Patents

Literature

94results about How to "Oxygen barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

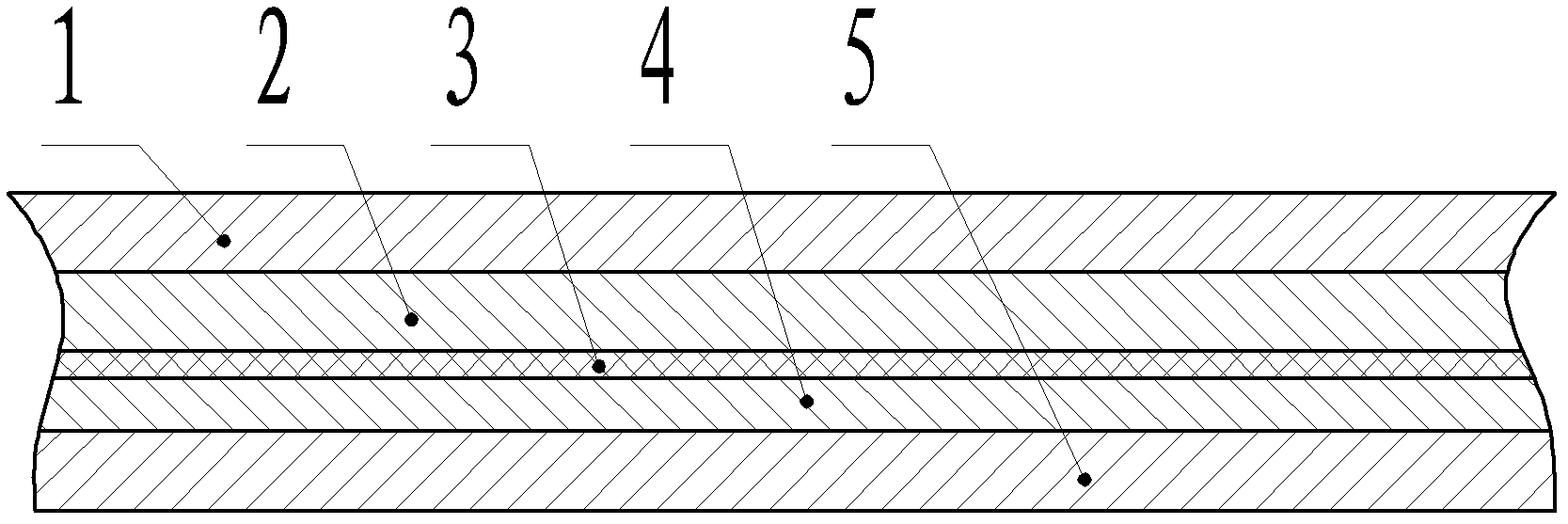

Covering film for medicinal PTP (press through packaging) and preparation method of covering film

InactiveCN105437695AHigh strengthAvoid breakingLamination ancillary operationsSynthetic resin layered productsPolyesterWater vapor

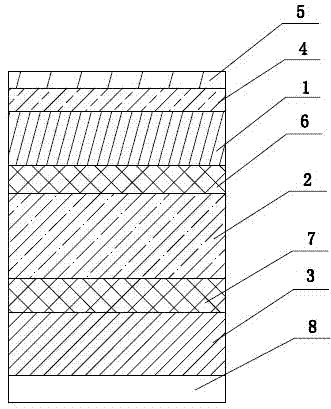

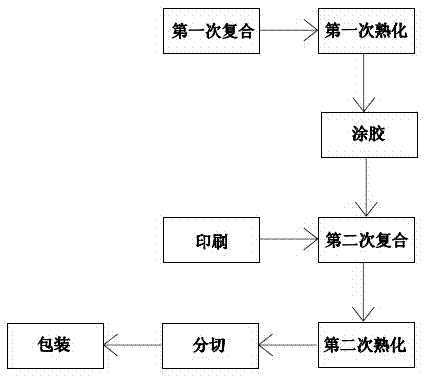

The invention discloses a covering film for medicinal PTP (press through packaging). The covering film is prepared from paper, a polyester film layer and an aluminum foil through composition, wherein an ink layer and a gloss oil layer are arranged on the outer surface of the paper; a first binder layer is arranged between the paper and the polyester film layer; a second binder layer is arranged between the polyester film layer and the aluminum foil; a hot-sealing layer is arranged on the other surface of the aluminum foil. A preparation method of the covering film comprises steps as follows: (1), printing; (2), the first time of composition; (3), the first time of curing; (4), glue applying; (5), the second time of composition; (6) the second time of curing; (7), slitting; (8), packaging. The paper, the polyester film and the aluminum foil are composited, accordingly, the strength of the covering film is improved, the covering film can be prevented from being broken by children, and the safety is improved; with the adoption of the aluminum foil, vapor and oxygen can be further blocked; the preparation method is simple and easy to implement; the pulling strength index of the covering film prepared with the method reaches 55.3-106.9 N / 15 mm, and the hot-sealing strength of the binder layers reaches 13.5-16.2 N / 15 mm.

Owner:ZHEJIANG INST FOR FOOD & DRUG CONTROL

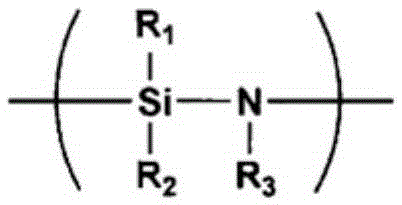

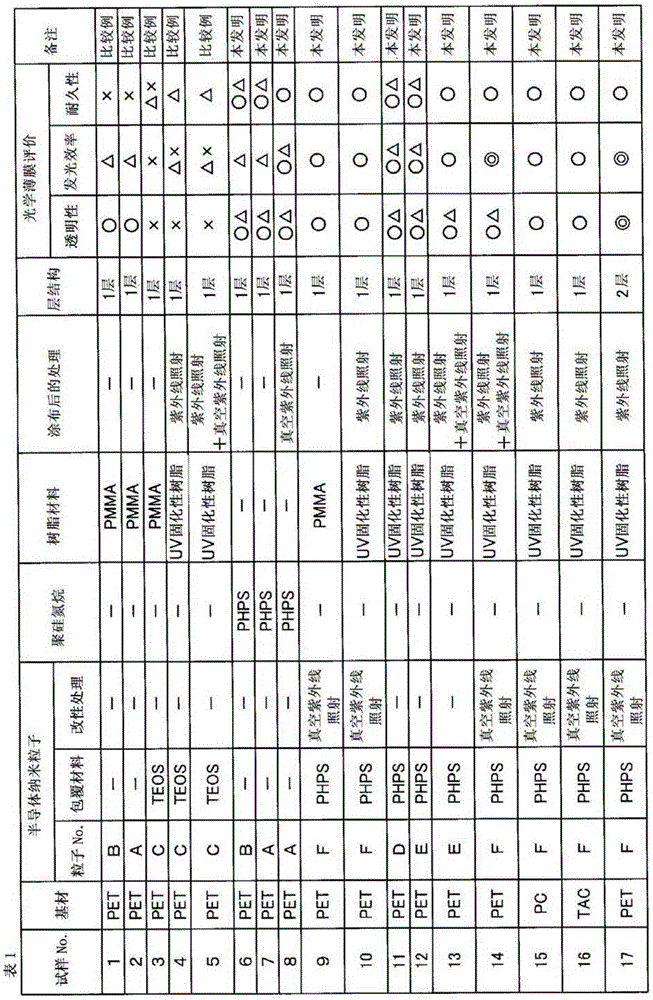

Optical material, optical film, and light-emitting device

InactiveCN105264042APrevent durabilityHigh transparencyLuminescent compositionsOptical elementsPolysilazaneSemiconductor Nanoparticles

