Patents

Literature

68results about How to "High preparation precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

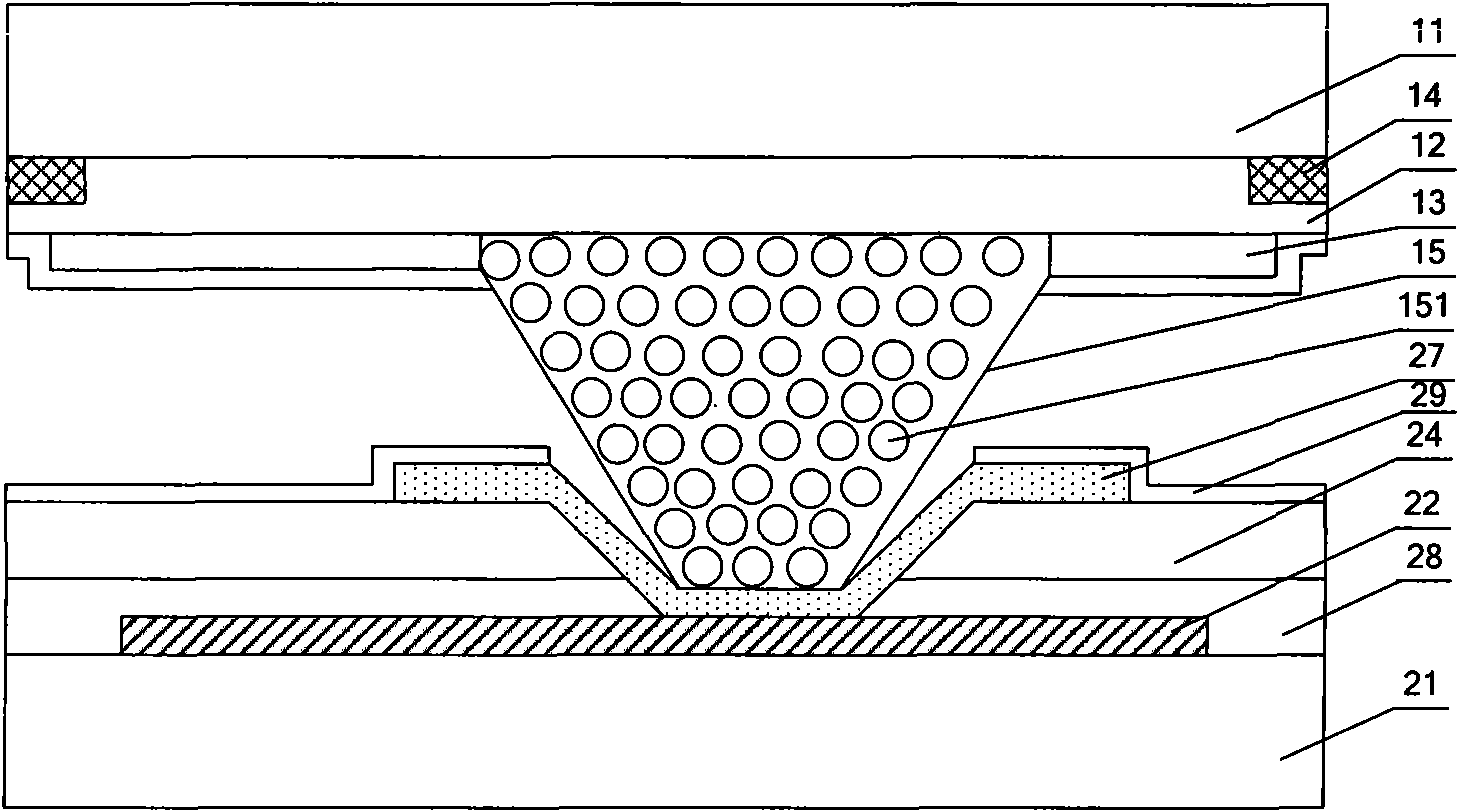

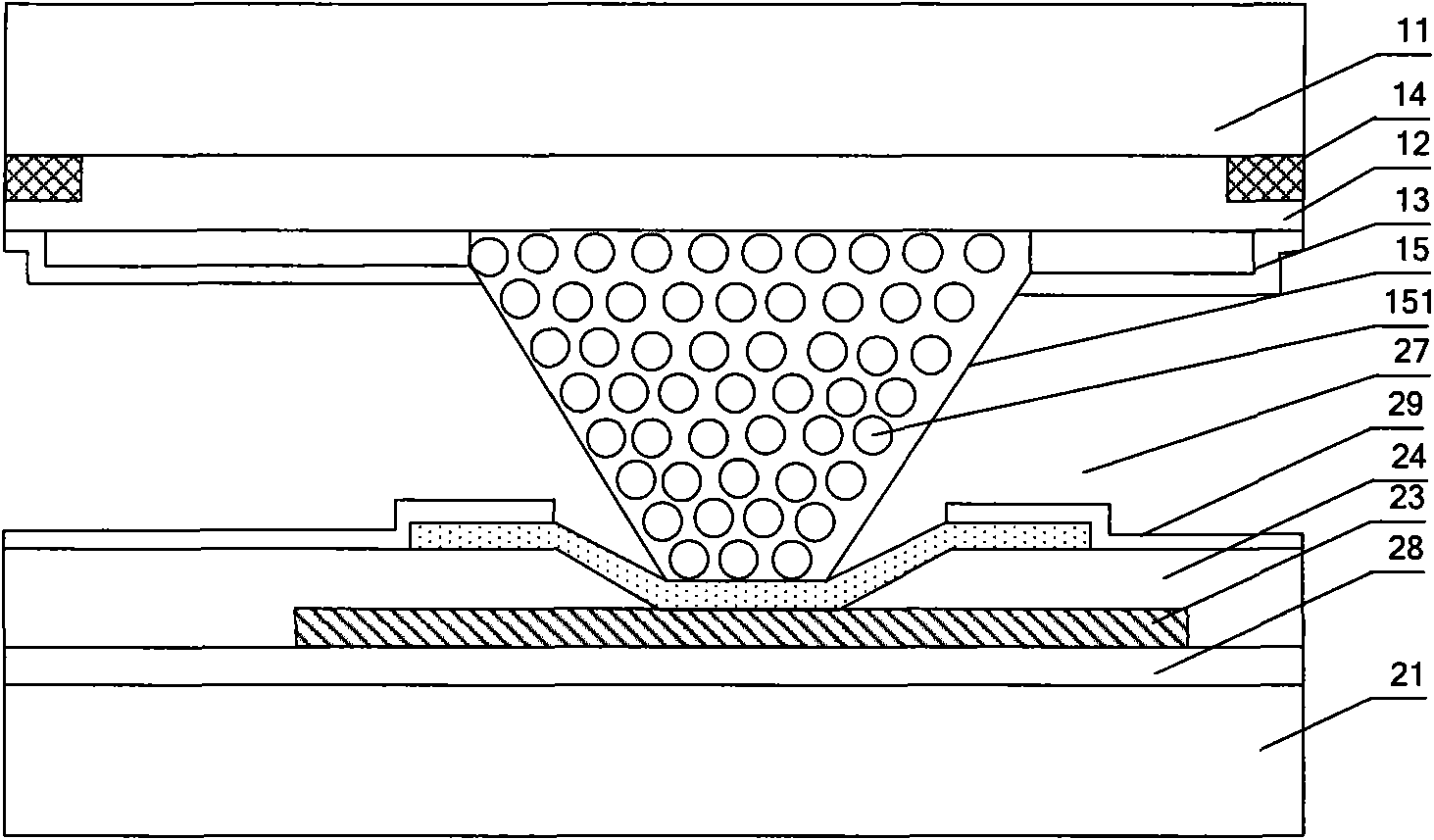

Touch display screen and manufacture method thereof

InactiveCN101825787AImprove color stabilityHigh preparation precisionStatic indicating devicesSolid-state devicesLiquid-crystal displayVoltage

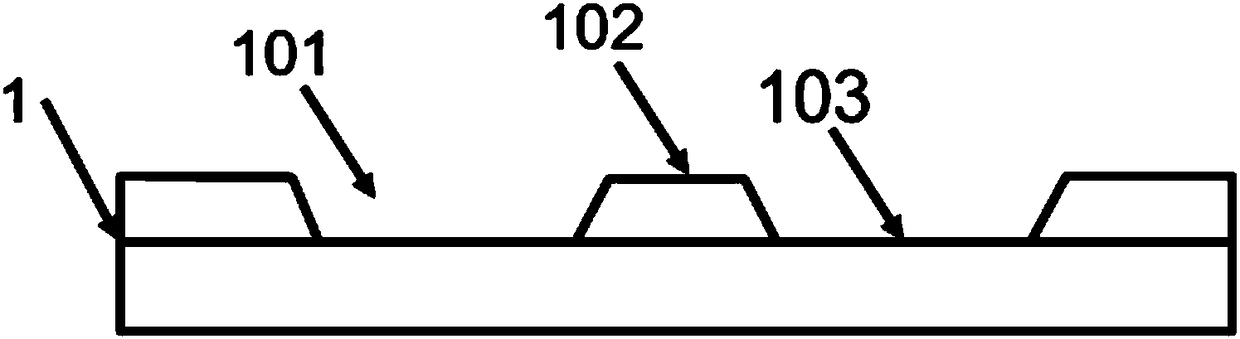

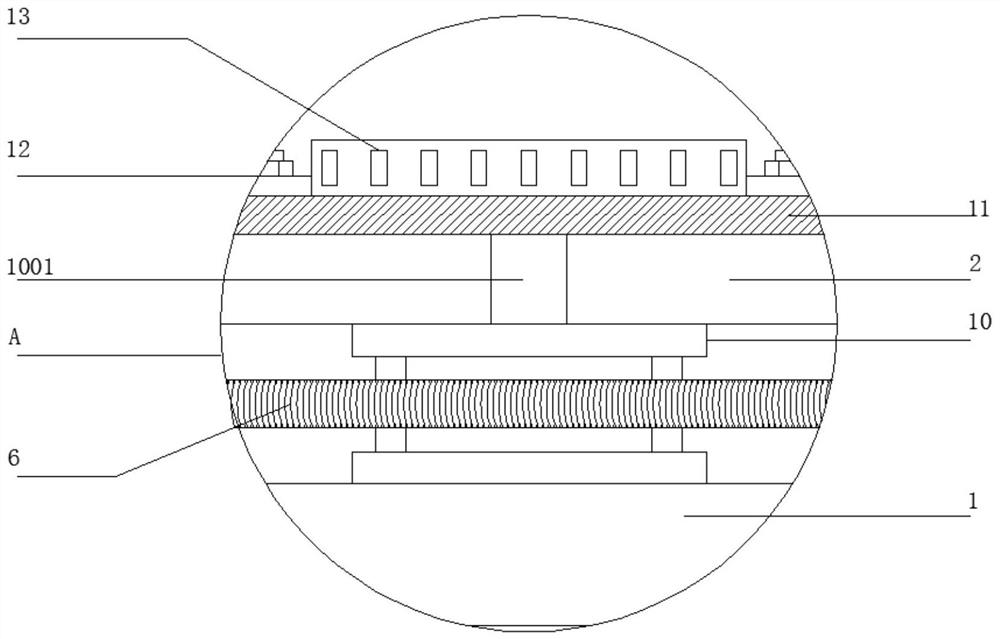

The invention discloses a touch display screen and a manufacture method thereof, relating to the field of liquid crystal display and solving the technical problems of high manufacture cost because two screens need to be manufactured for the touch display screen. The touch display screen comprises a color film substrate and an array substrate arranged corresponding to the color film substrate, wherein the color film substrate comprises an upper substrate and a common electrode formed on the upper substrate; the array substrate comprises a lower substrate and a grid line, a data link and a pixel electrode which are formed on the lower substrate; the common electrode is provided with a plurality of spacers which butt against the grid line or the data link and enables the common electrode to be respectively electrically conducted with the grid line and the data line under the action of pressure; the touch display screen also comprises a voltage detection circuit; the voltage detection circuit is connected with the grid line and the data line and is used for detecting whether voltages on the grid line and the data line are equal to the voltage of the common electrode or not. The invention is applied to the touch display screen of a liquid crystal display.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

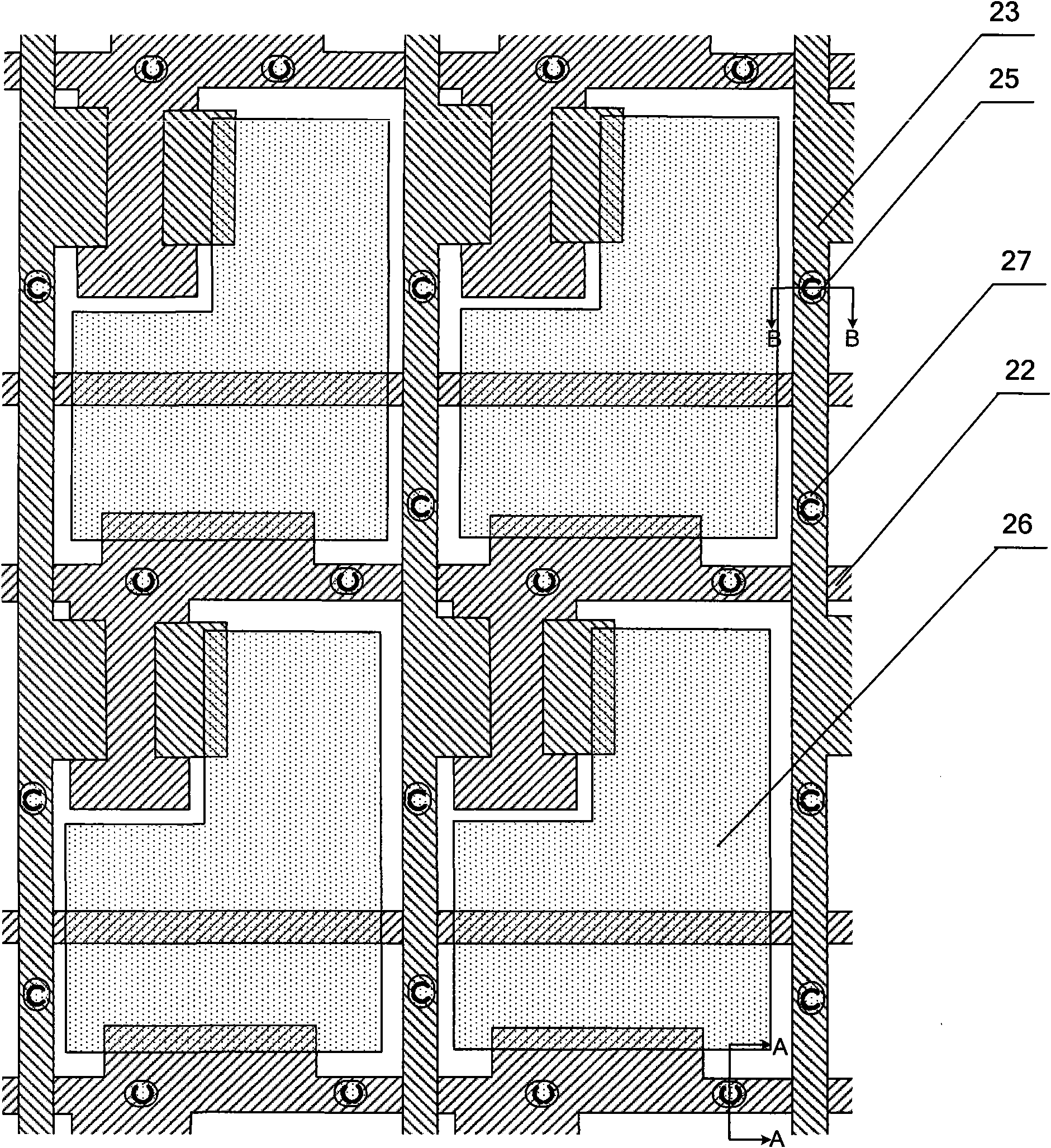

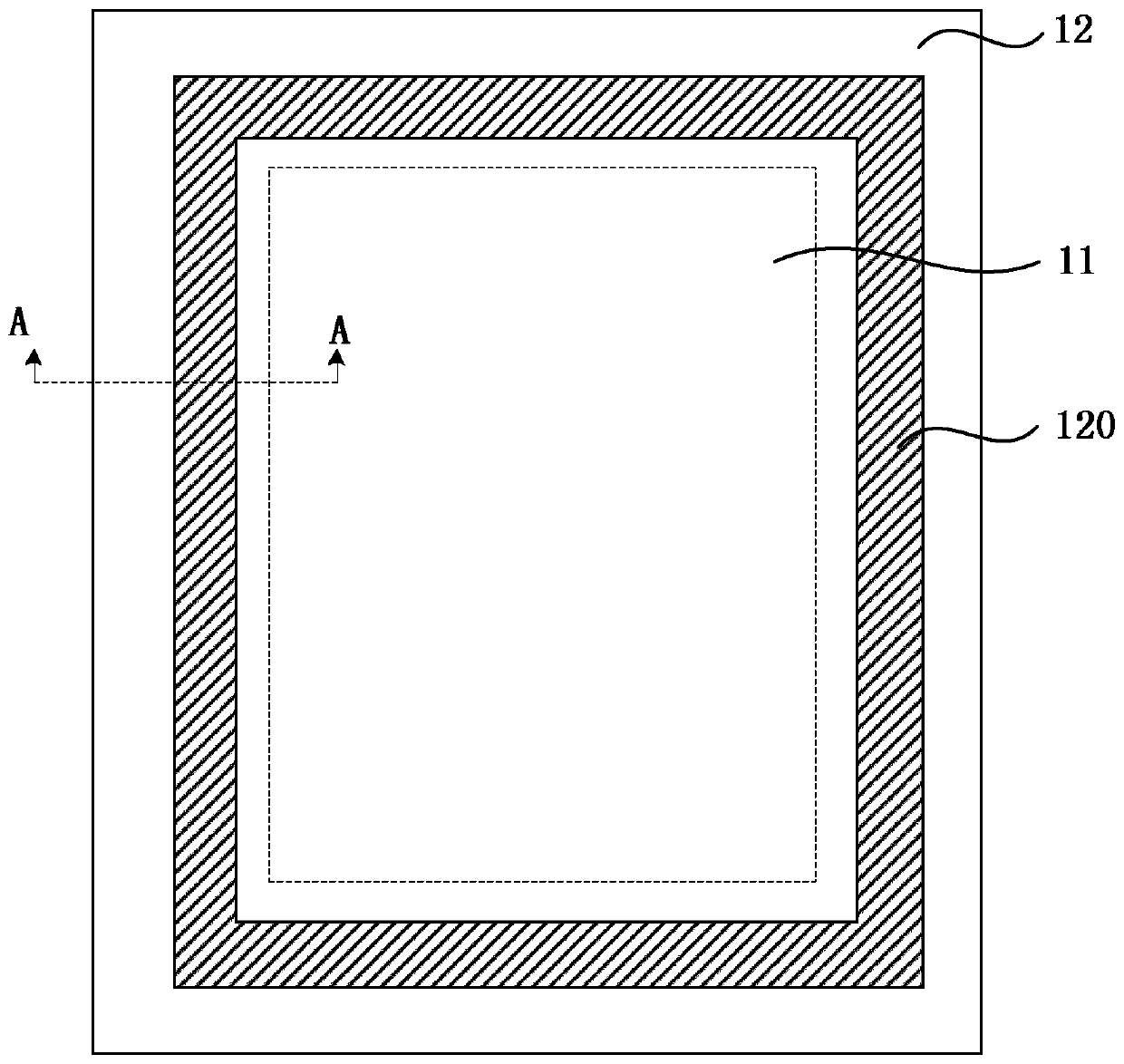

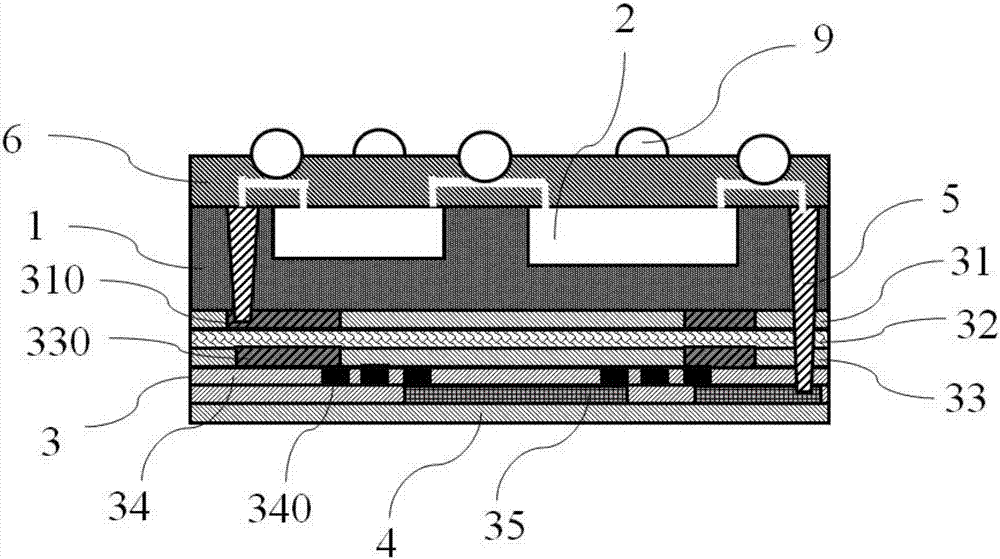

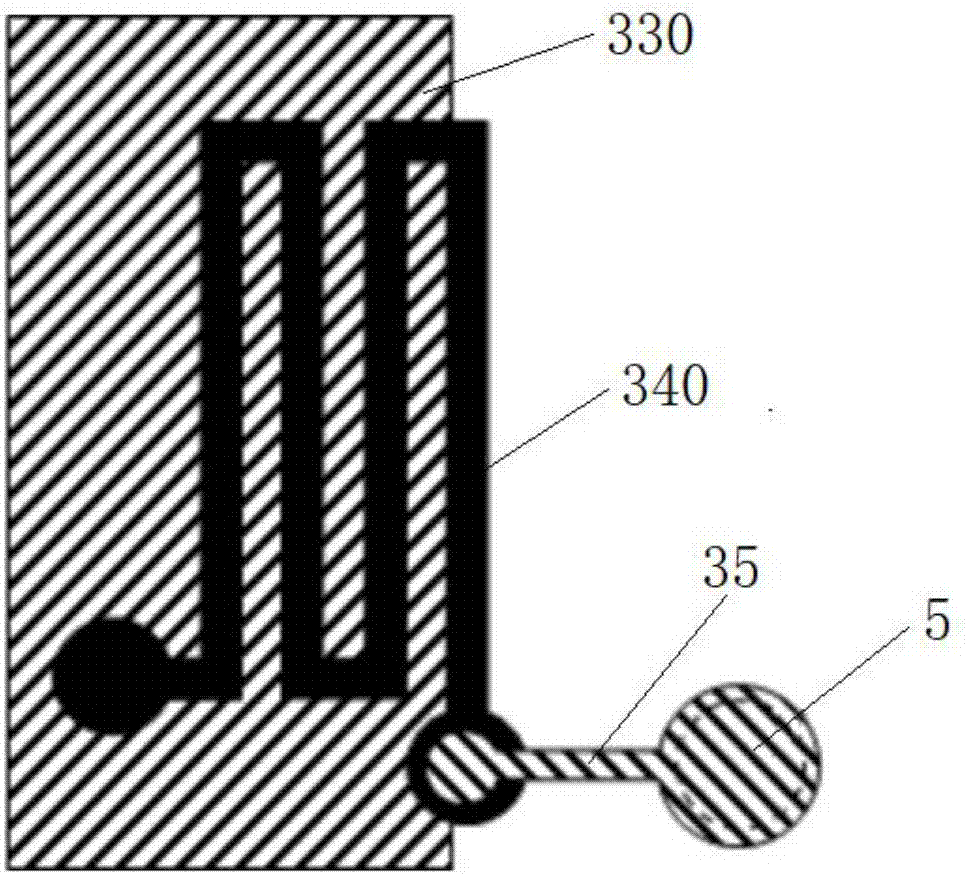

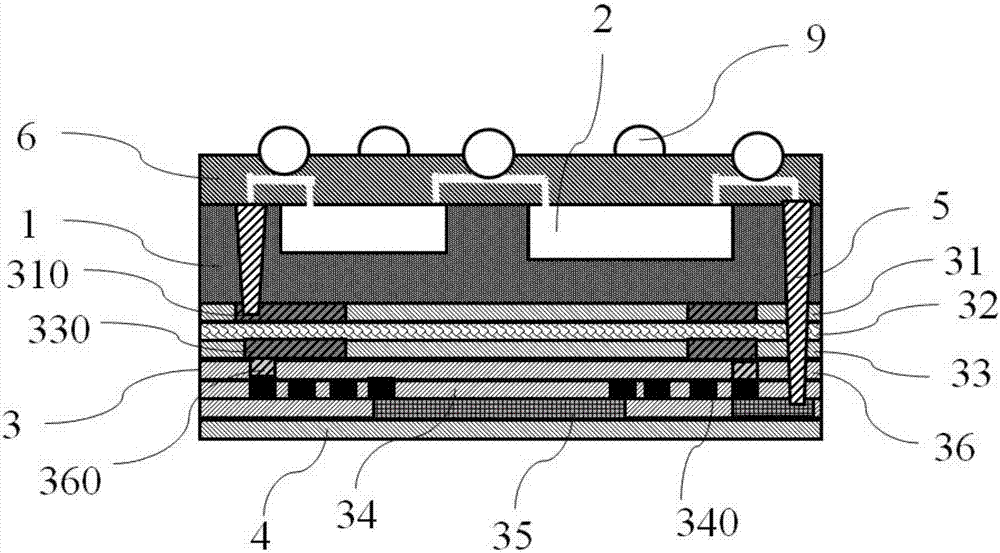

Display panel, display device and preparation method of display panel

InactiveCN109713023AReduce borderReduce production processSolid-state devicesSemiconductor/solid-state device manufacturingBlock effectDisplay device

The invention discloses a display panel, a display device and a preparation method of the display panel. The display panel comprises a substrate. The substrate comprises a display area and a non-display area surrounding the display area. The non-display area is provided with a retaining wall, and the retaining wall surrounds the display area. The display area is provided with a planarization layer, a pixel definition layer and supporting columns. The pixel definition layer is arranged on one side, far away from the substrate, of the planarization layer. The supporting columns are arranged on one side, far away from the substrate, of the pixel definition layer. The retaining wall, the supporting columns and at least one layer of the pixel definition layer and the planarization layer are made of the same material. According to the scheme of the embodiment of the invention, the preparation precision of the retaining wall is improved. The blocking effect of the retaining wall on a thin film packaging layer is ensured, and the frame of the display panel is reduced.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

