Patents

Literature

177 results about "Material Crack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering cement-based material crack by means of microorganism, culture fluid and repair nutrient fluid

ActiveCN101302484AImprove volume stabilityIncreased durabilityBacteriaBuilding repairsCulture fluidNutrient solution

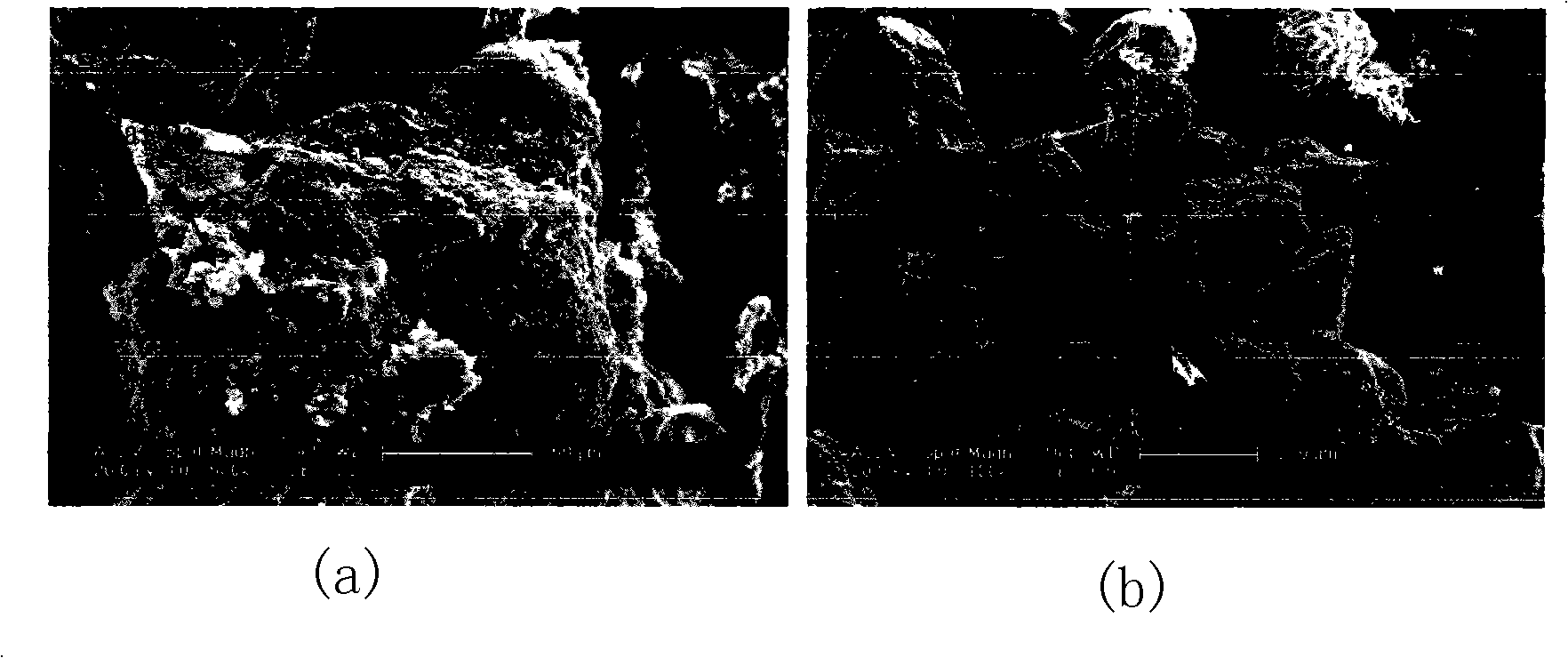

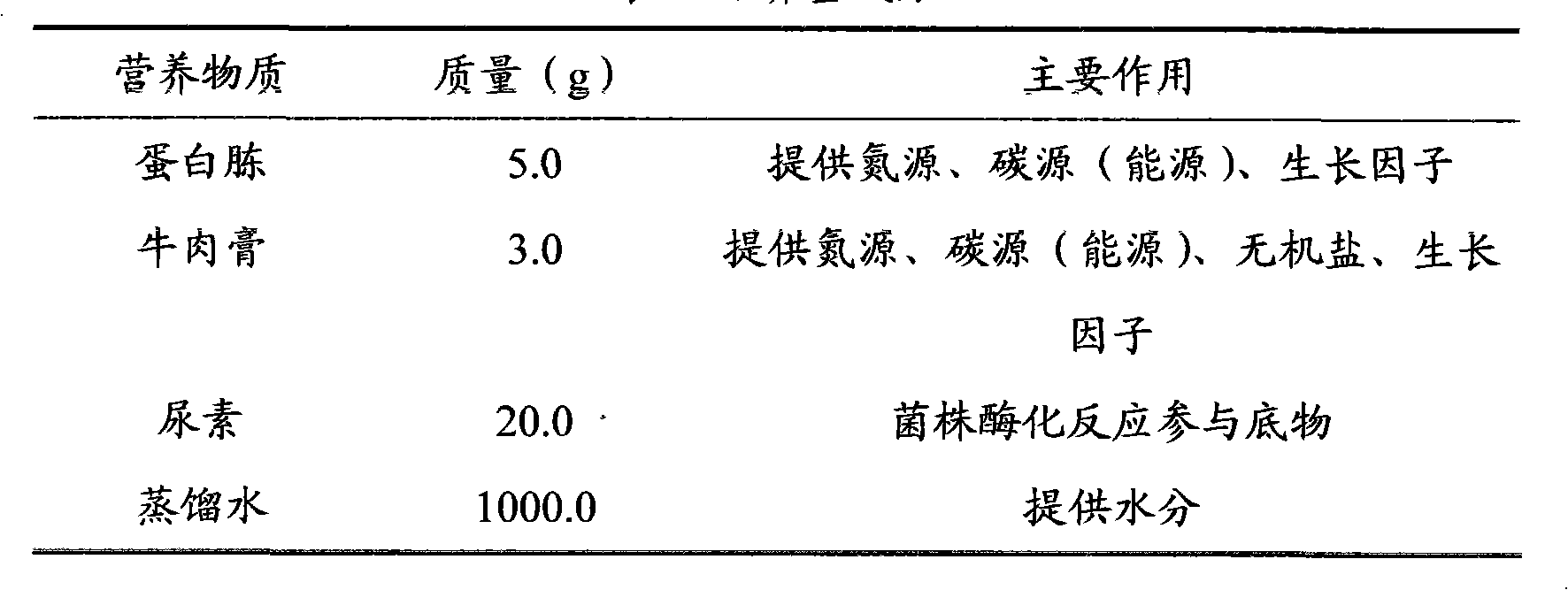

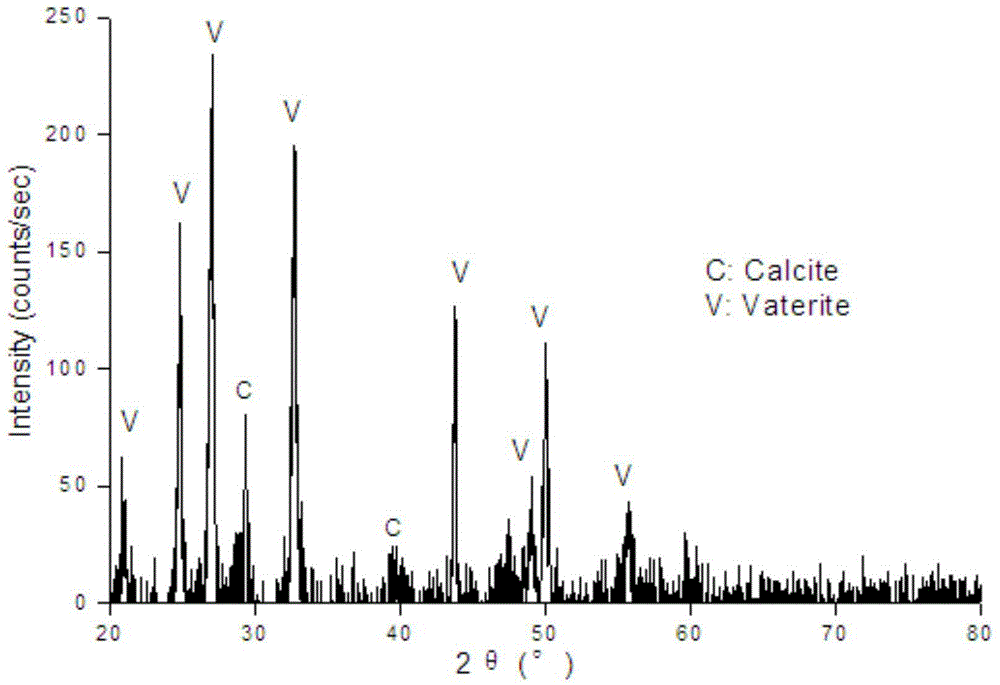

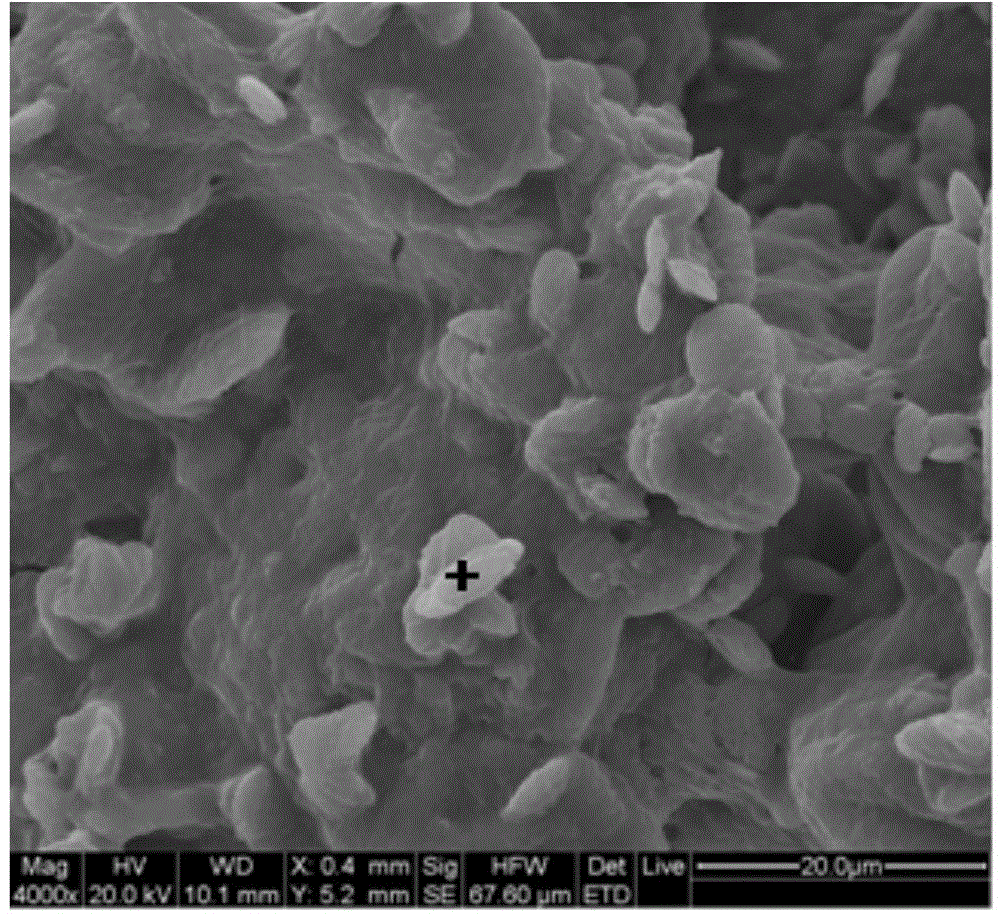

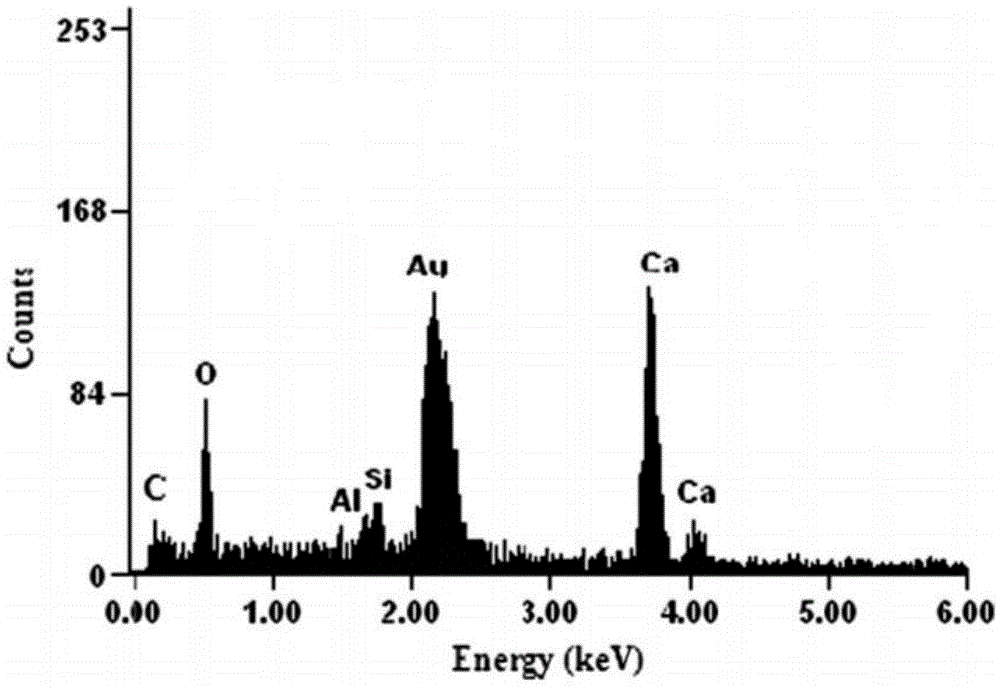

The invention discloses a method for repairing cement-based material cracks, as well as a culture solution and a repair nutrient solution. The method for repairing cement-based material cracks by through microorganisms comprises the following steps that: a Bacillus pasteurii strain is inoculate onto a culture medium provided with a urea-containing substrate; shake cultivation is carried out at a temperature of between 25 and 37 DEG C, and then a culture bacteria solution is taken out and centrifuged and has supernatant fluid removed; strain cells are collected through the culture solution; the concentration of the strain cells is controlled in a range of between 2x10<9> and 1x10<11> cell / ml; standard sand, urea and Ca(NO3)2.4H2O mixture are added to each milliliter of strain cell solution obtained through collection, mixed, stirred into slurry and injected into cement stone cracks; the frequency of the repair nutrient solution injection is not less than two times; finally, maintenance is carried out. In the culture solution, each liter of culture solution contains 4 to 6 g of peptone, 2 to 4 g of beef extract and 20 to 60 g of urea. The method fully utilizes microbial resources in nature; CO3<2-> decomposed out through microbial enzyme can chelate Ca<2+> in a substrate so as to be mineralized and deposit calcium carbonate, and is close in the combination with the substrate and good in stability.

Owner:SOUTHEAST UNIV

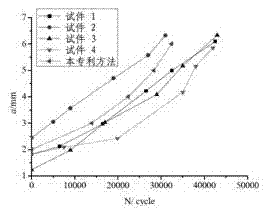

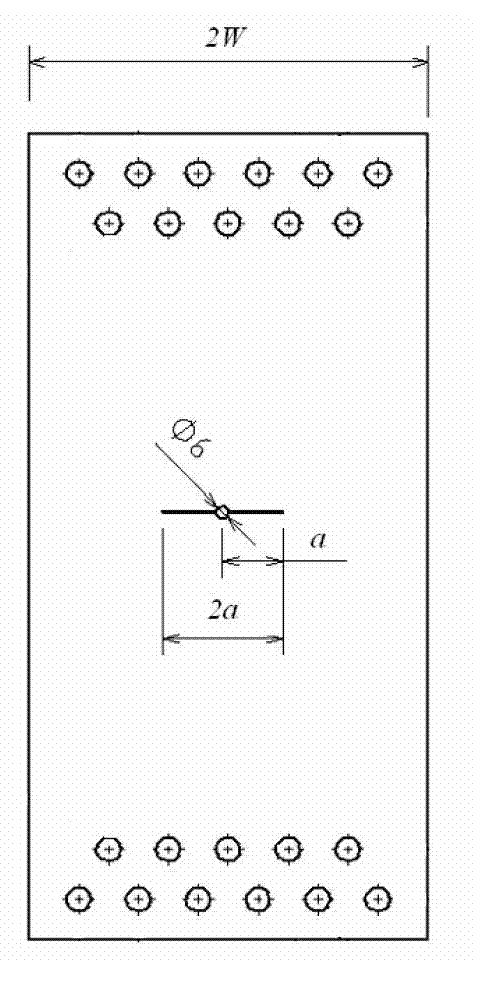

Metal structure fatigue crack propagation life prediction method based on material R curve

InactiveCN102778404APredicted Extended LifeStrength propertiesFatigue loadingCrack growth resistance curve

The invention relates to a metal structure fatigue crack propagation life prediction method based on a material R curve and is technically characterized in that based on the material crack propagation resistance curve (R curve) and crack propagation energy release rate theory, the effective energy release rate under fatigue load is defined as energy for crack propagation after a fatigue crack is completely expanded, the energy is equal to the consumed energy characterized by the crack propagation resistance curve in the same loading cycle, so that a fatigue crack propagation life prediction model capable of reflecting the physical nature of the crack propagation is proposed. By adopting the model, the crack propagation amount in each loading cycle can be calculated, the crack propagation life can be predicated through the accumulative calculation of the crack propagation amount, and the metal structure fatigue crack propagation life prediction method is suitable for predicting the fatigue crack propagation life of a metal structure in engineering and provides a reference method for tolerance evaluation of a structural damage.