Owner:KONICA MINOLTA INC

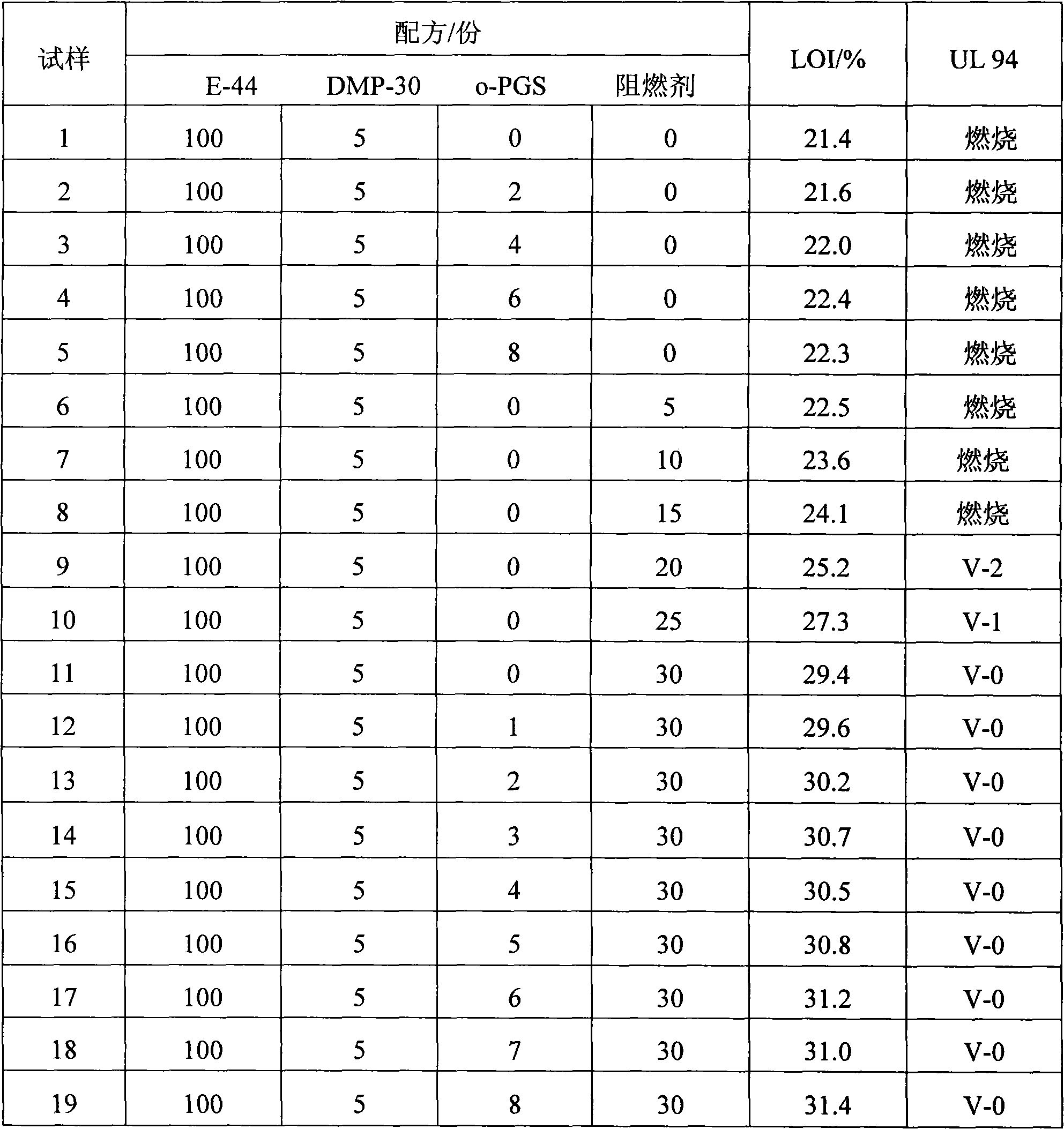

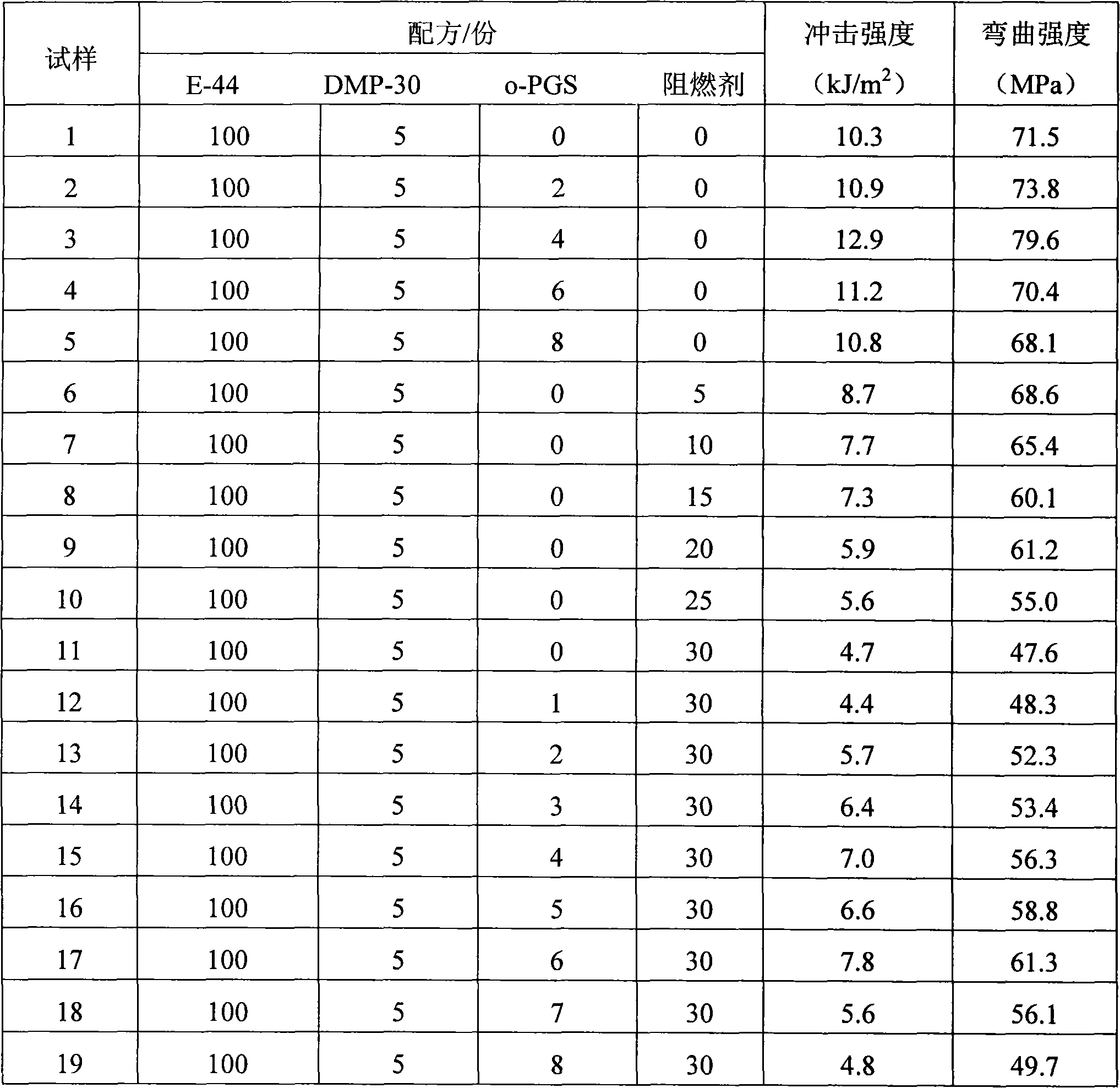

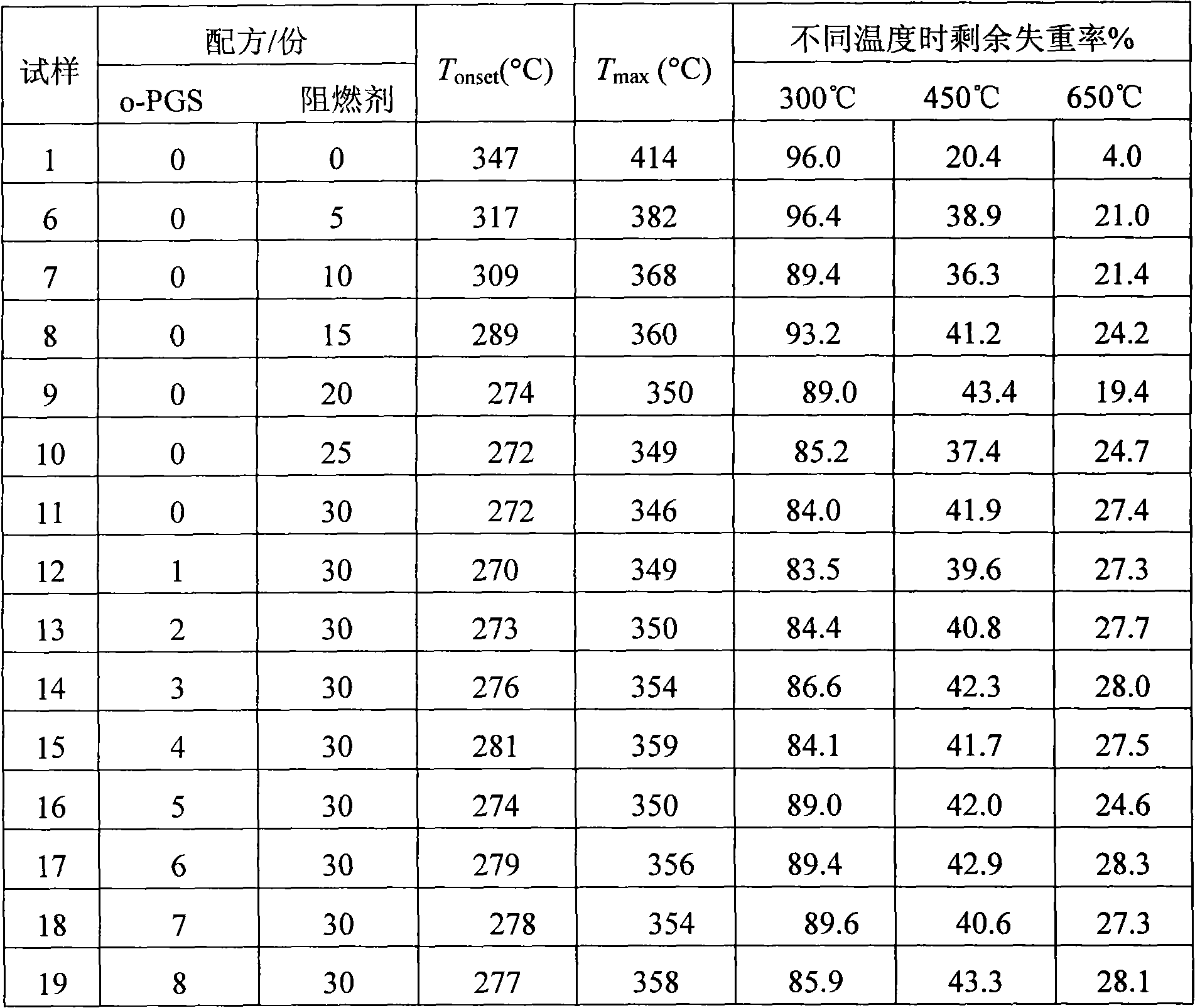

Nanometer grade paligorskite-flame retardant epoxide resin composite material

The invention provides a nano-palygorskite reinforced flame retarding epoxy resin composite material which disperses the nano-palygorskite into epoxy resin matrix by means of ultrasonic dispersion by mass ratio between 1:100 and 8:100 after surface treatment is carried out to the nano-palygorskite, then mix the obtained palygorskite epoxy resin mixture with a reactive-type flame retardant by the mass ratio between 100:5 and 100:30, and casting and curing are carried out. A plurality of P-N bond intermediates formed in the reactive-type flame retardant of the invention are phosphorylating agents better than routine phosphorus compounds, and water vapor generated from nano-palygorskite acting as a synergistic flame retardant during burning is in great favor for a phosphorous flame retardant, and the reinforcement of appropriate amount of nano-palygorskite compensates for the reduction of the mechanical property of the epoxy resin caused by adding the flame retardant to some extent, serving double effect of flame retardation and reinforcement, thus, the flame retarding epoxy resin composite material of the invention has the advantages of high oxygen index, good smoke suppression effect and excellent physical and mechanical properties.