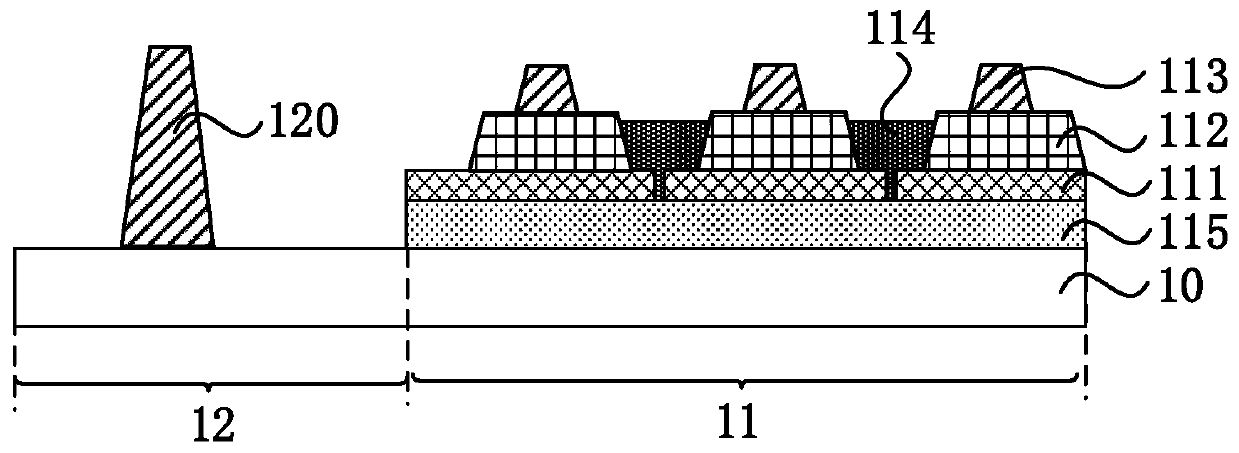

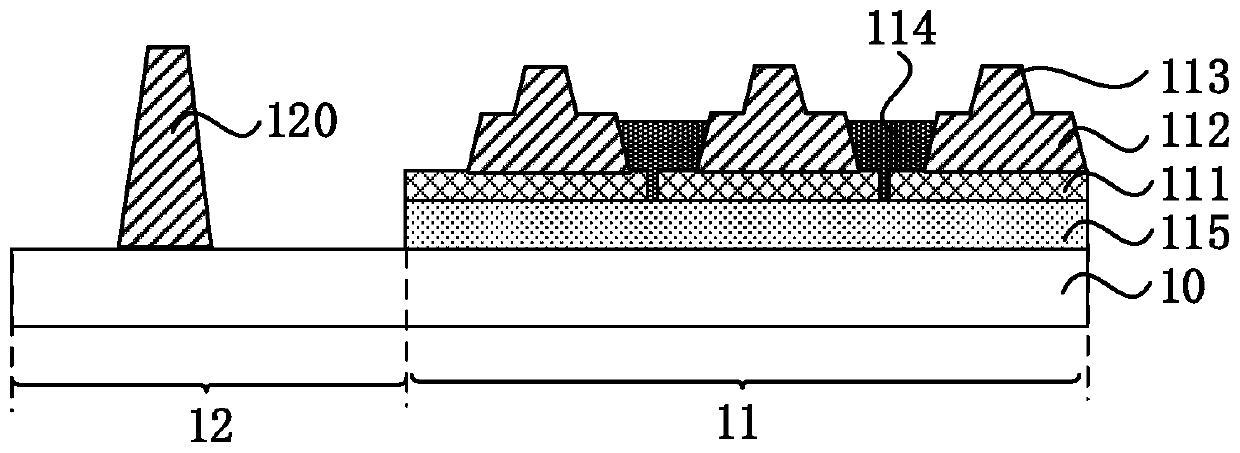

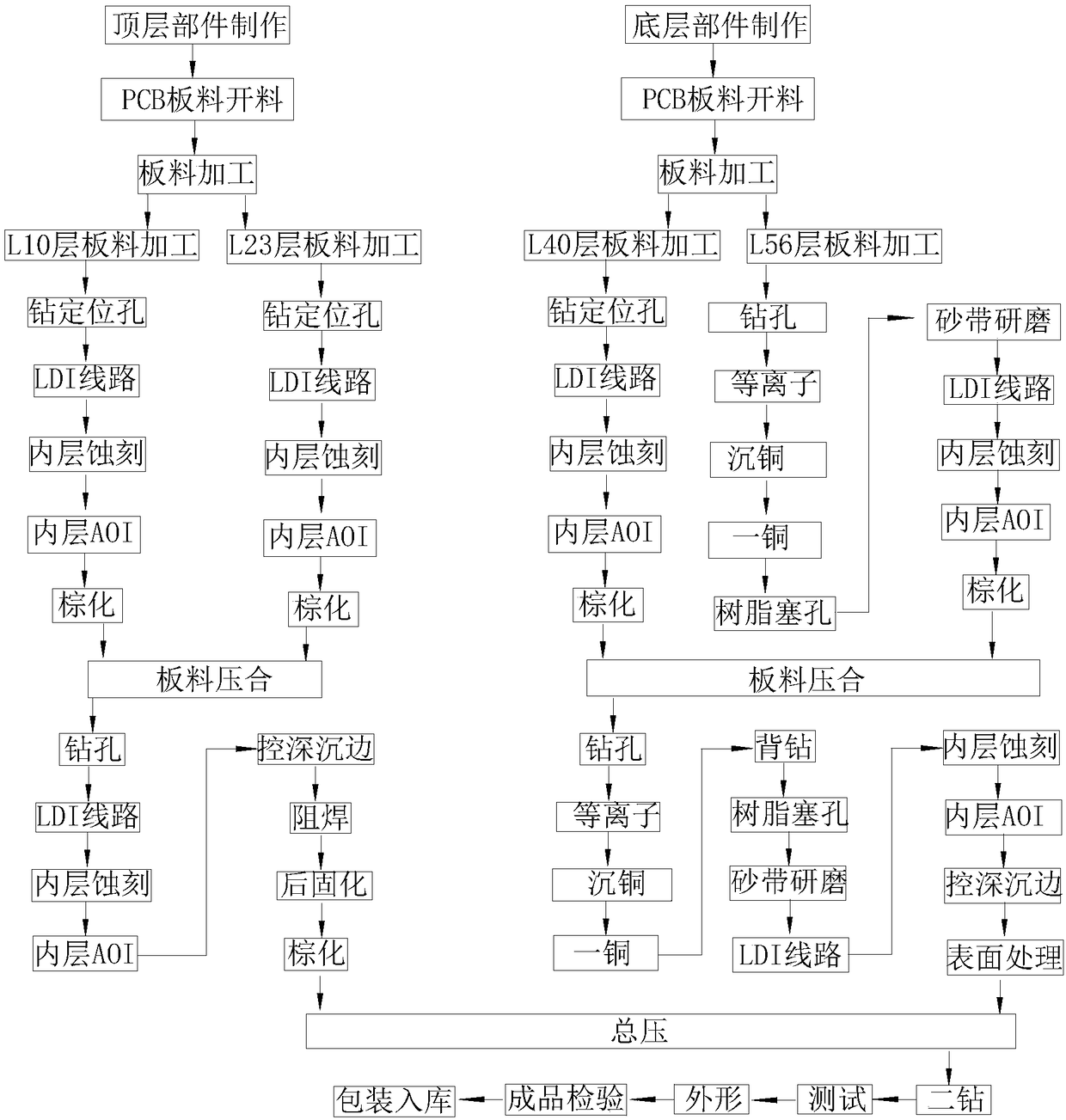

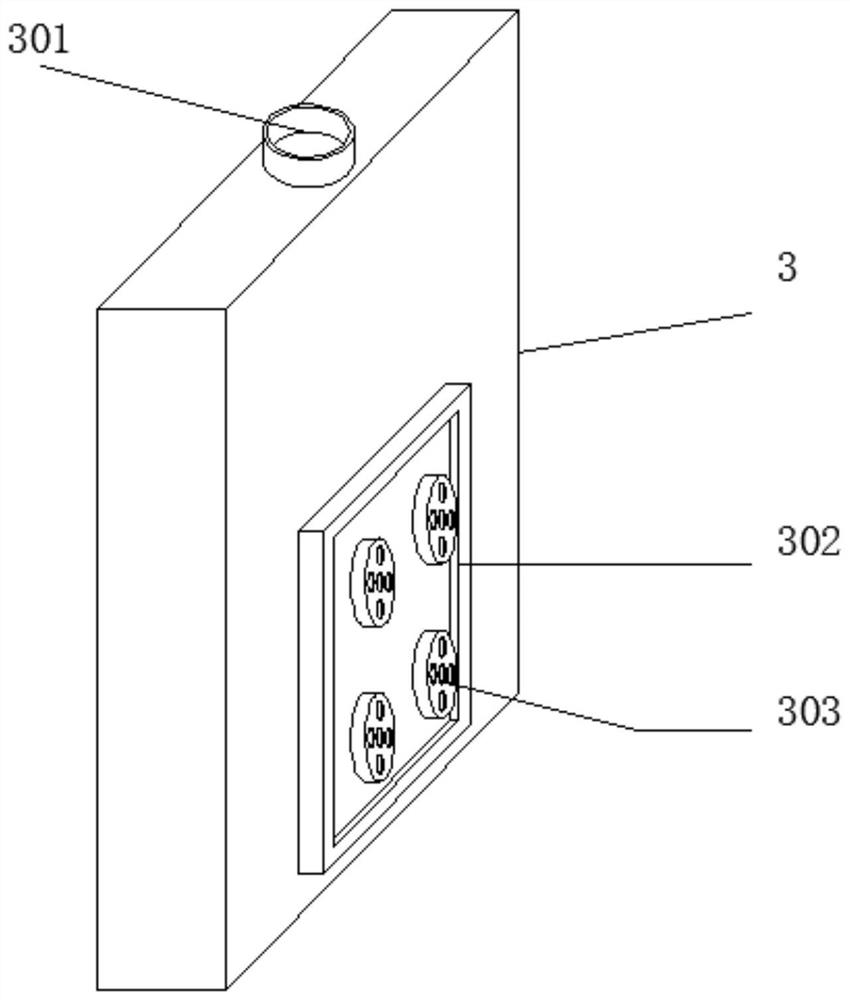

Ultra-thick 5G antenna PCB module processing method

ActiveCN108513458AReduce the difficulty of processingImprove product quality and precisionPrinted circuit aspectsInsulating layers/substrates working5GMaterials processing

The present invention discloses an ultra-thick 5G antenna PCB module processing method. The method comprises the following steps: (1) manufacturing a top layer part; (2) manufacturing a bottom layer part; and (3) manufacturing a finished product. The manufacture of the top layer part and the manufacture of the bottom layer part both comprise cutting, plate material processing and plate material pressing. According to the method, by optimizing the structure and the preparation process of an ultra-thick 5G antenna PCB module, the process difficulty is reduced, the machinable plate thickness reaches to 7-12 mm, the circuit, electroplating and etching requirement(s) of an ultra-thick plate can be effectively satisfied by using a conventional device, the preparation precision of the product isimproved, so that the shape deviation of the finished product is small, and thus the yield rate of the product is improved.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

Preparation method of molybdenum metal grille

ActiveCN109014230AHigh sphericityIncrease heatAdditive manufacturing apparatusIncreasing energy efficiencyUltimate tensile strength3d printer

The invention discloses a preparation method of a molybdenum metal grille. The preparation method comprises the steps of 1, conducting cold isostatic pressing, high-temperature sintering, hot fine forging and straightening treatment on molybdenum powder to obtain a molybdenum rod; 2, machining the molybdenum rod into spherical molybdenum powder through plasma rotating electrode powder manufacturing equipment; and 3, preparing a molybdenum metal grille molded part with the spherical molybdenum powder as a raw material through a powder bed electron beam 3D printer and then conducting annealing,hot isostatic pressing and alkaline washing in sequence to obtain the molybdenum metal grille. According to the preparation method, the molybdenum powder is prepared into the spherical molybdenum powder; the molybdenum metal grille is prepared through the powder bed electron beam 3D printer; according to the characteristics that the spherical molybdenum powder is good in fluidity, compact and uniform in particle and tight in combination after quick melting and the heat of electron beams is high, the defects that molybdenum metal is high in strength, low in plasticity, very easy to oxidize andpoor in formability and is not likely to be machined into complex structural parts and functional parts are overcome, the specification and using properties of the molybdenum metal grille are improved, and the preparation cost is saved.

Owner:JINDUICHENG MOLYBDENUM CO LTD

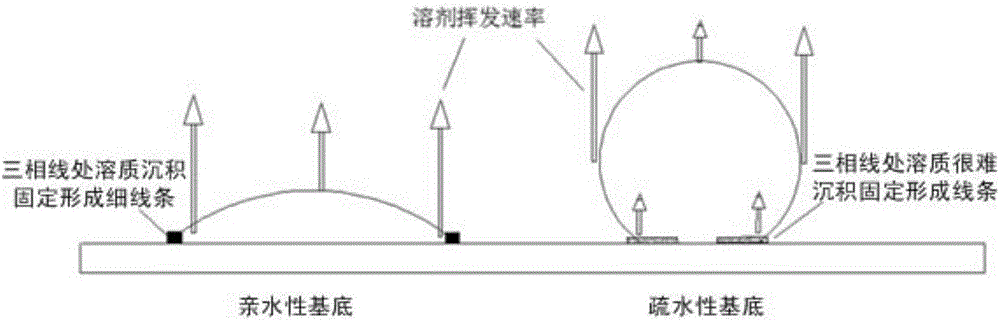

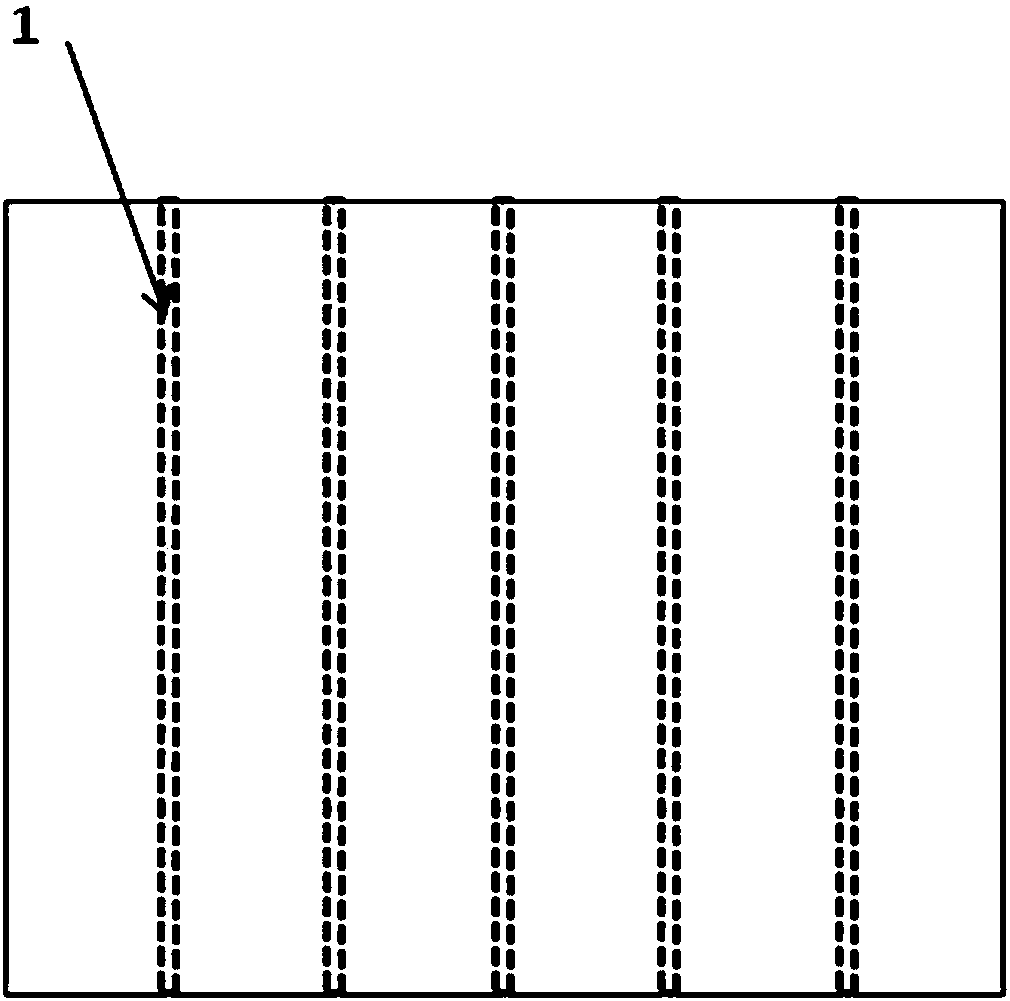

Touch screen manufacturing method, touch screen and displaying device

InactiveCN106648259AIncrease widthImprove adhesionPretreated surfacesCoatingsWire widthDisplay device

The invention provides a touch screen manufacturing method, a touch screen, and a displaying device. The touch screen manufacturing method includes: a step S10, modifying a substrate surface so as to allow the substrate surface to possess hydrophilic performance; and a step S11, adopting an ink-jet printing method to print graphene composite nano silver slurry on a substrate of the step S10 so as to form a latticed touch control electrode. The graphene composite nano silver touch control electrode acquired by the touch screen manufacturing method has a small wire width, has lower sheet resistance and excellent flexibility, and is low in manufacturing cost; the manufacturing precision of the touch control electrode is improved; a larger grid width can be acquired, and the higher light transmittance can be achieved; and in addition, the adhesive force of the graphene composite nano silver on the substrate surface is enhanced, the conductivity of the raphene composite nano silver touch control electrode is excellent, and circuit break can be avoided.

Owner:BOE TECH GRP CO LTD +1

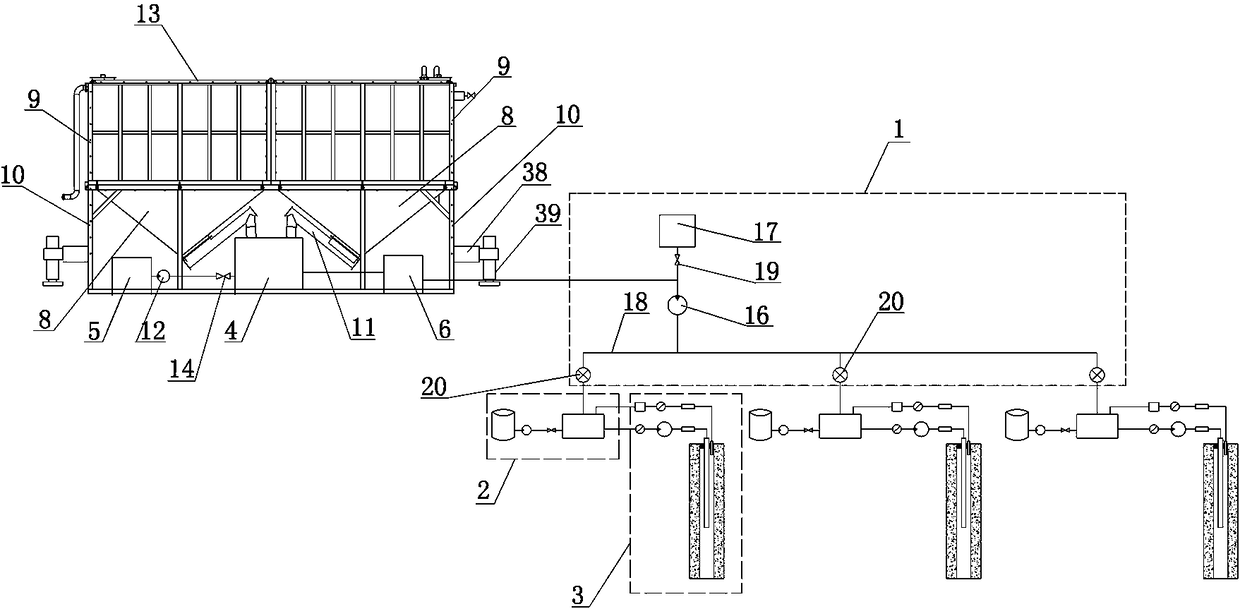

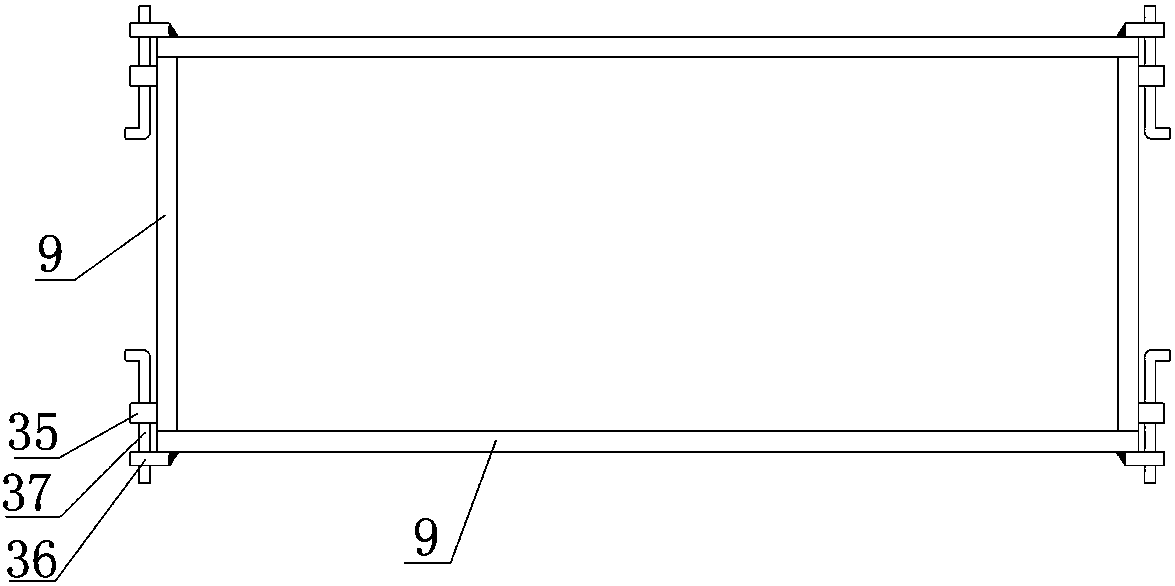

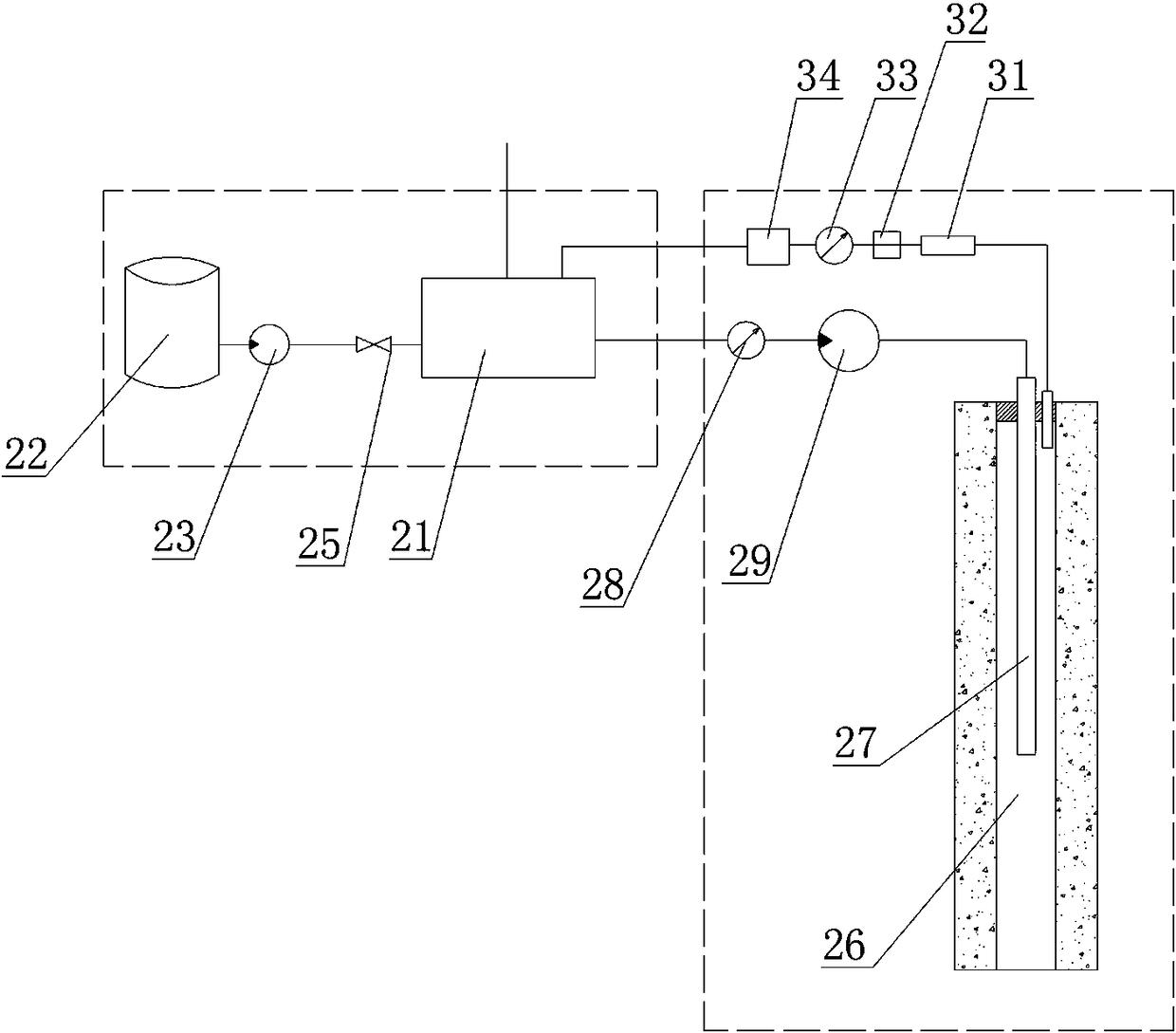

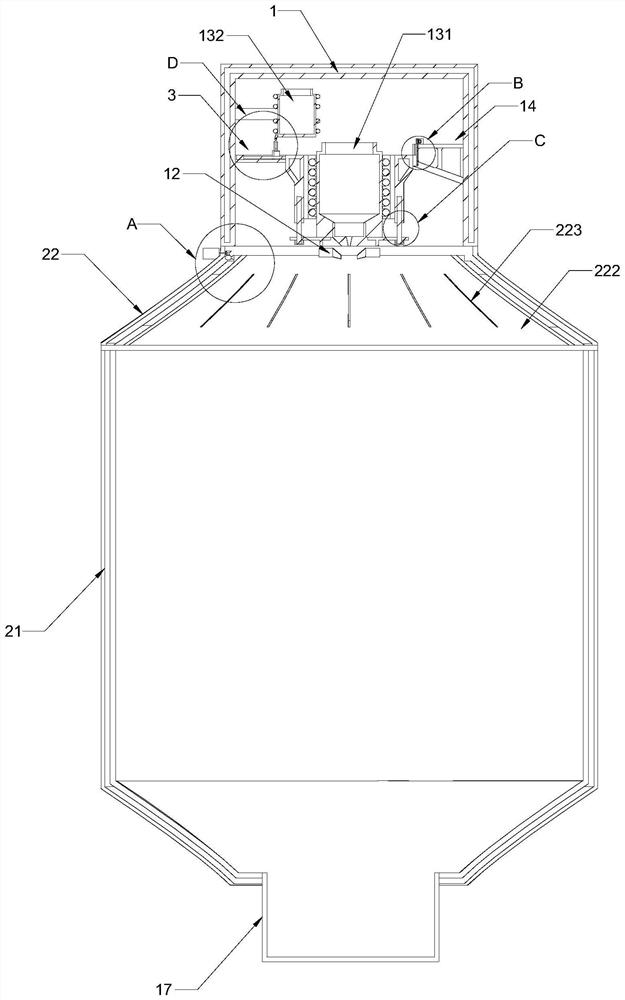

Automatic grouting production system

InactiveCN108705678ARealize continuous preparationEasy to controlMixing operation control apparatusFoundation engineeringControl systemMonitoring system

The invention discloses an automatic grouting production system. The automatic grouting production system comprises a control system, a grout making station, a grout conveying system, grout proportionstations and grouting monitoring systems. The automatic grouting production system has the advantages that the automation degree is high, the labor cost is saved, the operation is simple, the unmanned production or the flexible manpower line is realized, the proportion precision is improved, and the labor intensity is reduced.

