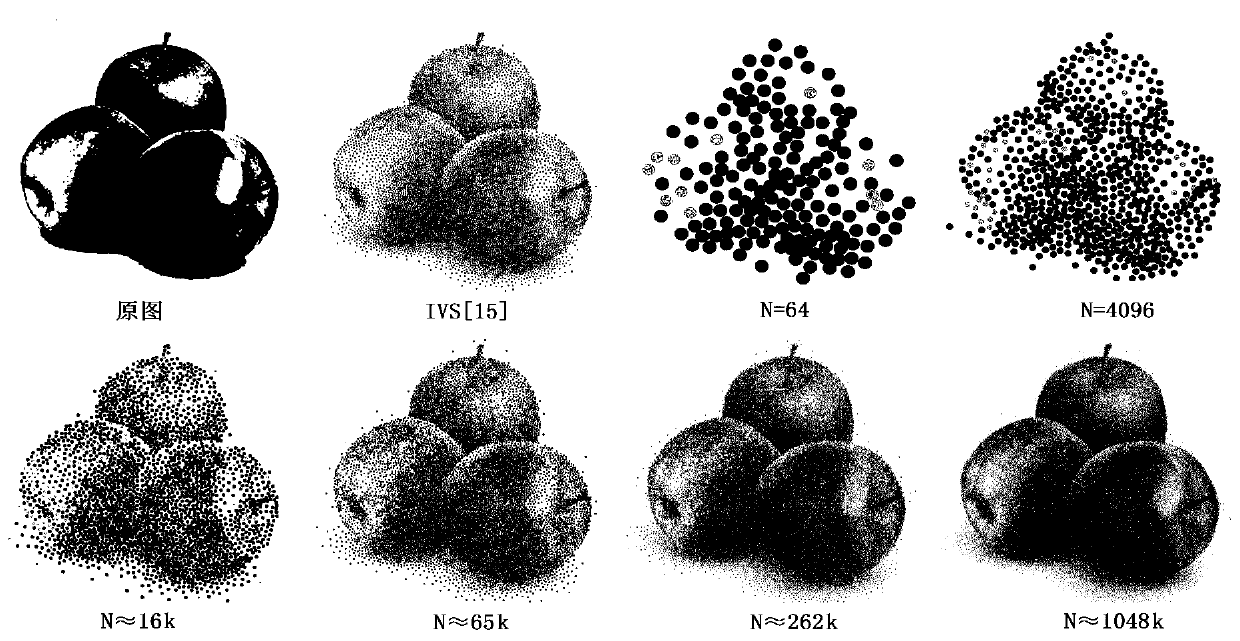

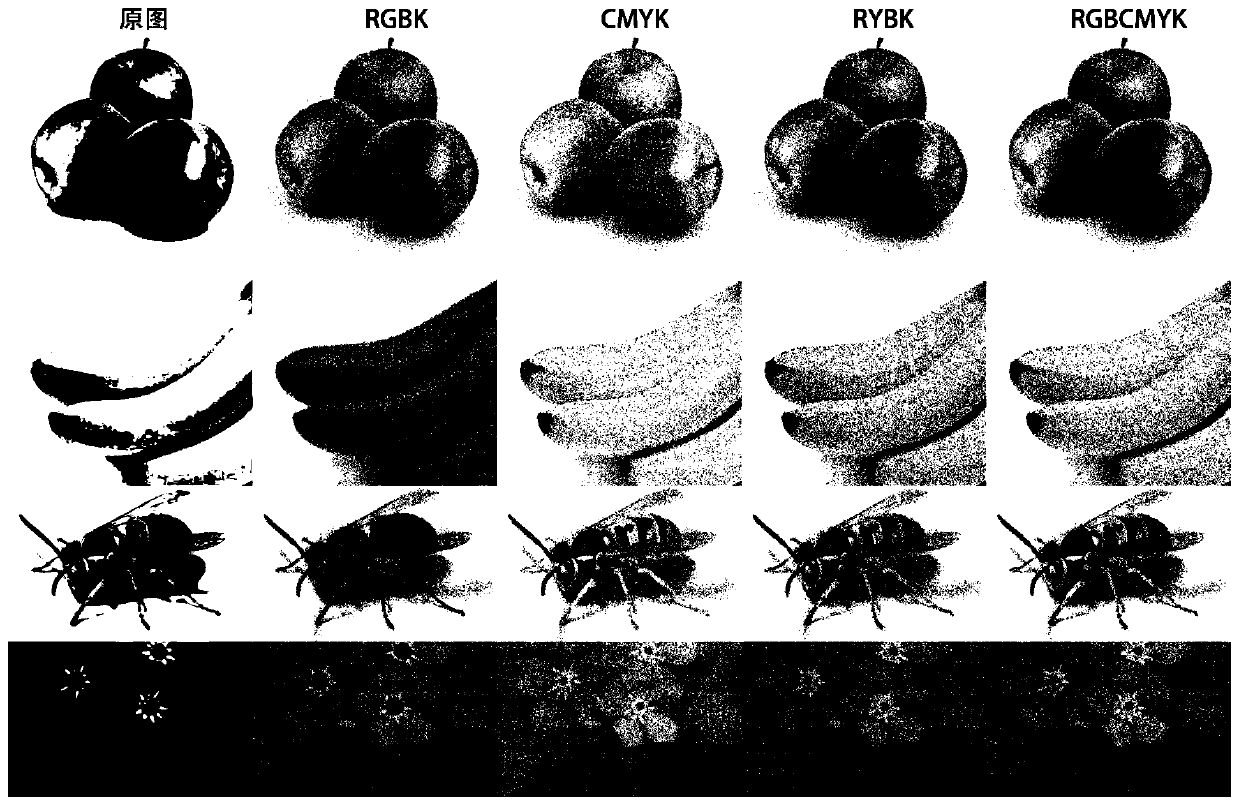

A method for instantly generating a color dot picture based on an incremental Voronoi sequence

