Foam cleaning method for drum washing machine

A technology of a drum washing machine and a washing method, which is applied to the control device of the washing machine, the washing device, textiles and papermaking, etc., which can solve the problems of foam generation and inability to complete washing smoothly, and achieve the effect of improving washing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

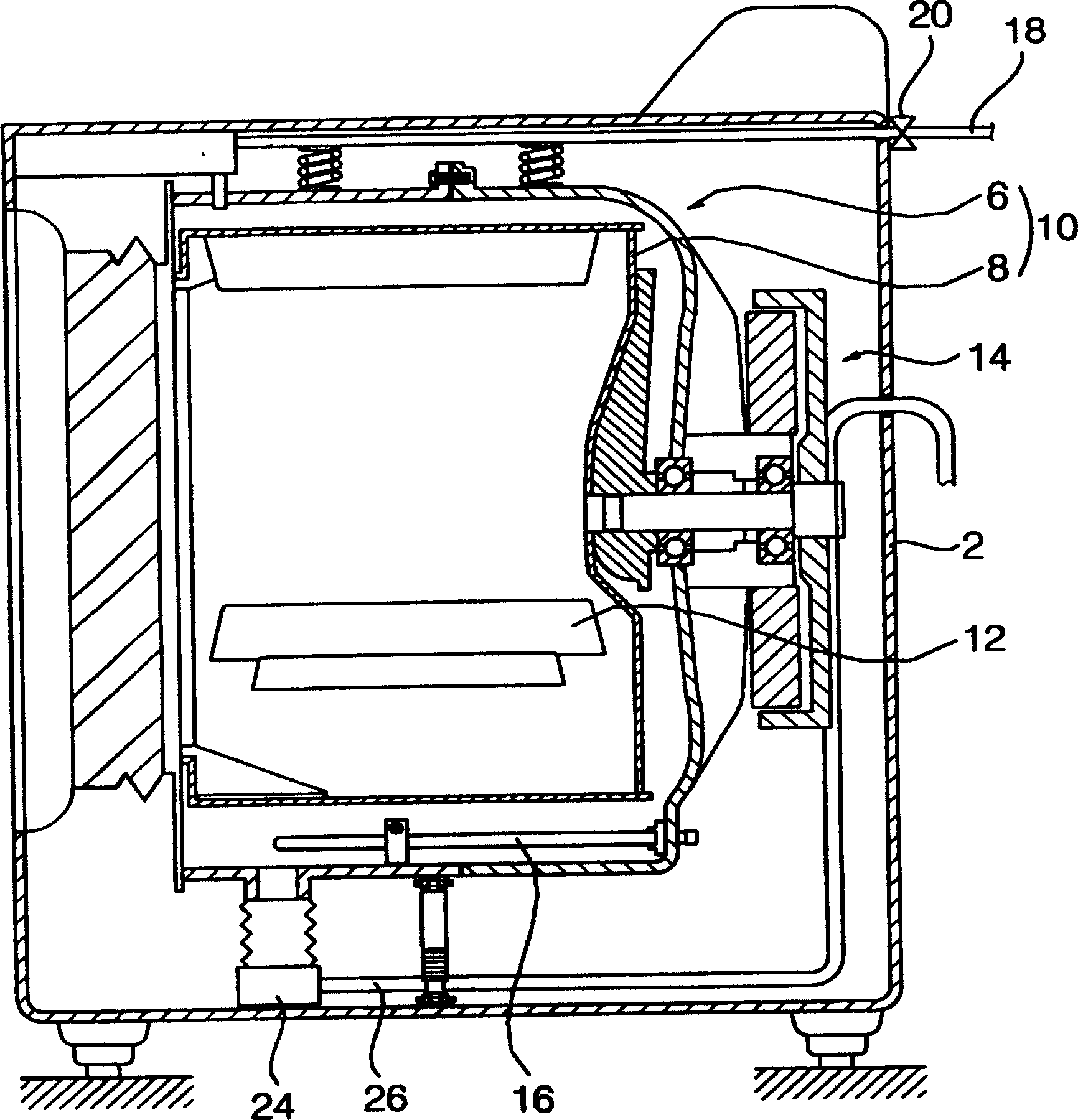

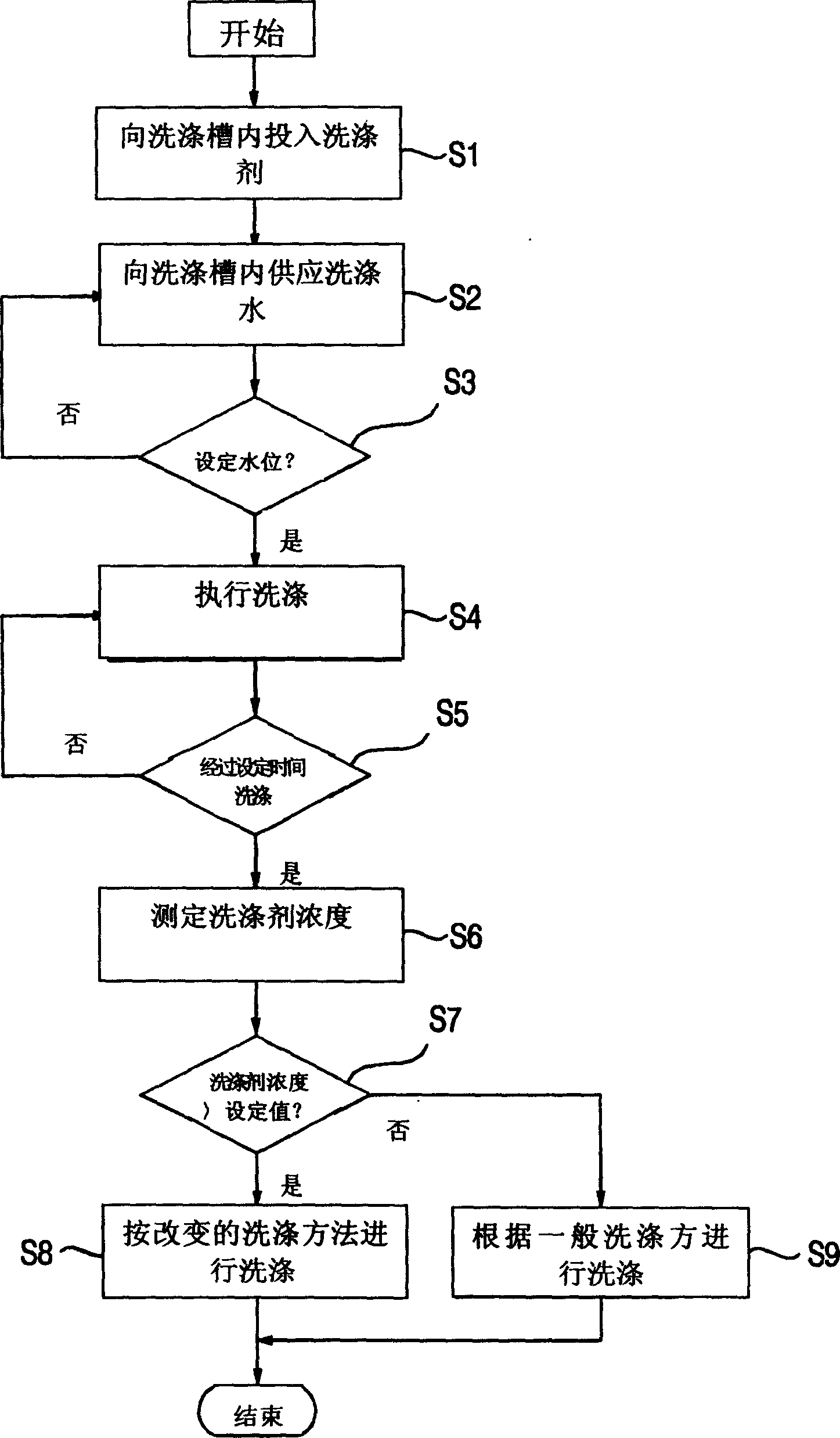

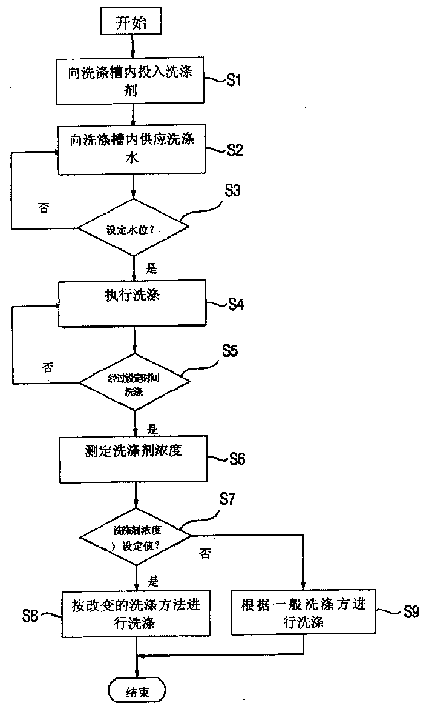

[0017] The foam removal method of the drum washing machine of the present invention will be described in detail with reference to the accompanying drawings and embodiments.

[0018] Such as figure 2 As shown, the foam removal method of the drum washing machine of the present invention is first, before washing in the first stage, put detergent into the washing tank 10 at a set water level and open the water supply valve 18 to supply washing water. (Refer to S1 and S2)

[0019] at this time, figure 2 Unspecified reference numbers are used with the above figure 1 same reference number.

[0020] The second stage is when the washing water in the first stage is supplied according to the set water level, and the washing is carried out according to the set time. (Refer to S3 and S4)

[0021] The third stage is to detect the concentration of detergent dissolved in the washing water after the set time of the second stage has passed. (Refer to S5 and S6)

[0022] At this time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com