Owner:AIR FORCE UNIV PLA

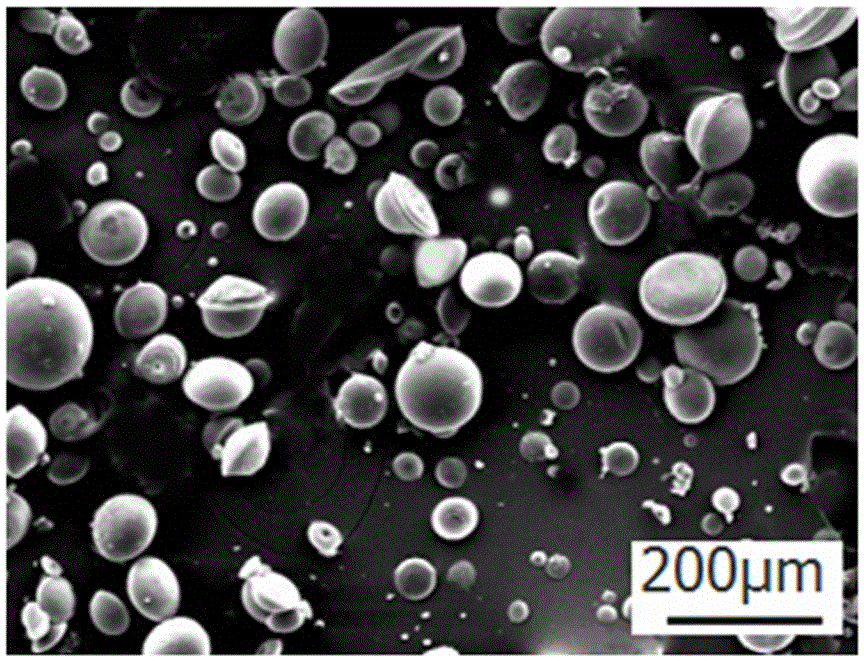

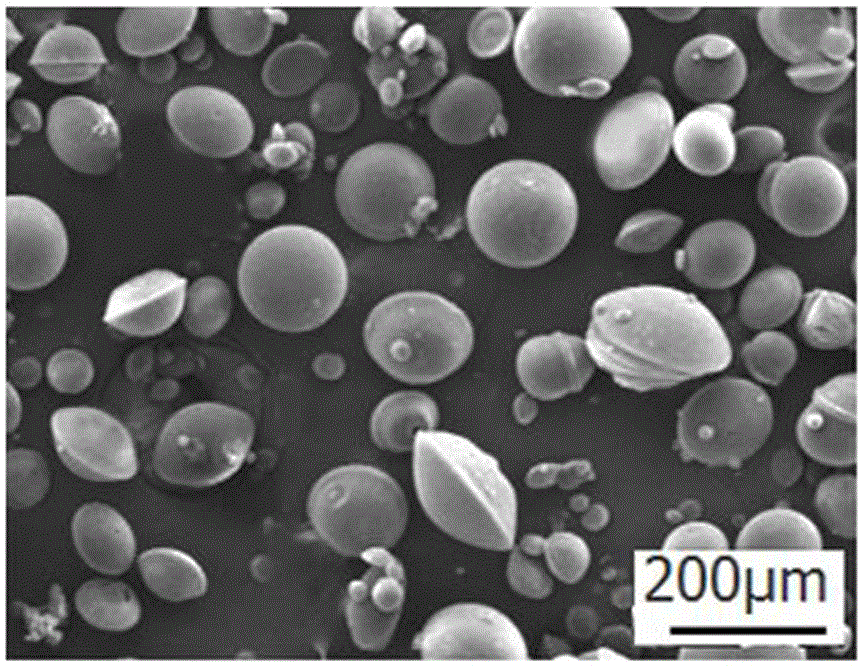

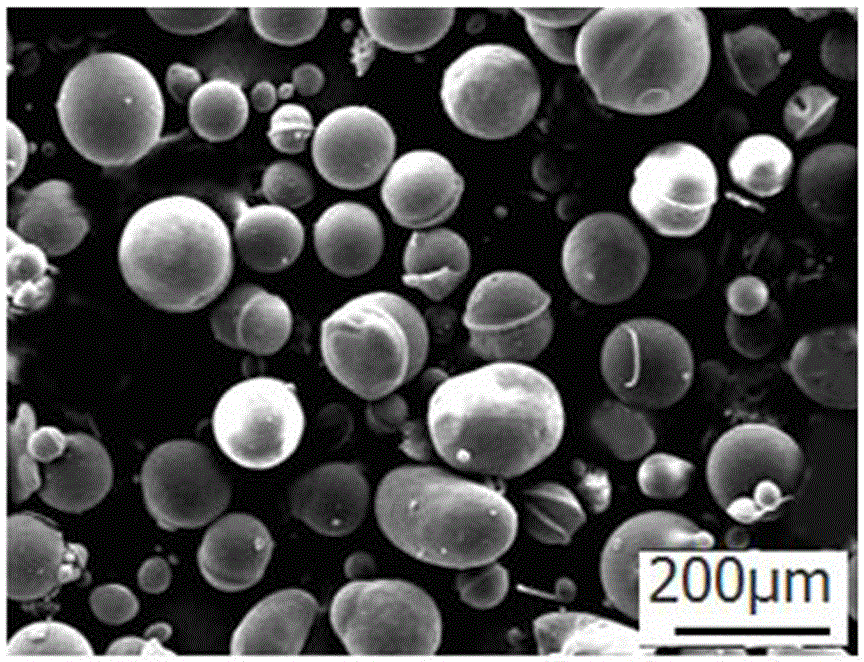

Microcapsule for continuous self-repairing of coal mine wind plugging material crack, and preparation method thereof

InactiveCN108823198AImplement automatic detectionAchieve automatic healingBacteriaOn/in inorganic carrierSporeHigh volume manufacturing

The invention provides a microcapsule for continuous self-repairing of a coal mine wind plugging material crack, and relates to the technical field of coal mine wind plugging material crack repairing.The microcapsule comprises a microcapsule core material and a microcapsule wall material, and the microcapsule core material is prepared from lyophilized bacterium powder and a substrate. Urease-producing bacteria are used to provide a method for protecting long-time survival of bacteria in a cement-based material, providing sufficient nutrients and reducing the influences of bacterium addition on the mechanical properties of the cement-based material. The microcapsule is prepared from the lyophilized bacterium powder and its substrate, and is added in the mixing process of the cement-based material, so once the concrete has a crack, the microcapsule is broken, and spores in the material are activated to perform normal metabolism and continuously induce calcium carbonate precipitation, soself-repairing of the crack in the coal mine wind plugging material is continuously achieved. The preparation method has the advantages of simplicity in operation, and realization of large-batch production.

Owner:SHANDONG UNIV OF SCI & TECH

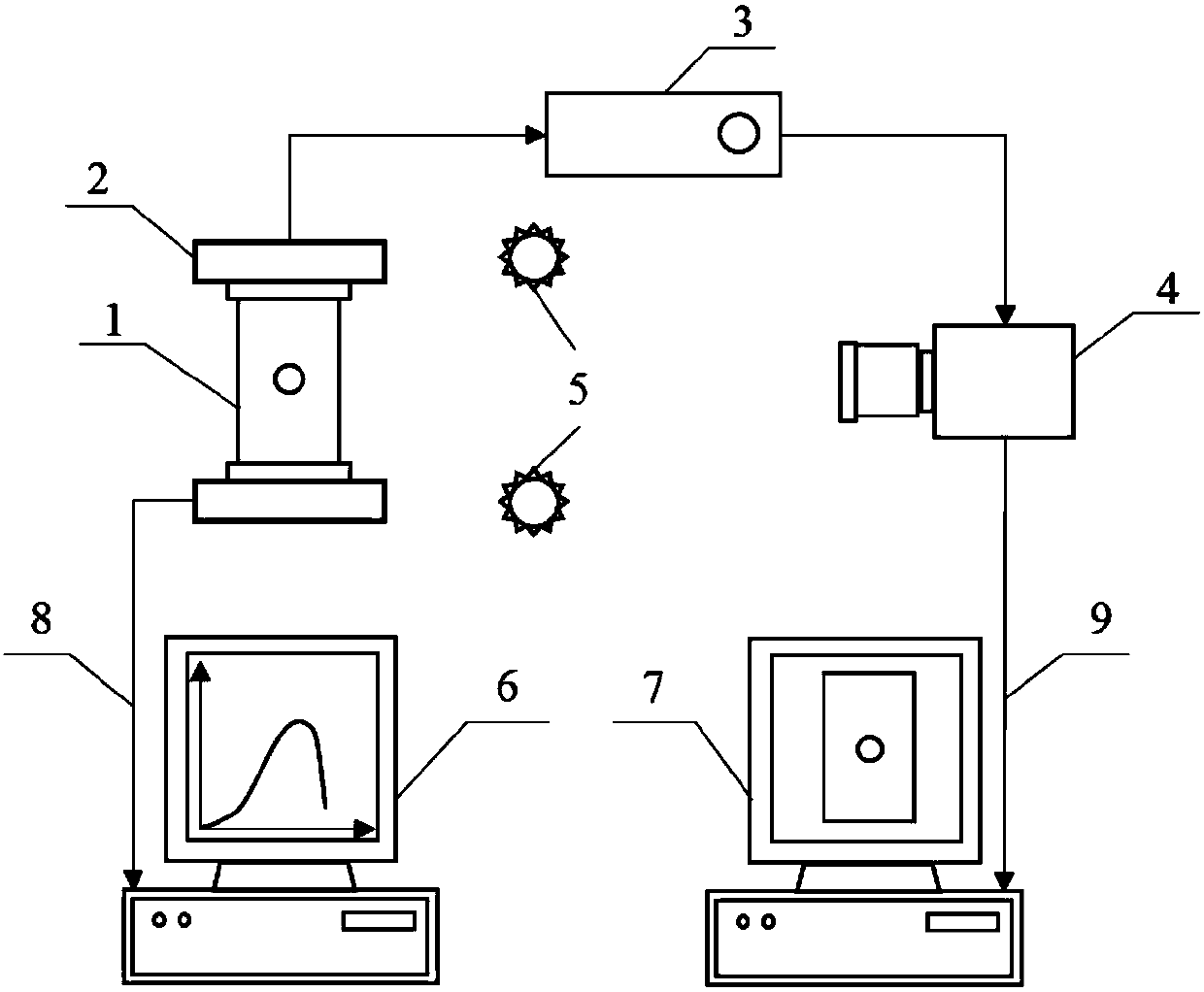

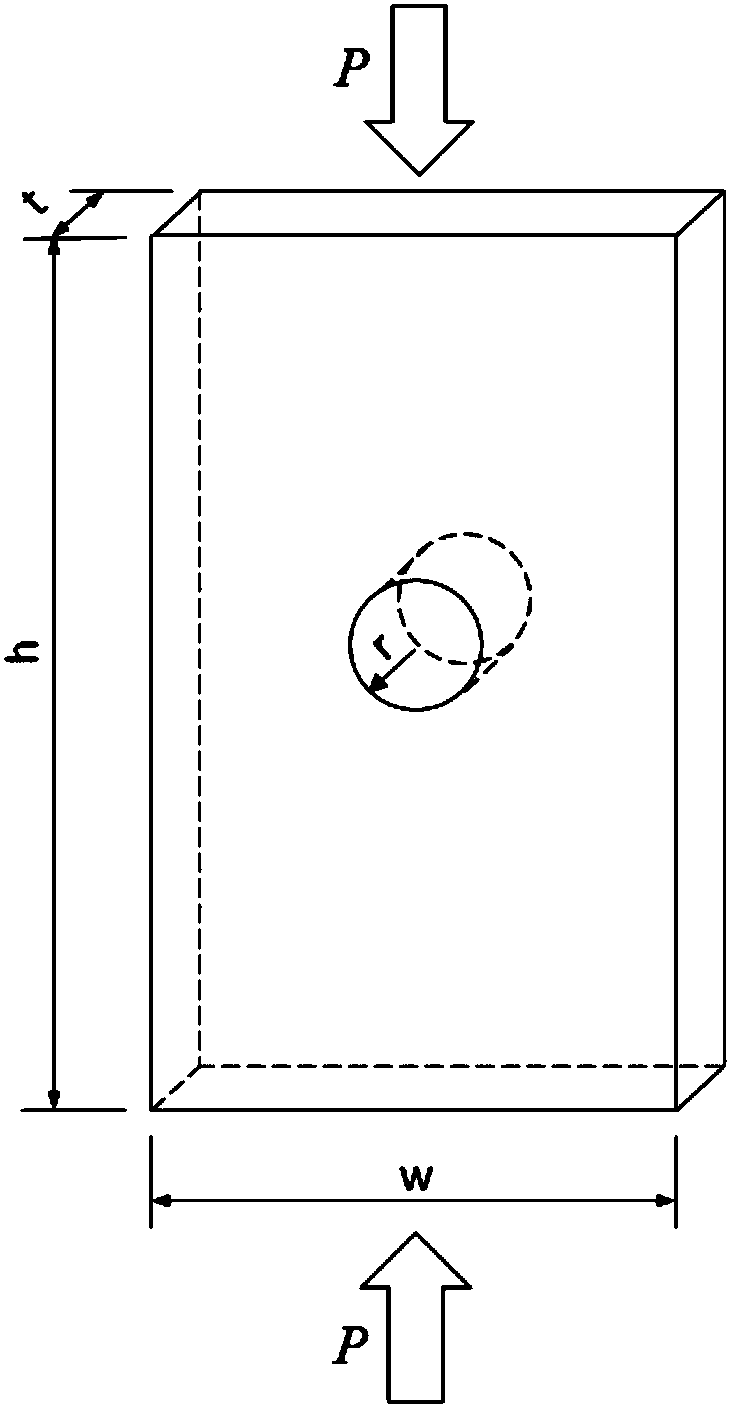

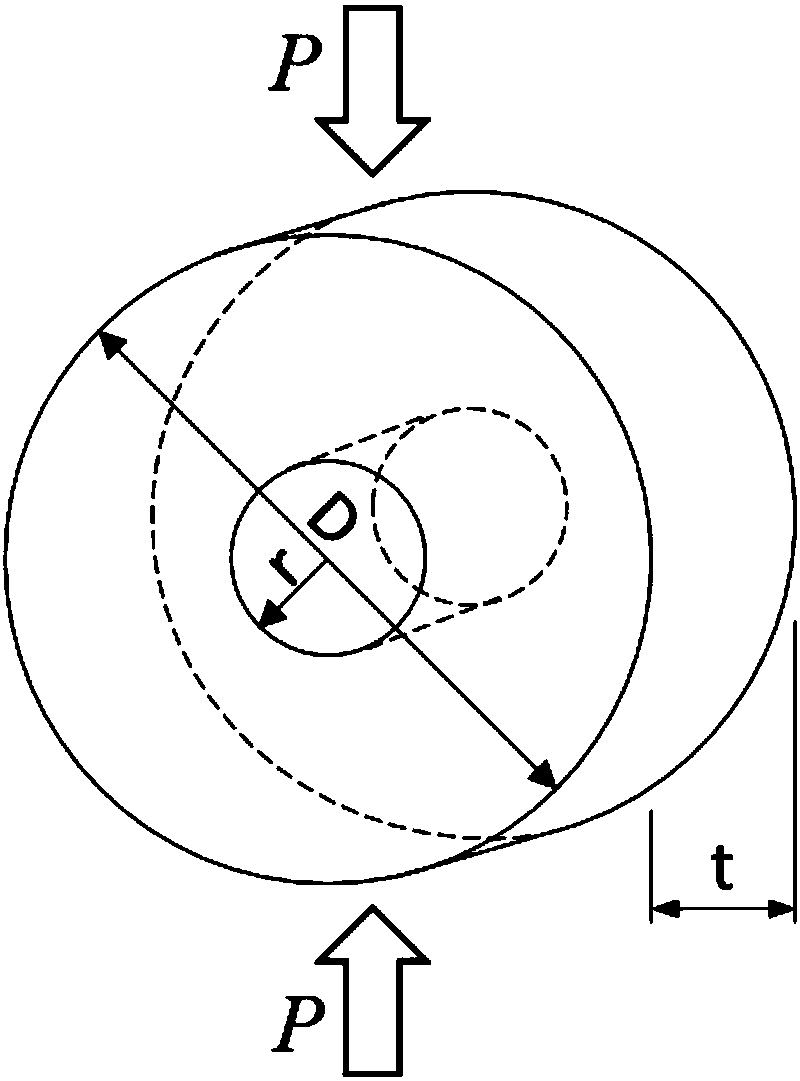

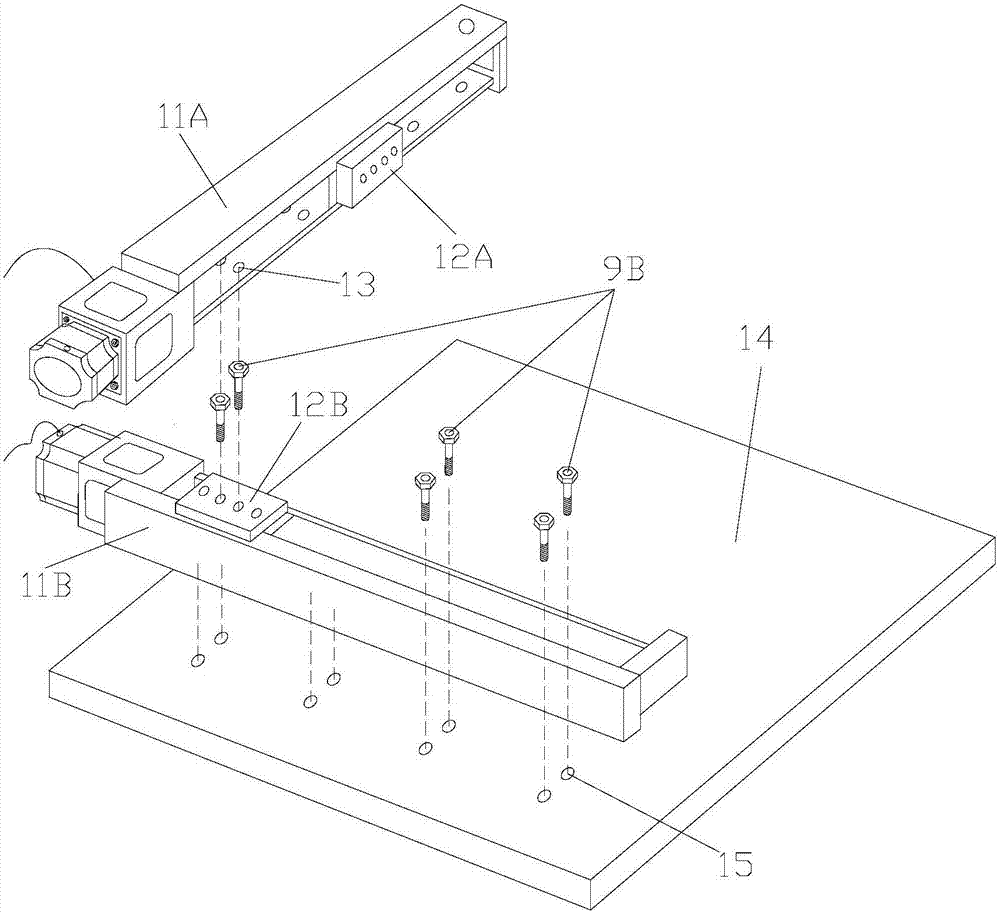

Brittle material crack initiation stress measurement system and brittle material crack initiation stress measurement method

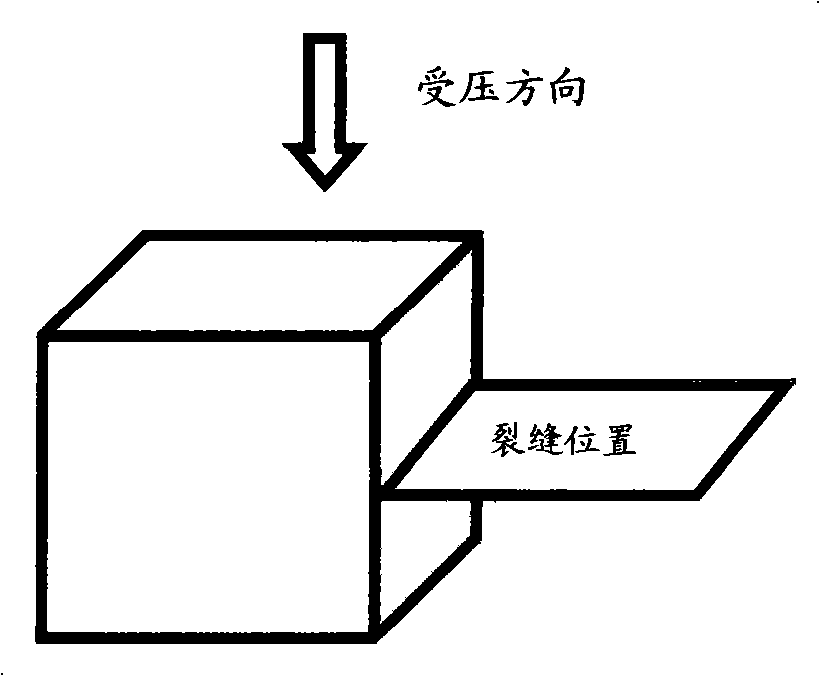

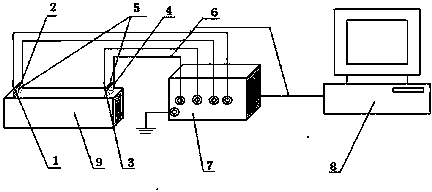

ActiveCN107782626AIncrease authenticityImprove reliabilityMaterial strength using tensile/compressive forcesContinuous measurementStress measurement

The invention discloses a brittle material crack initiation stress measurement system and a brittle material crack initiation stress measurement method. The brittle material crack initiation stress measurement system comprises a loading device, a CCD camera, a synchronizer trigger, a load-time signal receiving device and a digital image signal receiving device. The brittle material crack initiation stress measurement method includes synchronously triggering the loading device and the CCD camera by the synchronizer trigger, loading a sample and outputting a load-time signal; shooting sample surface images by the CCD camera in real time; not stopping shooting until the sample is destroyed; selecting a first frame of images shot by the CCD camera, marking 2 measurement points on the circumference of a through hole, continuously measuring tensile strain-time curves of the 2 measurement points in a whole loading process, and determining stress values, namely crack initiation stress sigmaci,on the stress-time curves corresponding to tensile crack initiation time T. The brittle material crack initiation stress measurement system and the brittle material crack initiation stress measurement method have the advantages that the position and the expansion direction of brittle material crack initiation can be controlled, the crack initiation time and the crack initiation stress can be determined objectively, precisely and quantitatively, authenticity and reliability of brittle material crack initiation stress measurement are improved effectively, and the method simple to operate, reliable in result and objective in quantization is provided for measuring crack initiation stress of rock-like brittle materials with prefabricated holes under uniaxial compression.