PendingCN109949384AGenerate efficientlyGood blue noise characteristicsImage analysis2D-image generationPattern recognitionSample sequence

The method for instantly generating the color point picture based on the increment Voronoi sequence comprises the following steps of: randomly generating seed points in the sampling area, dividing thesampling area into a Voronoi graph according to the generated seed points, obtaining sampling points by using a farthest point strategy according to the current Voronoi graph, adding the sampling points into Voronoi division, and performing algorithm continuous iteration to obtain a required sampling sequence; Initializing parameters of an input image I and an output image O, determining the number n of sampling points, selecting n sampling points from the generated IVS to form a sequence S, and calculating the size A of a sampling area of a picture; Determining the radius of a pure color point corresponding to the sampling point; Dividing the sampling sequence into a plurality of subsets; For each sampling point in the subset, calculating the position of the sampling point on the image I; allowing an Each channel to adopt a threshold strategy to determine the color selected by each sampling point in the set; And outputting the finally generated image O. The color dot picture generation method is high in efficiency, and the color dot picture can be generated approximately in real time.

Owner:YUNNAN UNIV

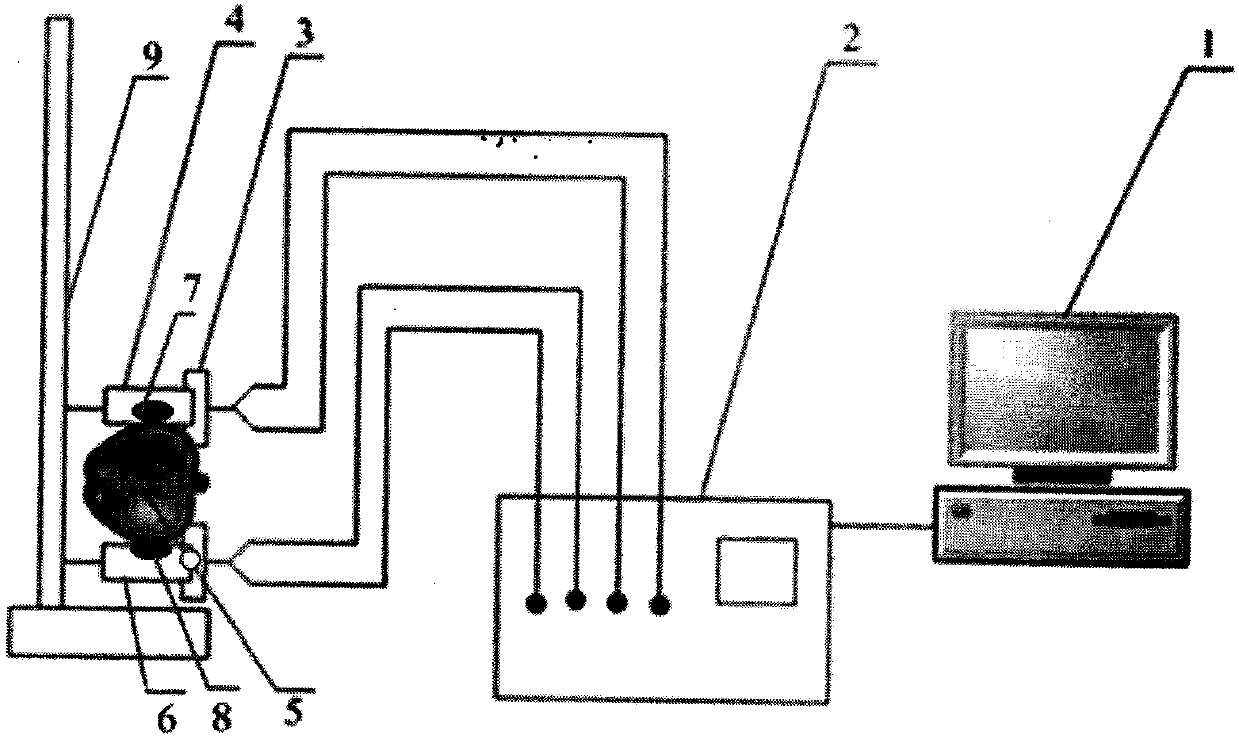

Tester for interior quality of apples

InactiveCN107843623AAutomatically measure the electrical characteristic parametersDetermine the qualityMaterial capacitanceElectricityMeasurement device

An apple internal quality measuring instrument is composed of a measuring frame, an LCR data acquisition instrument and a computer, which can automatically measure the electrical characteristic parameters of apples at multiple frequencies, and determine the internal quality or grade the apples according to these electrical characteristic parameters. The measuring frame is equipped with upper pressure sensor, lower pressure sensor, height measuring device and control circuit, which can control the automatic lowering, stopping and lifting of the upper electrode plate, so as to realize the automatic determination of apple quality. The height measuring device can measure the height or diameter of the apple.

