Method for preparing edible composite protein film

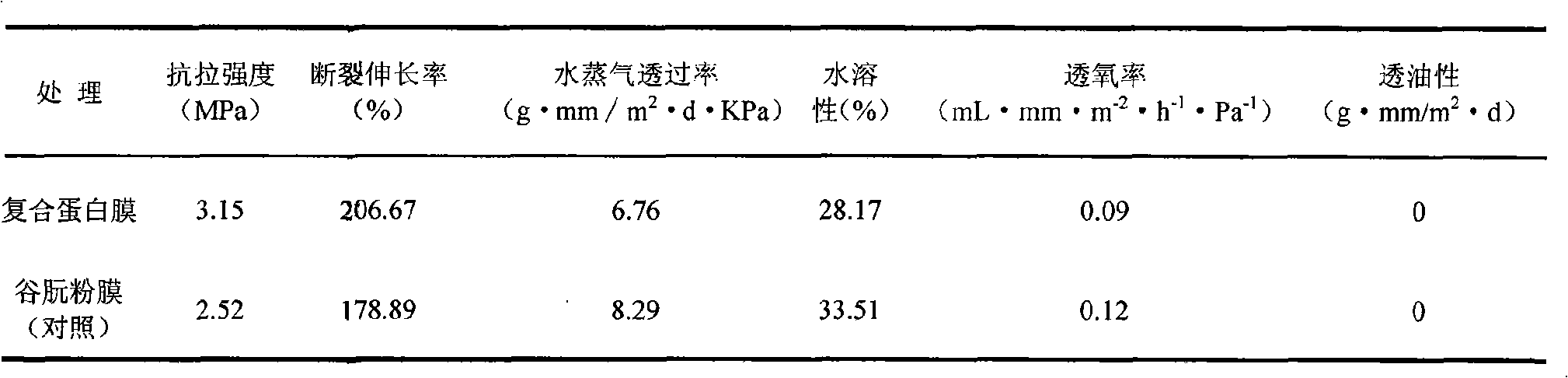

A composite protein and edible technology, which is applied in the field of preparation of edible composite protein film, can solve the problems of poor water resistance of edible protein film, insufficient mechanical strength of edible protein film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Step 1, the preparation of zein:

[0015] The corn gluten powder is crushed and passed through an 80-mesh sieve, dissolved in 80% ethanol solution according to the ratio of solid to liquid 1:6, adjusted to pH 12.0 with 10% NaOH solution, and stirred evenly. Under the action of ultrasonic waves with an ultrasonic power of 80 Hz, extract for 60 min, and take the supernatant after centrifugation. Dilute the ethanol concentration in the supernatant to 40% with deionized water, adjust the pH to 6.0 with 10% HCl solution, get the precipitate after centrifugation, wash the precipitate 3 times with deionized water, air-dry, ultrafine pulverize and pass 120 mesh sieve to obtain zein.

[0016] Step 2, preparation of gluten and zein composite membrane liquid

[0017] Mix zein and gluten, zein accounts for 20% of the total weight, adjust the weight of zein and gluten to account for 10% of the solution weight after dissolving in 50% ethanol solution, and uniformly Stir for 10 min...

Embodiment 2

[0028] Step 1, the preparation of zein:

[0029] The corn gluten powder is crushed and passed through a 60-mesh sieve, dissolved in 90% ethanol solution according to the ratio of solid to liquid 1:7, adjusted to pH 11.0 with 5% NaOH solution, and stirred evenly. Under the action of ultrasonic waves with an ultrasonic power of 100 Hz, extract for 45 min, and take the supernatant after centrifugation. Dilute the ethanol concentration in the supernatant to 45% with deionized water, adjust the pH to 5.0 with 5% HCl solution, get the precipitate after centrifugation, wash the precipitate twice with deionized water, air-dry, ultrafine pulverize and pass 100-mesh sieve to obtain zein.

[0030] Step 2, preparation of gluten and zein composite membrane liquid

[0031] Mix zein and gluten, zein accounts for 10% of the total weight, and after dissolving in 45% ethanol solution, adjust the weight of zein and gluten to account for 9% of the solution weight, at a uniform speed Stir for 1...

Embodiment 3

[0042] Step 1, the preparation of zein:

[0043]The corn gluten powder is crushed and passed through a 100-mesh sieve, dissolved in 70% ethanol solution according to the ratio of solid to liquid 1:5, adjusted to pH 13.0 with 15% NaOH solution, and stirred evenly. Under the action of ultrasonic waves with an ultrasonic power of 70 Hz, the extracts were extracted for 90 min, and the supernatant was obtained after centrifugation. Dilute the ethanol concentration in the supernatant to 35% with deionized water, adjust the pH to 6.5 with 15% HCl solution, get the precipitate after centrifugation, wash the precipitate 3 times with deionized water, air-dry, ultrafine pulverize and pass 140 mesh sieve to obtain zein.

[0044] Step 2, preparation of gluten and zein composite membrane liquid

[0045] Mix zein and gluten, zein accounts for 35% of the total weight, adjust the weight of zein and gluten to account for 11% of the solution weight after dissolving in 65% ethanol solution, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com