Owner:CENT SOUTH UNIV

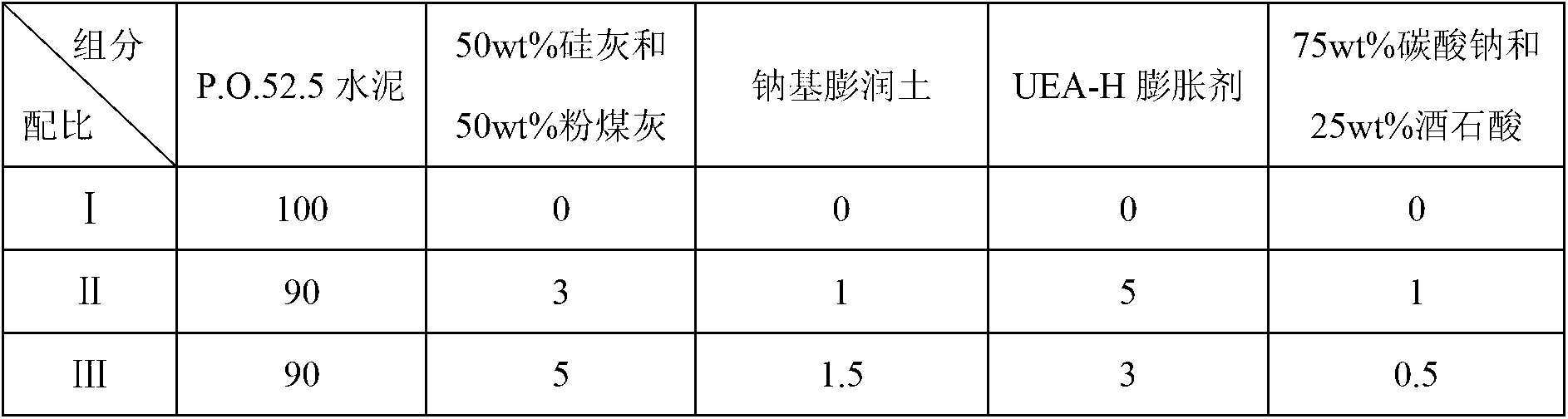

Mineral admixture for self-healing of cement-based material crack and preparation method and application of mineral admixture

The invention relates to a mineral admixture for self-healing of a cement-based material crack. The mineral admixture comprises the following components by weight percentage: 20-55% of silica-based mineral, 10-30% of silicate mineral, 30-60% of expansion mineral and 5-30% of crystal mineral. A preparation method comprises the steps of weighing the raw components, adding the weighed components into a stirrer, stirring for 3-10min until the components are mixed uniformly, and obtaining the mineral admixture. The mineral admixture is added into a cement-based material; when the cement-based material generates a crack, the mineral admixture generates an insoluble deposit in the cement-based material crack to fill and seal the cement-based material crack; and the self-healing of the cement-based material crack is realized.

Owner:TONGJI UNIV

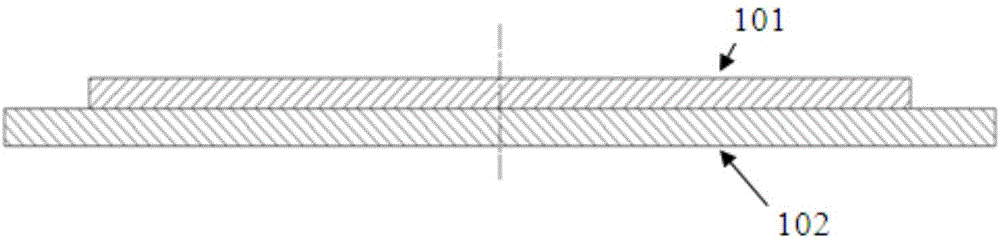

Binding method for ITO target material or other ceramic target materials

InactiveCN109136868AImprove cooling effectImprove electrical contact performanceVacuum evaporation coatingSputtering coatingIndiumHeat conducting

The invention relates to a binding method for an ITO target material or other ceramic target materials. The binding method comprises the following steps: S1, metallizing the surface of a target blank;S2, metallizing the surface of a back plate; S3, processing a binding indium layer; S4, binding the target material; and S5, cooling. The method is capable of binding the target blank and the back plate of ITO by using indium. The prepared ITO target material or the other ceramic target materials have good cooling and electric contact performance, and a good heat-conducting property, wherein a welded rate thereof is greater than 98%, and higher than the prior art. In a practical application, the prepared ITO target material or the other ceramic target materials have not non-uniform sputteringand target material cracking problems in a sputtering process.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

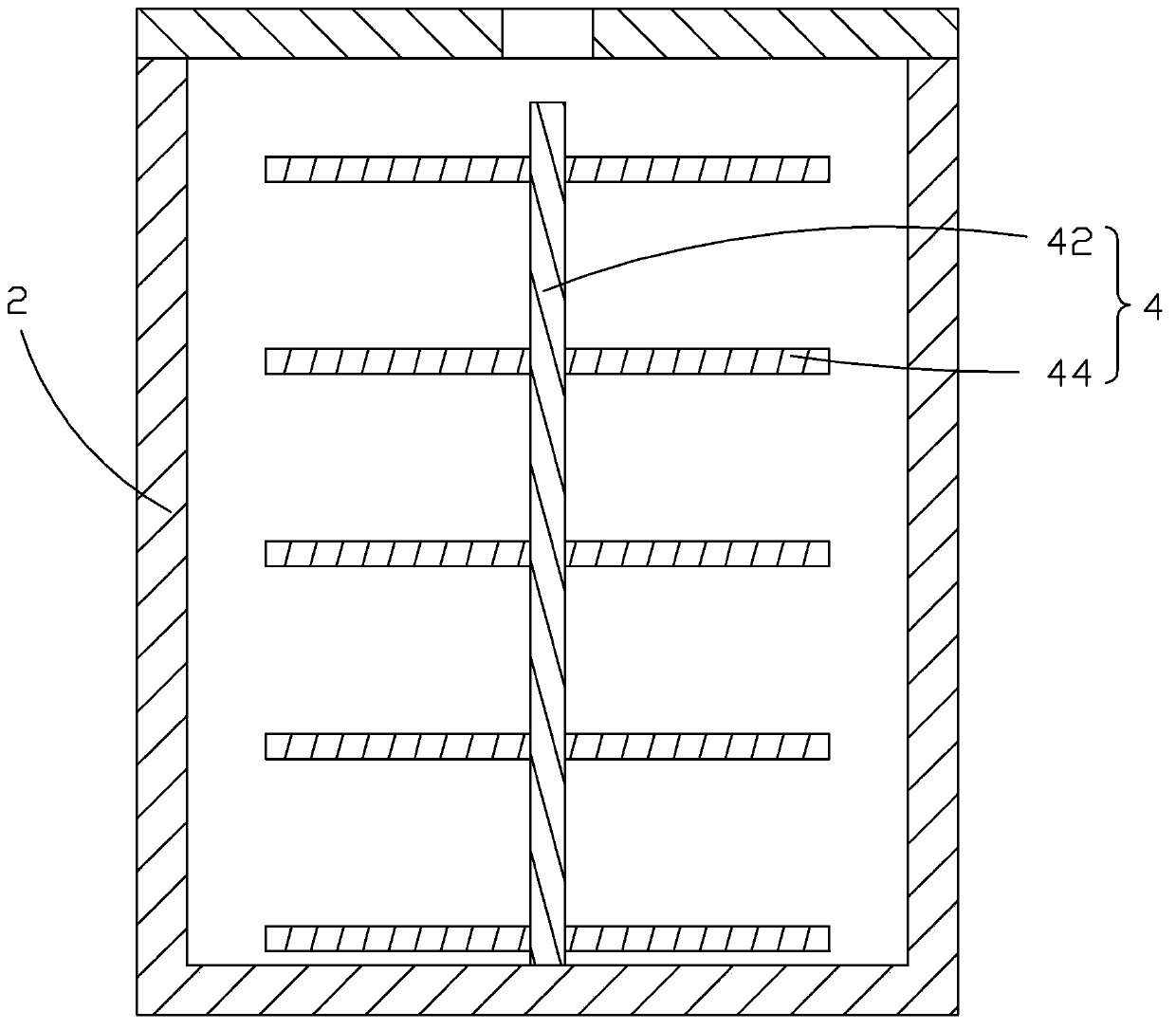

Crucible with heat conduction device

ActiveCN103388123AEvenly heatedAvoid crackingVacuum evaporation coatingSputtering coatingCrucibleMaterial Crack

The invention provides a crucible with a heat conduction device, comprising a crucible body and a heat conduction device arranged in the crucible body, wherein the heat conduction device is tree-shaped and comprises a heat dissipation trunk and a plurality of layers of heat dissipation branches arranged on the heat dissipation trunk, each layer of heat dissipation branch comprises a plurality of branch units, and the branch units are arranged by extending outwards from the outer surface of the heat dissipation trunk. For the crucible with the heat conduction device disclosed by the invention, since the tree-shaped heat conduction device is arranged in the crucible body, heat can be transferred to all directions of the crucible body, so that in evaporation, organic matters in the crucible body can be heated uniformly, the phenomenon in the prior art that partial organic material cracks due to non-uniform heating of the organic material is avoided, and the evaporation efficiency and the evaporation effect are effectively improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

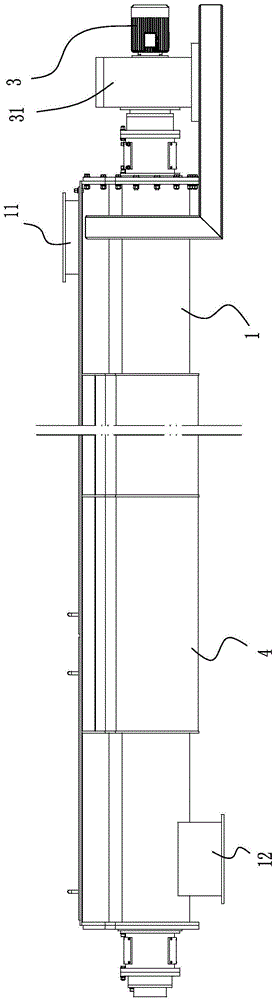

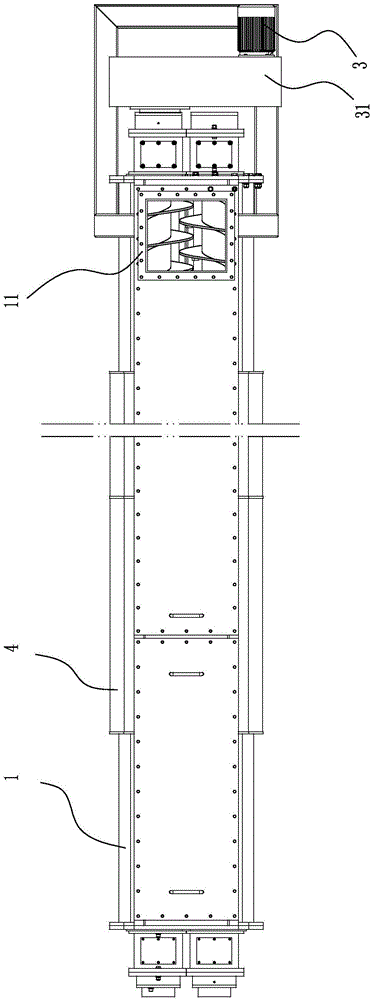

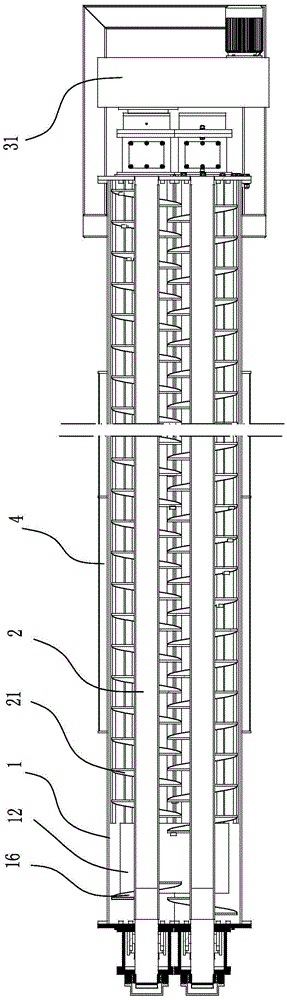

Double-spiral continuous cracking furnace

InactiveCN105542830ALysis completelyThe cracking process is continuousLiquid hydrocarbon mixture productionHydrocarbon oils treatmentMaterial CrackSpiral blade

The invention discloses a double-spiral continuous cracking furnace, which comprises a tubular furnace body and two propelling stirring shafts, wherein the two propelling stirring shafts are in parallel arrangement; material pushing spiral blades are fixedly arranged on the propelling stirring shafts; the material pushing spiral blade of one propelling stirring shaft is inserted into a gap of the material pushing spiral blade of the other propelling stirring shaft; the material pushing spiral blades of the two propelling stirring shafts have opposite spiral directions; a plurality of stirring teeth are fixedly arranged on the material pushing surfaces of the material pushing spiral blades; a furnace body heating device is arranged outside the tubular furnace body. The material pushing spiral blades respectively push materials in respective propelling cavities to realize the mutual stirring moving; shorter and smaller materials are stirred by stirring teeth during the advancing; longer and larger materials are mutually torn and crushed by the stirring teeth; the materials are continuously stirred, torn and pushed when being heated in the tubular furnace body; the physical and chemical forms of the materials are continuously changed; the material cracking process is continuous, stable and thorough; the double-spiral continuous cracking furnace belongs to the breakthrough improvement on cracking equipment.

Owner:刘振亮

Microbial composite additive used for cement-based material cracking self-repairing and applications thereof

InactiveCN104529217ADoes not interfere with normal hydrationGood compatibilityMaterial CrackAdditive ingredient

The invention relates to a microbial composite additive used for cement-based material cracking self-repairing. The microbial composite additive is obtained via mixing of a bacteria liquid, a repairing nutritional component, and an auxiliary ingredient; wherein the bacteria liquid is obtained by inoculating basic culture medium with target bacteria strain Bacillus cohnii via a conventional method for culturing, and then collecting bacteria strain wet cells, the final concentration of the bacteria liquid is controlled to be 20000000 to 40000000 cell / ml; the repairing nutritional component comprises calcium glutamate and yeast extract; and the auxiliary ingredient comprises silica powder and an air entraining agent. Compared with the prior art, the microbial composite additive can be dispersed in cement matrix preferably, in-time and effective repairing of cracks at any parts is ensured, a large amount of maintenance money is saved, a generated repairing medium is natural calcium carbonate, durability and size stability are high, compatibility with cement is high, and environmental friendliness is excellent. At the same time normal hydration of cement is not influenced, so that integral performance of structures is not influenced.

Owner:TONGJI UNIV

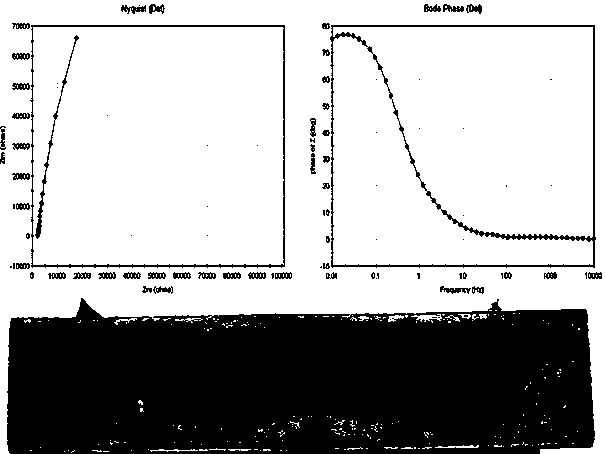

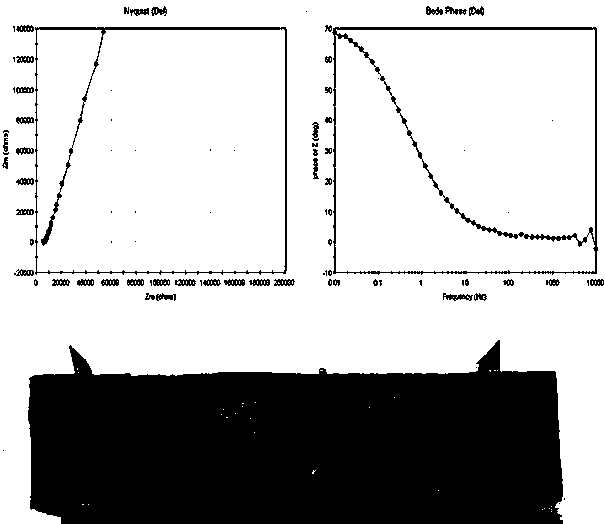

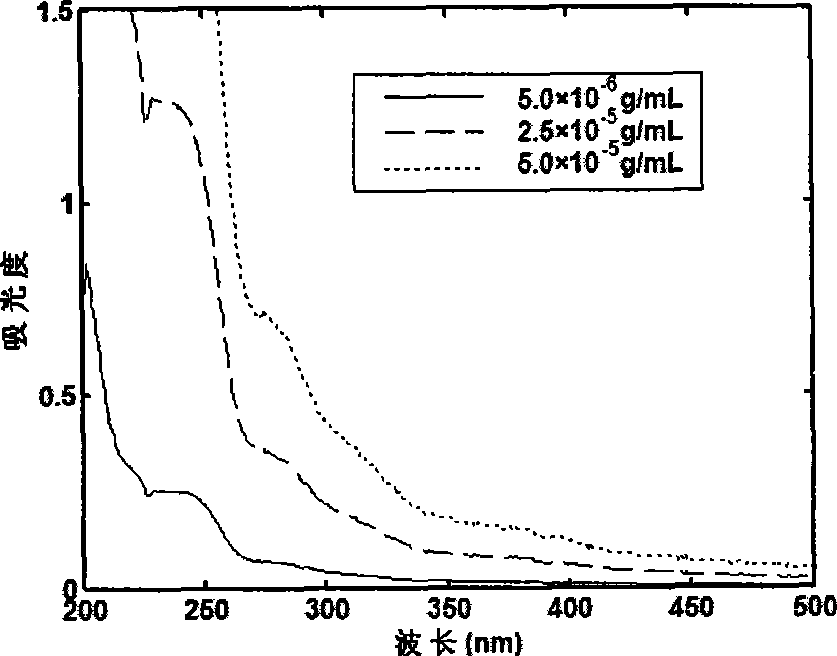

Method for monitoring cement-based material crack by using electrochemical impedance spectroscopy in real time

InactiveCN103995036ARealize the whole process monitoringFast measurementMaterial analysis by electric/magnetic meansData processing systemSignal on

The invention belongs to the field of civil construction, and particularly relates to a method for monitoring a cement-based material crack by using an electrochemical impedance spectroscopy in real time. The method comprises the steps: firstly, pre-embedding electrode plates on two ends of a cement-based material test piece or placing the electrode plates during implementing, connecting the electrode plates with an electrochemical working station data acquisition system through a lead, then connecting the electrode plates with a computer data processing system; then applying different frequencies of sine alternating-current voltage (current) disturbance signals on the cement-based material test piece through the electrode plates, generating corresponding response signals by the input disturbance signals after passing through the test piece, namely sine alternating-current current (voltage) signals, and processing the response signals through the electrochemical working station data acquisition system and the computer data processing system to obtain an electrochemical impedance spectroscopy of the test piece; and finally, monitoring the cracking condition of the cement-based material test piece crack through analyzing a characteristic change of the electrochemical impedance spectroscopy. The method is high in measurement speed, strong in interference resistance, and simple to operate.