Owner:NORTHWEST NORMAL UNIVERSITY

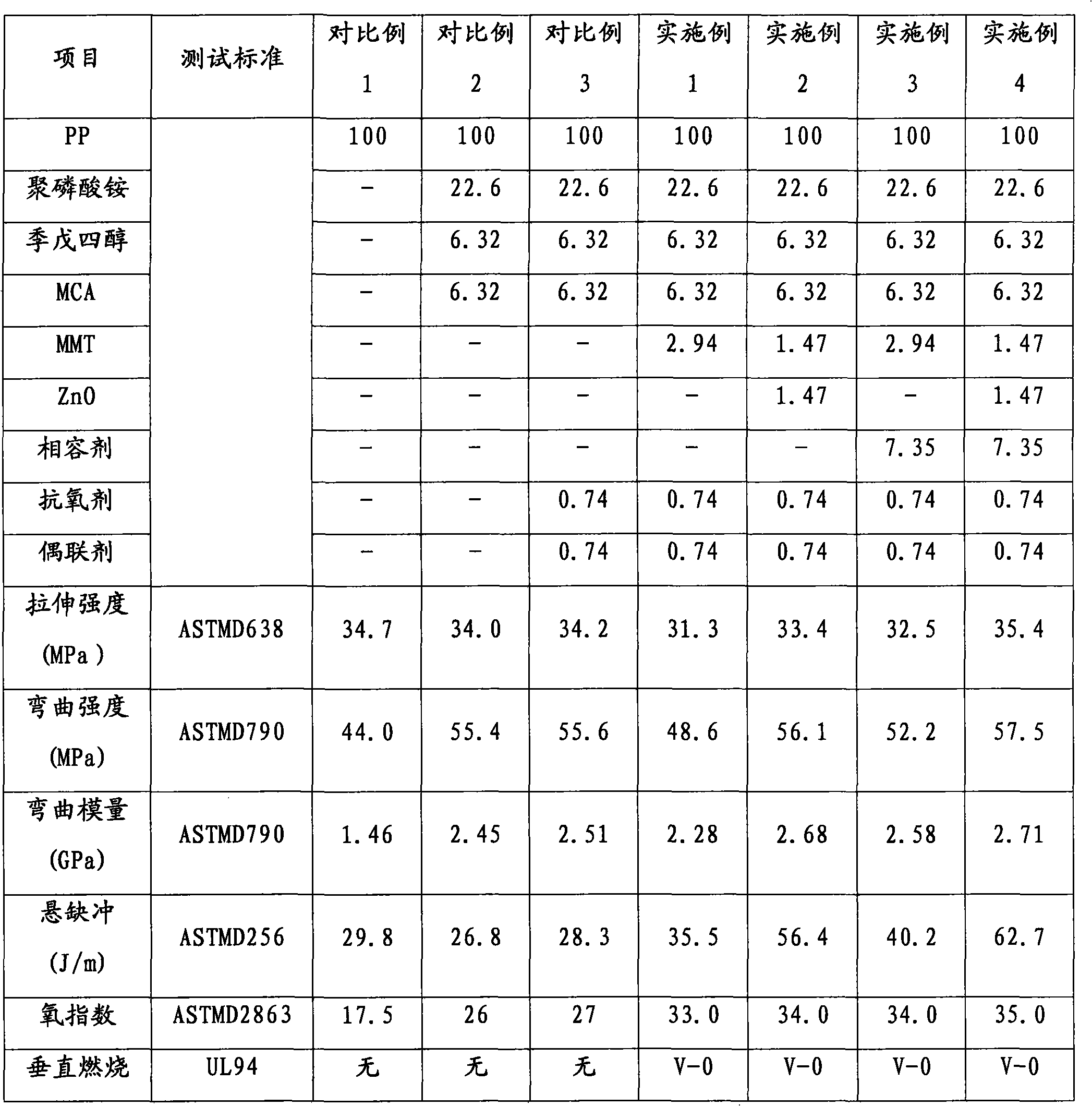

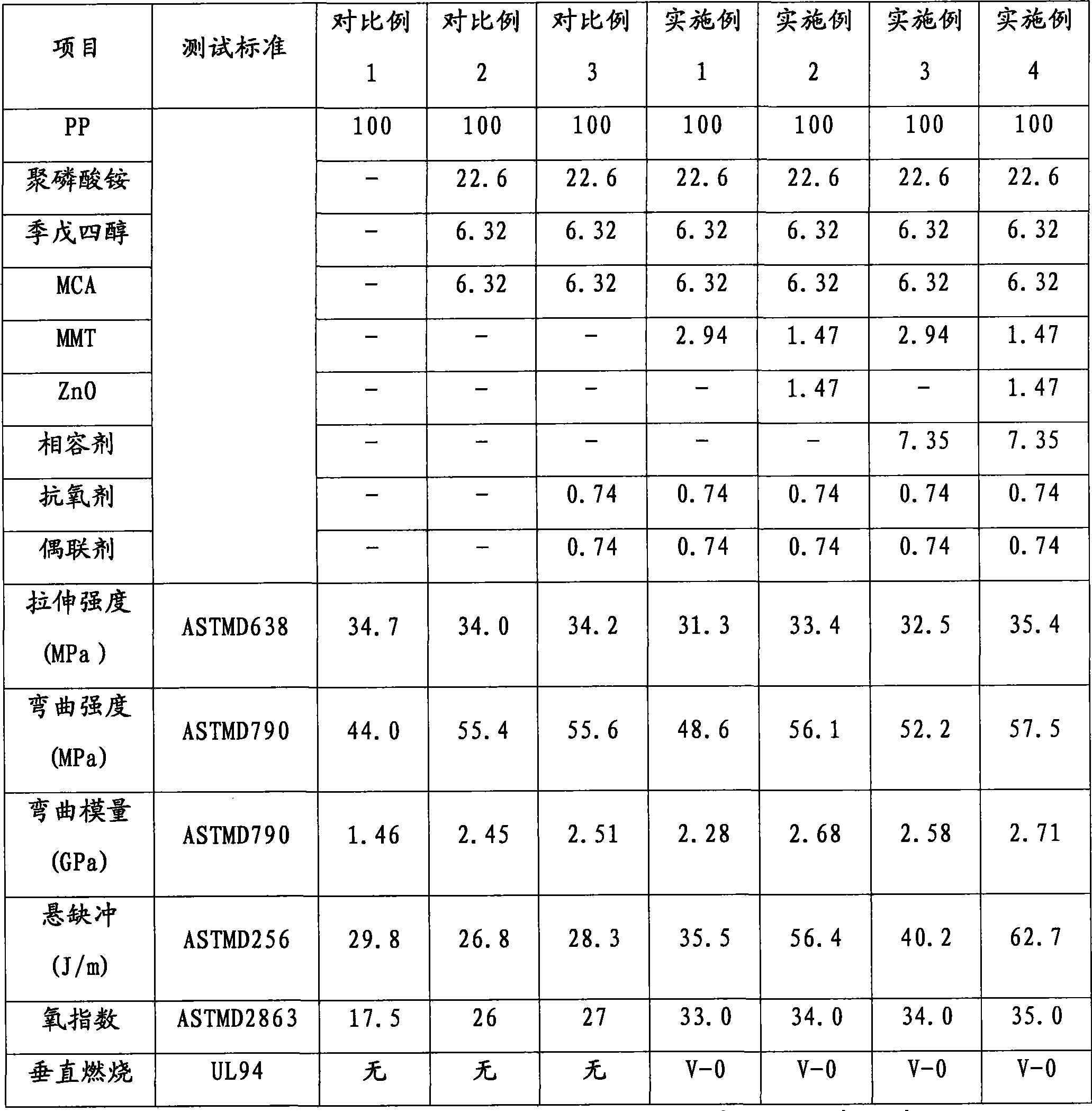

Expanded carbon flame-proof polypropelene composition and preparation method thereof

ActiveCN101293984AThe preparation method is simple and reliableGood flame retardant performanceAmmonium polyphosphateChemistry

The invention relates to an expansive char-forming flame-retardant polypropylene composition and a production method thereof. The composition comprises the following components: 100 weight parts of polypropylene, 10-30 weight parts of ammonium polyphosphate, 2.8-8.3 weight parts of pentaerythritol, 2.8-8.3 weight parts of melamine cyanurate and 0.5-5 weight parts of montmorillonite. The total additional amount of ammonium polyphosphate, pentaerythritol and melamine cyanurate is at least 31 weight parts. The production method comprises the following steps: proportioning all components (including polypropylene, ammonium polyphosphate, pentaerythritol, melamine cyanurate and montmorillonite) at the given ratios, melting, mixing, extruding and granulating. The composition has better flame retardation, good processability and mechanical property. The production method is simple and reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

Traditional poultry eggs compound nano material coating-film fresh-keeping method

InactiveCN101390531ASimple film forming processUniform film thicknessEggs preservation by coatingComposite filmPolyvinyl alcohol