Owner:NORTHWEST A & F UNIV

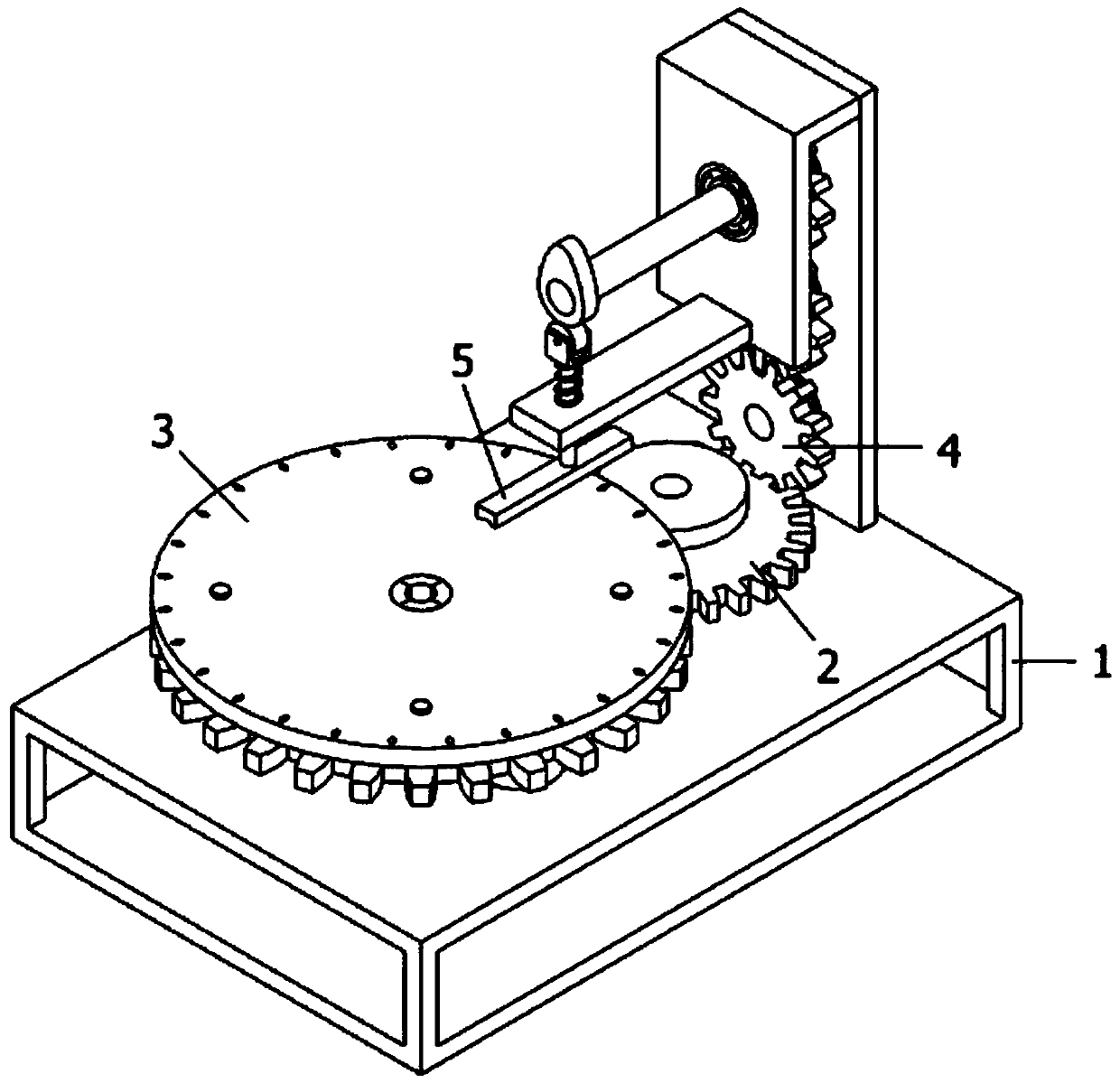

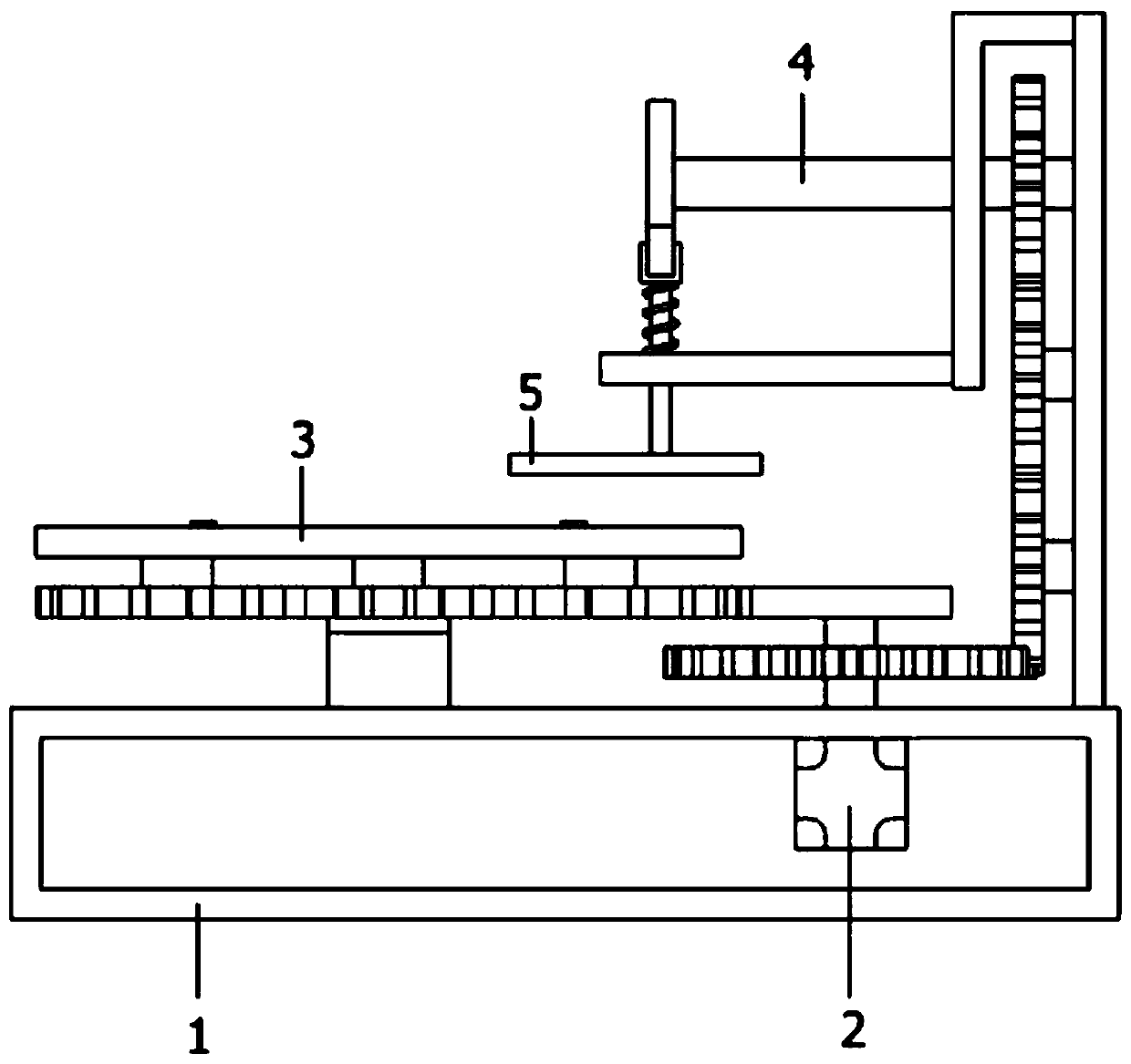

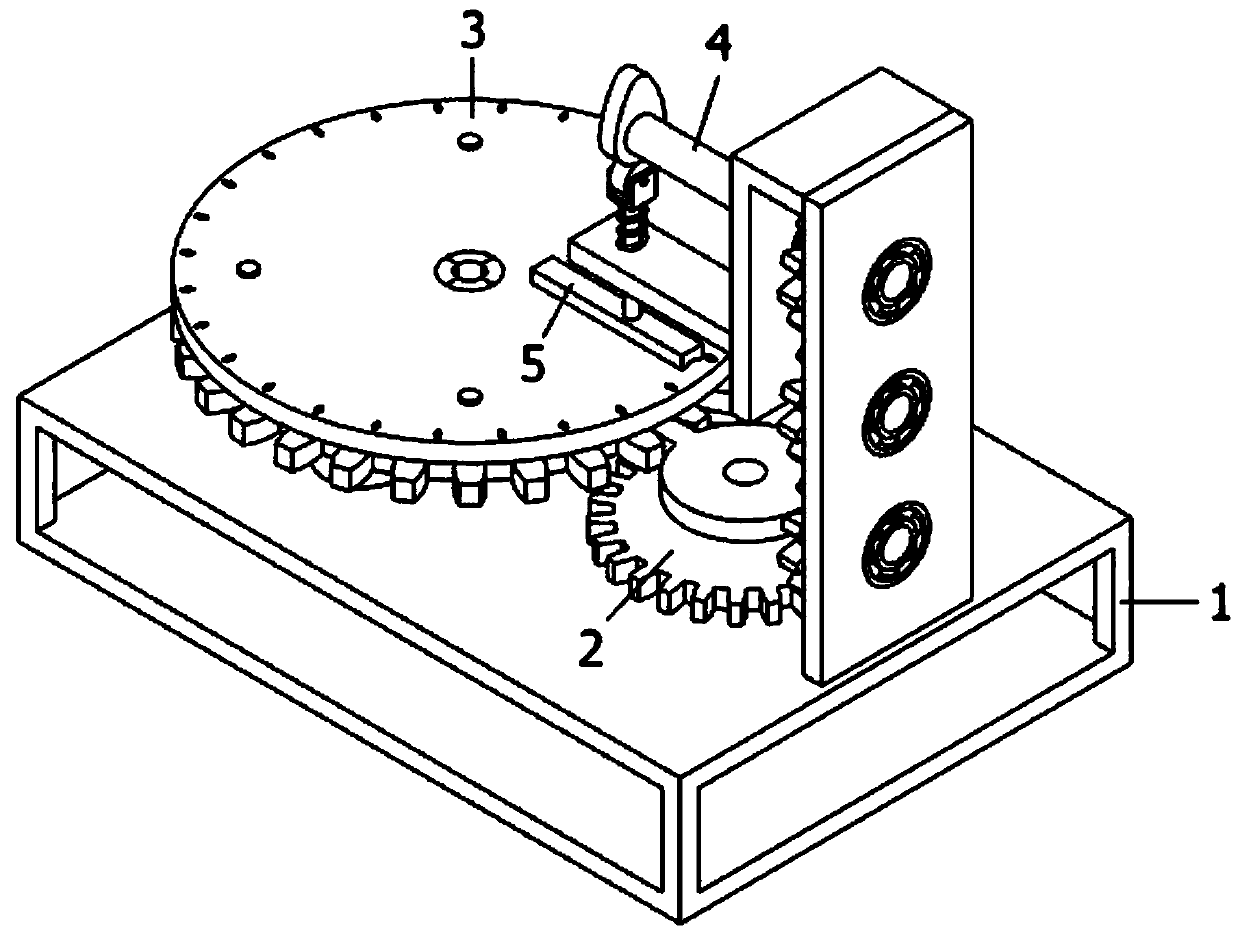

Automatic umbrella rib and oiled paper bonding and embossing mechanism for umbrella preparing

InactiveCN111421952AReduce workloadAutomate operationRotary pressesEngineeringStructural engineering

The invention provides an automatic umbrella rib and oiled paper bonding and embossing mechanism for umbrella preparing, and relates to the technical field of oiled paper umbrella preparing. The problems that in the existing manual oiled paper umbrella preparing process, due to excessive umbrella ribs, the operation that preparing personnel conducts embossing along each umbrella rib is complex, and time is wasted are solved. The automatic umbrella rib and oiled paper bonding and embossing mechanism for umbrella preparing comprises a bearing mechanism, and a drive mechanism is arranged at the right end of the bearing mechanism. Oiled paper and umbrella ribs are bonded and embossed, intermittent uniform feeding of the umbrella ribs is achieved through meshing transmission fit of the drive mechanism and an intermittent transmission mechanism, meanwhile, the drive mechanism is in meshing transmission fit with the transmission mechanism, a cam drives the bonding and embossing mechanism to reciprocate up and down, and the synchronous bonding and embossing operation is achieved. Through umbrella rib intermittent uniform feeding and bonding and embossing operation synchronous to umbrella rib intermittent uniform feeding, the umbrella rib and oiled paper bonding and embossing automatic operation can be achieved, and the work burden of oiled paper umbrella preparing personnel is greatlyrelieved.