Owner:XIYI AUTOMATION SYST ENG CHENGDU +1

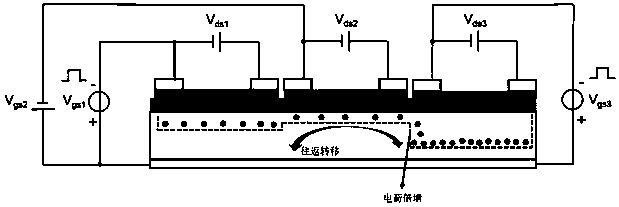

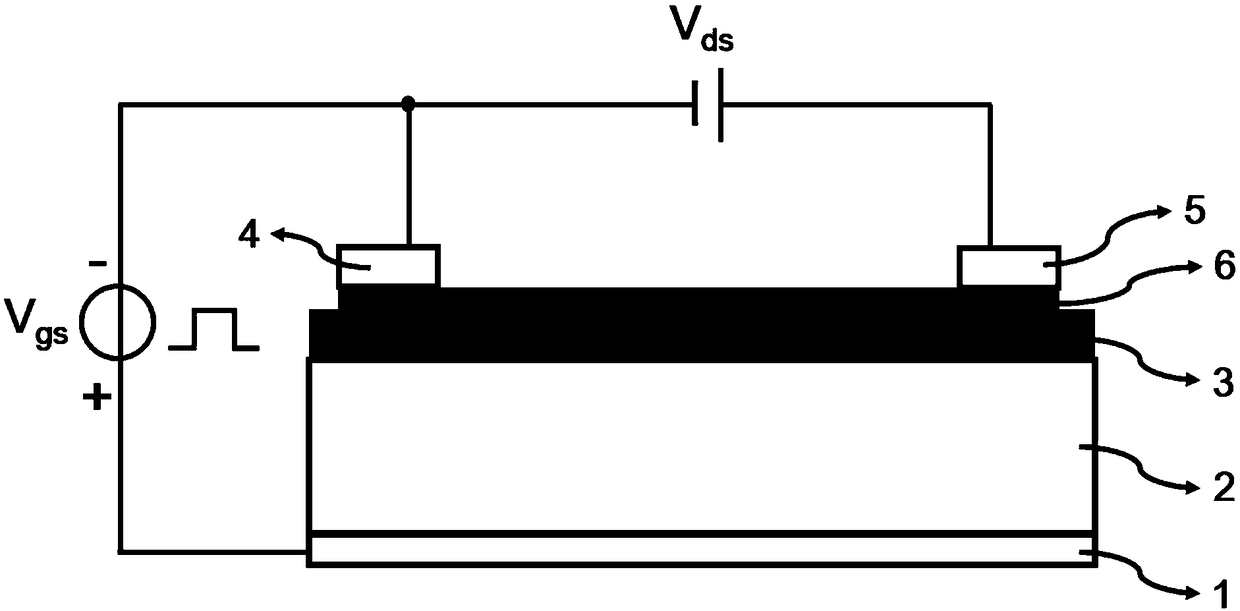

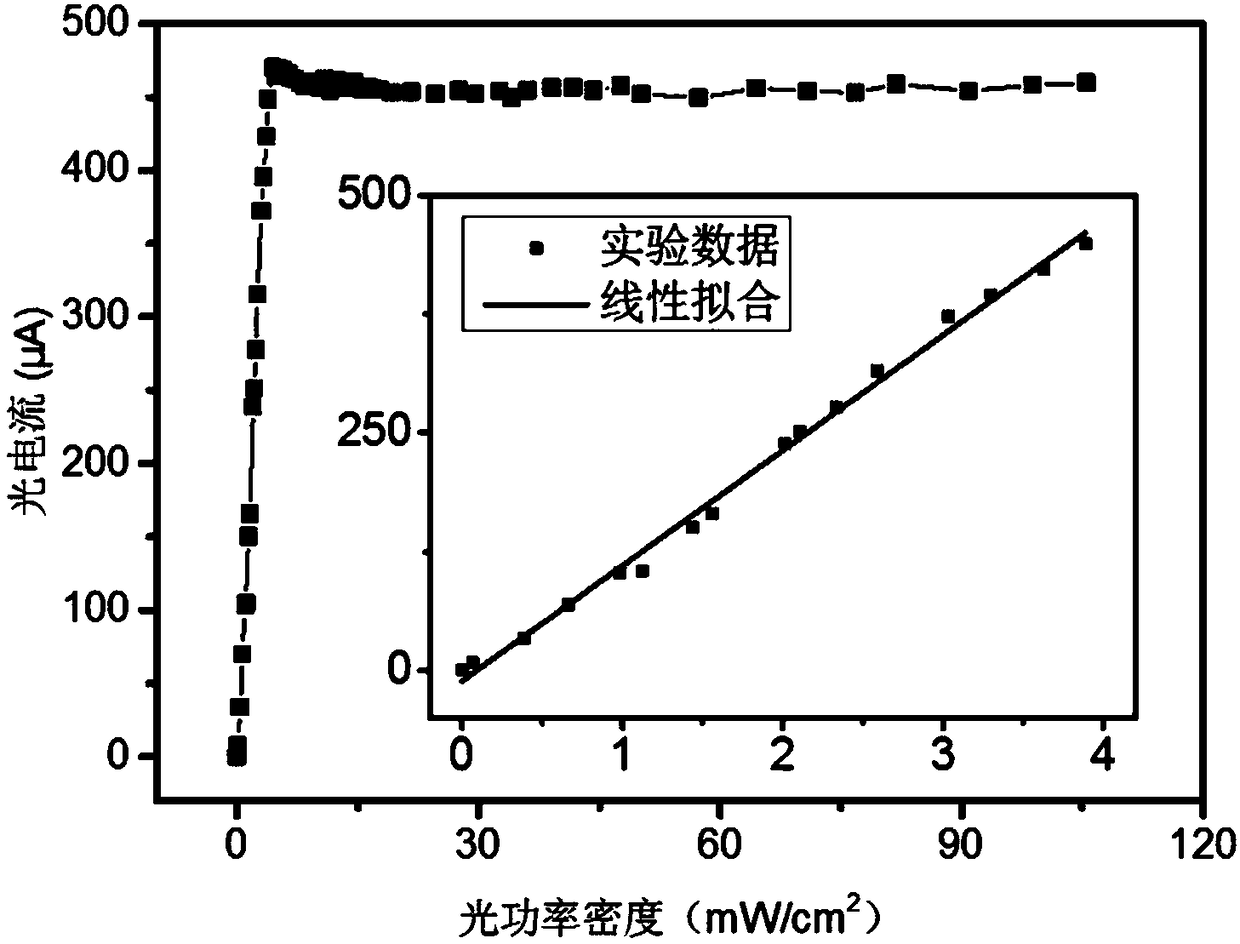

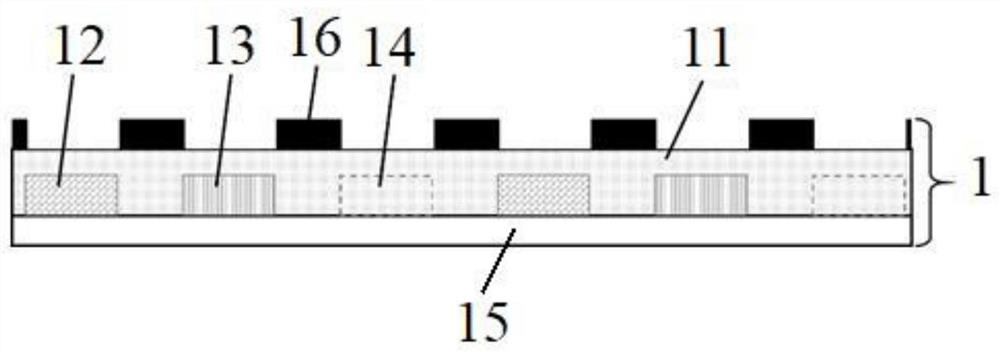

Charge-coupled device based on two-dimensional material films/insulating layers/semiconductor structures

InactiveCN108281454ALarge linear dynamic rangeImprove quantum efficiencySolid-state devicesRadiation controlled devicesCapacitanceSemiconductor structure

The invention discloses a charge-coupled device based on two-dimensional material films / insulating layers / semiconductor structures. The charge-coupled device comprises a plurality of pixels which forman array and sequentially comprise grid electrodes, semiconductor substrates, the insulating layers, two-dimensional material films, source electrodes and drain electrodes from bottom to top, the two-dimensional material films covers the upper surface of the insulating layers, the source electrodes and the drain electrodes are horizontally arranged on the upper surfaces of the two-dimensional material films at intervals, and the two-dimensional material films have photoelectric response and field effect. Incident light irradiates the surface of the device and is absorbed by the two-dimensional material films and the semiconductor substrates, two-dimensional materials have special natures and can effectively collect current carriers through capacitive coupling, generated photocurrent signals can directly outputted from a single pixel, local reading and random reading are achieved, a horizontal charge transferring mode between pixels is omitted, a signal reading mode of the charge-coupled device is fundamentally changed, response of a system is accelerated, the linear dynamic range of the system is widened, and reliability of the system is improved.

Owner:杭州紫元科技有限公司

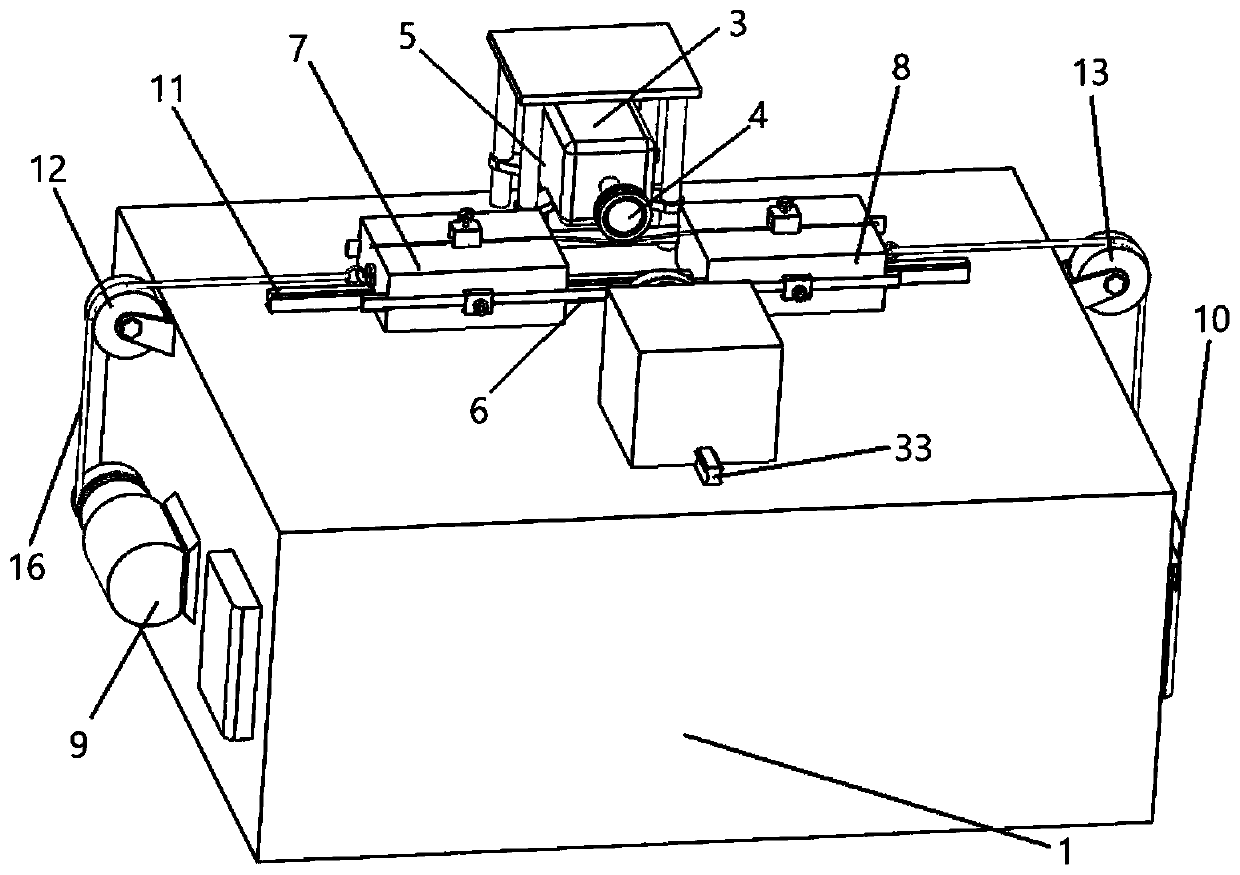

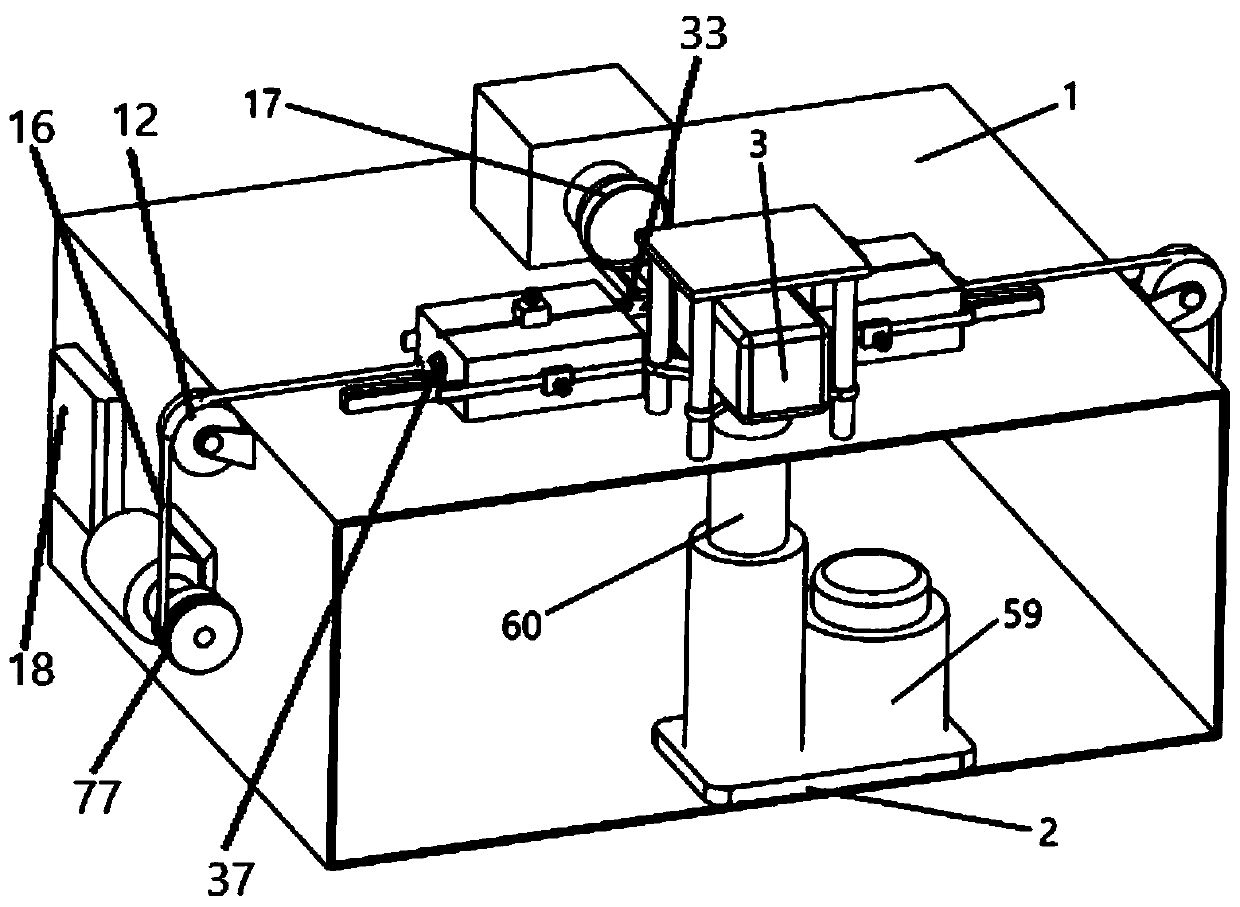

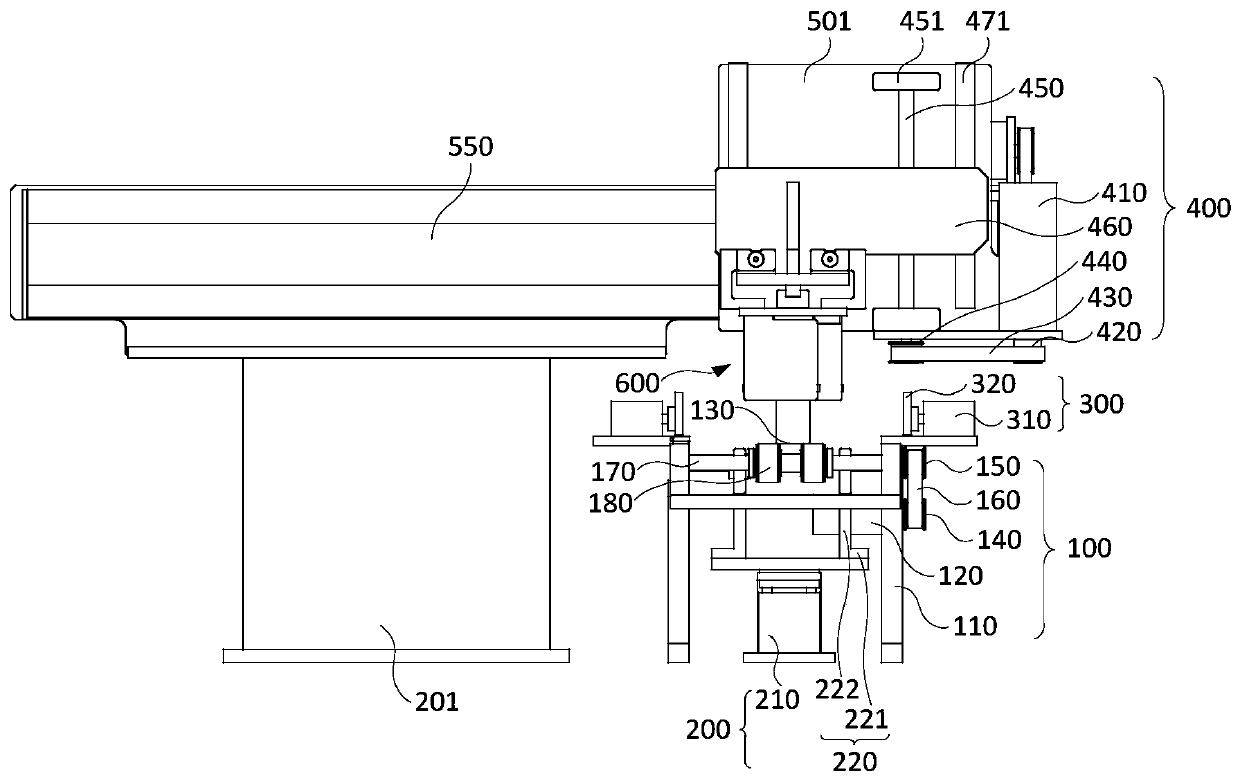

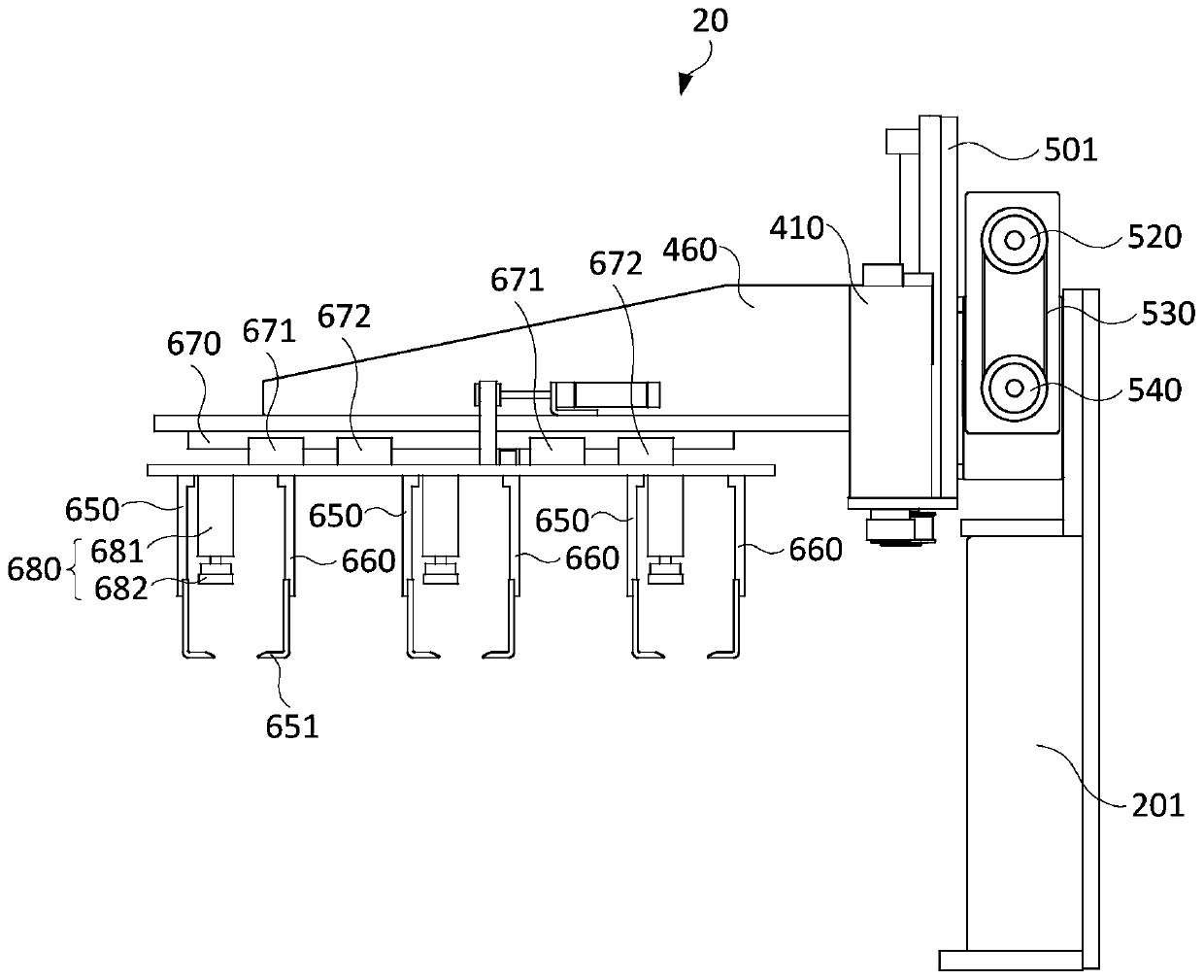

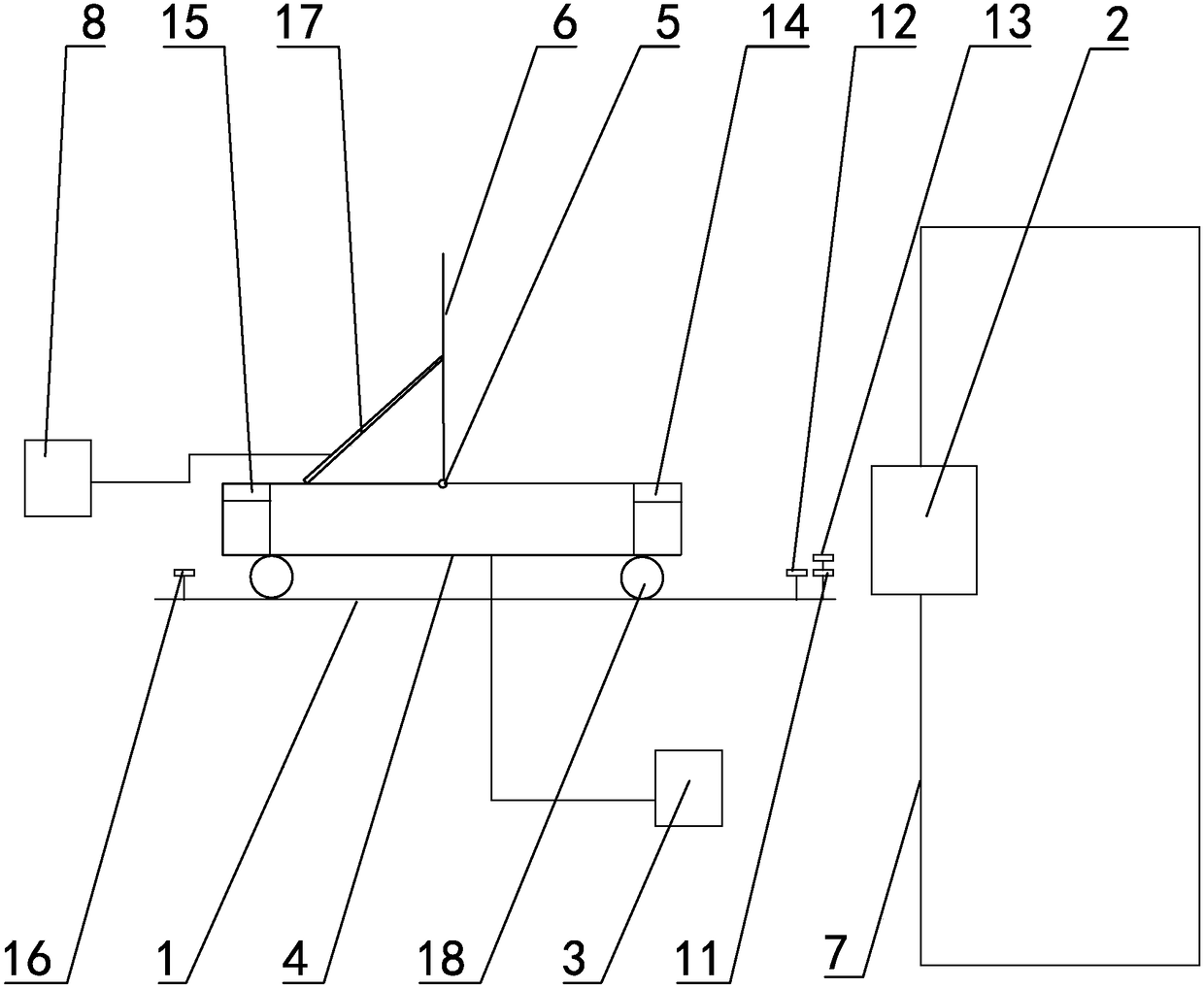

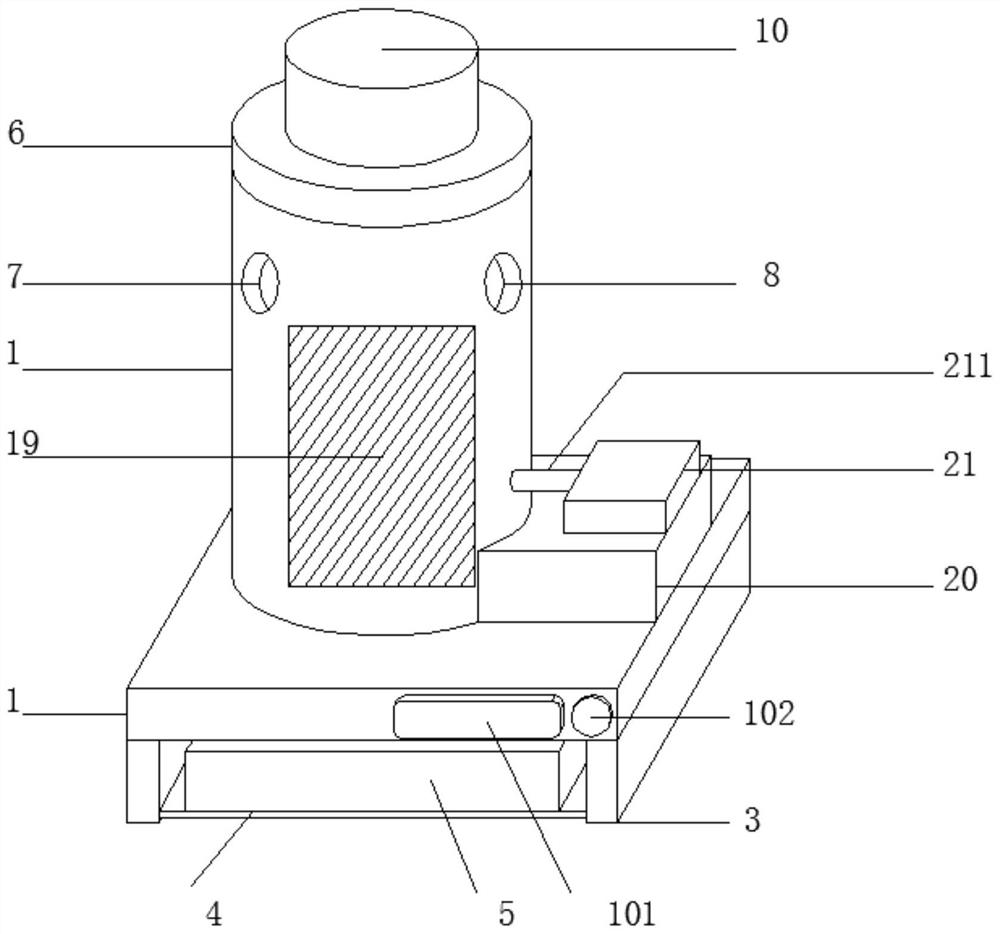

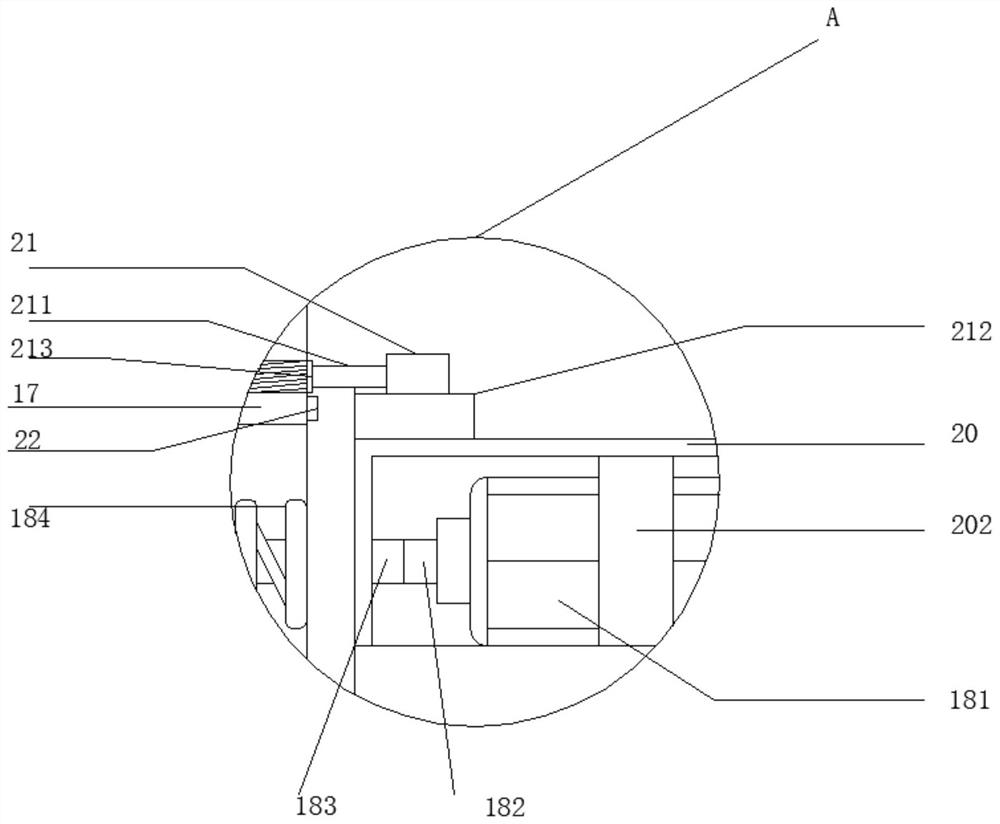

Polishing, grinding and tapering integrated device and method for preparing D-type and conical optical fibers

ActiveCN111596407AImprove stabilityStrong reliabilityGrinding feed controlCoupling light guidesFiberOptical fiber transmission

The invention provides a polishing, grinding and tapering integrated device and method for preparing D-type and conical optical fibers. The device comprises a platform main body, a lifting module, anoptical fiber polishing and grinding module, an optical fiber transmission module, a clamp module, an optical fiber heating module and the an optical fiber. The first end of the lifting module is fixedly connected with the lower end of the platform main body; the second end of the lifting module is fixedly connected with the optical fiber polishing and grinding module; the optical fiber polishingand grinding module, the optical fiber transmission module, the real-time monitoring module and the optical fiber heating module are located at the upper end of the platform main body. The optical fiber transmission module and the optical fiber heating module are both located between the optical fiber polishing and grinding module and the real-time monitoring module; a central control and communication module is located on one side face of the platform main body, a clamp module is located on the optical fiber transmission module, and the two ends of the optical fiber are fixedly connected withgrooves of flange sliding blocks through optical fiber fixing clamps respectively. Through the design of the flange sliding blocks, the problem of relative movement of the optical fiber and a polishing and grinding wheel is ingeniously solved, and side polishing and grinding of the optical fiber and tapering of the optical fiber can be implemented.