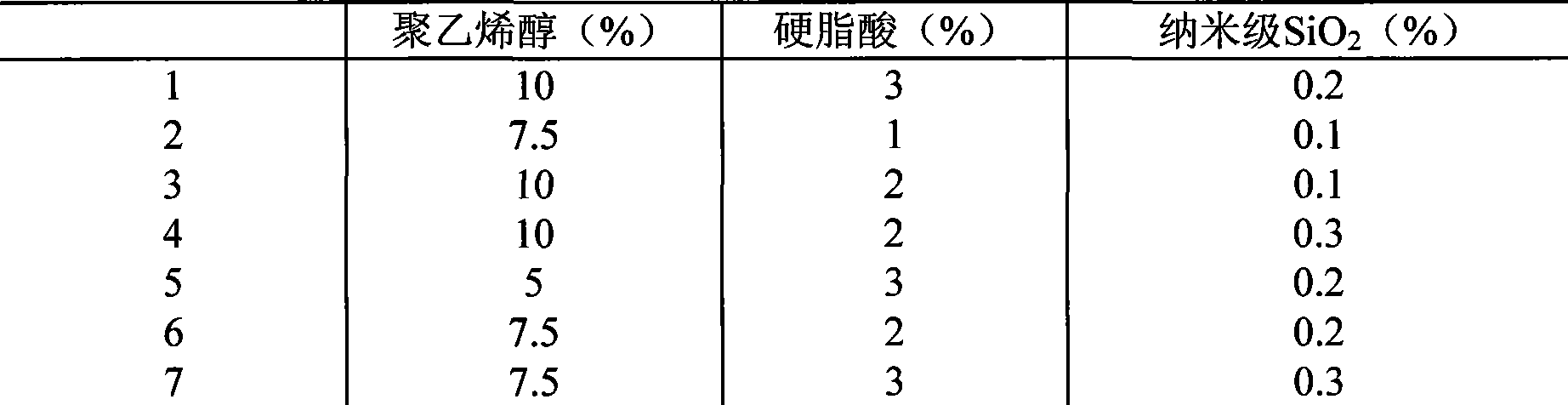

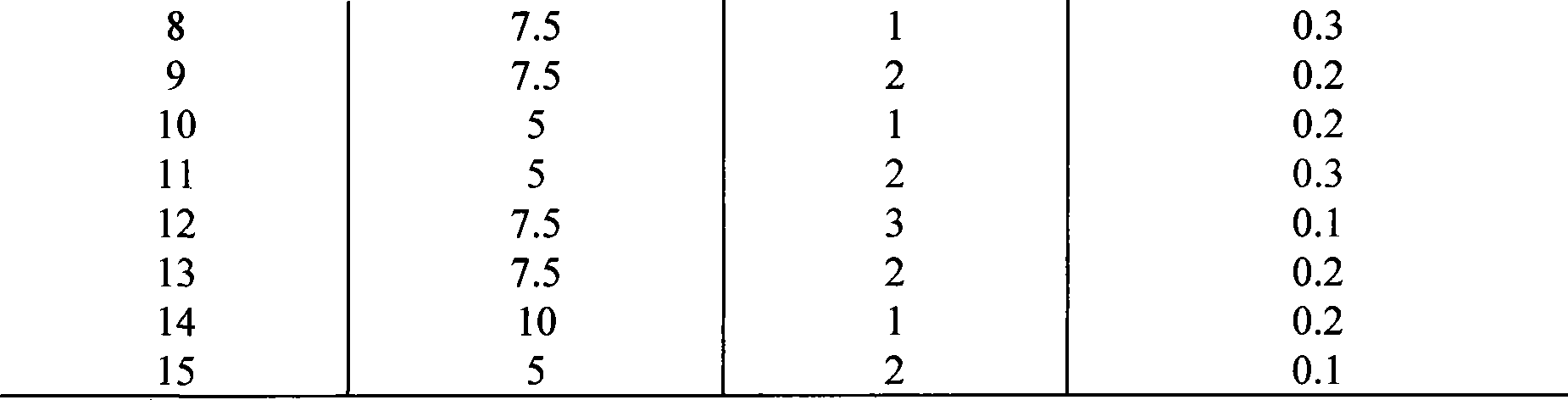

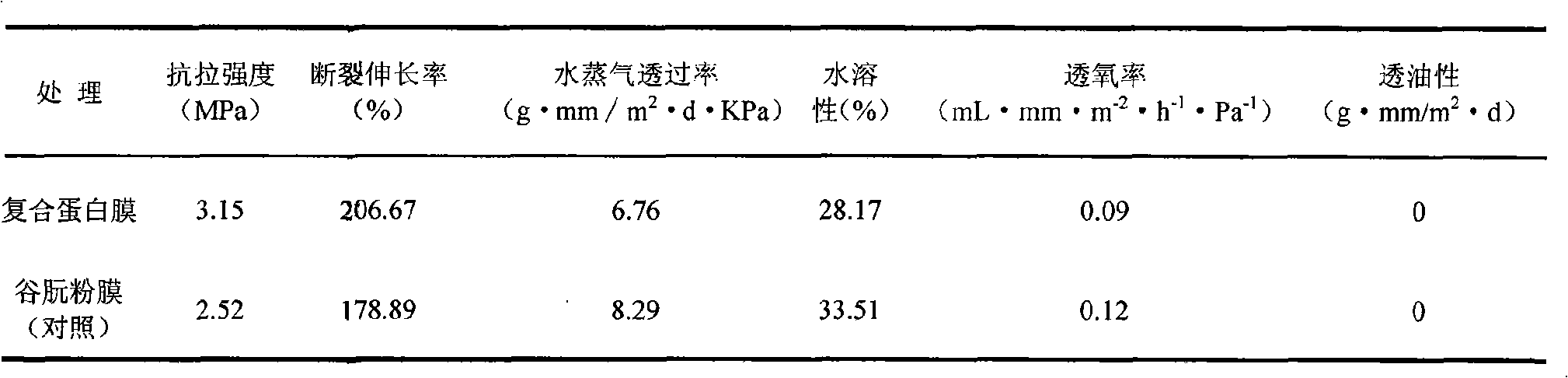

The invention relates to a traditional poultry egg product composite nano-material coating preservation method, belonging to the poultry egg fresh-keep packaging technical field. The method comprises the following steps: 5%-10% polyvinyl alcohol and 0.1%-0.5% nano-SiO2 are dissolved in water and heated; 1% -5% stearic acid is dissolved in (w / v is equal to 1:15-20) ethanol and heated; when the temperature of the polyvinyl alcohol solution and that of the stearic acid solution reach 80-85 DEG C at the same time, the two solutions are mixed, heated and stirred evenly to prepare the composite film coating agent; and the composite coating agent is hot-coated on the surface of the poultry egg and then dried with hot air and filmed. Compared with the cooked egg vacuum-packaging, the poultry egg coating preservation method can significantly reduce the using amount of packaging materials and simplify the packaging sterilization technique of the cooked eggs; besides, the poultry egg coating preservation method can achieve mechanized operation, effectively reduce the damage rate of eggs and significantly improve the economic benefits; moreover, the composite coating material is safe and degradable, which improves the marketability of products after being filmed on the egg surface and can also extend the shelf-life of the cooked egg products.

Owner:CHANGSHU YIHAO FOOD PACKAGING MATERIAL TECH +2

Method for preparing edible composite protein film

InactiveCN101580595AIncrease elasticityImprove toughnessFlexible coversWrappersComposite filmFood packaging

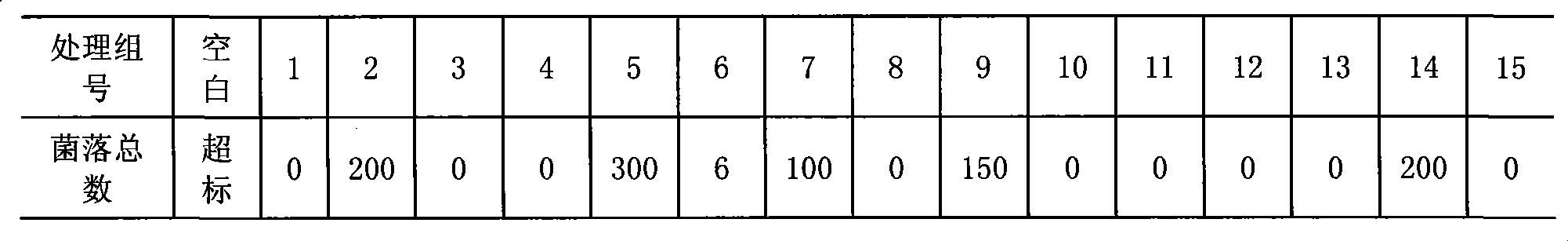

The invention relates to a method for preparing an edible composite protein film. The method adopts wheat gluten and zein as base materials, and adds a plasticizing agent and a reinforcing agent. The method overcomes the defect that the wheat gluten monomer is difficult to be applied in the actual production due to poor film-forming water resistance and mechanical strength. The method has the advantages of wide raw material sources and simple production process, has no environmental pollution, remarkably improves the mechanical strength and the water resistance of the modified wheat gluten-zein composite film, and has wide development prospect in the field of food packaging.

Owner:SHENYANG AGRI UNIV

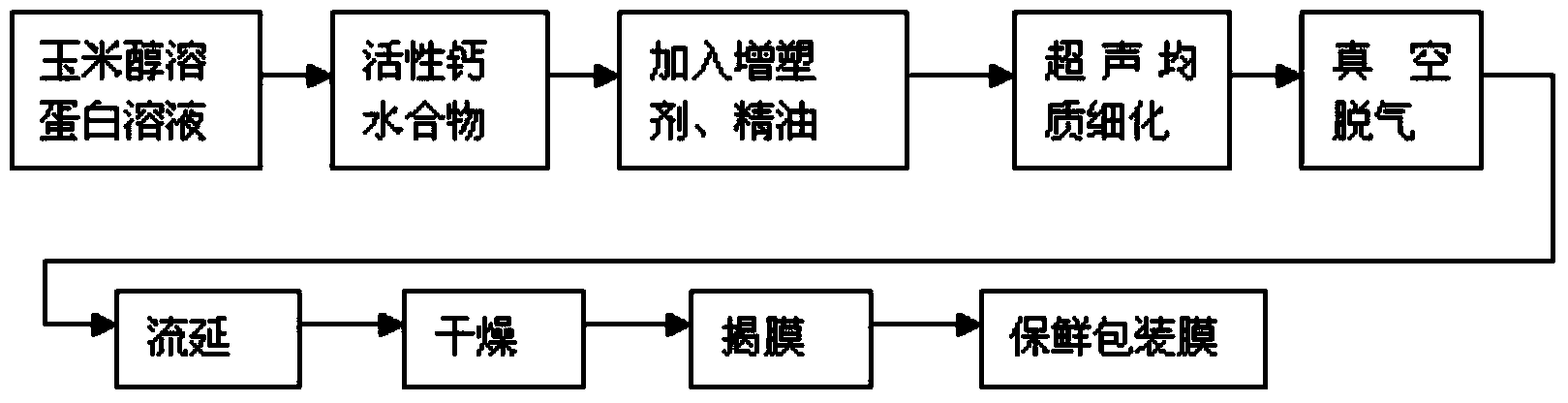

Preparation method of freshness-retaining packaging film with antibacterial and antioxidant function

The invention discloses a preparation method of a freshness-retaining packaging film with an antibacterial and antioxidant function. The preparation method comprises the followings steps: (1) dissolving 5-10 parts by mass of zein into 70-90 parts by mass of 80% alcohol and stirring for sufficiently dissolving so as to obtain a zein liquid; (2) adding a small amount of water into 5-25 parts by mass of active calcium to obtain an active calcium hydrate; (3) mixing the zein liquid with the active calcium hydrate to obtain a mixed liquid, adding 1-2 parts by mass of a plasticizer and 0.2-2 parts by mass of plant essential oil into the mixed liquid to obtain a film liquid; (4) ultrasonically homogenizing and refining; (5) degassing; (6) performing tape casting; and (7) drying and uncovering the film. The freshness-retaining packaging film prepared by the preparation method has excellent antibacterial property and antioxidant property, strong mechanical performance and high barrier property, and is easily available in raw materials, simple and easy in processing process, low in cost, free of toxicity and good in safety.

Owner:ANHUI SCI & TECH UNIV

Vermiculite compositional flame-retardant high-impact polystyrene composite material

The invention provides a halogen-free flame-retardant high impact polystyrene composite material prepared by taking vermiculite as a flame-retardant additive. The composite material is prepared by the following steps: mixing vermiculite powder crushed to 100 to 500 meshes and a halogen-free flame retardant according to the mass ratio of 1:1-1:10 to form a vermiculite composite flame retardant; and then banburying and injecting the vermiculite composite flame retardant and high impact polystyrene according to the mass ratio of 1:1-1:5. The halogen-free flame retardant is a compound of red phosphorus, expanded graphite and melamine. The flame-retardant composite material has low price, simple preparation process, better flame-retardant performance, and oxygen index of more than 27, and meets the requirements of a nonflammable material.

Owner:甘肃省交通科学研究院集团有限公司

Paper backing plastic aluminum compound packing material

InactiveCN101195429AHigh strengthOther qualities are not affectedFlexible coversWrappersPre conditioningPulp and paper industry

The invention relates to a paper-base packing material, in particular to flexible packing material which is used for the long-acting sterility and fresh keeping of drinking food. The paper-base plastic-aluminum composite packing material of the invention comprises a polyethylene outer layer, a base paper layer disposed behind the outer layer, a polyethylene binding layer arranged behind the base paper layer, an aluminum leaf mounted behind the binding layer, and an adhesive polyethylene layer and a polyethylene inner layer positioned behind the aluminum leaf, wherein the base paper layer is coated with base paper modified layer, and the weight per unit area of each layer includes the polyethylene outer layer 19-20 g / m2, the base paper layer 20-40 g / m2, the polyethylene binding layer 18-20 g / m2, the base paper modified layer 1-8 g / m2, the aluminum leaf 20-22 g / m2, the adhesive polyethylene layer 15-17 g / m2, and the polyethylene inner layer 17-18 g / m2. Both the utilization per unit area of the base paper of the invention and the total weight per unit area of the products are greatly reduced, thereby reducing the cost of products under the pre-condition of guaranteeing each property of the products.

Owner:MIANYANG XINKANG IND

Intelligent moisture control composite barrier film, and preparation method and application thereof

InactiveCN110305361AWith intelligent humidity control abilityPrevent dew condensationFlexible coversWrappersPolyvinyl alcoholPolystyrene

The invention belongs to the field of functional films, and relates to an intelligent moisture control composite barrier film, and a preparation method and application thereof. The intelligent moisture control composite barrier film comprises a base layer, and an additional layer or additional layers located on one side or both sides of the base layer. The base layer is a porous film comprising atleast one of polyethylene, polypropylene, polystyrene, polyterephthalic acid diol ester and polycaprolactam. The additional layer / layers is / are a dense film or dense films comprising polyvinyl alcohol, a metal salt, and an optional crosslinking agent and / or an optional antibacterial agent. The intelligent moisture control composite barrier film has an intelligent moisture control function, maintains the humidity of fruits and vegetables when the relative humidity is low, improves the moisture permeability when the relative humidity is high to prevent dewing and rotting of the fruits and vegetables, has oxygen barrier properties, and can be applied to fresh-keeping fruit and vegetable boxes and refrigerators with the fresh-keeping fruit and vegetable boxes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polystyrene coating

InactiveCN102977696AWith water resistanceOxygen barrierAnti-corrosive paintsPolyvinyl alcoholPolystyrene

The invention relates to a polystyrene coating comprising the following components in parts by weight: 100-120 parts of polystyrene-acrylate copolymer, 70-85 parts of polyvinyl alcohol, 6-9 parts of potassium silicate, 2-6 parts of acetone, 4-8 parts of cellulose acelate, 2-3 parts of corrosion remover, 3-8 parts of ethylene glycol and 2-7 parts of teflon. The polystyrene coating contains six parts of cellulose acelate. The polystyrene coating provided by the invention is improved on the basis of modified alkyd resin and an organic silicon copolymer so that the polystyrene coating has favorable flexibility and adhesive force, high temperature resistance and originalcorrosion preventing property and is widely applied to corrosion prevention of metal structures such as power plants, various chemical equipment and pipelines. The coating provided by the invention has excellent performances such as safety, no toxicity, water and oxygen blockage, good rust prevention effect and short drying time.

