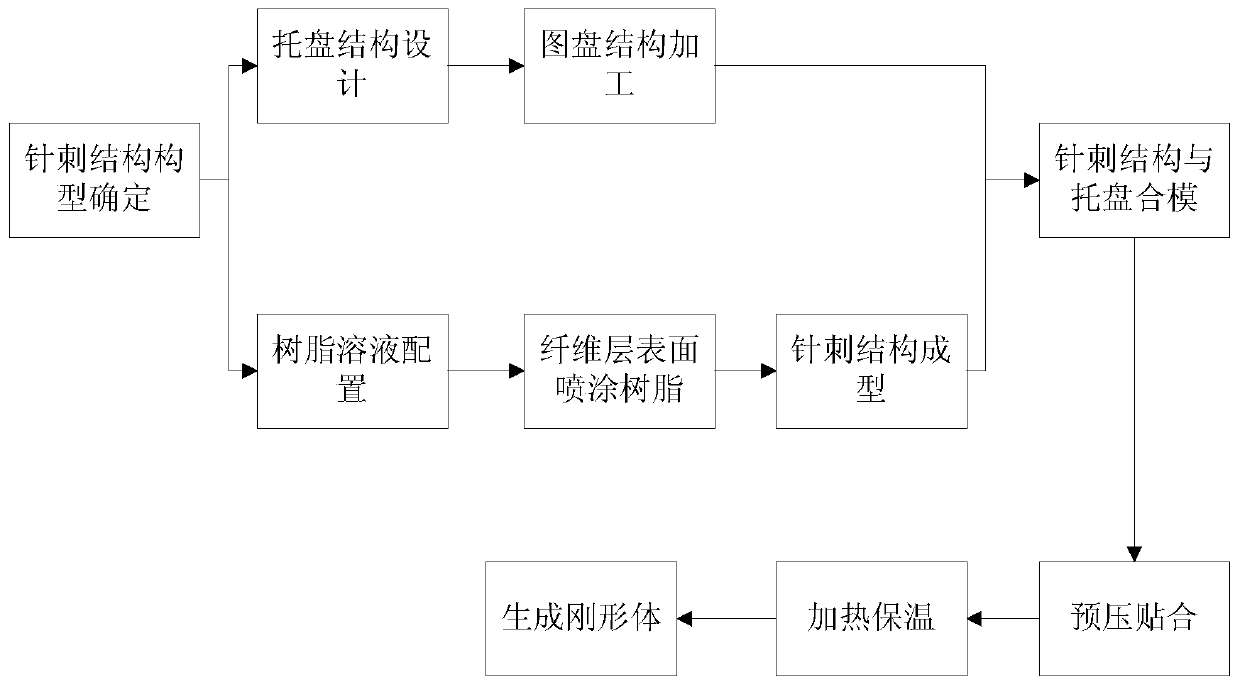

Size accuracy control method for large-sized low-density long fiber needle structure

A technology for structural size and precision control, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of difficult dimensional precision control and easy deformation in the molding process, so as to improve rigidity, controllable dimensional precision, and solve the problems of easy deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