Owner:HENAN POLYTECHNIC UNIV

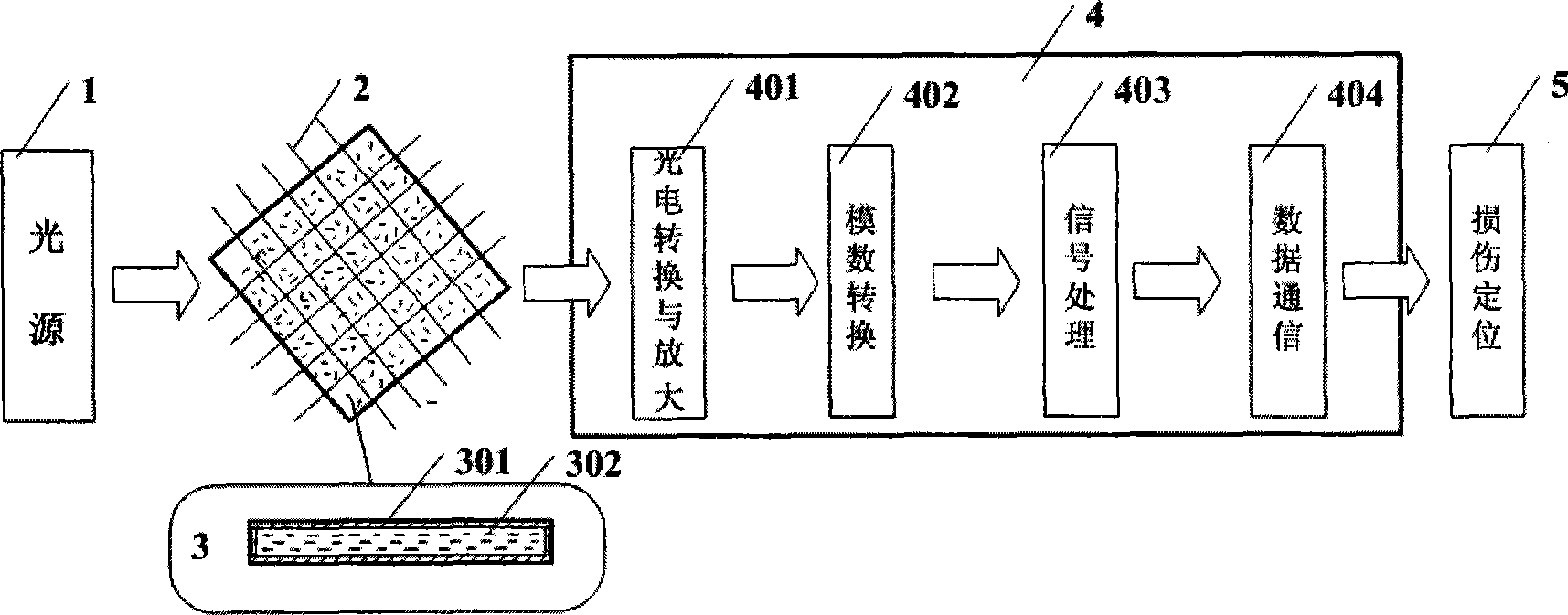

Intelligent structure self-healing method and health monitoring system based on light repairing technology

InactiveCN101544064ASelf-healingMethod implementationOther chemical processesOptically investigating flaws/contaminationSelf-healingDigital signal processing

The invention relates to an intelligent structure self-healing method and a health monitoring system, in particular to a brand-new intelligent structure self-healing and self-diagnostic method which utilizes solar energy and light-curing technology to realize damage self-healing of composite material and simultaneously realizes health monitoring on the basis of neural network and digital signal processing technologies. In the method, light-curing plasteringagent is taken as light-curing restoration agent and is arranged in tubular fibre coated with photomask agent and coupling agent; when material cracks, fibres at the front expansion edge of the crack rupture, and the light-curing restoration agent permeate into the damaged cracks and adopt sunlight as supply power resource to realize the self-healing of the damaged material; at the meantime, an optical fibre sensor used as a signalling and sensing element and a digital signal processing technology are combined to realize the status health monitor of the intelligent structure. The invention has the characteristics of strong practicality, low cost, environment protection, energy saving, and the like, and provides an effective solution for realizing the self-healing and the health monitor of composite material components.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

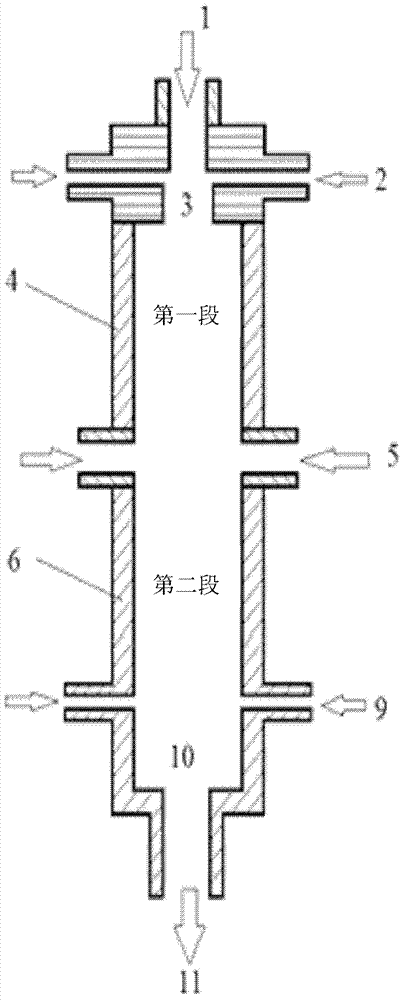

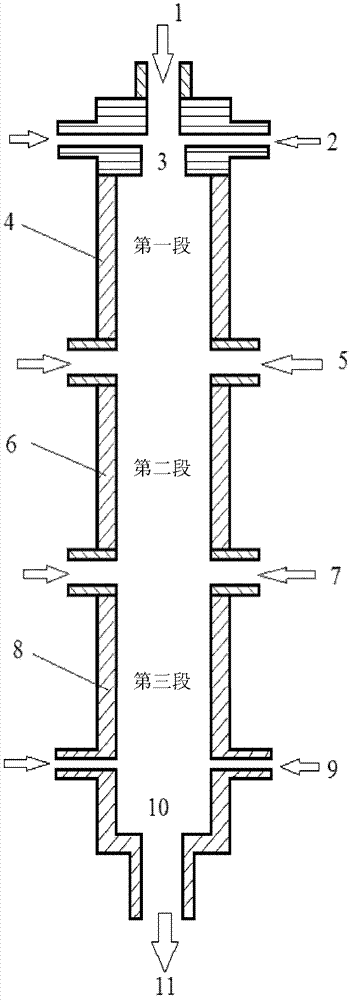

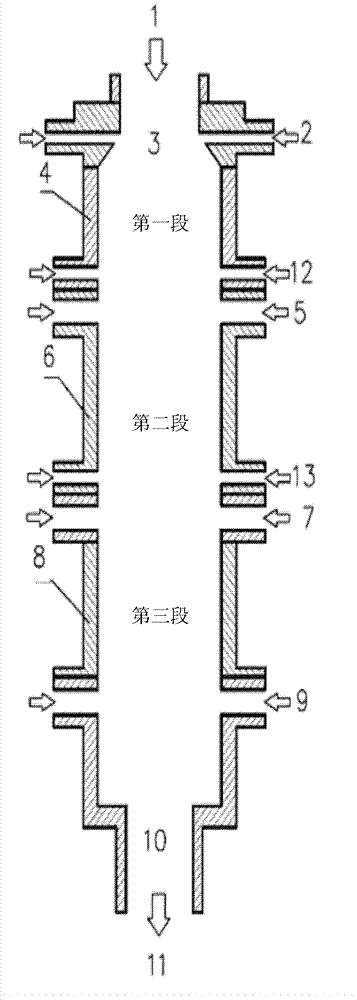

Multi-stage plasma carbon material cracking reactor, and method for producing acetylene by using carbon material

ActiveCN103084129AEnergy based chemical/physical/physico-chemical processesHydrocarbon by hydrocarbon crackingMaterial CrackPlasma Gases

The invention discloses a multi-stage plasma carbon material cracking reactor comprising a reaction pipe first section in which a carbon material, carrier gas and a first heating gas are mixed, and in which carbon material pyrolysis is carried out; reaction pipe second to N sections, wherein N is an integer no smaller than 2; at least one carbon material and carrier gas feed inlet positioned on a side of the reaction pipe first section; at least one first heating gas inlet positioned on the top of the reaction pipe first section; at least one second to N heating gas inlets arranged on the sides of the reaction pipe second to N sections, wherein the second to N section heating gas is high-temperature plasma gas; at least one chilling medium inlet used for chilling or freezing reaction products, and at least one chilling product and gas outlet positioned on the bottom or lower part of the reaction pipe last section.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

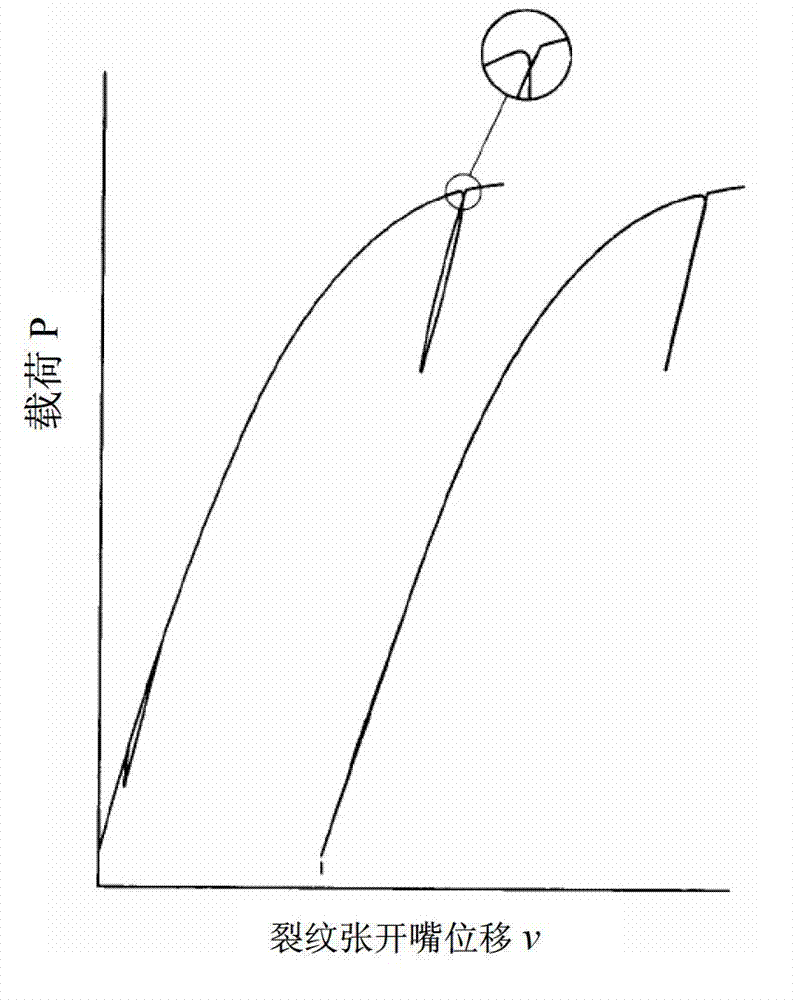

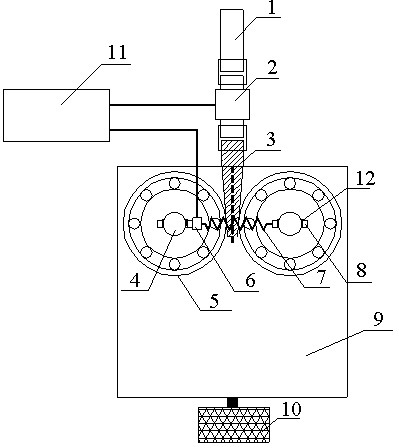

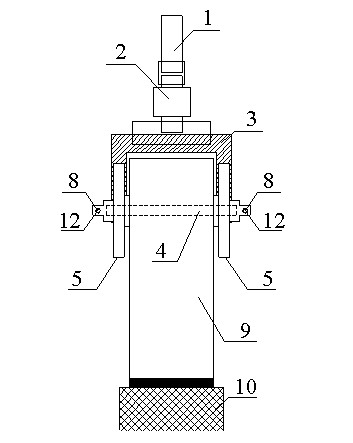

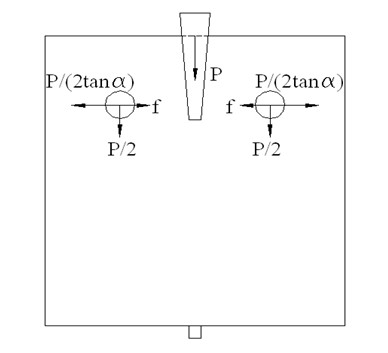

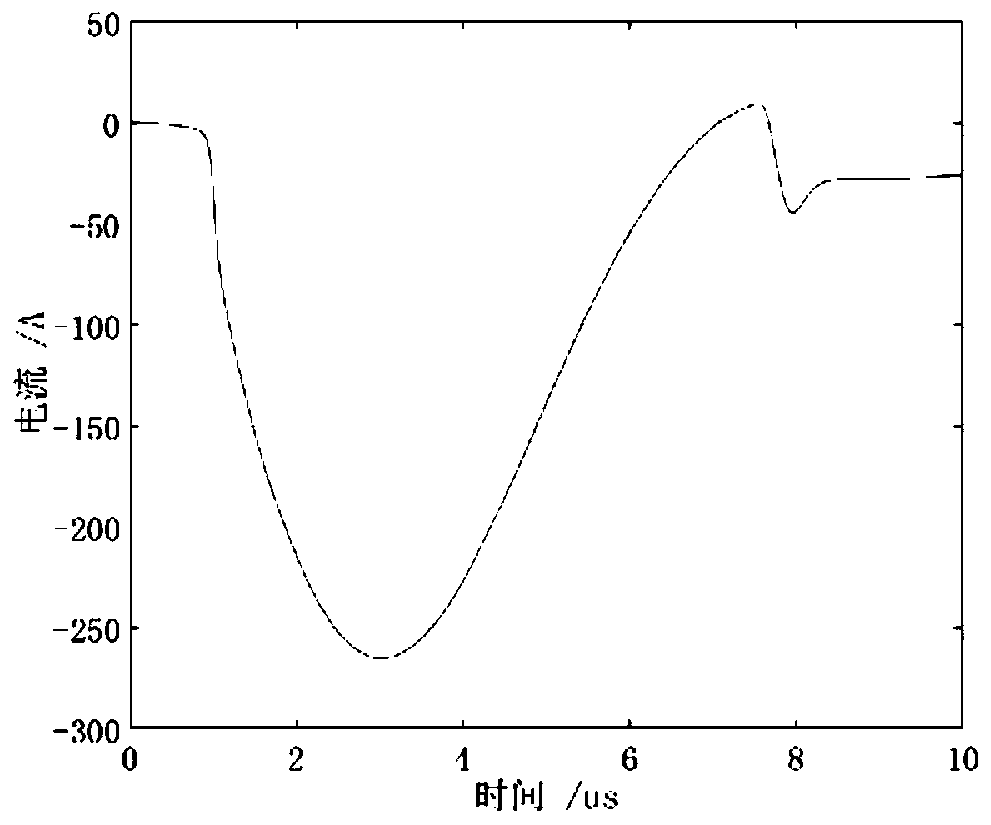

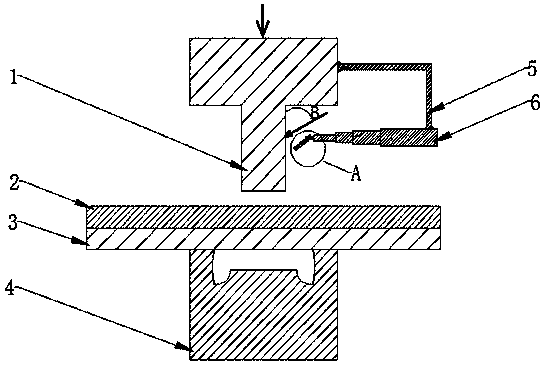

Loading device for concrete material crack growth test under dynamic load

InactiveCN102680341ALittle effect of gravityEasy to operateMaterial strength using repeated/pulsating forcesMaterial CrackForce sensor

The invention relates to a loading device for a concrete material crack growth test under a dynamic load. An actuation head of a fatigue tester is connected with a wedge loading frame through a vertical force sensor; steel shafts are arranged at two quartiles at the upper part of a concrete sample in a penetrating manner; both ends of each steel shaft are respectively and fixedly provided with a bearing and a horizontal stretching rod; a spring is stretched by adjusting a distance of each horizontal stretching rod at the both sides of the steel shaft, so as to supply horizontal pre-compression to the concrete sample; a dynamical data collector is connected by using vertical and horizontal sensors so as to measure actual tension of the spring at different time; an actual acting force acting on the concrete sample at each time can be calculated by a calculation formula provided according to a working principle; and finally, a load is supplied to the concrete sample. The loading device provided by the invention can supply the tension-compression dynamic load for opening and closing a crack for the concrete sample, so that the loading device can be used for testing a crack growth process of a concrete material under the dynamic load.

Owner:HOHAI UNIV

Oxide target material and preparation method thereof

ActiveCN105734508AReduce varianceReduce the problem of cracking or even crackingVacuum evaporation coatingSputtering coatingMaterials preparationSputtering

The invention belongs to the technical field of target material preparation and discloses an oxide target material and a preparation method thereof. Chamfers or round corners are machined on the edge of a sputtering surface of the oxide target material, groove structures are machined in a non-main-sputtering area of the sputtering surface, and chambers are machined at all the turning corners. The oxide comprises one or more of Al2O3, TiO2, Nb2O5, HfO2, La2O3, ZnO, MgO, ITO, AZO and IGZO. The preparation method comprises the steps that high-purity oxide powder is prepared into an oxide target billet through a sintering technique, then the chamfers or the round corners are machined on the edge of the sputtering surface of the oxide target billet through machining, the groove structures are machined in the non-main-sputtering area, the chamfers are machined at all the turning corners, and in this way, the oxide target material is formed. Through the optimum structural design for the oxide target material, the risk that the target material cracks in the sputtering process is reduced, and high-quality sputtering sputter coating is achieved.