Owner:JIAOZHOU FUTIAN CHEM ENG

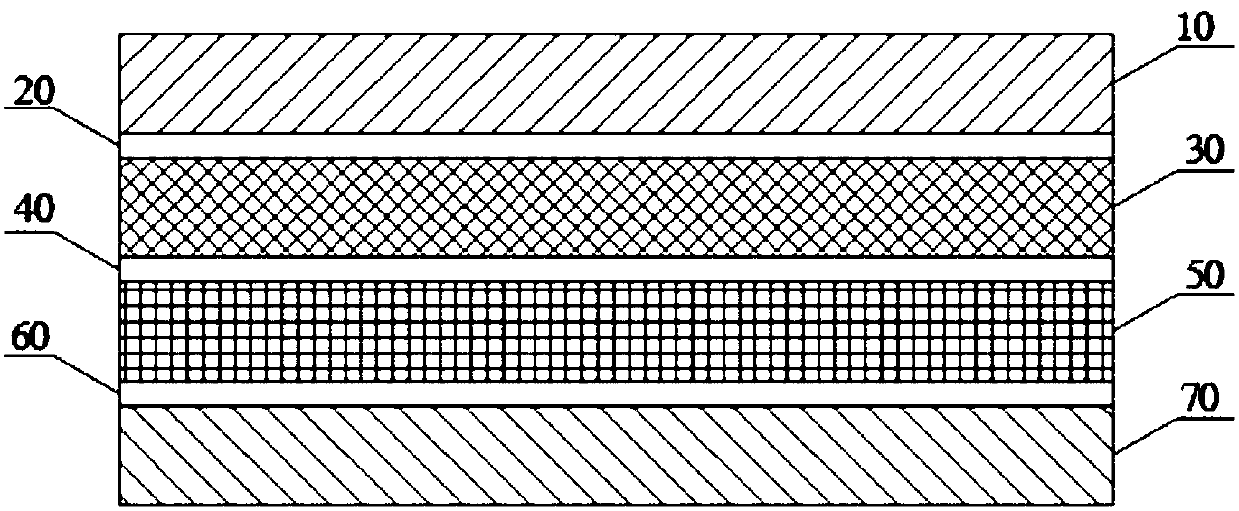

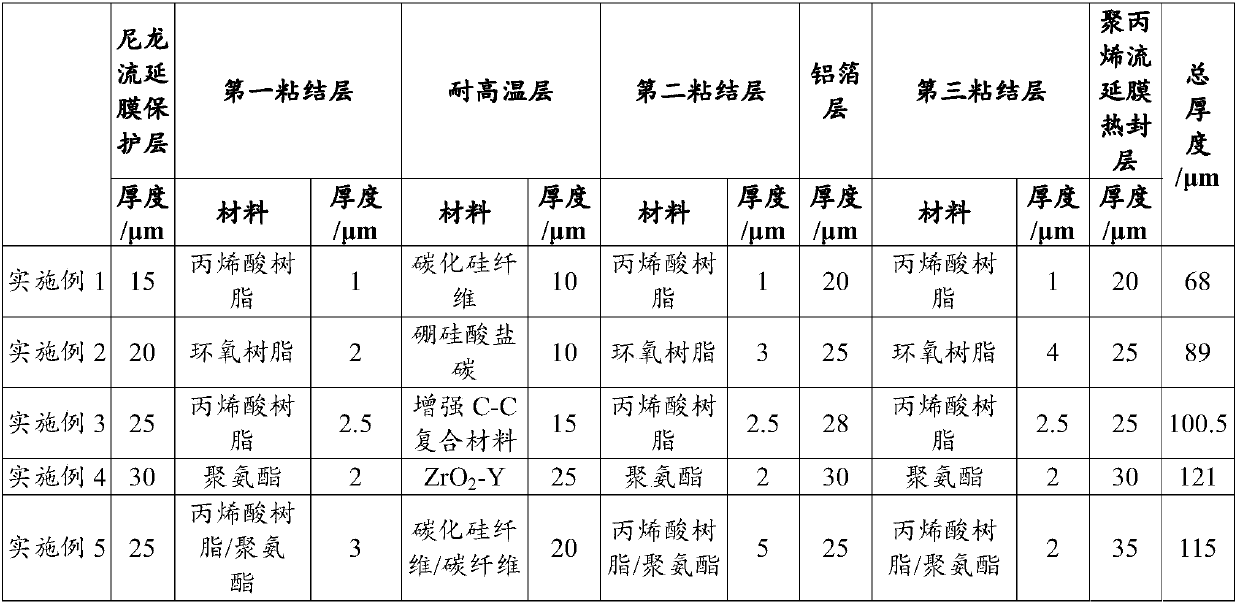

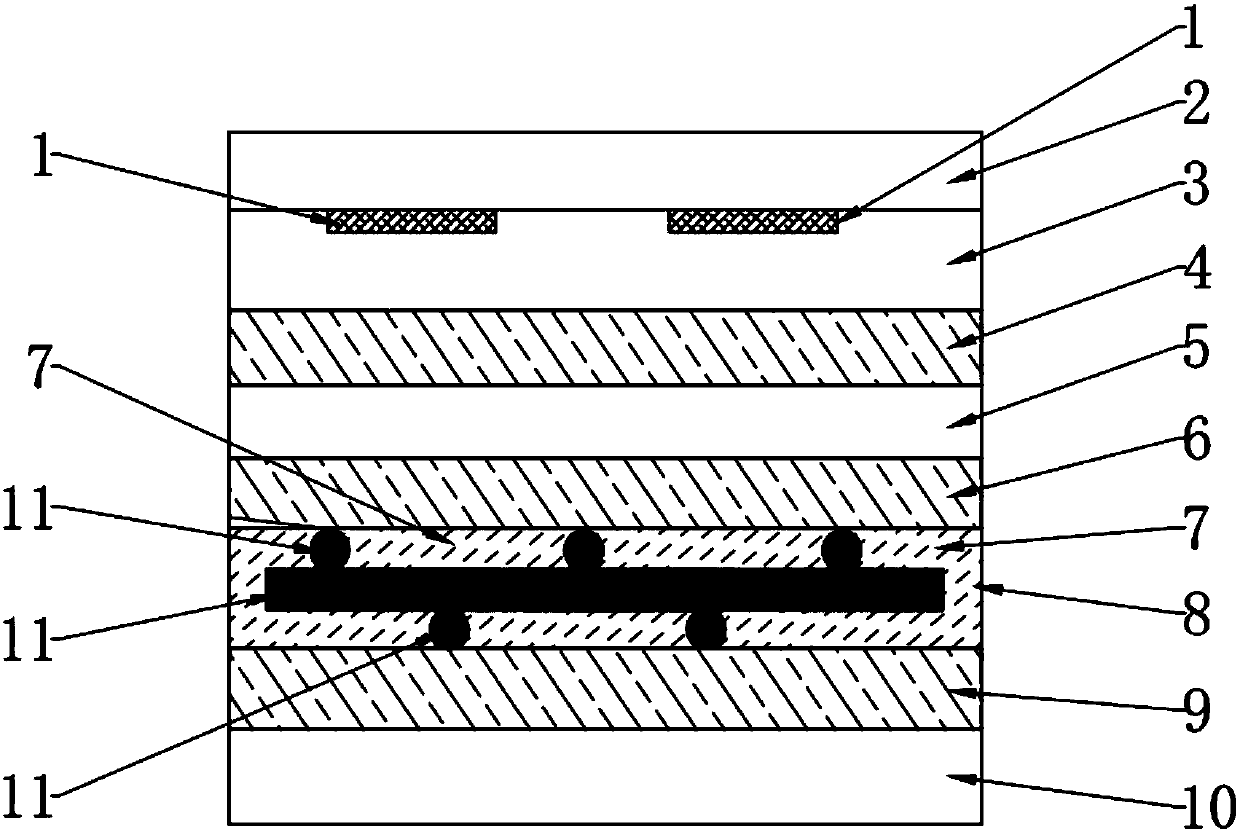

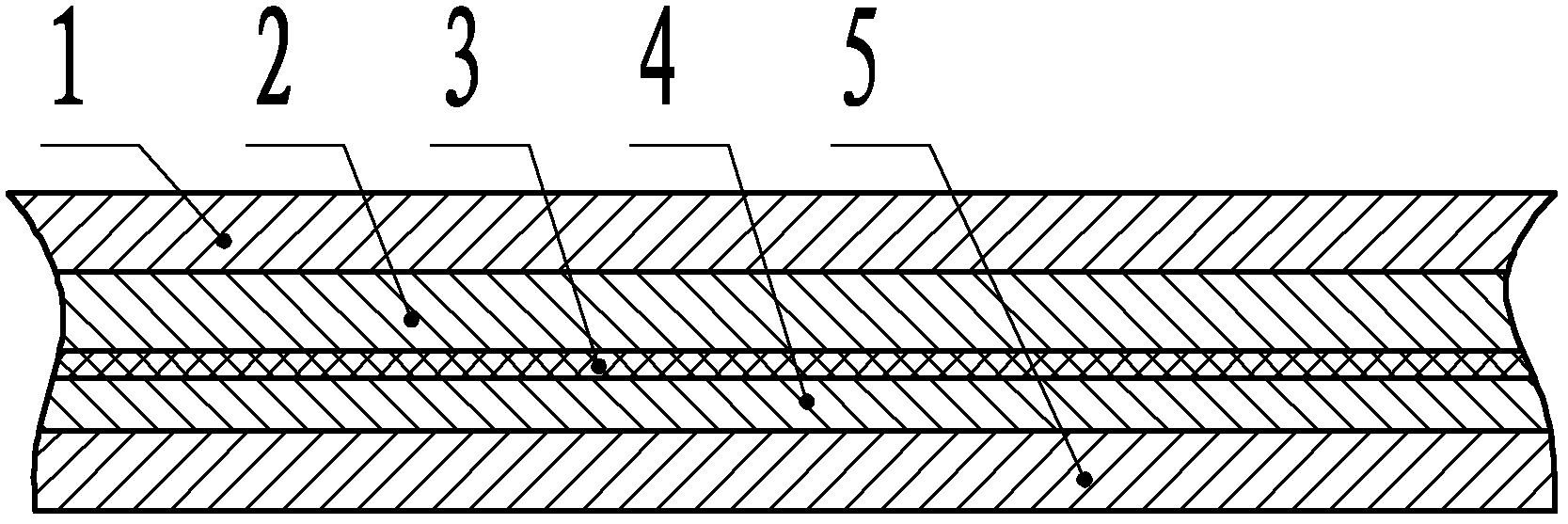

Lithium ion battery, and aluminum-plastic film

ActiveCN109986850AImprove securityAvoid sudden violent reactionsSynthetic resin layered productsSecondary cellsHeat resistanceOxygen

The invention discloses a lithium ion battery, and an aluminum-plastic film. The aluminum-plastic film comprises a protective layer, a first bonding layer, a high temperature resistant layer, a secondbonding layer, an aluminium foil layer, a third bonding layer, and a heat sealing layer; the first bonding layer is arranged between the protective layer and the high temperature resistant layer; thesecond bonding layer is arranged between the high temperature resistant layer and the aluminium foil layer; the third bonding layer is arranged between the aluminium foil layer and the heat sealing layer. Compared with the prior art, the advantages of the aluminum-plastic film are that: electrolyte corrosion resistance, water resistance, oxygen insulation performance, high temperature resistance,explosion-proof performance, and high packaging adhesive force are achieved, large scale popularization and applications in the field of flexible package lithium ion battery can be realized, the obtained lithium ion batteries are excellent in heat resistance, high in safety performance, and long in service life.

