Self-restoration microcapsule and preparation method thereof

A technology of self-healing microcapsules and microcapsule suspension, which is applied in the direction of microcapsule preparation and microsphere preparation, which can solve the problems of reducing the thermal performance of materials, low thermal performance of microcapsules, and complicated synthesis process of microcapsules, and achieve good interfacial interaction Excellent strength and heat resistance, highlighting the effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

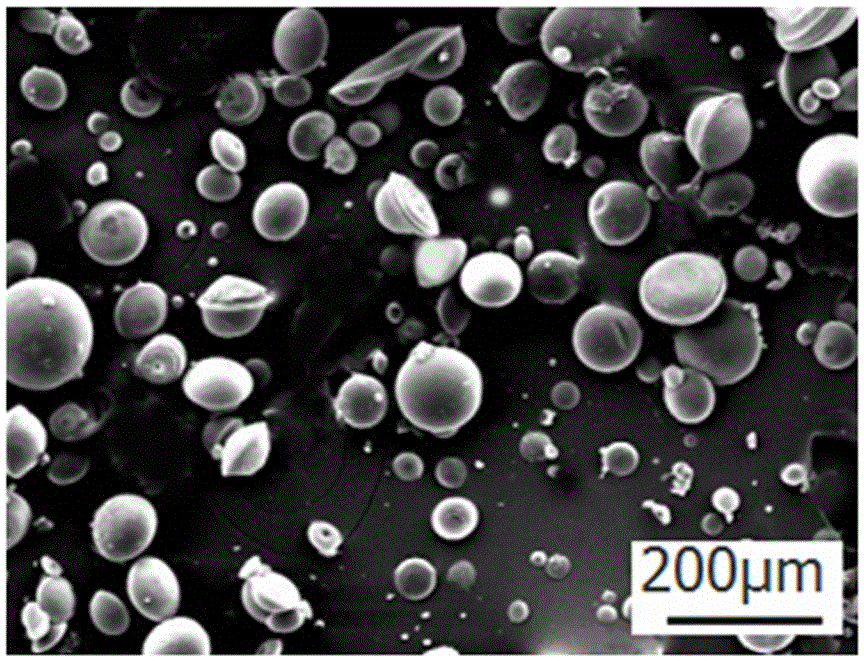

[0023] Dissolve 5g of polybenzimidazole powder in 90g of N,N-dimethylacetamide, after obtaining a clear and transparent solution, add 20g of bisphenol A type epoxy resin (the trade mark is E-51) under stirring conditions, and then stir Under certain conditions, the above mixed solution was dispersed in 1000 g of deionized water, and after 0.5 hour, a suspension of microcapsules was obtained. After washing with deionized water, suction filtration, and vacuum drying at room temperature for 45 hours, the microcapsule product is obtained as a light yellow powder. The storage period at room temperature is more than 1 year, and the yield is about 98%. figure 1 It is a scanning electron microscope (SEM) picture of the microcapsules in Example 1. The thermal decomposition temperature at 5wt% weight loss is 338°C.

