Flame-retardant ceramic slurry for lithium battery coating diaphragm and preparation method of flame-retardant ceramic slurry

A ceramic slurry and flame-retardant technology, which is applied to the field of flame-retardant ceramic slurry for lithium battery coating separator and its preparation, can solve the problems of increasing the thickness of the separator, general flame retardant effect, and reducing the production efficiency of the separator. The effect of preventing molten droplets, reducing combustion and explosion, and good fire retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

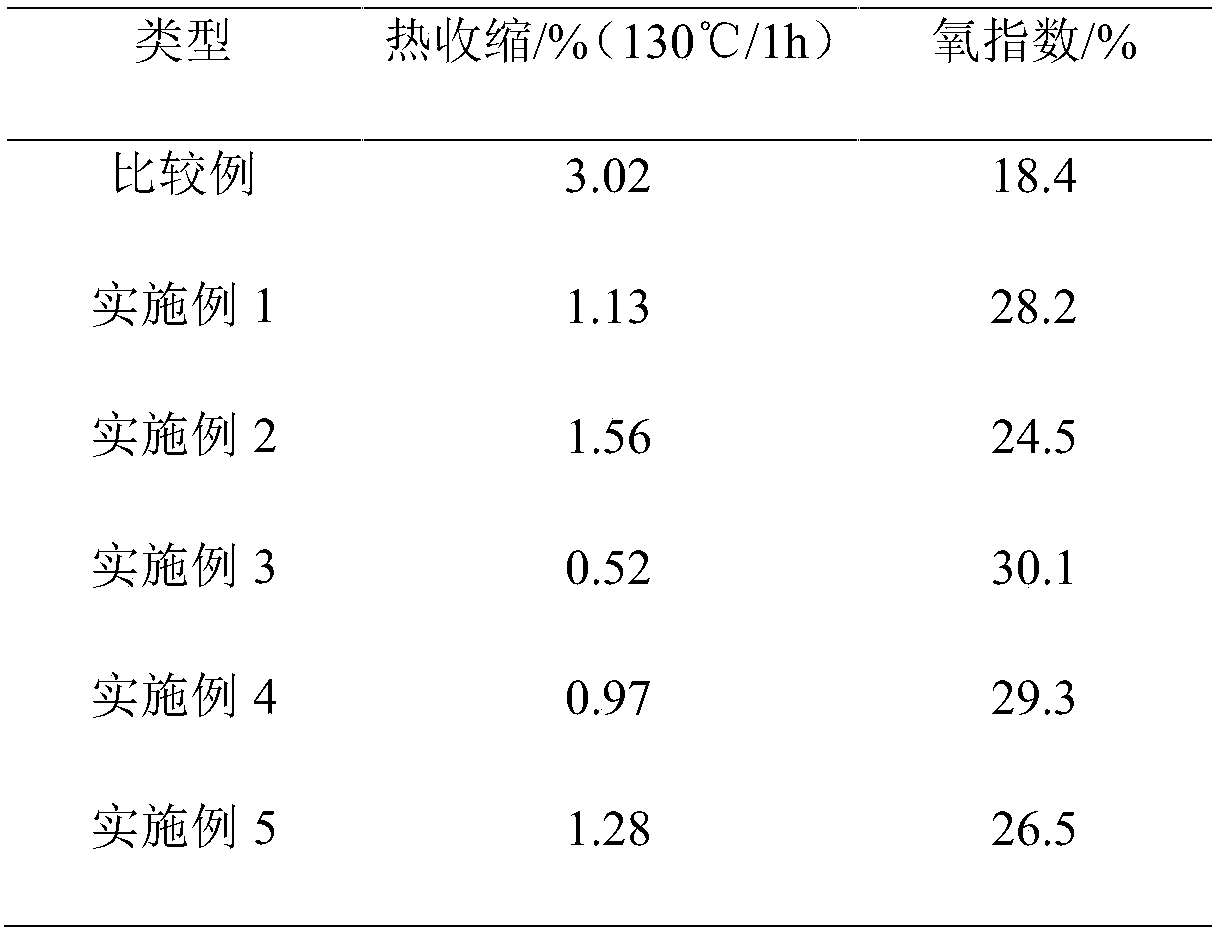

Examples

Embodiment 1

[0033] Add 40 parts of aluminum oxide, 0.5 part of sodium polyacrylate, 1 part of methyl cellulose, and 60 parts of water into a ball mill to disperse for 60 minutes to obtain a dispersion; add 0.5 parts of styrene-butadiene emulsion binder and 20 parts of bis( 2,6,7-Trioxa-1-phospha-bicyclo[2.2.2]octane-1-oxo-4-methyl)hydroxyphosphate melamine, using a disperser to stir for 5 minutes to obtain a flame-retardant ceramic slurry .

Embodiment 2

[0035] Add 20 parts of alumina, 0.05 parts of polyacrylate, 0.5 parts of hydroxypropyl methylcellulose, and 30 parts of water into a ball mill and disperse for 10 minutes to obtain a dispersion; add 1 part of polyacrylic acid binder and 5 parts of 3,9-Dihydroxy-3,9-dioxo-2,4,8,10-tetraoxa-3,9-diphosphaspiro[5,5]undecane-3,9-dimelamine , using a disperser to stir for 5 minutes to obtain a flame-retardant ceramic slurry.

Embodiment 3

[0037] Add 50 parts of boehmite, 1 part of polyethylene glycol, 2 parts of carboxymethyl cellulose, and 90 parts of water into a ball mill to disperse for 120 minutes to obtain a dispersion; add 6 parts of acrylic resin binder and 30 parts of A portion of 2-hydroxy-2-oxo-5,5-dimethyl-1,3-dioxa-1-phosphorinane-2-melamine was stirred for 60 minutes with a disperser to obtain a flame-retardant ceramic slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com