Owner:SHENZHEN GOLIGHT TECH

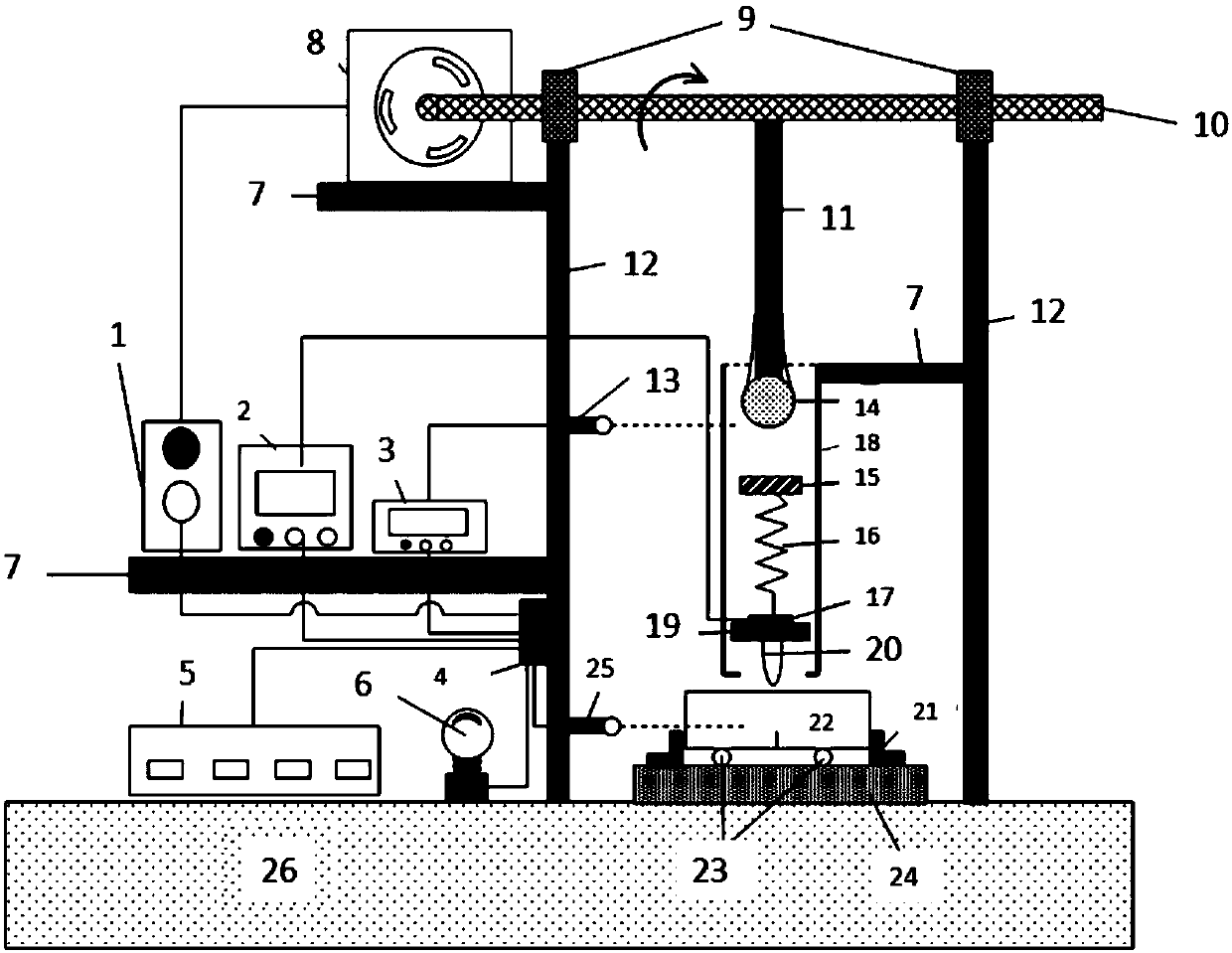

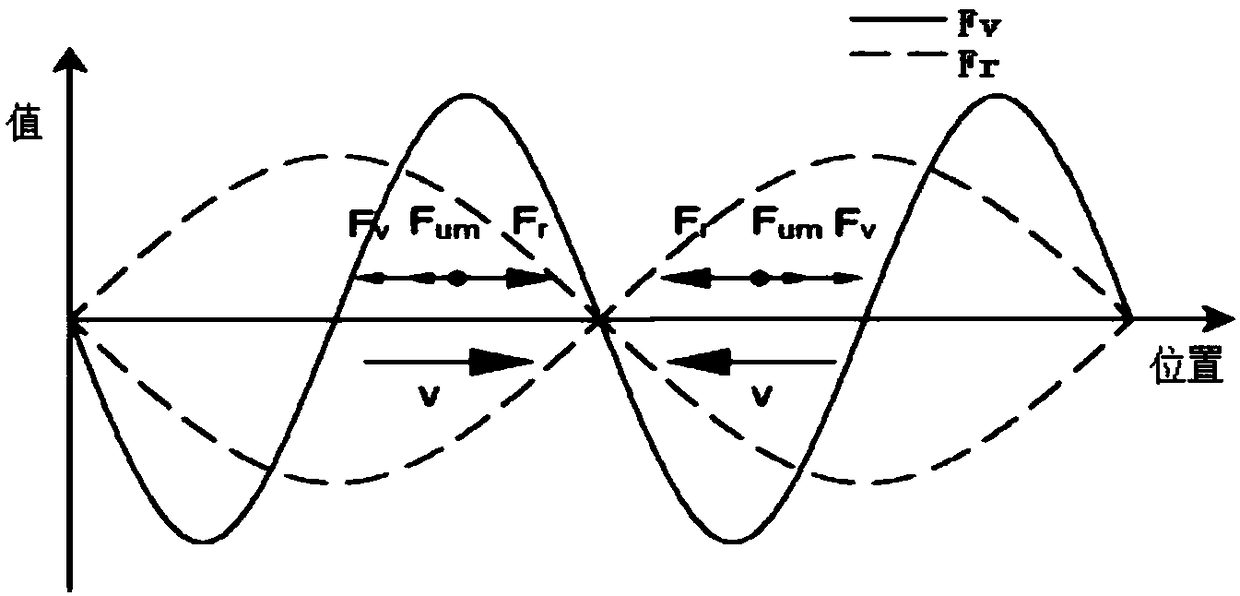

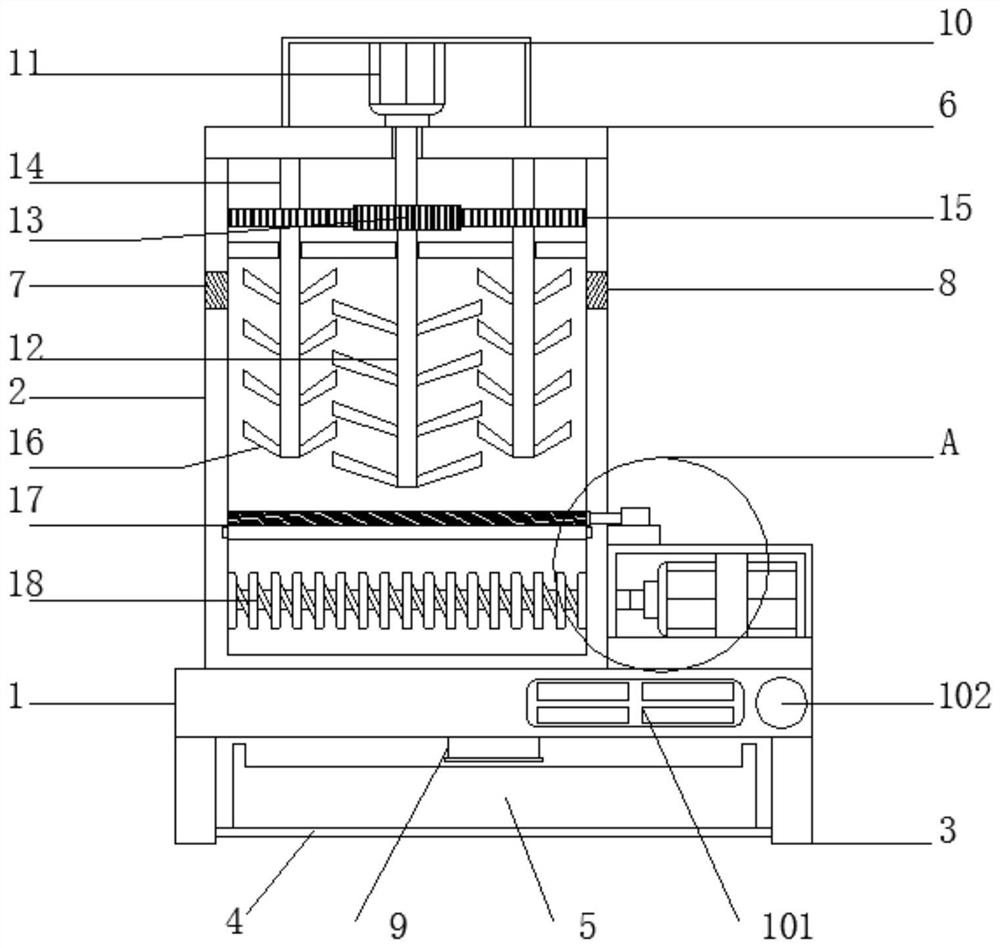

Brittle material fatigue crack prefabricating test machine

ActiveCN107607372ASave energySave experimental operation costPreparing sample for investigationControl systemLaser probe

The invention provides a brittle material fatigue crack prefabricating test machine. The test machine comprises a pedestal, a motor, a transmission shaft, an impact ball, a pressure head, a supportingframe, supporting plates, a laser counter, a pressure sensor, a laser signal controller, an alarm, a PLC control system, a compression spring, a limit barrel, a clamp and other parts. The loading ofdifferent sizes of load is realized through the pressure sensor by adjusting the position of the impact ball, a connecting rod and the limit cylinder to make the length of a prefabricated crack reacha required size, the PLC control system powers off the motor according to signal information fed back by a laser probe, and the alarm gives an alarm to prompt the completion of the prefabricating of the fatigue crack of a test piece. The test machine realizes unmanned guarding in the whole crack prefabricating process. The brittle material fatigue crack prefabricating test machine can greatly savemanpower and material resources, and also improves the crack preparation accuracy.

Owner:HARBIN ENG UNIV

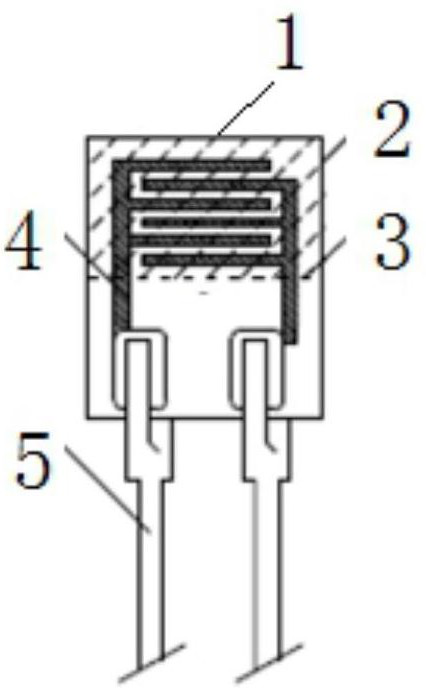

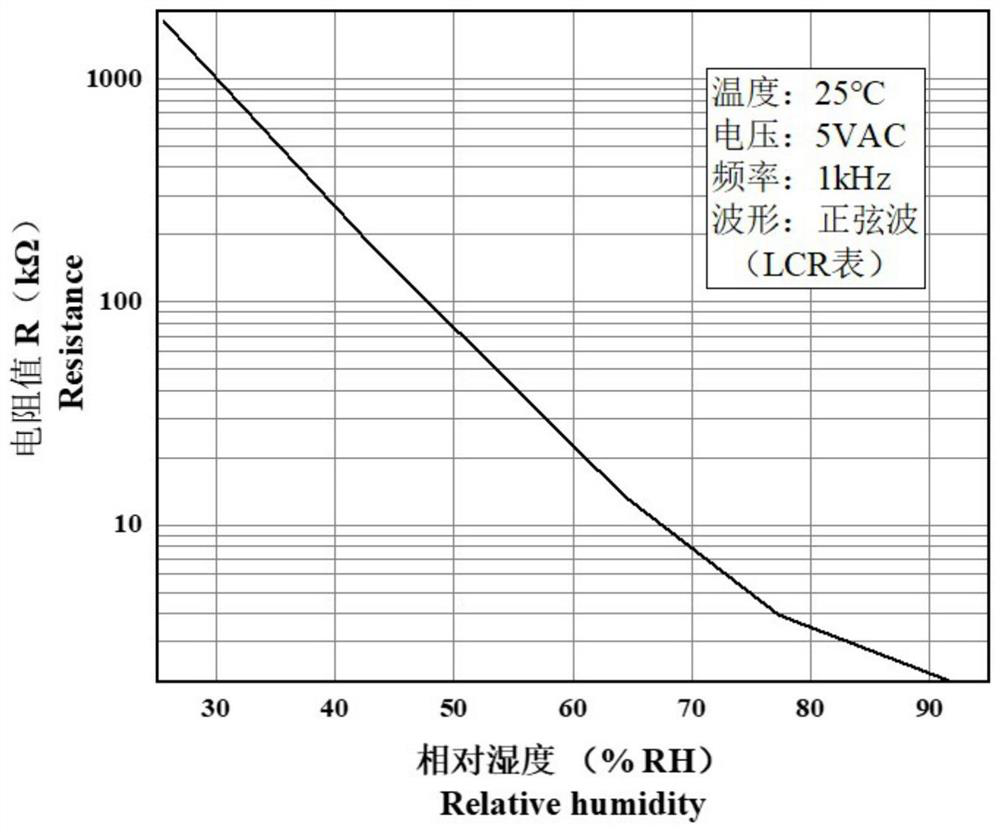

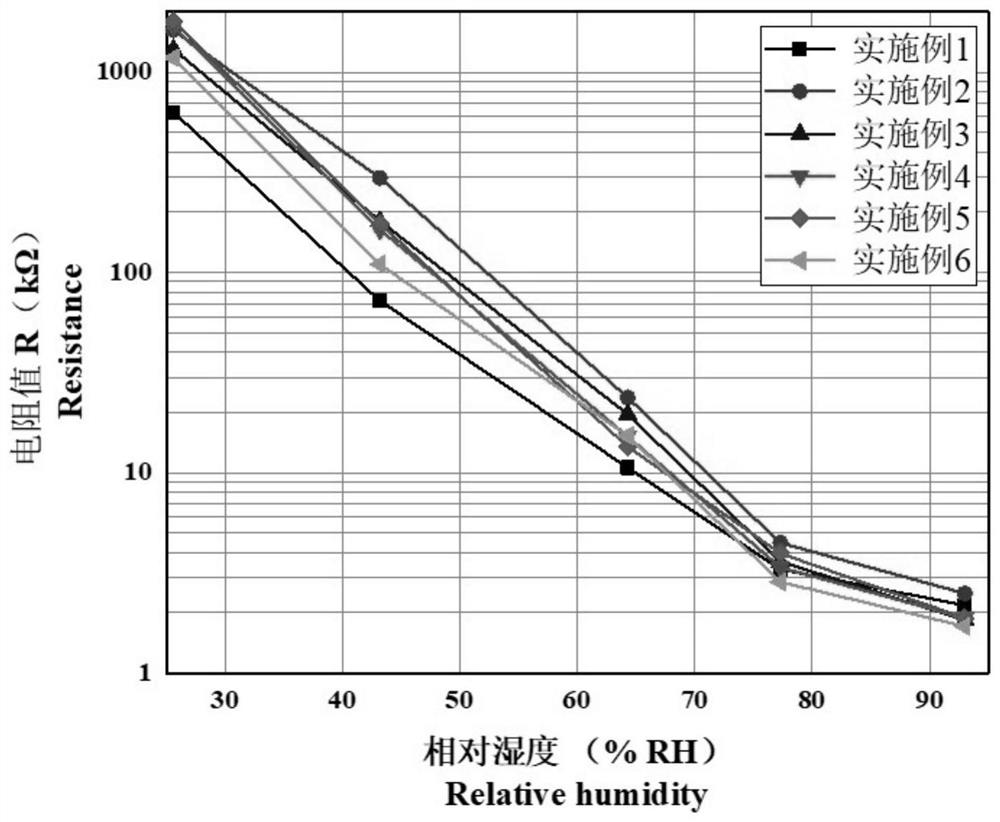

Polymer resistance type humidity-sensitive element and preparation method thereof

InactiveCN112611787ALower resistanceReduce resistance type humidityMaterial resistanceScreen printingPhysical chemistry

The invention relates to a macromolecule resistance type humidity-sensitive element. The element is characterized by comprising a packaging shell, a base body, a humidity-sensitive film, an interdigital electrode and pins, wherein the base body is a humidity-sensitive sensing base body, and the humidity-sensitive film is arranged on the surface of the interdigital electrode and the surface of the base body; the interdigital electrode comprises a transverse electrode and a longitudinal electrode. The organic polymer material is compounded by adopting a multi-layer brush coating technology, resistance of the polymer resistance type humidity sensor in a low-humidity environment is remarkably reduced, sensitive detection on the low-humidity environment is realized, deliquescence resistance of the film is improved by doping cellulose, in addition, precision of silk-screen printing based on a single screen printing plate is relatively low, and cost is relatively low. The element is advantaged in that the pattern of the interdigital electrode is split into the transverse electrode part and the longitudinal electrode part, the preparation precision of the interdigital electrode is improved through the multi-screen separate silk-screen printing technology, the adhesion between the electrode and the substrate is enhanced through copper doping of the conductive ink, and the humidity-sensitive characteristics of high sensitivity, good linearity, high response speed and high reliability are obtained.

Owner:WUXI HAOBANG HIGH TECH CO LTD

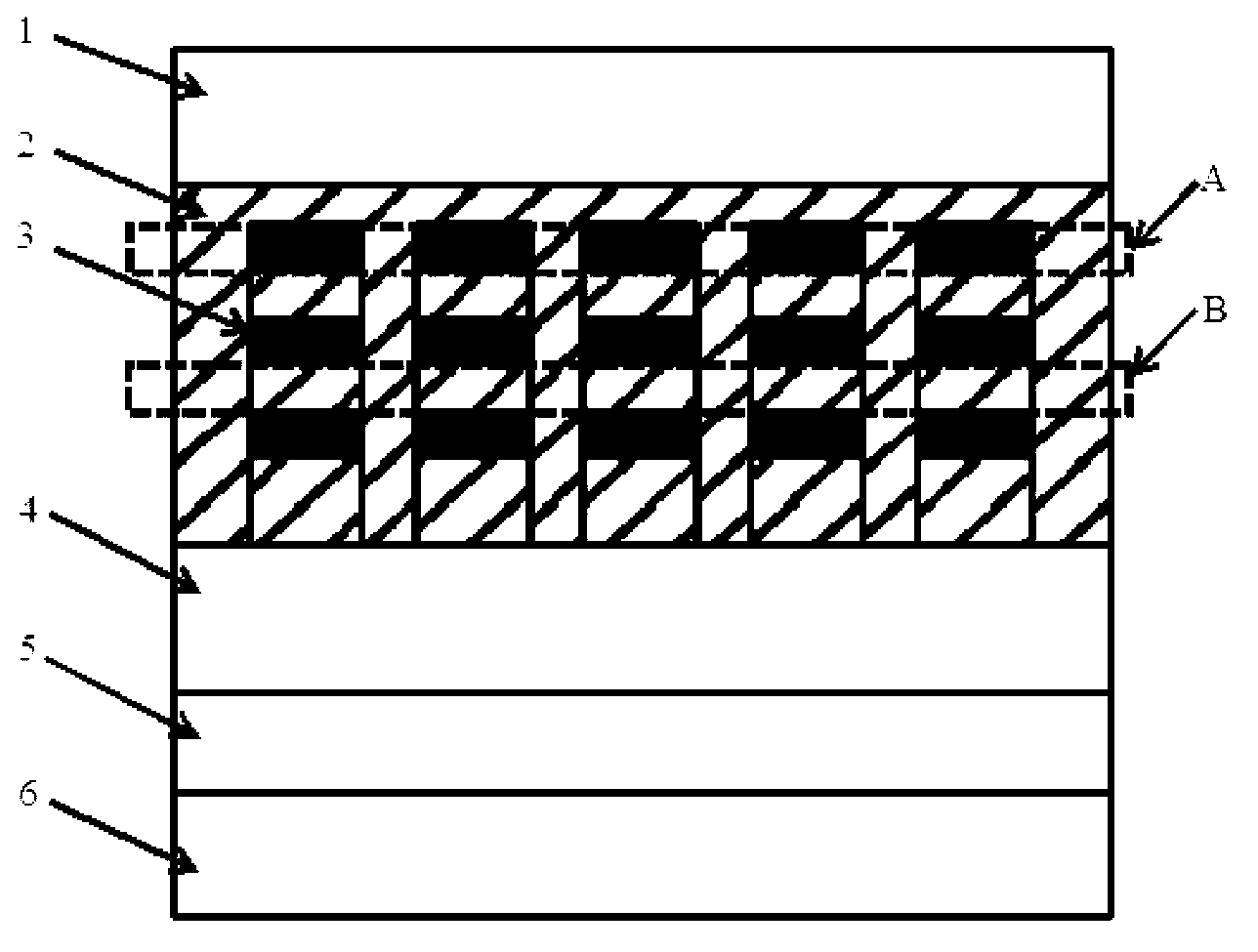

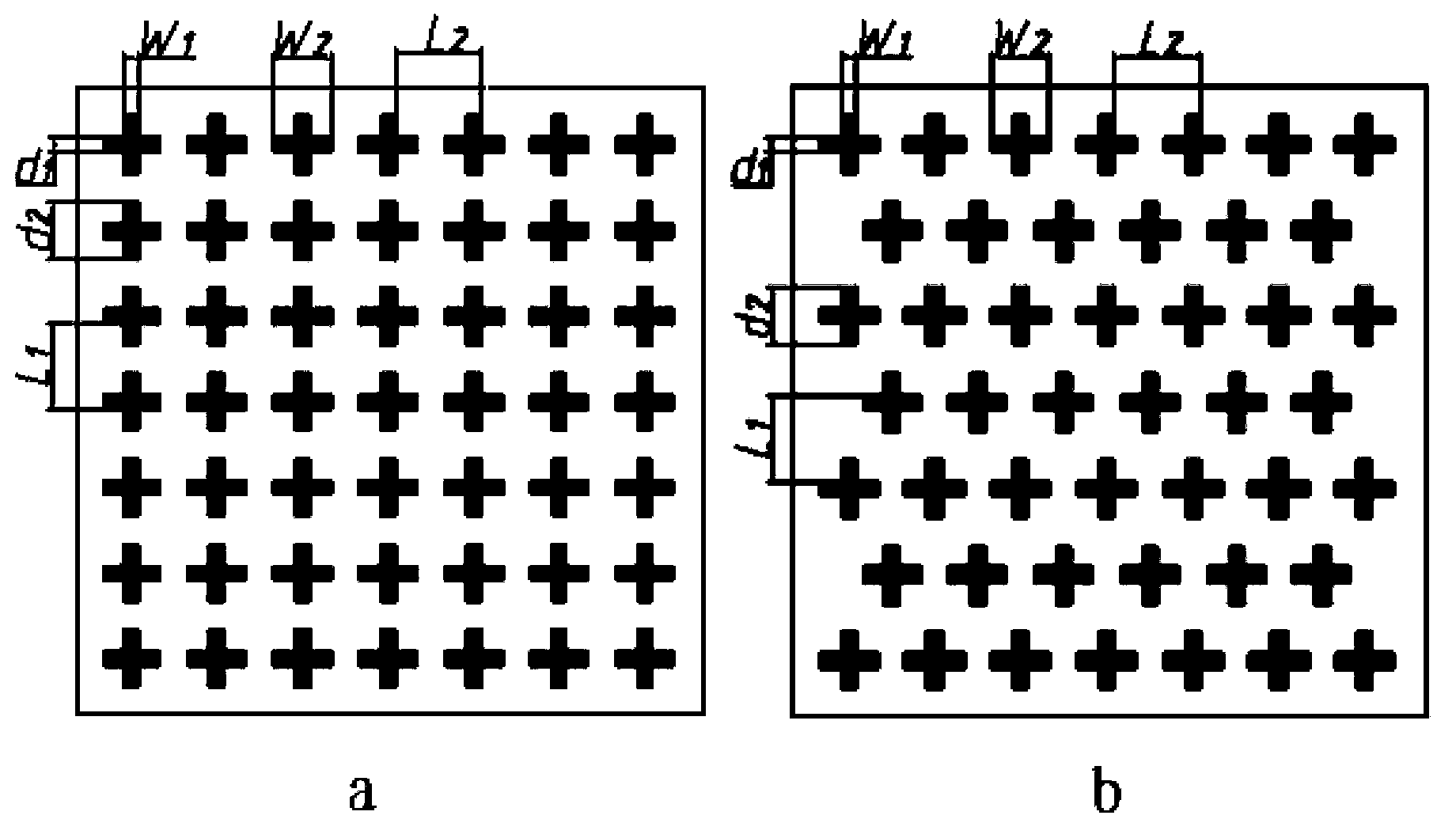

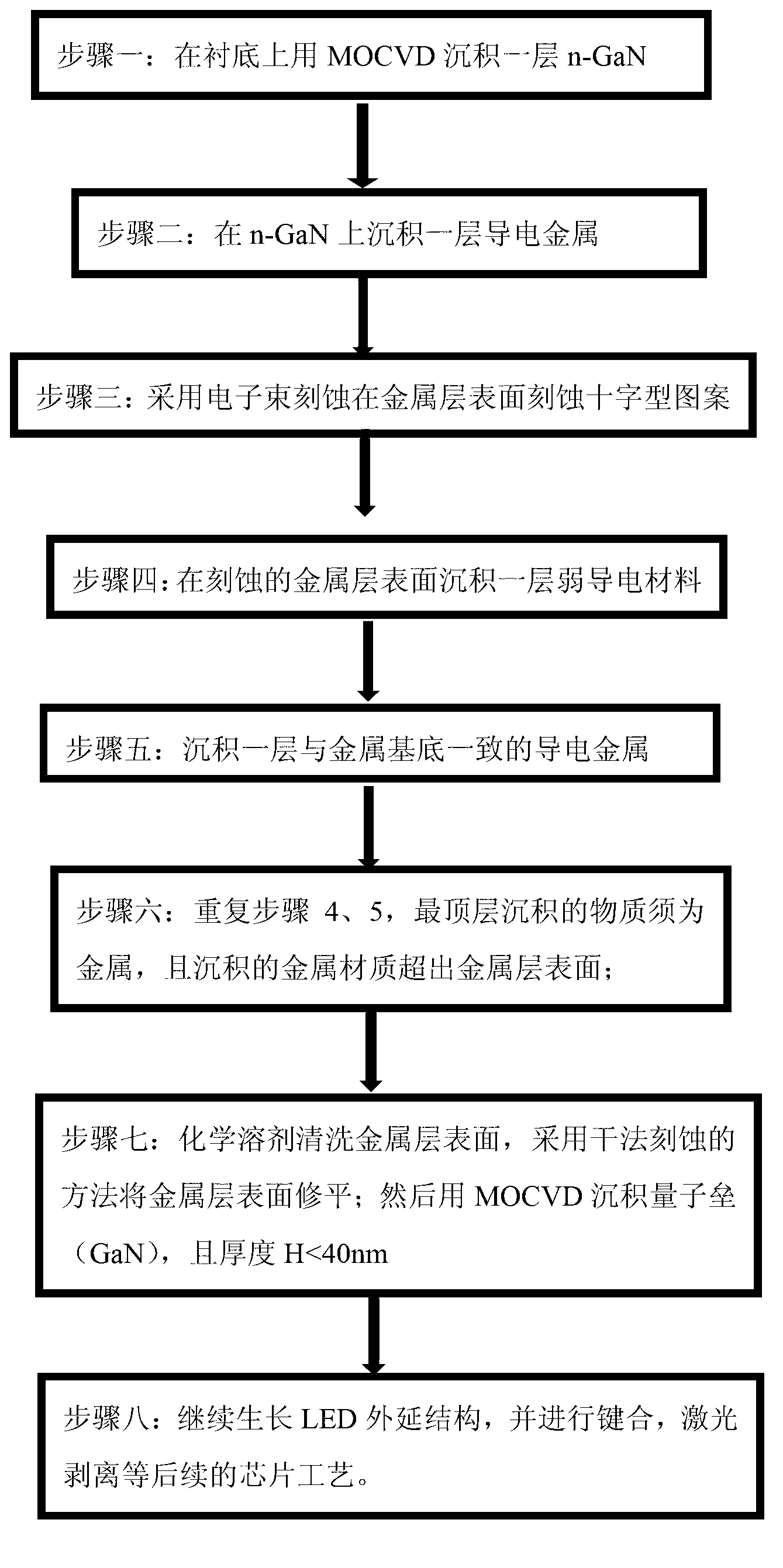

LED photonic crystal containing left-handed material and preparation method

ActiveCN103227254AHigh preparation precisionImprove and tune performanceSemiconductor devicesSurface plasmon polaritonBand gap

The invention relates to an LED (light emitting diode) photonic crystal containing a left-handed material and a preparation method. The LED photonic crystal is characterized in that (1), the photonic crystal is formed by arraying a right-handed material and the left-handed material alternately; (2), gaps in a left-handed material layer are in Swiss cross structures, can be arrayed rectangularly or triangularly, and are filled with weak conducting materials; (3), a substrate of the photonic crystal is made of conducting metal; and (4), the thickness of a quantum barrier GaN between the photonic crystal and an active layer is less than 40nm. According to the LED photonic crystal and the preparation method, the LED photonic crystal is prepared by combining higher-accuracy technologies such as electron beam etching, electron beam evaporation, PECVD (plasma enhanced chemical vapor deposition), and dry etching, so that a surface plasmon enhancement effect can be generated to couple out an evanescent wave in the active layer, and wider photonic band gaps can be generated; the luminous wavelength and a light emitting angle are controlled better; and the luminous efficiency and the light emitting power of an LED are improved and increased.

