High-efficiency beam combination laser fiber and drawing method thereof

A fiber drawing and beam-shaping technology, which is applied to lasers, clad optical fibers, optical waveguides, etc., can solve problems such as inability to realize multi-point pump light injection, inability to strip according to requirements, and difficulty in effective control and adjustment. Excellent pump light coupling performance, good optical performance and reliability, and easy combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

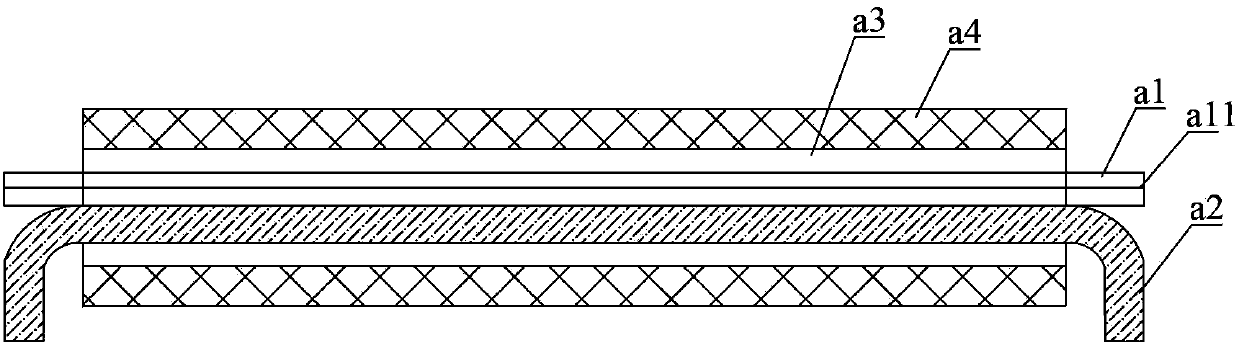

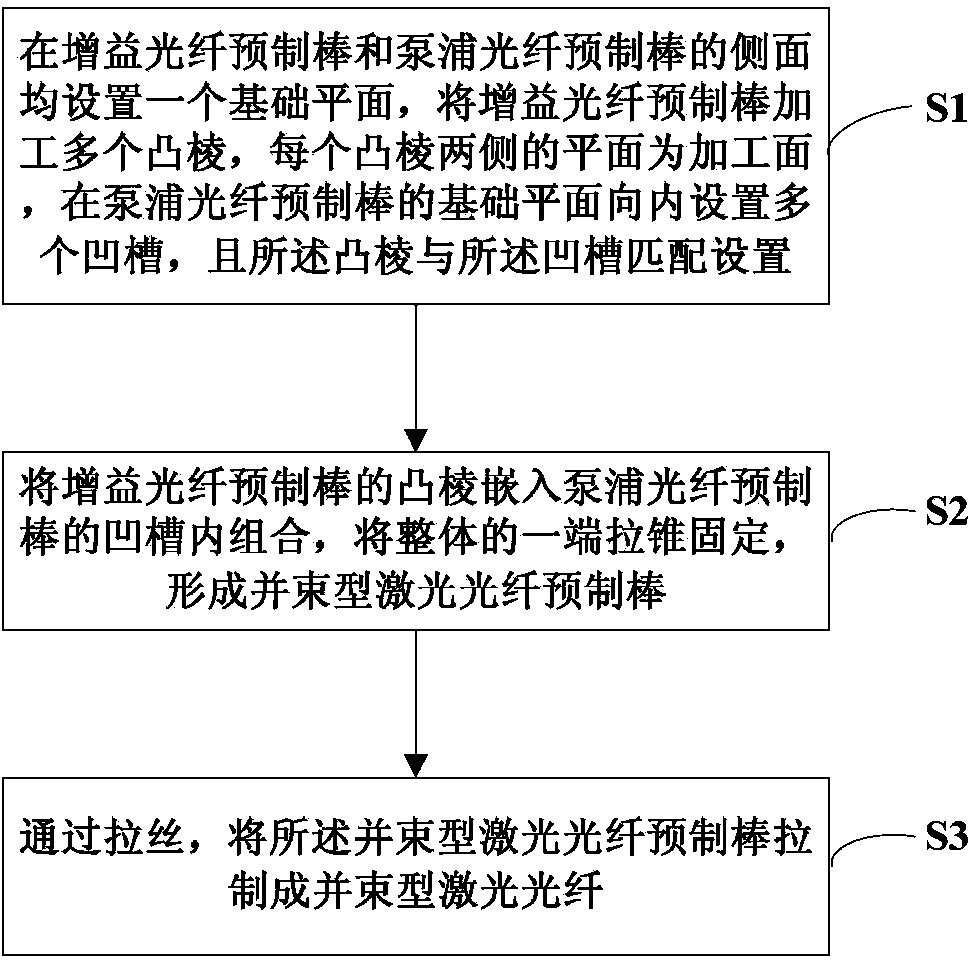

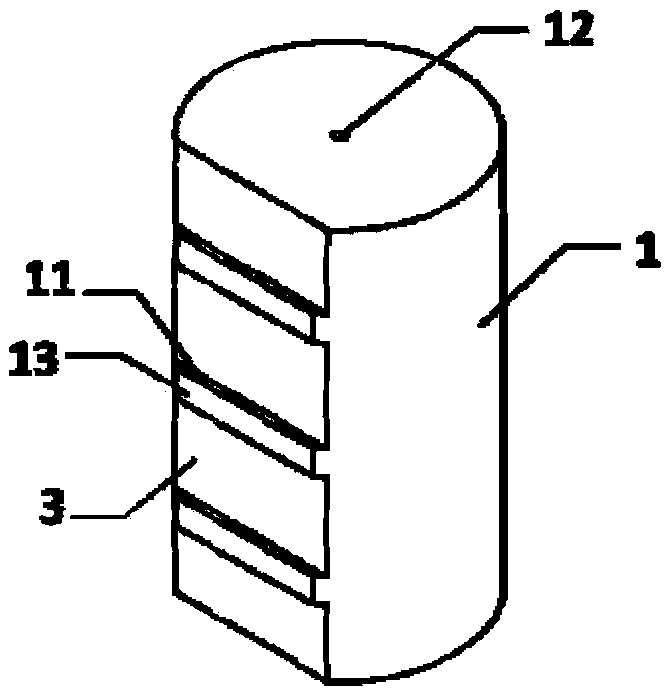

[0043] Such as Figures 3 to 7 As shown, the rare earth-doped gain fiber preform 1 in the core area is processed inwardly from the base plane 13 to form 25 ribs 11, and the height of the ribs 11 (that is, the distance from the processing plane 3 to the base plane 13) is 1.5mm , the length of the ribs 11 along the fiber axis is 10 mm, and the distance between the centers of two adjacent ribs 11 is 12 mm. The pump optical fiber preform 2 of the quartz component is processed inwardly from the base plane 13, and at the position corresponding to the rib 11 of the gain optical fiber preform 1, a plurality of rectangular grooves 21 are formed, and the processing of the grooves 21 The depth is 1.5mm.

