Covering film for medicinal PTP (press through packaging) and preparation method of covering film

A technology of blister packaging and covering film, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve problems such as poisoning, medicines are easy to be taken by children, single-layer aluminum foil is easy to break, etc., and the preparation method is simple Ease of operation, increased strength, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

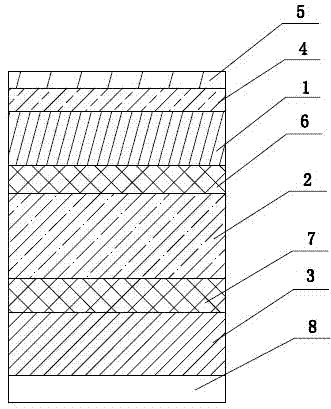

[0031] A cover film for medicinal blister packaging, which is composed of paper 1 with a dosage of 40 grams per square meter, a polyester film layer 2 with a thickness of 12 μm, and an aluminum foil 3 with a thickness of 20 μm. The outer surface of the paper 1 is arranged in sequence. There is an ink layer 4 and a varnish layer 5, a first adhesive layer 6 is arranged between the paper 1 and the polyester film layer 2, a second adhesive layer 7 is arranged between the polyester film layer 2 and the aluminum foil 3, and the aluminum foil 3 The other side is provided with a heat-sealing layer 8, and the heat-sealing layer 8 is uniformly sprayed with VC glue, and the amount of VC glue is 3.5 grams per square meter.

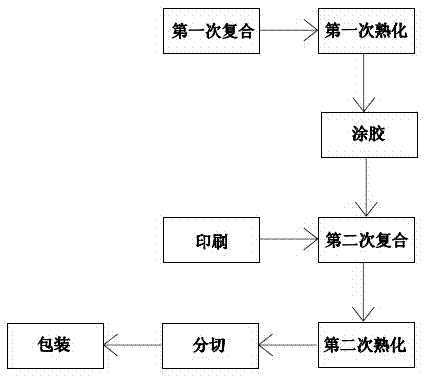

[0032] The preparation method of the cover film for blister packaging for traditional Chinese medicine in the present embodiment includes the following steps:

[0033] 1) Printing: The paper is sent to a gravure printing machine for printing, a printing layer is forme...

Embodiment 2

[0036] A cover film for medicinal blister packaging is composed of paper 1 with a dosage of 105 g / m2, a polyester film layer 2 with a thickness of 50 μm, and an aluminum foil 3 with a thickness of 60 μm, and the outer surface of the paper 1 is arranged in sequence. There is an ink layer 4 and a varnish layer 5, a first adhesive layer 6 is arranged between the paper 1 and the polyester film layer 2, a second adhesive layer 7 is arranged between the polyester film layer 2 and the aluminum foil 3, and the aluminum foil 3 The other side is provided with a heat-sealing layer 8, and the heat-sealing layer 8 is uniformly sprayed with VC glue, and the dosage of VC glue is 4.5 grams per square meter.

[0037] The preparation method of the cover film for blister packaging for traditional Chinese medicine in the present embodiment includes the following steps:

[0038]1) Printing: The paper is sent to a gravure printing machine for printing, a printing layer is formed on the outer surfac...

Embodiment 3

[0041] A cover film for medicinal blister packaging, which is composed of paper 1 with a dosage of 50 grams per square meter, a polyester film layer 2 with a thickness of 25 μm, and an aluminum foil 3 with a thickness of 35 μm. The outer surface of the paper 1 is arranged in sequence. There is an ink layer 4 and a varnish layer 5, a first adhesive layer 6 is arranged between the paper 1 and the polyester film layer 2, a second adhesive layer 7 is arranged between the polyester film layer 2 and the aluminum foil 3, and the aluminum foil 3 The other side is provided with a heat-sealing layer 8, and the heat-sealing layer 8 is uniformly sprayed with VC glue, and the amount of VC glue is 3.7 grams / square meter.

[0042] The preparation method of the cover film for blister packaging for traditional Chinese medicine in the present embodiment includes the following steps:

[0043] 1) Printing: The paper is sent to a gravure printing machine for printing, a printing layer is formed on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com