Owner:XI AN JIAOTONG UNIV

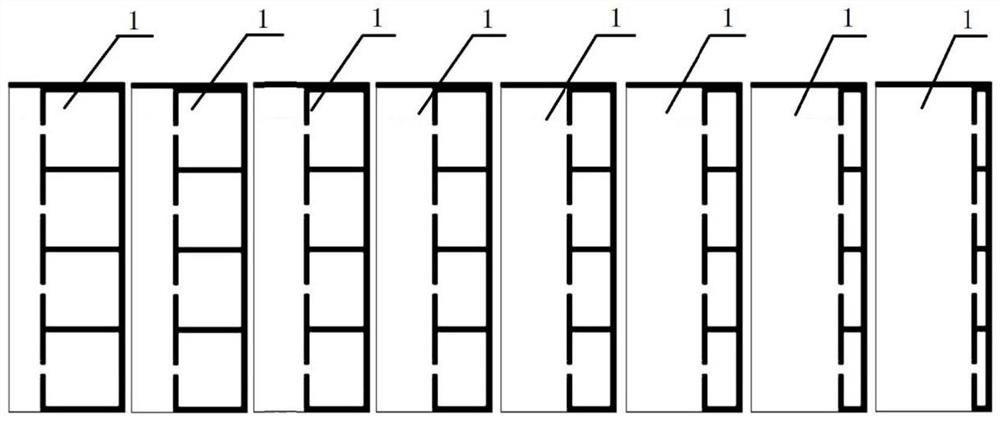

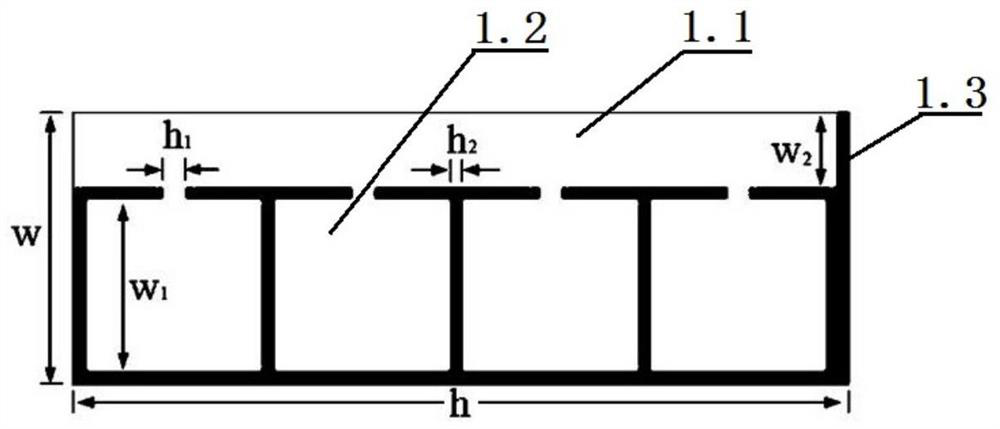

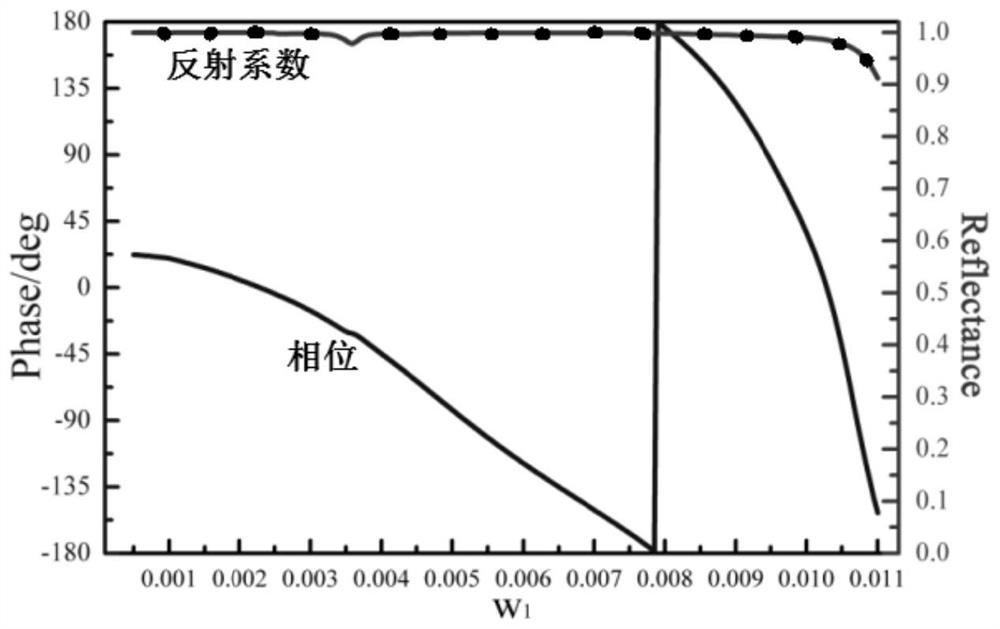

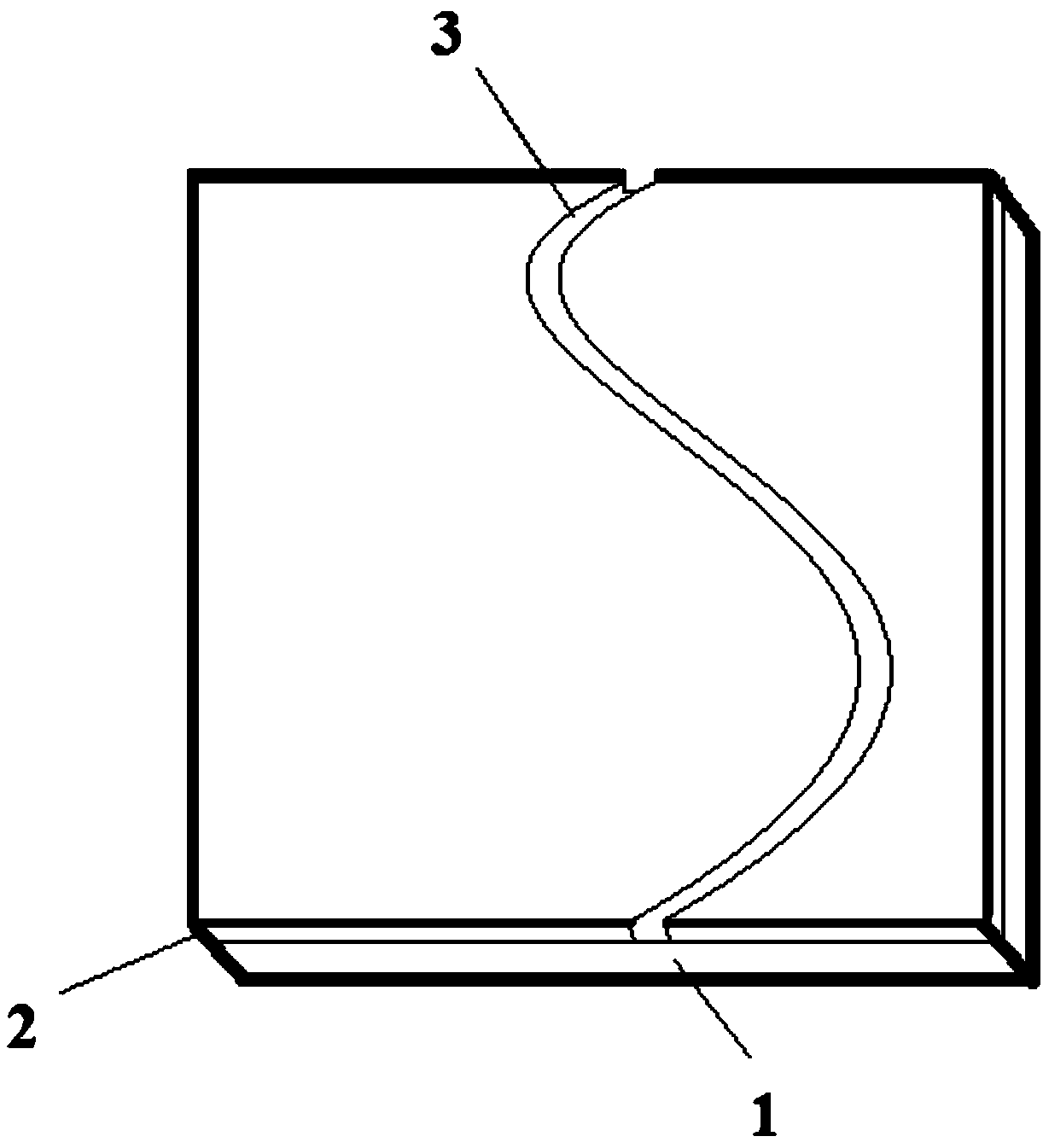

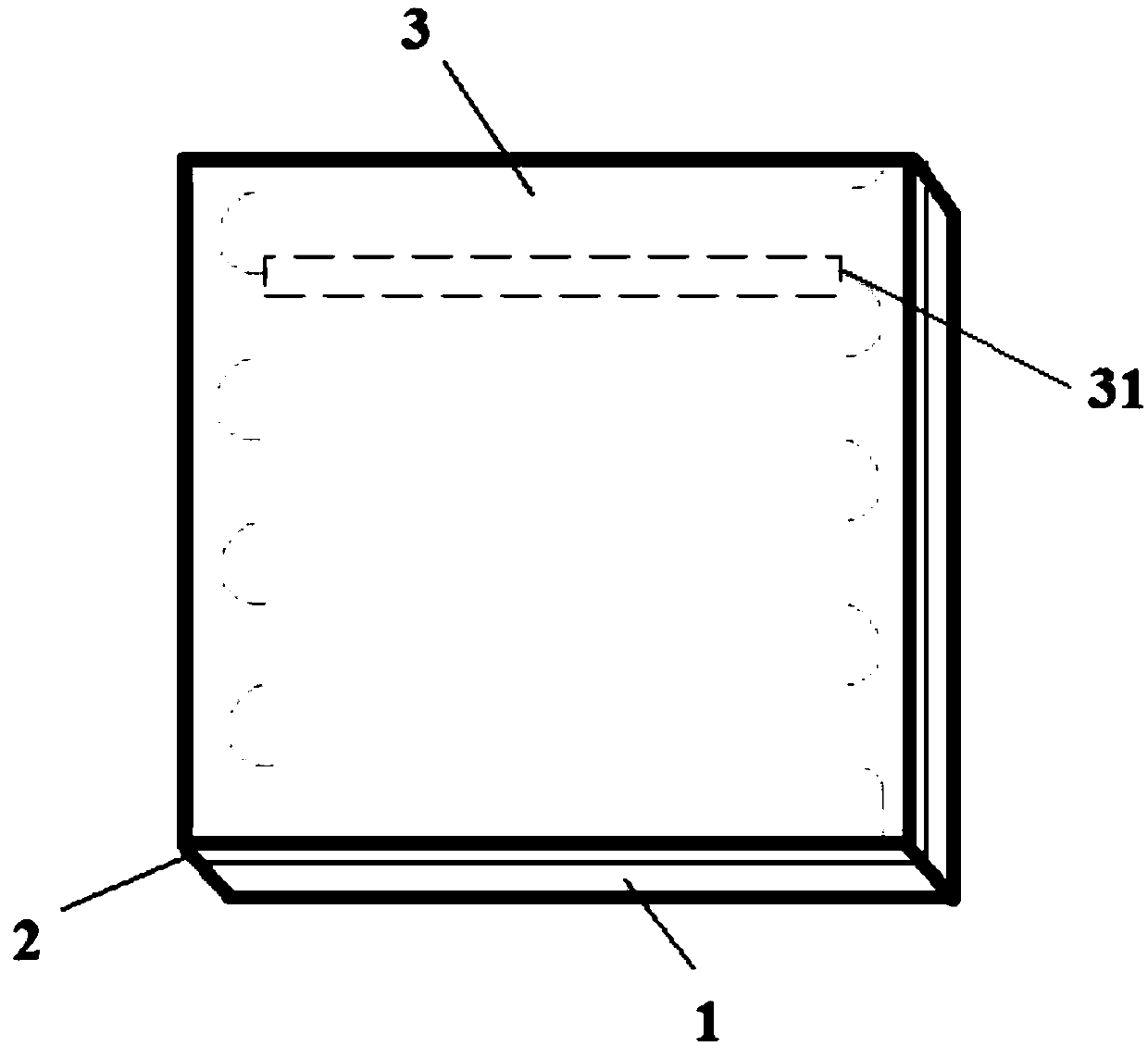

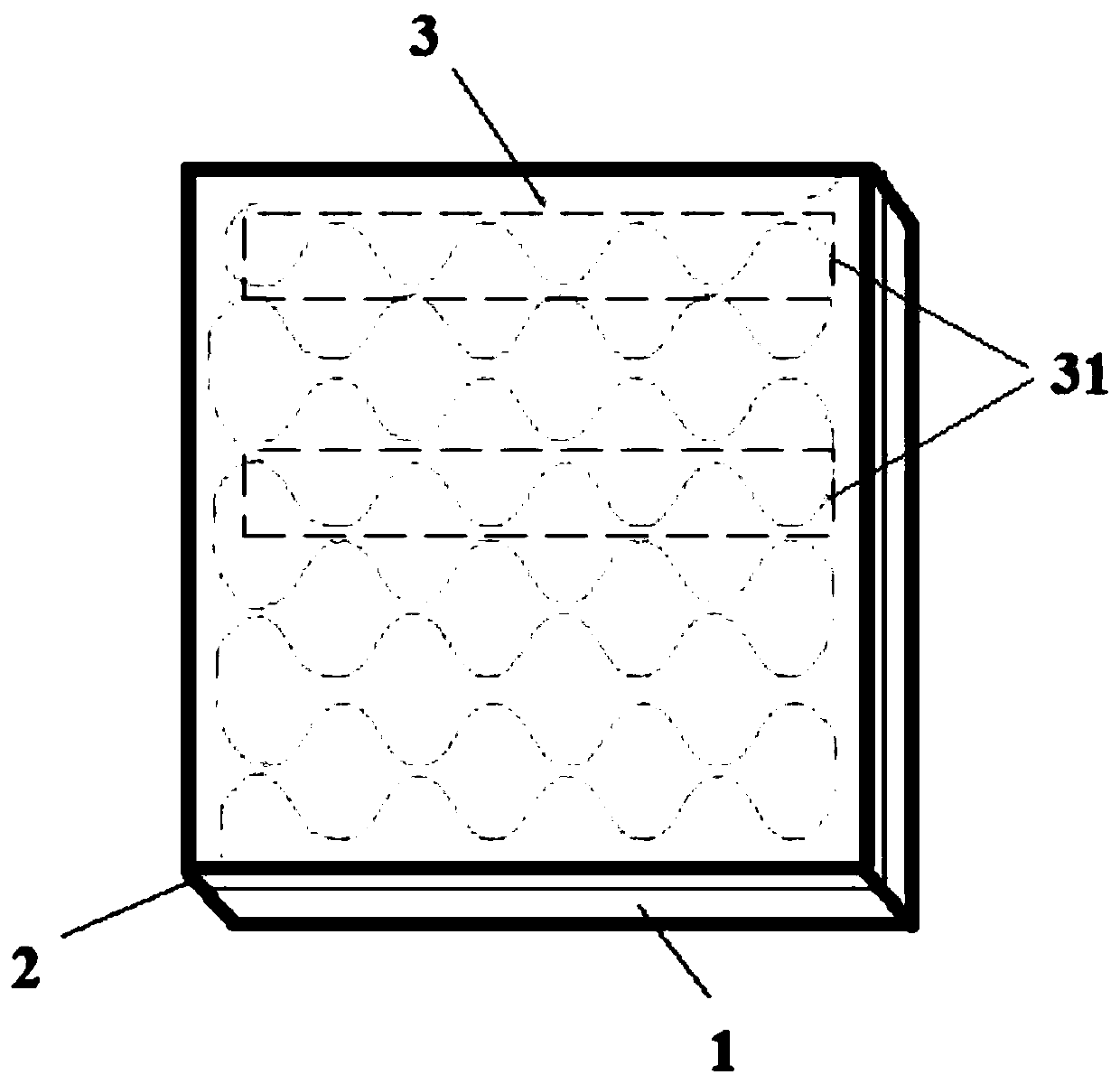

Sound wave reflection regulation and control device based on acoustic metasurface

PendingCN111933106AImplement reflectionImprove reflectivitySound producing devicesEngineeringSound wave

The invention relates to a sound wave reflection regulation and control device based on an acoustic metasurface. The device is formed by combining a channel, a plurality of cavities which are sequentially arranged at equal intervals and a reflection plate. The reflection plate is arranged at one ends of the cavities. The device provided by the invention has very high reflectivity and a simple structure, and can be used for printing a structure by 3D printing to realize reflection at multiple angles. Compared with the prior art, inherent loss caused by an independent design structure is overcome, the defects that an existing structure is complex in design, high in loss, large in size and high in cost are overcome, simplification of the structure and coupling of sound wave reflection units reduce procedures for preparation of an acoustic function device, the preparation precision is improved, and the performance is further improved.

Owner:GUANGDONG UNIV OF TECH

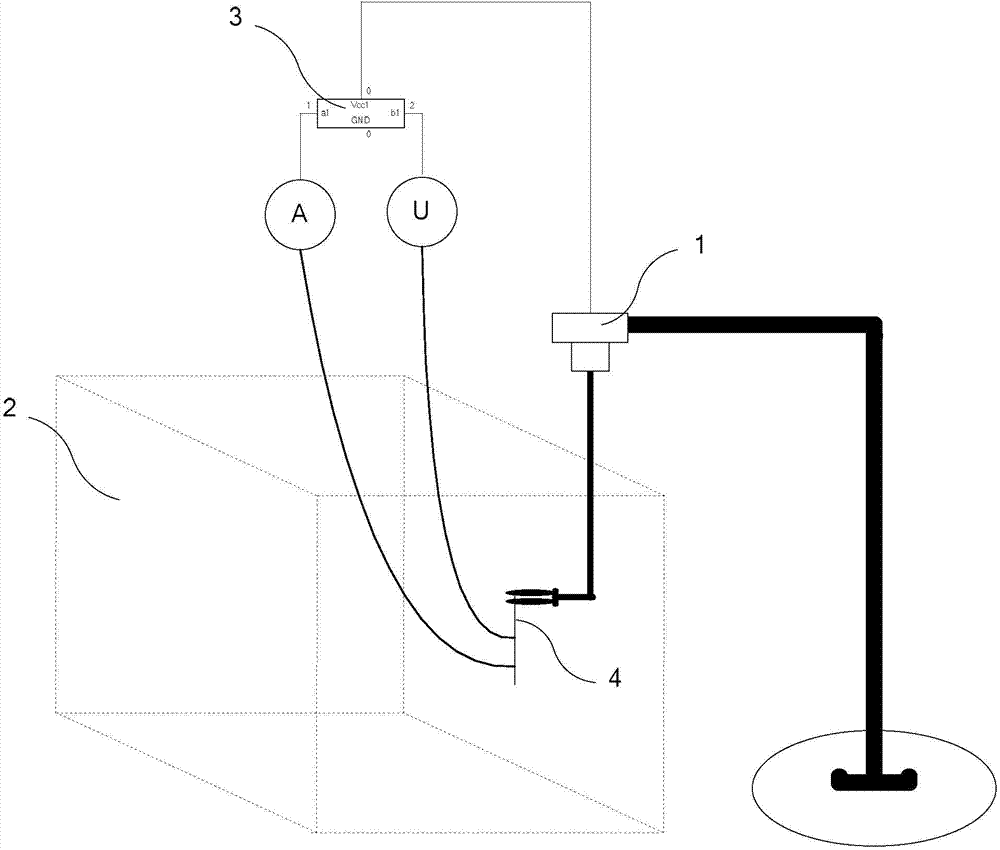

Ultramicroelectrode preparation system for electrophysiological recording of individual nerve cells

InactiveCN104490392AFast and fully automaticFully automatic withElectrolysis componentsDiagnostic recording/measuringPower flowEngineering

The invention provides an ultramicroelectrode preparation system for the electrophysiological recording of individual nerve cells, which comprises a constant voltage source, a step motor, an electrolytic cell, a digital ampere meter and a control chip; the control chip controls the constant voltage source to apply preset voltage on a microelectrode submerged in electrolyte solution, so that the microelectrode is electrochemically corroded; the step motor is controlled to drive the microelectrode to go up in the electrolyte solution, and by controlling the speed of the step motor, the tip of the microelectrode is corroded to form a taper; the detection result of the digital ampere meter is acquired, when the current change on the microelectrode is judged to reach a preset condition, the constant voltage source is switched off, the step motor is controlled to speed up to lift the microelectrode out of the electrolyte solution, and thereby an ultramicroelectrode, which is formed by microelectrode corrosion and the tip diameter of which is less than 1 micron, is obtained. The ultramicroelectrode preparation system remarkably increases the precision and speed of preparation, shortens the time of preparation, and helps to popularize the application of ultramicroelectrodes in the fields of individual nerve cell recording and fruit fly olfactory unit receptor recording.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

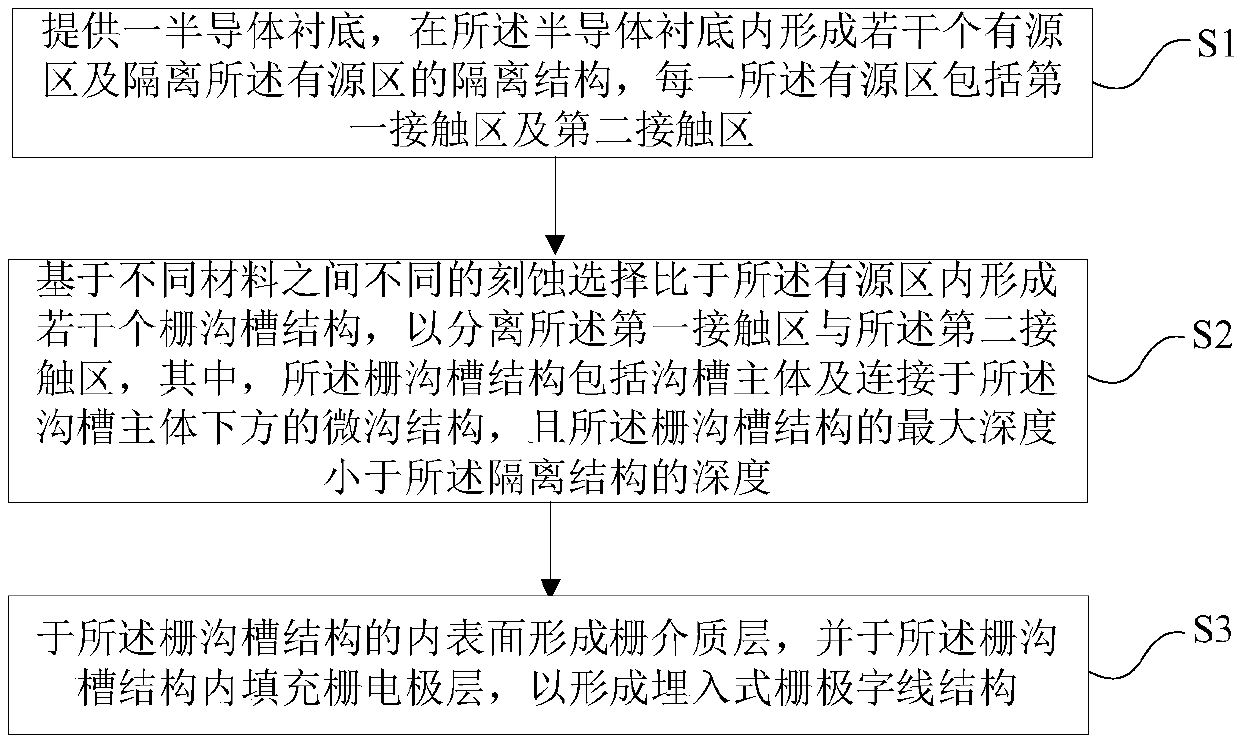

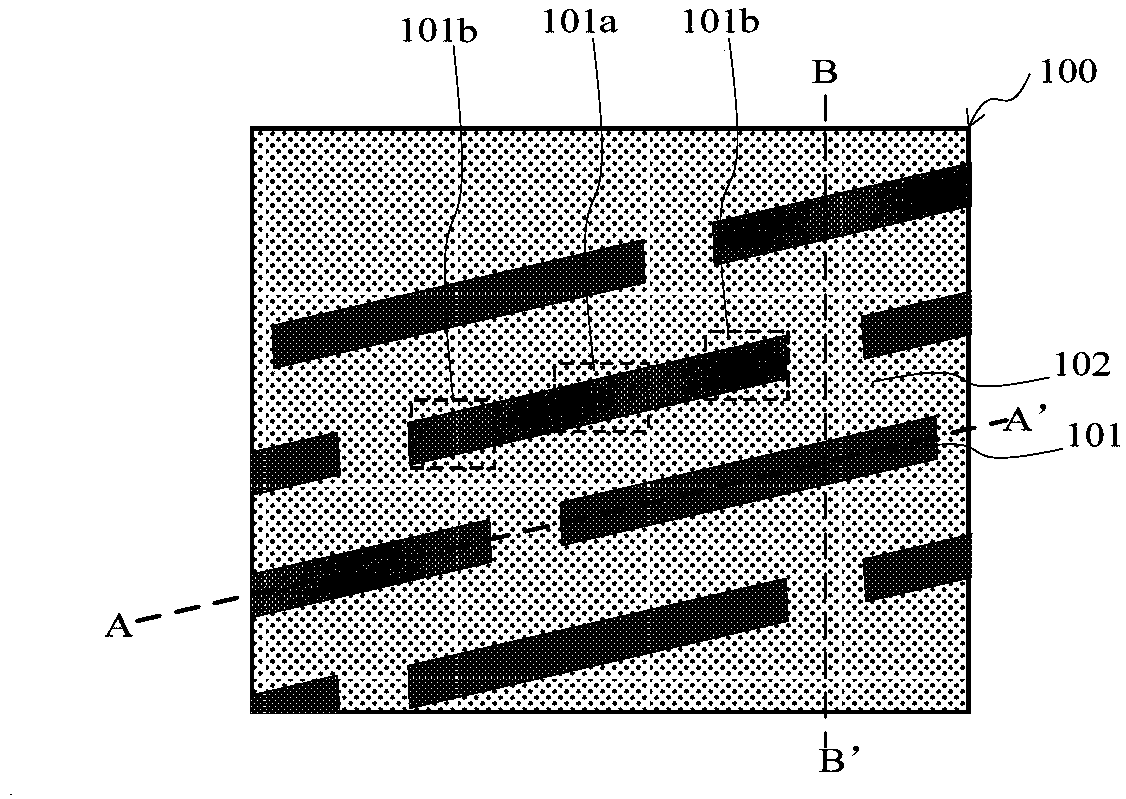

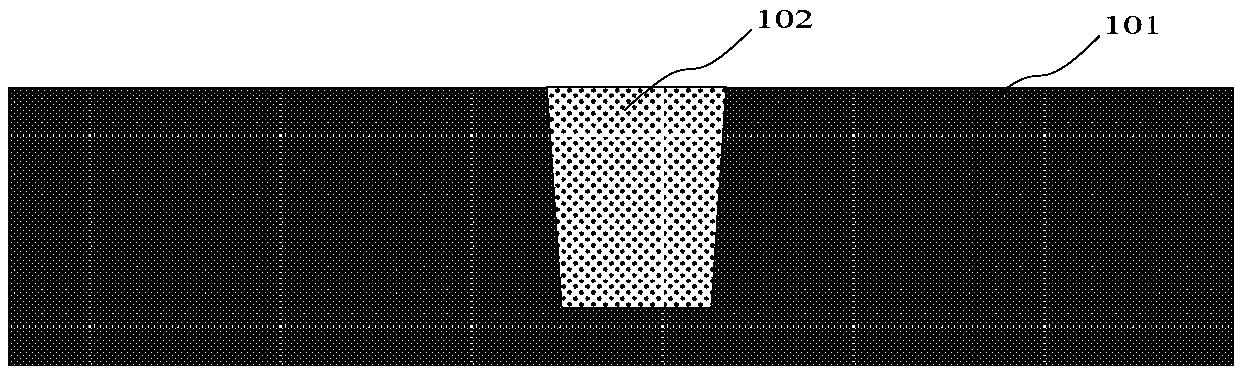

Semiconductor device structure and preparation method thereof

PendingCN110880510AImprove performanceIncrease widthSolid-state devicesSemiconductor devicesDevice materialEngineering

The invention provides a semiconductor device structure and a preparation method thereof, and the preparation method comprises the steps of providing a semiconductor substrate, and forming a pluralityof active regions and an isolation structure for isolating the active regions, wherein each active region comprises a first contact region and a second contact region; forming a plurality of gate trench structures in the active regions based on different etching selection ratios among different materials so as to separate the first contact region from the second contact region, wherein each gatetrench structure comprises a trench main body and a micro-trench structure, and the maximum depth of each gate trench structure is smaller than the depth of the isolation structure; and forming a gatedielectric layer on the inner surfaces of the gate trench structures, and filling a gate electrode layer in the gate trench structures to form an embedded gate word line structure. According to the invention, a special micro-channel structure is formed through different etching selection ratios among different materials, the preparation process is simplified, the preparation precision is improved, the channel area is increased on the basis of keeping the size of an original device, the width of a transmission channel can be further increased, and the device performance of a field effect transistor is improved.