Owner:孟凡明

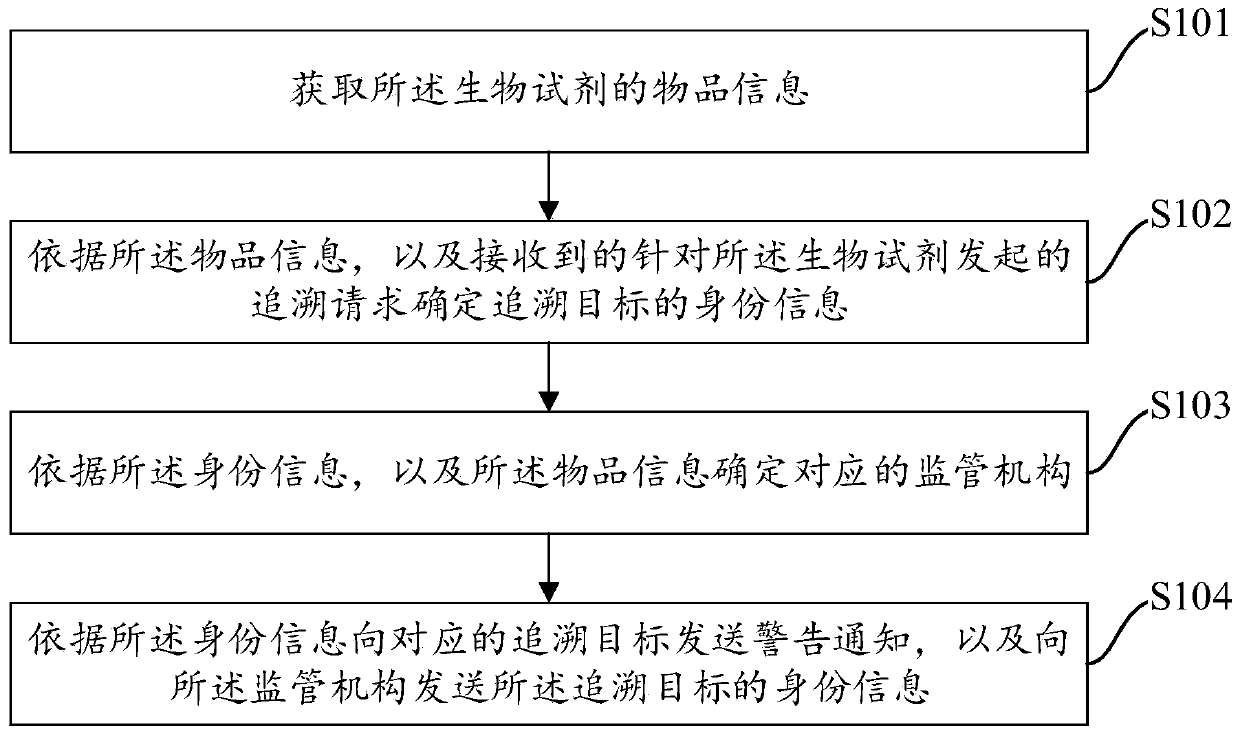

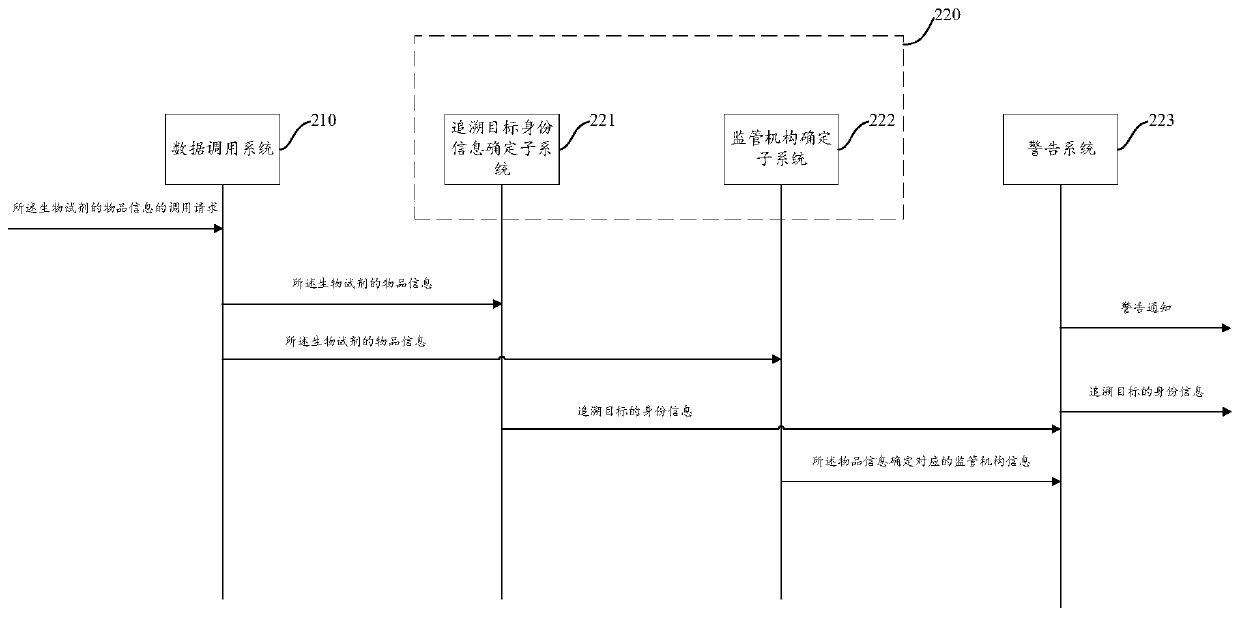

Management method, system, equipment for entry and exit biological reagents of border port, and medium

The invention provides a management method, system and equipment for an entry and exit biological reagent of a border port and a medium, the system is applied to tracing of the entry and exit biological reagent, and under the condition that the biological reagent is traced, the method comprises the following steps: obtaining article information of the biological reagent; determining identity information of a tracing target according to the article information and a received tracing request initiated for the biological reagent; determining a corresponding supervision mechanism according to theidentity information and the article information; and sending a warning notification to a corresponding tracing target according to the identity information, and sending the identity information of the tracing target to the supervision institution. The method can well determine the overseas calendar or source of the scientific research biological reagent and the safety and quality of the scientific research biological reagent, and fully meets the requirements of customers.

Owner:SHENZHEN ACAD OF INSPECTION & QUARANTINE

Production machine and method for operating the production machine for rod-shaped articles in the tobacco processing industry

ActiveCN103315391ADetermine the qualityCigarette manufactureTobacco smoke filtersData acquisitionContinuous operation

The present invention relates to a production machine and a method for operating the production machine for rod-shaped articles in the tobacco processing industry. The method involves coining a first wrapping material strip (33), acquiring the image data of a rod made of a strip material wrapped by the coined first wrapping material or a rod-shaped article cut off via the dimension of the strip, detecting the quality and / or position of the coined structure according to the image data, and controlling or adjusting the production machine to run according to the quality and / or position. The production machine possesses a first wrapping material strip processing device, a strip forming device, an image data acquisition device arranged when the strip material is conveyed in the longitudinal axial conveying direction (13') and wound by the first wrapping material strip, and used to record the image data of the strip wound by the first wrapping material strip, an image data processing device used to detect the quality and / or position of the coined structure applied to the first wrapping material strip, and a controlling and / or adjusting device used for controlling and / or adjusting parameters in the continuous operation of the production machine according to the detected quality and / or position of the coined structure.