Owner:CONTEMPORARY AMPEREX TECH CO

Production method of dealcoholic drink containing aquilaria sinensis tea fungus gel

InactiveCN103156245APromote growth and reproductionEnhance hangover functionFood preparationAlcoholismsGellan gum

The invention belongs to the technical field of health care drinks and in particular relates to a production method of a dealcoholic drink containing aquilaria sinensis tea fungus gel. The production method provided by the invention comprises the following steps of: adding black tea fungus into an extracting solution of fresh aquilaria sinensis leaves and hovenia dulcis thub and fermenting to obtain a tea fungus solution, then adding gellan gum to prepare gel granules containing the tea fungus solution, bottling, then adding fruit and vegetable honey juice prepared by tomatoes, sea-buckthorn juice and honey, and sealing, wherein a sterile clean operation is adopted in the production process, and the dealcoholic drink containing aquilaria sinensis tea fungus gel is prepared. The dealcoholic drink containing aquilaria sinensis tea fungus gel has the effects of preventing alcoholism, quenching thirst, preventing or arresting vomiting, protecting gastric mucosa and protecting liver.

Owner:南通市星期七旅游开发有限公司

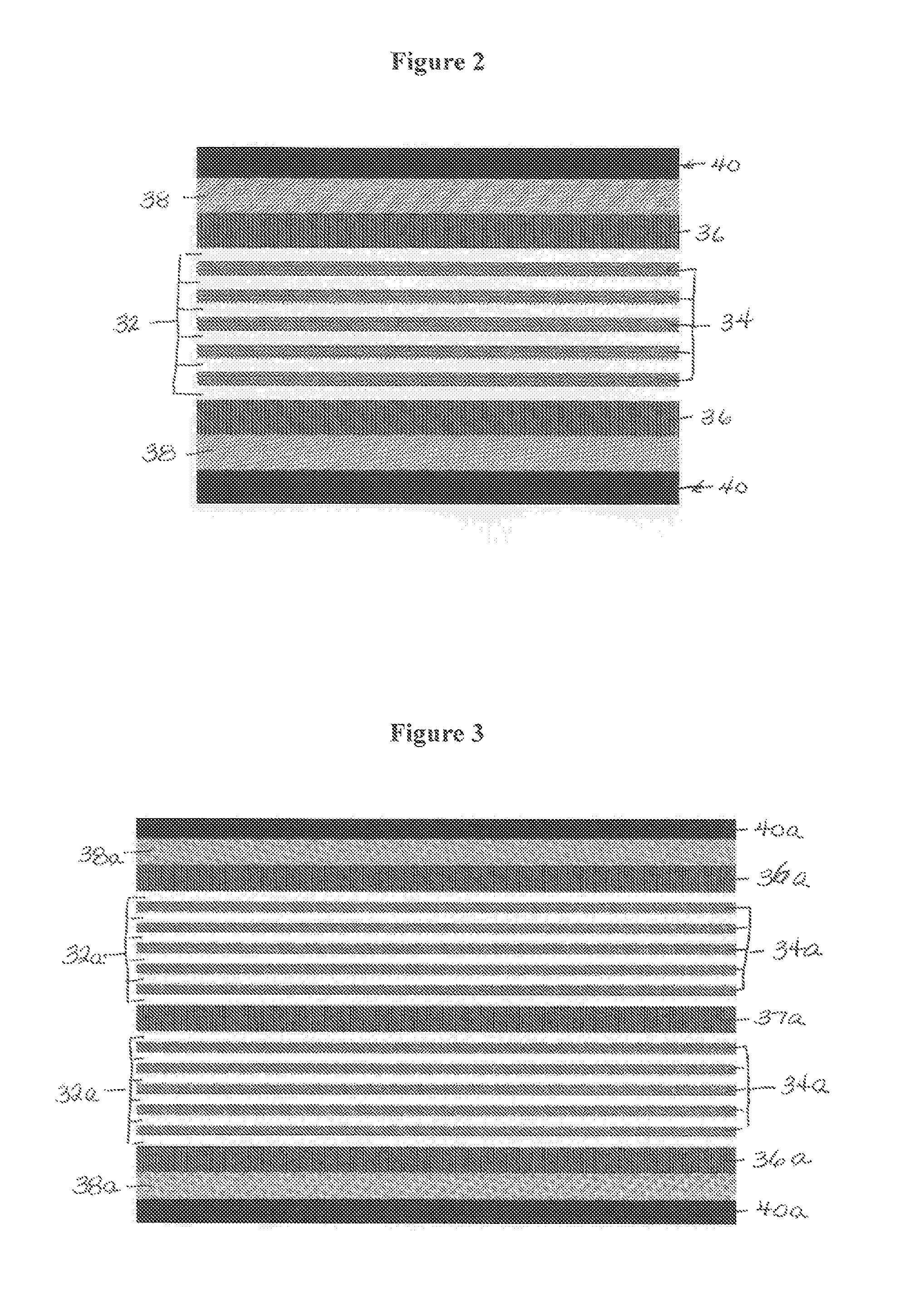

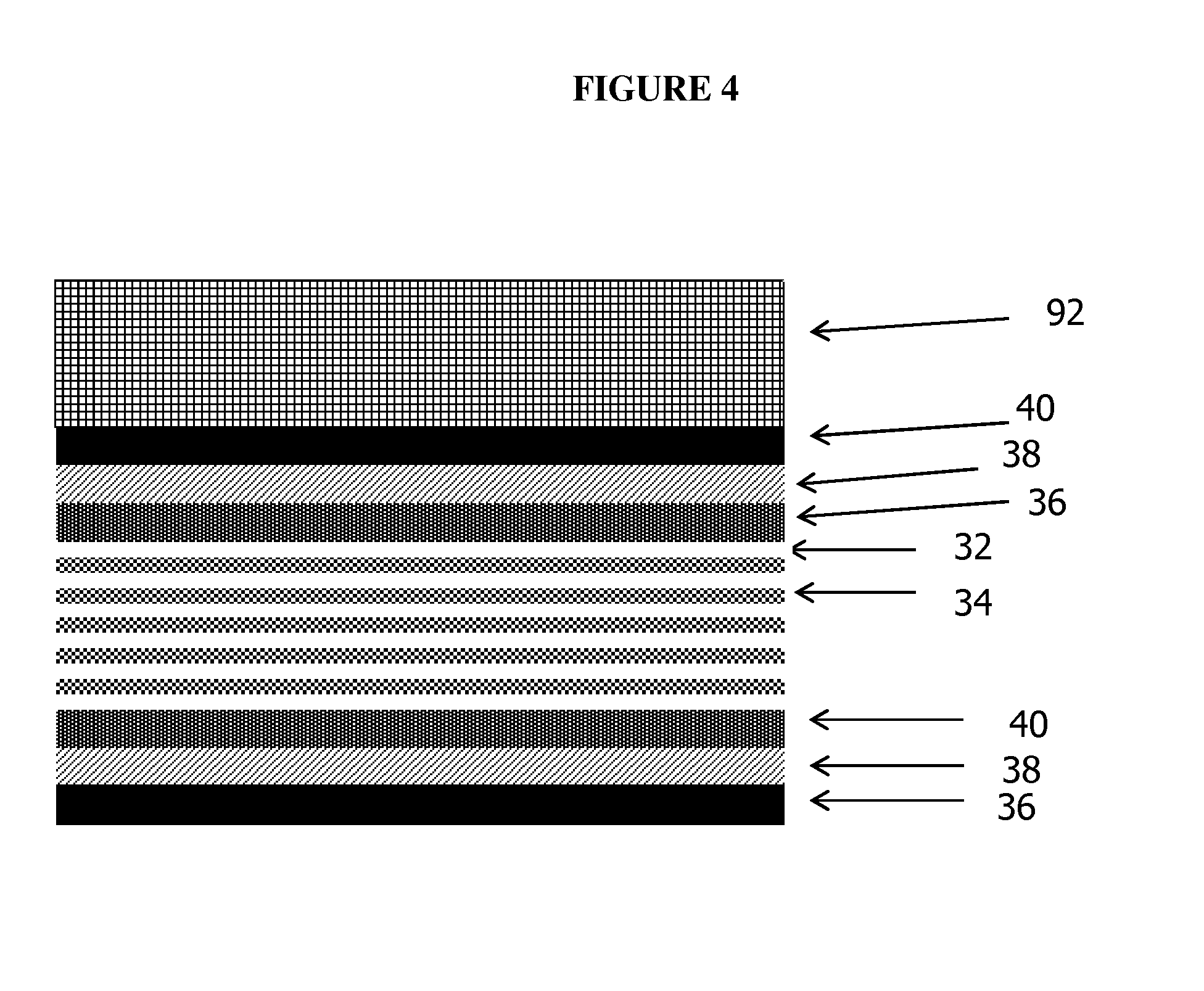

Microlayer extrusion coating and laminating for flexible packaging

ActiveUS8986823B1Raise the barrierOxygen barrierSynthetic resin layered productsLaminationPolymerMaterials science

The present development is a process for coating a substrate with a microlayered extrusion coating, or for producing a laminate from a first substrate, a microlayered extrudate and a second substrate. The present development also includes a microlayered extrusion coating used for laminating two or more plastic extrudates. The microlayered extrusion coating comprises a microlayer core comprising a plurality of layers of gas barrier material having a thickness of less than five microns per layer with alternating tie layers. The microlayer core is sandwiched between polymeric boundary layers which are further sandwiched between polymeric skin layers. The present microlayered extrudate surprisingly exhibits a gas barrier significantly better than conventional thicker single barrier layers and increased opacity in the extrudate using white pigmented LDPE enhances the printed graphics in a laminate structure using a printed substrate.

Owner:THE BRYCE CO LLC

Processing method for maintaining elasticity and flavor of clam meat

InactiveCN101946920APrevent contamination and reproduceStay flexibleFood preparationFood flavorRefrigeration

The invention discloses a processing method for maintaining the elasticity and the flavor of clam meat, which comprises the steps of: selecting claw materials, temporarily breeding the clam to disgorge sands, sterilizing the clam by ozone after the clam is cleaned, then vacuum-packaging the clam by using high-barrier gas composites, then atmospherically cooking the packed clam, and finally cooling and freezing the clam for storing. The method can effectively maintain the elasticity and the sauce flavor of the clam and also can effectively prevent air in or outside a packaging bag from mutually penetrating during the refrigeration and the shelf life of the clam because the clam is vacuum-packaged by using the high-barrier gas composites, ensures the quality of the clam and prolongs the shelf life of the product.

