Patents

Literature

144results about How to "The combination is firm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

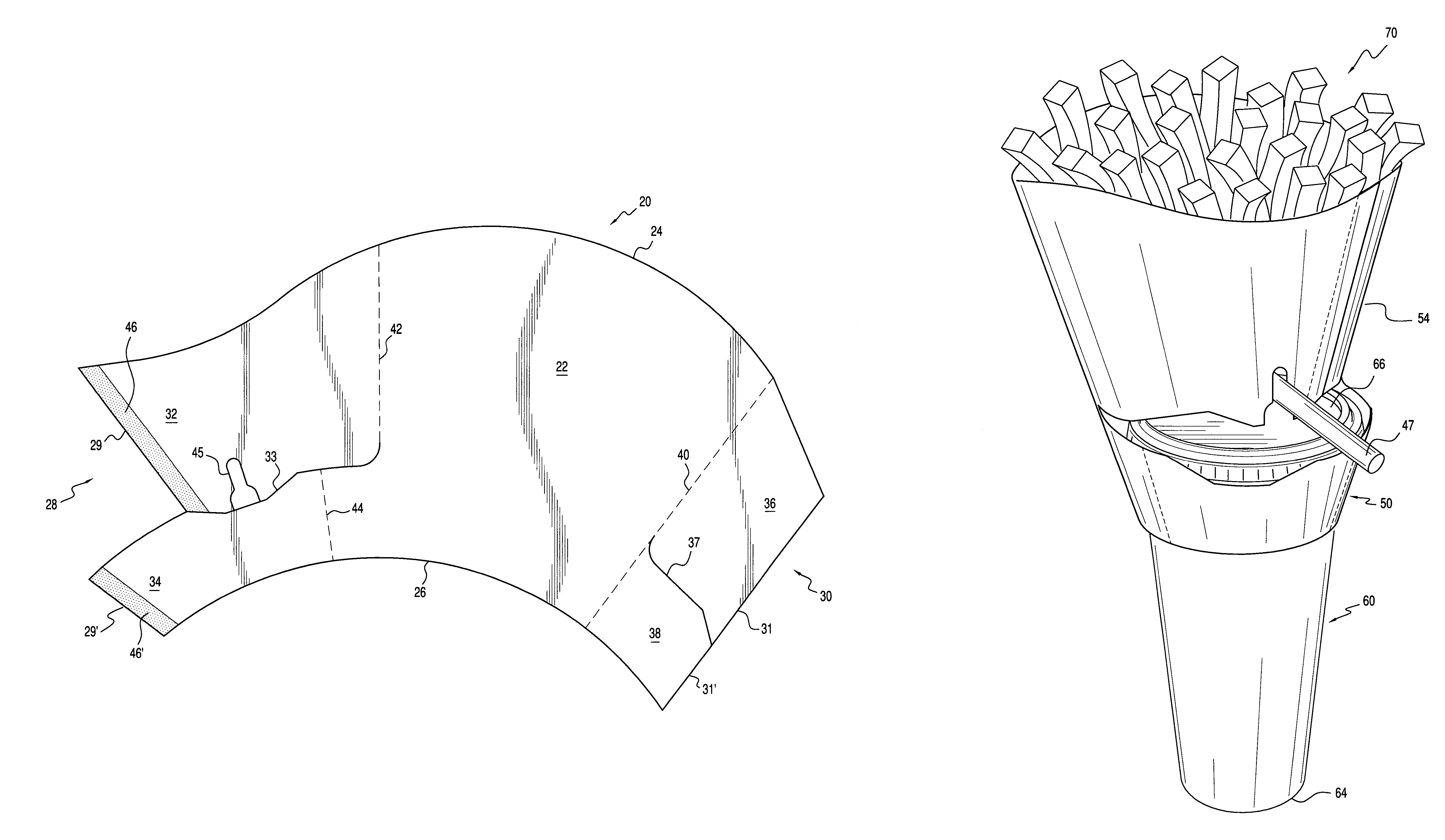

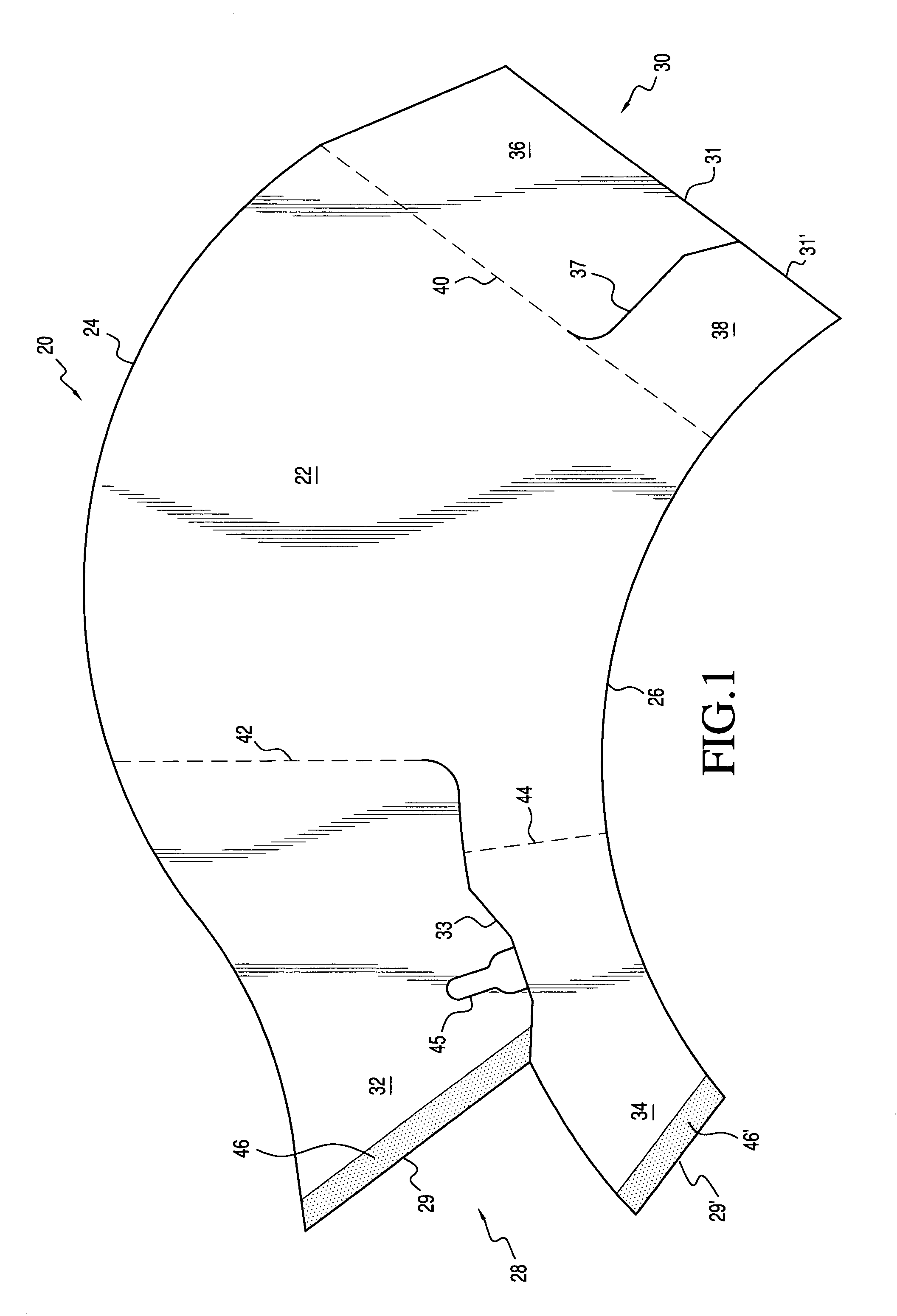

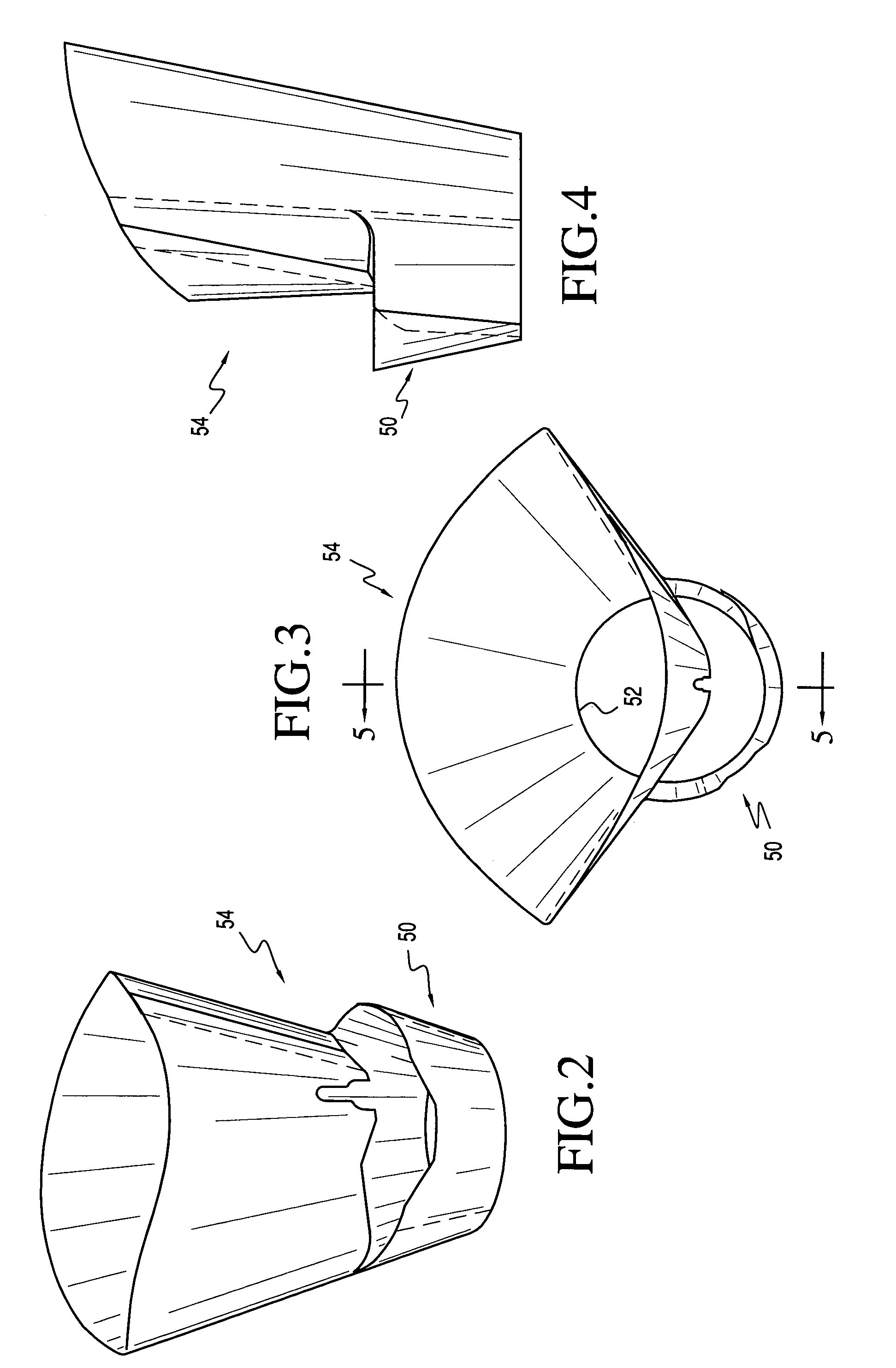

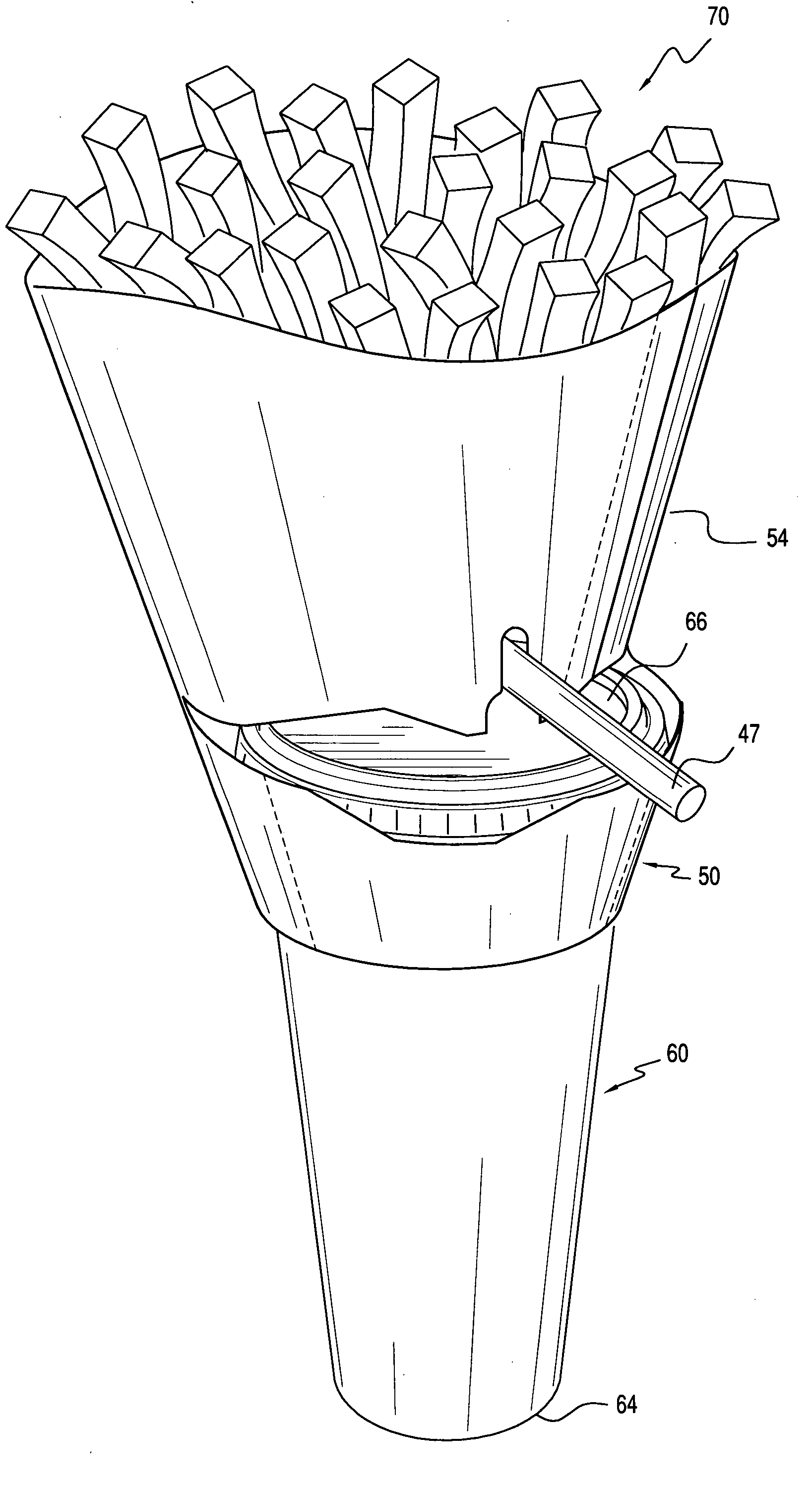

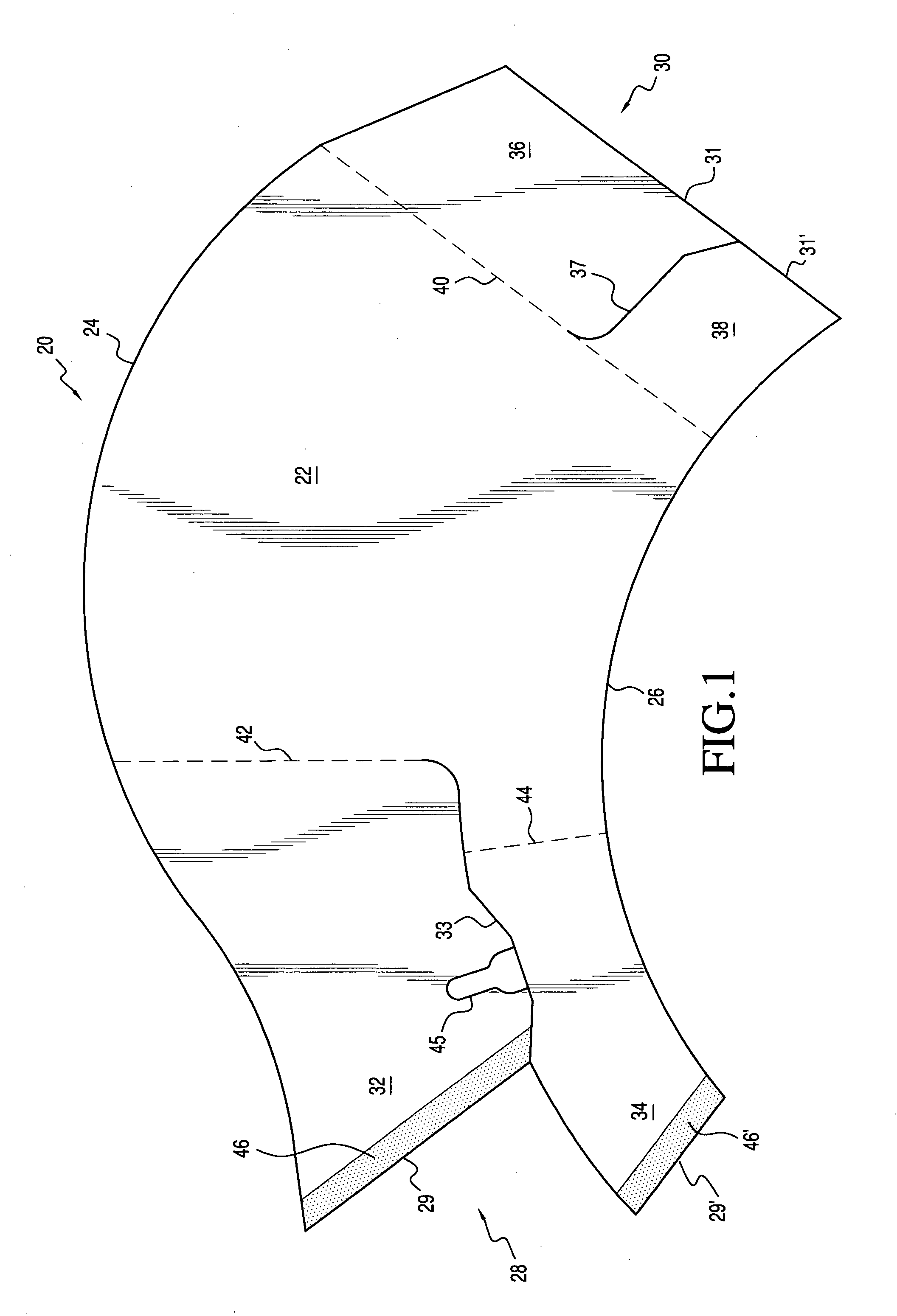

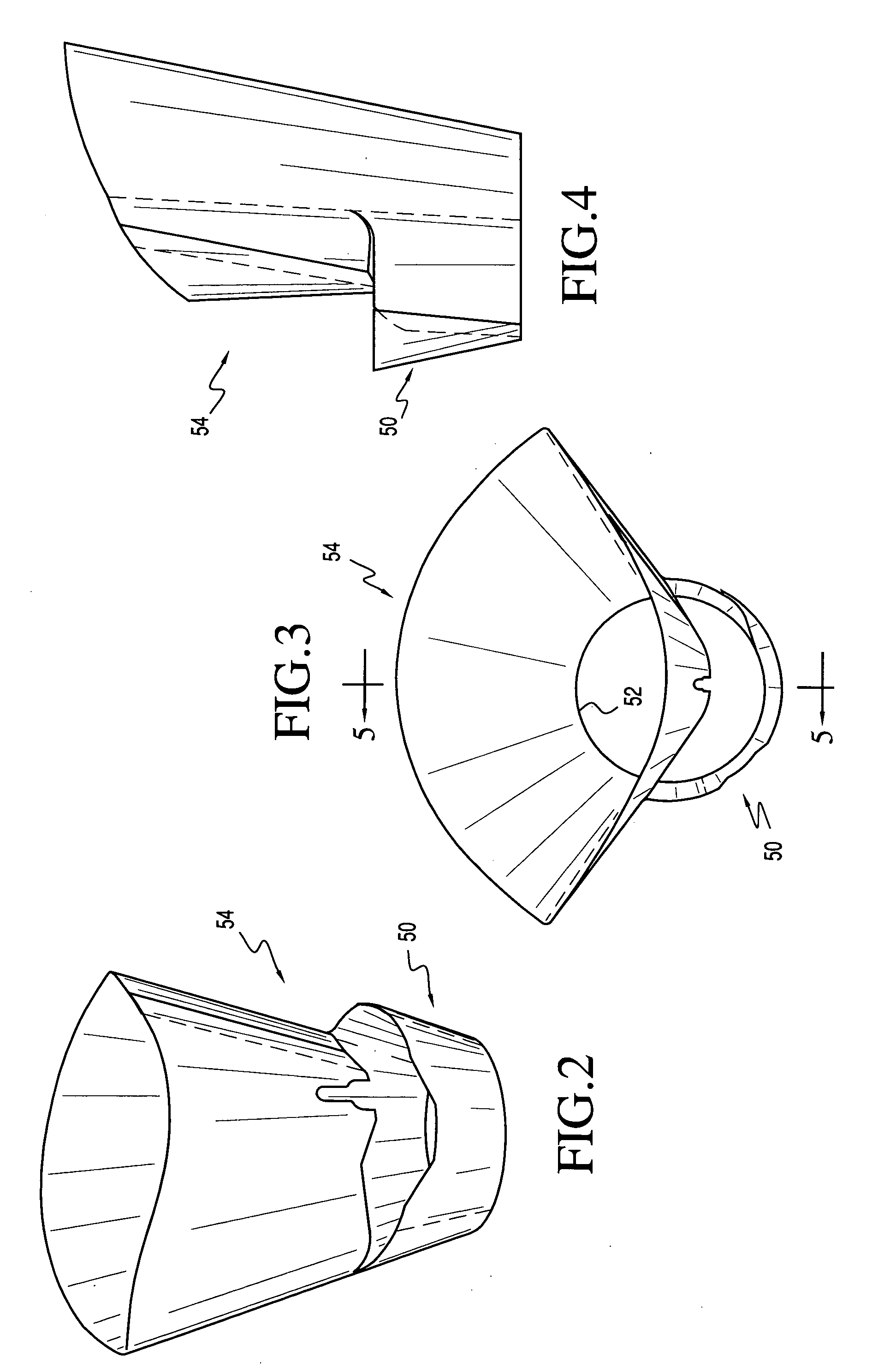

Food container for use with a beverage receptacle

InactiveUS7182242B2The combination is firmSmall dimensionInternal framesPaper/cardboardFood contact materialsEngineering

