Air returning window for dust-free workshop

A technology of dust-free workshop and air return window, which is applied in ventilation layout and other directions, can solve the problems of inconvenient disassembly, loud noise, loose window, etc., and achieve the effect of improving filtering effect, increasing filtering area and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

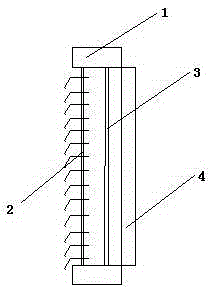

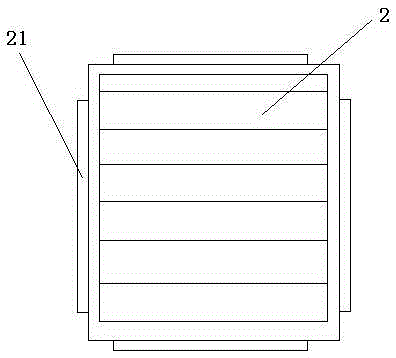

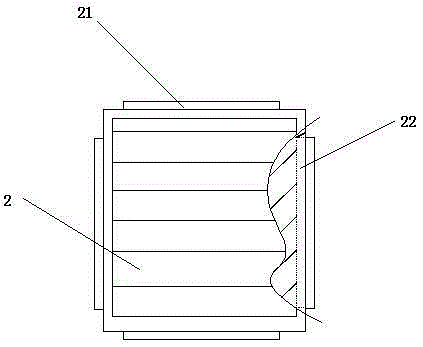

[0020] Such as Figure 1-5 As shown, a return window for a clean room includes a bottom frame 1 for fixing on a building, and a return air louver panel 2 fitted on the bottom frame 1, the bottom frame 1 and the return air louver panel 2 A filter device 3 is provided between them, and the filter device 3 includes a filter screen and a filter screen support frame 30, the filter screen is a non-planar filter screen with pleats, more specifically, as Figure 5 As shown, the filter net is a wavy curved surface filter net.

[0021] Grooves are provided on the inner walls around the bottom frame 1, the grooves include a first groove group (not shown), and the return air louver panel 2 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com