Food fresh-keeping packaging bag and manufacturing method thereof

A food preservation and packaging bag technology, applied in the field of packaging bags, can solve the problems of large preservation time and inability to meet long-term preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

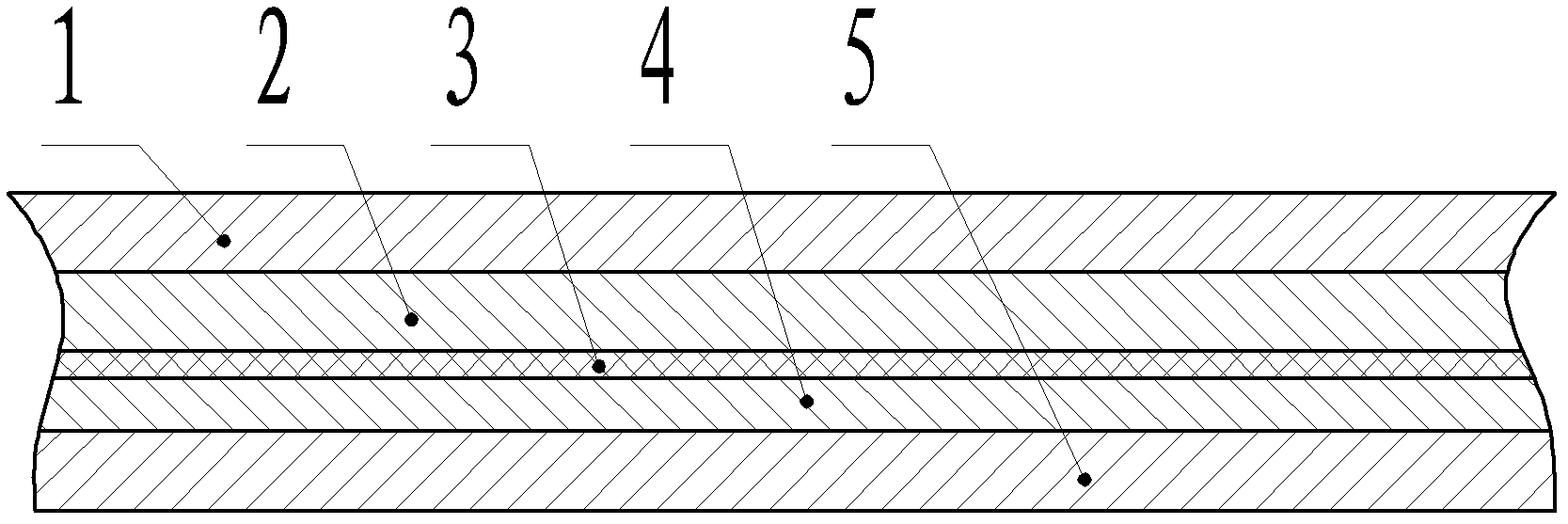

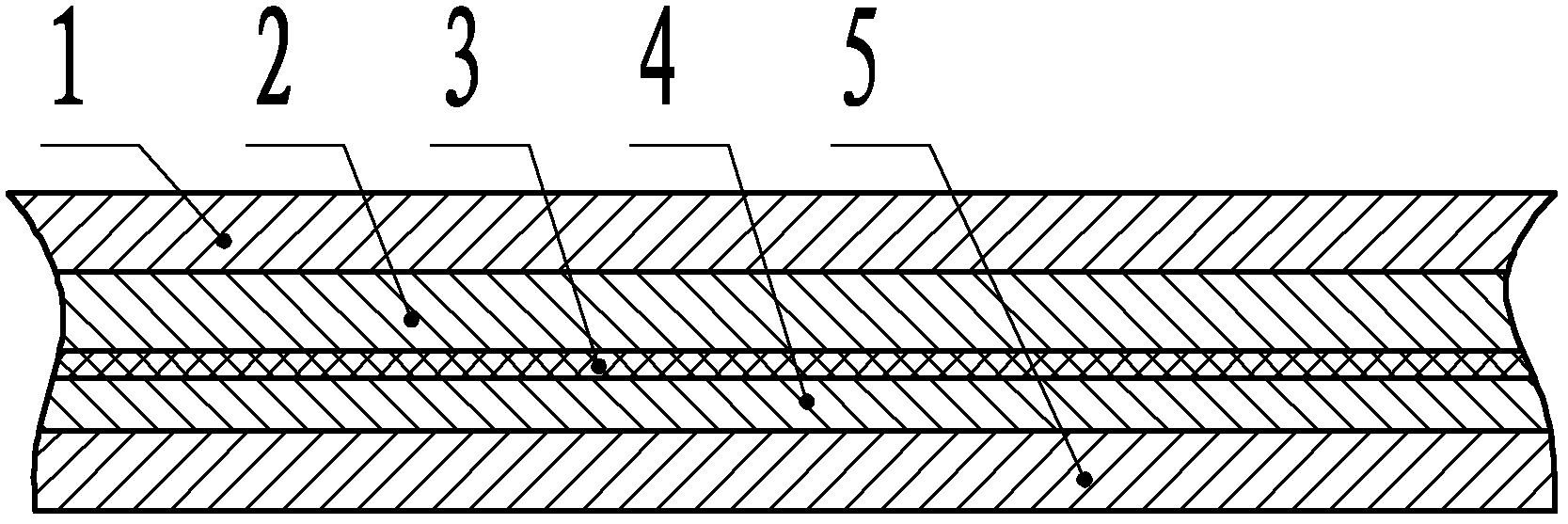

Image

Examples

specific Embodiment 1

[0020] A method for manufacturing the food fresh-keeping packaging bag, comprising the steps of:

[0021] 1) Composite high-barrier layer, apply the high-barrier material PVDC on the nylon film layer, form a high-barrier layer after drying, the drying temperature is 65°C, and wind the composite film into a roll;

[0022] 2) Print patterns, print patterns on the high barrier layer, dry the ink at a temperature of 55°C, and wind the ink into rolls after drying;

[0023] 3) Composite polyethylene film layer, apply polyurethane glue on the high barrier layer with a glue roller, dry at a temperature of 65 ℃, extrude and compound through an extrusion roller, wind it into a roll, put it into a curing room at 50 After curing for 48 hours at ℃, cool naturally;

[0024] 4) Make food preservation packaging bags on the bag making machine.

Embodiment 2

[0026] A method for manufacturing the food fresh-keeping packaging bag, comprising the steps of:

[0027] 1) Composite high-barrier layer, apply the high-barrier material PVDC on the nylon film layer, form a high-barrier layer after drying, the drying temperature is 70°C, and wind the composite film into a roll;