Owner:DOPACO

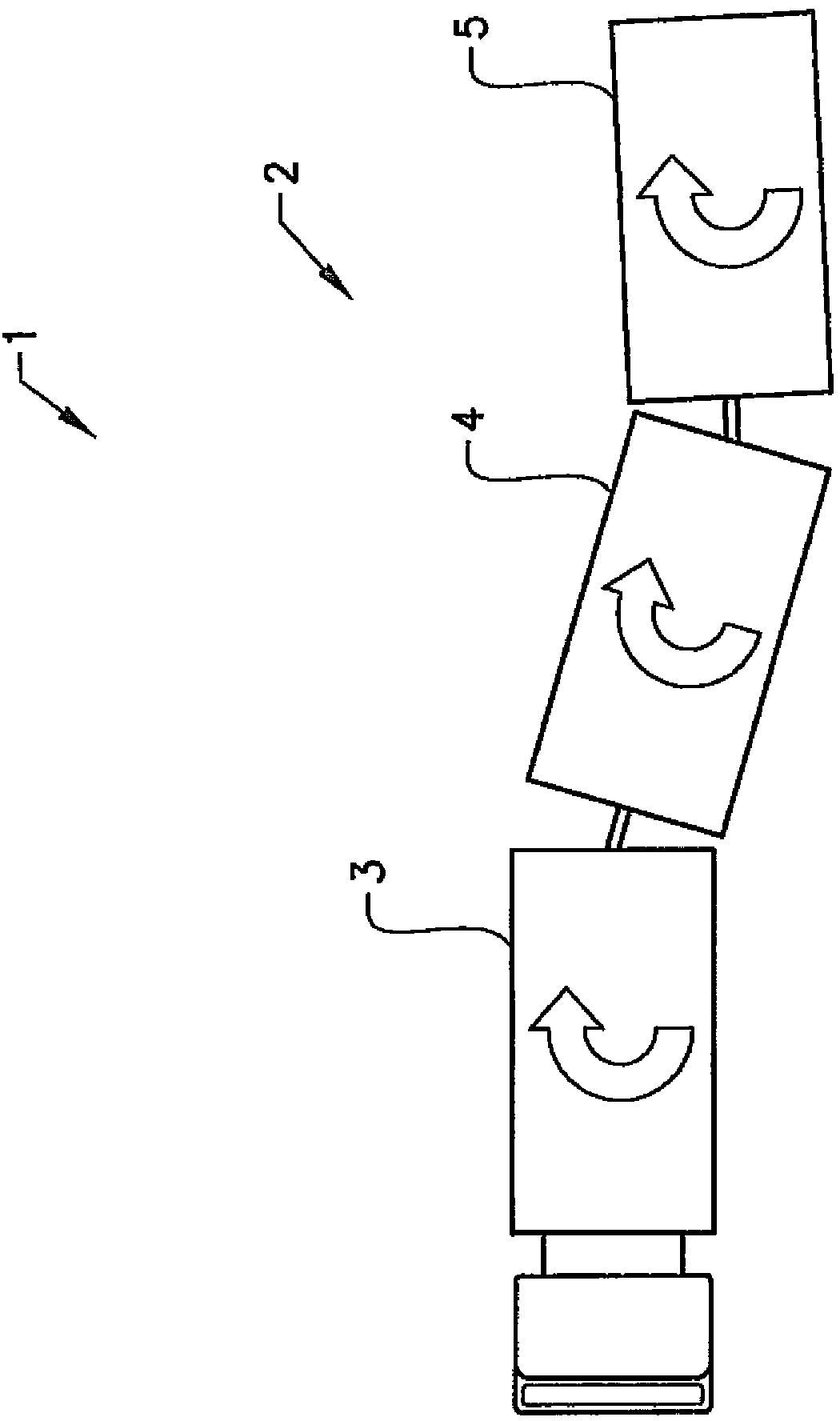

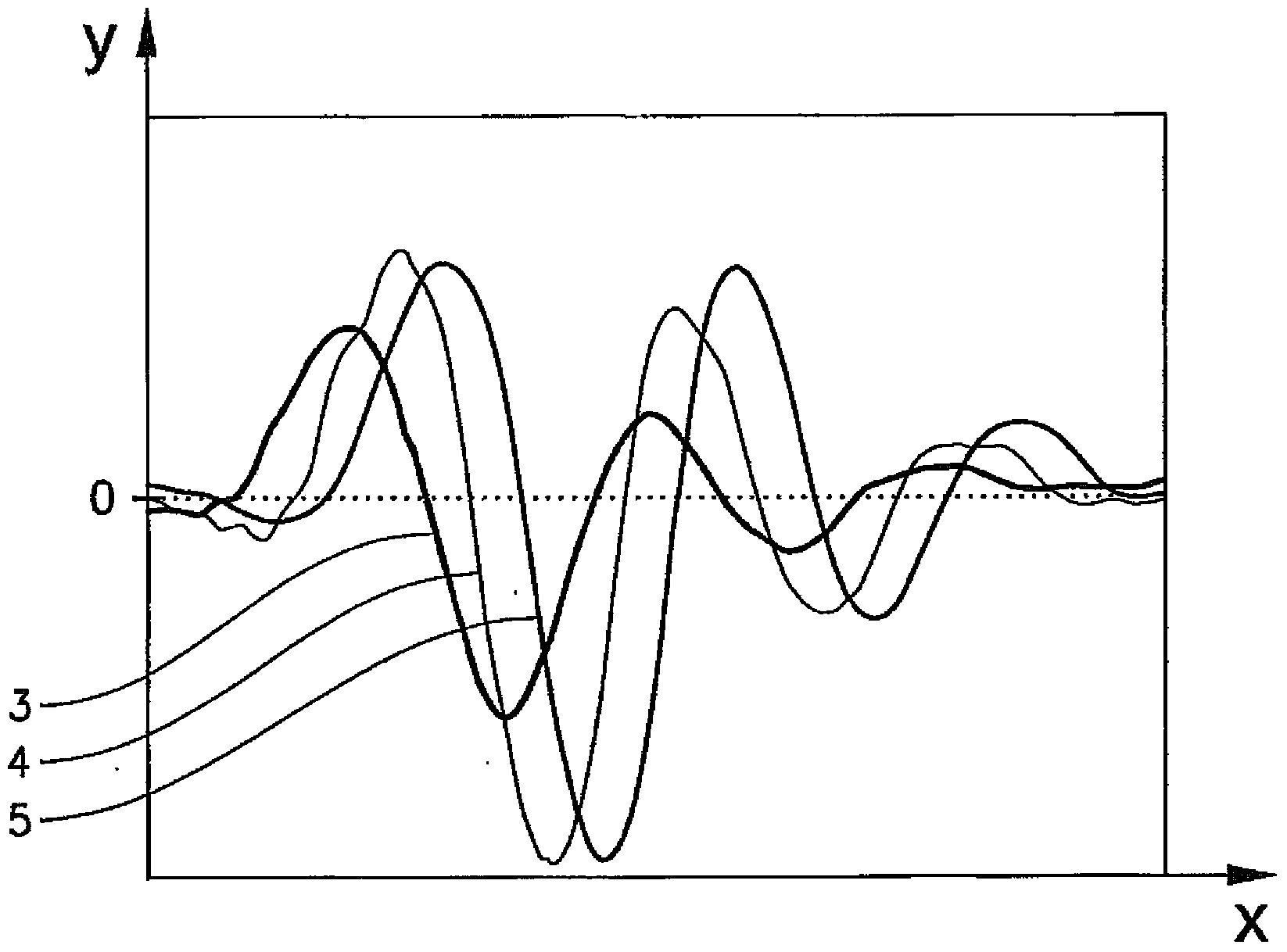

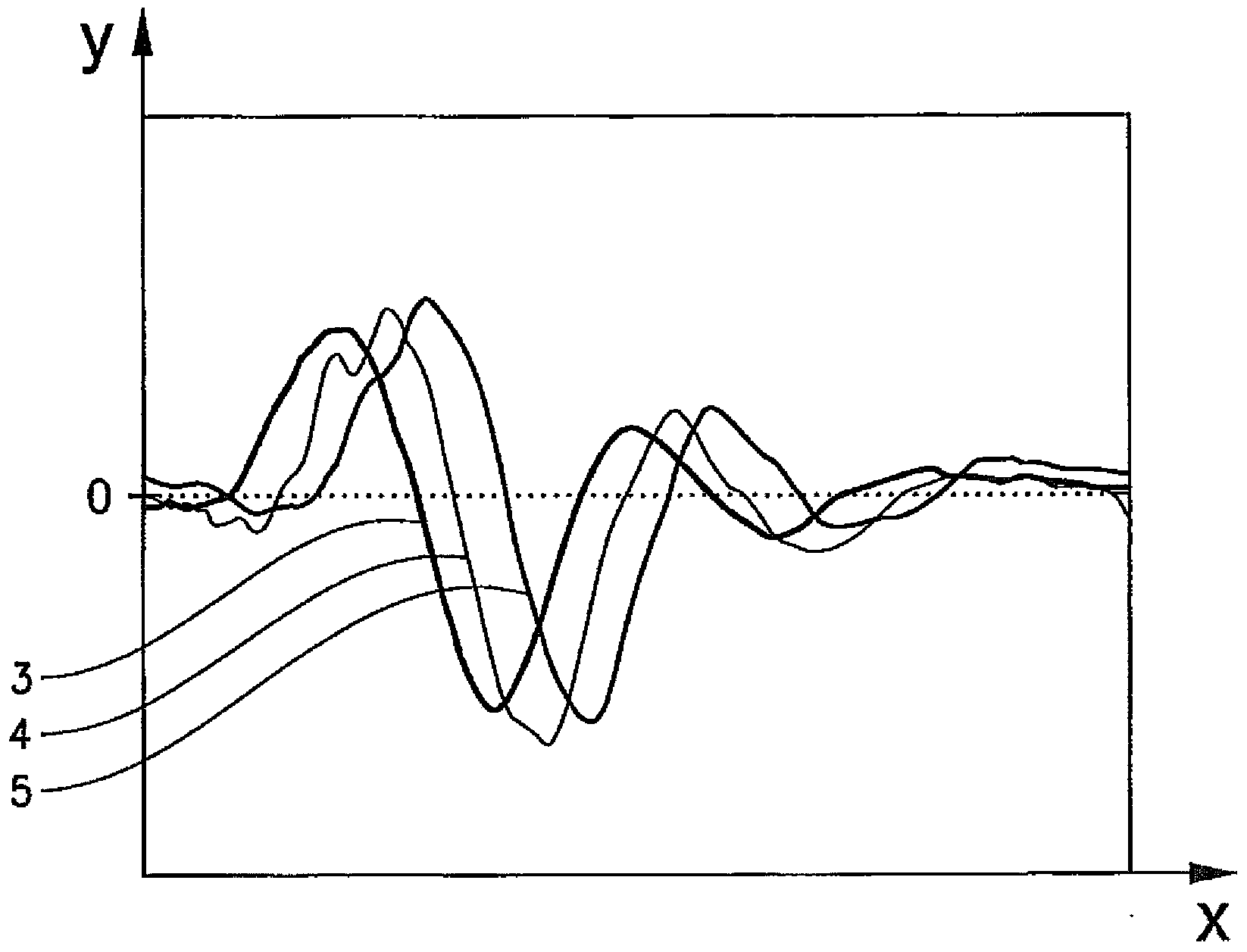

Method and arrangement for vehicle stabilization

InactiveCN103958313AThe combination is firmBrake system interactionsTractor-trailer combinationsSelf-stabilizationActive steering

An arrangement for improving stability of a vehicle combination comprising a towing vehicle and at least one towed vehicle, where the at least one towed vehicle comprises at least one actively steered axle and / or individual brake on at least one axle, where the towing vehicle and the at least one towed vehicle each comprises a yaw rate determining means for determining the yaw rate of the vehicle and the at least one towed vehicle, where the arrangement further comprises a vehicle combination model adapted for determining a desired delay value between the yaw rate of the towing vehicle and the yaw rate of the at least one towed vehicle, where the arrangement is adapted to stabilise the at least one towed vehicle by using the determined yaw rate of the towing vehicle and the desired delay value for the at least one towed vehicle to establish a desired yaw rate for the at least one towed vehicle, and to control the steered axle and / or the individual brake of the at least one towed vehicle such that the determined yaw rate of the at least one towed vehicle corresponds to the desired yaw rate of the at least one towed vehicle. The yaw rate may be estimated or measured. The advantage of the invention is that the stability of a vehicle combination can be improved, which in turn improves the road safety.

Owner:VOLVO TRUCK CORP

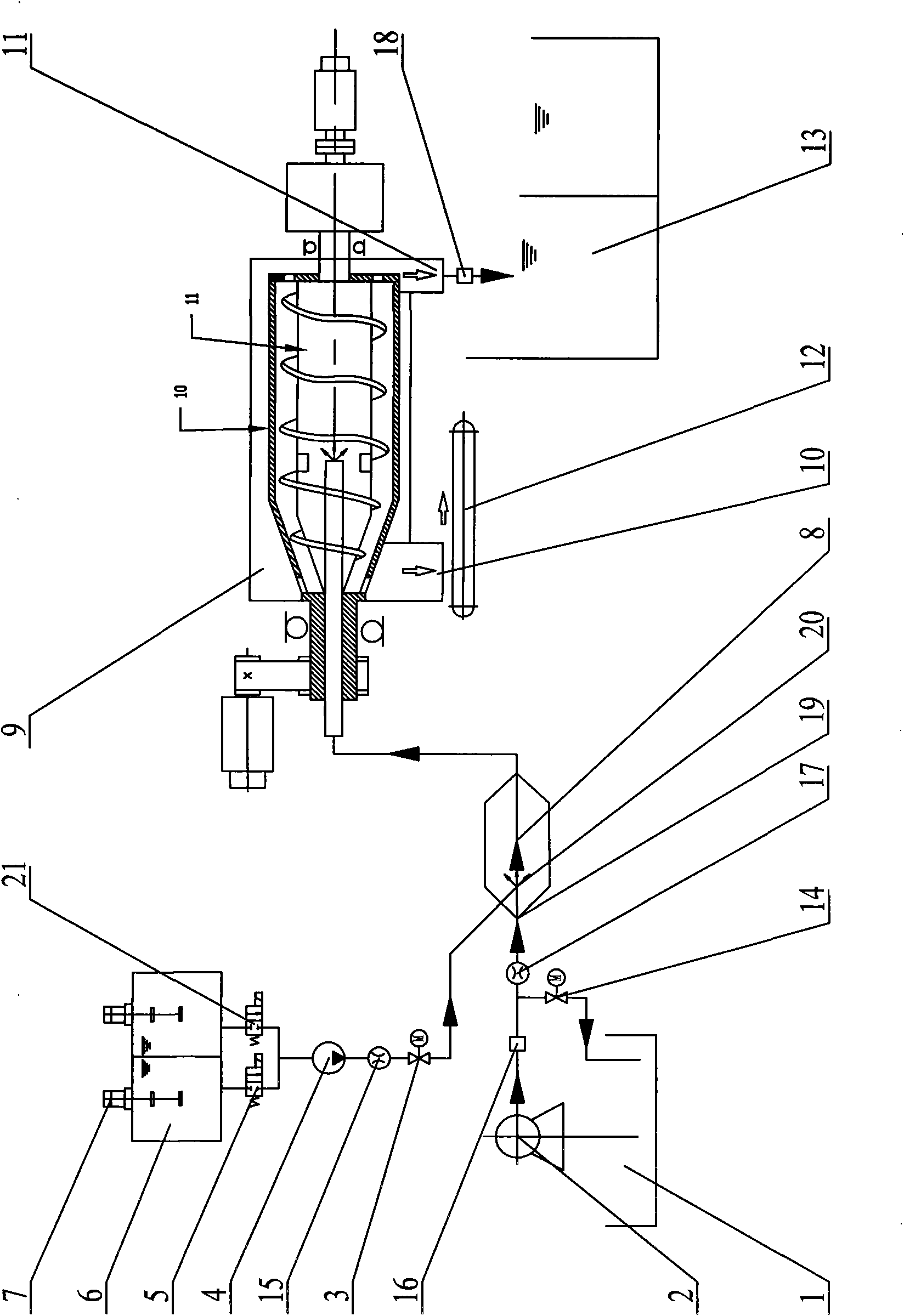

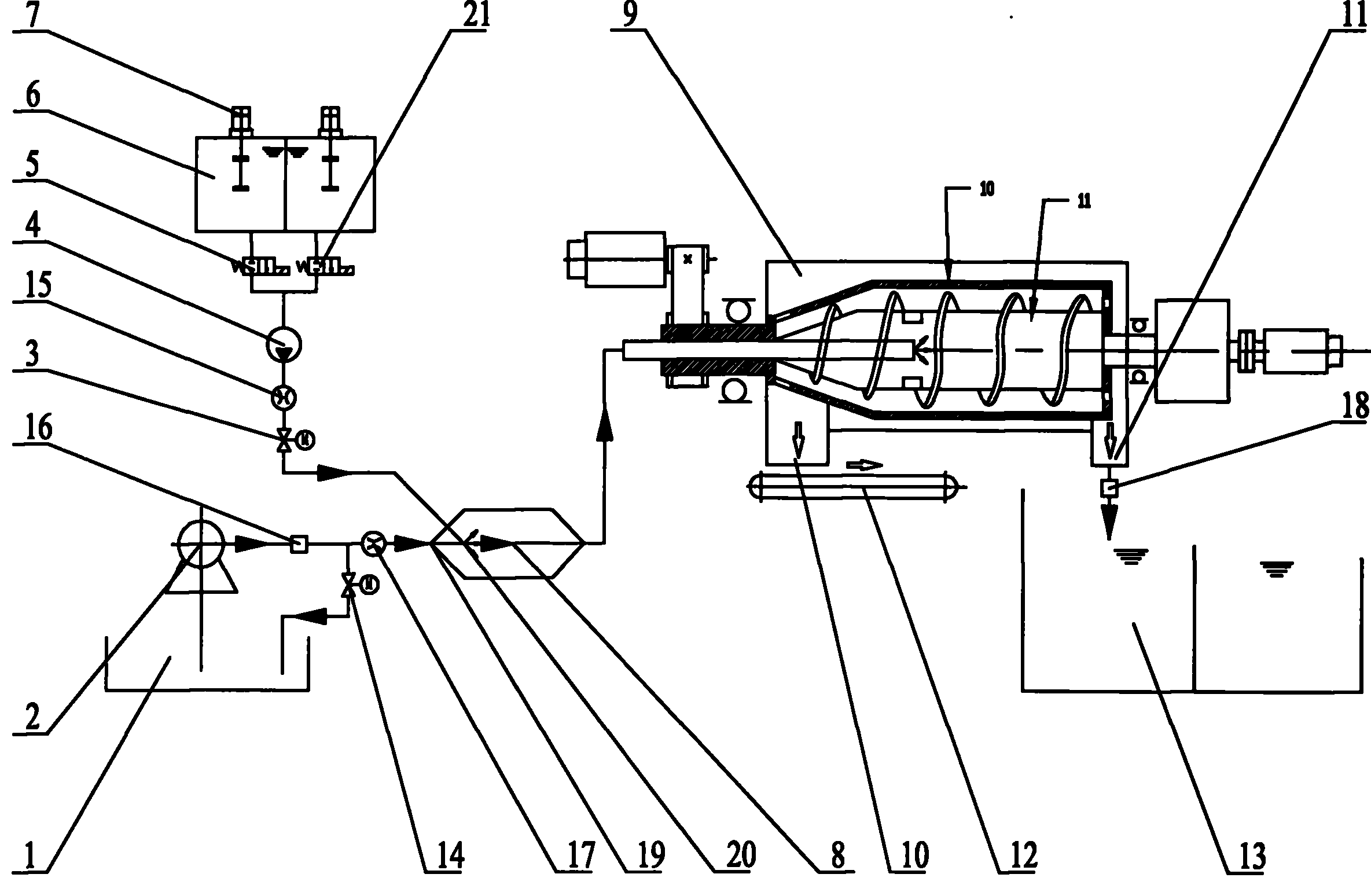

Slurry dehydration combined system

ActiveCN101913751AImprove work efficiencyImprove purification efficiencySludge treatment by de-watering/drying/thickeningDiluentEngineering

The invention relates to a slurry dehydration combined system, which is characterized in that: one end of a mixer is provided with a slurry inlet and a medicament inlet, and the other end of the mixer is provided with an outlet; a slurry pump is arranged in a slurry turnover box and serially connected with a slurry concentration detector and a second flowmeter in turn through a pipeline and then connected with the slurry inlet on the mixer; a medicament diluent box comprises a medicament box and a diluent box; a medicament outlet is formed on the medicament box, and a diluent outlet is formed on the diluent box; the medicament outlet and the diluent outlet are connected with a first electromagnetic valve and a second electromagnetic valve respectively; the first electromagnetic valve and the second electromagnetic valve are in parallel connection through a pipeline and then serially connected with an electromagnetic valve, a medicament delivery pump, a first flowmeter and a first electric valve in turn; the first electric valve is connected with the medicament inlet on the mixer; and the output on the mixer is connected with the input end of a centrifuge through a pipeline. The invention has high work efficiency and purification efficiency and can realize large-scale centralized treatment.

Owner:JIANGSU JIANGDA ECOLOGICAL SCI & TECHCO +1

Food container for use with a beverage receptacle

InactiveUS20050133580A1The combination is firmSmall dimensionInternal framesPaper/cardboardFood contact materialsEngineering

Owner:DOPACO

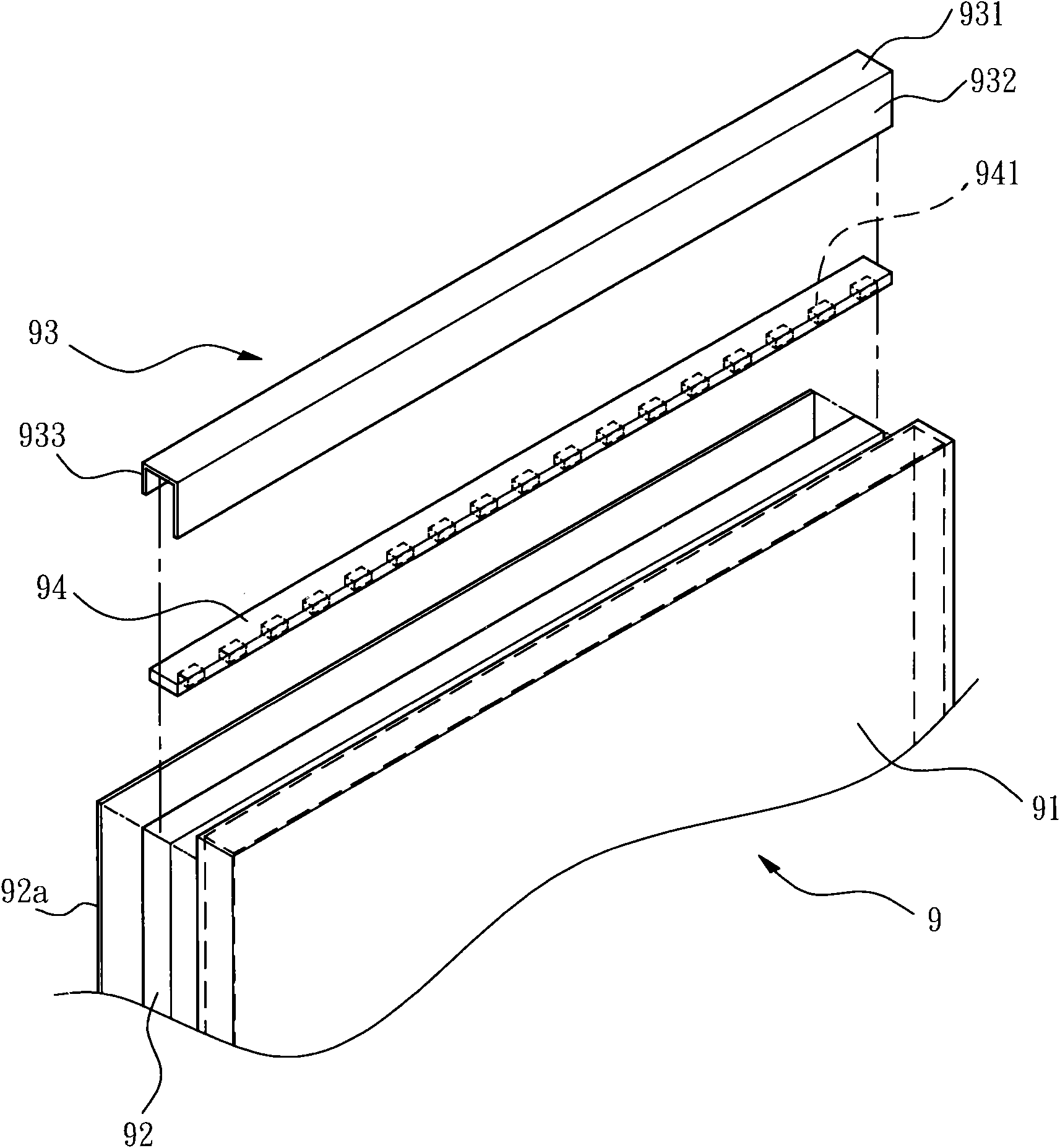

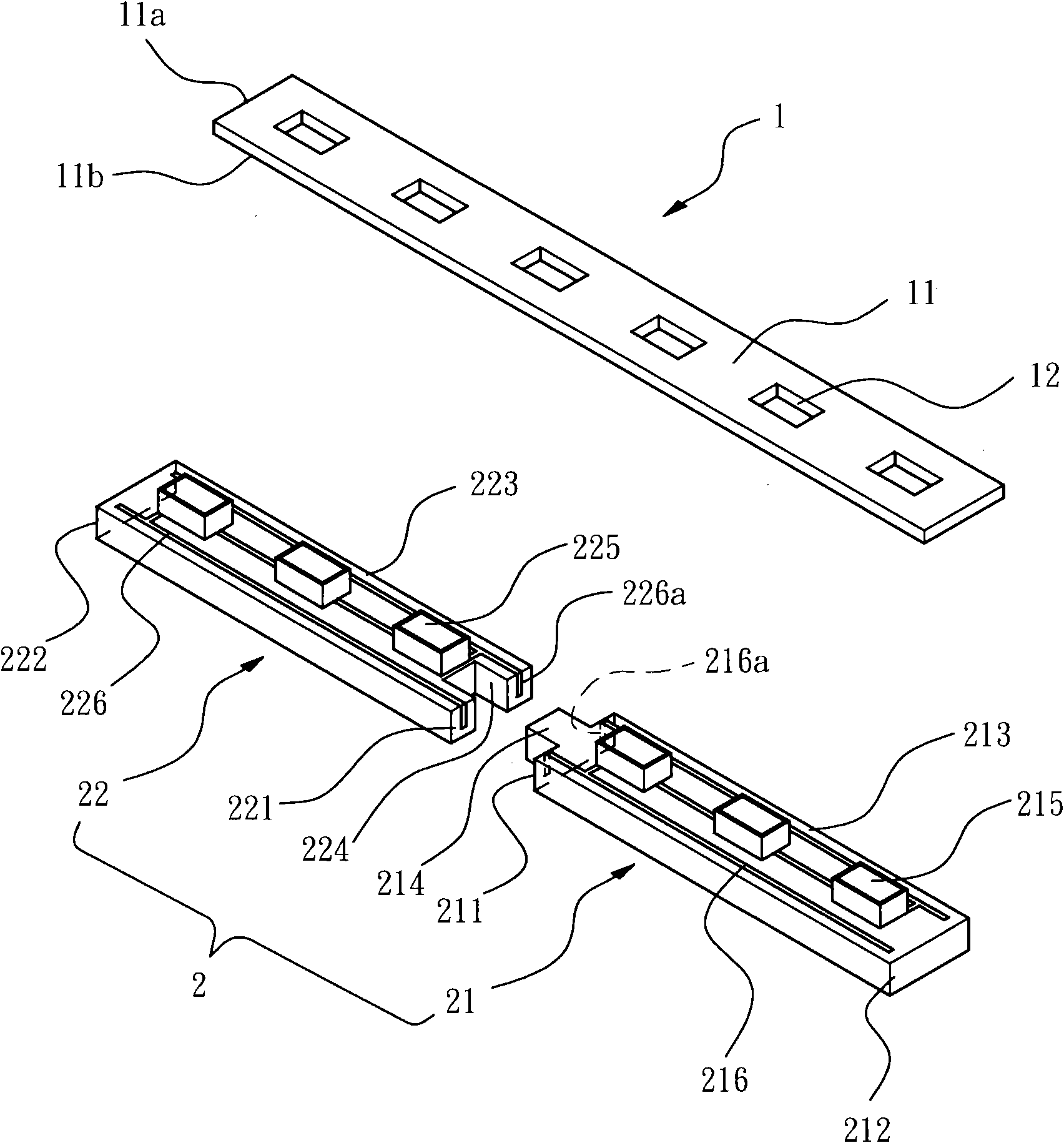

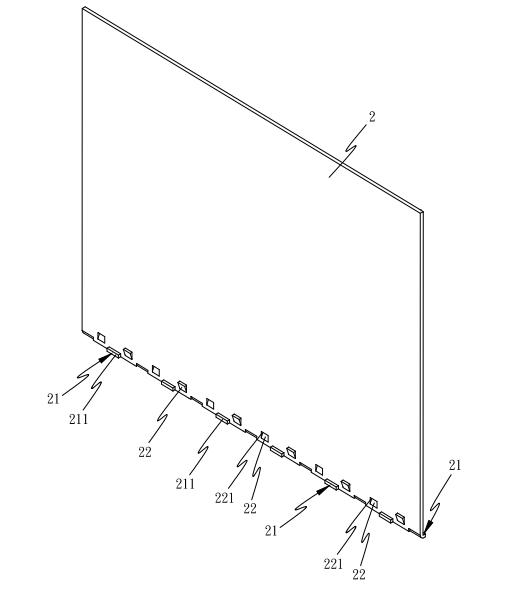

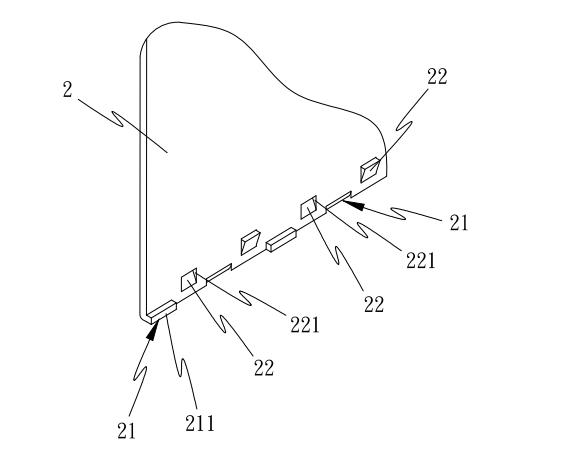

Light source group and side-view backlight module

InactiveCN101644421AEasy job replacementThe combination is firmPoint-like light sourceElectric circuit arrangementsLight guideEngineering