Owner:KOERBER TECH GMBH

Preparation method of large-particle zinc sulfate

The invention provides a preparation method of large-particle zinc sulfate, which comprises the following steps: putting zinc hypoxide and zinc oxide in the waste residue generated by the preparationof the zinc into a raw material pool filled with dilute sulfuric acid to generate a zinc sulfate solution, and then introducing the zinc sulfate solution into a reaction pool to remove iron, cobalt and copper impurities in the zinc sulfate solution through a filter; introducing the impurity-removed zinc sulfate solution into a storage tank for precipitation treatment, and then obtaining the zinc sulfate concentrate solution through preheating treatment and evaporation concentration; starting to cooling slowly to 32-36 DEG C when the temperature of the solution is 48 DEG C, fine crystals beginning to appear in a crystallizer; then rapidly raising the temperature of the solution to the point where the crystal is completely dissolved; slowly cooling the solution to 36-38 DEG C, adding 9-12g / Lof crystal, rapidly cooling the solution to 25-29 DEG C, and keeping the solution at a constant temperature for 7.5-9hours to obtain large-size zinc sulfate crystals. The method of adding seed crystal can obtain large-size zinc sulfate crystals and can shorten the crystallization time, reduce the energy consumption in the cooling process and improve the production efficiency.

Owner:湖州惠鹏达节能环保科技有限公司

A kind of rock mass quality evaluation method

ActiveCN105046080BDetermine rock mass qualityDetermine the qualitySpecial data processing applicationsDeformation modulusRock sample

The invention discloses a rock mass quality evaluation method. In order to understand the rock mass quality of an open-pit mine, a certain range is determined by sampling from four characteristic positions of surrounding rock, ore body roof, ore body and ore body floor in a certain vertical range of the open-pit mine. The quality of the open-pit mine, rock compressive strength, cohesion, internal friction angle and rock mass deformation modulus are used as the evaluation index system, and five levels of single-factor index rock mass classification are formed to determine the open-pit within a certain vertical range. The rock mass samples at the four characteristic positions of the mine are subject to the five levels of rock mass classification, and softened to determine the rock mass quality of the sample, thereby determining the rock mass quality of the entire slope. The invention can be used to determine the quality of rock samples at four characteristic positions of an open-pit mine within a certain range, thereby determining the quality of the entire slope rock mass.

