Brittle material crack initiation stress measurement system and brittle material crack initiation stress measurement method

A technology for stress measurement and brittle materials, which is applied in the direction of measuring devices, analyzing materials, and testing the strength of materials by applying stable tension/pressure, which can solve the problem of small number of acoustic emission events, large influence of micro-cracks, and cracks that are not easy to be monitored. and other problems, to achieve reliable results, convenient operation, and improve authenticity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

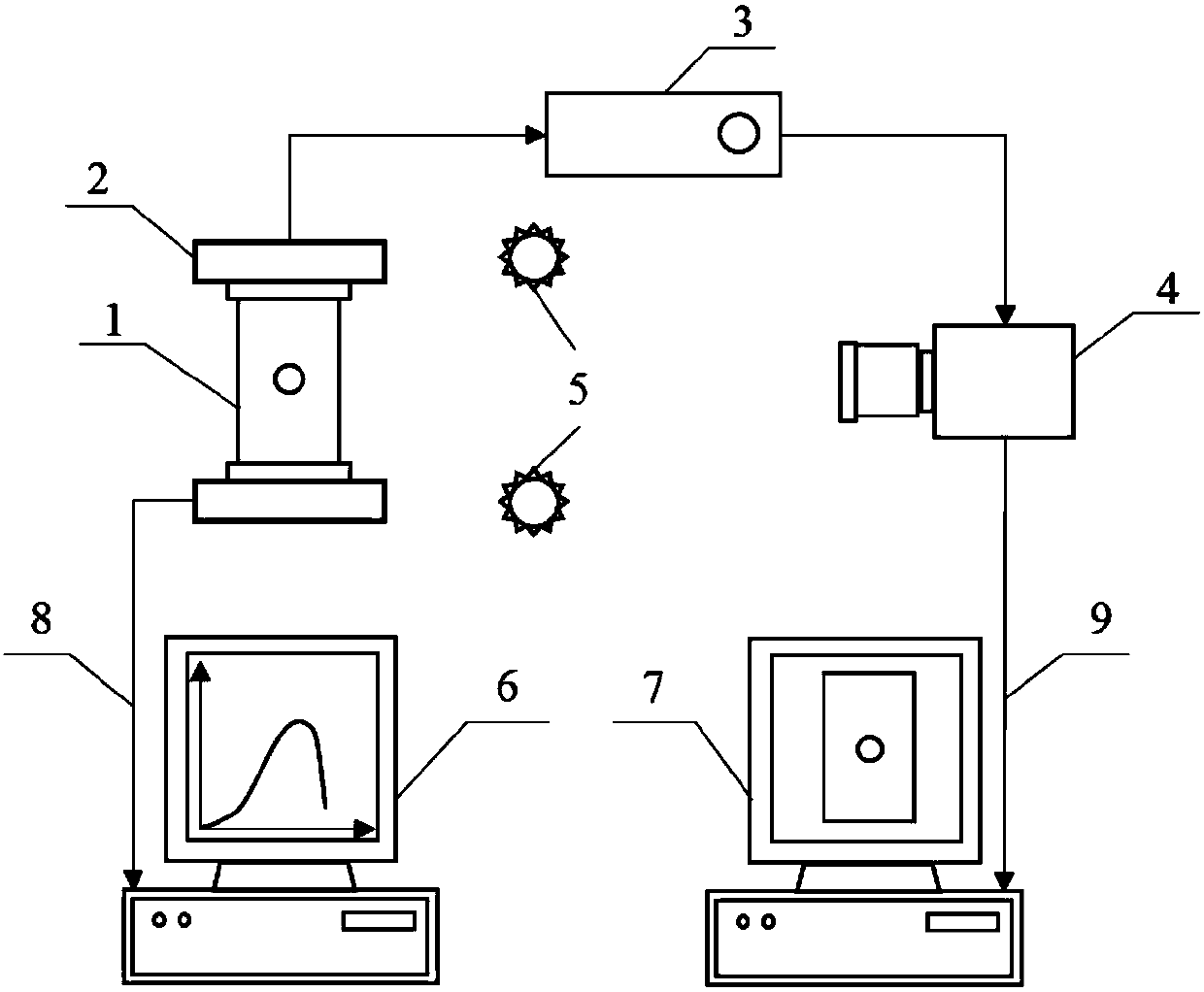

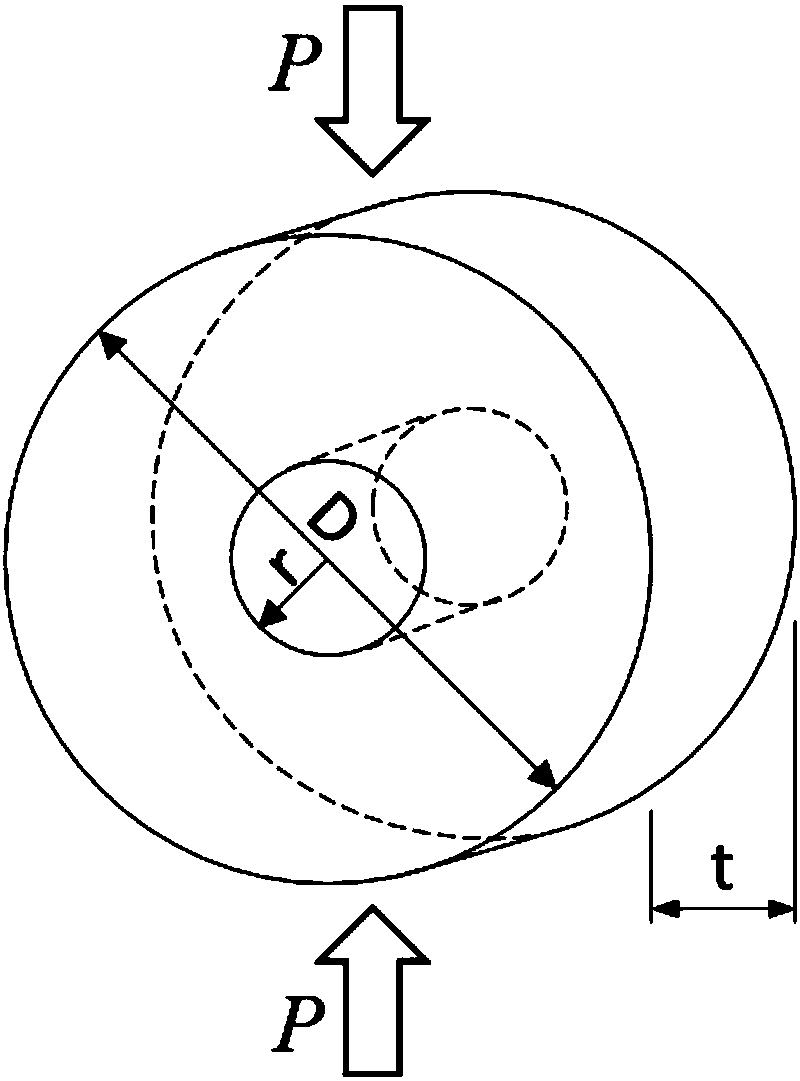

[0050] See attached figure 1 , 2 , 3, 5, a kind of brittle material initiation stress measuring system of the present invention, described measuring system comprises load-time signal receiving device 6, digital image signal receiving device 7, lighting equipment 5, CCD camera 4, synchronous trigger 3, Loading device 2, sample 1; a circular through hole is prefabricated in the center of the sample 1, and an artificial speckle field is produced by spraying a matte white primer on the surface of the sample 1, and spraying a matte black paint on the surface of the primer; The sample 1 is placed between the loading devices 2 as required; the loading device 2 and the CCD camera 4 are controlled by the synchronous trigger 3 to realize synchronous triggering and real-time measurement; the CCD camera 4 is installed on the axis of the circular hole of the sample, And the camera lens plane is perpendicular to the axis of the through hole, and the lens plane is approximately parallel to ...