The embodiment of the invention provides a light source group and a side-view backlight module. The light source group comprises a lamp shade and a plurality of unit bodies. The lamp shade is providedwith a plurality of light source openings; each unit body is provided with at least one connecting part, at least one luminous element and a circuit; and the luminous elements of the unit bodies correspond to the plurality of light source openings of the lamp shade, and can be serially connected to form a strip light source assembly. The side-view backlight module comprises a back plate, a lightguide plate, an optical diaphragm group, a light source group, a side cover plate and an outer frame of the backlight module. When a single luminous element is damaged, the damaged unit body is only needed to be replaced simply and easily in the side-view backlight module, and the whole light source group is not needed to be replaced, so that materials and time for the repair and maintenance are greatly saved.

Owner:CORETRONIC (SUZHOU) CO LTD

Heat transfer compositions and methods

ActiveCN102803427ALow global warming potentialIncrease capacityHeat-exchange elementsRefrigerantsChemistryFood science

Owner:HONEYWELL INT INC

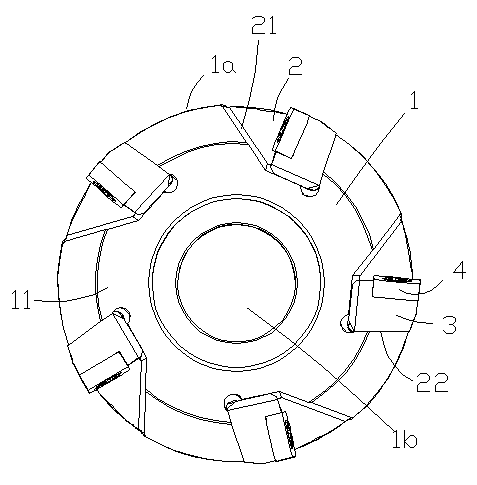

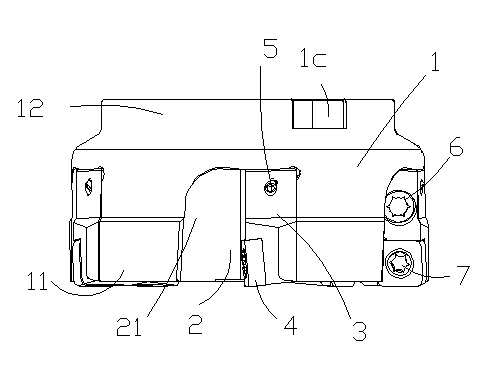

Milling cutter device with function of adjusting height of blade

InactiveCN103008748AHeight adjustableThe combination is firmMilling cuttersDrive shaftMilling cutter

The invention provides a milling cutter device with a function of adjusting the height of a blade. The milling cutter device comprises a cutter plate body, wherein the center of the cutter plate body is provided with a driving shaft hole; at least one cutter placing groove is upward inscribed in the circumference of the cutter plate body and the cutter placing groove extends to the front side face of the plate body; the cutter placing groove is internally provided with a tool holder; a chip removal inclined plane is arranged at a part of the cutter placing groove, corresponding to the tool holder; the tool holder is fixedly provided with the blade; one part of the blade stretches out of the circumference; and the tool holder is provided with an equal-height adjusting screw for adjusting the height of the blade. The milling cutter device with the function of adjusting the height of the blade disclosed by the invention has the advantages that the height of each blade can be effectively adjusted, the chip removal is convenient, a machining effect is good, and the combination of the blade and the cutter plate is firm.

Owner:NINGBO CHUANJINGYU MECHANICAL TECH DEV

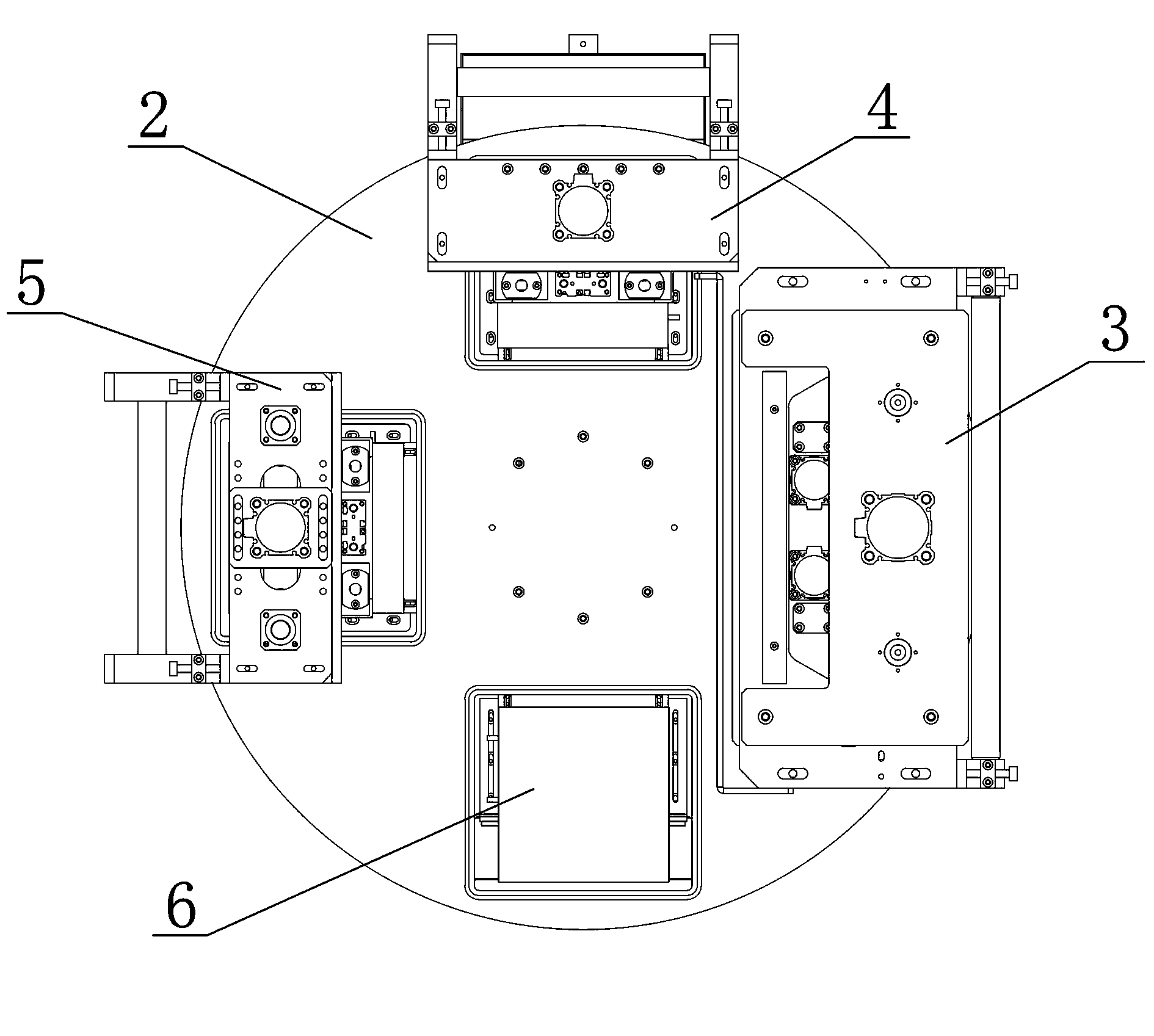

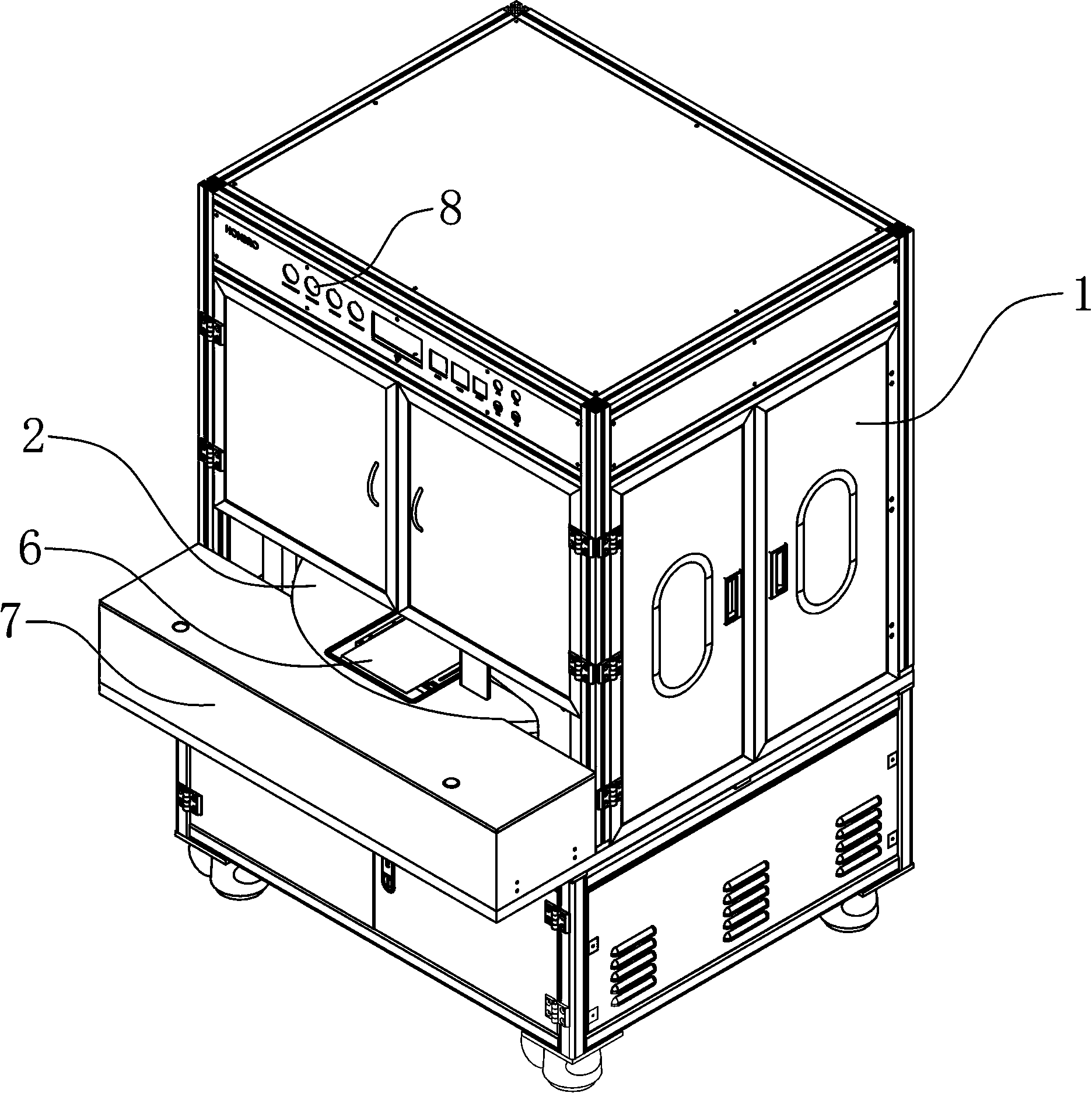

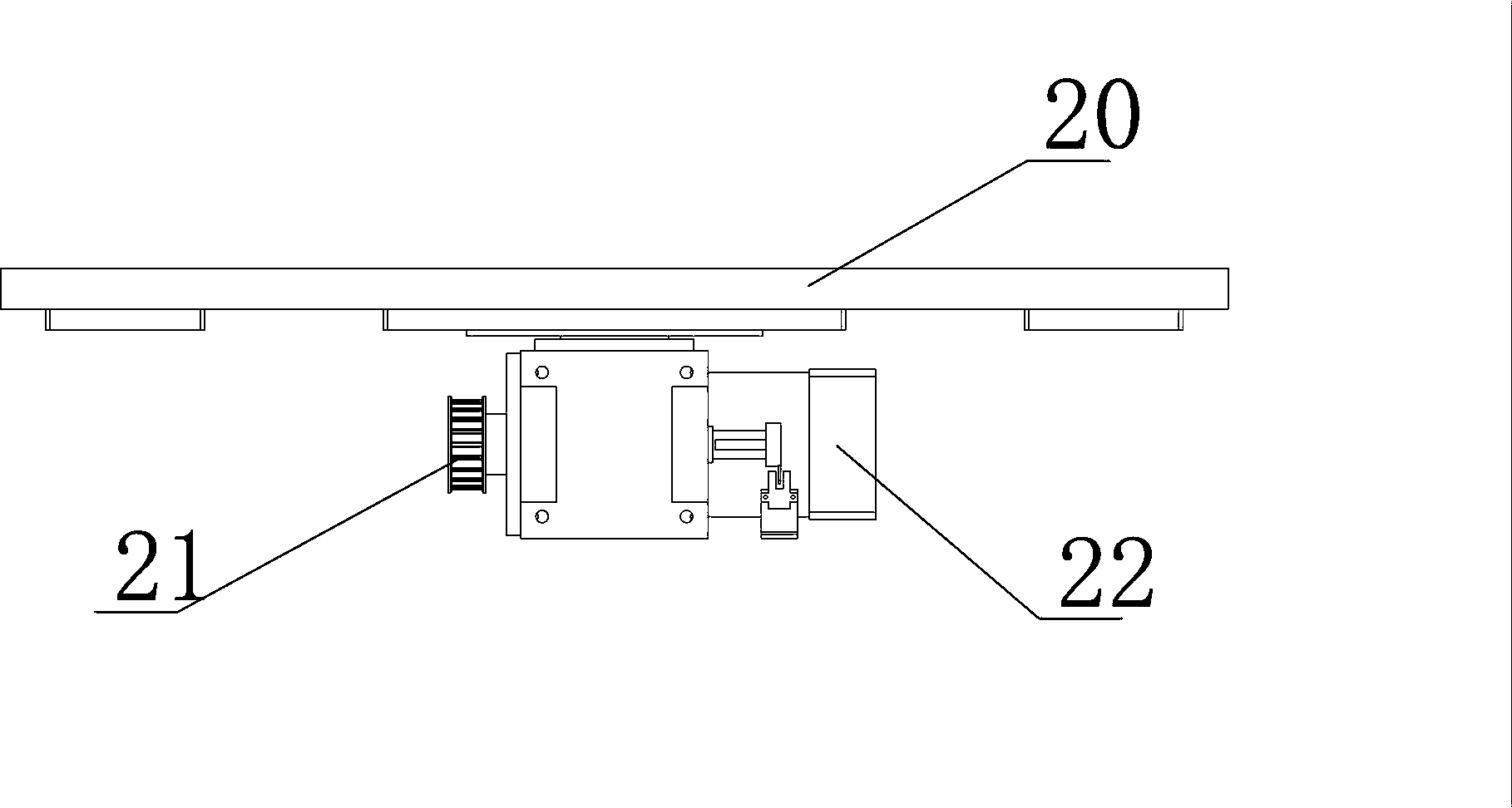

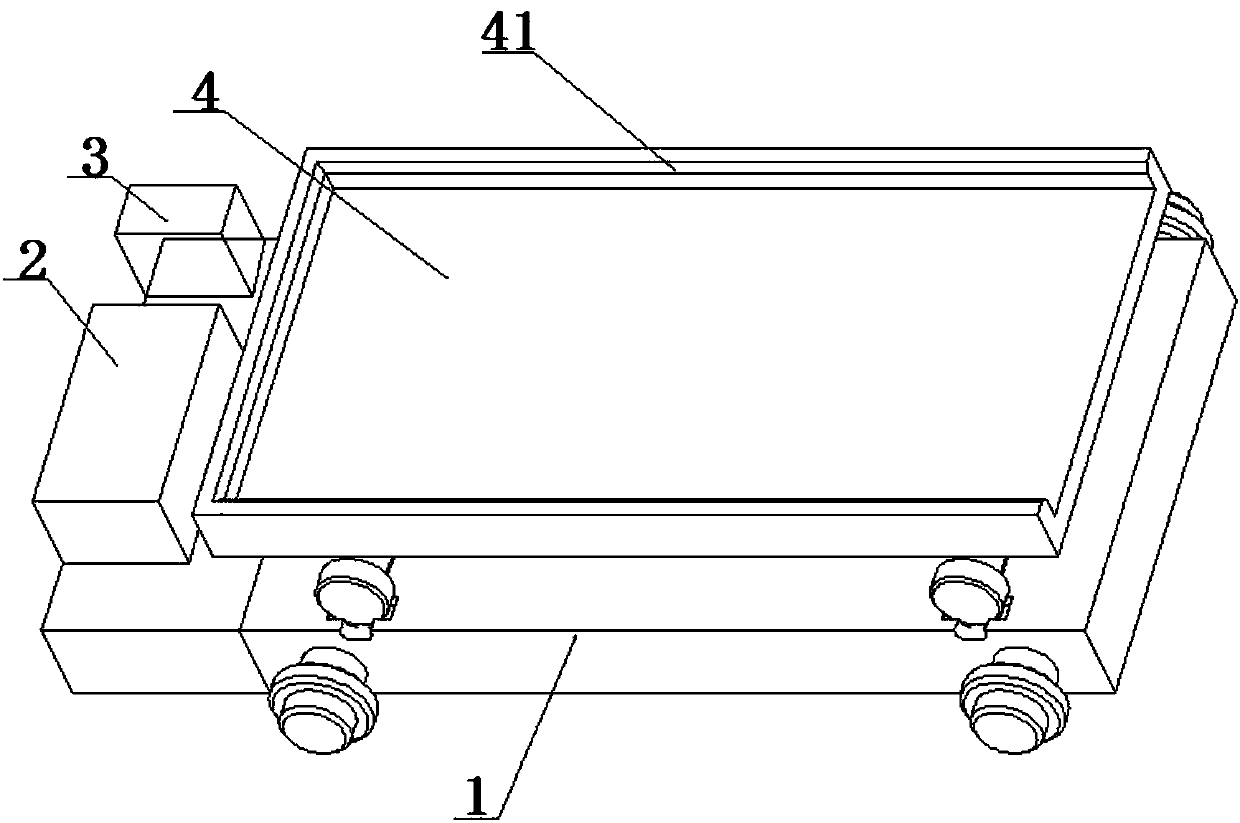

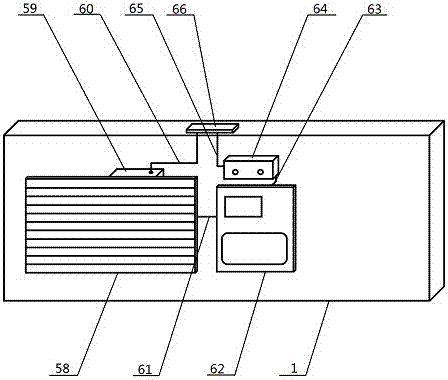

Vacuum packaging, edge cutting and secondary packaging machine

ActiveCN103490097AImprove production efficiencyCompact structureAssembling battery machinesFinal product manufactureMachine buildingEngineering

The invention discloses a vacuum packaging, edge cutting and secondary packaging machine which is characterized by comprising a machine case, a rotary disc mechanism, a vacuum packaging mechanism, an edge cutting mechanism (4) and a secondary packaging mechanism. The rotary disc mechanism is arranged inside the machine case, and the vacuum packaging mechanism, the edge cutting mechanism (4) and the secondary packaging mechanism are respectively arranged in the quartering directions of the circumference of the rotary disc mechanism. The rotary disc mechanism comprises a circular rotary disc, a cutting device and a motor, a feeding station and at least two machining stations are evenly arranged on the rotary disc at intervals in the circumferential direction, and a piece to be machined is placed on the feeding station. The vacuum packaging, edge cutting and secondary packaging machine is compact in structure, saves space and enables the structure to be optimized, the production efficiency is improved through reasonable combinations, the production cost is saved, the productivity achieves 4-6PPM, the packaging thickness and non-packaging areas are accurately and stably controlled, the edge cutting accuracy achieves + / -0.2MM, the product pass percent of the whole machine is higher than 99.9%, and the interactive rate is higher than 97%. According to the vacuum packaging, edge cutting and secondary packaging machine, unified standardization is carried out on parts of various structures or with similar functions in a traditional vacuum packaging, edge cutting and secondary packaging machine, the manufacturing efficiency of the machine is greatly improved, and equipment maintenance difficulty is simplified.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

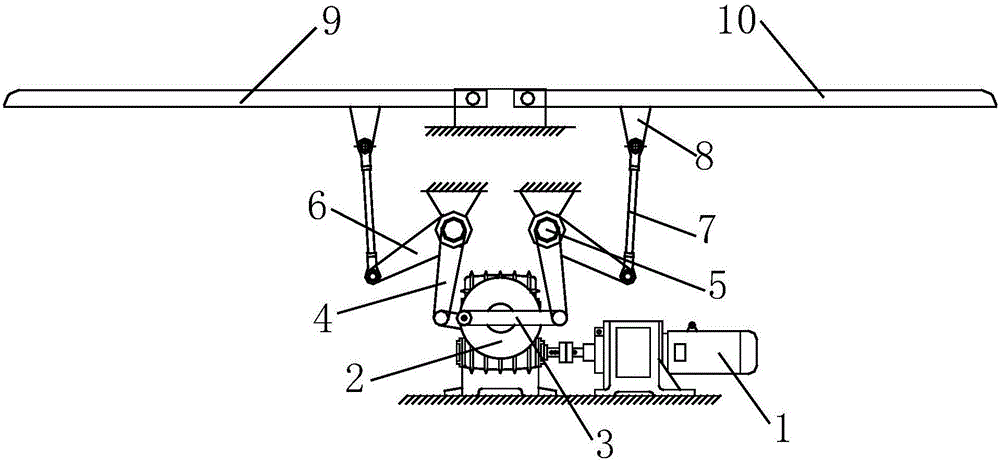

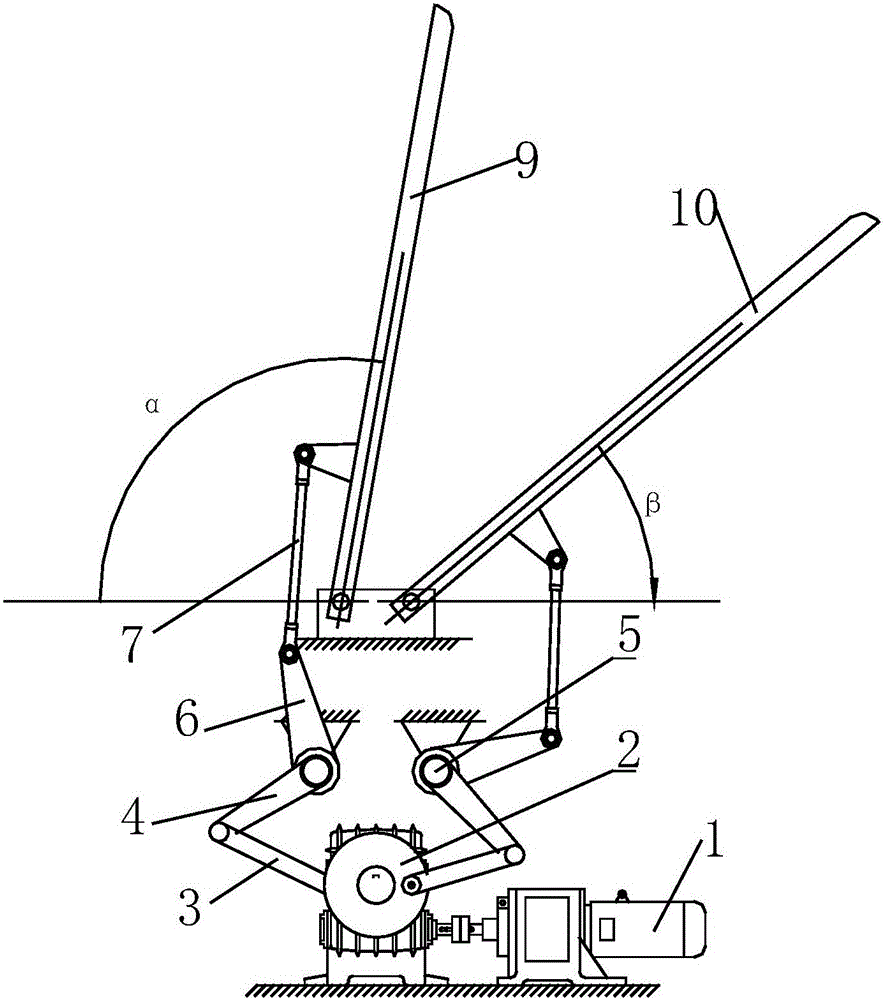

Gypsum board stacking machine and stacking method

ActiveCN105858232AImprove work efficiencyThe combination is firmConveyorsStacking articlesEngineeringElectrical and Electronics engineering

The invention provides a gypsum board stacking machine and a stacking method. A board overturning fork and a board receiving fork are symmetrically arranged on two sets of rotating mechanisms. A trimmed gypsum board is received and overturned by the board overturning fork. An original gypsum board on a board discharging fork is also rotated by the board discharging fork and gets close to the board overturning fork. The board overturning fork releases the overturned gypsum board, and the overturned gypsum board is made to be stacked with the gypsum board on the board receiving fork in a back-to-back manner. Afterwards, the board discharging fork reversely rotates to the horizontal position to send the boards out of a work platform to be stacked. By means of the gypsum board stacking machine, the stacking work efficiency is high, the stacking process is stable, noise is low, and the probability that the gypsum boards are damaged can be avoided.