Owner:GRIKIN ADVANCED MATERIALS

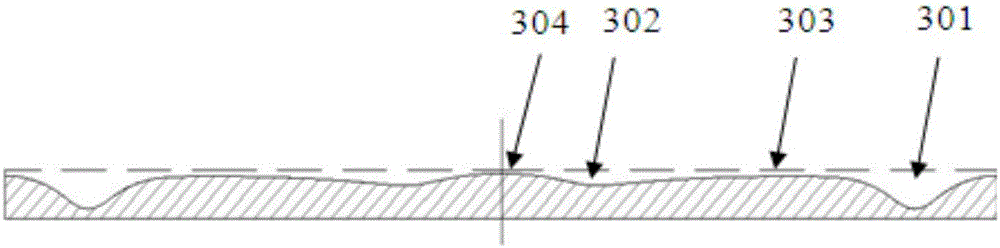

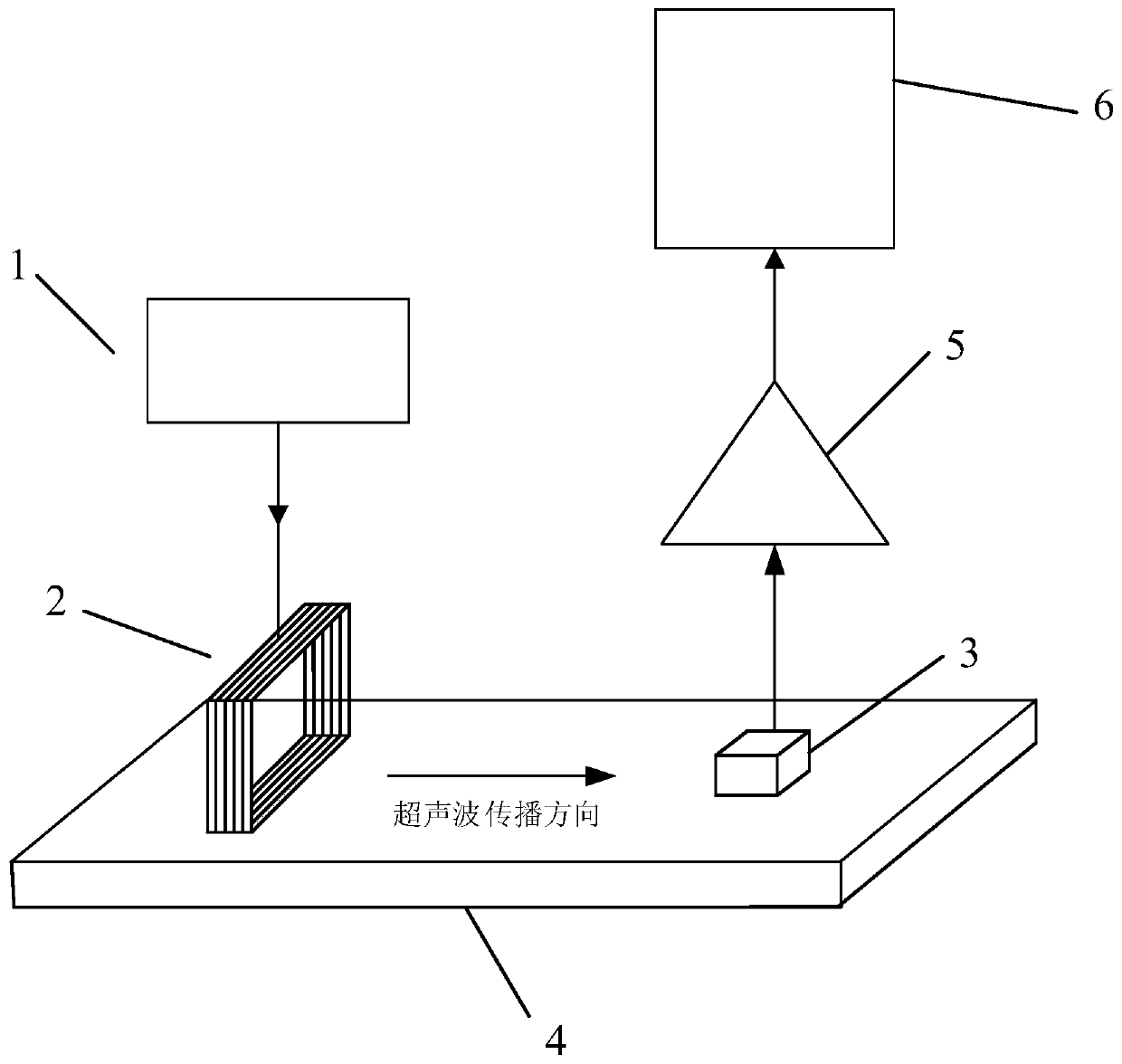

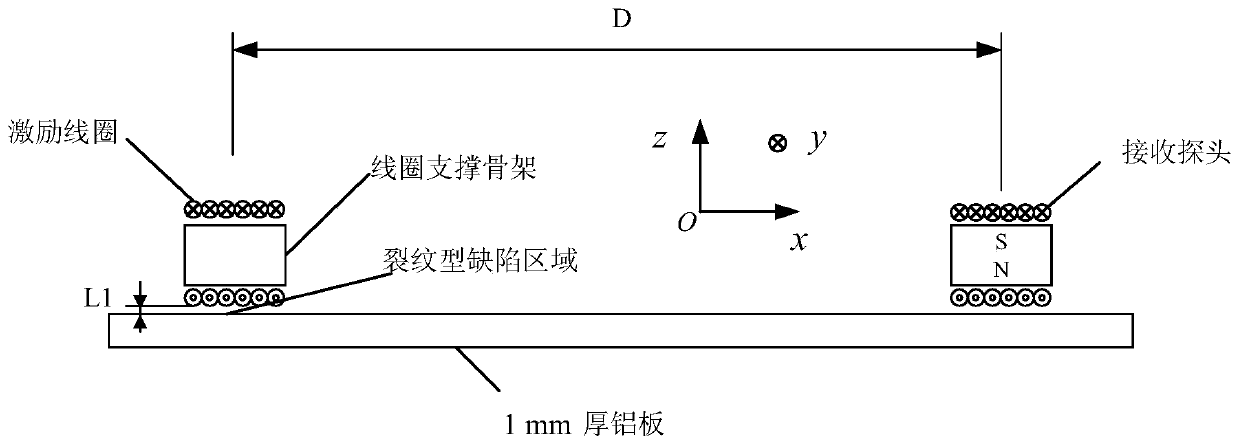

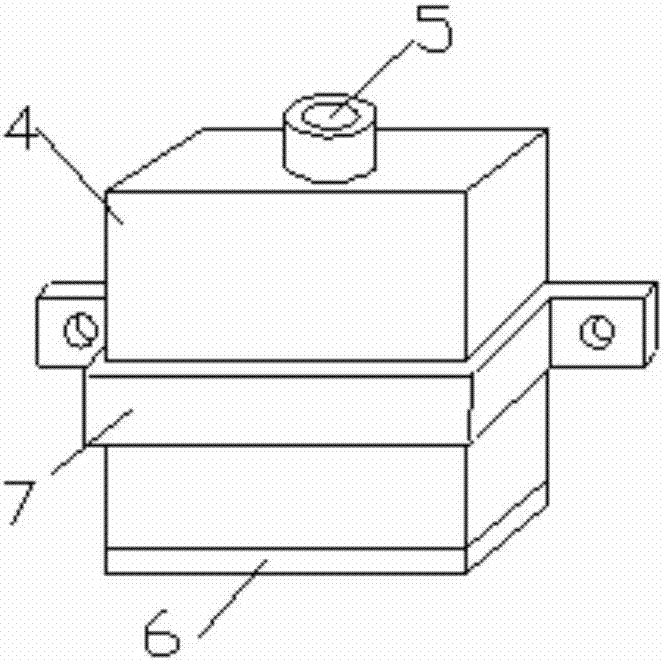

Metal material crack type defect depth measuring device and method

InactiveCN109737899AHigh detection sensitivitySimple signal processingAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansMetallic materialsPeak value

The invention discloses a metal material crack type defect depth measuring device and method. A pulse generator (1) emits a pulse signal to drive a multi-turn coil (2) to generate ultrasonic waves ina metal sample (4) based on a Lorentz force mechanism, a receiving probe (3) receives the ultrasonic waves and converts same into an electrical signal, the electrical signal is amplified by a signal amplifier (5), and the peak-to-peak value of the ultrasonic waves is recorded by a signal recording and analyzing module (6). The method comprises the following steps: in a calibration stage, measuringthe standard sample without defects, recording the peak-to-peak value of the S0 Lamb wave as A0, artificially fabricating grooves of different depths h on the standard sample to obtain the peak-to-peak value Ah of the S0 Lamb wave when the depth of the groove is h, calculating the enhancement coefficient E=Ah / A0 of the S0 Lamb wave, and plotting a (h, E) graph; and in an actual measurement stage,using the metal material to be tested as the metal sample (4), obtaining the peak-to-peak value of the S0 Lamb wave as Ad, calculating E=Ad / A0, and obtaining the depth h of the crack type defect by the (h, E) graph.

Owner:UNIV OF SCI & TECH BEIJING

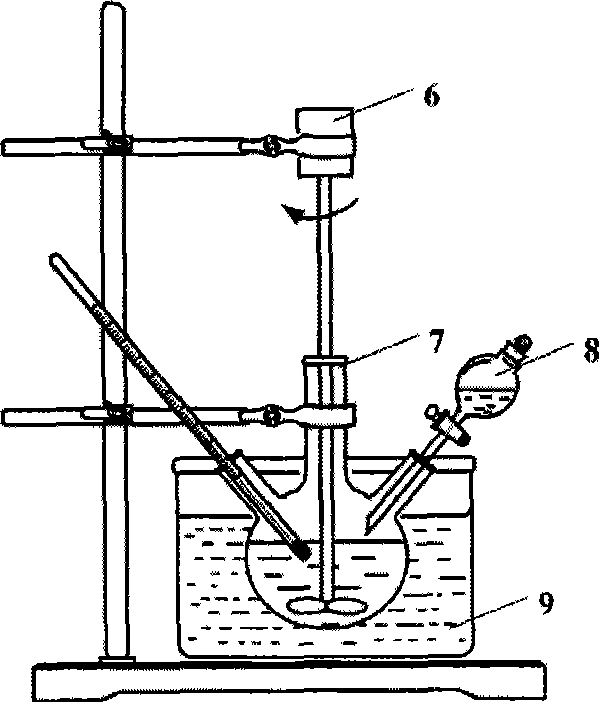

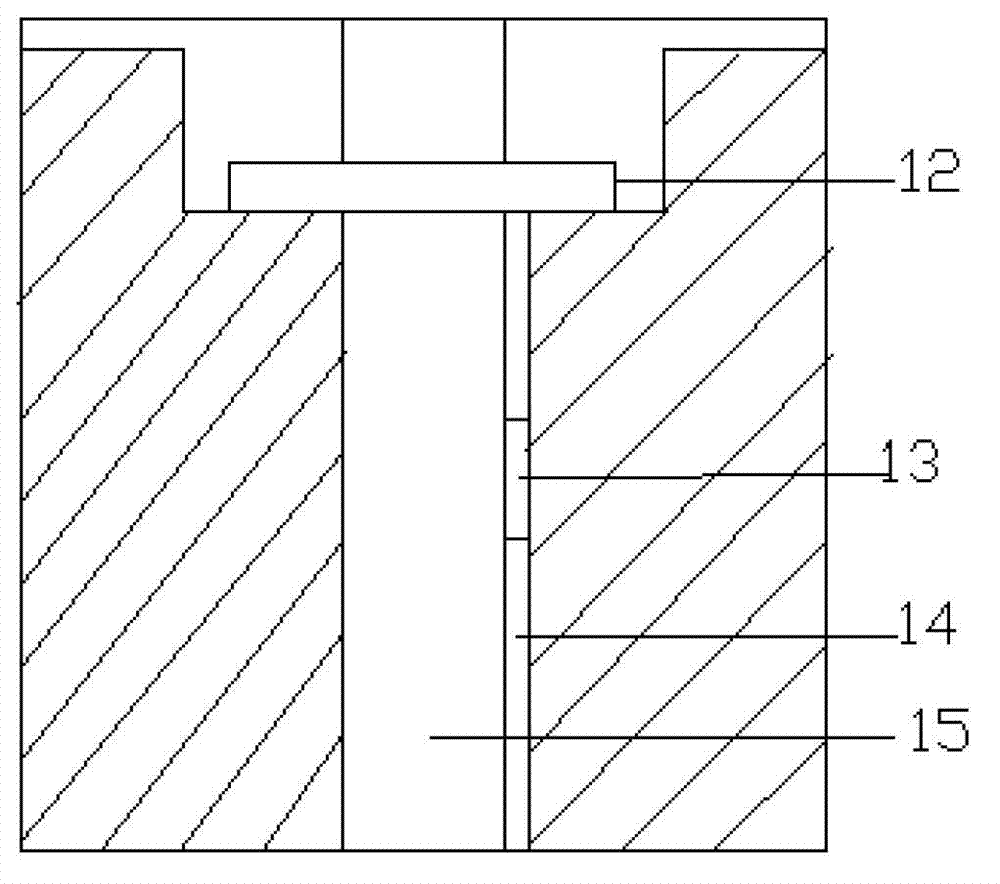

Continuous loading indentation stress corrosion tester and test method therefor

InactiveCN103163035ALow costImprove stabilityWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceHysteresisElectrochemistry

The invention relates to a continuous loading indentation stress corrosion tester and a test method therefor. The continuous loading indentation stress corrosion tester is used for researching hysteresis growth and related mechanical behaviors of material cracks and especially for researching rules of the influence produced by different stresses, environmental mediums and temperatures on crack nucleation and growth, and clearly expounds the rule and the mechanism of material invalidation under the stress-environment coupling condition. The test method comprises the following steps of 1, through contact between a pressure head and a test sample under a certain load, determining fracture toughness of a brittle material, and observing the influence produced by the environment on crack growth under the continuous loading condition, 2, determining threshold stress of hysteresis growth of cracks of the brittle material by radial cracks having certain length under a certain environmental condition, 3, in a solution medium, researching crack growth of a toughness material by indentation, and 4, observing a change of electrochemical parameters in crack growth by connection with an electrochemical workstation. The continuous loading indentation stress corrosion tester can be operated conveniently and simply, realize control of an experimental environment and a load, is especially suitable for long-term loading in different environments, has a simple structure, is convenient for operation and has a large application prospect.

