A multifunctional combined corner connector of a flat-plate solar collector frame

A solar collector and multifunctional combination technology, applied in the field of solar energy, can solve the problems of poor sealing performance and poor installation stability of thermal insulation collectors, and achieve novel appearance and structure, improved safety, sealing and thermal insulation. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

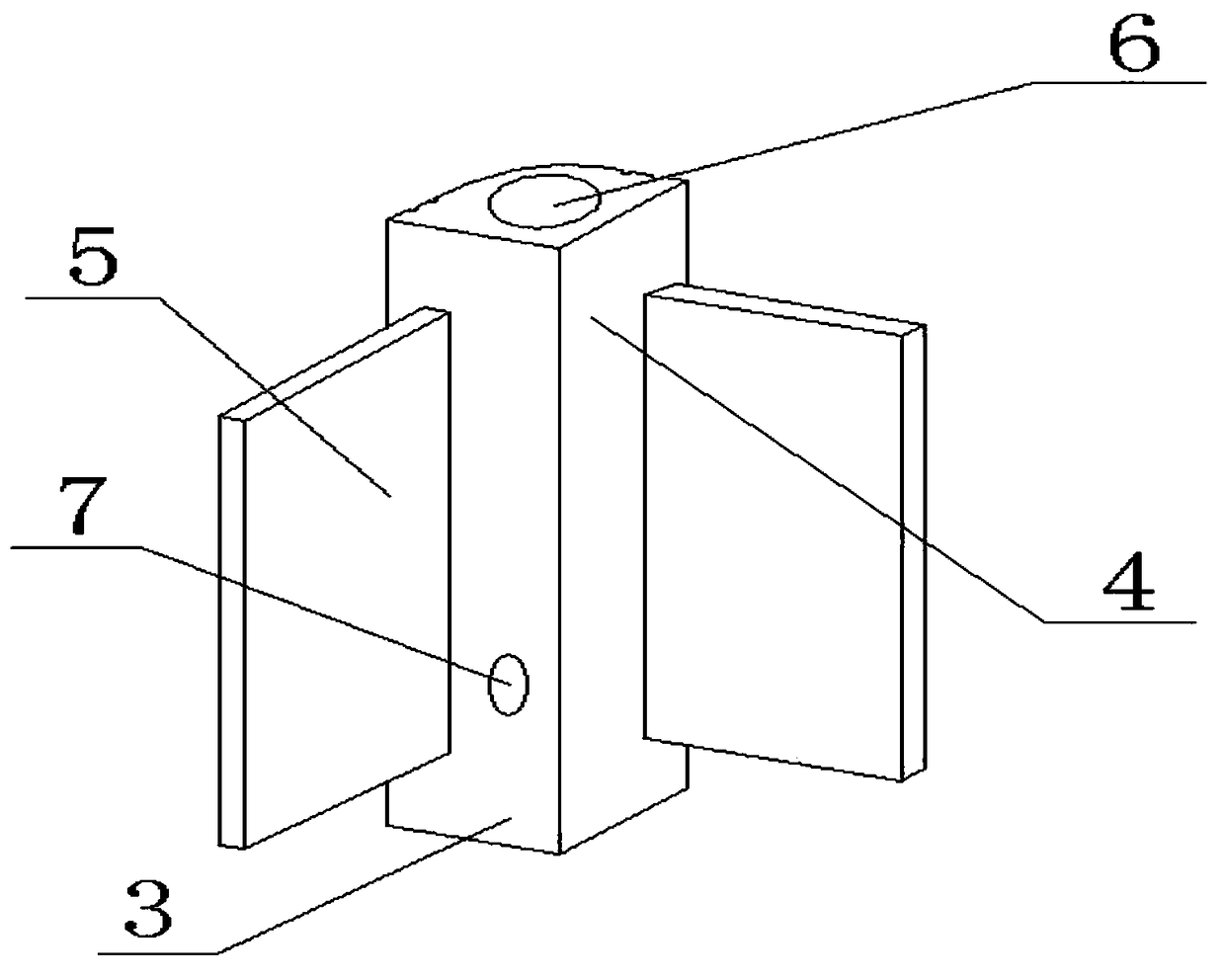

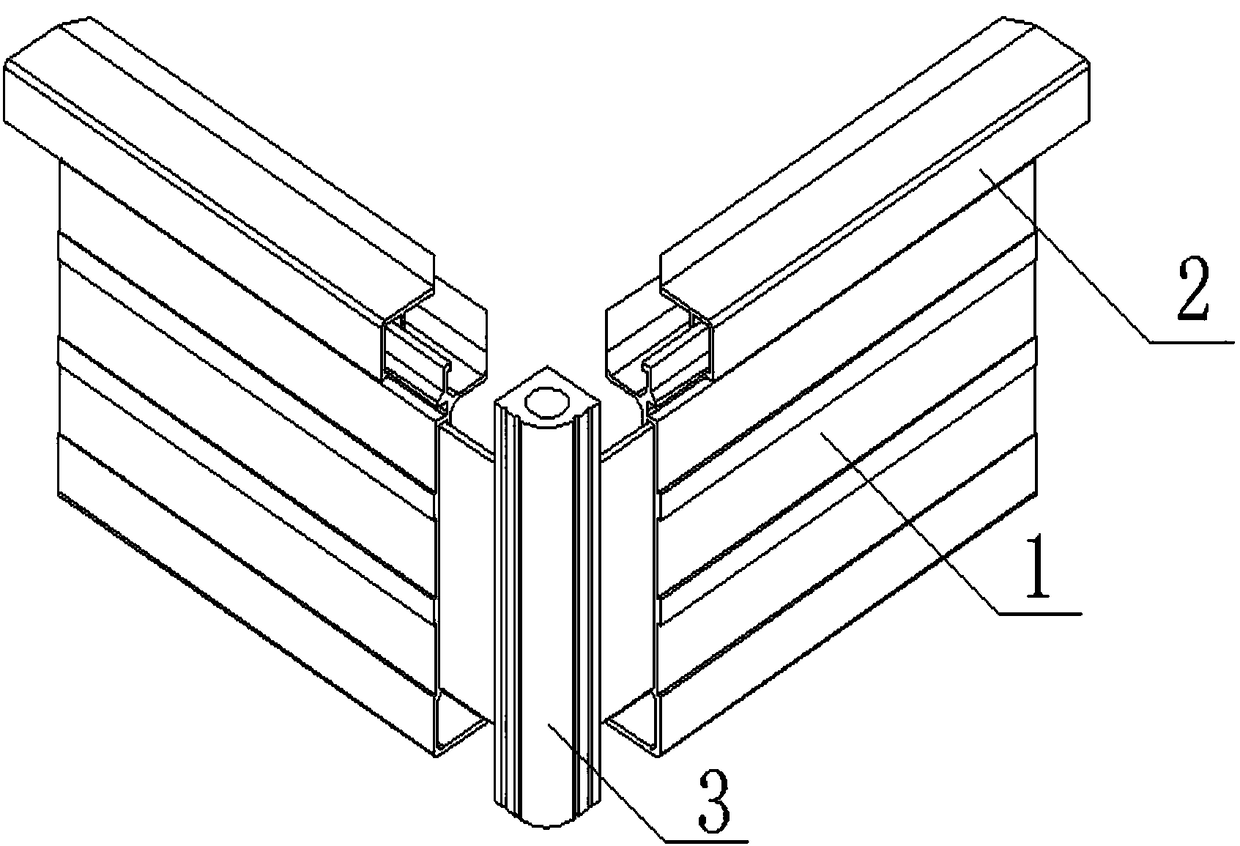

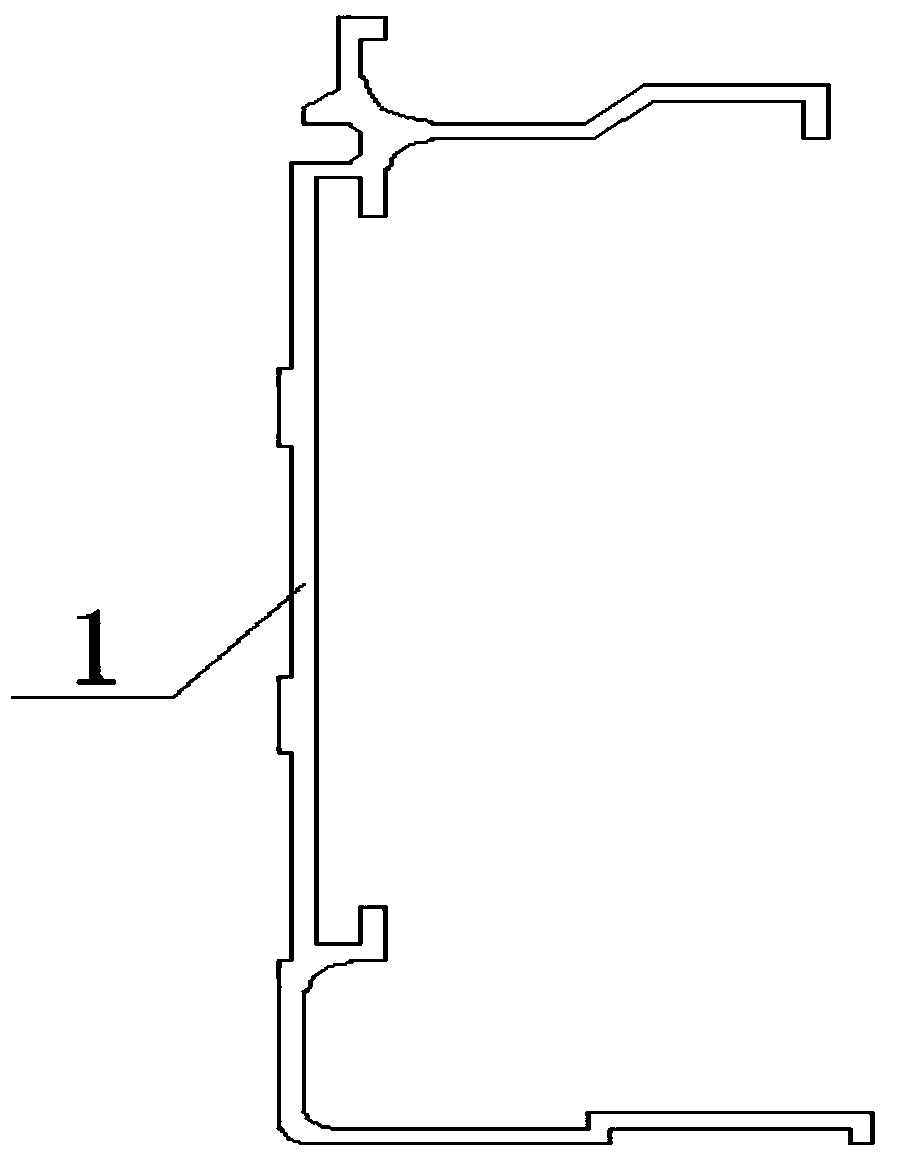

[0029] A multi-functional combination corner connector for the frame of a flat-plate solar heat collector, such as Figure 1-7 As shown, it includes frame 1, multifunctional corner connector 3, bead 2, frame 1 cooperates with multifunctional corner connector 3, multifunctional corner connector 3 is inserted and matched with vertical and horizontal frame 1, and bead 2 is connected with vertical and horizontal frame 1 to up and down buckle; frame 1 and multifunctional corner connector 3 are firmly riveted or crimped, and the transition mode is right angle or rounded or chamfered; bead 2 is buckled with frame 1; multifunctional