Owner:FUQING LONGYU FOOD DEV

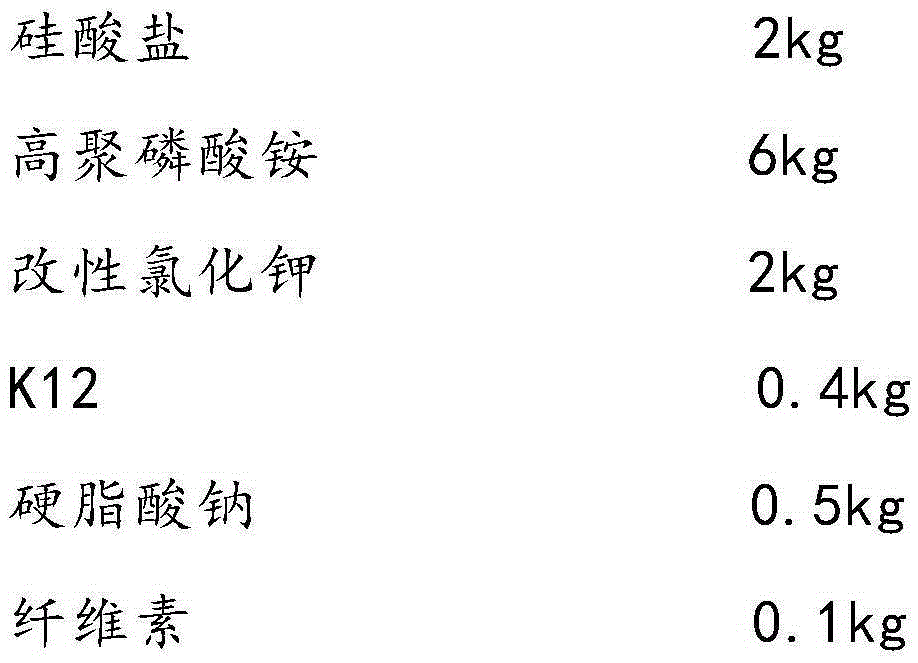

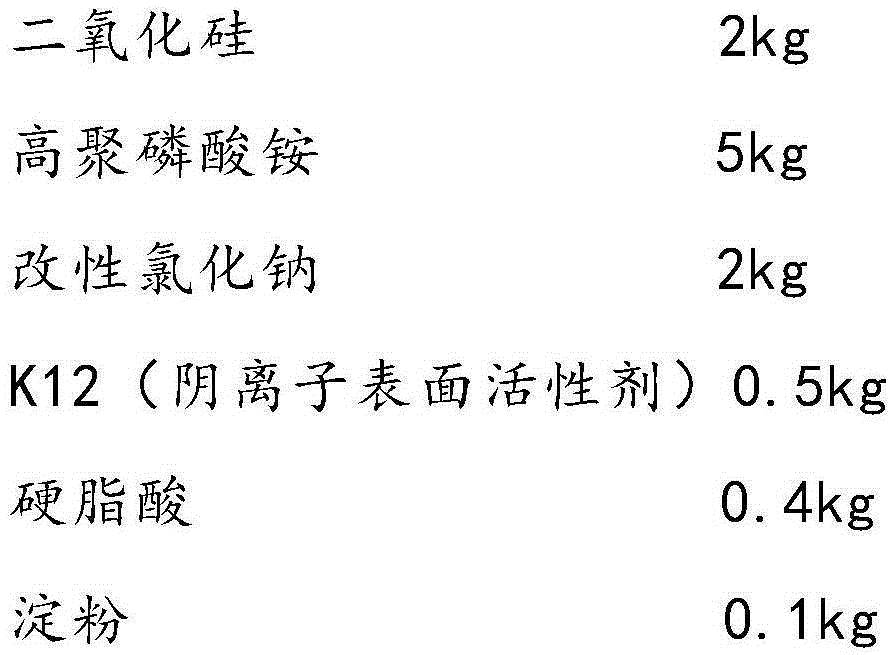

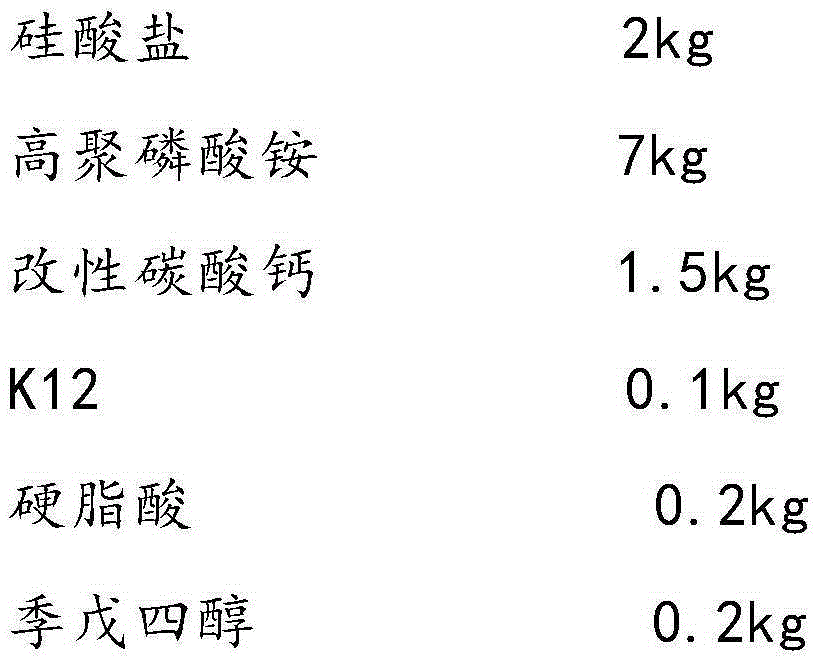

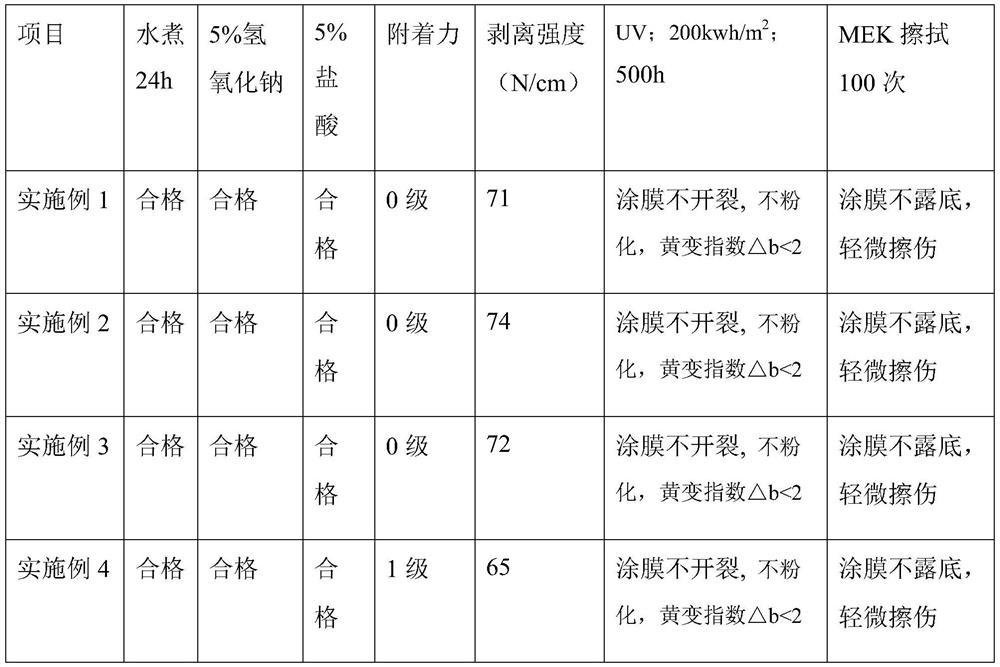

Flame-retardant ceramic slurry for lithium battery coating diaphragm and preparation method of flame-retardant ceramic slurry

InactiveCN108847469ATo preventReduce combustion explosionCell component detailsInorganic particleHeat resistance

The invention discloses a flame-retardant ceramic slurry for a lithium battery coating diaphragm and a preparation method of the flame-retardant ceramic slurry, wherein the slurry comprises inorganicparticles, an intumescent flame retardant, a dispersing agent, a binding agent, a thickening agent and a solvent; the preparation method comprises the following steps of adding the inorganic particles, the dispersing agent, the thickening agent and the solvent into a ball mill according to the proportion to be dispersed, so as to obtain a dispersion liquid; and then adding the binding agent and the intumescent flame retardant into the dispersion liquid, and carrying out dispersing by using a dispersing machine to prepare the flame-retardant ceramic slurry. The ceramic slurry disclosed by the invention can improve the heat resistance of the diaphragm, the lithium battery can be prevented from burning and exploding in a large range, and the safety performance of the lithium battery is improved.

Owner:瑞固新能(上海)材料科技有限公司

D type dry powder extinguishing agent

ActiveCN105288924APrevent and repair burn throughPrevent escapeFire extinguisherFoaming agentMaterials science

The invention relates to a D type dry powder extinguishing agent. The D type dry powder extinguishing agent is prepared from, by weight, 10-20 parts of a blocking agent, 50-70 parts of a foaming agent, 15-20 parts of a filling agent, 1-5 parts of a stabilizing agent, 1-5 parts of impregnating compounds and 1-5 parts of catalysts.

Owner:DAQING YINGBO FIRE FIGHTING EQUIP

Water-based fluorinated acrylate copolymer emulsion and preparation method thereof

The invention discloses a water-based fluorine-containing acrylate copolymer emulsion and a preparation method thereof. According to the scheme, methyl methacrylate, butyl methacrylate, methacrylic acid and other monomers are copolymerized to prepare a fluorocarbon resin emulsion; fluorine-containing acrylate monomers such as trifluoroethyl acrylate, octafluoropentyl methacrylate and hexafluorobutyl methacrylate are introduced in a preparation scheme, fluorine-containing groups are easy to migrate to the surface and are enriched on the surface, so that a coating film is endowed with excellent hydrophobic performance, and due to the advantages of excellent weather resistance, chemical resistance stability and the like of a fluorine-containing polymer, the hydrophobic property of the coating film is greatly improved. It can be guaranteed that a coating film has the properties of low surface energy, low friction, stain resistance, good water and oil resistance, self-cleaning performance and the like, and the comprehensive practicability is high. And meanwhile, pretreatment and parameter limitation are carried out on the PET film in cooperation with the scheme, so that the adhesive force between the coating film and the PET film is further improved.

Owner:上海水立方新材料有限公司

Polystyrene antirust paint

InactiveCN103627264AWith water resistanceOxygen barrierAnti-corrosive paintsPolyether coatingsPolystyreneOxygen

The invention discloses a polystyrene antirust paint which is prepared from the following raw materials in parts by weight: 80-110 parts of polystyrene resin, 20-30 parts of diphenyl ether resin, 12-15 parts of hydroxyethyl cellulose, 10-14 parts of thiosinamine, 10-22 parts of epoxy phenolic resin, 6-8 parts of cobalt oxide, 5-9 parts of calcium oxide, 4-8 parts of hydrazine citrate and 6-10 parts of phenyltrimethoxysilane. The commercial test proves that the paint has the advantages of excellent water resistance, excellent oxygen resistance, favorable antirust effect, short drying time, lower requirements for materials and techniques and higher cost performance, can effectively avoid or reduce metal loss, and is beneficial to popularization.

Owner:WUJIANG LINSU PRECISION MACHINERY

Process for prolonging rice shelf life by using nano technology

The present invention relates to nanometer technological method of prolonging shelf life of rice, and belongs to the field of food producing and storing technology. Rice coating improver solution is first prepared through adding alcohol soluble corn protein powder into alcohol solution, heating in a water bath, centrifuging and taking supernatant, adding nanometer silica, potassium sorbate and sucrose ester into the supernatant and mixing via stirring at room temperature; and then added into rice in certain ratio during rice production. The rice coating improver solution, after evaporating, forms in the surface of rice one homogeneous compact film layer with low water vapor and oxygen permeation rate, high mechanical performance and other features, so that it can prolong the shelf life of rice.

