Hole-free disassembly and assembly type aluminum form

An aluminum formwork, non-porous technology, applied in formwork/formwork components, formwork/formwork/work frame connectors, on-site preparation of building components, etc., can solve the problem of poor flexibility and versatility, adjust the cavity size and other issues, to achieve the effect of large flexibility, improved efficiency and good structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

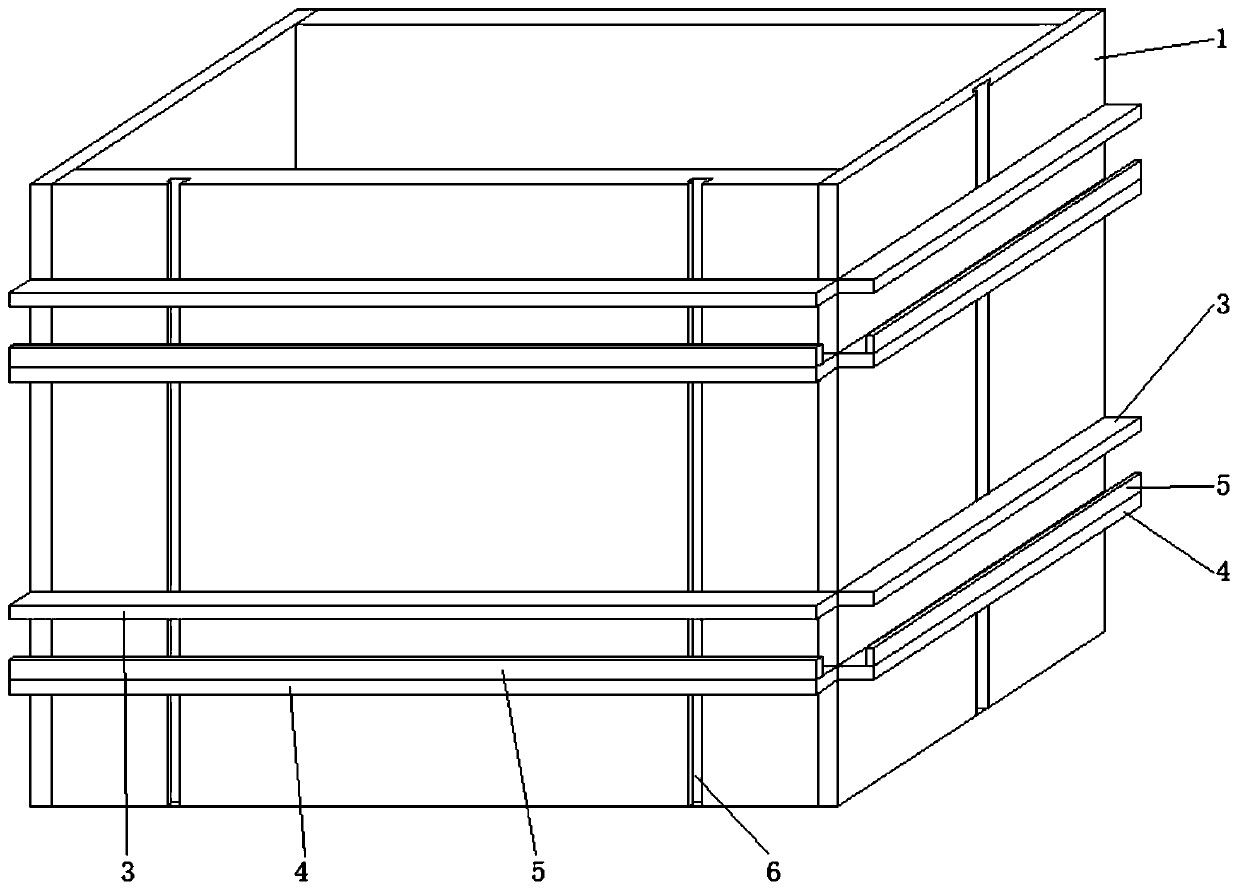

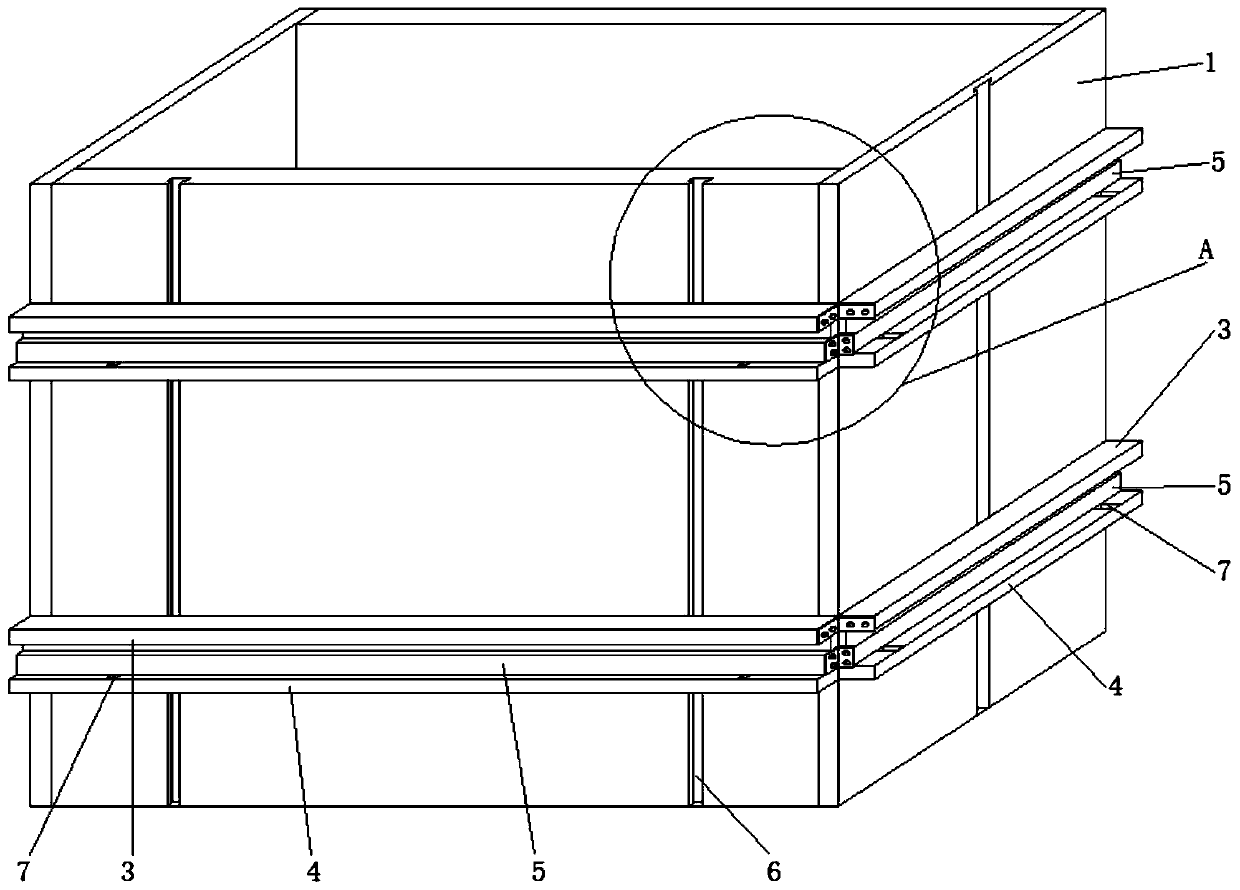

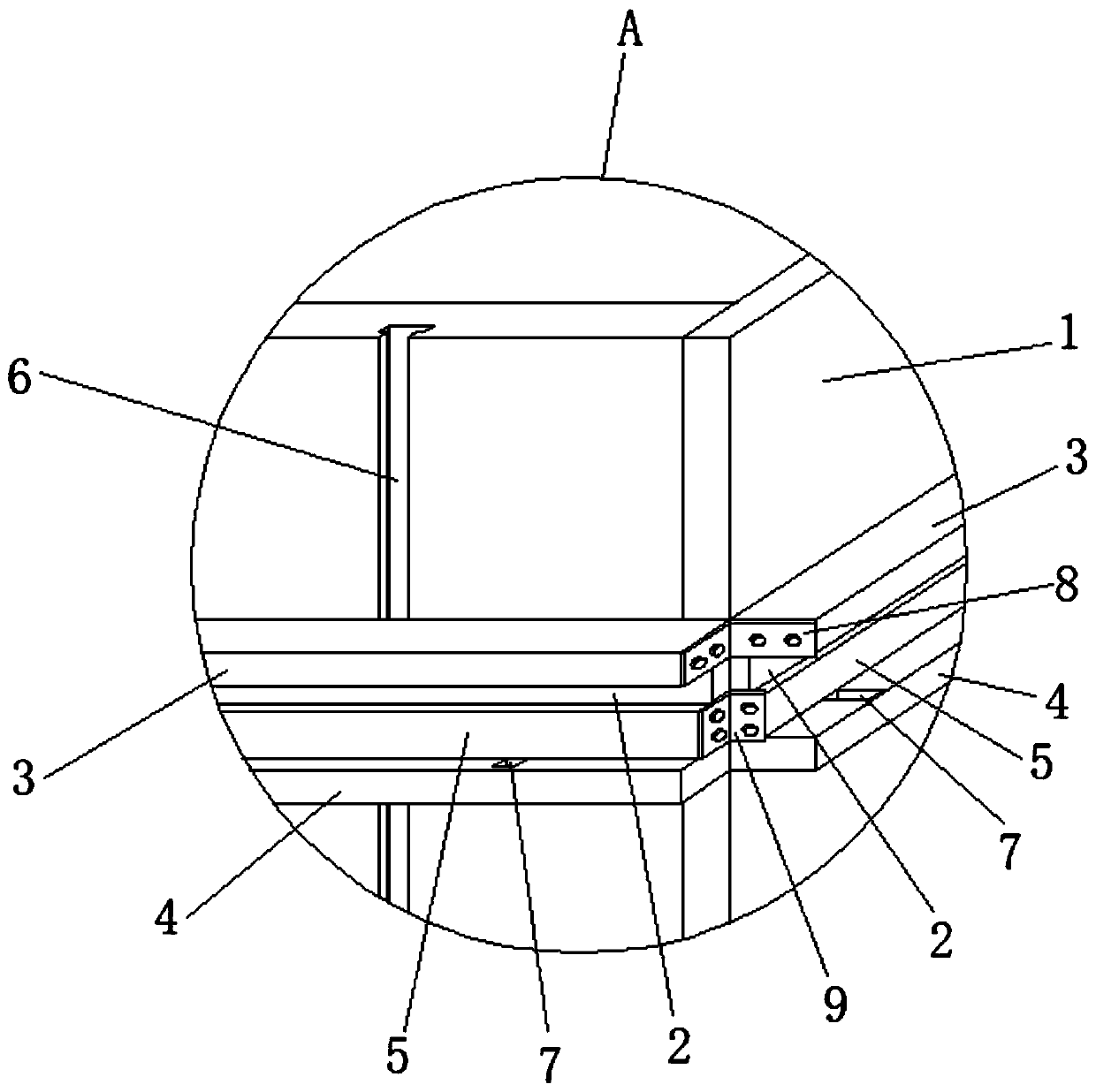

[0027] The invention provides a non-porous detachable aluminum formwork, specifically as Figure 1 to Figure 3 As shown, it includes formwork main body 1 and back flute 2, and an accommodating cavity for accommodating back flute 2 is arranged on the outside of