Owner:CHANGXIN MEMORY TECH INC

Cell grabbing equipment

PendingCN111153201AAchieve crawlingImprove handling efficiencyConveyor partsFinal product manufactureComputer hardwareEngineering

The invention discloses cell grabbing equipment. The cell grabbing equipment comprises a positioning and conveying device and a grabbing device. The positioning and conveying device comprises a conveying mechanism and multiple positioning mechanisms. The conveying mechanism is used for bearing and conveying multiple cells in the first direction, and the multiple positioning mechanisms are used forpositioning the multiple cells on the conveying mechanism. The grabbing device and the positioning and conveying device are oppositely arranged, and the grabbing device is used for grabbing the multiple cells which are positioned and are separated from the conveying mechanism. According to the cell grabbing equipment, the multiple cells can be grabbed at the same time, the grabbing positions areaccurate, and therefore the carrying efficiency of the cells can be improved, and the preparation precision of the cells can be improved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

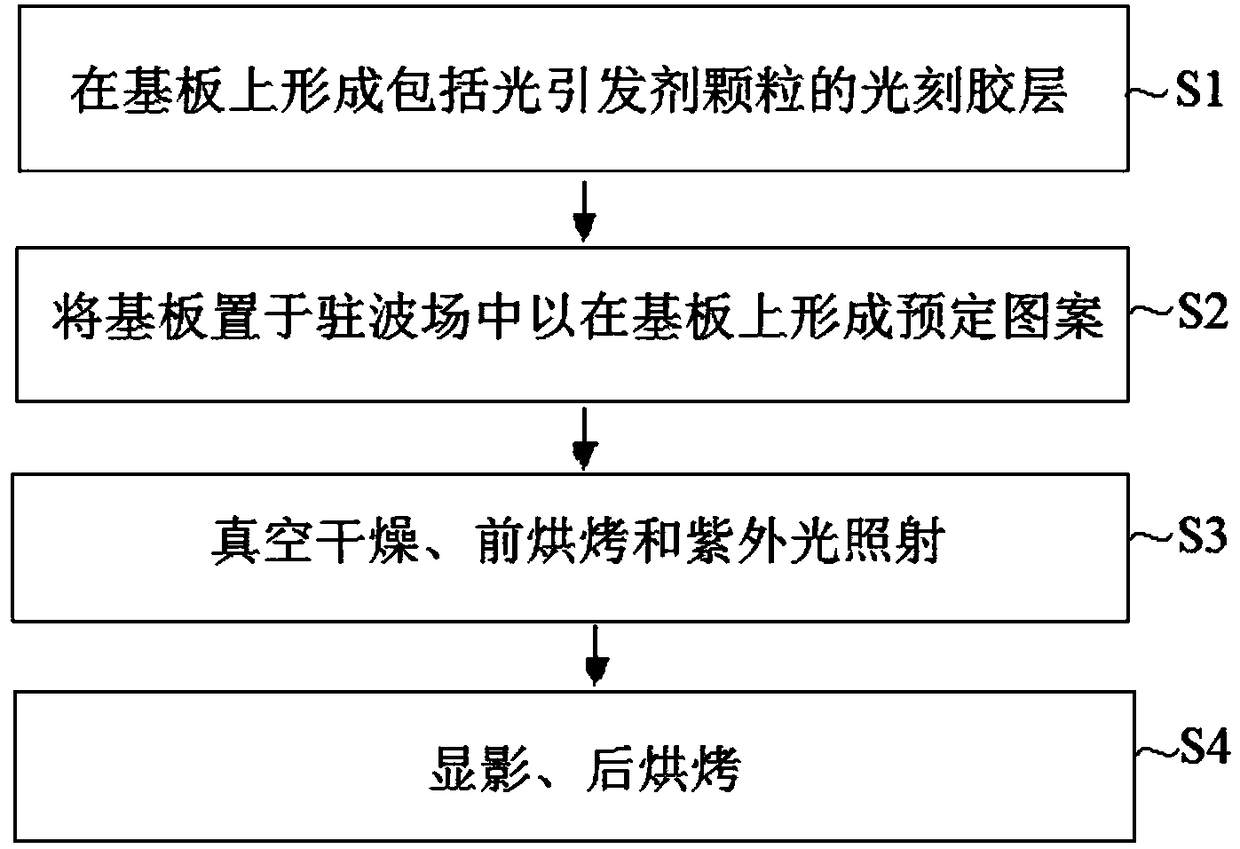

Photoresist pattern preparing method

InactiveCN108153109AHigh preparation precisionLow costPhotomechanical apparatusCross-linkCooking & baking

The invention provides a photoresist pattern preparing method. The photoresist pattern preparing method comprises forming a photoresist layer containing photoinitiator particles on a substrate; placing the substrate with the formed photoresist layer inside a standing wave field so that the photoinitiator particles can be aggregated on the substrate to form a preset pattern; vacuum-drying, pre-baking and ultraviolet-radiating the substrate with the preset pattern to subject the photoinitiator particles in standing wave points to cross-linking reaction; removing photoresist in areas without cross-linking reaction through developing, performing an after-baking process to obtain a planned photoresist pattern. The photoresist pattern preparing method prepares the photoresist pattern according to the principles of standing wave fields, thereby saving a photomask, reducing costs and the operation complexity and improving the preparation precision of the photoresist pattern.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

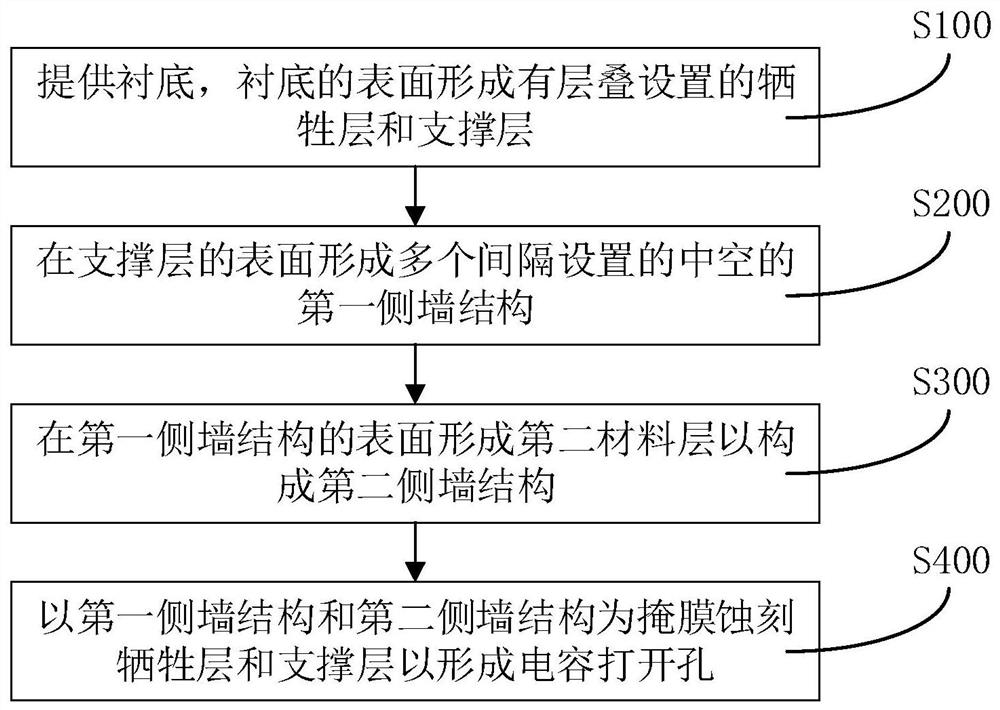

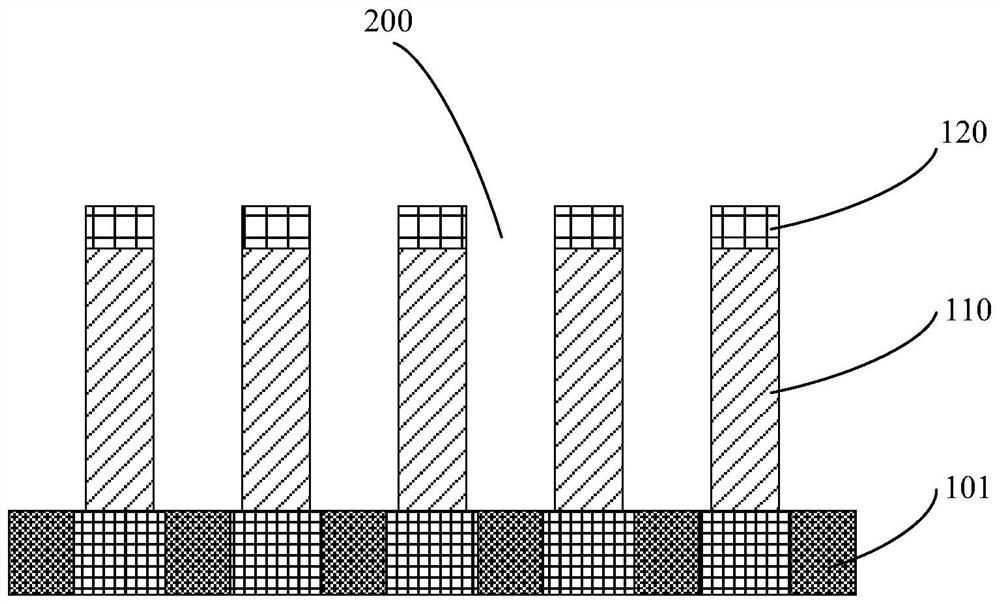

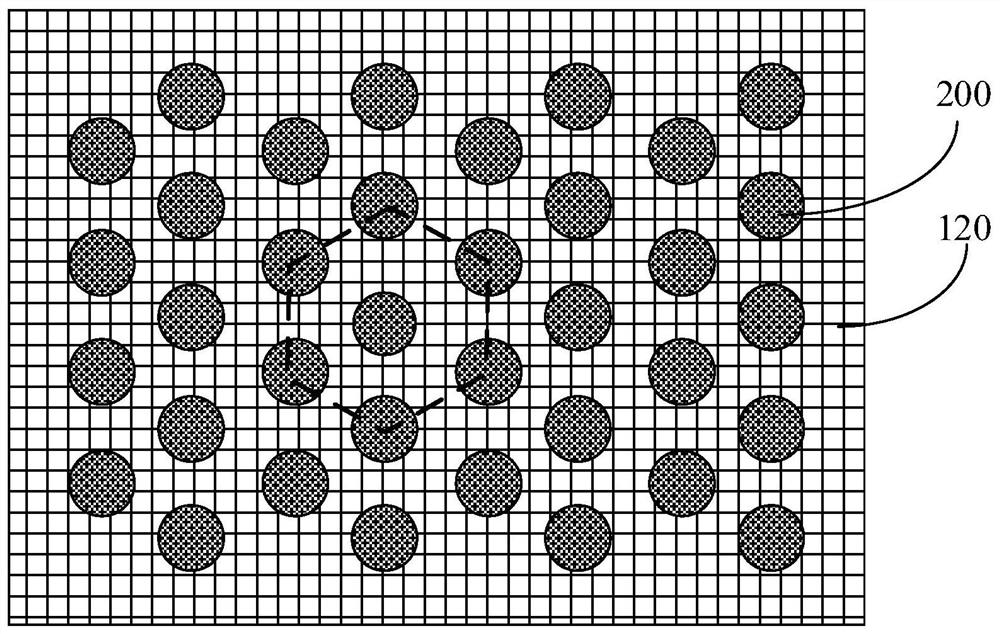

Forming method of capacitor opening hole and forming method of memory capacitor

ActiveCN113659075AImprove connectivityHigh preparation precisionTransistorSolid-state devicesCapacitanceStructural engineering

The invention relates to a forming method of a capacitor opening hole and a forming method of a memory capacitor. The forming method of the capacitor opening hole comprises the steps of providing a substrate, forming a sacrificial layer and a supporting layer which are stacked on the surface of the substrate, and forming a plurality of hollow first side wall structures which are arranged at intervals on the surface of the supporting layer; forming a second material layer on the surface of the first side wall structure to form a second side wall structure; and etching the sacrificial layer and the supporting layer by taking the first side wall structure and the second side wall structure as masks so as to form the capacitor opening hole. Through the steps, the first side wall structure and the second side wall structure which are tightly arranged can be formed, the capacitor opening hole is further formed, based on the forming method of the tightly-arranged double-side-wall structure, the communication effect of the capacitor opening hole can be achieved, the capacitor opening hole with a smaller size can be prepared, and then the preparation precision of the capacitor opening hole is improved.

Owner:CHANGXIN MEMORY TECH INC

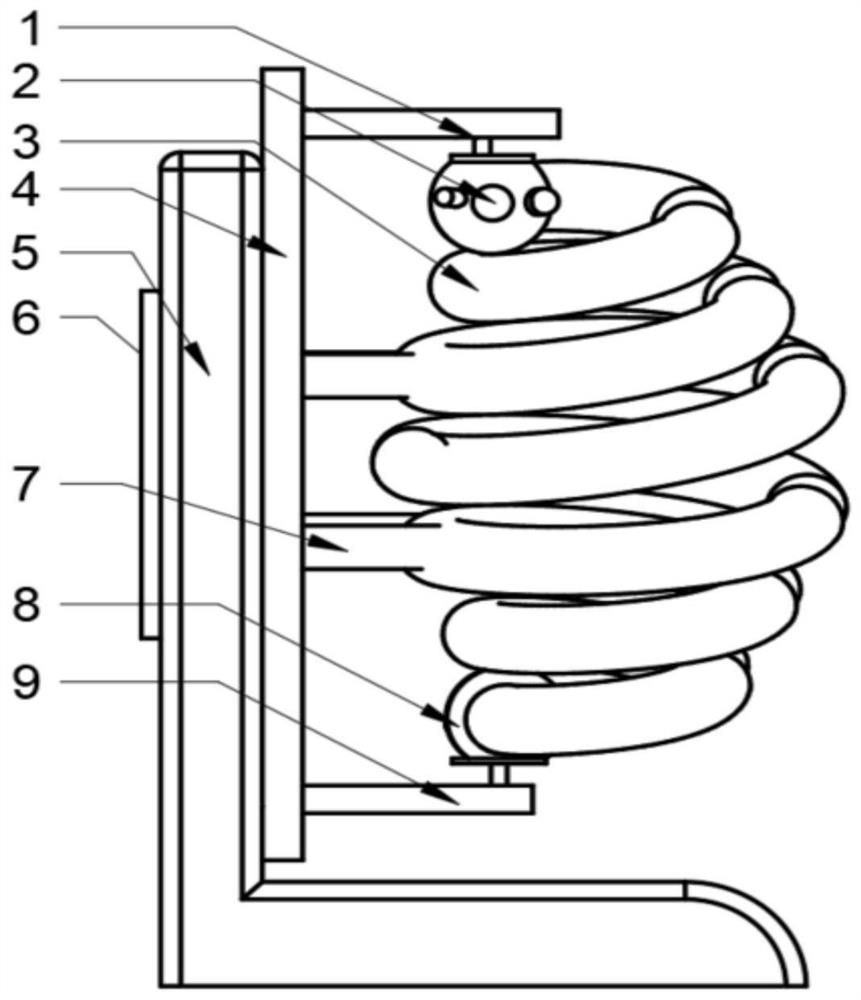

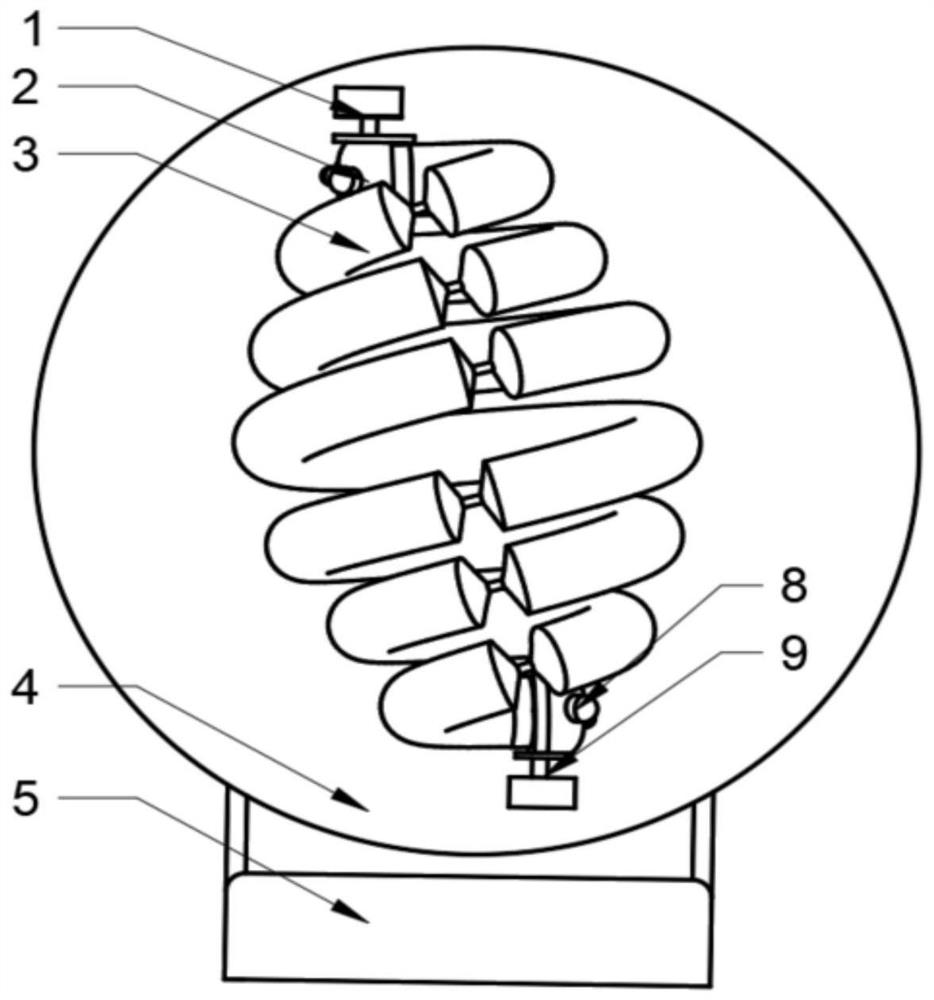

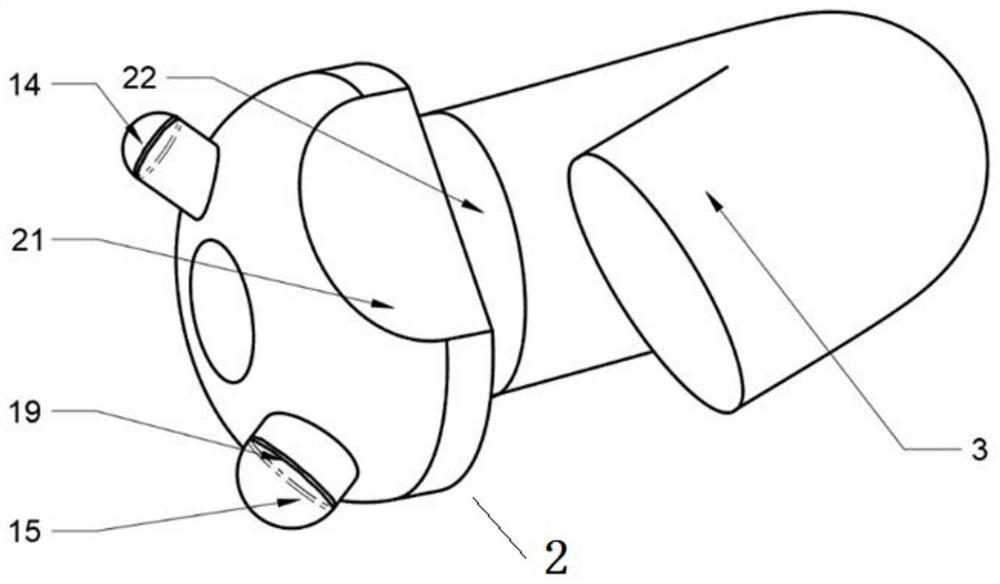

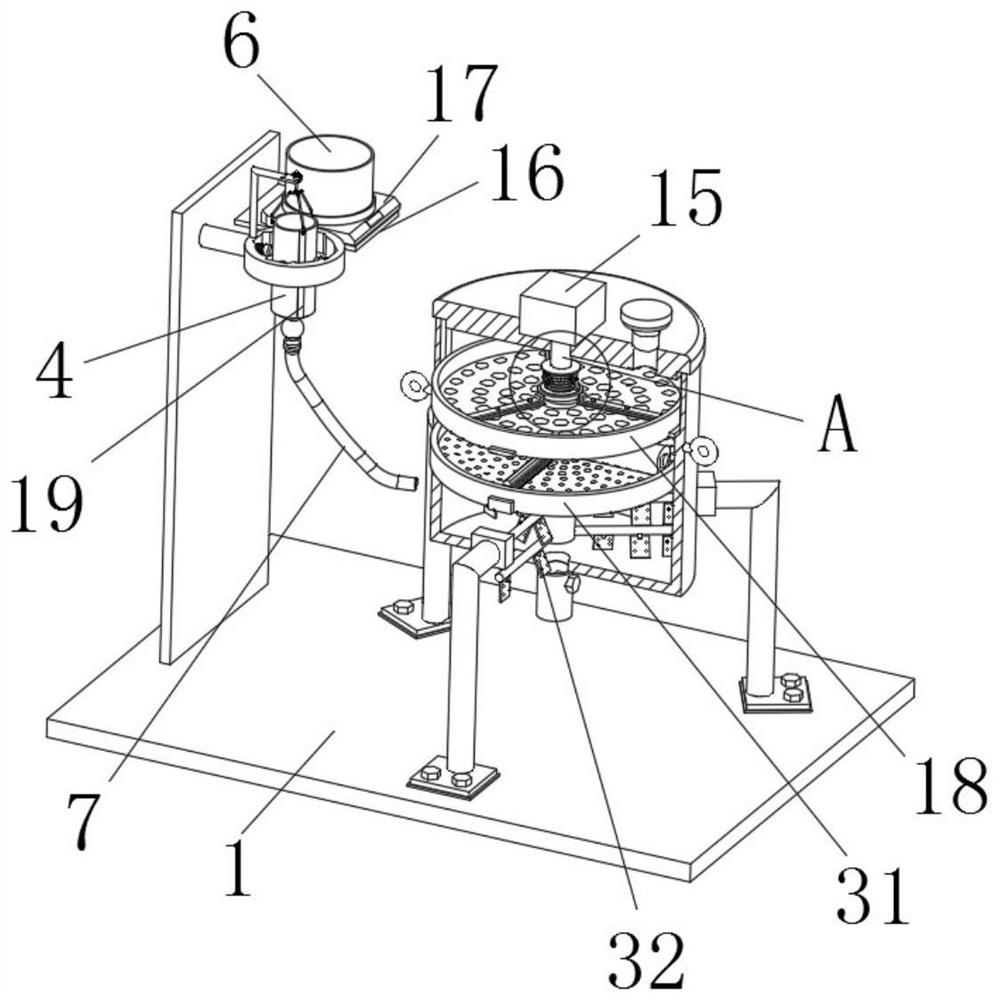

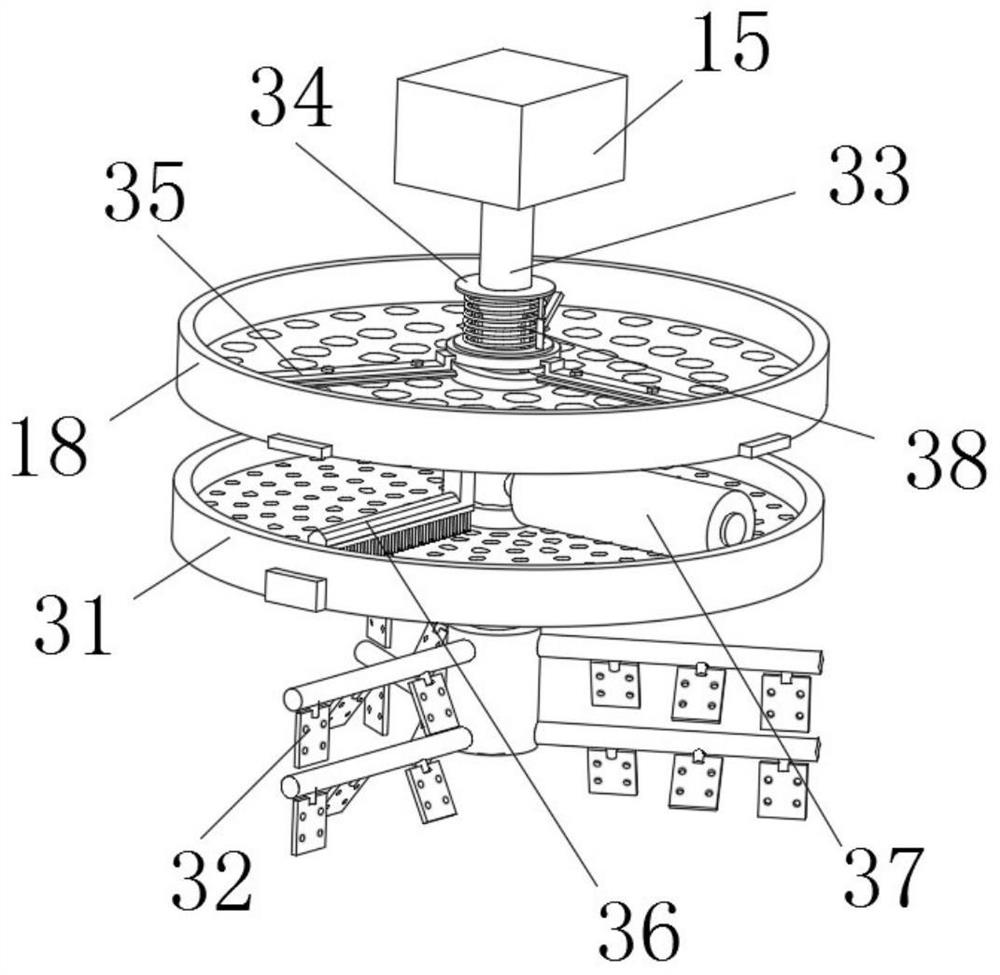

Device and method for preparing two-dimensional nanosheet material through cooperation of ball milling and cavitation

ActiveCN113617494AThe process of preparing the material is considerableSimple processGrain treatmentsEngineeringStructural engineering

The invention discloses a device and method for preparing a two-dimensional nanosheet material through cooperation of ball milling and cavitation. An output shaft of a motor is coaxially and fixedly connected with the center of a rotating disc, a spiral container is arranged on the front face of the rotating disc, the upper end of the spiral container is connected with an upper feeding and discharging head, and the lower end of the spiral container is connected with a lower feeding and discharging head; an upper magnetic force generator is arranged at the upper end of the upper feeding and discharging head, a lower magnetic force generator is arranged at the lower end of the lower feeding and discharging head, and the upper magnetic force generator and the lower magnetic force generator are the same in structure and each composed of a first connecting plate, a connecting rod, a second connecting plate, electromagnets, bridge type switches and a power source, wherein the multiple electromagnets are fixedly embedded inside the lower end of the second connecting plate, each electromagnet is wound with a coil, and all the coils are connected with the power supply through the bridge switches; a small-diameter section is arranged in the middle of the front surface of each coil of solenoid of the spiral container, and grinding balls can just pass through the small-diameter sections; and the two-dimensional nanosheet material is prepared by spontaneously generating cavitation through common ball milling, so that the efficiency and the preparation precision are effectively improved.