Owner:UNIV OF SCI & TECH BEIJING

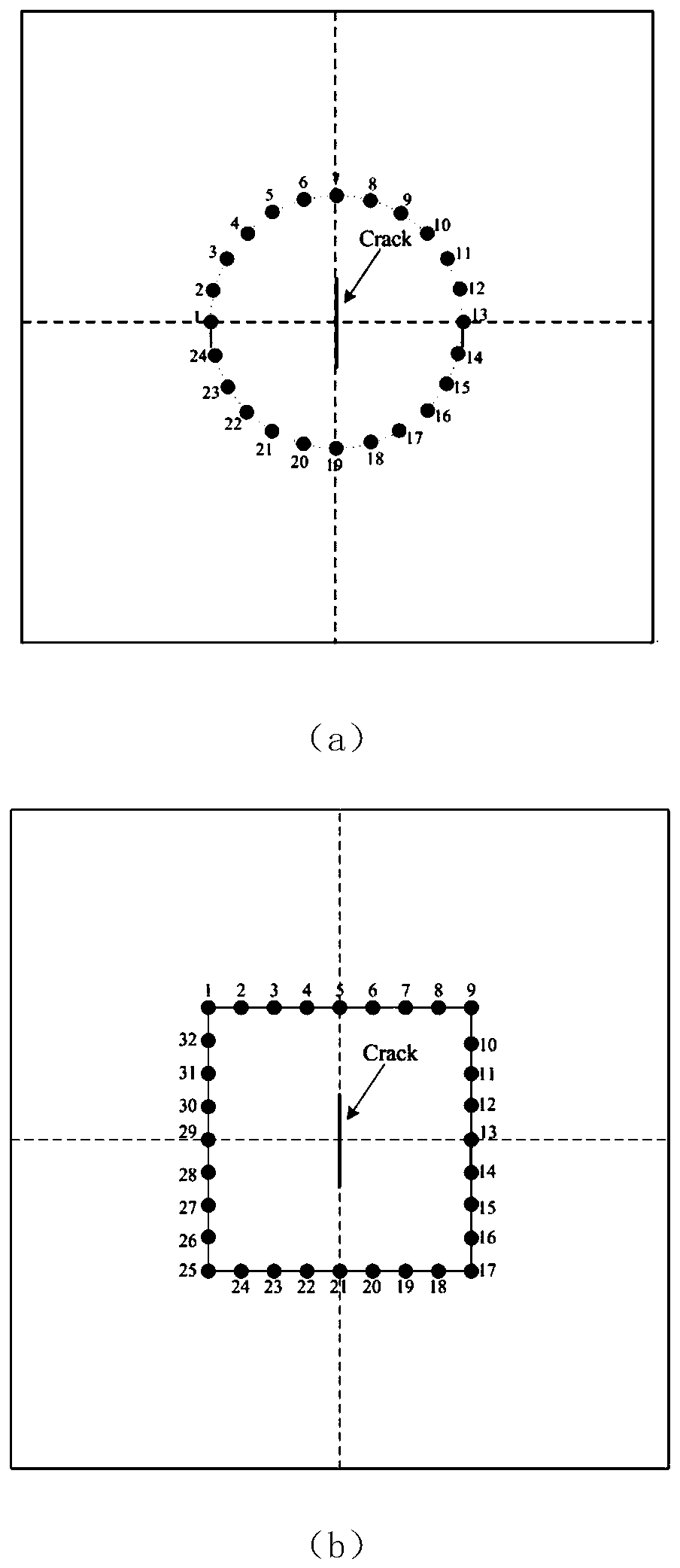

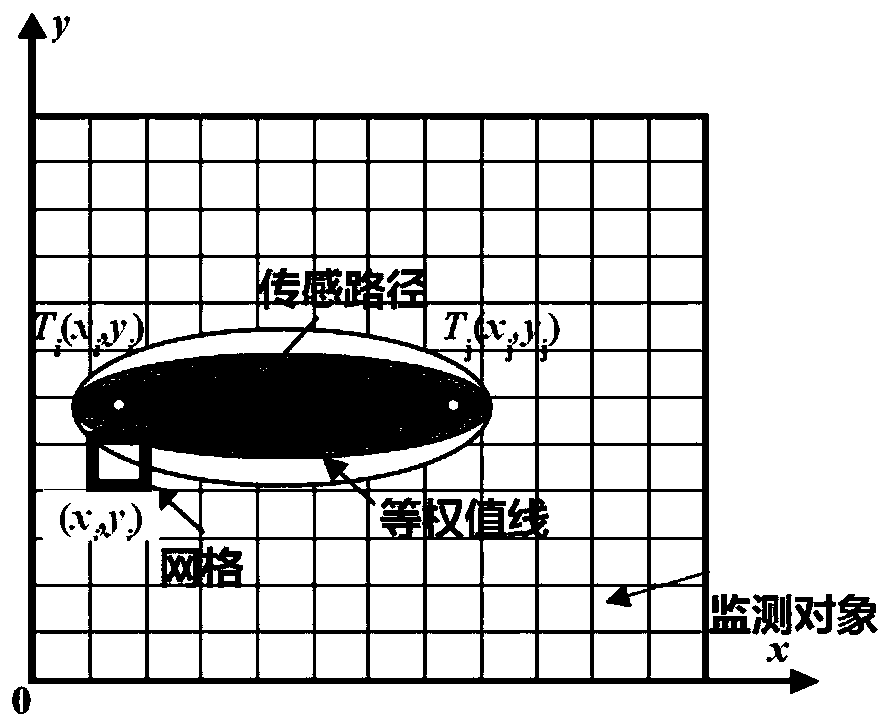

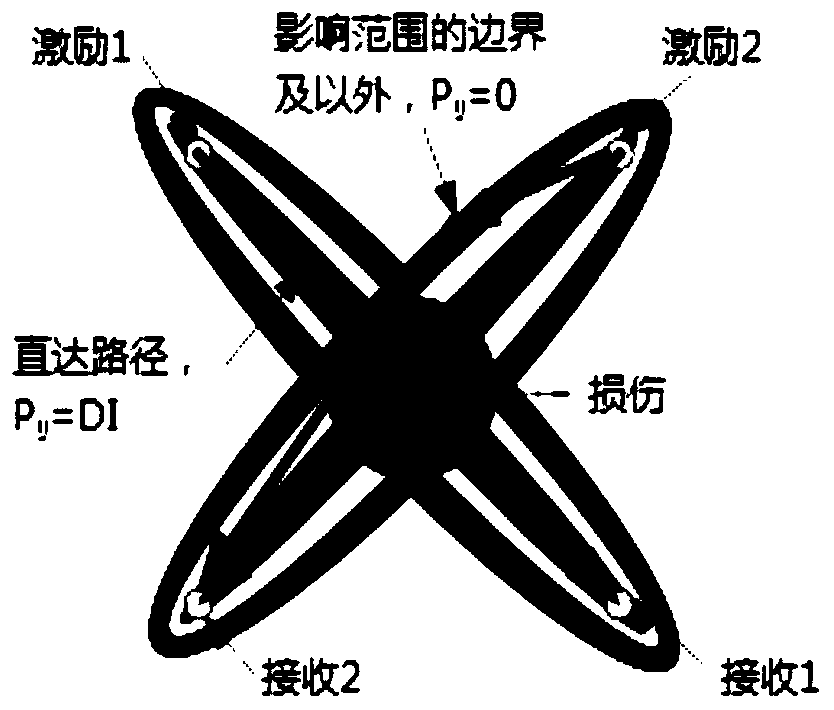

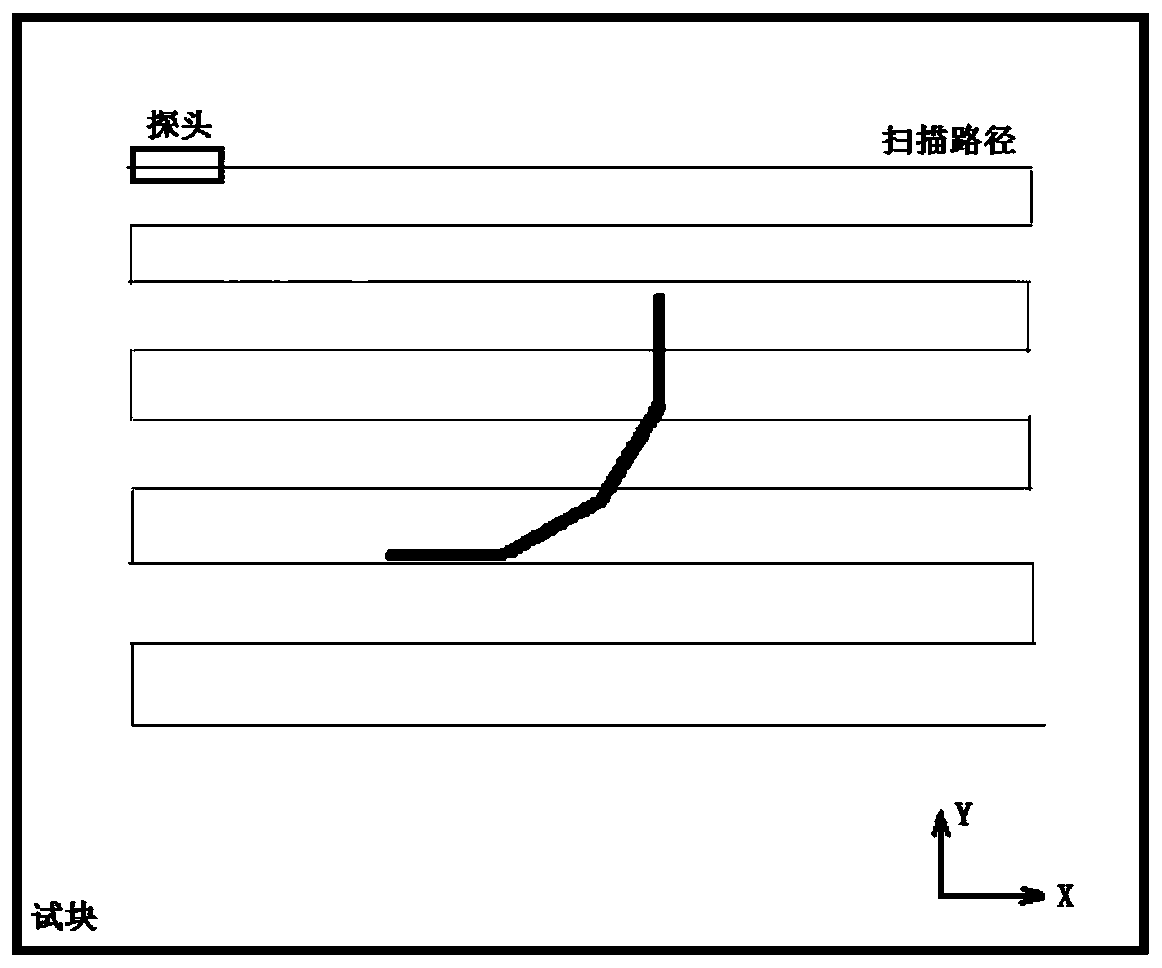

Metal material crack quantitative monitoring method based on ultrasonic guided wave

ActiveCN109900804ARealize real-time online quantitative monitoringExpand the scope of monitoringAnalysing solids using sonic/ultrasonic/infrasonic wavesStructure health monitoringMaterial Crack

The invention relates to the equipment structure health monitoring field and discloses a metal material crack quantitative monitoring method based on a ultrasonic guided wave. The method comprises thefollowing steps of using a sensor network with a specific shape to carry out an excitation test on a metal material so as to obtain monitoring signals under different conditions; obtaining a damage index value through a damaged monitoring signal and a reference signal without damage; constructing a crack quantitative evaluation model of the metal material through a damage path probability imagingmethod; from monitoring imaging of a damage area of the crack quantitative evaluation model of the metal material, acquiring a slope of a straight line where a crack is located; setting a specific threshold, averaging coordinate values of discrete points which are greater than the specific threshold, and obtaining the coordinate values of the points through which the crack passes; acquiring an equation of the straight line where the crack is located through the slope of the straight line and the coordinate values of the points through which the crack passes; and through an intersection pointof the straight line and a damaged boundary line in a damaged imaging graph, acquiring end points of the crack. The method has advantages of being sensitive to small defects, having a large monitoringrange and the like.

Owner:招商中特智检(北京)技术有限公司

Self-restoration microcapsule and preparation method thereof

ActiveCN106215826AAffect thermal performanceAffect chemical reactivityMicroballoon preparationMicrocapsule preparationEpoxyFiltration

The invention relates to a self-restoration microcapsule and a preparation method thereof. Polybenzimidazole is dissolved into a solvent; then, epoxy compounds are added to obtain a mixed solution; next, the mixed solution is dispersed into a deionized water solution containing surfactants or deionized water; after 0.5 to 2 hours, microcapsule suspension liquid is obtained; the microcapsule suspension liquid is washed by the deionized water, and is subjected to suction filtration and vacuum drying to obtain the self-restoration microcapsule. The polybenzimidazole material is used as a wall material; epoxy resin / epoxy vinyl resin is used as a core material; the polybenzimidazole microcapsule is prepared by a solvent volatilization method. The obtained microcapsule has excellent heat-resistant performance, and can be used for restoring damage defects of material cracks and the like; the preparation method is simple and convenient; the industrialization is easy.

Owner:SUZHOU UNIV

Sound absorption noise reduction thermal insulation wallboard and manufacturing method therefor

The invention discloses a sound absorption noise reduction thermal insulation wallboard. On the one hand, soybean straw fibers are subjected to high temperature steam pretreatment, then part of pectin is removed, acetic acid is added, acetylation treatment is carried out, free hydroxide radicals in cellulose are enclosed, the hydrophobic performance and the thermal stability of the material are raised, then a waterproof agent immersion method is employed for processing, the material water absorption is lowered, the alkali corrosion resistance of the material in a cement-based material is raised and the capability of resisting microorganisms from depolymerization is raised. On the other hand, river sludge, phosphogypsum powder and the like are modified, utilized, and blended with nano tin antimony oxide and polypropylene , granulation is carried out, the intensity and the toughness of the product are raised, the product is not easy to fracture, the thermal insulation wallboard prepared according to the method is low in cost, the added modified soybean straw fibers can absorb released energy when a cement-based material cracks, therefore extension of the crack in the cement-based material is stopped, namely, the toughness of the material is raised, the compression toughness index is raised, and the provided thermal insulation wallboard has advantages of high hardness, sound absorption, noise reduction, thermal insulation, good adsorbability and the like.