Embodiment 2

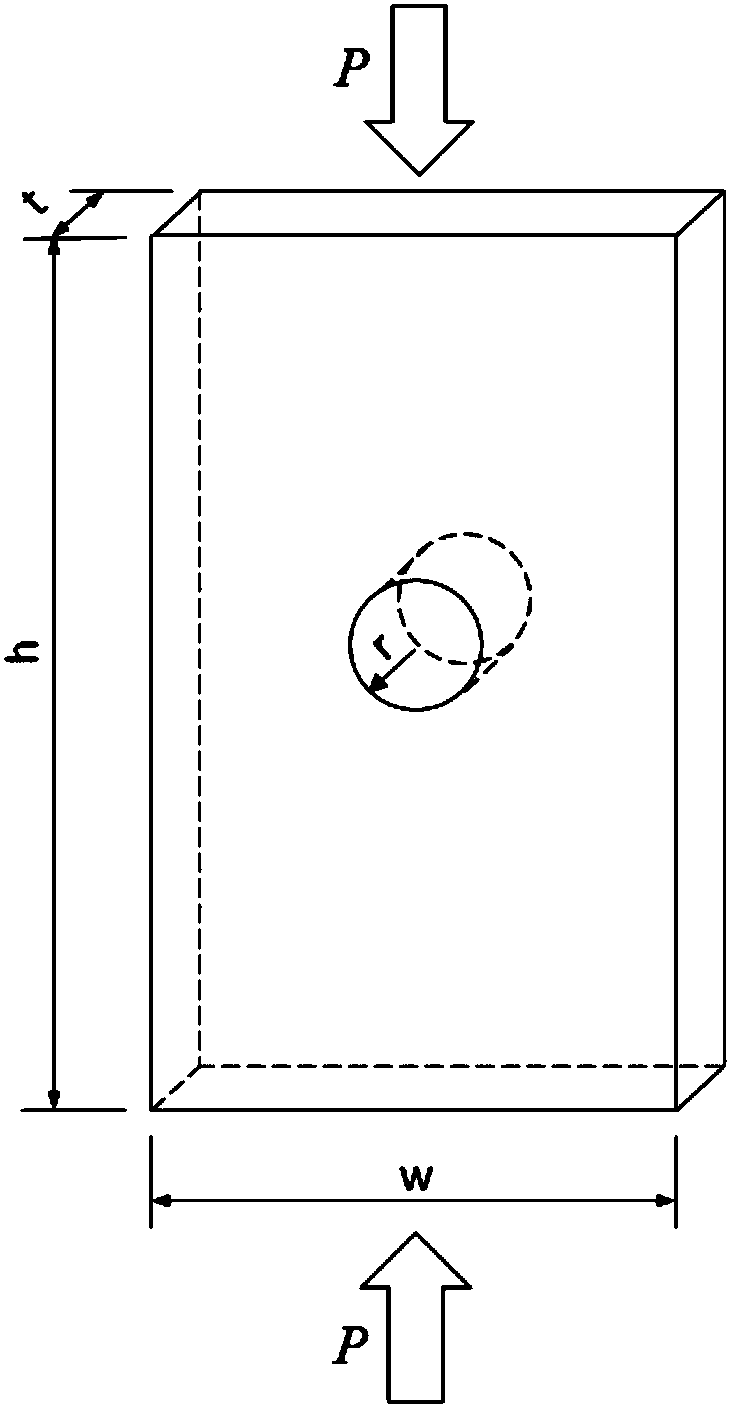

[0052] Embodiment 2, sample is marble cuboid sample, and size is:

[0053] h×w×t=100mm×60mm×20mm, circular hole radius r=7.5mm;

[0054] A method for measuring crack initiation stress of brittle materials, comprising the steps of:

[0055] Firstly, the marble rock sample is processed into a cuboid sample whose size is h×w×t=100mm×60mm×20mm, and then a circular through hole with radius r=7.5mm is prefabricated in the geometric center of the sample; The surface is made of artificial speckle field with spray paint. First, the surface of the sample is cleaned and then sprayed with white paint evenly. After it dries, black paint is randomly sprayed to form random speckle ( Figure 5 ); then place the speckle sample between the loading devices as required; adjust the lens of the CCD camera on the axis of the circular through hole, and the camera target surface is approximately parallel to the surface of the sample, and the object-to-image ratio is 0.0588mm / pixel; set the shooting...

Embodiment 3

[0062] Using the same marble sample as in Example 2, the radius of the central circular hole is reduced to r=5.0mm, the loading rate is 0.01mm / s, and the sample size and test implementation steps are the same as in Example 2. The measured crack initiation time T=24.90s; the crack initiation stress corresponding to this time is σ ci =55.72MPa, the peak stress of the sample is σ c =85.46MPa; Substituting the data into it, it can be obtained that the crack initiation stress level of this sample is K=65.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak stress | aaaaa | aaaaa |

| Peak stress | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com