corner connector 3 includes a column 4 and fins 5, the fins 5 are arranged symmetrically with the column 4 perpendicular to the ground, the surface of the fins 5 is smooth type, any one of right angle groove type and arc groove type, multifunctional angle connection The edges of both ends of the fin 5 of the member 3 are lower than the upper and lower edge...

Embodiment 2

[0033] The assembly of the flat plate heat collector illustrates the working principle and working process of the present invention, such as Figure 1-7 Shown:

[0034] The right-angle fins 5 on the column 4 of the multifunctional corner connector 3 are processed to the size matching the notch in the frame 1, and one frame in the vertical and horizontal frame 1 is selected, and the inner matching parts are cut up and down, and the vertical and horizontal bead 2 is processed to To meet the requirements, another right-angled fin 5 on the column 4 of the multifunctional corner connector 3 is inserted into the inner notch of the vertical and horizontal frame 1 respectively, and the bottom of the frame 1 is placed on the heat preservation backboard 10 and the heat absorbing body core 9, and the multifunctional corner connection Part 3 is riveted and fixed to one side of the vertical and horizontal frame 1, and the thermal insulation edge strip 11 is placed, and the transparent cove...

Embodiment 3

[0036] The installation of flat plate heat collector illustrates that heat collector of the present invention fixes working process, as Figure 1-7 Shown:

[0037] When installing the flat plate heat collector formed by the combination of multifunctional corner connectors 3, the heat collector is first placed on the supporting surface of the lower purlin steel 12 and the upper purlin steel 13, and the lower purlin steel 12 and the upper purlin steel 13 on the supporting surface There are round holes, and the hole distance matches the cylindrical hole distance of the multifunctional corner connector 3. After the fixing hole 6 on the multifunctional corner connector 3 is aligned with the round holes of the lower purlin steel 12 and the upper purlin steel 13, insert the screw 14 and nut 15 are fixed with the lower purlin shaped steel 12 and the upper purlin shaped steel 13, completing the installation and fixing of the solar heat collector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com