Owner:LIAONING TECHNICAL UNIVERSITY

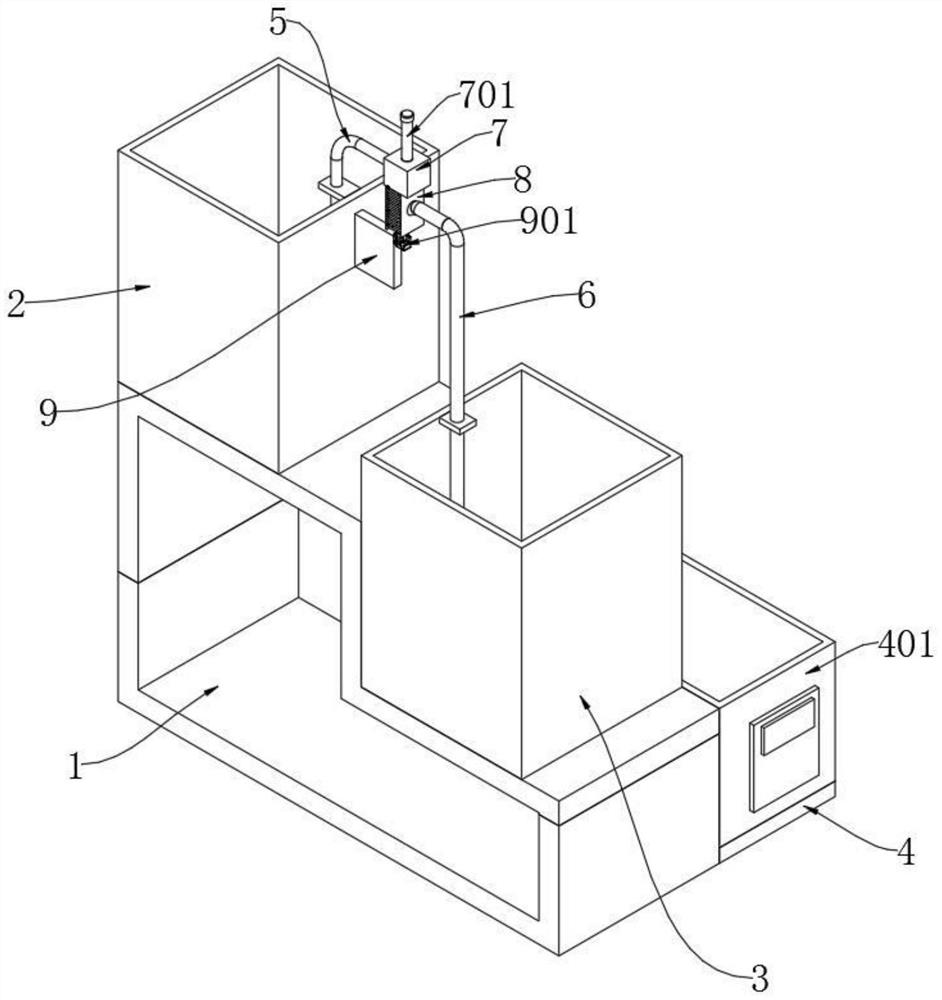

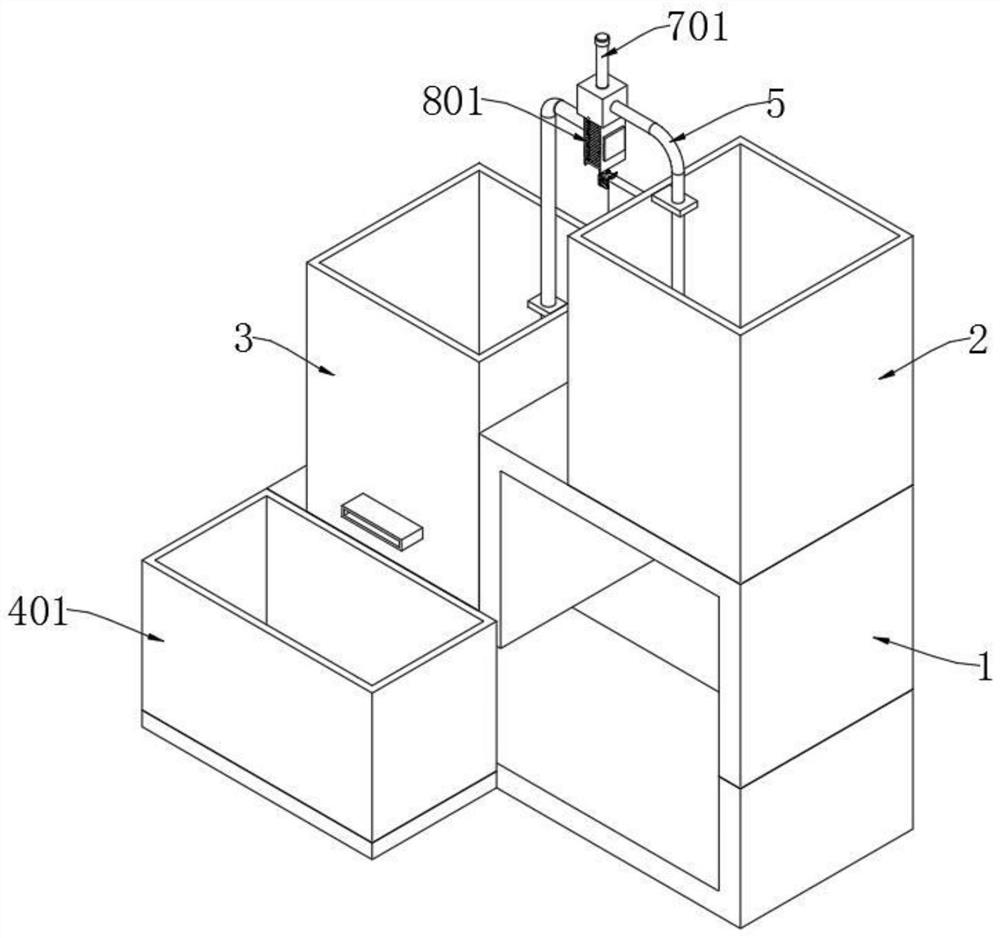

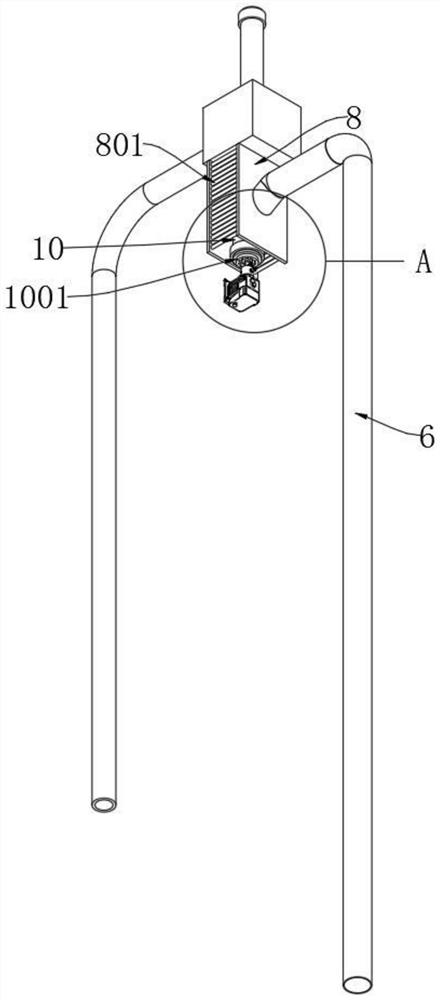

Siphon type petroleum single well metering device for oilfield exploitation

InactiveCN114704241ADetermine the qualityEasy to fillSurveyVolume/mass flow measurementBuffer tankOil field

The invention provides a siphon type oil single well metering device for oilfield exploitation, and relates to the technical field of metering devices. An upper tank body is fixedly mounted at the top of the left end of the supporting table; a lower tank body is fixedly mounted at the top of the right end of the supporting table; the bottom of the rear end of the supporting table is fixedly in butt joint with a weighing table. An upper siphon is vertically mounted at the right end of the inner cavity of the upper tank body; a lower siphon is vertically mounted at the left end of the inner cavity of the lower tank body; the upper end of the upper siphon is in butt joint with a buffer tank; and the lower end of the buffer tank is fixedly butted with a metering cylinder. The platform scale is arranged in the weighing table and can be used for weighing the weight of discharged petroleum, so that the weight of the discharged petroleum is conveniently compared with the measured volume, on one hand, whether metering is accurate or not can be determined through mutual comparison, on the other hand, whether the petroleum density is consistent with the conventional petroleum density or not can be reversely deduced, and therefore the oil quality is determined, and the problem that measurement is prone to being inaccurate is solved.

Owner:郭亮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com