Owner:BEIJING NEW BUILDING MATERIAL

Method for preparing oat plant base material through multi-enzyme combination

InactiveCN112401007AImprove digestibilityImprove biological potencyPre-extraction tea treatmentFrozen sweetsVegetable oilPulp and paper industry

The invention provides a method for preparing an oat plant base material through a multi-enzyme combination. The method comprises the following steps: pouring cooked oat paste into a colloid mill, andperforming pulping to obtain oat pulp; uniformly mixing the oat pulp with water according to a ratio of 1:10, adding the obtained mixture into a reaction tank, adding the multi-enzyme combination, and carrying out enzymolysis at 45 DEG C for 0.5 h; carrying out enzyme deactivation treatment on the oat pulp after enzymolysis to obtain oat pulp after enzymolysis reaction terminating; carrying out centrifugal residue filtering on the oat pulp after enzymolysis reaction terminating to obtain an oat stock solution, and performing constant volume treatment; adding 1-2% of vegetable oil and 0.01-0.05% of edible salt into the oat stock solution, and performing uniform stirring; homogenizing the obtained oat liquid to obtain a homogenized oat liquid; carrying out sterilization treatment on the homogenized oat liquid to obtain a sterilized oat liquid; and carrying out sterile cold filling on the sterilized oat liquid to obtain the finished oat base material. The fine oat plant base material isprepared through the steps.

Owner:谷之禅张家口食品有限公司

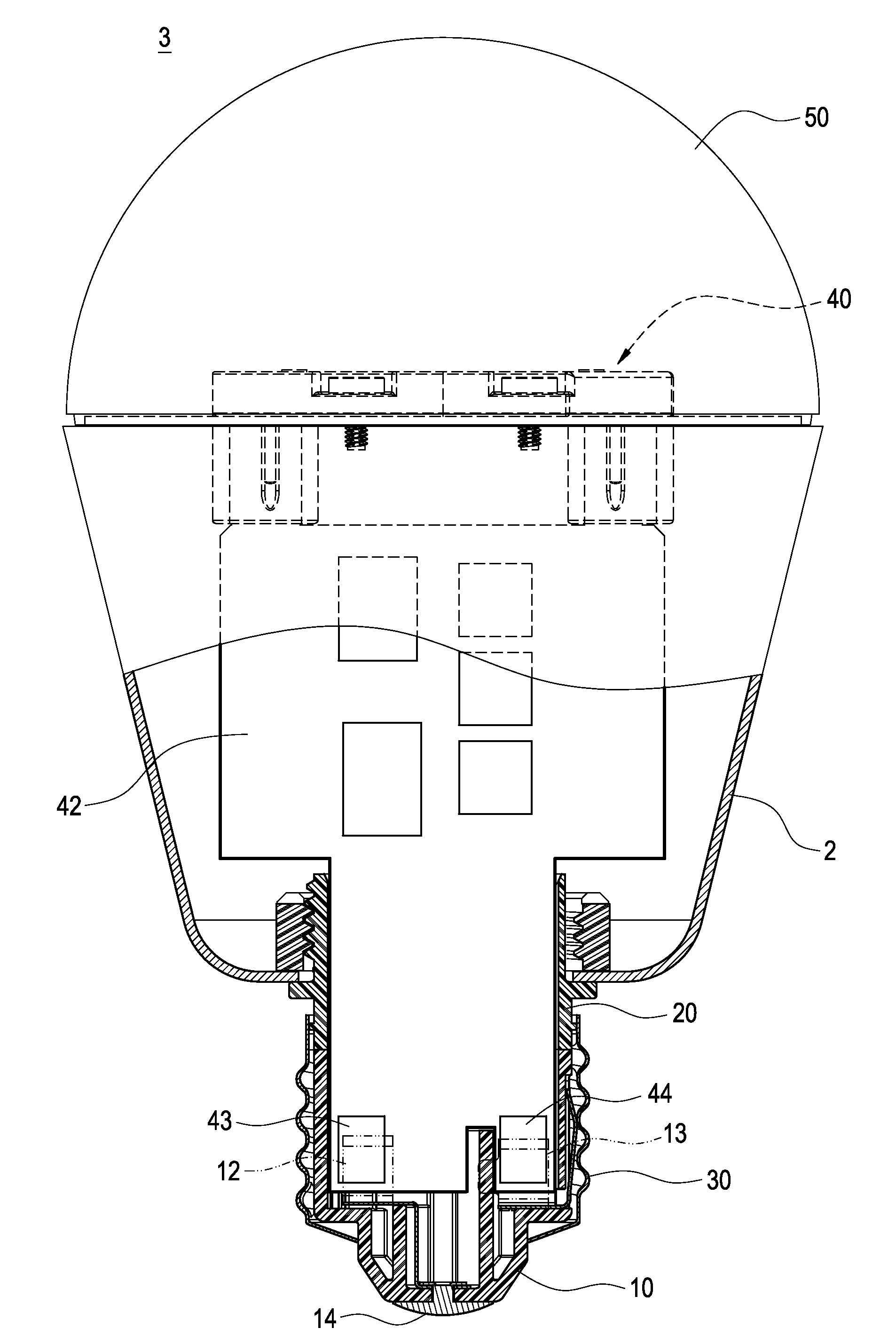

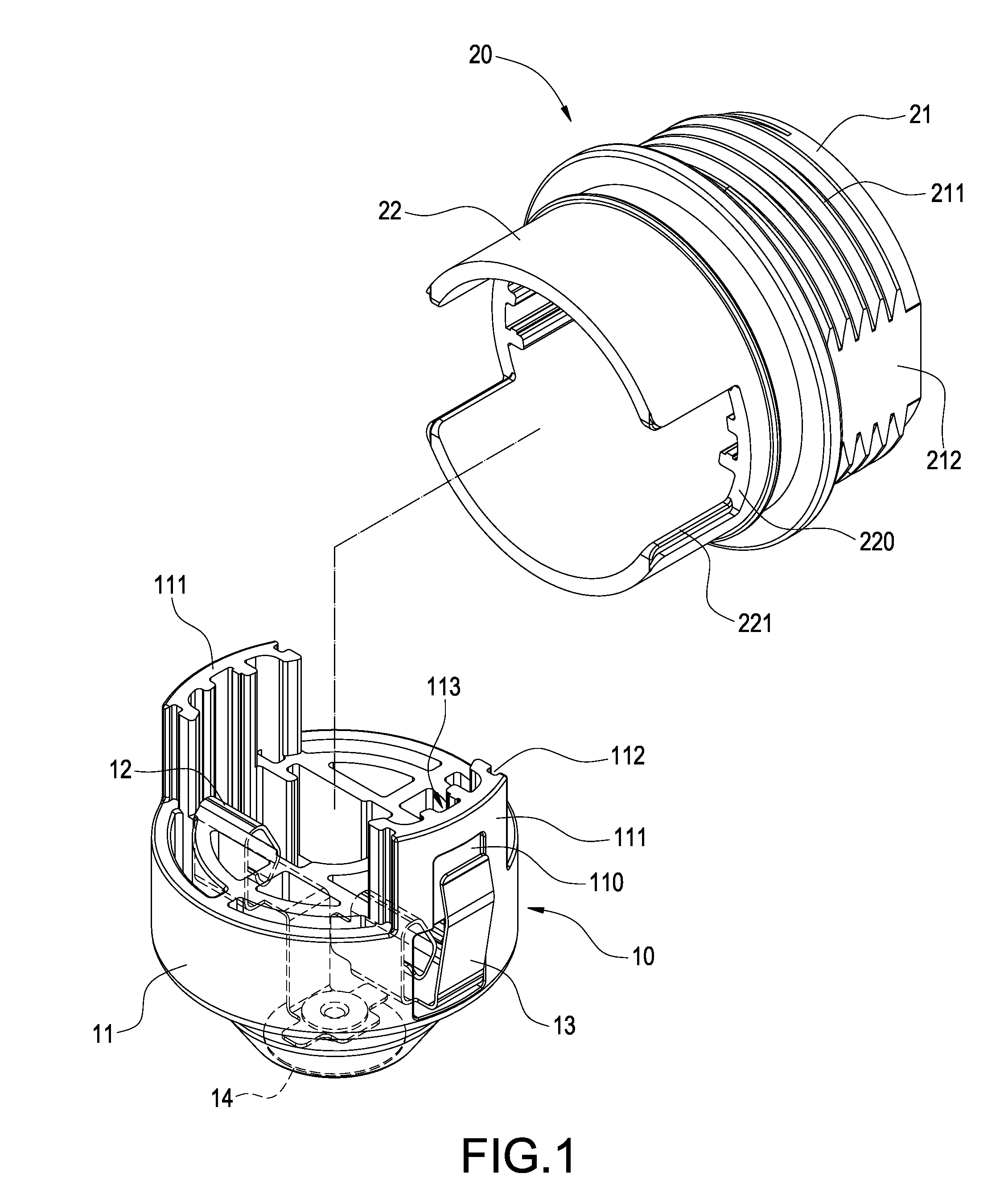

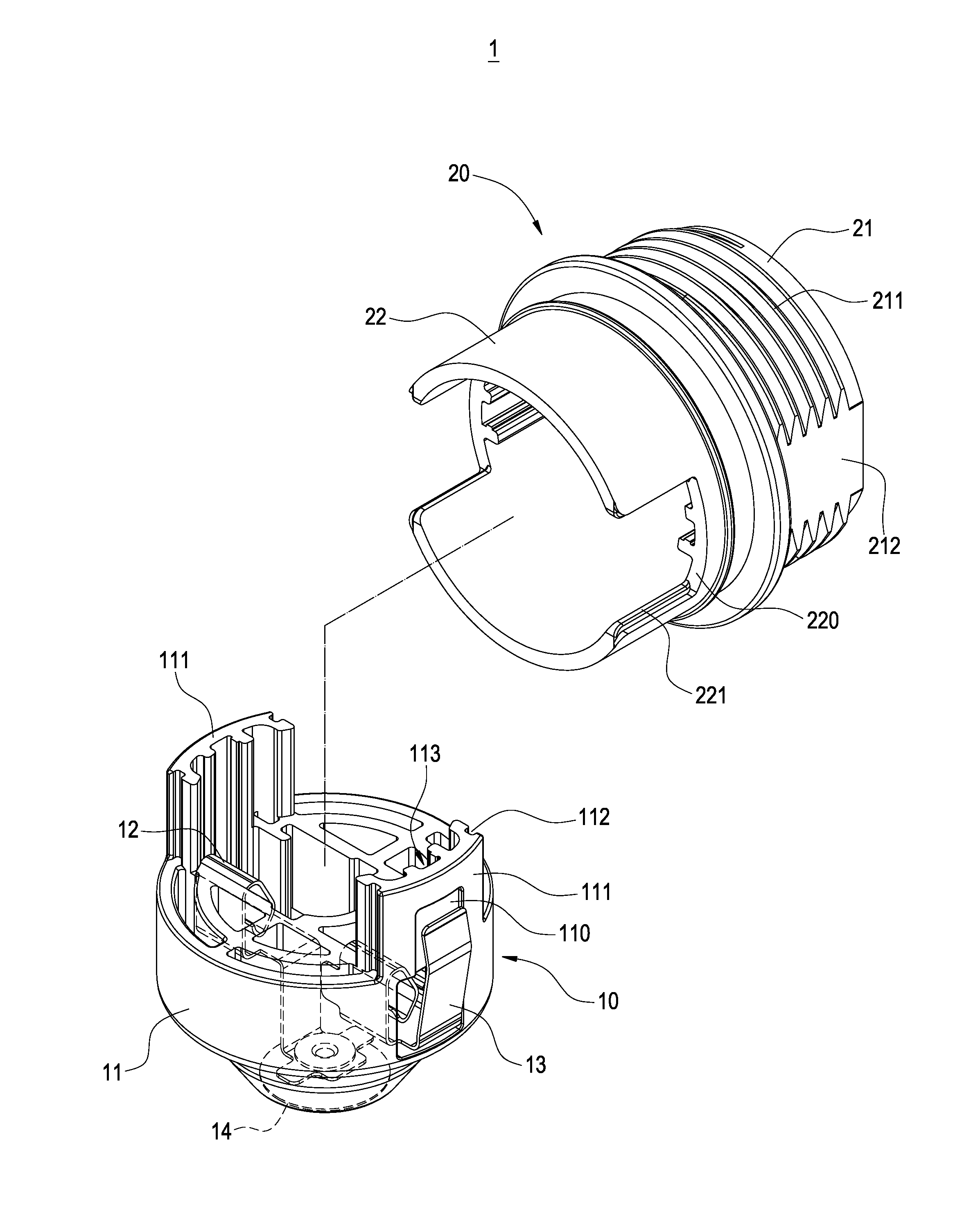

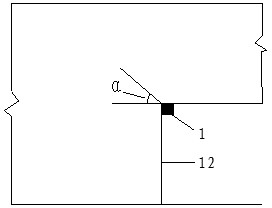

LED bulb and lamp head assembly with positioning structures

ActiveUS20150070908A1Shorten development timeLow production costCoupling device connectionsLighting support devicesEngineeringLight head

The present invention provides a lamp head assembly with positioning structures for combining with a lamp base. The lamp head assembly includes a conducting head and a supporting barrel. The conducting head has an insulating seat, a first conducting plate and a second conducting plate and a conduction piece. The conduction piece is electrically connected with the first conducting plate. A portion of the second conducting plate is protruded out of the insulating seat, and an end of the insulating seat is formed with a inserting plate. The supporting barrel includes a supporting section connected and an assembling section; wherein, the supporting barrel is assembled on the conducting head through a positioning of the inserting plate and the slot.

Owner:AMPHENOL LTW TECH

Broth for preventing and treating ralstonia solanacearum and preparation method thereof

InactiveCN106465734AImprove efficacyStrong targetingBiocideDead animal preservationNicotiana tabacumRalstonia solanacearum

The invention discloses a broth for preventing and treating ralstonia solanacearum and a preparation method thereof. According to the invention, different biocontrol fungus are combined, then mixed according to different proportions and fermented, and a stable and effective combination is screened, the screened combination can effectively control the ralstonia solanacearum through a root watering application method; the broth for preventing and treating ralstonia solanacearum is prepared by fermenting streptomyces pluricolorescens seed liquid, streptomyces recifensis seed liquid, a bacillus safensis broth, a brevibacilluscentrosporus broth, trichoderma rufobrunneum seed liquid, cane molasses, soybean molasses, cottonseed meal powder, composite amino acid raw powder, potassium fulvic acid, calcium carbonate, magnesium sulfate, and 800 parts of water.