Owner:JIANGNAN UNIV

Vacuum skin packaging film and cross-linking treatment method thereof

ActiveCN107627701AImprove insuranceImprove securitySynthetic resin layered productsCross-linkSurface layer

The invention relates to a vacuum skin packaging film. The vacuum skin packaging film comprises a surface layer, a first structural layer, a barrier layer, a second structural layer and a heat-sealinglayer from top to bottom, a three-dimensional code layer is arranged between the surface layer and the first structural layer, stereoscopic three-dimensional code structures are arranged at the middle-upper part of the three-dimensional code layer, or planar three-dimensional structures adopting two-dimensional codes of the color and the gray scale to represent three-dimensional information is printed in the upper surface of the three-dimensional code layer; and an inflating heat insulation layer and a third structural layer are also arranged between the second structural layer and the heat-sealing layer from top to bottom. The vacuum skin packaging film can effectively insulate heat, has a high structural strength, and has an excellent anti-counterfeiting effect due to the adoption of the three-dimensional code structures to record product information and anti-counterfeiting encryption information; and the vacuum skin packaging film has excellent sealing and heat-sealing effects, meets performance requirements of vacuum skin packaging, and has excellent market benefits.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

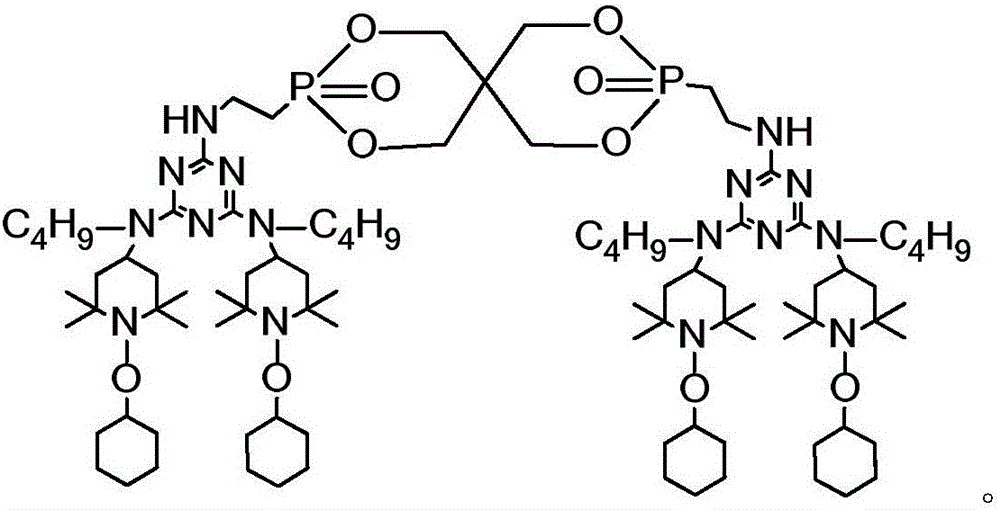

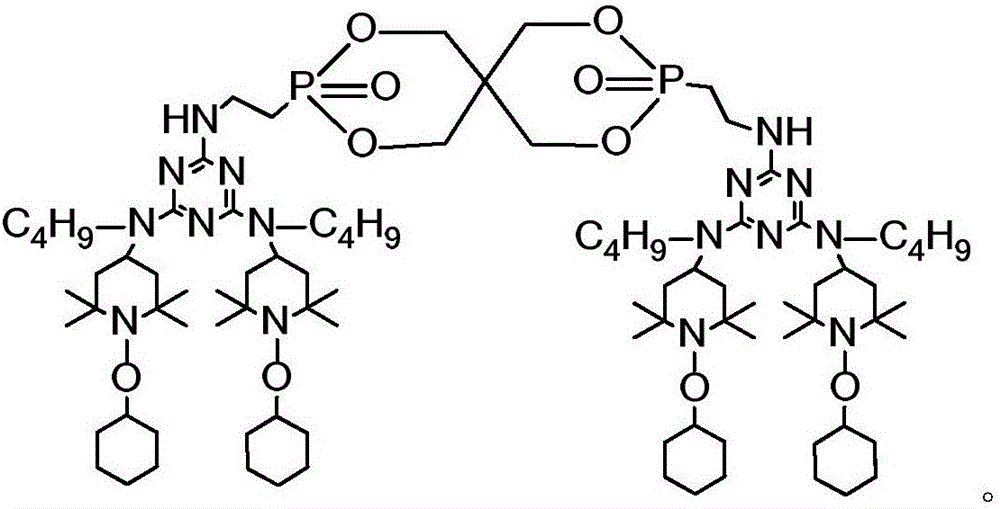

Flame-retardant agent containing spirane structure and having antioxidant function and preparation method

The invention relates to a flame-retardant agent containing a spirane structure and having an antioxidant function and a preparation method, and belongs to the technical field of flame-retardant agents. High-activity phosphoryl chloride on phosphorus oxychloride and hydroxyl groups on pentaerythritol have nucleophilic substitution reaction to prepare a spirocyclic phosphate intermediate SPDPC, then active chlorine on SPDPC and alcoholic hydroxyl groups on hindered amine are used for nucleophilic substitution reaction, and the flame-retardant agent containing the spirane structure and having the antioxidant function is formed. The spirocyclic phosphate structure contains pentaerythritol units and can provide sufficient carbon sources for an expansion flame-retardant system. Besides, the hindered amine can effectively capture active radials generated during decomposition of polymer, and chain reaction is delayed.

Owner:CHANGZHOU UNIV

Expanded carbon flame-proof polypropelene composition and preparation method thereof

The invention relates to an expansive char-forming flame-retardant polypropylene composition and a production method thereof. The composition comprises the following components: 100 weight parts of polypropylene, 10-30 weight parts of ammonium polyphosphate, 2.8-8.3 weight parts of pentaerythritol, 2.8-8.3 weight parts of melamine cyanurate and 0.5-5 weight parts of montmorillonite. The total additional amount of ammonium polyphosphate, pentaerythritol and melamine cyanurate is at least 31 weight parts. The production method comprises the following steps: proportioning all components (including polypropylene, ammonium polyphosphate, pentaerythritol, melamine cyanurate and montmorillonite) at the given ratios, melting, mixing, extruding and granulating. The composition has better flame retardation, good processability and mechanical property. The production method is simple and reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

Food fresh-keeping packaging bag and manufacturing method thereof

InactiveCN102275364AGuaranteed not to leakExtended shelf lifeFlexible coversWrappersStore foodEngineering

The invention discloses a food fresh-keeping packaging bag. The food preservation packaging bag includes a polyethylene film layer, a printing layer and a nylon film layer from the inside to the outside, a high barrier layer is arranged between the polyethylene film layer and the nylon film layer, and a high barrier layer is arranged between the high barrier layer A printing layer is provided. The food fresh-keeping packaging bag adopting this technical scheme, the high barrier layer can effectively keep the fresh molecules of pickled vegetables from leaking out, so that the freshness of pickled vegetables can be preserved for 3 to 6 months, and the crispness can be kept for 3 months. extended to 12 months. The invention also discloses a method for manufacturing the food fresh-keeping packaging bag. The method comprises the steps of compounding a high barrier layer, printing patterns, compounding a polyethylene film layer, and making a machine bag. The method is scientific and reasonable, and is suitable for large-scale industrial production.

Owner:扬州科信包装印刷有限公司

Preparation method of natural degradable antimicrobial wrapping paper

The invention discloses a preparation method of natural degradable antimicrobial wrapping paper. The method basically comprises steps of raw material preparation, defibering, beating, pulp preparationand fine grinding, papermaking, squeezing and drying. The formed natural degradable antimicrobial wrapping paper has the advantages of oxygen isolation, good antibacterial property and degradation. The preparation method adopts a nanometer embedding technology, adopts chitosan Arabic gum and essential oil to prepare a nanometer compound to be added into pulp, improves the oxygen resistance and the antibacterial property of the paper, is simple, and convenient to operate, further provides a novel approach for processing of by-products through peel agricultural and forestry products, sufficiently utilizes resources, and relieves environmental pollution.

Owner:NANJING FORESTRY UNIV

Metal type dry powder extinguishing agent

The invention relates to a metal type dry powder extinguishing agent. The metal type dry powder extinguishing agent is characterized by comprising components including, by weight, 10-20 parts of a blocking agent, 50-70 parts of a foaming agent, 15-20 parts of a filling agent, 1-5 parts of a stabilizer, 1-5 parts of an impregnating agent and 1-5 parts of a catalyst.

Owner:TIANJIN SHENGAN XIAOKE TECH CO LTD

Process for manufacturing composite material water pipe special for drinking water

The invention relates to a process for manufacturing a composite pipe material and in particular relates to a process for manufacturing a composite material water pipe special for drinking water. The process for manufacturing the composite material water pipe special for drinking water comprises the following steps: mixing and heating polyphenylene sulfone, polyether sulphone and polybutene materials; adding a processing aid, a reinforcing agent, a stabilizing agent and a plasticizing agent; and extruding a pipe by virtue of extrusion equipment. The produced pipe is low in manufacturing cost, good in performance and very beneficial for popularization.

Owner:李红国

Sargassum polysaccharide food packaging film and preparation method thereof

InactiveCN110305371AHigh tensile strengthStable structureFlexible coversWrappersSolubilityPlasticizer

The invention provides a sargassum polysaccharide food packaging film and a preparation method thereof, and belongs to the technical field of food packaging films. According to the food packaging filmprovided by the invention, sargassum is taken as a raw material, and sargassum polysaccharide is extracted in a combination mode of ultrasonic and enzymolysis, so that the extraction rate of polysaccharide is increased, and extraction efficiency is improved. The sargassum polysaccharide has good water solubility, has high viscosity and solidification capability and is good in film-forming property. Hydrophobic agent glycerol and plasticizer gelatin are added into the formula, so that hydrophilicity of the polysaccharide is reduced, and mechanical properties of the film are improved. The obtained food packaging film has various effects of resisting oxidation, reducing blood fat, resisting radiation, being safe and harmless, being degradable and the like.

Owner:李光宽

Environmental degradable express bag film material and preparation method thereof

InactiveCN109320828AReduce pollutionRapid photooxidative degradationLow-density polyethyleneLinear low-density polyethylene

The invention discloses an environmental degradable express bag film material and a preparation method thereof. The degradable express bag film material is prepared from starch, polylactic acid, an adipic acid-terephthalic acid-butanediol ester copolymer, a coupling agent, talcum powder, a degradation accelerant, masterbatch and linear low density polyethylene. 5-10% of the starch, 10-30% of the talcum powder, 0.01-5% of the degradation accelerant, 20-40% of the polylactic acid, 40-60% of the adipic acid-terephthalic acid-butanediol ester copolymer, 0.1-0.5% of vinyl trimethoxysilane and 0-20%of the linear low density polyethylene are mixed at a high speed to prepare a degradation material; in percentage by weight, 8-30% of degradation materials and 65-85% of the linear low density polyethylene and 2-7% of the masterbatch are mixed to prepare the express bag film material and then prepare express bags. The expression bag can be rapidly degraded after used.

Owner:北京国瑞新源投资有限公司

Intelligent moisture control film, and preparation method and application thereof

InactiveCN110302679AWith intelligent humidity control abilityPrevent dew condensationSemi-permeable membranesMembranesPolyvinyl alcoholRefrigerated temperature

The invention belongs to the field of functional films, and relates to an intelligent moisture control film, and a preparation method and application thereof. The intelligent moisture control film comprises a base layer, and an additional layer or additional layers located on one side or both sides of the base layer. The base layer is a porous film with the pore diameter of 0.005-250 micrometers and the porosity of 30-80%, and pores with the pore diameter being one order of magnitude higher or lower than the average pore diameter account for more than 50%. The additional layer / layers is / are adense film or dense films comprising polyvinyl alcohol, a metal salt, and an optional crosslinking agent and / or an optional antibacterial agent. The intelligent moisture control film has an intelligent moisture control function, maintains the humidity of fruits and vegetables when the relative humidity is low, improves the moisture permeability when the relative humidity is high to prevent dewingand rotting of the fruits and vegetables, has oxygen barrier properties, and can be applied to fresh-keeping fruit and vegetable boxes and refrigerators with the fresh-keeping fruit and vegetable boxes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com