Preservation method of fresh plants by combination of vacuum pre-cooling and acidic electrolyzed oxidizing water

A technology of oxidizing potential water and freshness, which is applied in the fields of fruit and vegetable preservation, fruit/vegetable preservation through freezing/refrigeration, food preservation, etc. It can solve the problems of dehydration of deli meat, poor freshness preservation effect, and reduced commodity value. Achieve the effect of reducing the breathing rate, better fresh-keeping effect, and reducing operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

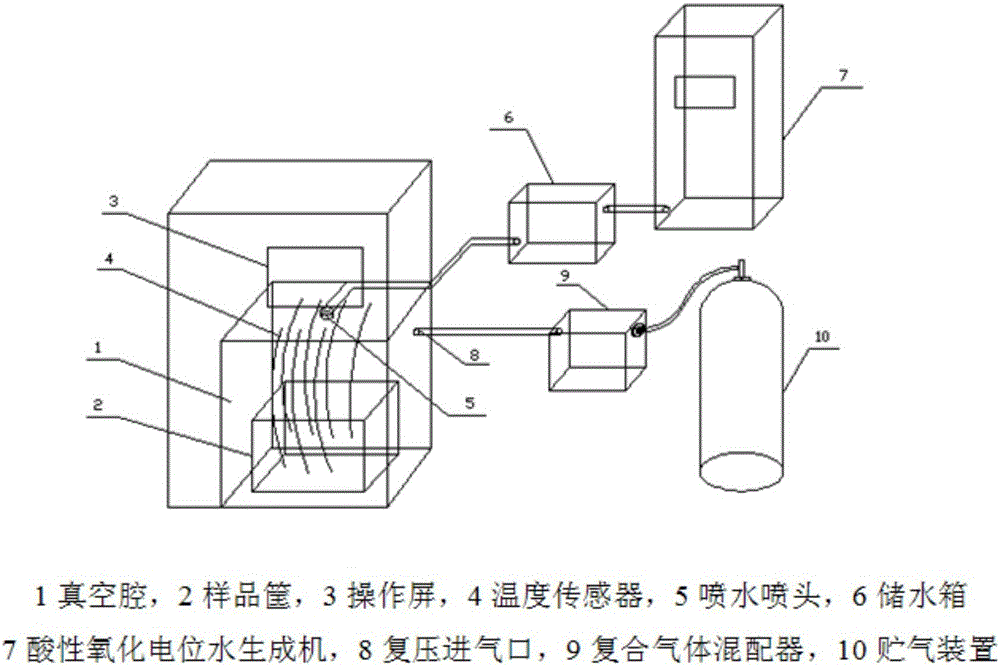

Embodiment 1

[0062] Select lettuce with uniform size, uniform maturity, and no obvious defects, and pre-cool it within 3 hours after harvesting, stack the lettuce neatly in the sample basket, and put it into a pre-cooling vacuum machine (Dongguan Kemeisi Refrigeration Equipment Co., Ltd., VC-1601) in the vacuum chamber for pre-cooling treatment, the pre-cooling time is set to 12min through the operation panel, and the final pre-cooling temperature is 1°C. Turn on the acidic oxidation potential water generator (Guangzhou Meimei Medical Technology Co., Ltd., AEOW-2000), after pre-cooling for 5 minutes, start the first stage to spray acidic oxidation potential water, the duration is 30s, the holding time and the second stage to spray acidic oxidation potential water The time is 20s, and the repressing time is 1min. After the pre-cooling final temperature is reached, repressurization is carried out immediately: the pre-mixed gas (Dansensor gas mixer: Denmark Dansensor company, MAPMixProV3-Gas)...

Embodiment 2

[0066] Choose green peppers with consistent maturity, clean, fresh, crisp and tender, free from rot, odor, chilling damage, freezing damage, and machine damage as raw materials, and pre-cool them within 3 hours after picking, stack the green peppers neatly in the sample basket, and put them in the pre-cooling The pre-cooling treatment is carried out in the vacuum chamber of the vacuum machine (Dongguan Kemeisi Refrigeration Equipment Co., Ltd., VC-1601). The pre-cooling time is set to 40 minutes through the operation panel, and the final pre-cooling temperature is 15°C. Turn on the acidic oxidation potential water generator (Guangzhou Meimei Medical Technology Co., Ltd., AEOW-2000), pre-cool for 10 minutes and start the first stage of spraying acidic oxidation potential water, the duration of 150s, the holding time and the second stage of spraying acidic oxidation potential water The time is 60s, and the repressing time is 3min. After the pre-cooling final temperature is reach...

Embodiment 3

[0070] Choose broccoli with the same maturity and size, uniform color, no obvious defects, no mechanical damage, diseases and insect pests, and stack them neatly in the sample basket, and put them into the pre-cooling vacuum machine (Dongguan Kemeisi Refrigeration Equipment) within 3 hours after harvesting. Co., Ltd., VC-1601) vacuum pre-cooling treatment is carried out in the vacuum chamber, the pre-cooling time is set to 21min through the operation panel, and the final pre-cooling temperature is 5°C. Turn on the acidic oxidation potential water generator (Guangzhou Meimei Medical Technology Co., Ltd., AEOW-2000). After 7 minutes of pre-cooling, start the first stage of spraying acidic oxidation potential water for 90s, the holding time and the second stage of spraying acidic oxidation potential water for 40s, and the repressurization time for 2 minutes. After the pre-cooling final temperature is reached, repressurization is carried out immediately after the pre-cooling final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com