Brittle material fatigue crack prefabricating test machine

A technology for fatigue cracks and brittle materials, applied in the field of fatigue crack prefabrication testing machines for brittle materials, can solve the problems of prefabricated crack direction deviation, specimen damage and scrapping, prefabricated cracks, etc., to achieve low assembly cost, reduce the probability of failure, The effect of increasing effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

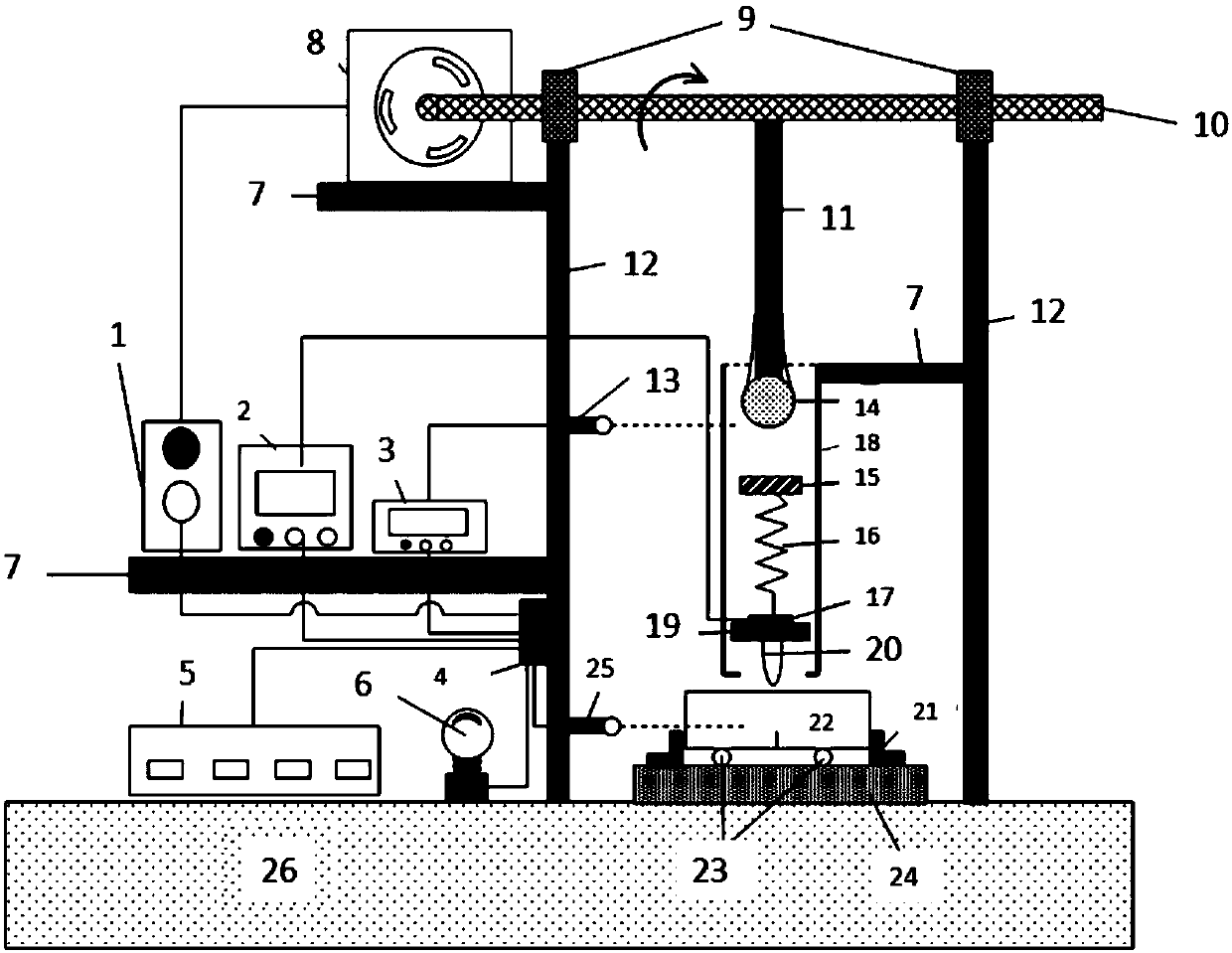

[0027] The schematic diagram of the overall structure of the brittle material crack prefabrication testing machine is as follows: figure 1 As shown, the whole includes base and support system, power output system, control system, limit protection, and sample fixture system. The support frame is made of high-strength steel, and the bearing 9 and the transmission shaft 10 are fixed on the top of the support frame 12. After the two ends of the bearing are kept horizontal, the transmission shaft of the left end bearing is connected with the motor 8, and the motor is fixed on the support plate connected to the support frame. superior. The support plate and the support frame are connected by flanges, and the motor and the support plate are connected by bolts. Two laser probes 13 and 25 with different functions are respectively connected to designated positions on the steel frame by bolts, and the upper and lower positions can be adjusted.

[0028] The limiting cylinder 18 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com