Owner:FOSHAN YANHUI BIOTECH CO LTD

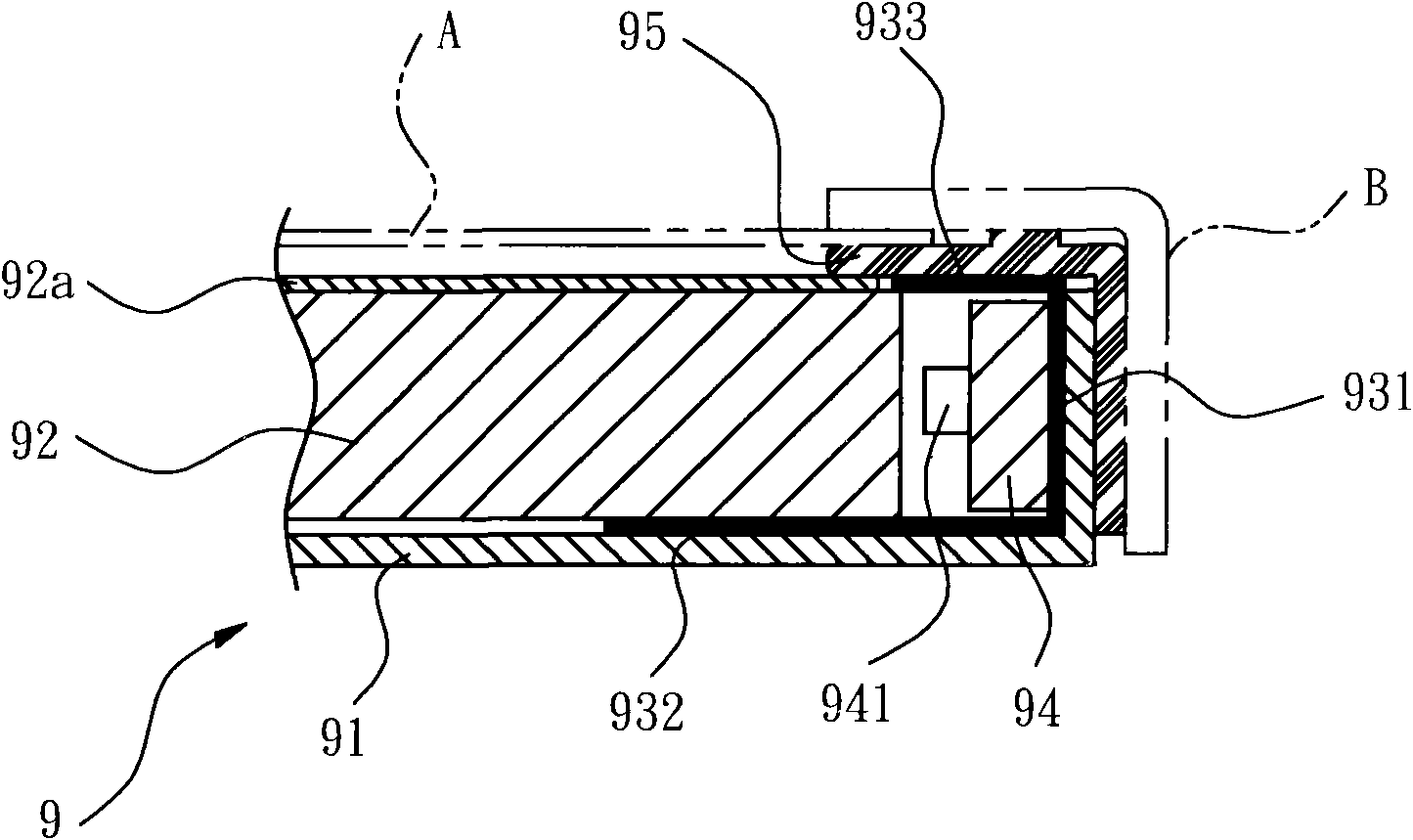

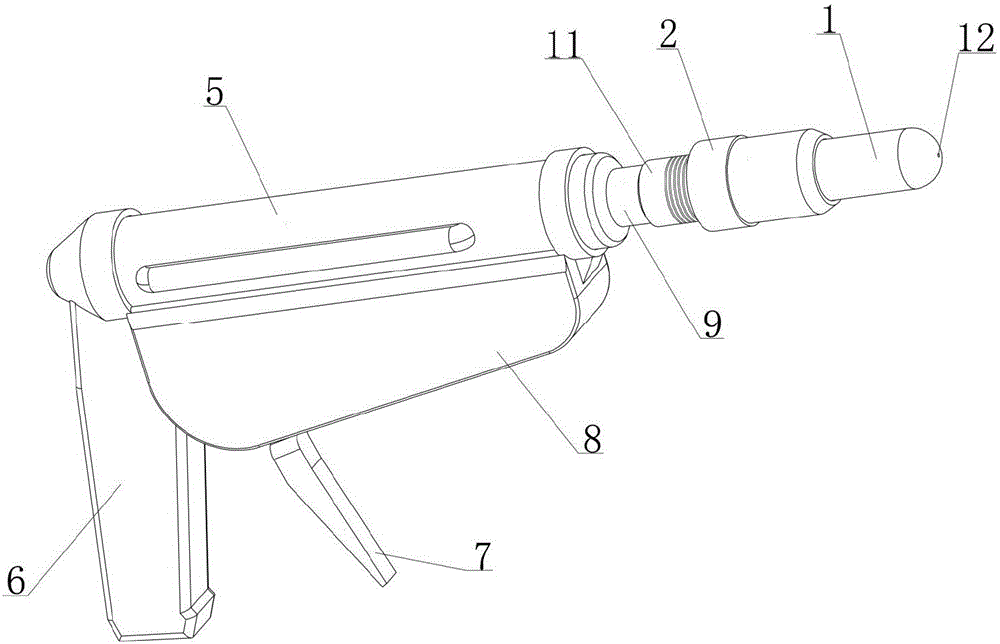

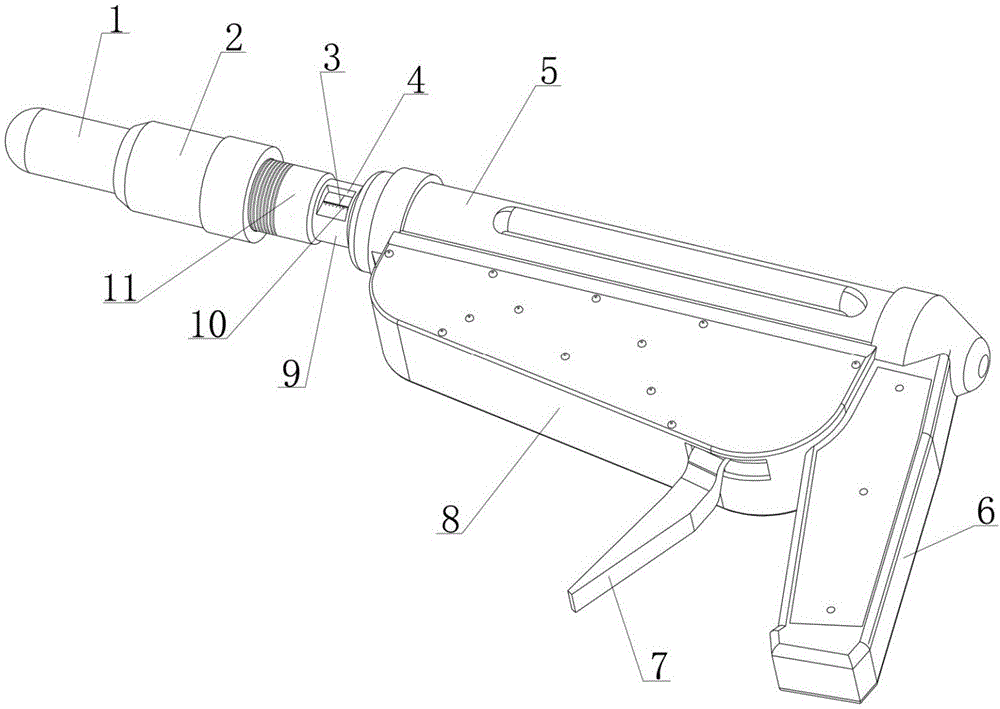

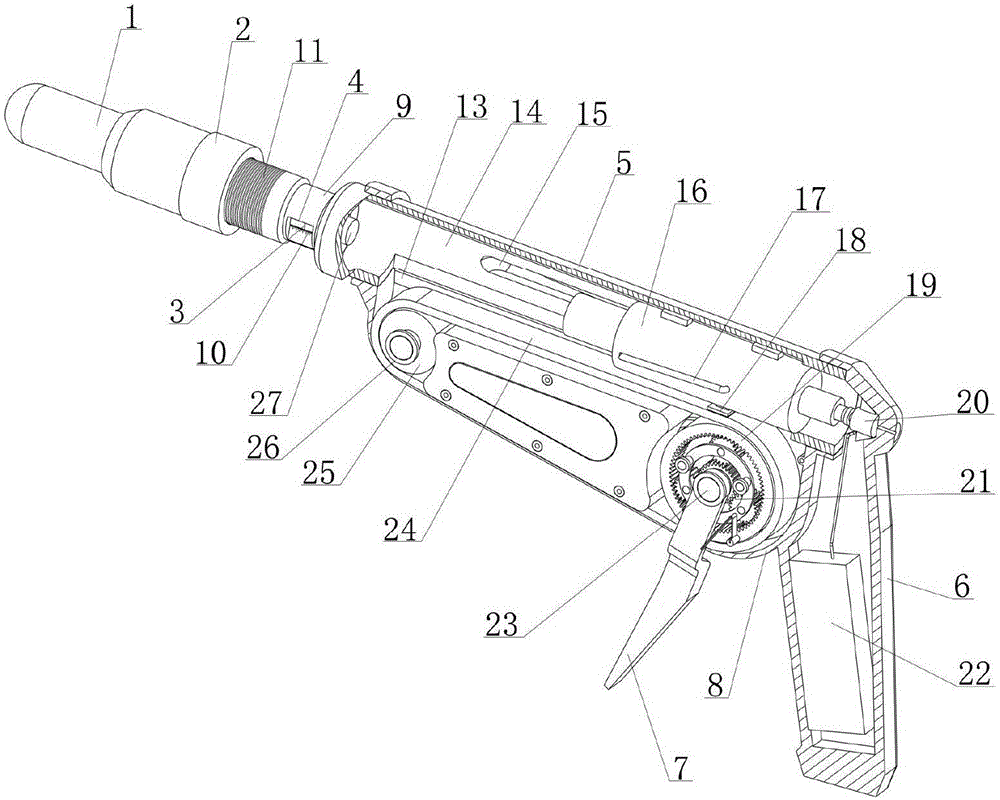

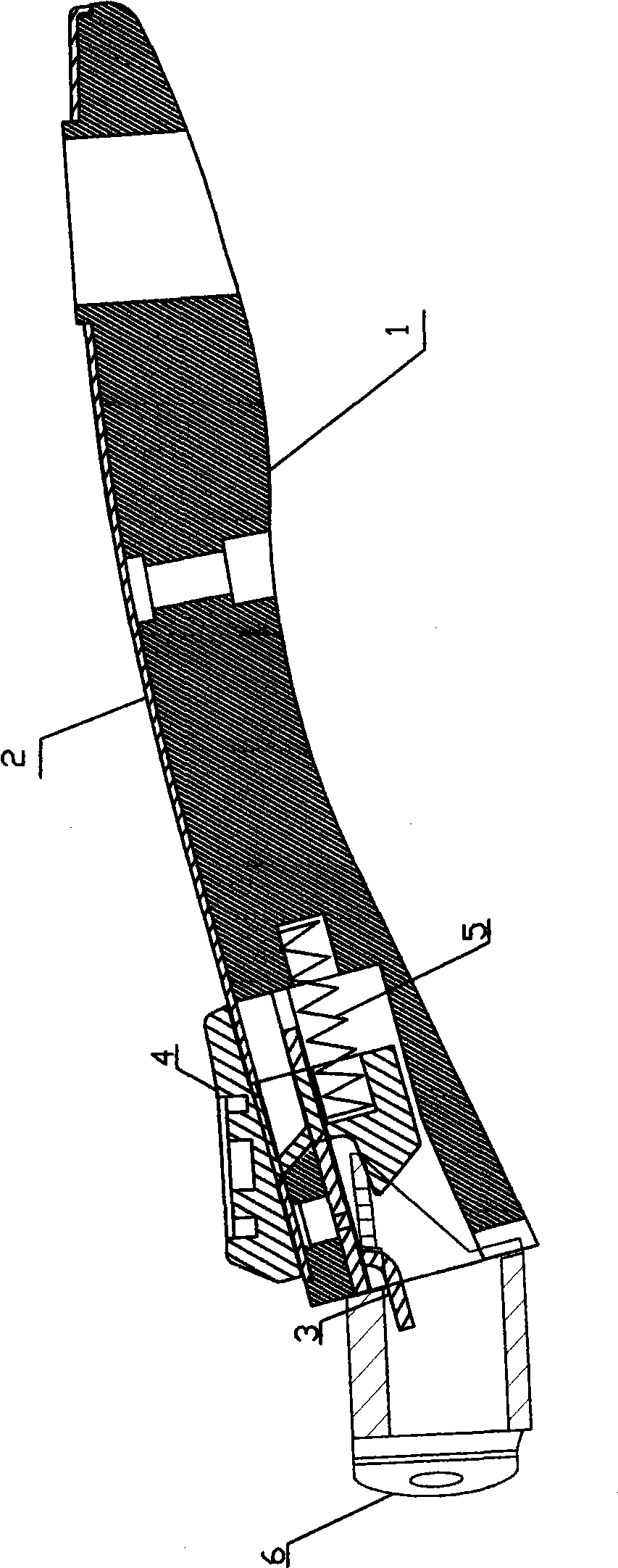

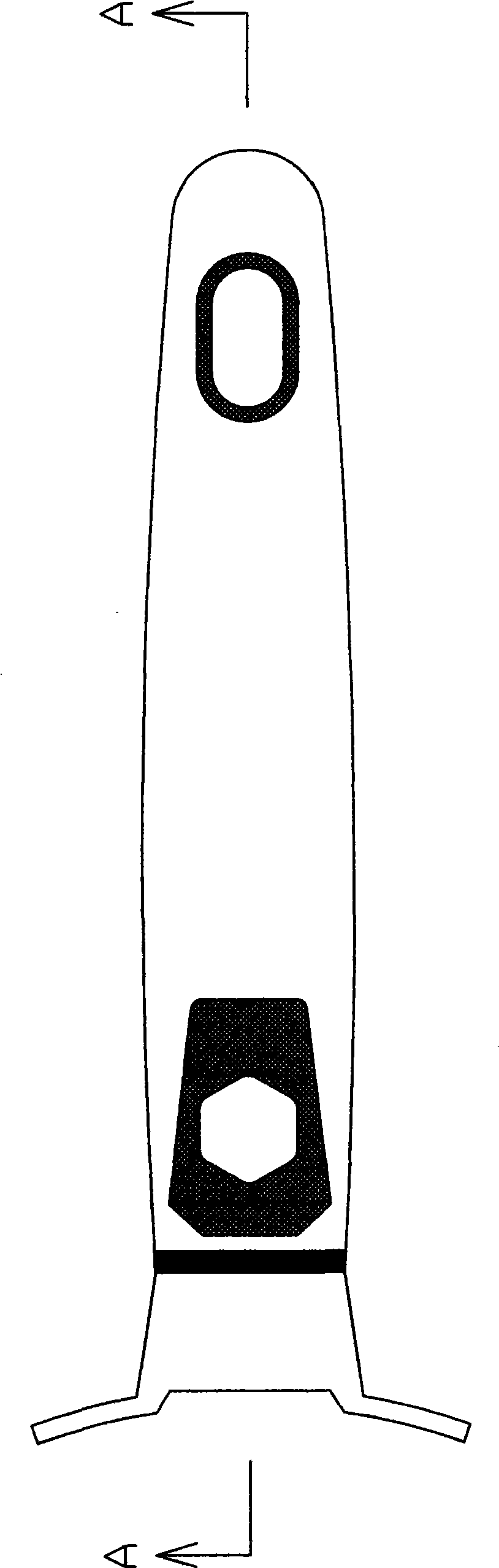

A Needle-Free Injector

ActiveCN106334240AThe combination is firmEase of exertionJet injection syringesMedical devicesNeedle freeNeedle Free Injection

The invention discloses a needle-free injector, which consists of a gun body, a hammer assembly, a circulation drag assembly, a trigger assembly and a terminal injection assembly. The gun body is composed of a gun frame and a barrel, and is used to provide supporting and operating space for other components. The hammer assembly is composed of a hammer body, an elastic rope and a pressing-type alarm device, which provides impact force for the terminal injection assembly through the axial movement of the hammer body in the barrel. The circulating drag component is positioned in the driving chamber to drive the hammer assembly to reach the chamber and to control the trigger of the hammer body. The trigger assembly is used for driving the circulation drag component to operate; the terminal injection assembly is constituted by a cartridge, a piston and a push rod, and is powered by the hammer assembly to realize the needle-free injection. Advantages: the needle-free injector has scientific and reasonable structure, convenient to hold, easy to operate, and it can achieve multiple successive injections of large-dose medicine, thus expands the application range of needle-free injector in clinical injection field. It is convenient to apply, with high utilization rate and low production cost.

Owner:SUZHOU CHUANGMING SOFTWARE TECH CO LTD

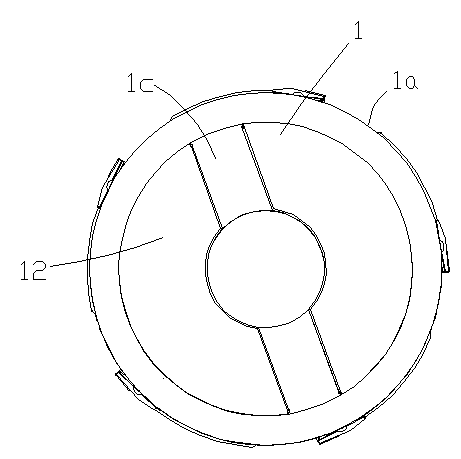

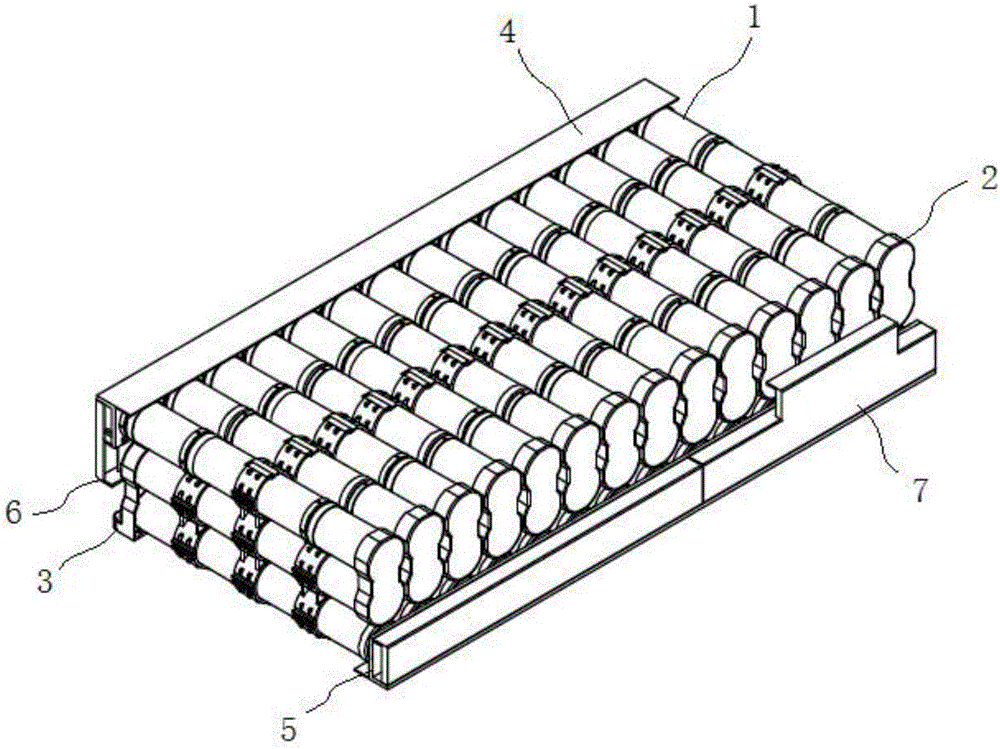

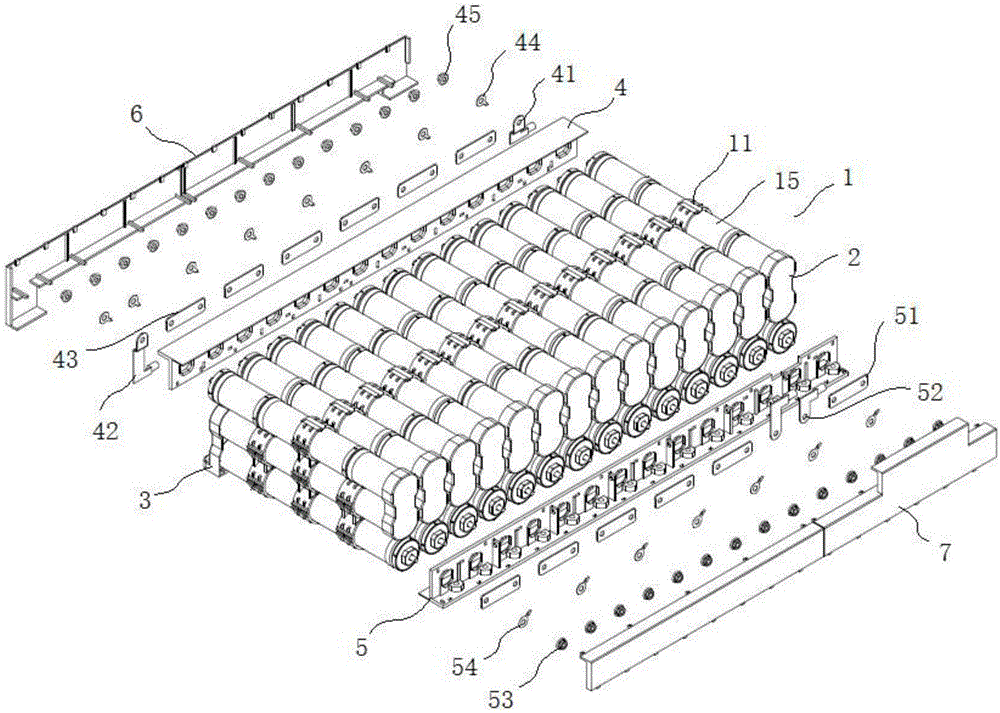

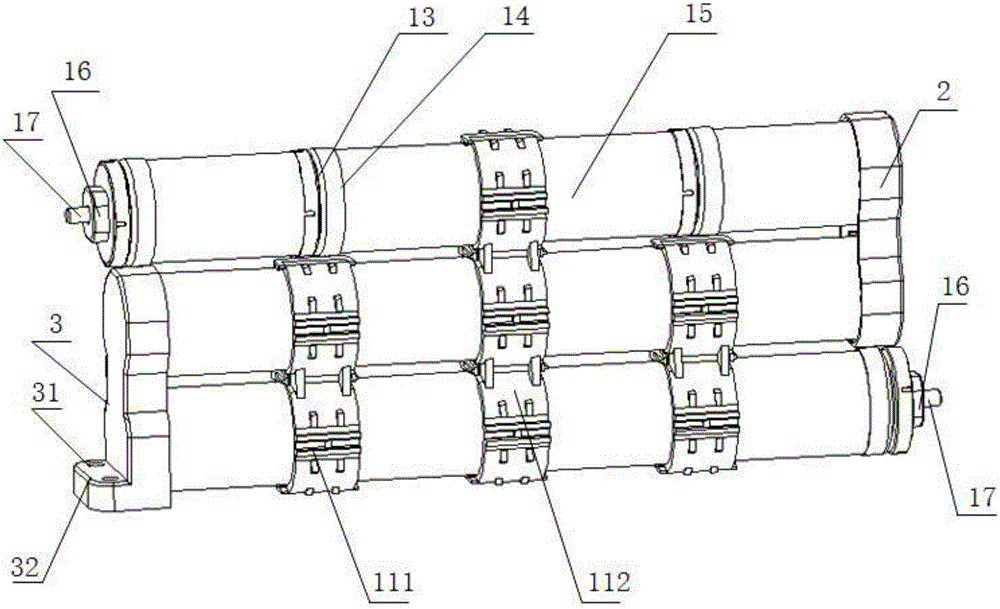

Battery module for hybrid electric vehicle and battery pack thereof

ActiveCN106384794AImprove stabilityImprove reliabilitySecondary cellsCell component detailsElectrical batteryHybrid electrical vehicle

The invention discloses a battery module for a hybrid electric vehicle. The battery module comprises at least two electrically connected battery rods and a clamp hoop, wherein the clamp hoop uses a duplex clamp hook; the duplex clamp hoop comprises two duplex clamp hoop sub bodies; each duplex clamp hoop sub body comprises two clamp hoop sub bodies with mutually connected outer walls; a position clamping buckle and a position clamping block which are anastomotic with each other are arranged on the duplex clamp hook body; the two duplex clamp hook sub bodies are connected through buckling the position clamping buckles and the position clamping blocks; the two clamp hook sub bodies form a clamp hook monomer; a battery monomer is fixed in the clamp hook monomer. The invention also discloses a battery pack using the battery module. The battery module and the battery pack provided by the invention have the characteristics that the structure is reasonable; the space utilization rate is high; the heat radiation performance is good.

Owner:INNER MONGOLIA XIAOKE HYDROGEN STORAGE ALLOY CO LTD

Intelligent parking lot

The invention discloses an intelligent parking lot, and belongs to the field of electromechanical systems. The intelligent parking lot mainly includes mobile trolleys, parking spaces and an operatingsystem. The mobile trolleys are used for installing various parts and loading the parking spaces. When vehicles are parked in the parking spaces, the mobile trolleys automatically transport the parking spaces to the garage and arrange the parking spaces in order or transport the parking spaces to vehicle pick-up sites at the exit. The operating system is used during vehicle parking and pick-up process, and controls the movement status of the mobile trolleys and the parking spaces through the Internet. The intelligent parking lot has the beneficial effects that it facilitates vehicle managementby parking lot administrators, reduces the waste of manpower and material resources, further ensures the safety of the vehicle owners, prevents theft, prevents the vehicles from sun and rain, and avoids accelerated aging of the vehicles.

Owner:湖北亘华工科有限公司

LED bulb and lamp head assembly with positioning structures

InactiveUS9151451B2The combination is firmShorten development timePoint-like light sourceElectric discharge tubesEngineeringLED lamp

The present invention provides a lamp head assembly with positioning structures for combining with a lamp base. The lamp head assembly includes a conducting head and a supporting barrel. The conducting head has an insulating seat, a first conducting plate and a second conducting plate and a conduction piece. The conduction piece is electrically connected with the first conducting plate. A portion of the second conducting plate is protruded out of the insulating seat, and an end of the insulating seat is formed with a inserting plate. The supporting barrel includes a supporting section connected and an assembling section; wherein, the supporting barrel is assembled on the conducting head through a positioning of the inserting plate and the slot.