Embodiment 2

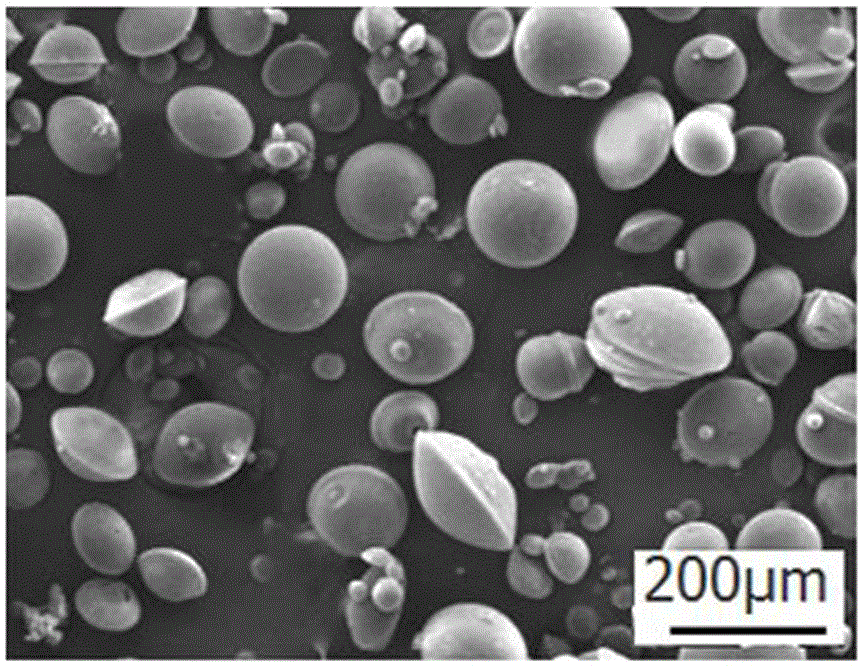

[0025] 5g of polybenzimidazole powder was added to 90g of N,N-dimethylacetamide, and after the solution became transparent, 30g of novolak epoxy resin (brand F-51) was added under stirring conditions to obtain a mixed solution. Under stirring conditions, the above mixed solution was dispersed in 800 g of deionized water, and after 1 hour, a microcapsule suspension was obtained. After washing with deionized water, suction filtration, and vacuum drying at room temperature for 50 h, the microcapsule product was obtained as a light yellow powder. The storage period at room temperature was more than 1 year, and the yield was about 100%. figure 2 It is a scanning electron microscope (SEM) picture of the synthesized microcapsules in Example 2. The thermal decomposition temperature at 5wt% weight loss is 352°C.

Embodiment 3

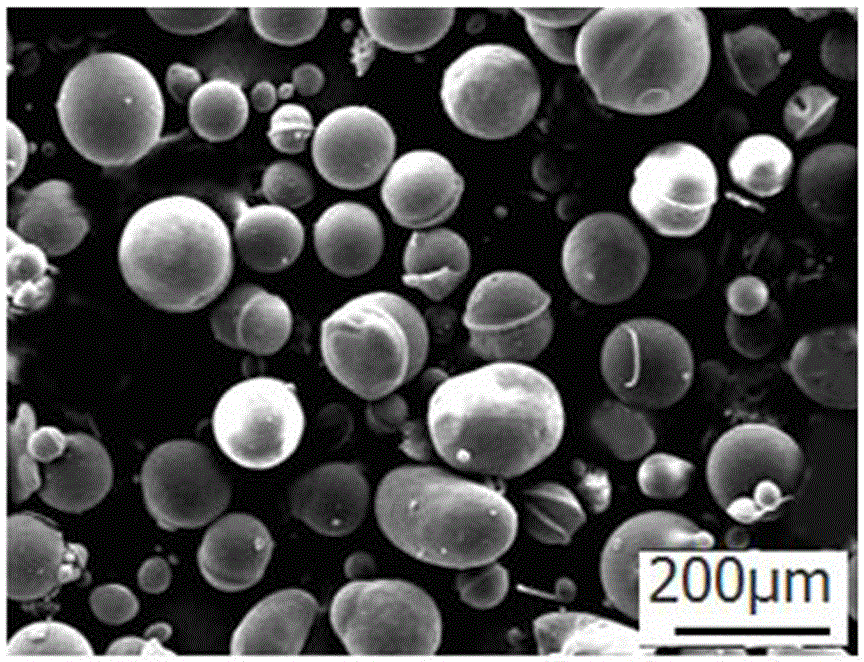

[0027] Add 10g of polybenzimidazole powder to 100g of N,N-dimethylacetamide. After the solution is clear and transparent, add 60g of bisphenol A epoxy resin (brand E44) under stirring conditions. The above mixed solution was added to 2000 g of aqueous solution containing 10 g of styrene-maleic anhydride copolymer, and microcapsule suspension was obtained after 2 hours. After washing with deionized water, suction filtration, and vacuum drying at room temperature for 45 hours, the microcapsule product is obtained as a light yellow powder. The storage period at room temperature is more than 1 year, and the yield is about 100%. image 3 It is the SEM figure of the microcapsule of 3 in the embodiment. The thermal decomposition temperature at 5wt% weight loss is 346°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com