formwork main body 1, and the accommodating cavity is composed of top plate 3, bottom plate 4 and baffle plate 5 arranged on bottom plate 4 The bottom plate 4 is fixedly connected with the formwork body 1, the top plate 3 is slidably connected with the formwork body 1 along the height direction of the formwork body 1, a group of first through grooves 7 are arranged on the bottom plate 4 along the width direction, and the bottom of the baffle plate 5 is provided with connecting rods and Stopper, the upper end of the connecting rod is fixedly connected with the bottom of the baffle plate 5, the lower end of the connecting rod is fixedly connected with the stopper, the connecting rod passes through the first through groove 7...

Embodiment 2

[0034] Such as Figures 4 to 6As shown, in this embodiment, the top plate 3 is provided with a second through groove 10 cooperating with the first through groove 7 along the width direction, and the second through groove 10 and the first through groove 7 are connected by fixing bolts 11, and the fixing bolts 11 The limit nut is screwed on the bottom. When this embodiment is in use, on the basis of connecting and fixing the adjacent two top plates 3 and the adjacent two baffle plates 5 through the first angle code 8 and the second angle code 9, the fixing bolt 11 is connected from the second through The groove 10 is passed through the first through groove 7, and the fixing bolt 11 is close to the baffle plate 5, and the limit nut is installed on the bottom of the bottom plate 4 to fasten it on the fixing bolt 11, so that the back flute 2 is more stable. Other structures are the same as the cabinet in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com