Owner:AMPHENOL LTW TECH

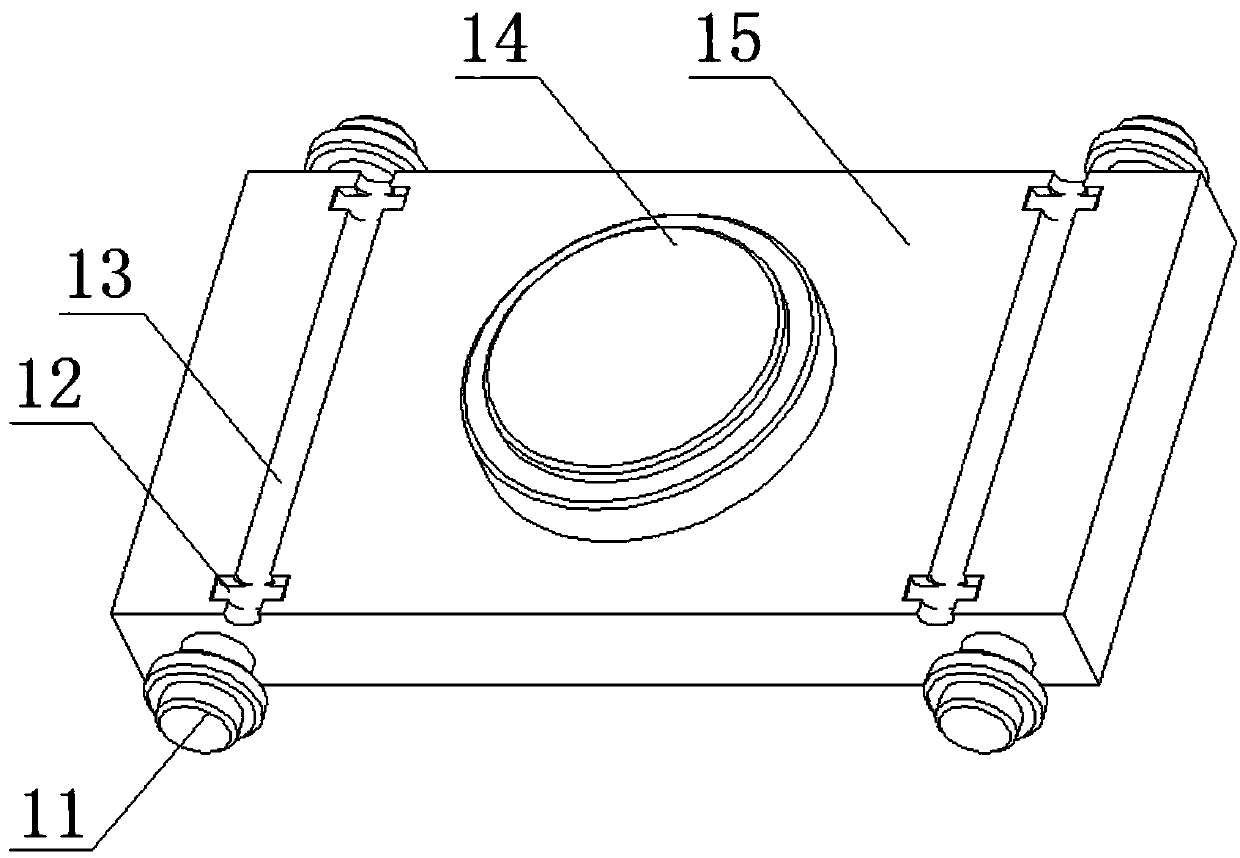

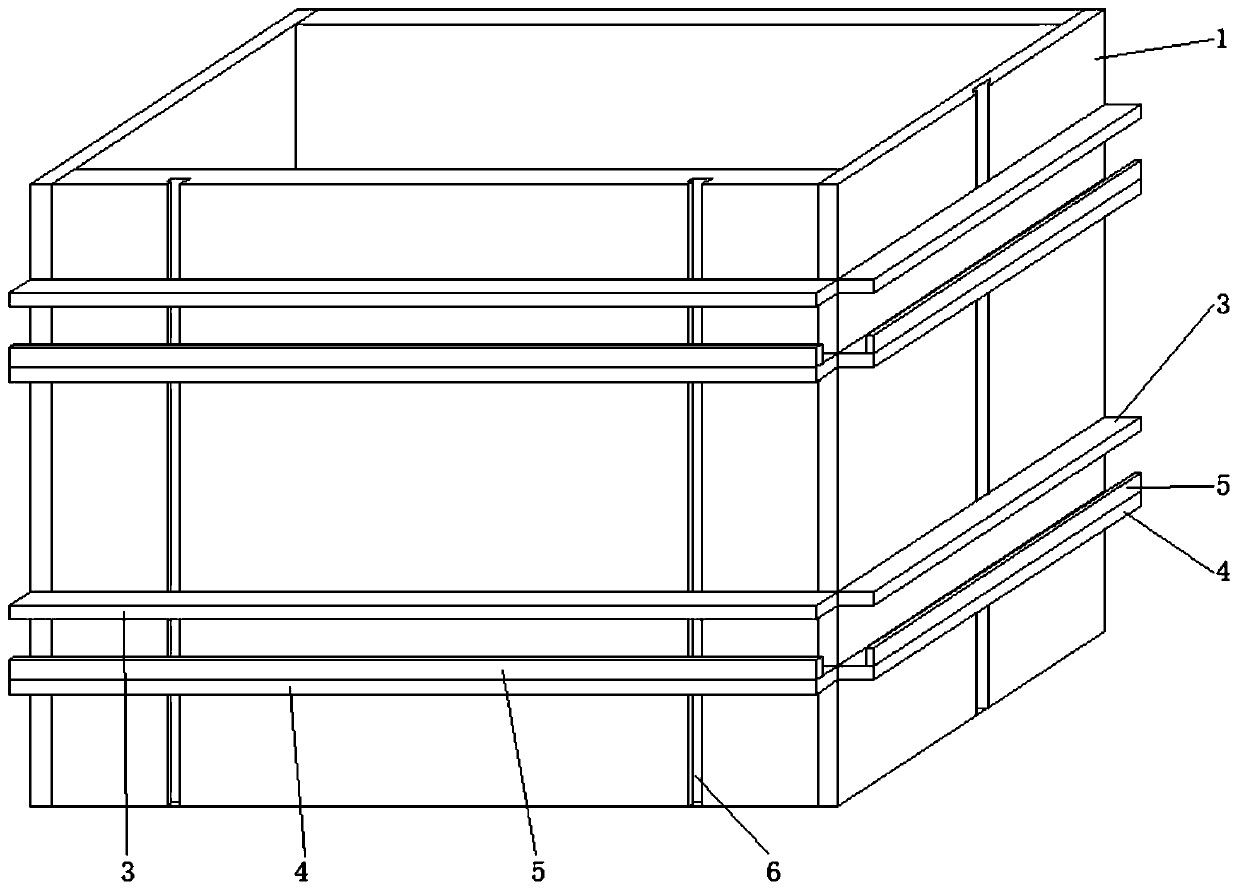

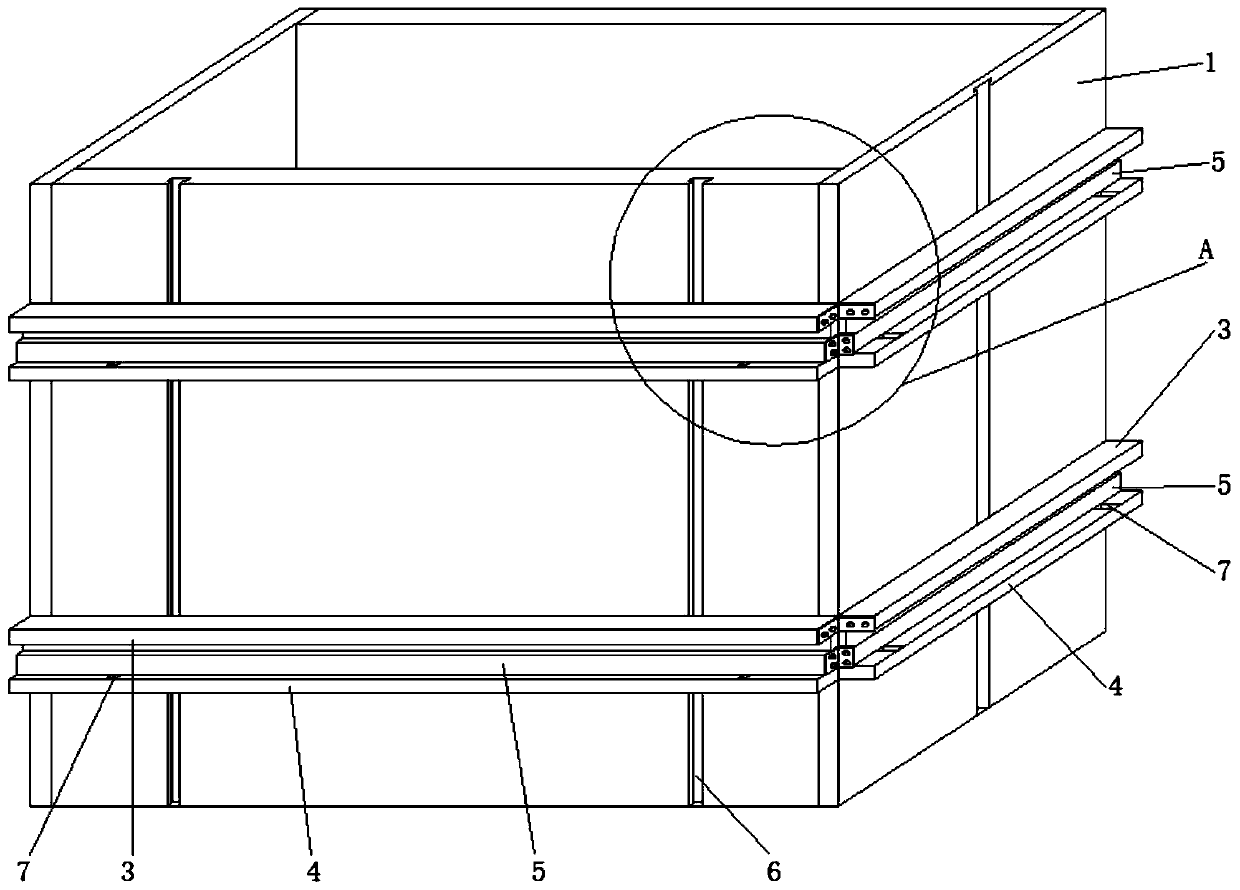

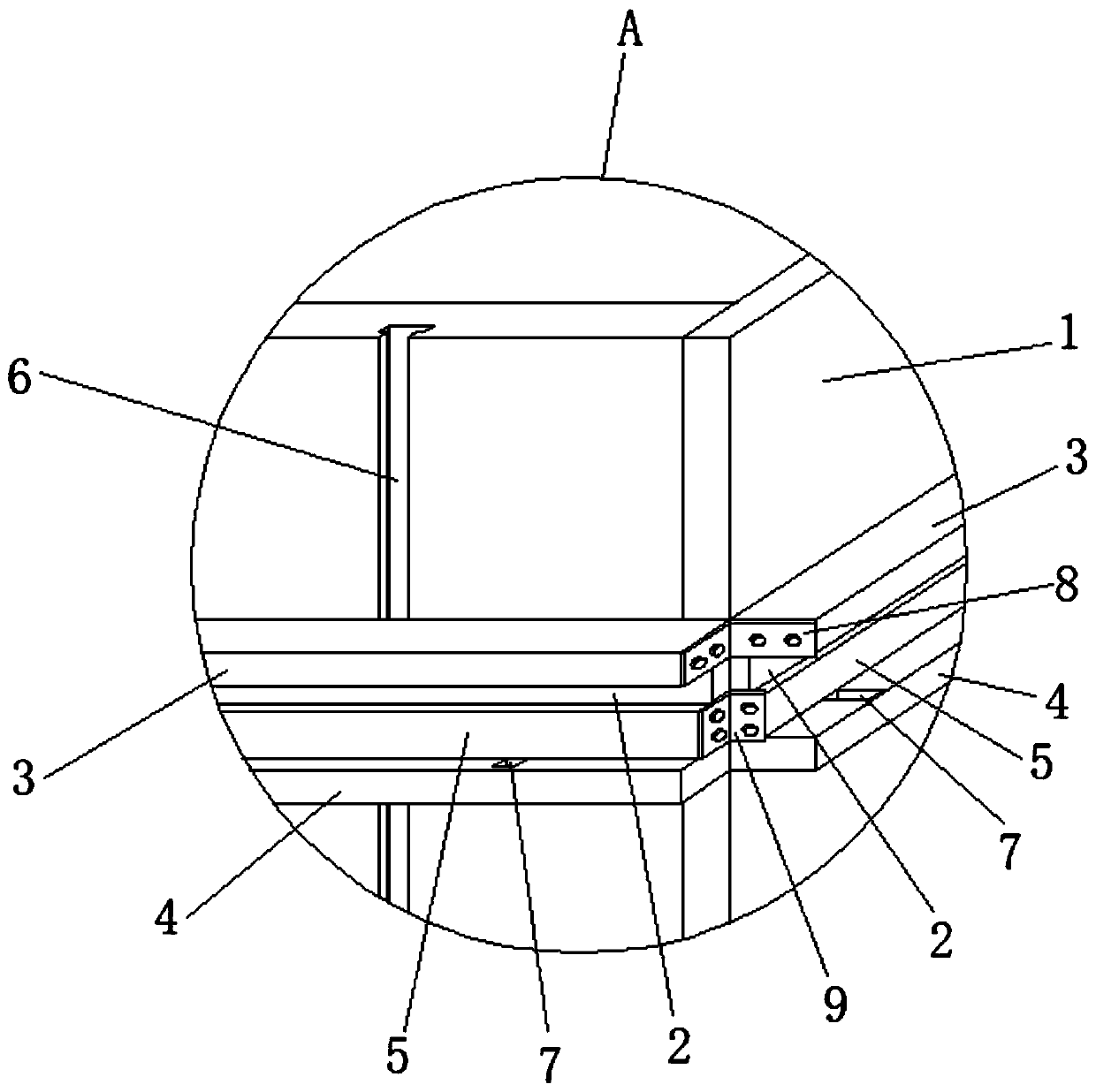

Hole-free disassembly and assembly type aluminum form

ActiveCN110607904ASimple structureImprove structural performanceAuxillary members of forms/shuttering/falseworksForming/stuttering elementsEngineeringFastener

The invention provides a hole-free disassembly and assembly type aluminum form, and belongs to the field of building forms. The hole-free disassembly and assembly type aluminum form comprises form main bodies and dorsal bars, the outer sides of the form main bodies are provided with containing cavities for containing the dorsal bars, each containing cavity is composed of a top plate, a bottom plate and a baffle are arranged on the corresponding bottom plate, the bottom plates are fixedly connected with the form main bodies, the top plates are in sliding connection with the form main bodies inthe height direction of the form main bodies, a group of first through grooves are formed in each bottom plate in the width direction, connecting rods and stop blocks are arranged at the bottoms of the baffles, the upper ends of the connecting rods are fixedly connected with the bottoms of the baffles, the lower ends of the connecting rods are fixedly connected with the stop blocks, the connectingrods penetrate through the first through grooves, the stop blocks are arranged at the bottoms of the bottom plates, the dorsal bars are arranged in the containing cavities, and the top plates or thebaffles of every two adjacent form main bodies are connected through fasteners. According to the aluminum form, the dorsal bars of different models can be installed in a hole-free mode according to requirements, the supporting strength requirement is met, and the structural performance of a poured and formed concrete pouring piece is better.

Owner:中铁一局集团建筑安装工程有限公司

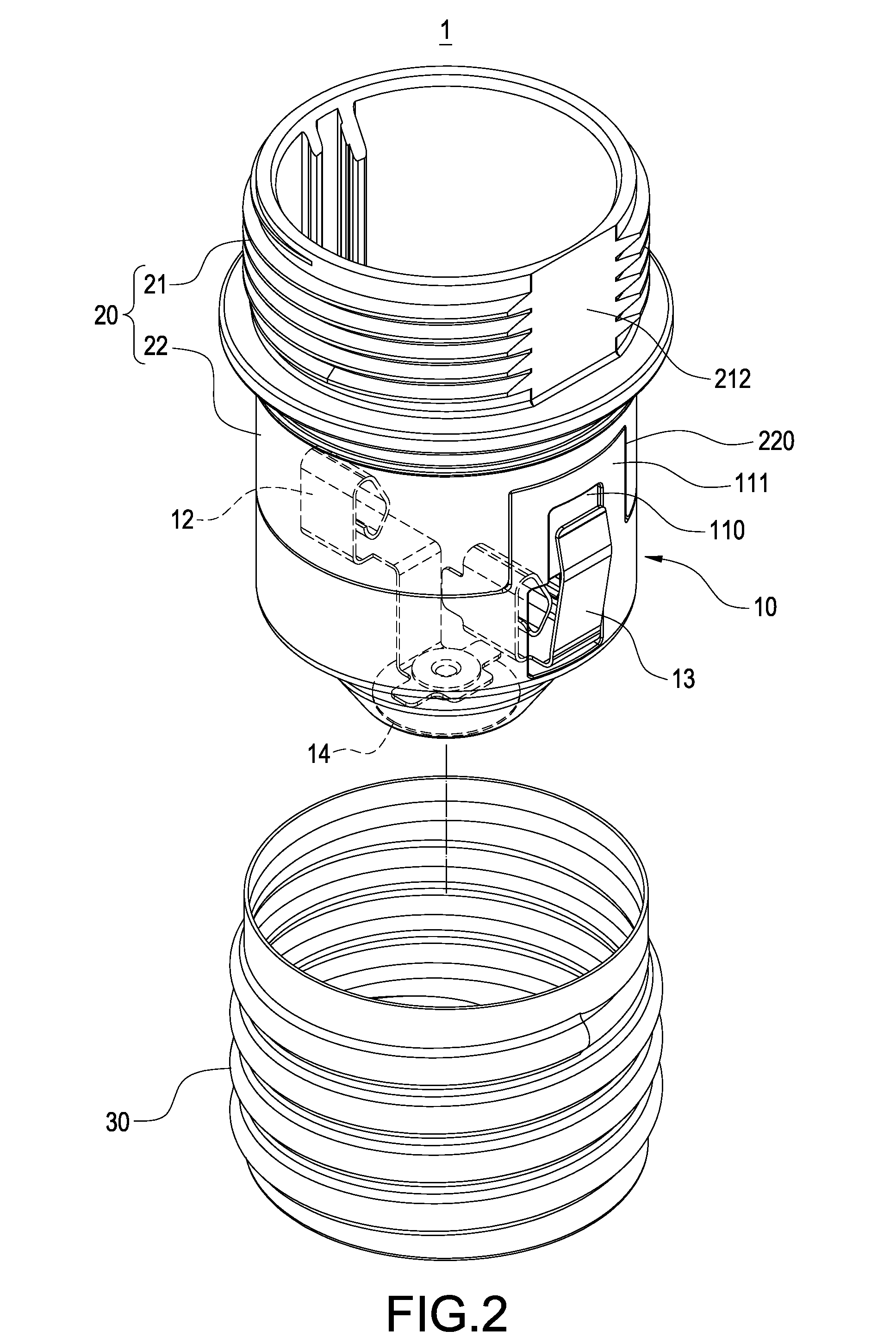

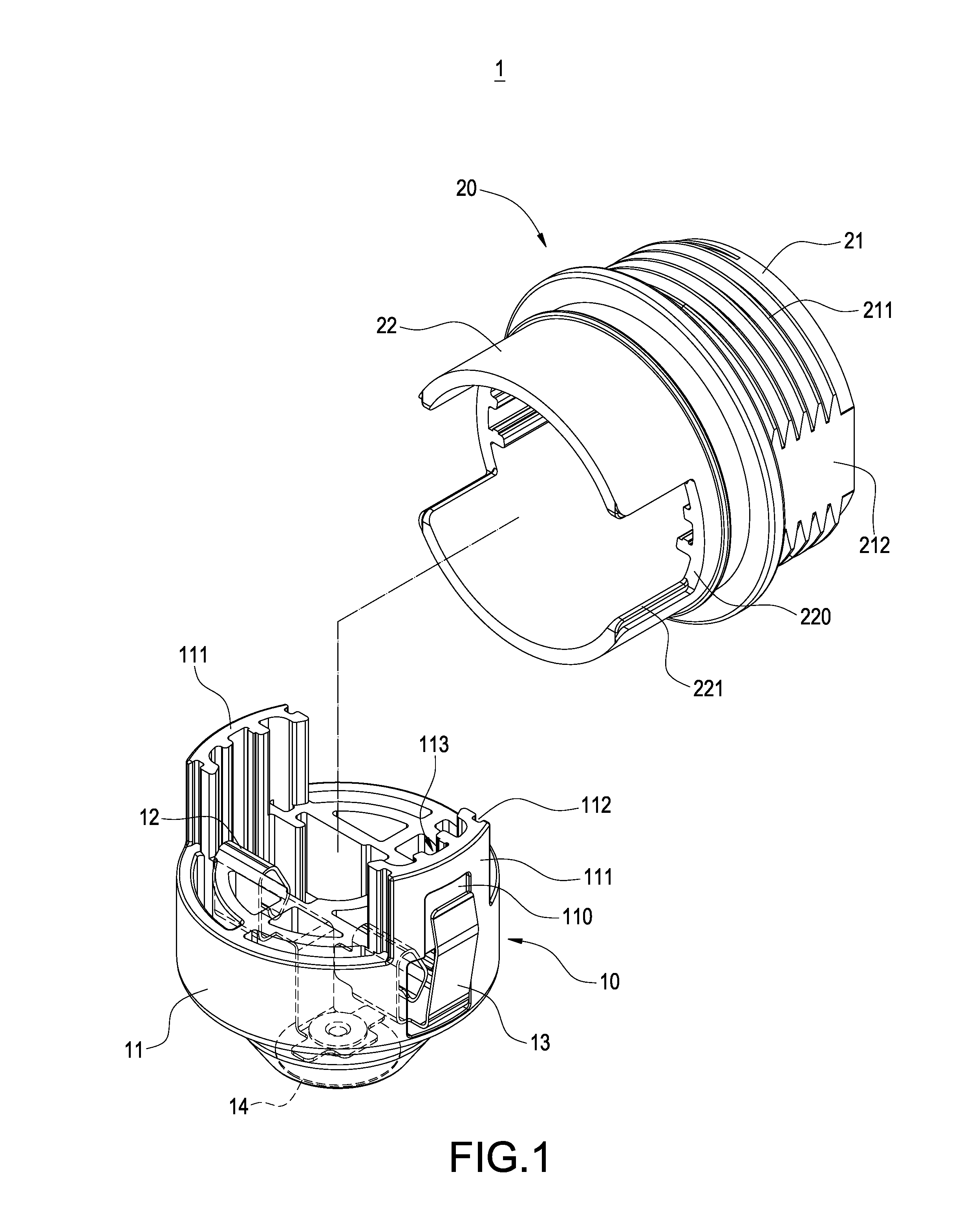

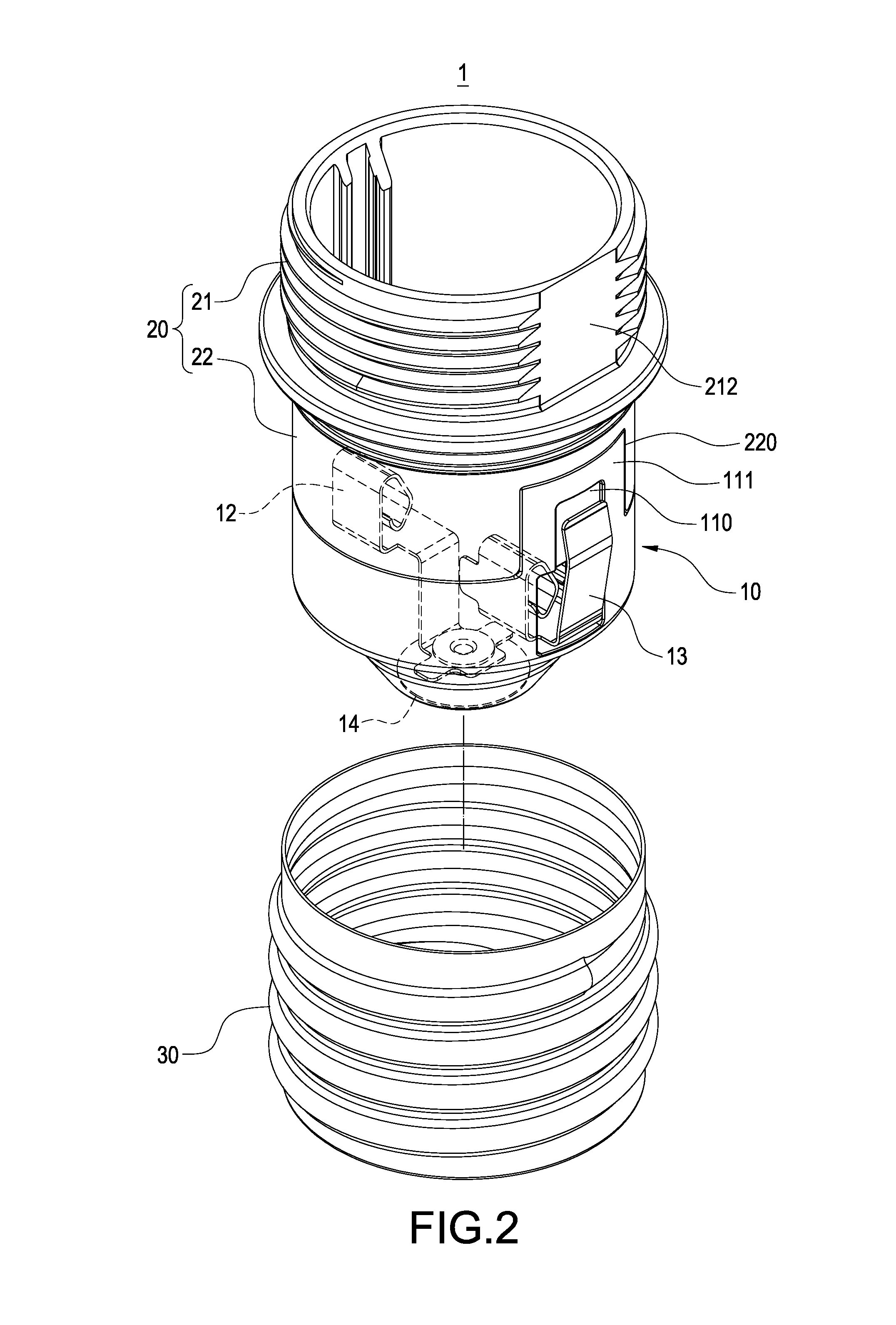

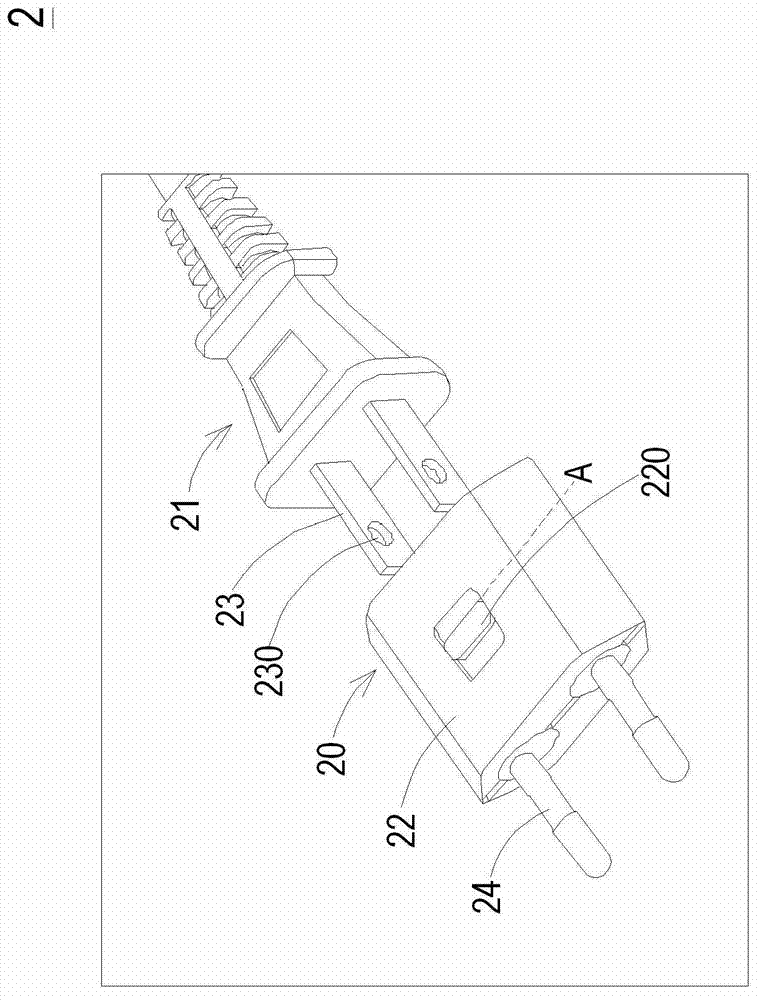

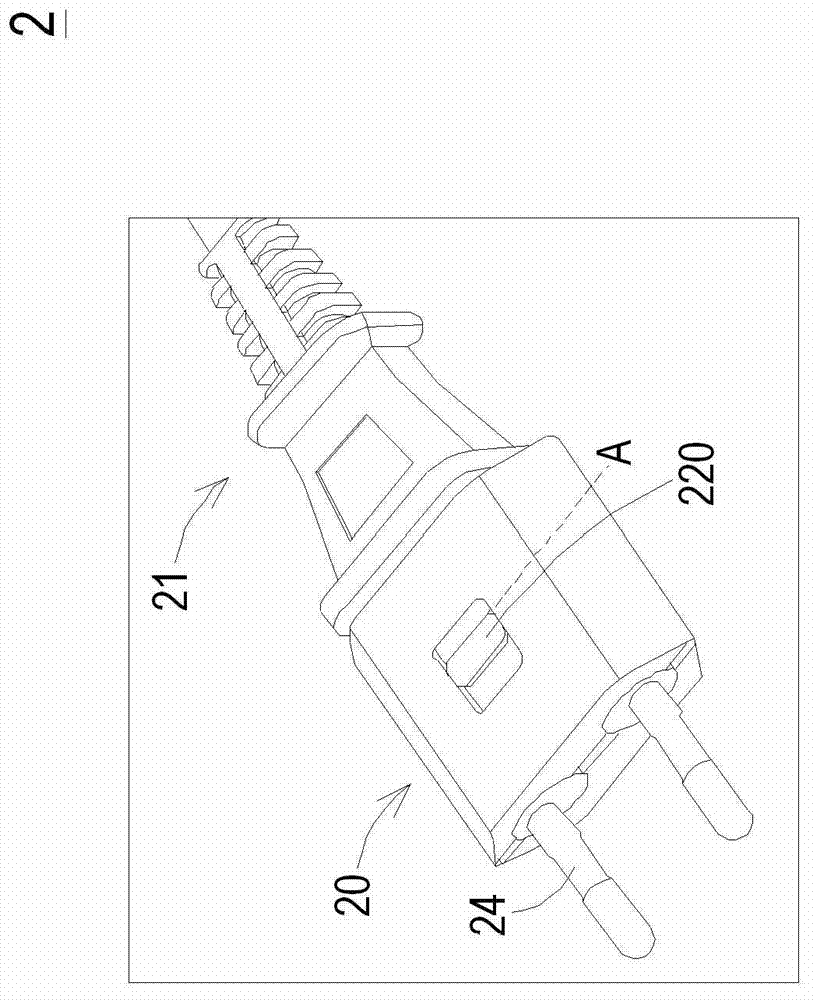

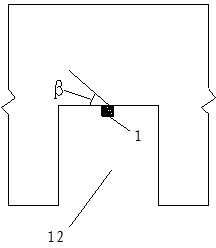

Power connector assembly and adapter plug

InactiveCN103367997AThe combination is firmReduce manufacturing costTwo pole connectionsCoupling device detailsMaterial PerforationElectrical and Electronics engineering

A power connector assembly (2) includes an appliance plug (21) and an adapter plug (20). The appliance plug (21) has at two first contact terminals (23), wherein each of the first contact terminals (23) has a perforation (230). The adapter plug (20) includes a casing (22), a switching element (220), at least two second contact terminals (201), and at least two locking elements (202). Each of the locking elements (202) has a protrusion part (202c). When the switching element (220) is located at a first position (A), the protrusion part (202c) of the locking element (202) is accommodated within the perforation (230) of the corresponding first contact terminal (23), so that the locking element (202) is in a locked state. In the locked state, the first contact terminal (23) and the corresponding locking element (202) are coupled with each other and the first contact terminal (23) and the corresponding second contact terminal (201) are electrically connected with each other.