Owner:JIANGSU UNIV

Multi-circle QFN package lead frame manufacturing method

InactiveCN103474358AHigh preparation precisionGuaranteed accuracySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringPlastic packaging

The invention relates to a multi-circle QFN package lead frame manufacturing method, and belongs to the technical field of semi-conductor packaging. According to the technical scheme, the multi-circle QFN package lead frame manufacturing method comprises the following steps that 1 a substrate is provided and needed lead foot graphs are formed on the front face of the substrate; 2 multiple circles of needed outer lead feet are formed on the substrate by the utilization of the lead foot graphs on the substrate; 3 a needed packaging chip is arranged on the substrate and the packaging chip is electrically connected with the outer lead feet on the substrate through connecting lines; 4 plastic packaging is conducted on the packaging chip on the substrate to obtain a plastic packaging body, and the plastic packaging body enables the packaging chip, the connecting lines and the outer lead feet to be pressed on the substrate in a covering mode; 5 etching is conducted on the back face of the substrate so as to separate the packaging chip from the outer lead feet. According to the multi-circle QFN package lead frame manufacturing method, the structure is compact, the technology is simple and convenient to implement, the compatibility is good, the cost is low, and the machining precision and the machining efficiency are high.

Owner:NAT CENT FOR ADVANCED PACKAGING

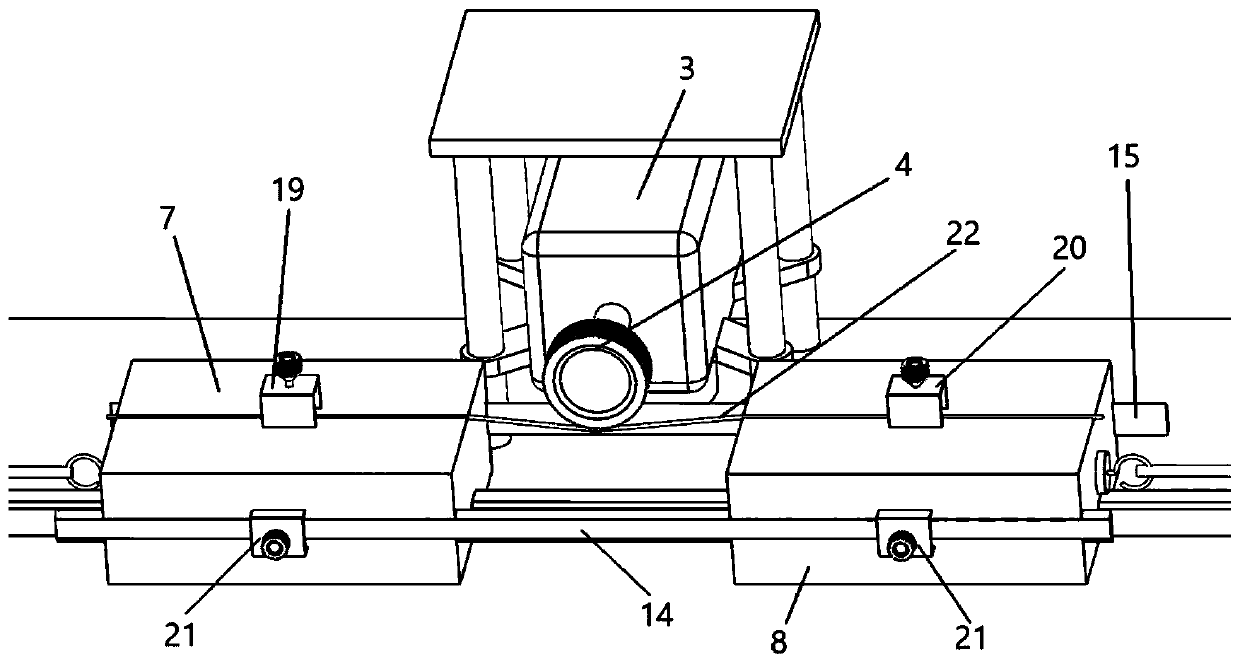

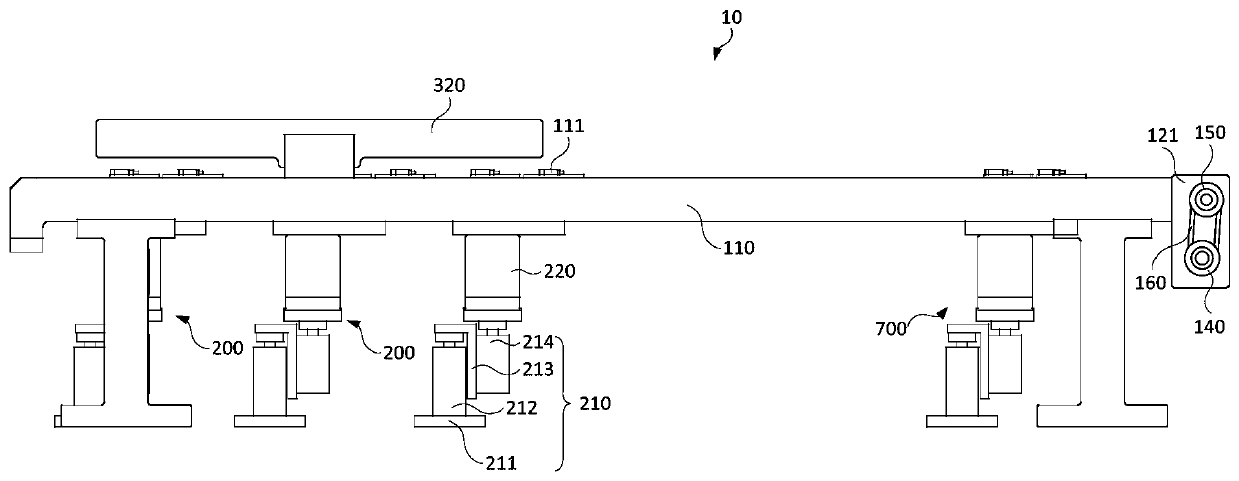

Supporting fork type loading device suitable for modification regeneration of denitration catalyst

PendingCN108584468AHigh preparation precisionImprove performanceDispersed particle separationLoading/unloadingAutomation

The invention discloses a supporting fork type loading device suitable for a modification regeneration of a denitration catalyst. The supporting fork type loading device comprises a laid rail, a powerdevice, a loading device which can move along the rail, a charging trolley and a control cabinet; the charging trolley and the control cabinet are arranged at one end of the rail; the rail is provided with a trigger switch component used for detecting the states of the loading device and the charging trolley; the charging trolley and the power device is connected with the control cabinet; the loading device comprises a base, a rotary shaft transversely arranged at the middle part of the base and an overturning platform which is movably connected with the rotary shaft; the overturning platformis provided with a supporting fork; and the supporting fork clamps a material, the loading device moves to the beside of the charging trolley, the overturning platform reaches a space above the charging trolley after rotating around the rotary shaft, and the material falls into the charging trolley under the effect of the gravity. The supporting fork type loading device is simple and convenient to operate, simple in structure and convenient to maintain and realizes automation, so that the standardized production level of modification regeneration of the denitration catalyst is increased, andthe problems that the catalyst is damaged caused by transportation during regeneration and the like are solved.

Owner:浙江浙能温州发电有限公司 +1

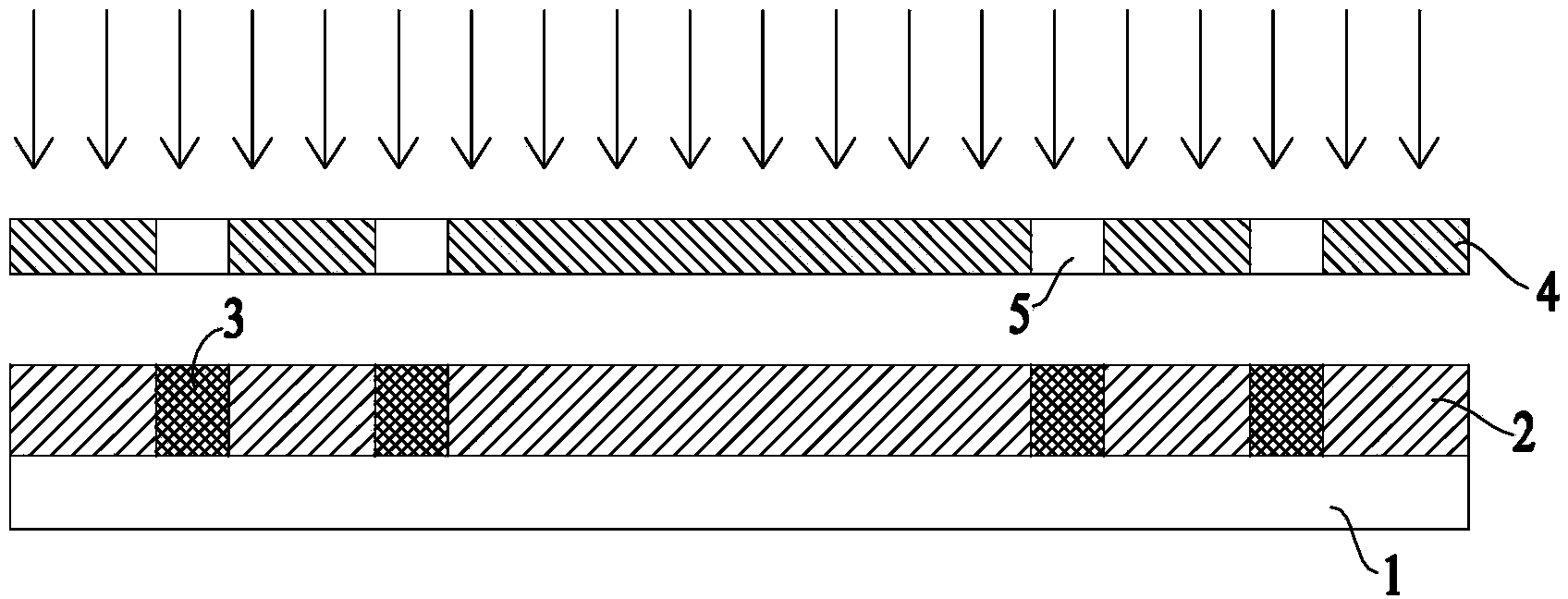

Quantum dot color conversion layer and preparation method thereof

InactiveCN112768587AFew stepsHigh preparation precisionSolid-state devicesSemiconductor devicesQuantum dotMaterials science

The invention provides a quantum dot color conversion layer and a preparation method thereof. The quantum dot color conversion layer comprises a transparent substrate and a micro-channel substrate which are in press fit, and the micro-channel substrate comprises at least one pixel point; each pixel point comprises at least one group of quantum point positions used for injecting a quantum dot solution, a liquid inlet hole used for enabling the quantum dot solution to flow in and a liquid outlet hole used for enabling the quantum dot solution to flow out, and the inlet and the outlet of each quantum point position in each pixel point are respectively communicated with the corresponding liquid inlet hole and the corresponding liquid outlet hole through micro-channels which are not crossed with each other; and the quantum dot solution is injected into each group of quantum dots, and quantum dots for realizing color conversion are formed after the quantum dots are photo-cured. According to the quantum dot color conversion layer, only one micro-channel substrate is needed, color conversion of different colors can be achieved at the same time, a photoetching agent is not doped in quantum dots, and the quantum dots cannot be degraded, so the conversion efficiency of the quantum dots cannot be reduced, and a large amount of waste of the quantum dots cannot be caused.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

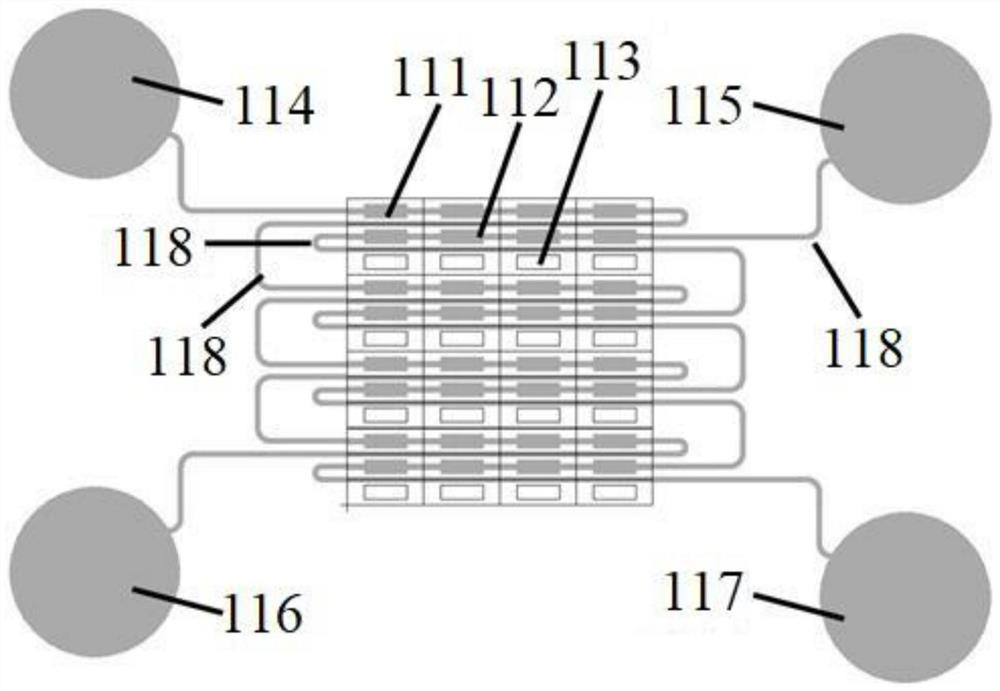

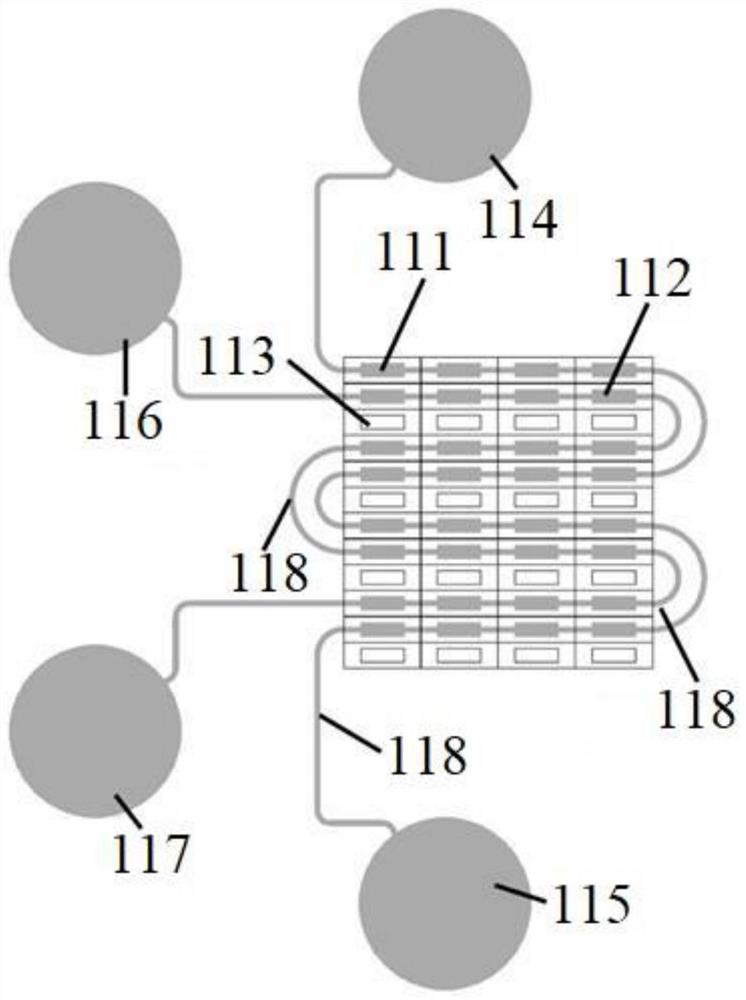

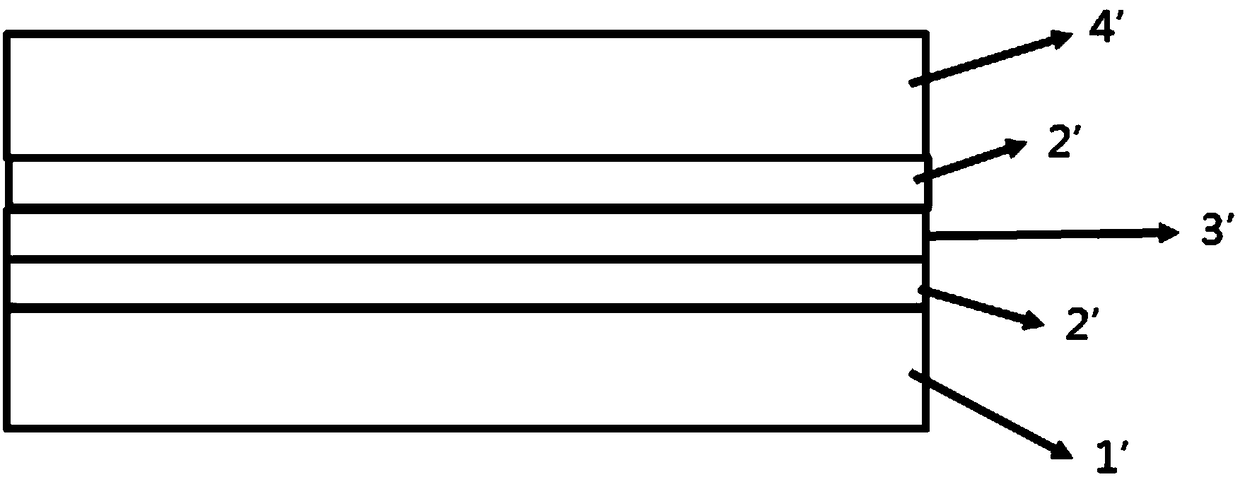

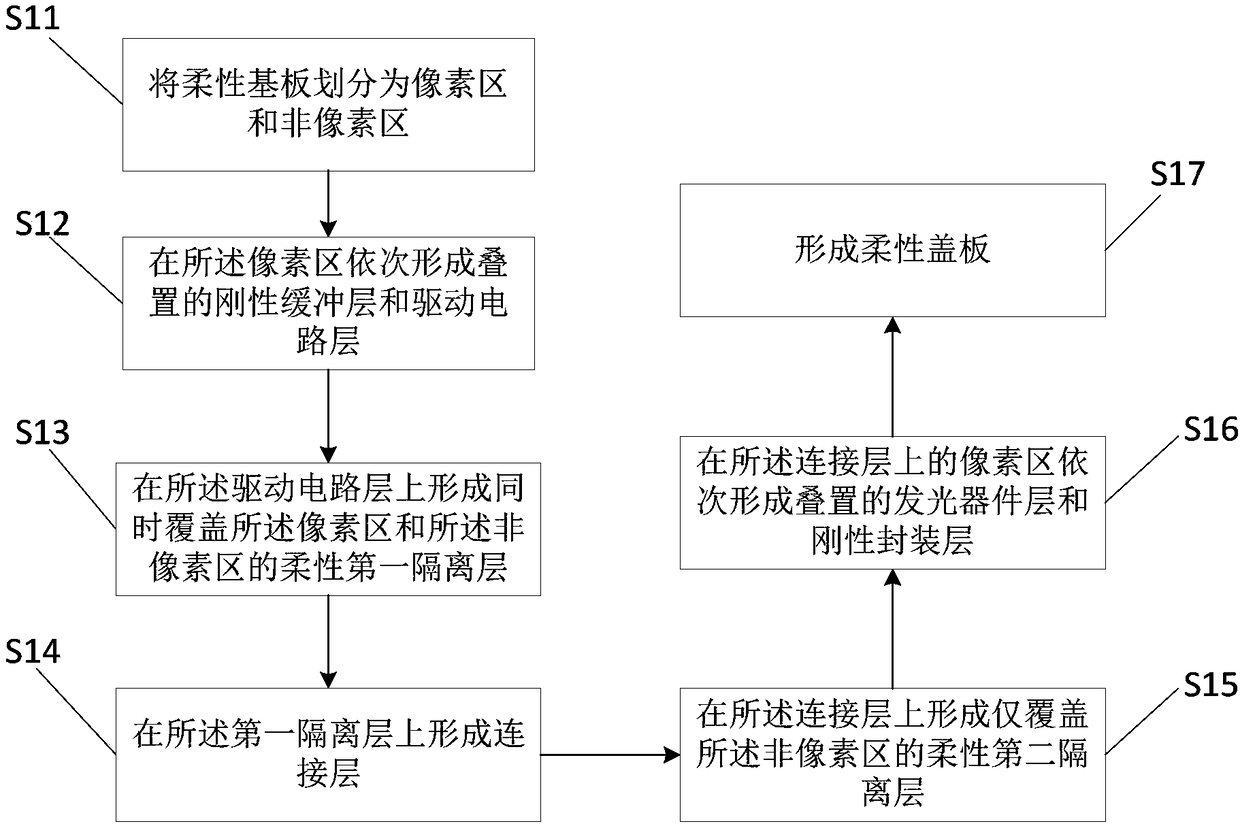

Flexible display device and method for preparing the same

ActiveCN108305958AGood flexibility and bending effectImprove reliabilityFinal product manufactureSolid-state devicesIsolation layerEngineering

The invention, which relates to the field of the display technology, discloses a method for preparing a flexible display device. The method comprises: a flexible substrate is divided into a pixel region and a non-pixel region; a rigid buffer layer and a driving circuit layer that are stacked are formed in the pixel region successively; a flexible first isolation layer covering both the pixel region and the non-pixel region is formed on the driving circuit layer; a connection layer is formed on the first isolation layer; a flexible second isolation layer only covering the non-pixel region is formed on the connection layer; a light-emitting device layer and a rigid encapsulation layer that are stacked are formed in the pixel region on the connection layer successively; and a flexible cover plate is formed. According to the preparation method, the rigid buffer layer and the driving circuit layer are only formed in the pixel region, the flexible first isolation layer, the connection layerand the flexible second isolation layer are only formed in the non-pixel region, and thus the stress mainly is connected in the non-pixel region. Therefore, the flexible bending effect is good; a phenomenon that the device characteristics are changed due to bending is avoided; and the reliability and the use effect of the flexible display device are improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

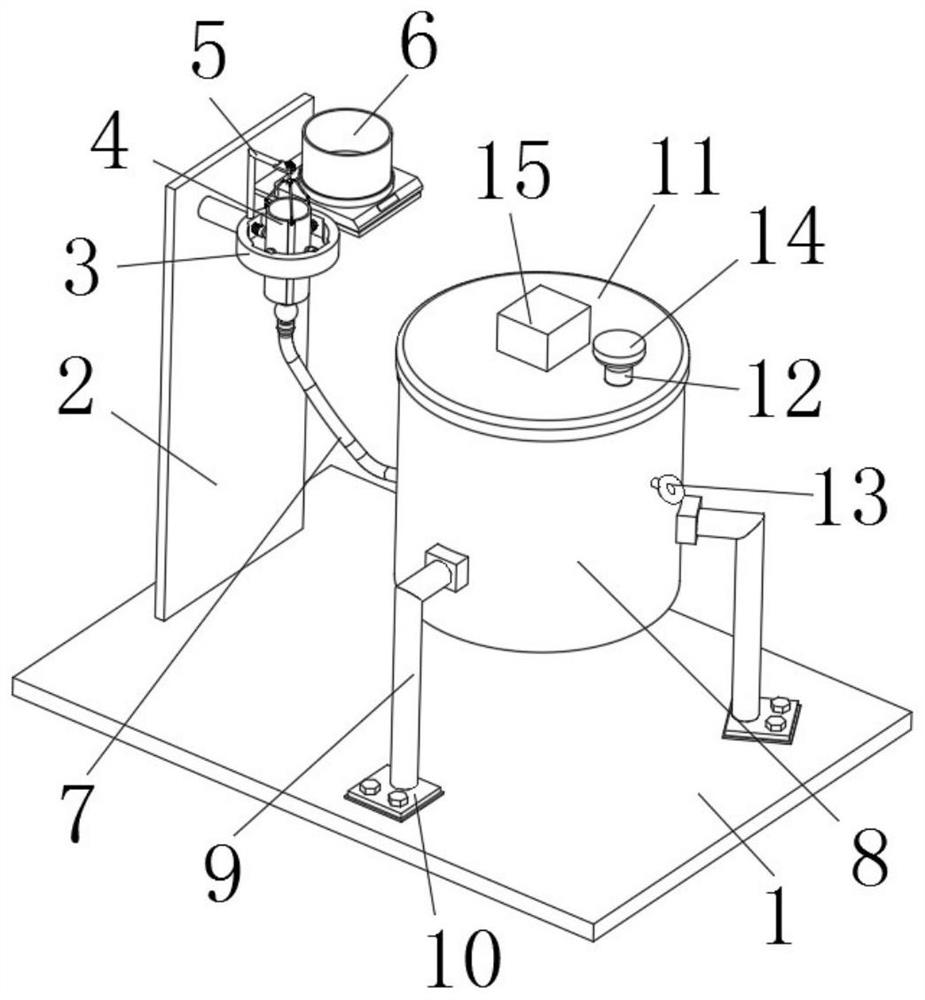

Binder preparation device for producing hollow glass of textile machinery

InactiveCN112975776AAffected readingsFast manufacturingRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a binder preparation device for producing hollow glass of textile machinery, and relates to the technical field of binder preparation devices. The binder preparation device comprises a bottom plate, a side plate is fixedly connected to the top of the bottom plate, a fixing frame is fixedly connected to the side wall of one side of the side plate, and a measuring cylinder clamping part is installed on the fixing frame. A measuring cylinder balancing part is installed on the fixing frame, a measuring cylinder is installed on the measuring cylinder balancing part, the measuring cylinder and the measuring cylinder clamping part are arranged in a matched mode, and a scale plate is fixedly connected to the side wall of the measuring cylinder. A placing plate is fixedly connected to the side wall of one side of the side plate, an electronic metering scale is installed at the top of the placing plate, and a placing box is arranged at the top of the electronic metering scale. The binder preparation device for producing the hollow glass of the textile machinery is reasonable in structure, measurement, smashing, grinding and stirring are integrated, the integration effect is good, the preparation speed of a binder is increased, and the binder is prepared uniformly.