Owner:冯丹

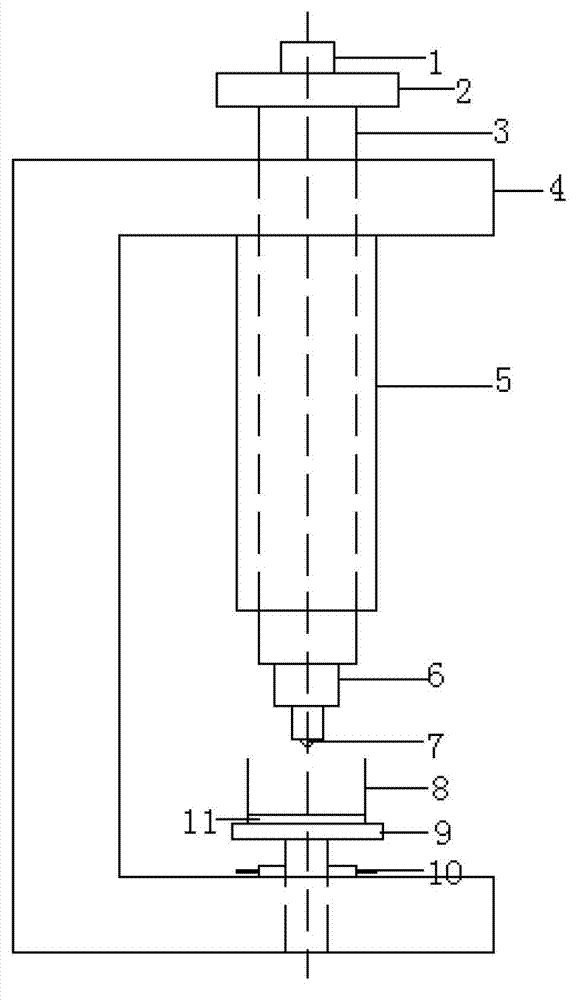

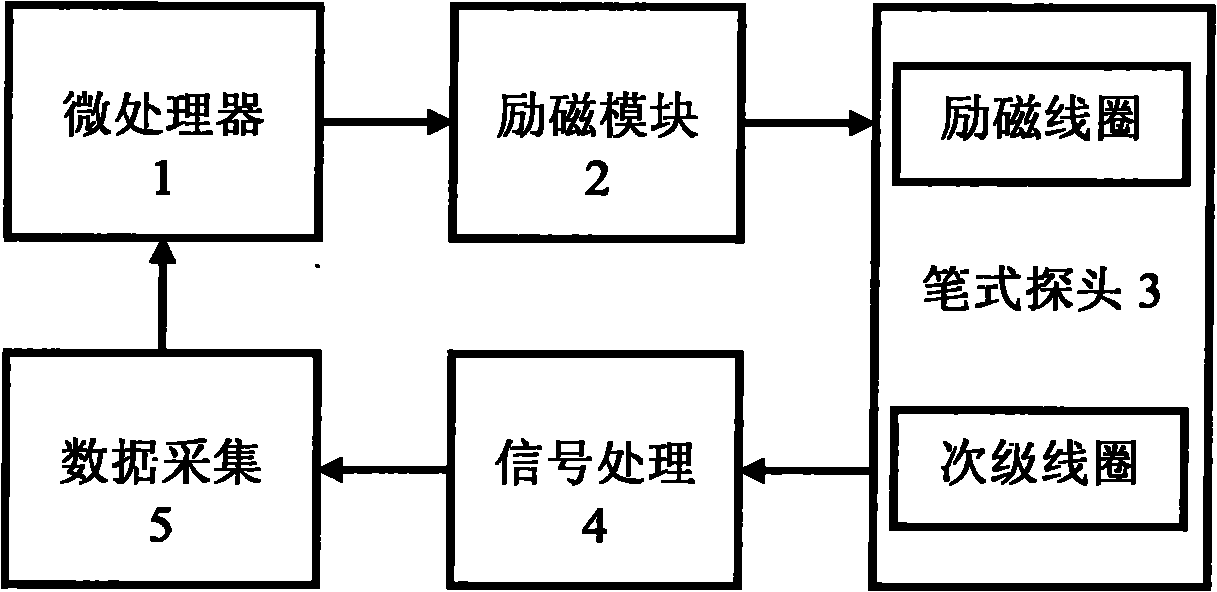

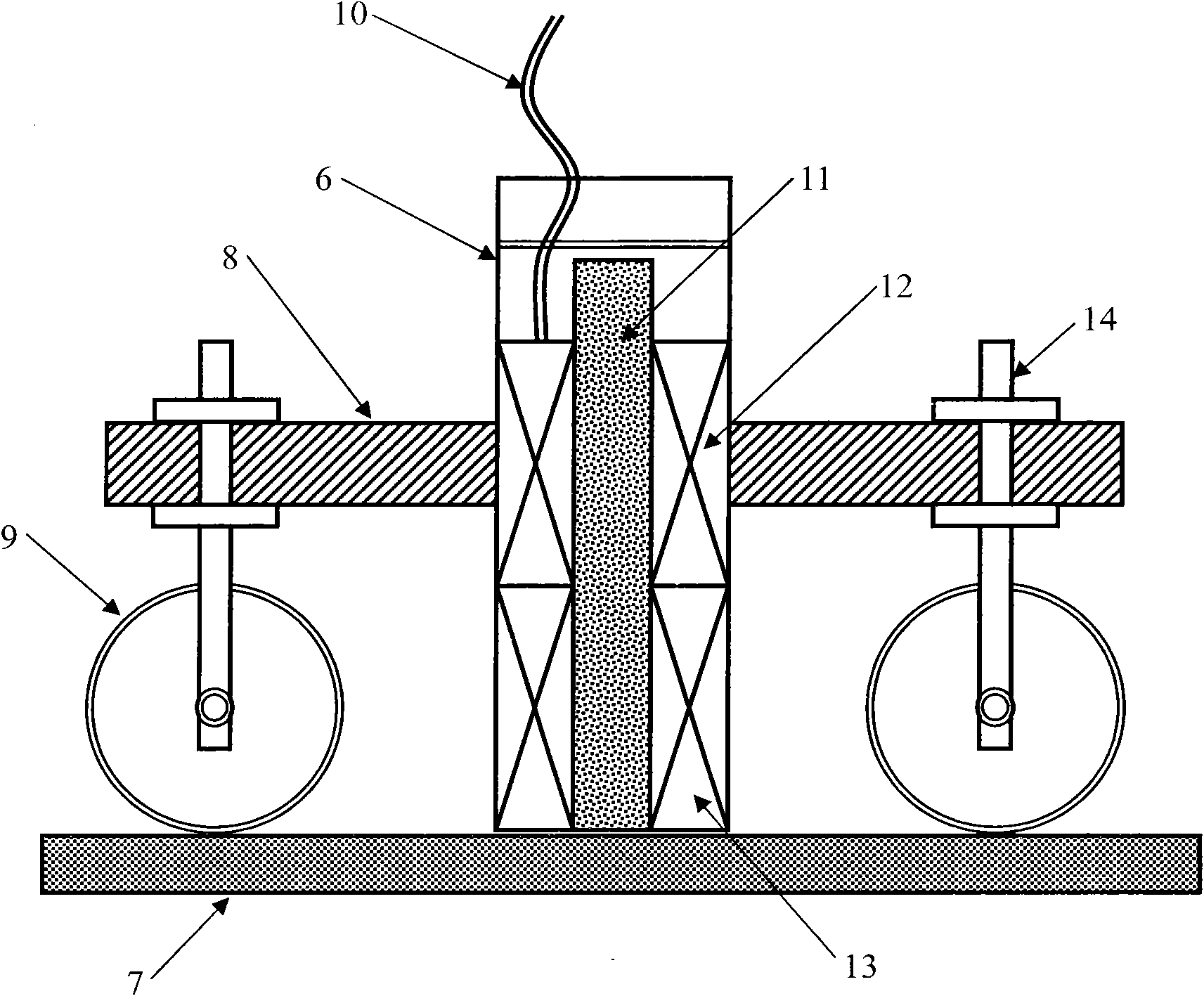

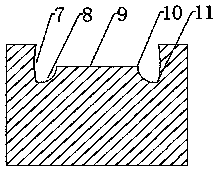

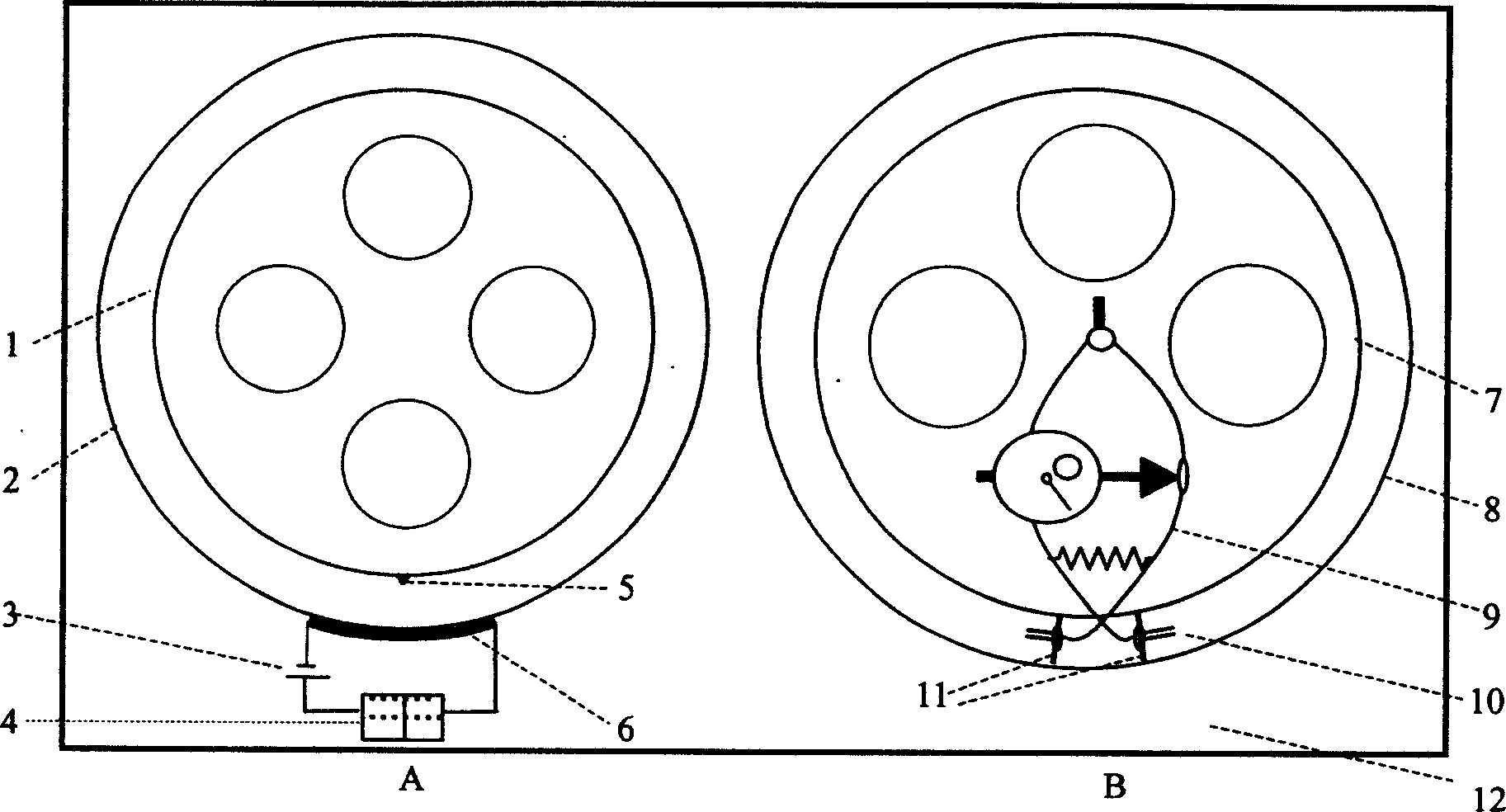

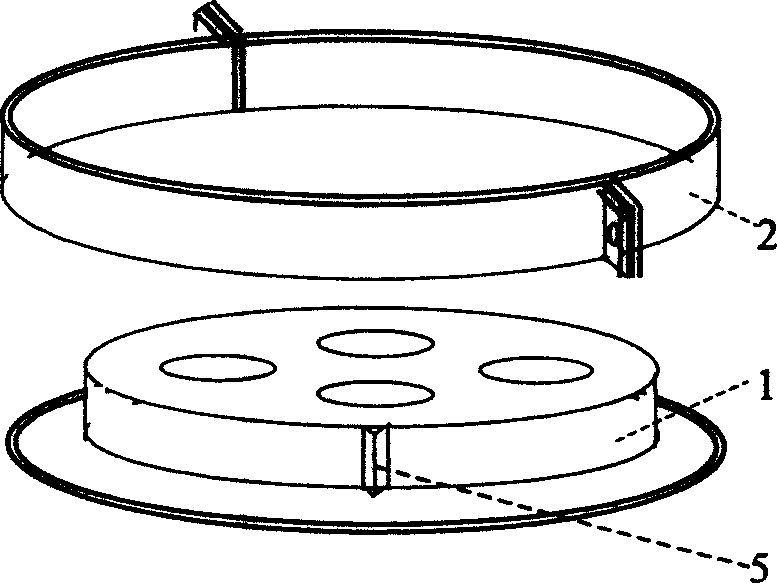

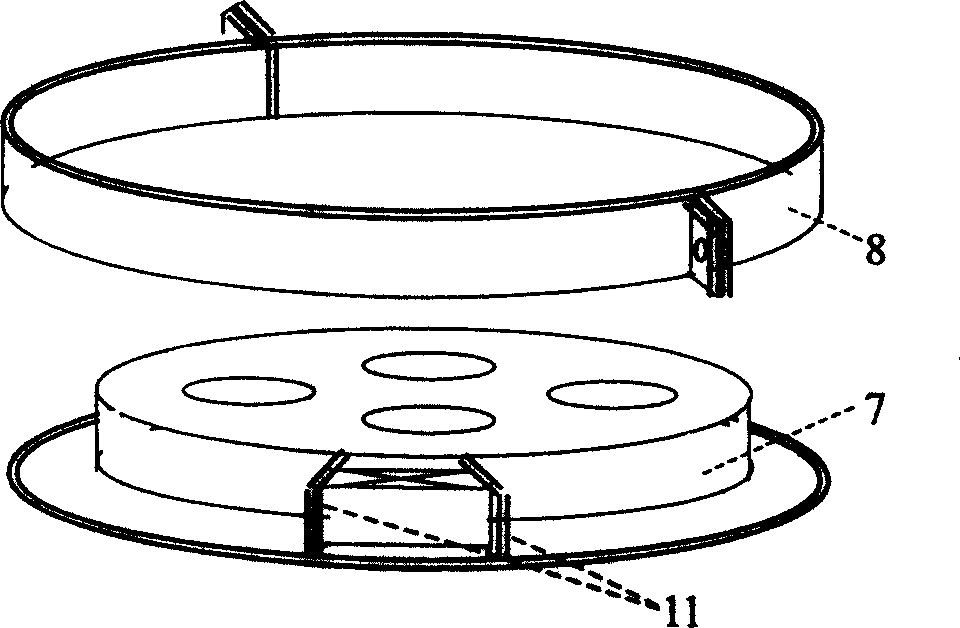

Ferromagnetic material crack warning detection method and apparatus

InactiveCN101858887ALow surface requirementsMaterial magnetic variablesCorrelation coefficientMaterial Crack

The invention discloses a crack detection warning method and a crack detection warning apparatus for monitoring the quality of a ferromagnetic material. The apparatus comprises a microprocessor 1, an excitation module 2, a pen-type probe 3, a signal processor 4 and a data acquisition device 5, wherein the pen-type probe comprises a probe shell 6, the ferromagnetic material 7, a probe bracket 8, rollers 9, a probe lead 10, a ferrite magnetic core 11, an excitation coil 12, a secondary coil 13 and roller brackets 14. The method is characterized by comprising the following steps of: monitoring the material quality anomaly of the ferromagnetic material by detecting the fluctuation of an initial magnetic conductivity parameter, and judging a crack or the probability of a potential crack trend according to the material quality anomaly; and if the shapes of the one-dimensional or two-dimensional data of detection results are different, a great amount of data scattered beyond the interval of ['mean value-standard difference', 'mean value+standard difference'] appears at a certain position, and a correlation coefficient between the current data and historical data of an area is less than a certain characteristic value beta (beta is more than or equal to 0 and less than or equal to 1), determining the material quality anomaly exists in the area where the position is, and suspecting the crack or the existence of the potential crack trend according to the material quality anomaly.

Owner:帅立国

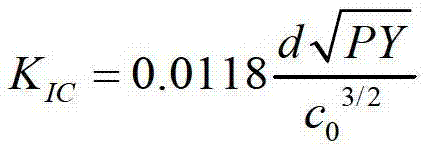

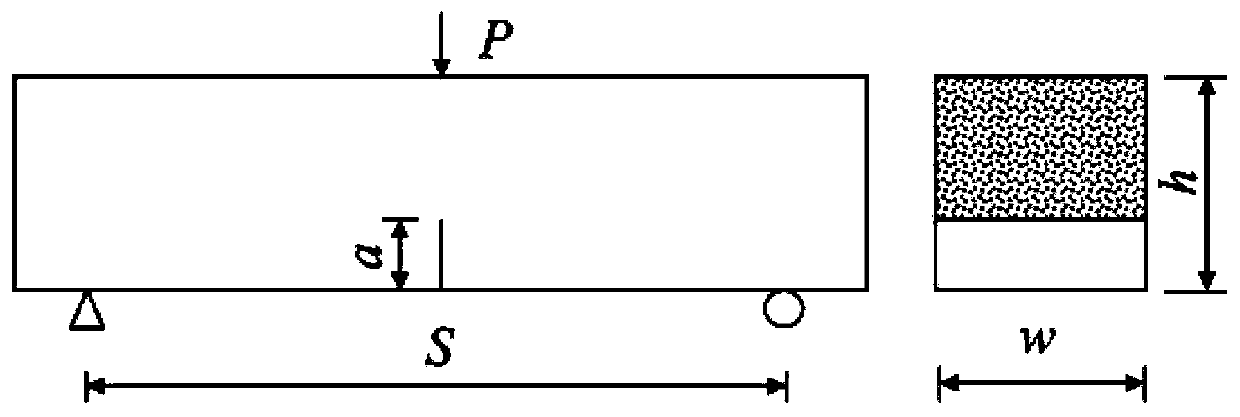

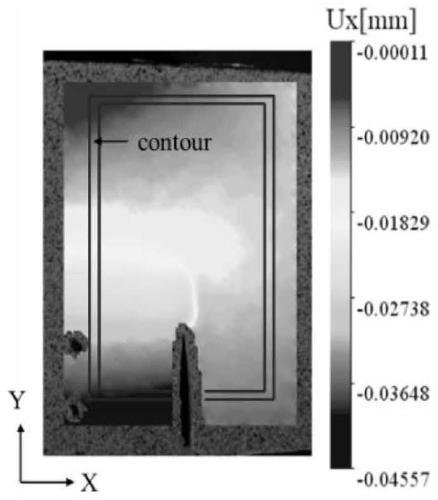

Heterogeneous material crack stress intensity factor calculation method applying DIC technology

ActiveCN111398057AImprove general performanceImprove efficiencyMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesCrazingStress intensity factor

The invention discloses a heterogeneous material crack stress intensity factor calculation method applying a DIC technology. The heterogeneous material crack stress intensity factor calculation methodcomprises the steps of: preparing a standard compression or tensile test piece of a heterogeneous material, carrying out unidirectional compression or stretching on the standard compression or tensile test piece to obtain an elastic modulus and a Poisson's ratio; preparing a heterogeneous material standard fracture test piece with cracks, and preparing speckles for carrying out a DIC test on thesurface of peripheral regions of the cracks; implementing a fracture experiment on the test piece to obtain a displacement field and a crack size of the region near a crack tip under different loads;selecting different integral paths, dividing subunits in an integral region, and calculating J-integral values of the subunits; performing filtering processing on the J-integral values, then performing superposition to obtain J-integral values on the integral paths, and converting the J-integral values into stress intensity factors K; repeating the above steps, calculating J-integral values underdifferent loads / displacements, and acquiring the stress intensity factor K at each loading moment. The heterogeneous material crack stress intensity factor calculation method has the advantages of high efficiency, high precision, high universality and the like.

Owner:SOUTH CHINA UNIV OF TECH

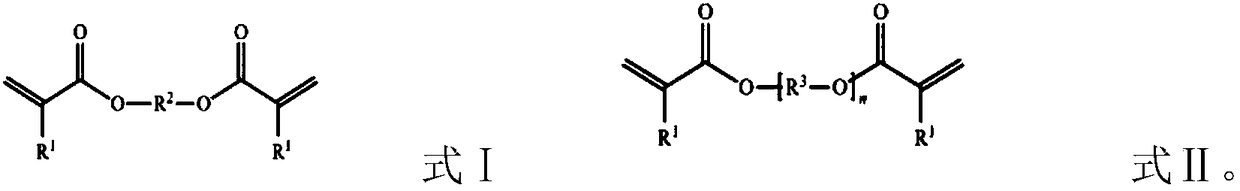

High-performance spray-applied waterproof acrylate material and preparation method thereof

The invention discloses a high-performance spray-applied waterproof acrylate material and a preparation method thereof. The high-performance spray-applied waterproof acrylate material is prepared fromthe following raw materials: 40 to 95 parts of an aqueous acrylate solution, 1 to 30 parts of a compound containing two C=C double bonds which are connected via a flexible carbon chain, 0.5 to 10 parts of an oxidizing agent, 0.5 to 10 parts of a reducing agent, 0 to 10 parts of pigment and 0 to 10 parts of a cosolvent. The waterproof acrylate material of the invention can effectively overcome theproblem that a film formed by the spray-applied waterproof acrylate material cracks at low humidity from molecular structure, can retain moisture in a long period of time, and is applicable to waterproof projects like subways, urban underground utility tunnels, tunnels and underground constructions.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

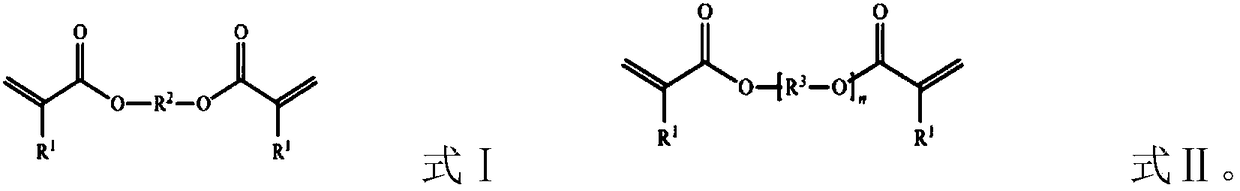

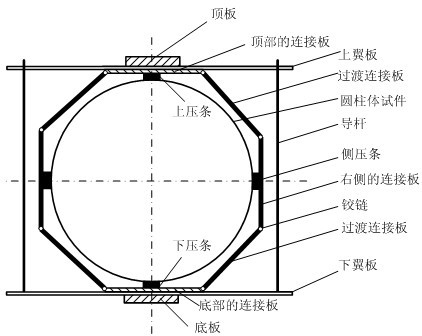

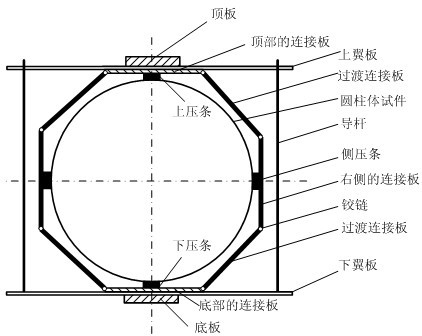

Fixture and test method for two-way alternating split test of road material cylinder specimen

InactiveCN102435495ARealize the loadThe force characteristics conform toMaterial strength using repeated/pulsating forcesMaterial CrackRoad surface

The invention provides a fixture and test method for a two-way alternating split test of a road material cylinder specimen. The fixture comprises a front end surface unit and a back end surface unit which have the same structure and are arranged at an interval, and a connecting piece arranged between the front end surface unit and the back end surface unit, wherein both the front end surface unitand the back end surface unit comprise an upper wing plate, a lower wing plate and eight connecting plates, and the connecting piece comprises an upper pressure strip, a lower pressure strip, side pressure strips, a top plate and a bottom plate. After the fixture is fixed, the fixture is connected with a loading device; the cylinder specimen is placed in the fixture, so that an equal distance respectively is reserved at the two ends of the specimen; a compression and tensile load is exerted on the top plate of the fixture in the vertical direction in a circulating way, and the specimen generates tensile and compression deformation, accordingly, the results of the tensile-compression alternating two-way split fatigue test are obtained. The fixture realizes the alternating compression-tensile loading of the specimen in the vertical and horizontal directions, the actual anti-fatigue performance of a road surface material under the loading condition is obtained, and the fixture and the test method can be used for studying the propagation and healing rule of internal material cracks.

Owner:广东大象交通科技有限公司

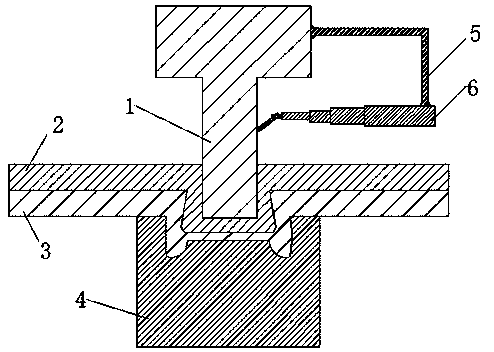

Ultrasonic-assisted impressing connecting device and method

ActiveCN107695215AReduced downforceReduce resistanceNon-electric welding apparatusUltrasonic assistedMaterial Crack

The invention relates to an ultrasonic-assisted impressing connecting device and method and belongs to the technical field of impressing connecting. The ultrasonic-assisted impressing connecting device comprises a punch pin, a lower riveting die, a curved frame, a telescopic rod and an ultrasonic generator. The upper end of the punch pin is connected with an external impressing system. One end ofthe curved frame is welded to the sidewall of the punch pin, and the other end of the curved frame is welded to the tail end of the telescopic rod. Two ribbed plates are welded to the top end of the telescopic rod. The two ribbed plates are both provided with corresponding threaded through holes. The ultrasonic generator is mounted at the top end of the telescopic rod. By adopting the ultrasonic-assisted impressing connecting device, the problems that a difficult-to-deform material cracks, is difficult to deform, has gaps and poor in metallurgical bonding during impressing connecting are solved; the problems that light beam reflection and plasma shielding effects during aluminum laser welding through an aluminum alloy welding method, and the defects of cracks, pores welding joints softenedand the like occur easily are solved; the hold-down resistance borne by the punch pin is reduced by applying ultrasonic vibration. Mechanical-metallurgical combined connection is realized. The mechanical properties of joints are improved.