Owner:DELTA ELECTRONICS (THAILAND) PUBLIC CO LTD

Subtropic evergreen lawn composite prescription, its lawn construction method and application

The invention belongs to the field of engineering technique for ecological greening town in subtropical zones. The employed combined lawn strains are Ling zhi tall fescue, hound tall fescue, beck tall fescue, Jiao zhan tall fescue, midnight English grass, De bi perennial ryegrass and common Bermuda grass, sowing seeds according to the proportion of tall fescue strains 50%, English grass strains 20%, perennial ryegrass strains 10% and Bermuda grass 20%, for two working times and even sowing, through scientific caring and management, in areas of normal climate and management such as Nan jing, the lawn yearly green period is above 320 days, the oversummering and overwintering rate is above 95%, the structure is stable, there are little weeds, the lawn is temperature-resistant, cold-resistant and trample-resistant, and the cost of lawn forming and caring is low, suitable for forming lawns in the green place, square and sportsground.

Owner:NANJING UNIV

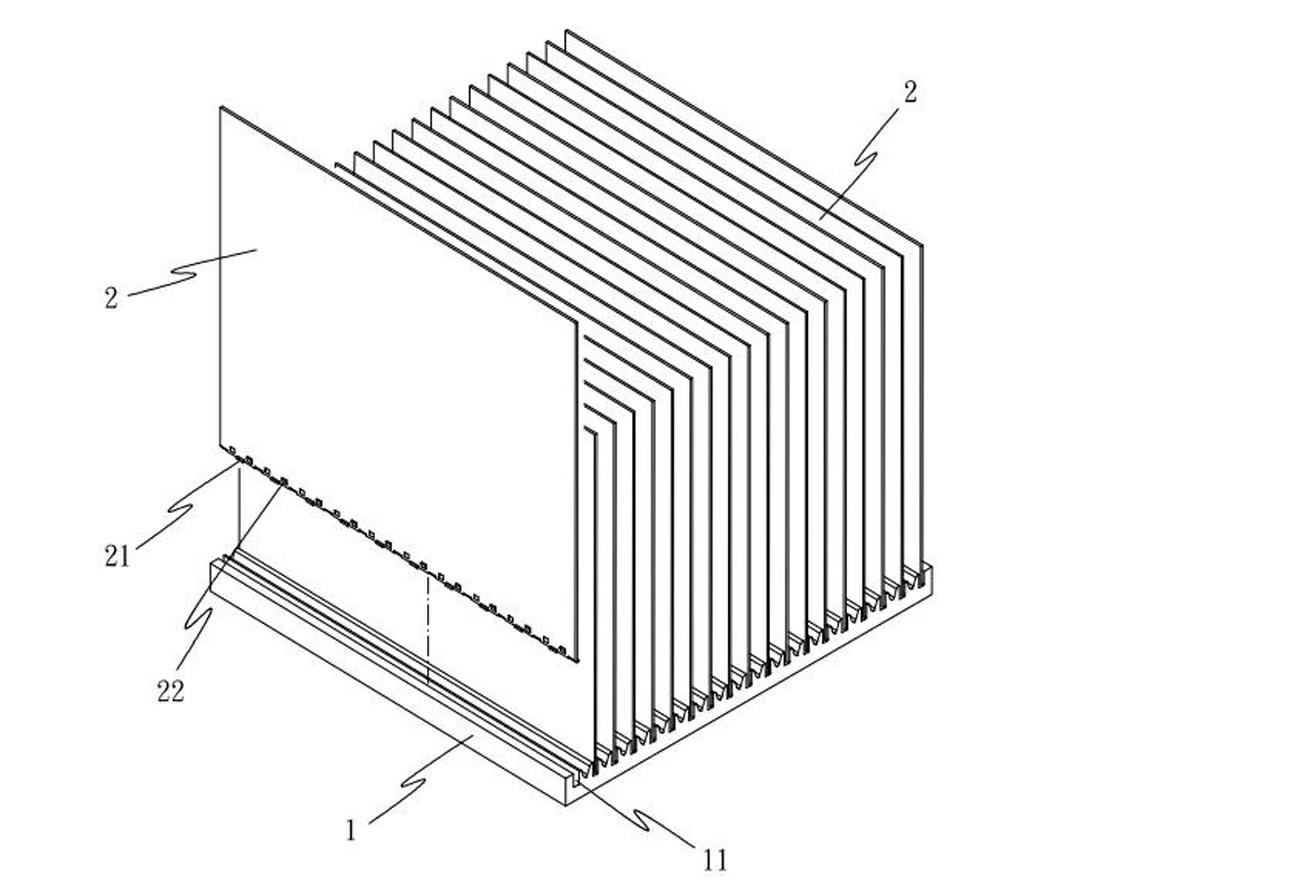

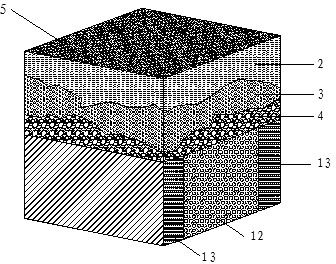

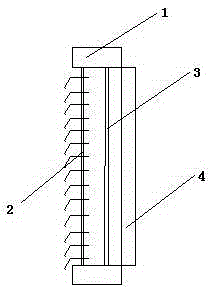

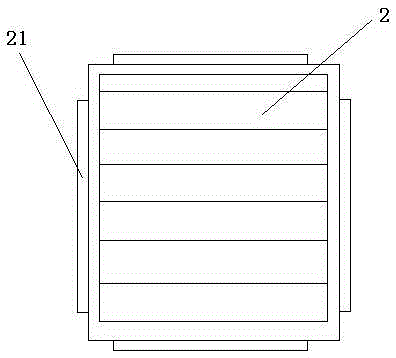

Radiating fin and base combination structure

ActiveCN102636069AThe combination is flat and stableStand steadyHeat exchange apparatusEngineeringExtrusion

The invention relates to a radiating fin and base combination structure design. The radiating fin and base combination structure comprises a base and a plurality of radiating fins, a plurality of adjacent grooves are arranged on the radiating base for respectively implanting the radiating fins in an inserting way, the radiating fins are tied at the bottom end to be stamped and form bending parts and wing hook parts which are intersected, so that the bottom ends of the radiating fins are inserted in the grooves of the radiating base in a matching manner and can be combined by burying or tightly clamped in the grooves by means of a pouring or extrusion manner, the radiating fins can be buried or clamped in the grooves of the radiating base by utilizing the bending parts and the wing hook parts which are intersected at the bottom end, so as to achieve the stable positioning and combining effects.

Owner:DONG GUAN HAN XU HARDWARE & PLASTIC TECH CO LTD

Coal-rock composite roof difference scale anchor rod combined supporting method

InactiveCN102661158AEasy to operateEffective control of large deformationDetection using electromagnetic wavesAnchoring boltsGeomorphologyElectromagnetic pulse

The invention discloses a coal-rock composite roof difference scale anchor rod combined supporting method, which comprises the following steps of: transmitting electromagnetic pulses within the roof range of a pre-dug roadway by using a geological radar for advanced detection, determining interfaces of a complete rock area, a cracked rock area and a crashed rock area in the composite roof range of 50-100 meters of the pre-dug roadway according to a reflected signal received by the geological radar, and forming a three-dimensional composite roof structure geologic model by means of a computer; and calculating the length of a difference scale anchor rod through subarea geometric parameters of the section of the model, and selecting an appropriate anchor rod to support a composite roof and to assist a metal net and a steel belt to form a combined supporting structure. As the three-dimensional composite roof structure geologic model is built, complex geological data of the roof can be expressed very visually and accurately; the form of the visual interface is advantageous for field staff to operate and determine the length of the anchor rod. Besides, the deformation of the roof can be effectively controlled, the number of the anchor rods can be reduced, and a great quantity of supporting materials and a great amount of maintenance cost can be saved; and as a result, the per unit area yield and the per unit area input are improved, and the safety production is guaranteed.

Owner:SHANXI FENXI MINING GRP +1

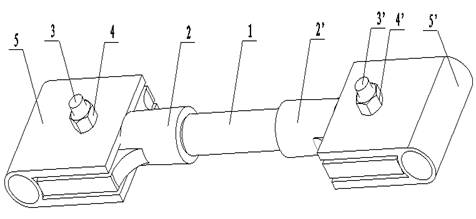

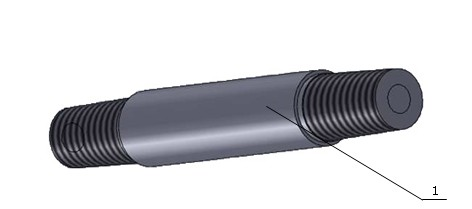

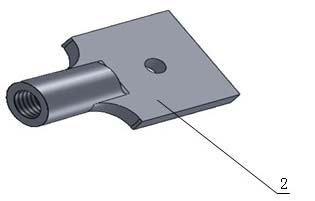

Connection construction member capable of regulating tightness and manufacturing and assembling method thereof

The invention discloses a connection construction member capable of regulating tightness for a transmission tower and a manufacturing and assembling method thereof. The connection construction member is assembled by a connecting rod, two connecting plates and two U-shaped connecting plates, wherein the connecting rod is made of glass fiber reinforced plastic composite material, and two ends of the connecting rod are provided with male threads. The manufacturing and assembling method for the connection construction member capable of regulating the tightness comprises the following steps of: 1) carrying out pultrusion on the connecting rod, and lathing a positive-buckling male thread and a reverse-buckling male thread on two ends of the connecting rod; 2) carrying out pultrusion on a pin, and lathing the male thread on two ends of the pin; 3) carrying out pultrusion on two pairs of nuts; 4) forming the connecting plates and the U-shaped connecting plates in a vacuum flow guide technology; 5) processing pin holes in the center positions where the connecting plates are opposite to the U-shaped connecting plates; and 6) fixedly connecting the connecting rod, the two connecting plates and the two U-shaped connecting plates into a connection construction member by the pin holes, the pin and the nuts. The manufacturing and assembling method is simple and easy to operate, has the characteristics of light weight, corrosion resistance and electric insulation, is adjustable, is safe to assemble, does not need to maintain and repair because the weather resistance lasts for 20 years, and is favorable for popularizing and applying.

Owner:北玻电力复合材料有限公司

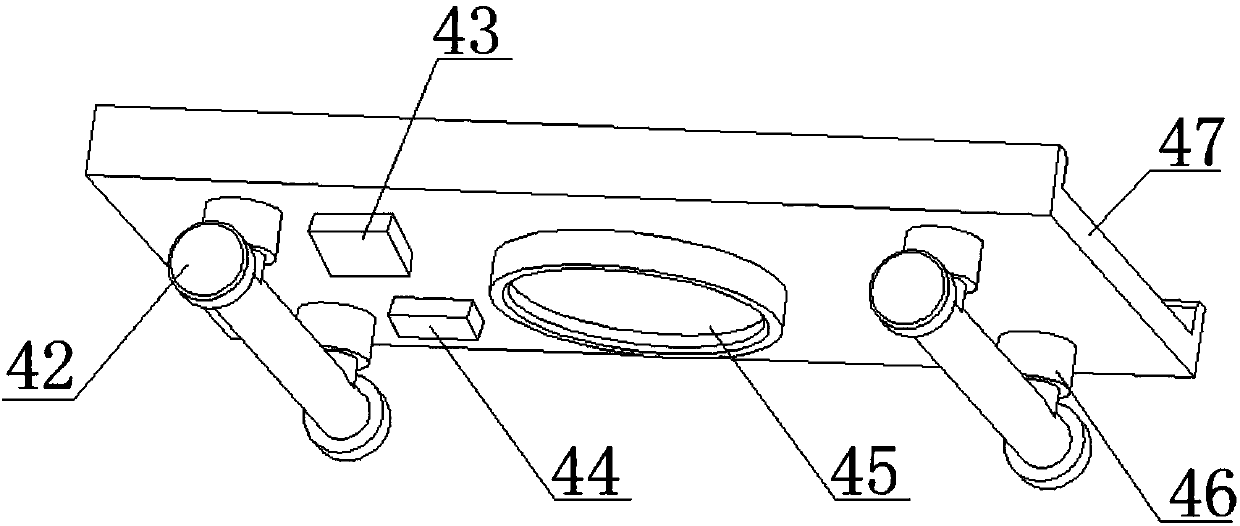

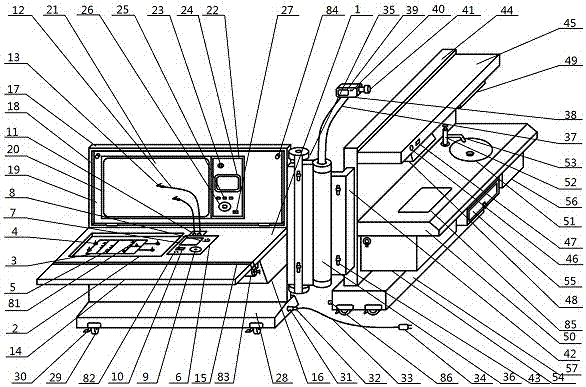

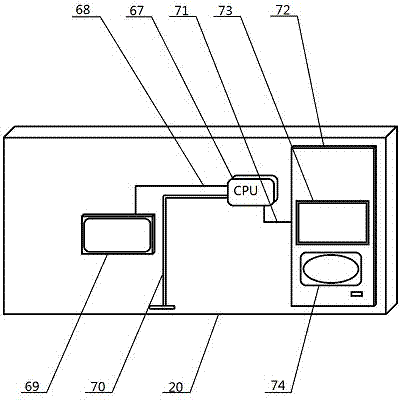

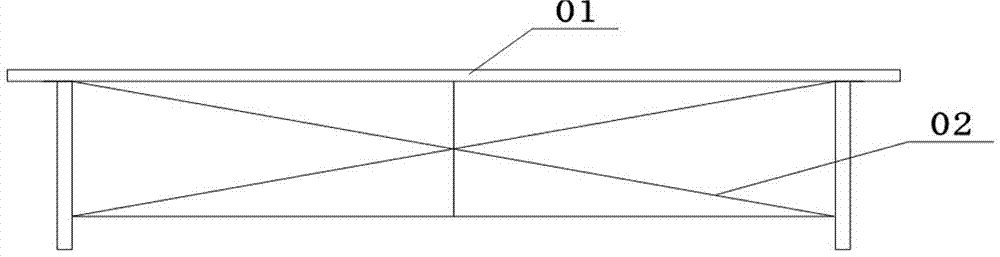

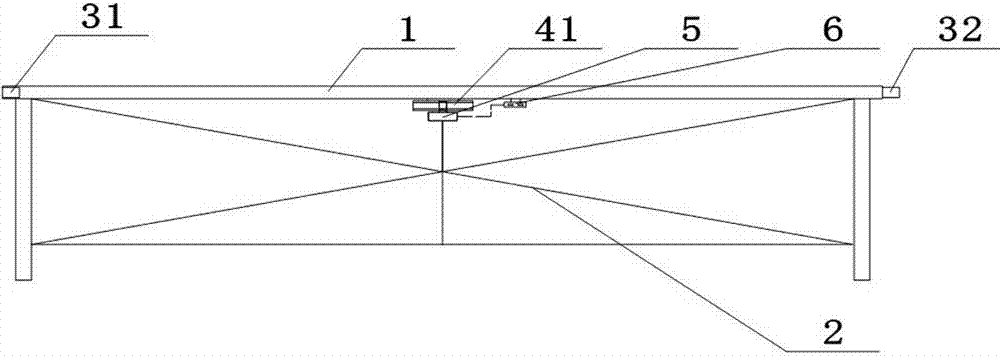

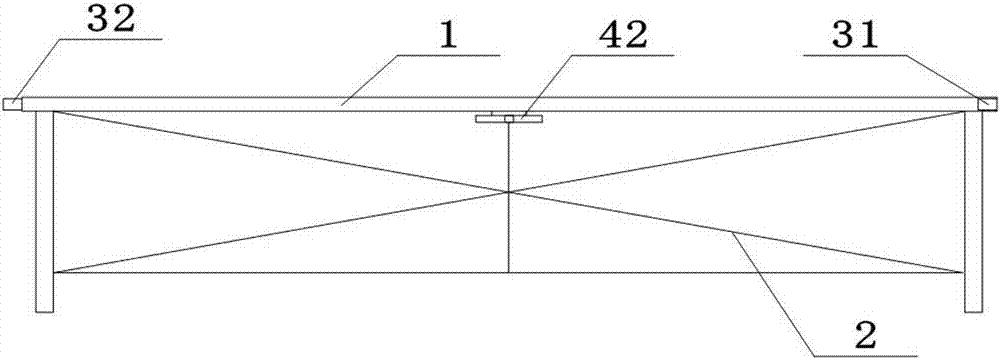

Multifunctional physical and chemical experiment mobile display platform

InactiveCN107085980AThe combination is firmEasy to operateEducational modelsElectrical appliancesChemical reactionEngineering

The invention relates to a multifunctional physical and chemical experiment mobile display platform and relates to the technical field of student appliances. The technical purpose is to provide the multifunctional physical and chemical experiment mobile display platform; the multifunctional physical and chemical experiment mobile display platform includes a physical experiment platform, a circuit experimental groove is formed in the upper side of the physical experiment platform, and an experimental circuit is mounted on the upper side of the circuit experimental groove. According to the multifunctional physical and chemical experiment mobile display platform, combination is firm, dismounting, combination and use are convenient, a convenient physical weak current circuit experiment device and an electronic screen convenient for displaying are arranged, a cleaning tank and a ventilation device are mounted on the chemical display platform, experimental operation of a chemical reaction is convenient, and more convenient equipment is provided for experimental teaching of students.

Owner:杨雨衡

Demountable pot handle

The invention relates to a detachable pot handle. A hollow cavity formed by an upper cover and a base is internally provided with a bolt, a bottom and a spring. The lower half section of a T-shaped button frontwards protrudes to form a hook body which is a peak, the rear end of the hook body is roofed and pressed by the spring; the rear end of the bolt is provided with a gap in a slit way, two tail wings of the gap are blocked on the hook body, and the bolt end at the front end protrudes out of the end surface of the handle; a lug seat fixed on the wall of a pot is provided with a lug seat body and a sharp block, an insert hole is arranged between the lug seat body and the sharp block, the bolt end is inserted from the insert hole and the handle is pressed down, the blot is blocked into the lug seat, and the hook body clamps the sharp block on the lug seat so as to achieve the purpose of firmness. The pot handle has free detachment, skilled structure, less part and easy manufacture, can be matched with a plurality of pots, and is suitable for daily pots of various types.

Owner:广东三A不锈钢制品集团有限公司

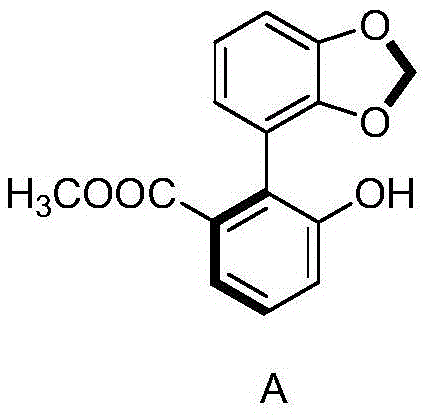

Preparation method of esomeprazole magnesium trihydrate for treating digestive system diseases

InactiveCN105418589AHigh yieldImprove reaction efficiencyOrganic chemistryManganesePotassium hydroxide

The invention discloses a preparation method of esomeprazole magnesium trihydrate for treating digestive system diseases. The preparation method comprises the following steps: (1) in the presence of an alkaline compound, carrying out a reflowing reaction on 2-chloromethyl-3,5-dimethyl-4-methoxylpyridine hydrochloride and 2-sulfydryl-5-methoxylbenzimidazole in THF (Tetrahydrofuran) to obtain omeprazole thioether; (2) mixing the omeprazole thioether with a compound represented by formula A and an inorganic metal salt in acetone to obtain a mixture B; (3) adding an oxidant into the mixture B to carry out an oxidization reaction at a temperature of 10 to 50 DEG C; after the reaction is finished, adding a potassium hydroxide methanol solution to obtain esomeprazole potassium; (4) mixing the esomeprazole potassium and anhydrous magnesium chloride in methanol, and stirring and reacting; then centrifuging and separating to obtain the esomeprazole magnesium trihydrate, wherein the inorganic metal salt is cobalt (II), iron (II) or manganese (II) metal salt. The preparation method has high yield, good selectivity and high reaction efficiency and is suitable for industrial large-scale production.

Owner:QINGDAO CENT HOSPITAL

Combined stage

InactiveCN107143161AThe combination is firmEasy to assemble and disassembleTheatresTongue and grooveStructural engineering

The invention discloses a combined stage, and belongs to the technical field of performance facilities. The combined stage comprises stage units. The stage units are provided with base frames and square face plates, the face plates are positioned on the base frames, a tenon is arranged at the edge of one side of each face plate, and a corresponding mortise is arranged at the edge of the other opposite side of each face plate; at least two embedding grooves are formed in each base frame and correspond to two adjacent side edges of the corresponding face plate, and at least two embedding plates corresponding to the corresponding embedding grooves are arranged on each base frame and correspond to two other adjacent side edges of the corresponding face plate; push-pull electromagnets are arranged below the embedding grooves, movable iron cores of the push-pull electromagnets extend towards the embedding grooves, through holes are formed in the embedding plates and the embedding grooves, the movable iron cores are nested in the through holes, and sound control switches are arranged at control ends of the push-pull electromagnets. The combined stage has the advantage that the problem of potential safety hazards of collapse due to the fact that existing stage units are not firmly connected with one another when the various existing stage units are butted to one another can be solved by the aid of the combined stage.

Owner:周存慧

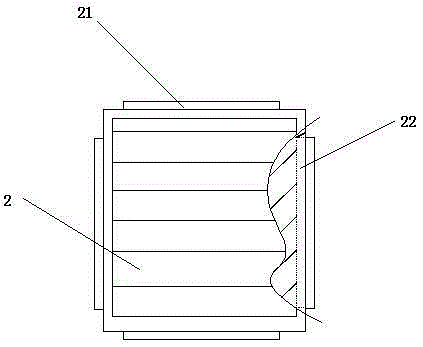

Air returning window for dust-free workshop

InactiveCN105317356ACompact structureThe combination is firmVentilation arrangementFilter effectWaste management

The invention discloses an air returning window for a dust-free workshop. The air returning window comprises a bottom frame fixed on a building and an air returning shutter panel connected to the bottom frame in a matched mode; a filter device is arranged between the bottom frame and the air returning shutter panel and comprises a filter screen and a filter screen support frame, and a non-planar filter screen with folds is adopted as the filter screen; the inner walls of the periphery of the bottom frame are all provided with grooves, each groove comprises a first groove set, and first protrusion sets matched with the first groove sets are arranged at the periphery of the air returning panel. According to the shutter air returning window, the structure is compact, combination is firm, and the non-planar filter screen with the folds can increase the filter area, so that the filter effect is improved.