Owner:杭州柔谷防护用品有限公司

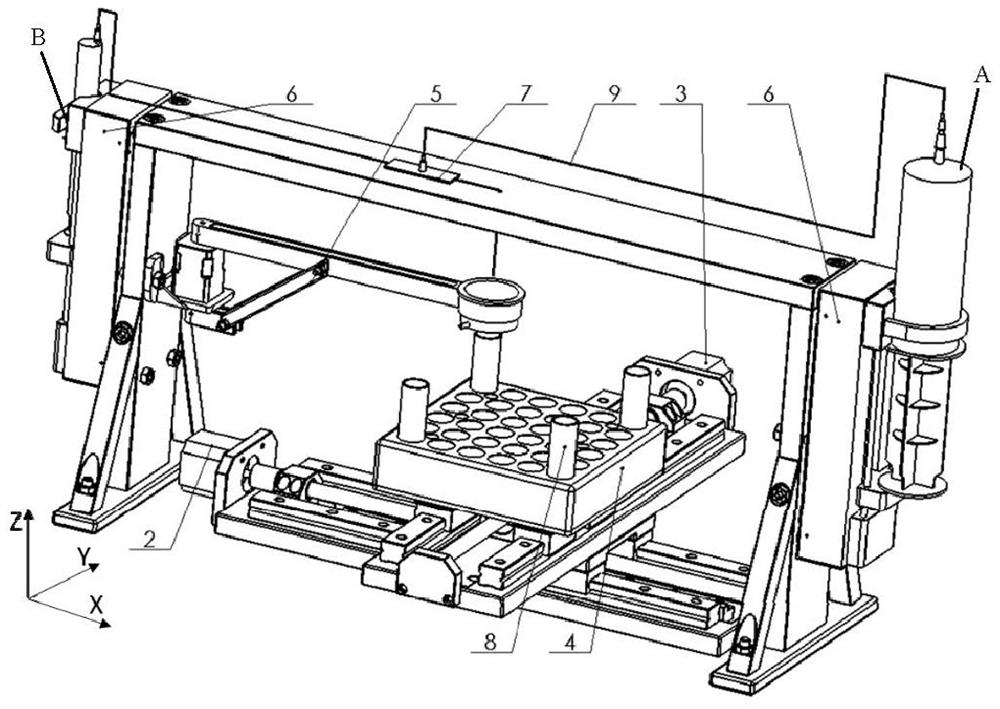

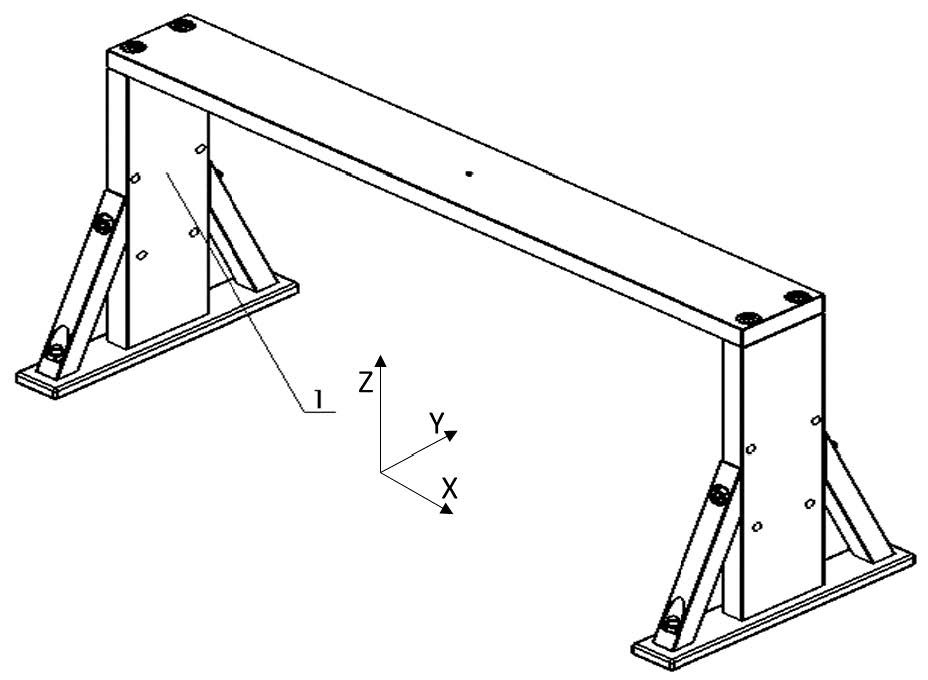

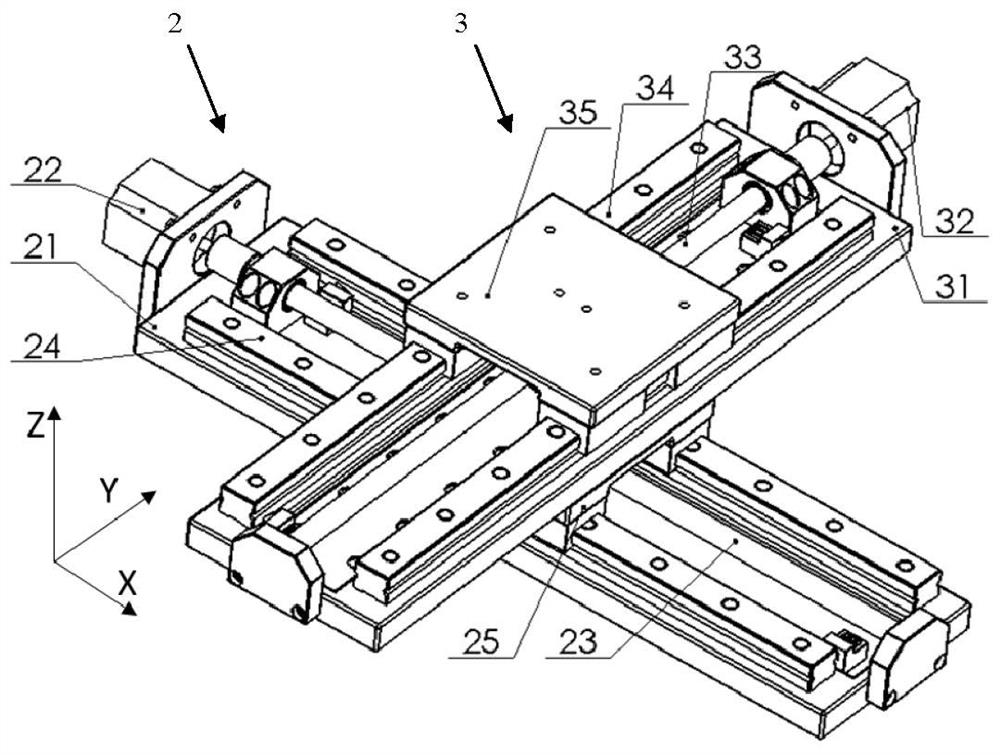

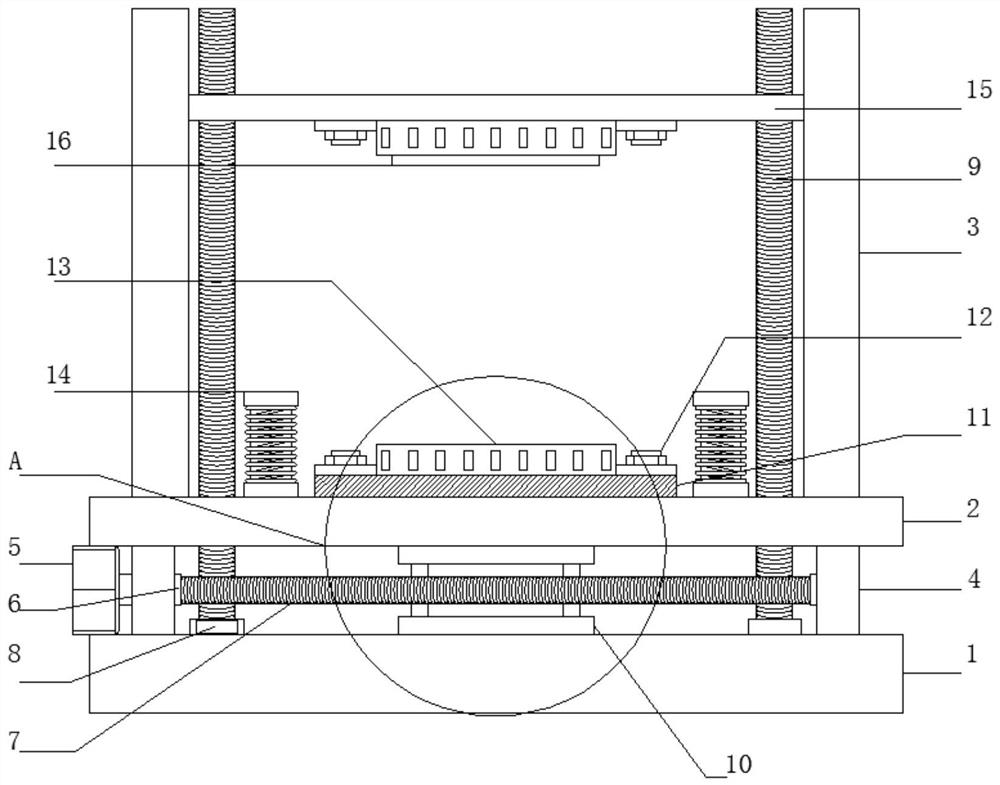

High-flux material synthesis equipment and method based on micro-fluidic chip

InactiveCN113019262AEasy to detectEasy to manufactureProcess control/regulationChemical/physical/physico-chemical microreactorsMaterial synthesisHigh flux

The invention provides high-flux material synthesis equipment and method based on a micro-fluidic chip. The equipment comprises a bracket with a suspended part, at least two injection pump mechanisms arranged on the bracket and filled with original samples, a micro-fluidic chip arranged at the suspended part of the bracket, a pipeline connected with the micro-fluidic chip and the injection pump mechanism, an objective table, a moving device and a control device; at least two original sample injection ports of the micro-fluidic chip are correspondingly connected with the injection pump mechanism; the objective table is arranged below the micro-fluidic chip and carries array test tubes; the moving device is used for moving the objective table on a horizontal plane; and the control device can enable the moving device to drive the objective table to move until one test tube is positioned right below a sample outflow port, and can enable the specified injection pump mechanism to be synchronously started, so that original samples separately enter a pipeline assembly and react to obtain a group of reaction samples, and the group of reaction samples flow into one corresponding test tube. Therefore, various materials can be prepared and collected into each test tube at one time.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

High-precision quick-cooling crankshaft mold structure

The invention discloses a high-precision quick-cooling crankshaft mold structure. The structure comprises a base; a mounting plate is arranged at the upper end of the base; side plates are arranged onthe two sides of the upper end surface of the mounting plate; a supporting frame is arranged between the base and the mounting plate; a motor is arranged on one side of the supporting frame; a turbine is arranged in the supporting frame; bearings are arranged at the bottoms of the two sides of the base; threaded rods are sleeved with the bearings; a hydraulic cylinder is arranged in the center ofthe base; a containing seat is arranged at the upper end of the mounting plate; a lower mold is arranged between two locking assemblies; buffer assemblies are arranged on the two sides of the mounting plate; a mounting frame is erected at the upper ends of the side plates; and an upper mold is arranged on the mounting frame through the locking assemblies. According to the high-precision quick-cooling crankshaft mold structure, the buffer assemblies and the hydraulic cylinder are arranged, so that the structure has the relatively-high preparation precision, and unnecessary waste of materials is avoided; and a spraying plate and a heat dissipation assembly are arranged, so that the structure has the good cooling efficiency, and the preparation time is greatly shortened.

Owner:MAANSHAN CHANGYE HEAVY IND TECH

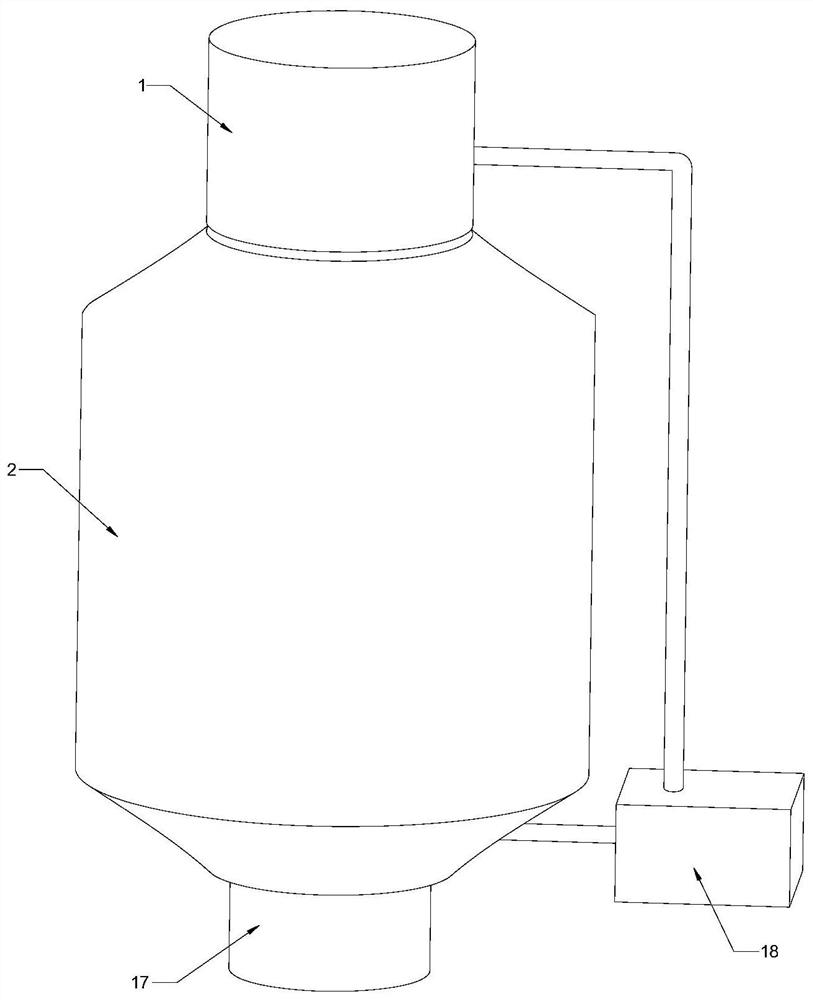

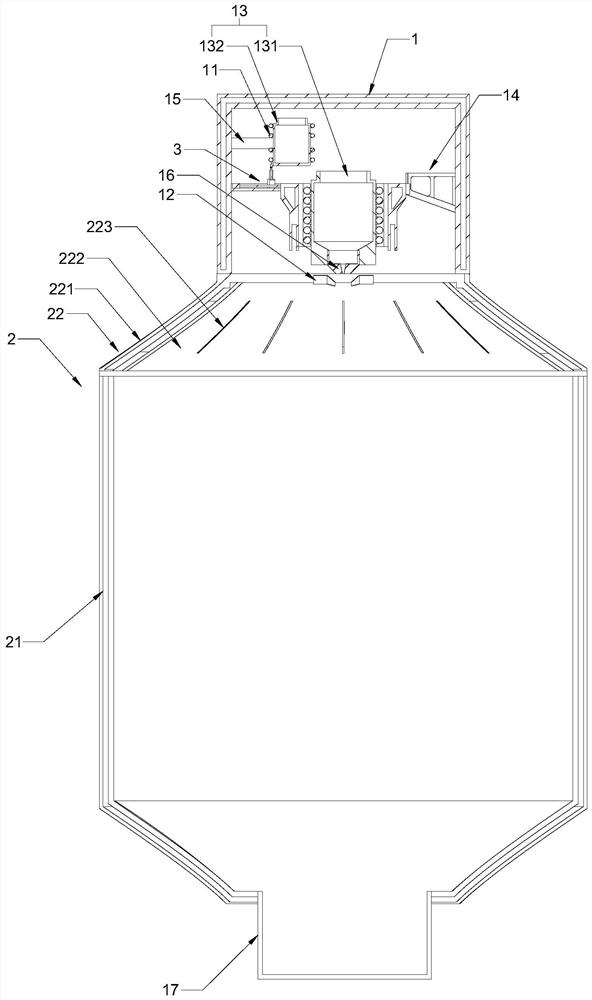

Metal powder preparation device and method through vacuum induction melting and double-flow gas atomization

PendingCN113210621ANot prone to cooling and solidificationReduce formationTransportation and packagingMetal-working apparatusCrucibleMetal powder

The invention discloses a metal powder preparation device and method through vacuum induction melting and double-flow gas atomization. According to the technical scheme, the device is characterized by comprising a smelting chamber, an atomization chamber arranged below the smelting chamber, an atomization chamber bottom shell and a gas introducing shell arranged on the base, wherein the smelting chamber is communicated with the atomization chamber, an induction coil, an atomization nozzle and a smelting crucible for smelting metal are arranged in the smelting chamber, the gas introducing shell comprises an outer casing and a gas curtain shell, a gas compression chamber is formed between the outer casing and the gas curtain shell, a high-pressure gas inlet pipeline is arranged on the outer casing, a plurality of gas curtain ports are formed in the gas curtain shell in a circumferential array manner, and the gas curtain ports are arranged in a long-strip shape; and a collecting tank and a gas recovery device are arranged at the lower end of the bottom shell and both connected with the shell. The metal powder preparation device through vacuum induction melting and double-flow gas atomization can be used for preparing the fine spherical metal powder, and the effects of reducing satellite powder and improving the preparation precision of the metal powder are achieved.

Owner:江苏智仁景行新材料研究院有限公司

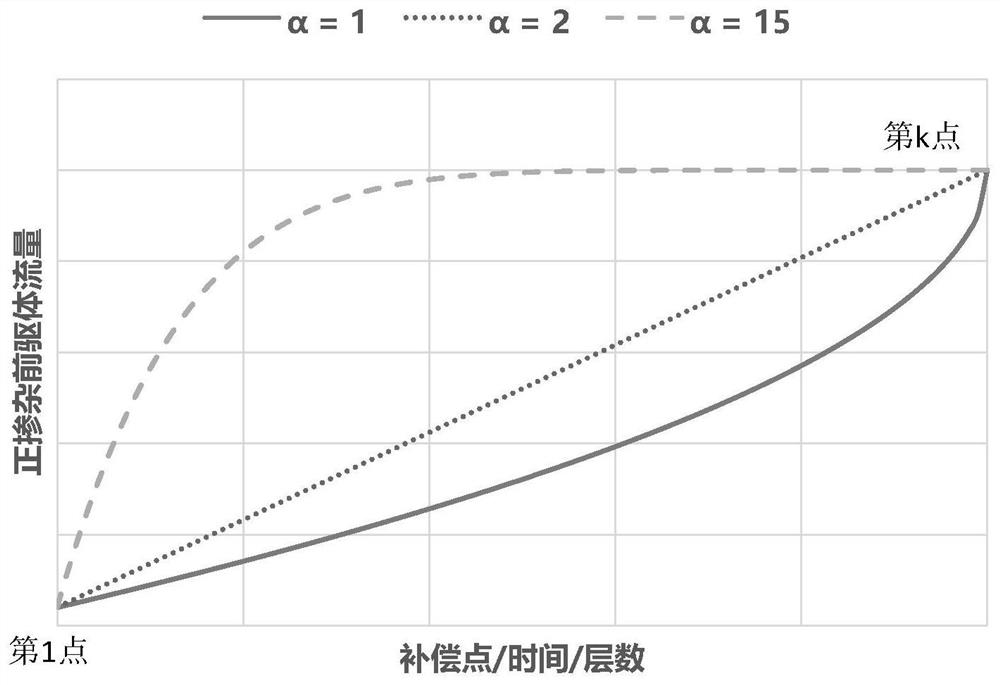

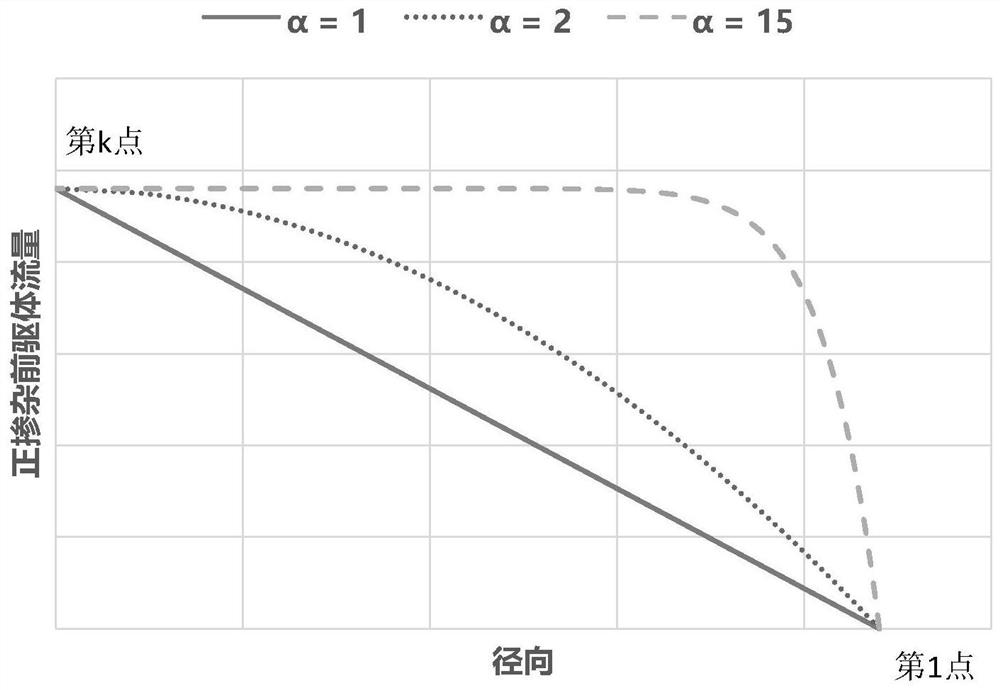

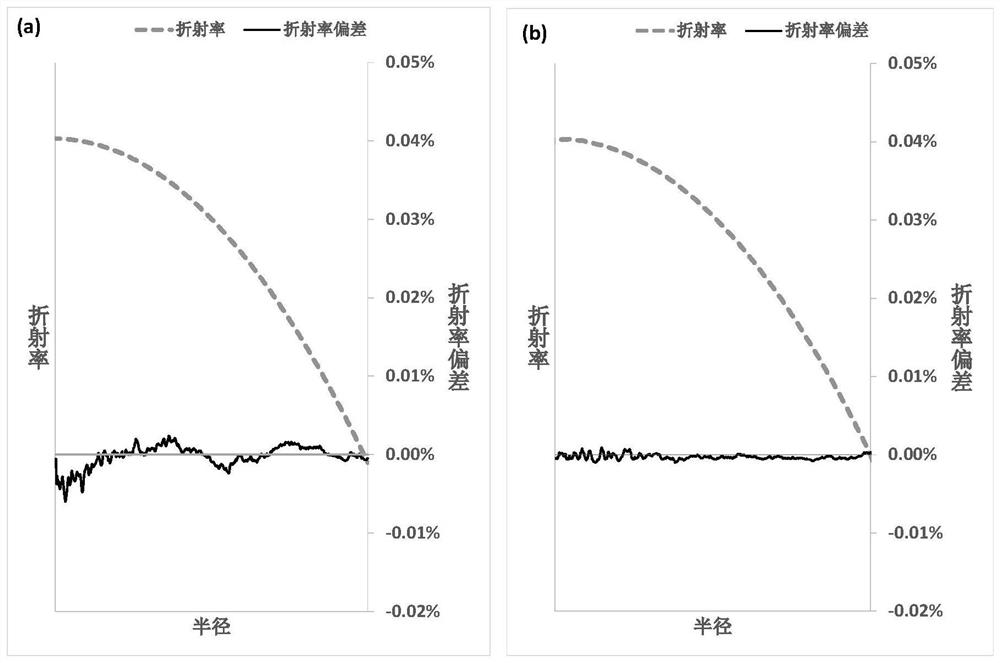

Method for depositing core layer of optical fiber preform with gradient refractive index profile

ActiveCN113292240AImprove radial accuracyImproved Axial ConsistencyGlass making apparatusResonant cavityMaterials science

The invention relates to a method for depositing a core layer of an optical fiber preform with a gradient refractive index profile, which comprises the following steps of clamping a quartz glass tube or a target rod on a rotary chuck, axially reciprocating a microwave resonant cavity or a flame blast burner along the quartz glass tube or the target rod, and introducing reaction gas by controlling the opening degree of a flow meter to form a doped quartz glass deposition layer. The method is characterized in that a whole core layer deposition area is divided into k*(m+1) matrix point locations, a doped deposition vector of each point location is a calibrated doped deposition vector after a mother rod is measured and calculated, and the calibrated doped deposition vector is used for controlling and adjusting the opening degree of a reaction gas flow meter, and the opening control and adjustment of the flow meter are continuously and gradually changed among the point positions. The axial consistency of the core rod can be controlled and improved while the radial precision of the core layer is controlled and improved, so that the preparation precision and the effective rod length of the core layer of the gradient refractive index optical fiber preform rod are improved, and the qualified ratio of optical fiber output is improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Electrostatic adsorption device and preparation method thereof

InactiveCN110861113AReduce manufacturing difficultyHigh preparation precisionGripping headsLaminationEngineeringNanotechnology

The embodiment of the invention provides an electrostatic adsorption device and a preparation method thereof. The electrostatic adsorption device and the preparation method thereof solve the problemsthat the electrode machining precision of an existing electrostatic adsorption device is difficult to control, the insulating property of an electrode structure is poor, and the generated adsorption force is poor. The electrostatic adsorption device provided by the embodiment comprises an insulating layer, a conductive layer and an insulating line region, the conductive layer is arranged on the surface of the insulating layer, the insulating line region is arranged on the surface of the insulating layer, wherein the insulating line region penetrates through the conductive layer to divide the conductive layer into a positive electrode region and a negative electrode region.

Owner:MAGIC ADHESION BEIJING TECH CO LTD

Pre-mixing mechanism for concrete production and processing

InactiveCN112192750AControl operationReduce the difficulty of operationDischarging apparatusCement mixing apparatusElectric machineryPipe

The invention discloses a pre-mixing mechanism for concrete production and processing. The pre-mixing mechanism comprises a workbench, wherein a mechanism body is arranged at the top of the workbench,a material storage grid is arranged at the upper end of a connecting frame and located at the bottom of the workbench, a liquid inlet pipe opening and a material inlet pipe opening are formed in thetwo sides of the outer wall of the mechanism body, and the output end of a first motor is connected with a driving rotating shaft; and driving gear teeth are arranged at the top of the end, penetrating through the mechanism body, of the driving rotating shaft, driven rotating shafts are arranged in an inner cavity of the mechanism body and located on the two sides of the driving rotating shaft, driven gear teeth are arranged at the positions, corresponding to the driving gear teeth, of the driven rotating shafts, and mixing stirring paddles are arranged at the bottom end of the driving rotating shaft and the bottom ends of the driven rotating shafts. According to the pre-mixing mechanism for concrete production and processing, through arrangement of the driving rotating shaft, the driven rotating shafts and a second mixing mechanism, materials are pre-mixed twice, the stirring efficiency is improved, the materials are pre-mixed more uniformly, through arrangement of the material storage grid, the materials can be collected more conveniently, and the manpower input is reduced.

Owner:CHONGQING FEIQIANG CONCRETE CO LTD

Chip packaging structure and method of integrated passive element

InactiveCN107978597ASolve the thickerReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

The invention discloses a chip packaging structure and method of an integrated passive element. The chip packaging structure of the integrated passive element comprises a packaging body, a passive element layer, a first insulating layer, a conductive column, a rewiring layer, wherein a chip is packaged in the packaging body; a device surface of the chip and a first surface of the packaging body are located at the same plane; the passive element layer is arranged at a second surface of the packaging body; the first insulating layer is arranged on the passive element layer; the conductive columnis arranged in the packaging body, one end of the conductive column is coupled to the passive element layer, and the other end of the conductive column is located at the same plane with the first surface of the packaging body; and the rewiring layer is arranged at the first surface of the packaging body and is coupled to the chip and the conductive column. The chip packaging structure is providedwith the passive element layer at the second surface of the packaging body, thereby solving a problem of great thickness of the chip packaging structure integrated with a plurality of passive elements due to embedment of the passive elements in the rewiring layer in the prior art, and reducing the thickness of the packaging structure of the plurality of passive elements.

Owner:NAT CENT FOR ADVANCED PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com