Automatic umbrella rib and oiled paper bonding and embossing mechanism for umbrella preparing

A technology of embossing mechanism and transmission mechanism, which is applied to printing machines, rotary printing machines, printing, etc., can solve the problems of heavy burden on preparation personnel, affecting the efficiency of oil-paper umbrella preparation, time-consuming, etc., and achieve the effect of reducing work burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

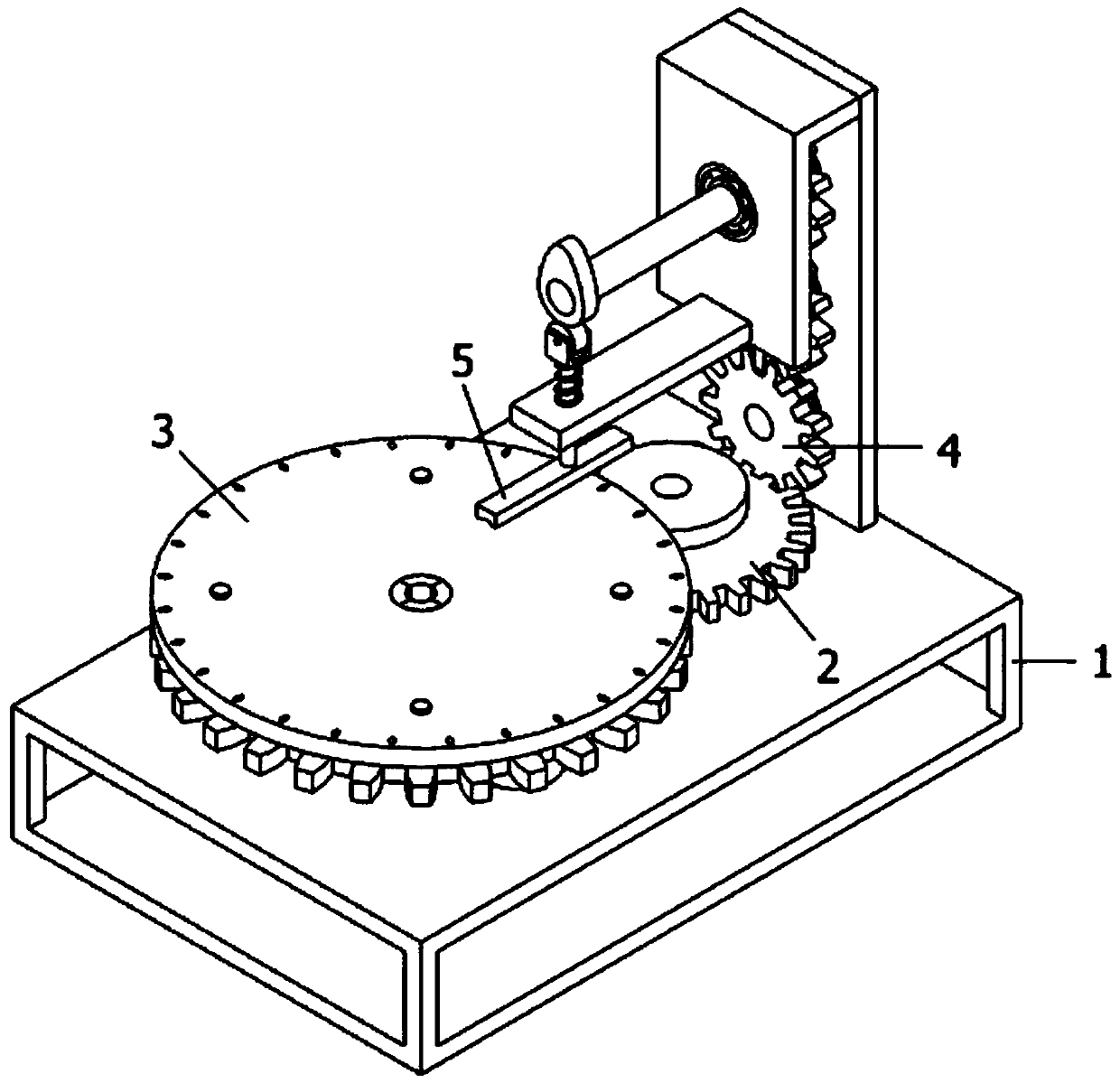

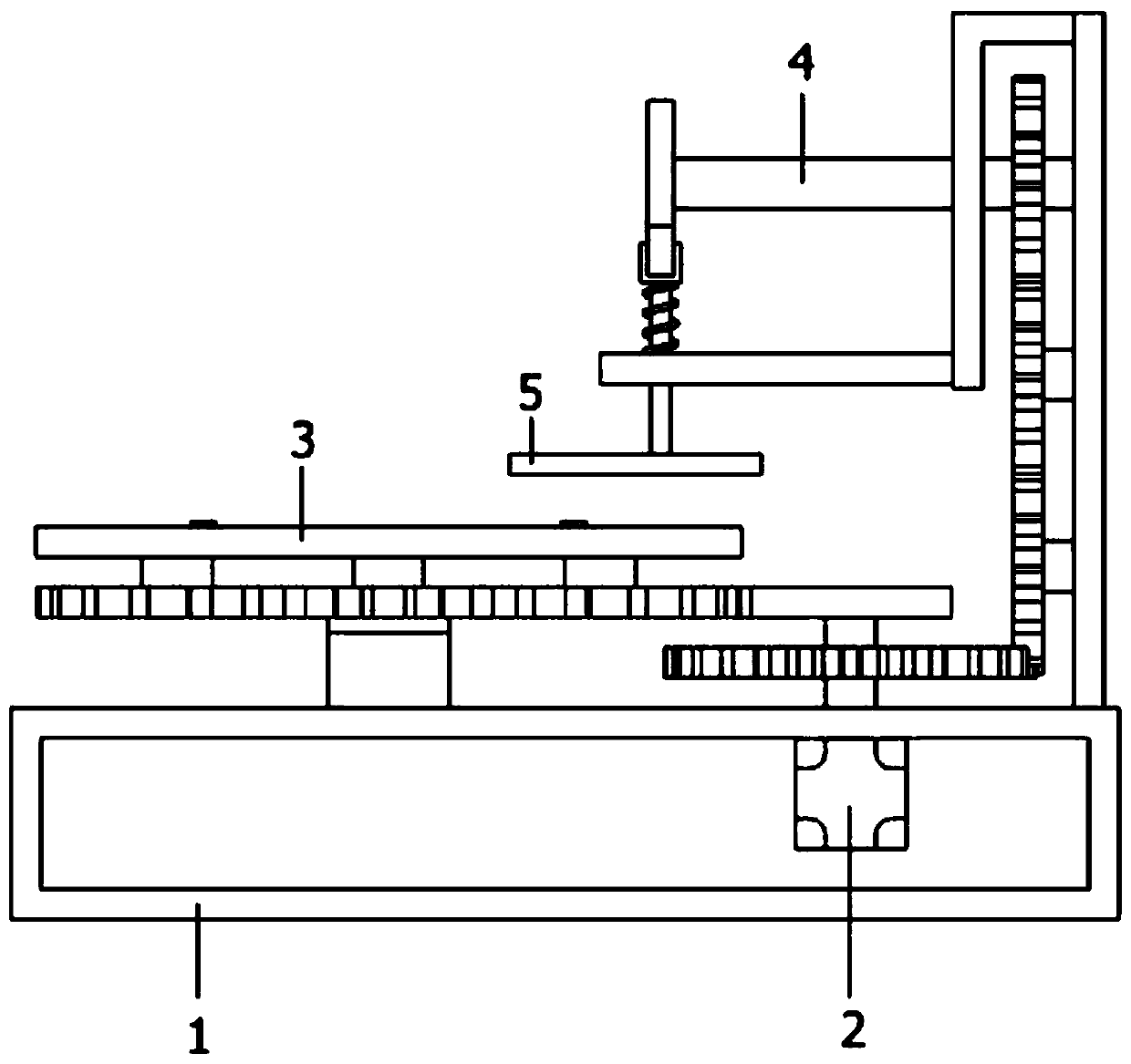

