Preparation method of freshness-retaining packaging film with antibacterial and antioxidant function

A fresh-keeping packaging and anti-oxidation technology, applied in the field of food packaging materials, can solve problems such as toxic and side effects, and achieve the effects of reducing environmental damage, good safety, and reducing the total number of colonies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

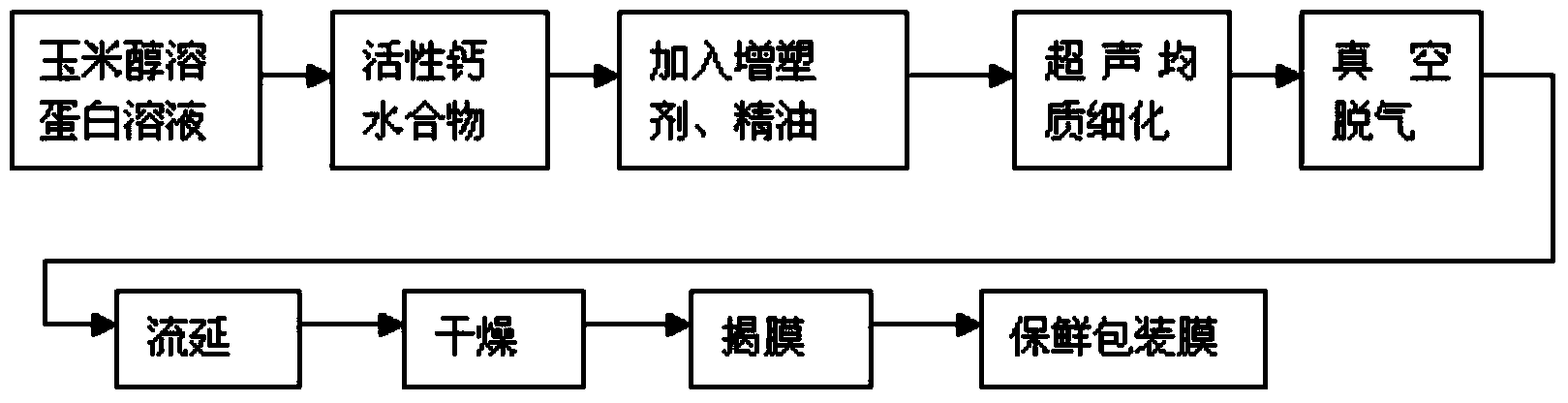

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a fresh-keeping packaging film with antibacterial and anti-oxidative functions, the fresh-keeping packaging film comprises the following components by mass: 5 parts of zein, 5 parts of active calcium, 88.5 parts of 80% ethanol, glycerin 1 part, clove oil 0.5 part. Specific steps are as follows:

[0028] (1) Preparation of zein solution: dissolve zein in 80% ethanol, stir to make it fully dissolve, and obtain zein solution;

[0029] (2) Preparation of active calcium hydrate: Calcinate the wastes in the food industry production process, such as egg shells and shells, at 1000°C for 3 hours to obtain active calcium with a particle size below 50 μm, and add a small amount of water to the active calcium In, make it absorb water, get active calcium hydrate;

[0030] (3) Add plasticizer and vegetable essential oil: mix zein solution and active calcium hydrate to obtain a mixed solution, then add glycerin and clove oil to the mixed solution, and mix to o...

Embodiment 2

[0038] A method for preparing a fresh-keeping packaging film with antibacterial and anti-oxidative functions, the fresh-keeping packaging film includes the following components in parts by mass: 10 parts of zein, 10 parts of active calcium, 77.5 parts of 80% ethanol, and 2 parts of alcohol, 0.5 part of mustard oil. Specific steps are as follows:

[0039] (1) Preparation of zein solution: dissolve zein in 80% ethanol, stir to make it fully dissolve, and obtain zein solution;

[0040] (2) Preparation of active calcium hydrate: Calcining the waste in the food industry production process, eggshells, shells, etc. at 1200 ° C for 2 hours to obtain active calcium, the particle size is below 50 μm, and adding a small amount of water to the active calcium In, make it absorb water, get active calcium hydrate;

[0041] (3) Adding plasticizer and plant essential oil: mixing zein solution and active calcium hydrate to obtain a mixed solution, then adding sorbitol and mustard oil to the m...

Embodiment 3

[0049] A method for preparing a fresh-keeping packaging film with antibacterial and anti-oxidative functions, the fresh-keeping packaging film includes the following components in parts by mass: 5 parts of zein, 20 parts of active calcium, 73 parts of 80% ethanol, glycerin 1.5 parts, oregano oil 0.5 parts. Specific steps are as follows:

[0050] (1) Preparation of zein solution: dissolve zein in 80% ethanol, stir to make it fully dissolve, and obtain zein solution;

[0051] (2) Preparation of active calcium hydrate: the waste in the food industry production process, eggshells, shells, etc., is calcined at 900 ° C for 3 hours to obtain active calcium, the particle size is below 50 μm, and a small amount of water is added to the active calcium to absorb water to obtain active calcium hydrate;

[0052] (3) Add plasticizer and vegetable essential oil: mix zein solution and active calcium hydrate to obtain a mixed solution, then add glycerin and oregano oil to the mixed solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com