Soil-free culture system with closed ecological tank and application thereof

A technology for soilless cultivation and ecological trough, which is applied in the field of closed ecological trough soilless cultivation system, can solve the problems of soil pollution, difficulty in making full use of water, and unfavorable large-scale promotion of soilless cultivation. Wide-ranging and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

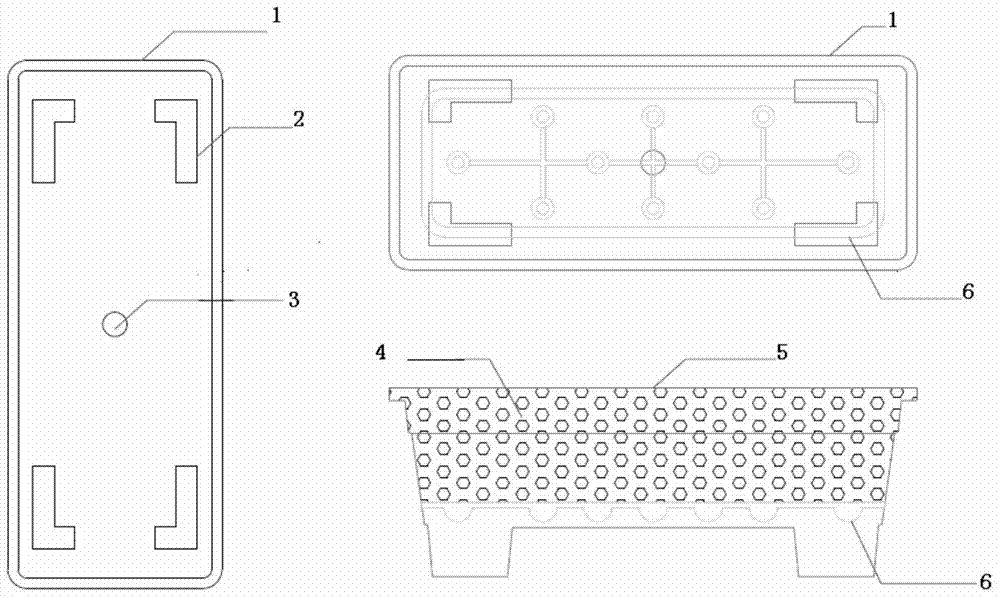

[0041] This embodiment relates to a closed ecological tank soilless cultivation system, which includes two parts: a cultivation system and a water circulation system. The cultivation system is as follows: figure 1 As shown, it comprises a three-dimensional trapezoidal cultivation tank 1 of the high foot type, supports a high foot 2, a porous partition 6 arranged successively from bottom to top in the cultivation groove, a porous material (not shown) that plays a filtering role, and a cultivation tank. Substrate 4 and a cover plate 5 with a planting hole, the cover plate completely covers the opening of the cultivation tank, and the lower surface of the cultivation tank is provided with a downwardly protruding cylindrical drainage outlet 3;