[0044] Combine the processed gain fiber preform 1 with a rare earth doped core diameter of 1.7 mm and a cladding of 17.3 mm with the pump fiber preform 2 with a grooved cladding of 17.3 mm, that is, the convexity of the gain fiber preform 1 The rib 11 is embedded in the groove 21 of t...

Embodiment 2

[0049] Such as Figures 3 to 7 As shown, the rare earth-doped gain fiber preform 1 in the core area is processed inwardly from the base plane 13 to form four ribs 11, and the height of the ribs 11 (that is, the distance from the processing surface 3 to the base plane 13) is 4 mm. The ribs 11 have a length of 50 mm along the fiber axis, and the distance between the centers of two adjacent ribs 11 is 120 mm. The pump optical fiber preform 2 of the quartz component is processed inwardly from the base plane 13, and at the position corresponding to the rib 11 of the gain optical fiber preform 1, a plurality of rectangular grooves 21 are formed, and the processing of the grooves 21 The depth is 4mm.

[0050] Combine the processed gain fiber preform 1 with a rare earth doped core diameter of 3.6 mm and a cladding of 36 mm with the pump fiber preform 2 with a cladding of 36 mm after slotting, that is, the rib 11 of the gain fiber preform 1 Embedded in the groove 21 of the pump optic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com