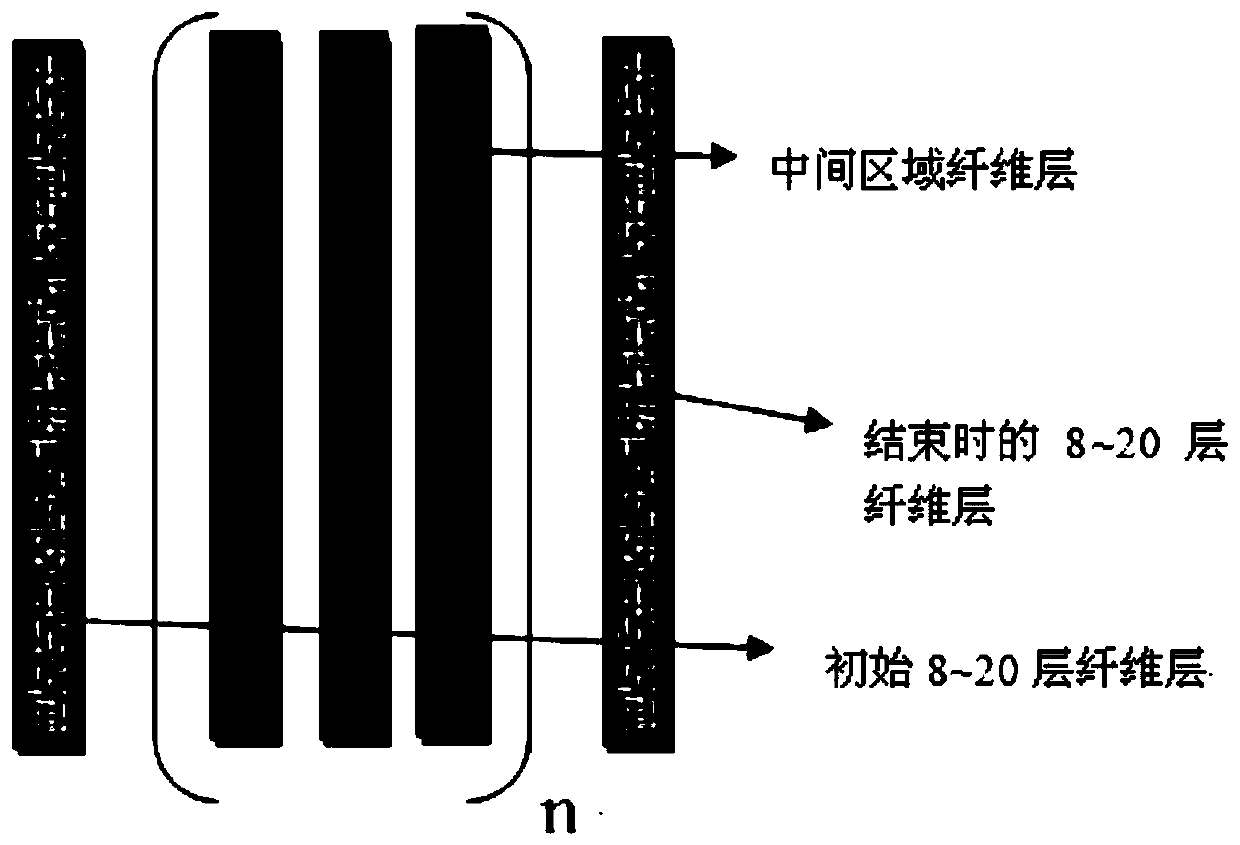

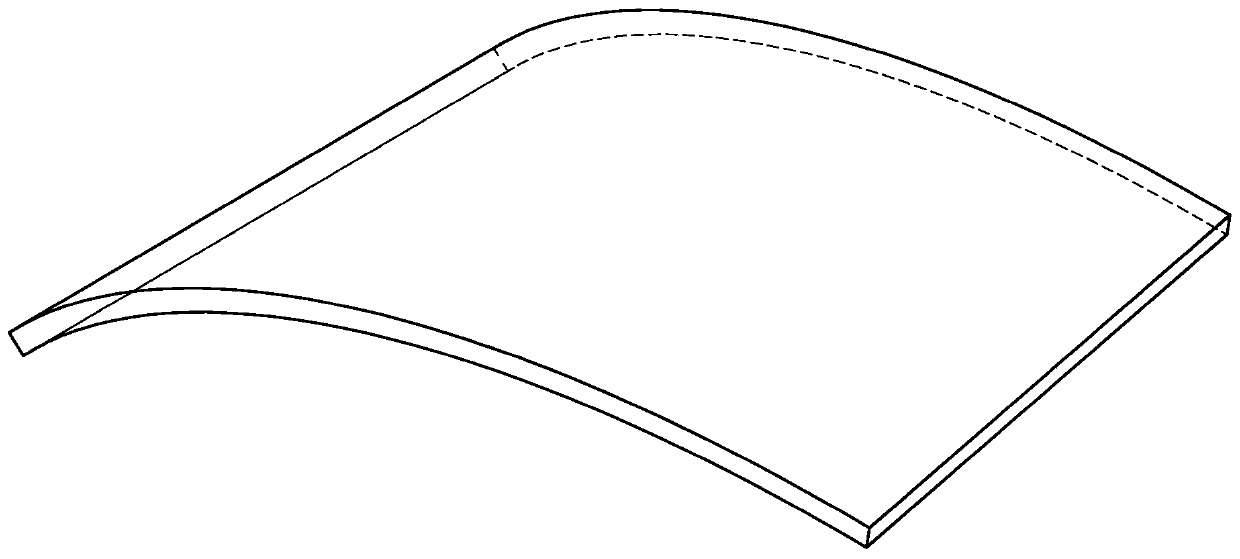

Embodiment 1

[0064] In the preparation of a large curvature fan-shaped structure with a thickness of 25mm and an in-plane area greater than 2㎡ ( image 3 ), firstly, design and process Figure 4 tray structure. Then, the phenolic resin was dissolved in ethyl acetate in a container to form a phenolic solution with a phenolic mass content of 2% and a content of 8%. Then, evenly spray 3 times of phenolic solution with a content of 8% on the surface of the needle-punched fiber layer of the large-curvature fan-shaped structure needled with the initial 10 layers and the final 10 layers of carbon fiber, and spray evenly on the surface of the remaining intermediate fiber layers with a content of 2 times. % phenolic solution. The acupuncture structure molding is completed on the acupuncture mould. Then, under the protection of the acupuncture mould, the mold clamping of the acupuncture structure and the tray structure is completed, and the inner surface is evenly pressurized by the acupuncture m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com