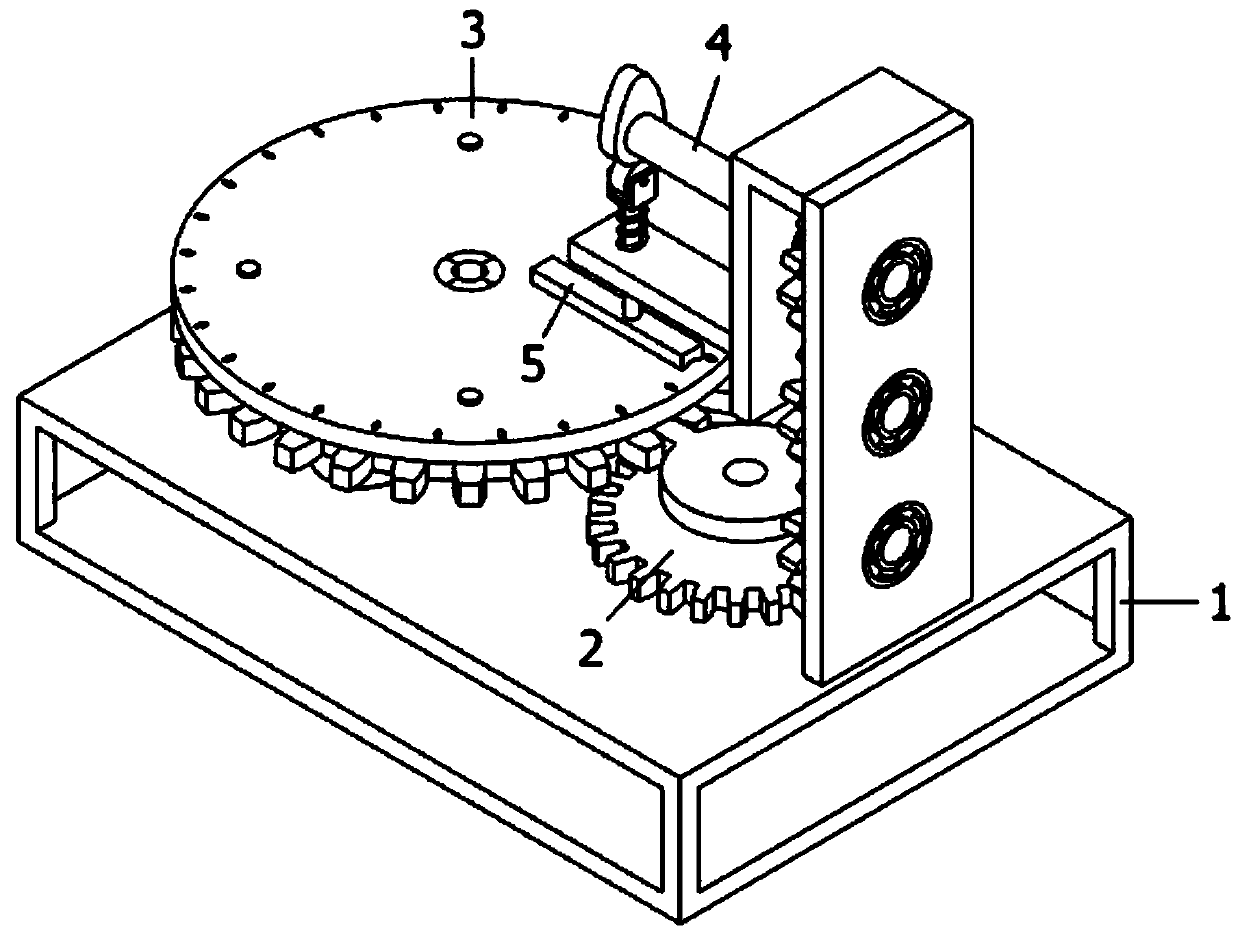

[0037] as attached figure 1 to attach Figure 17 Shown:

[0038] The present invention provides an automatic bonding and embossing mechanism for umbrella ribs and oil paper prepared by umbrellas. Connecting rod 103, bearing A104, rotating shaft A105, columnar protrusion 106, rubber pad 107, rectangular support plate 108, bearing B109, L-shaped plate 1010, bearing C1011, rectangular extension plate 1012, limit sliding hole 1013, rectangular top plate 101 The four corners of the bottom end and the four corners of the top surface of the rectangular bottom plate 102 are fixedly connected by a square connecting rod 103, and a bearing A104 is embedded in the center right of the top surface of the rectangular top plate 101, and the rectangular top plate 101 A rotating shaft A105 is fixedly connected to the left part of the center of the top surface, and a columnar protrusion 106 is fixedly connected to the top surface of the rectangular top plate 101 adjacent to the front side and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com