[0028] 2) Print patterns, print patterns on the high barrier layer, dry the ink at a temperature of 70°C, and wind the ink into rolls after drying;

[0029] 3) Composite polyethylene film layer, apply polyurethane glue on the high barrier layer with a glue roller, dry at a temperature of 70°C, extrude and compound through an extrusion roller, wind it into a roll, put it into a curing room at 70°C After curing for 48 hours at ℃, cool naturally;

[0030] 4) Make food preservation packaging bags on the bag making machine.

Embodiment 3

[0032] A method for manufacturing the food fresh-keeping packaging bag, comprising the steps of:

[0033] 1) Composite high-barrier layer, apply the high-barrier material PVDC on the nylon film layer, form a high-barrier layer after drying, the drying temperature is 68°C, and wind the composite film into a roll;

[0034] 2) Print patterns, print patterns on the high barrier layer, dry the ink at a temperature of 63°C, and wind the ink into rolls after drying;

[0035] 3) Composite polyethylene film layer, apply polyurethane glue on the high barrier layer with a glue roller, dry at a temperature of 68°C, extrude and compound through an extrusion roller, wind it into a roll, put it into a curing room at 60°C After curing for 48 hours at ℃, cool naturally;

[0036] 4) Make food preservation packaging bags on the bag making machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com