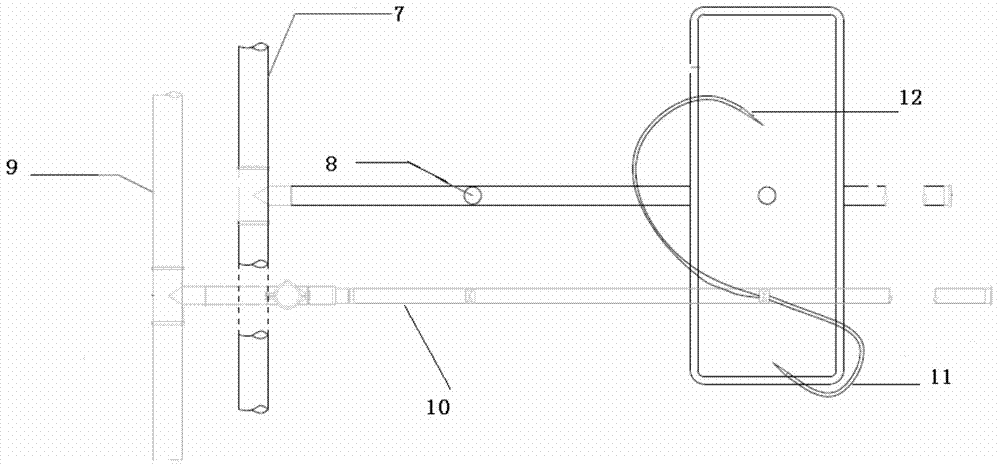

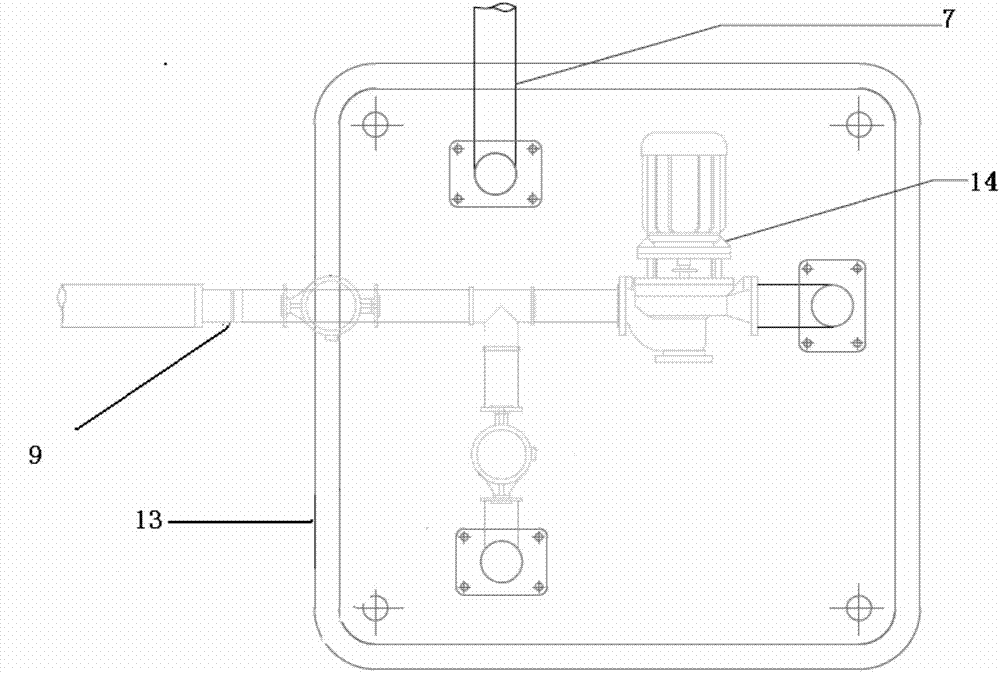

[0042] Described water circulation system comprises supplying nutrient solution pond 13, water pump 14 (as image 3 shown), a water supply main pipe 9, a water supply branch pipe 10, a water supply capillary hose 11, a return water branch ...

experiment example 1

[0049] Closed ecological groove cultivation tomato

[0050]Experimental design: There are two treatments of total closed circulation matrix groove culture and traditional "M" drip irrigation soil culture under film, and each treatment is repeated three times.

[0051] "M" drip irrigation cultivation under film film before planting, combined with site preparation, general application of high-quality decomposed organic fertilizer 4000-5000 kg per mu, 50 kg of compound fertilizer, deep plowing 20 cm,

[0052] Make a furrow after leveling the land, the height of the furrow is 15cm, the width of the furrow is 70cm, and the width of the furrow is 50cm. The daily management of fertilizer and water is in accordance with the technical specifications for spring tomato cultivation in energy-saving solar greenhouses (Liu Mingchi, Chen Diankui. Technical specifications for spring tomato cultivation in energy-saving solar greenhouses. Vegetable World, 1997(10):39-40), and the water consumpt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com