Owner:SUZHOU XINGYA PURIFICATION ENG

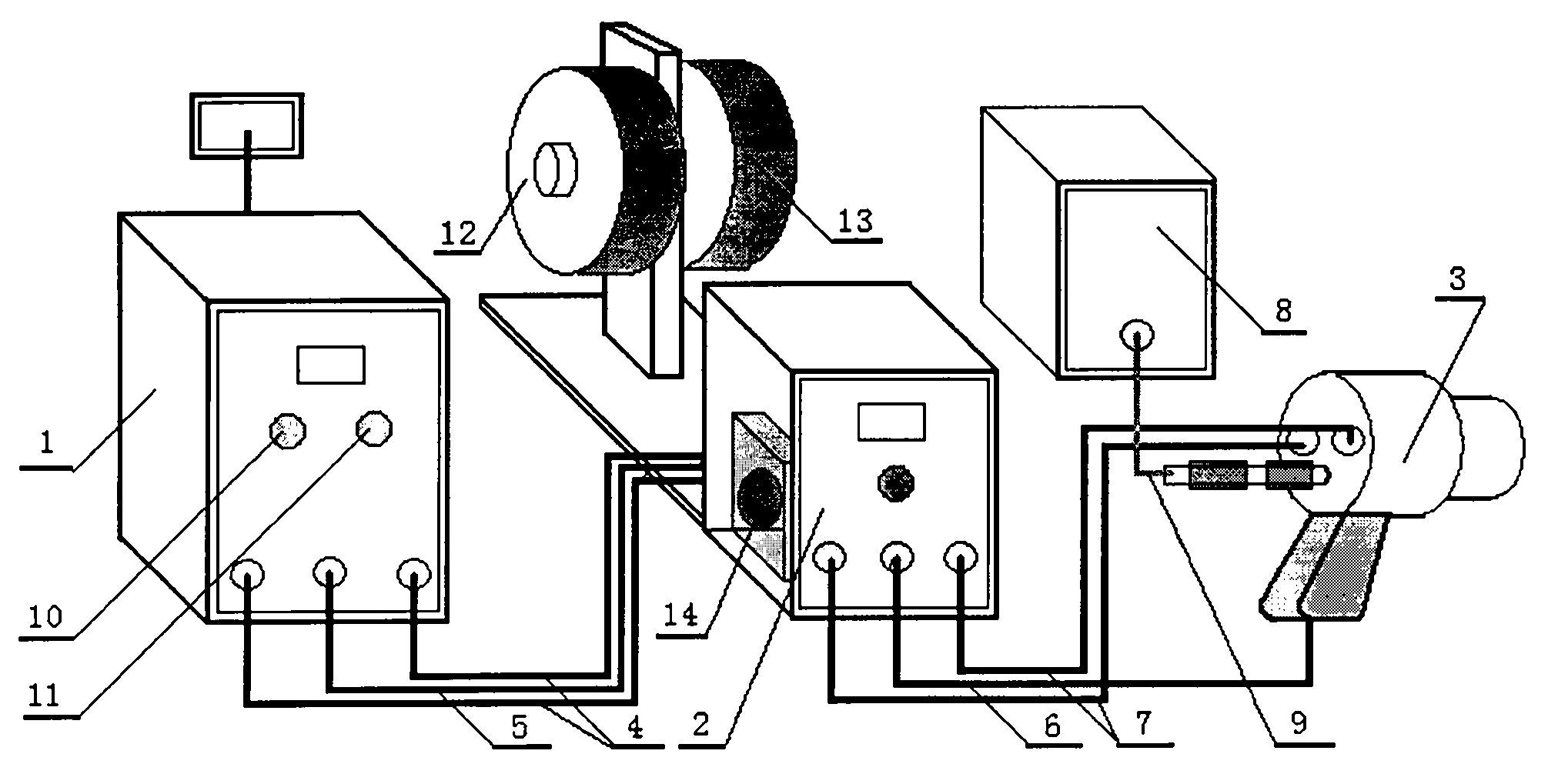

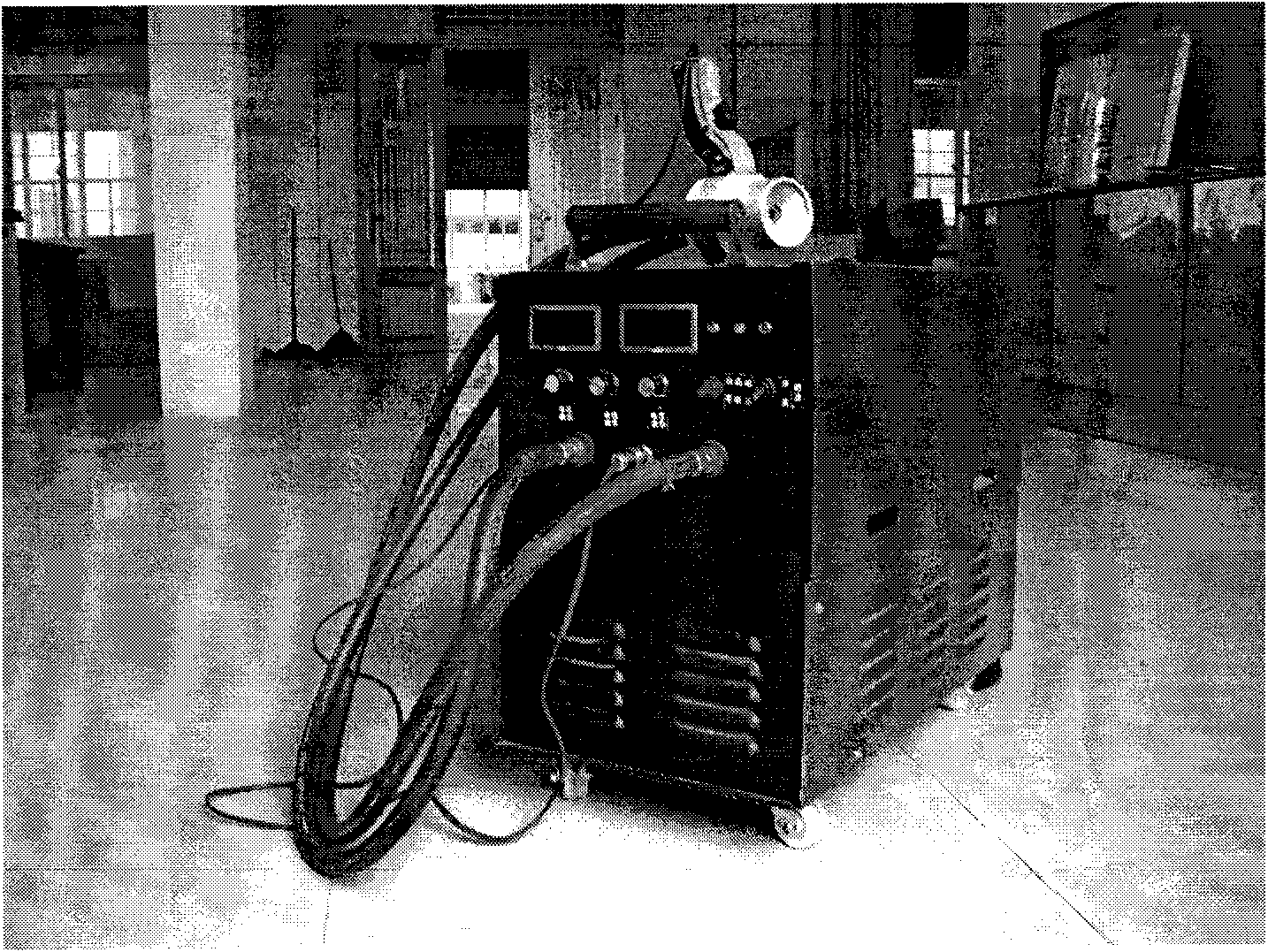

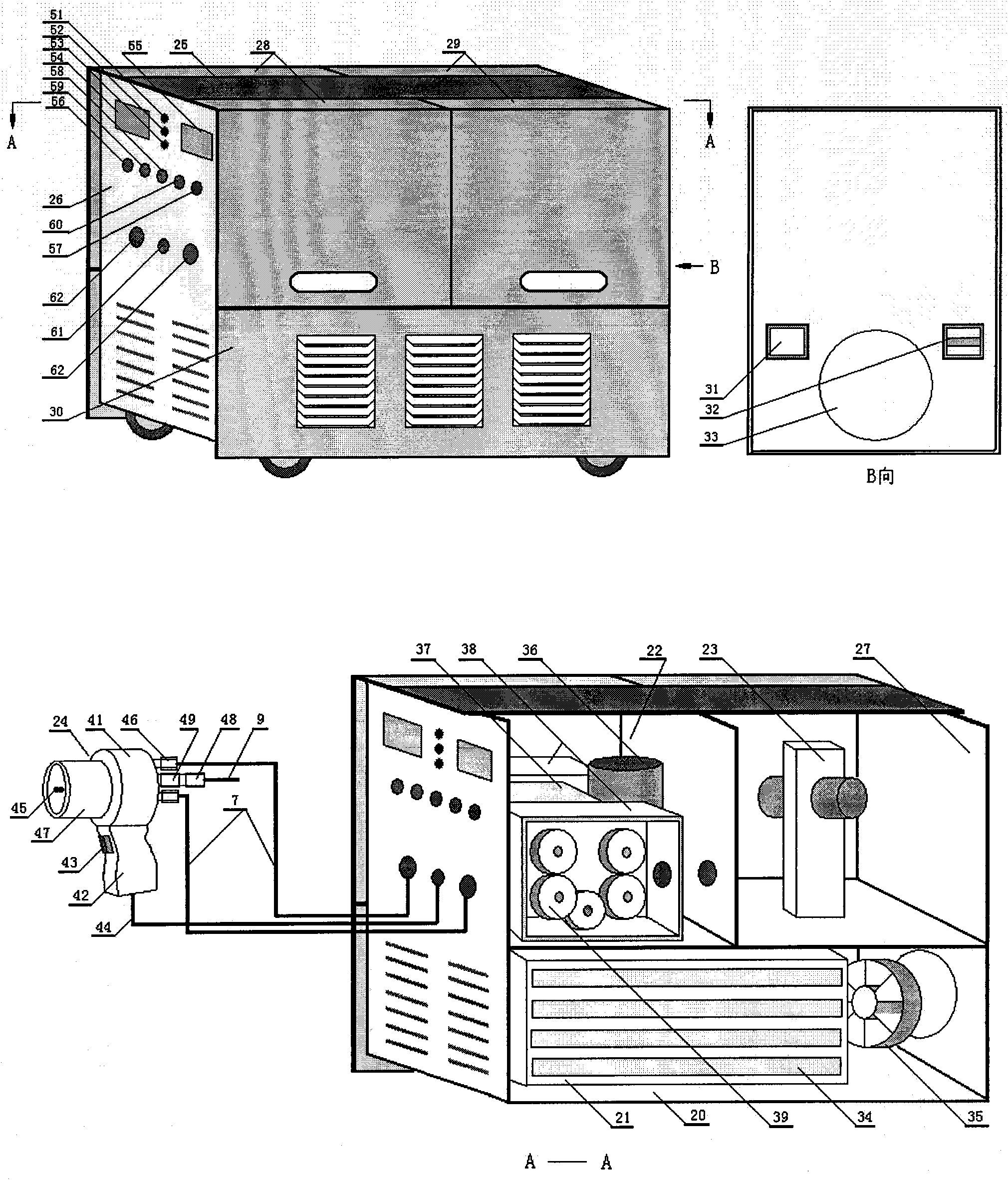

Integral push-wire-type electric arc spraying equipment

InactiveCN101864550AReduce volumeReduce weightMolten spray coatingElectric arc sprayingThermal sprayingWhole body

The invention relates to an integral push-wire-type electric arc spraying equipment used for thermal spraying, which can be seen in an attached figure of the abstract. The equipment adopt an inverter-type spraying power supply, has the technical scheme of combining and closing the spraying power supply, a wire feed device and a wire reel bracket (including a wire reel) into a whole body, and is matched with a home-made electric arc spray gun. The integral push-wire-type electric arc spraying equipment solve the problems of heavy weight, large volume, dispersed devices, more externally connected cables and the like of the push-wire-type electric arc spraying equipment. The equipment have the function of stepless regulation for output voltage within the range of 10-50V, and can freely adjust the parameters without stopping a machine in the spraying process; the equipment is provided with a manual / automatic spraying and wire detection / spraying switch, thus being convenient for the selection of operation way and preventing electric arc from hurting people and damaging equipment when in the process of installing, adjusting and checking spraying wires; and due to the full-closed structure, the blockage phenomenon of a wire guide pipe is avoided. The equipment has the characteristics of small volume, light weight, convenient carrying, safe and reliable equipment performance, convenient use, simple operation, stable spraying quality and the like.

Owner:慈溪光华金属复合材料有限公司

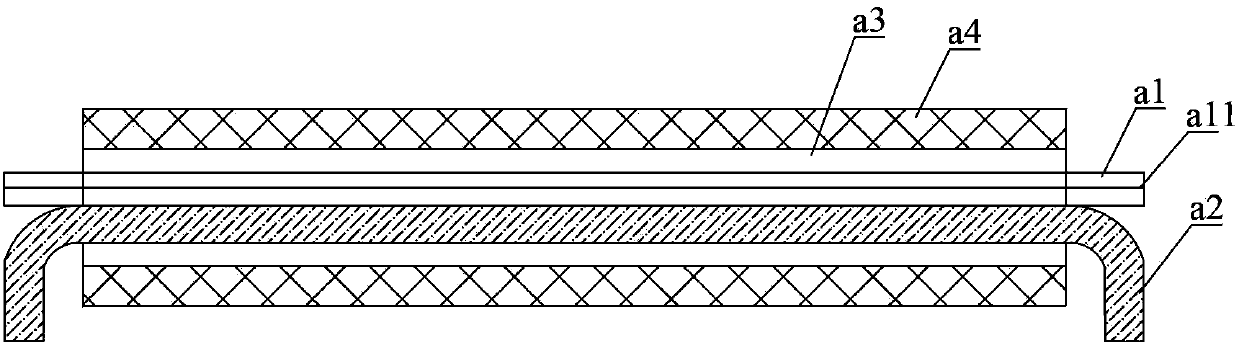

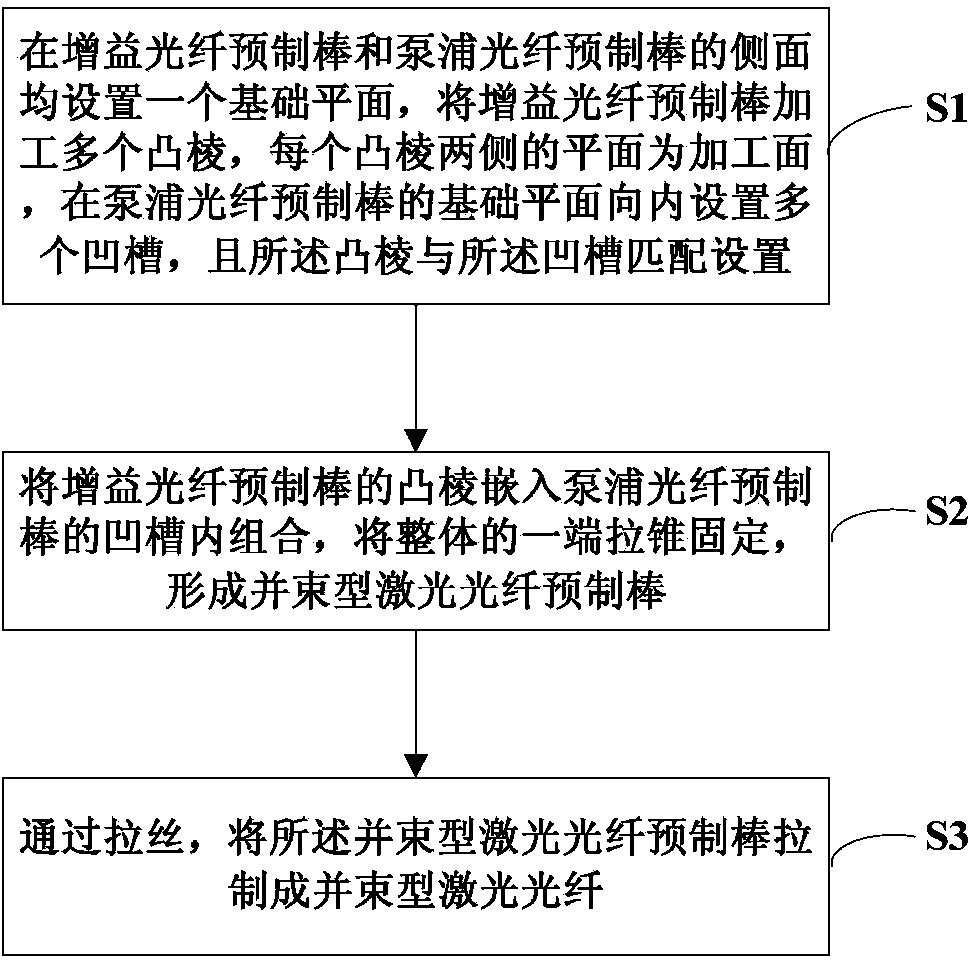

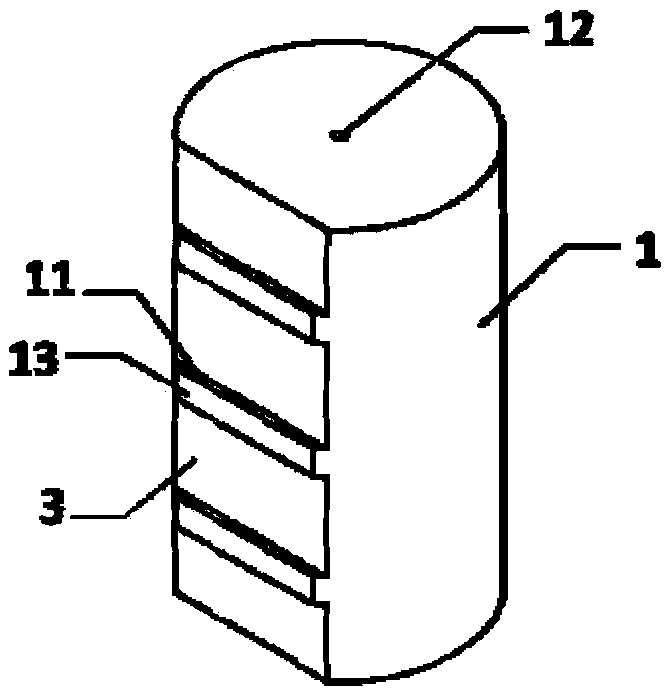

High-efficiency beam combination laser fiber and drawing method thereof

ActiveCN103466934AImprove the finishImprove processing efficiencyLaser detailsCladded optical fibreOptoelectronicsRepeatability

The invention discloses a drawing method of a high-efficiency beam combination laser fiber, and relates to the technical field of fiber laser transmission and amplification. The method comprises the steps that S1, a basic plane is arranged on each of the side surfaces of a gain fiber preform and a pump fiber preform; the basic plane of the gain fiber preform is processed inwards; a plurality of ribs are raised; planes on the two sides of each rib are processing surfaces; a plurality of grooves are formed inwards in the basic plane of the pump fiber preform; the ribs are matched with the grooves; S2, the ribs of the gain fiber preform are embedded into the grooves of the pump fiber preform; after combination of the ribs and the grooves, one end of a whole combination body is fixed by a taper to form a beam combination laser fiber preform; and S3, the beam combination laser fiber preform is drawn into the beam combination laser fiber by wire drawing. The drawing method is higher in technology repeatability; and obtained beam combination laser can achieve pump fiber stripping in a set area, and facilitates achieving multipoint pump photoinjection in a length direction of the beam combination laser fiber.

Owner:FENGHUO COMM SCI & TECH CO LTD

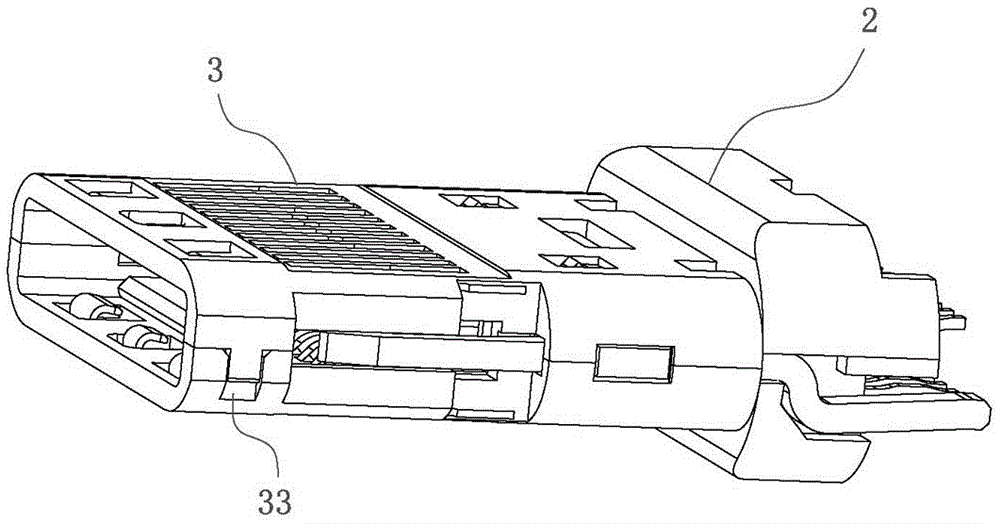

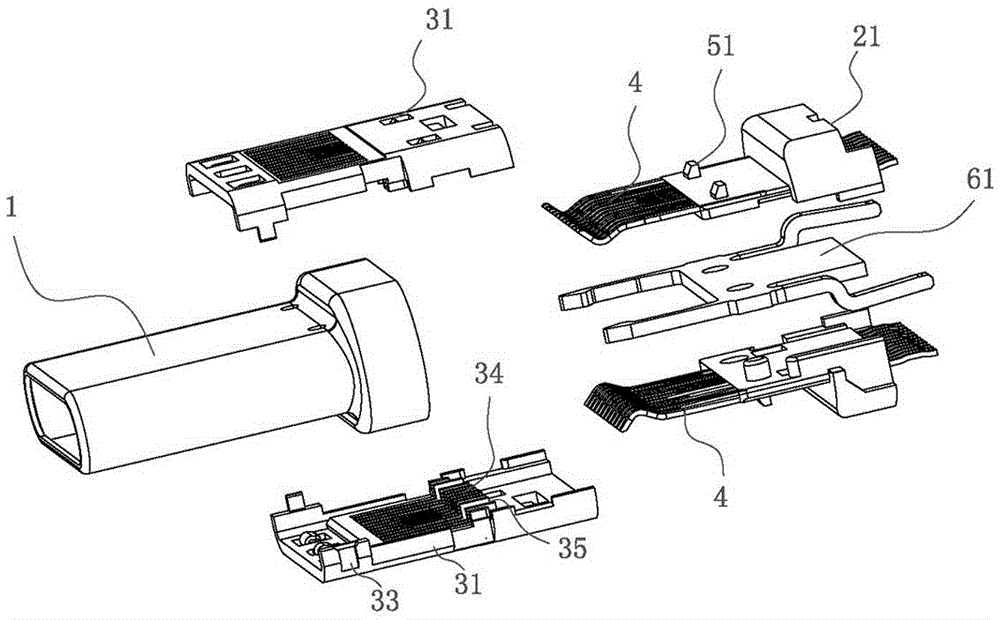

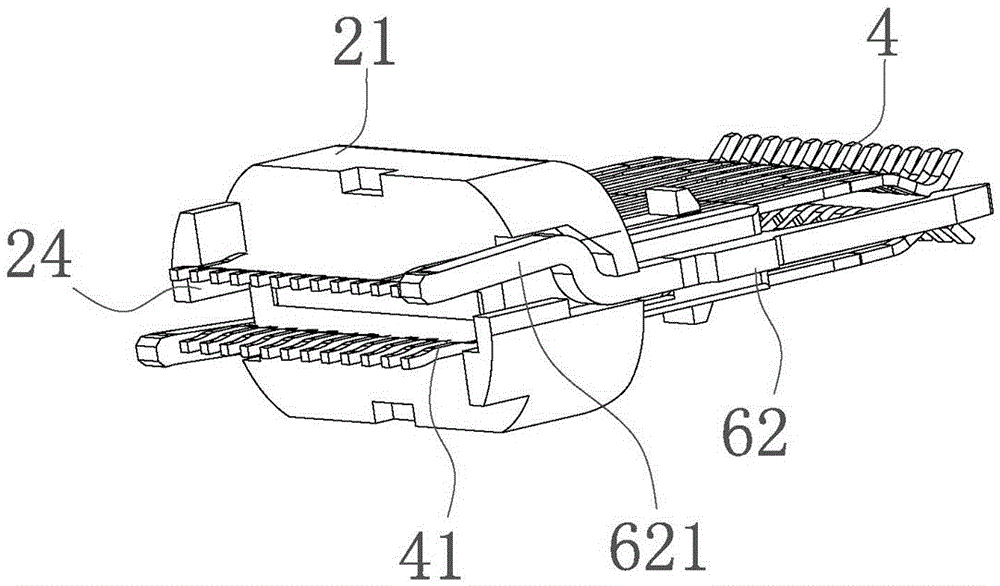

Connector production method and connector structure

ActiveCN105826793ASimple structureCompact structureContact member cases/bases manufactureContact member assembly/disassemblyStructural engineeringInjection moulding

The present invention provides a connector production method. When production, a row of terminals are subjected to injection moulding to form a rear rubber core unit, the rear rubber core unit is fixedly connected with a front rubber core unit to form a connector unit, and any two connector units are assembled together to form the main body of the whole connector. The terminals and the rear rubber core unit are steadily fixed, so that the problem is solved that a traditional injection moulding rear rubber core module group is difficult to demould, it is ensured that the terminals are tidily arranged at the rear rubber core unit, and the requirement is satisfied that the connector is compactly and firmly assembled. The present invention further provides a connector structure, and the connector structure is cooperated with the production method provided by the invention. The rear rubber core module group is formed by two rear rubber core units with the same structure through buckling, and the front rubber core module group is formed by two front rubber core units with the same structure through buckling, and the rear rubber core units and the front rubber core units are produced on a large scale, then any two rear rubber core units and any two front rubber core units can be combined.

Owner:韶关胜蓝电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com