Owner:KUNMING UNIV OF SCI & TECH

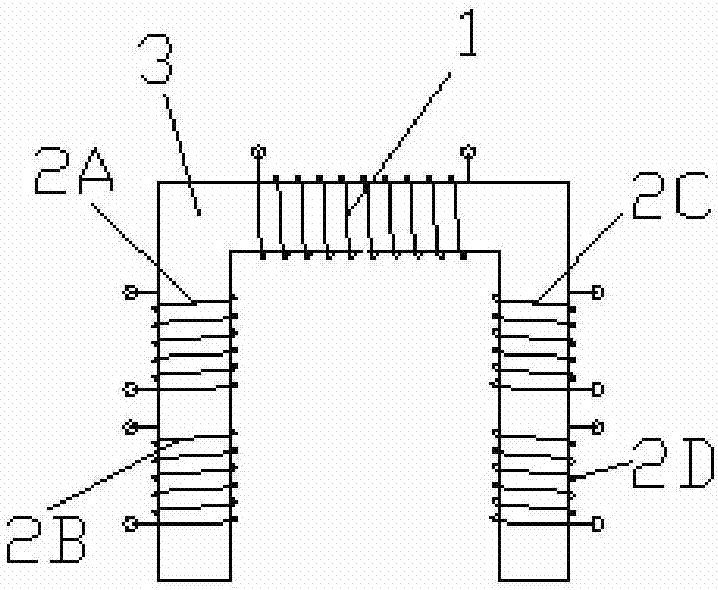

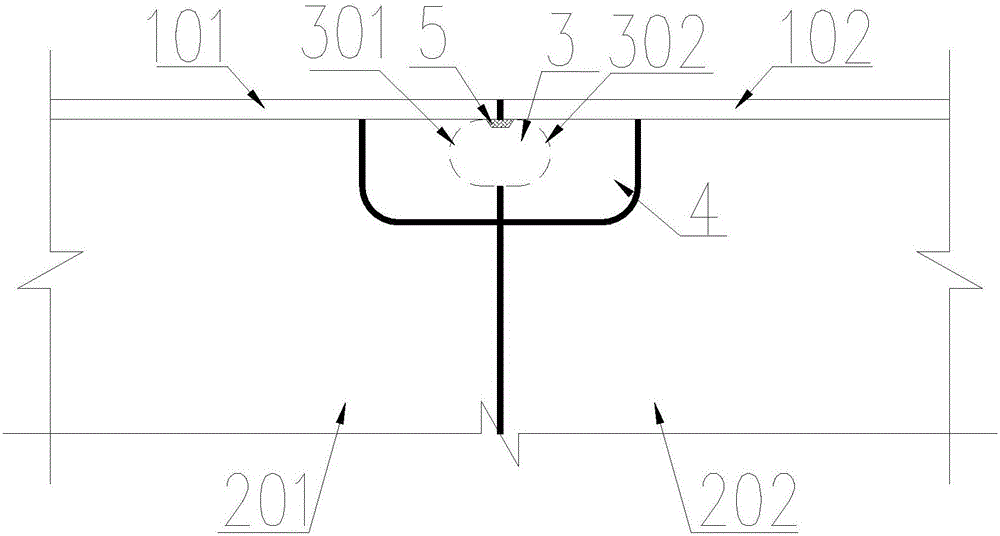

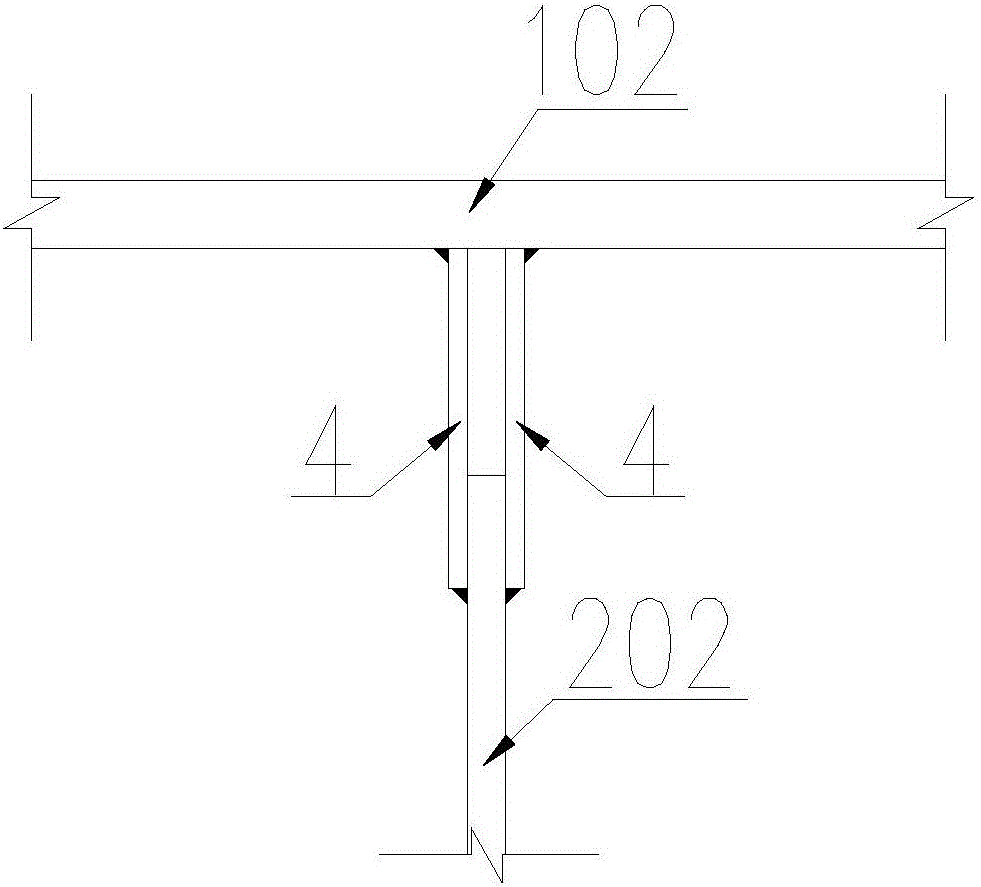

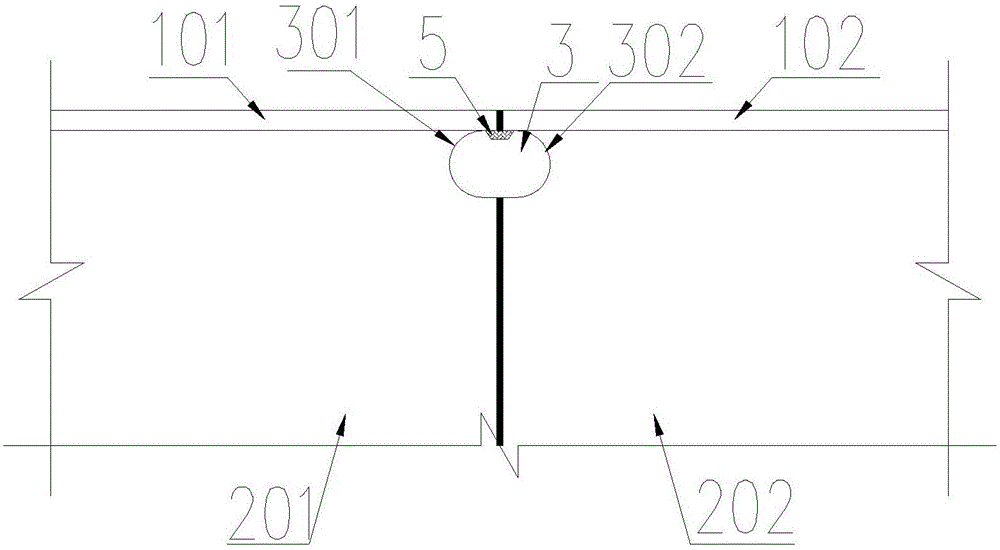

U-shaped two-stage differential eddy current probe, detection system and detection method

InactiveCN107153094APrecise crack defectAccurate detection of crack defectsMaterial magnetic variablesMicrocontrollerDifferential signaling

The invention relates to a U-shaped two-stage differential eddy current probe, a detection system and a detection method, and belongs to the technical field of nondestructive inspection. The U-shaped two-stage differential eddy current probe comprises a wiring terminal, a U-shaped iron core, an exciting coil, an induction coil and a bottom cover, wherein the eddy current detection system consists of a U-shaped differential probe, a microcontroller, a mechanical scanning device, a waveform generator, a power amplifier, a data collecting card, a serial communication module, a signal modulation module and a PC (personnel computer) host computer. The detection method comprises the following steps of performing wavelet transformation on differential signals; extracting front and back peak and trough values of the signals; calculating the front and back trough time differences; solving the crack length according to the time difference. The probe and the induction coil share an identical magnetic path; the differential signal output error due to induction coil lifting height disconformity or asymmetry of the induction coil in a conventional cylindrical iron core differential probe can be overcome; the lifting effect influence can be effectively inhibited. The detection method provided by the invention has the advantages that the engineering realization can be easily realized; the material crack defects can be fast and precisely detected.

Owner:KUNMING UNIV OF SCI & TECH

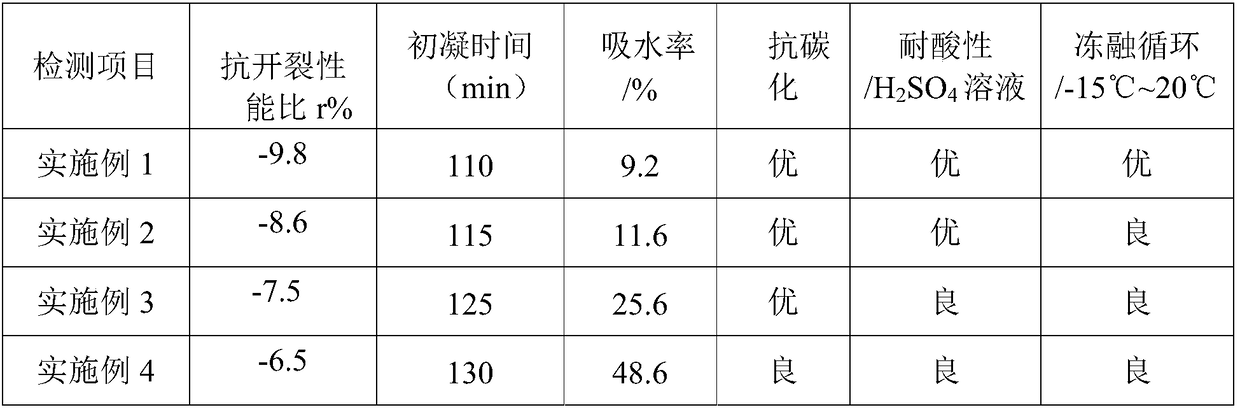

Foamed geopolymer and preparation method and application thereof

ActiveCN108975795AImprove crack resistanceImprove waterproof performanceCement productionCeramicwareFreeze thawingCarbonization

The invention discloses a foamed geopolymer and a preparation method and application thereof. The foamed geopolymer is prepared from the following ingredients in parts by weight: 30-50 parts of metakaolin, 40-50 parts of an alkali-activator, 1-4 parts of coal ash, 2-5 parts of a foaming agent, 0.3-0.7 part of a foam stabilizer, 0.3-0.8 part of modified sisal fiber, 1-4 parts of paraffin emulsion,5-10 parts of water and 0.3-0.7 part of absolute ethyl alcohol. Compared with a traditional anti-permeability waterproof cement base material and a cement base protection material, the foamed geopolymer has the good material crack resistance, excellent waterproof performance and the outstanding endurance quality, good using performance can be maintained for a long time, and the foamed geopolymer has the properties of acid resistance, alkaline corrosion resistance, freeze thawing resistance and carbonization resistance, and can be widely applied to the field of basic engineering such as tunnelcomposite linings.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Steel bridge three-dimensional intersectional welding seam structure and construction method thereof

ActiveCN106670676AAvoid Weld ConcentrationAvoid stressWelding/cutting auxillary devicesAuxillary welding devicesMaterial CrackButt joint

The invention discloses a steel bridge three-dimensional intersectional welding seam structure and a construction method thereof. The steel bridge three-dimensional intersectional welding seam structure comprises perpendicularly welded webs and wing plates. The side edge of the first web of the webs is longitudinally welded to the bottom face of the first wing plate of the wing plates to form a first steel structural unit. The side edge of the second web of the webs is longitudinally welded to the bottom face of the second wing plate of the wing plates to form a second steel structural unit. The lateral edges of the first web and the second web are separately provided with a first opening and a second opening through cutting. The first steel structural unit is welded to the second steel structural unit in a butt joint mode. The first opening is in butt joint with the second opening to form an over weld hole, and an opening is formed in the portion, at a butt-jointed seam of the first wing plate and the second wing plate, of the over weld hole. One sides or the two sides of the portions, at the over weld hole, of the webs are covered with reinforcing plates. The outer edges of the reinforcing plates are continuously welded to the webs and the wing plates correspondingly. By adoption of the steel bridge three-dimensional intersectional welding seam structure and the construction method thereof, the problems that according to a traditional three-dimensional intersectional welding seam structure, the section suddenly changes, the anti-fatigue effect is weak, and over weld hole blocking materials crack and fail are solved.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

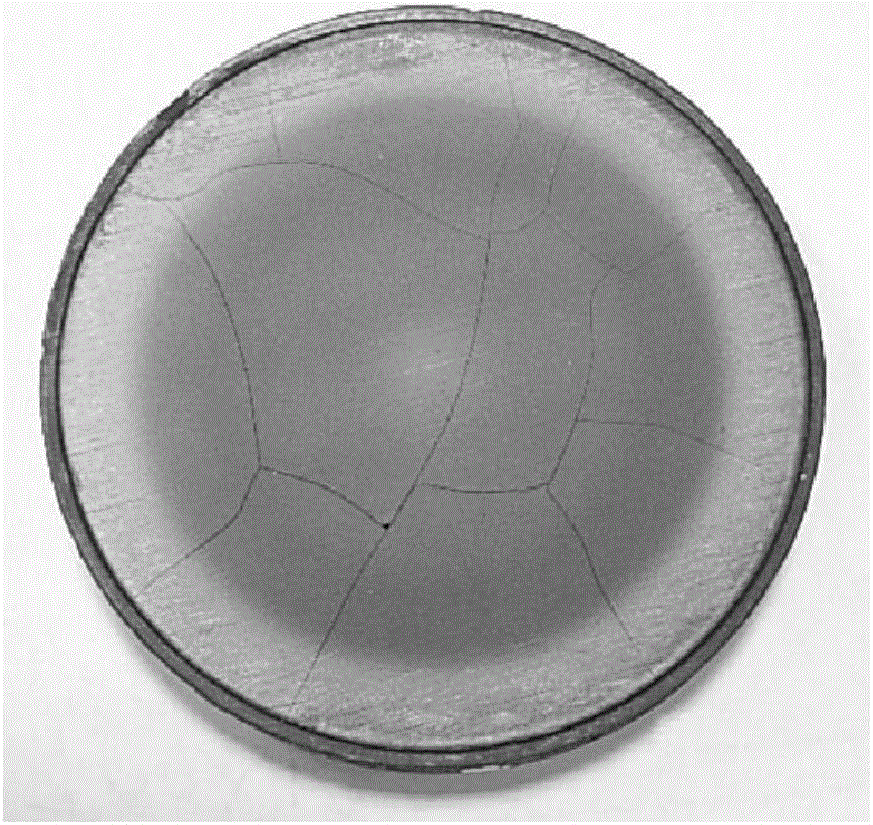

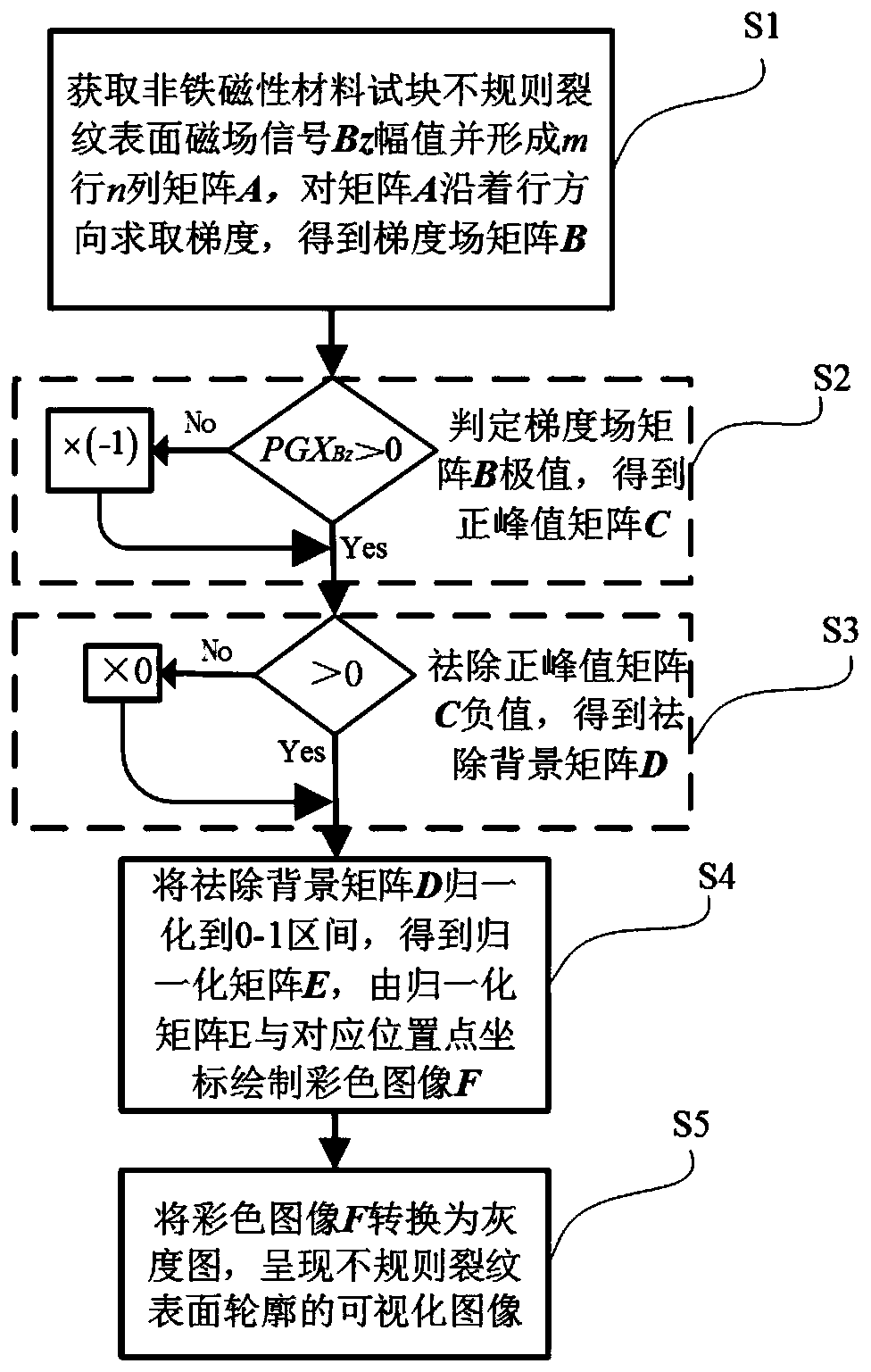

Non-ferromagnetic material irregular crack imaging method based on AC electromagnetic field

The invention discloses a non-ferromagnetic material irregular crack imaging method based on AC electromagnetic field detection, relating to the technical field of nondestructive detection defect imaging. The method comprises steps of acquiring an AC electromagnetic field plane scanning result-a magnetic field signal Bz amplitude matrix by using a grid scanning method, acquiring a gradient field matrix of distorted magnetic field signal Bz maximum distortion value by using a gradient field, so as to reflect aggregation conditions of induced current at irregular crack end points and edges; andfurther, obtaining a surface profile intuitive imaging result of the non-ferromagnetic material irregular crack through resolving of the extreme value, elimination of the background, normalization andgrayscale conversion. The method can assess the non-ferromagnetic material crack visually and predict remaining service life accurately.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Tester and testing method for cement-base material cracking and contracting characleristics

InactiveCN1645138AGuaranteed test accuracyMaterial analysis by electric/magnetic meansElectrical testingMaterial CrackMicrometer

A test method includes forming test sample by model A and detecting out the first cracking time of test sample by detection circuit under constraint state, forming test sample by mode B and detecting out shrinkage property of test sample by measuring calipers under the constrant state, using the wedging on model A to ensure cracking position and utilizing micrometer on calipers to measure out shrinking performance. The device for realizing the method can test both of cracking and shrinking properties at the same time.

Owner:WUHAN UNIV OF TECH

Application of hollow porous fiber in plastering cement substrate material

InactiveCN100999393ASignificant anti-cracking effectSignificant energy savingFoam concretePolymer science

The invention relates to a porous hollow fibers application in plastering cement-based materials. the porous hollow fiber is polypropylene strengthen fiber, it's section has hollow and 3 to 9 holes structure, hollow is greater than 20%, hollow shaping rate of fiber greater than 98%, fiber diameter 20 mum m ~ 50 mum m, intensity is more than 500N / sq mm, elastic modulus is more than 3500N / mm2, elongation of 15 ~ 30%, 6 ~ 25mm length, the number of fiber 76 ~ 200 million / kg, density more than 0.70g / cu cm, used for the wall plastering , the day-leveling floor, parking lot microlith concrete wearing carpet, foam concrete and other plastering cement-based materials, can improve plastering cement-based materials crack resistance, thermal insulation properties, but also enhance its anti-fire burst performance.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com