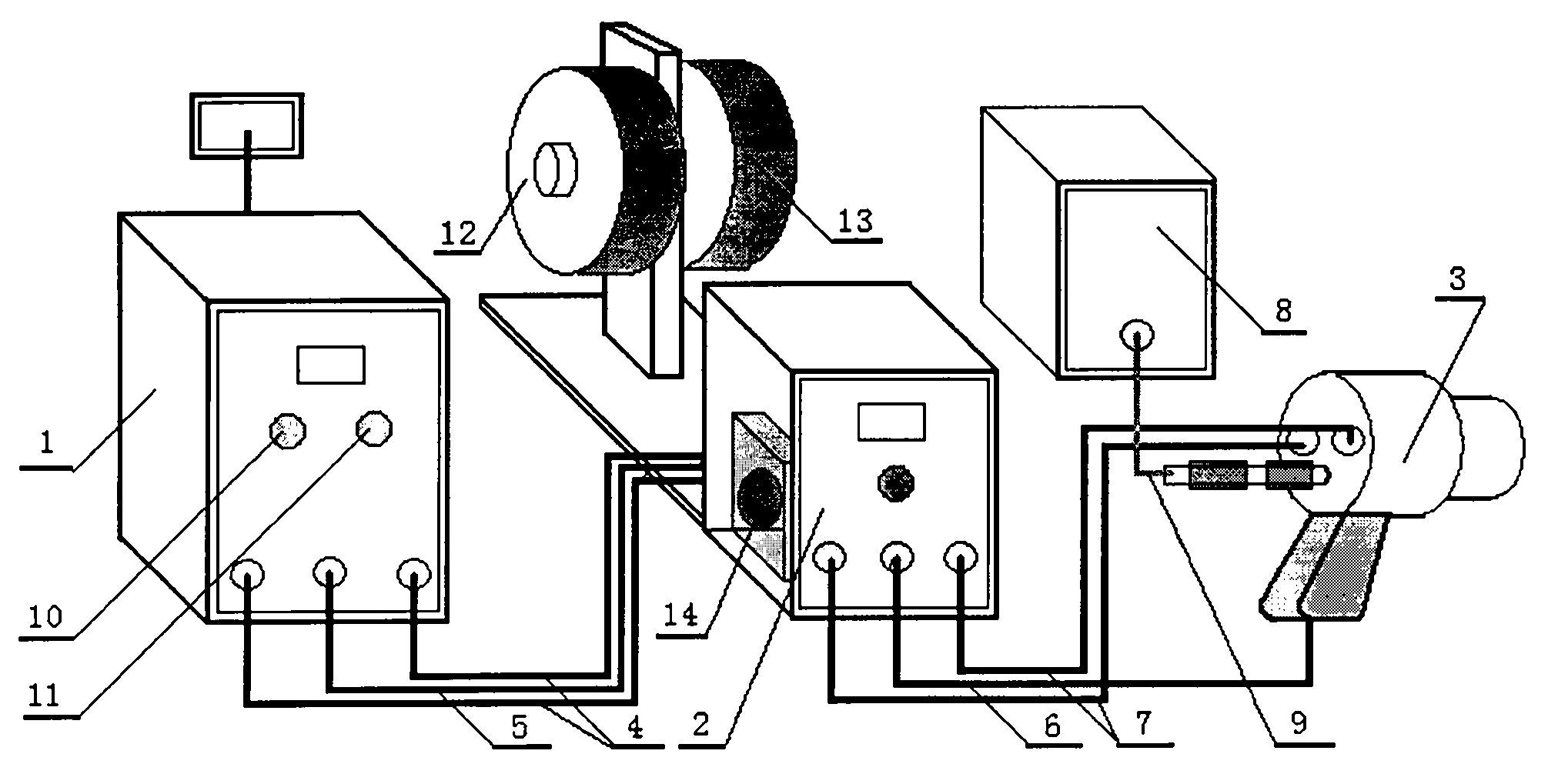

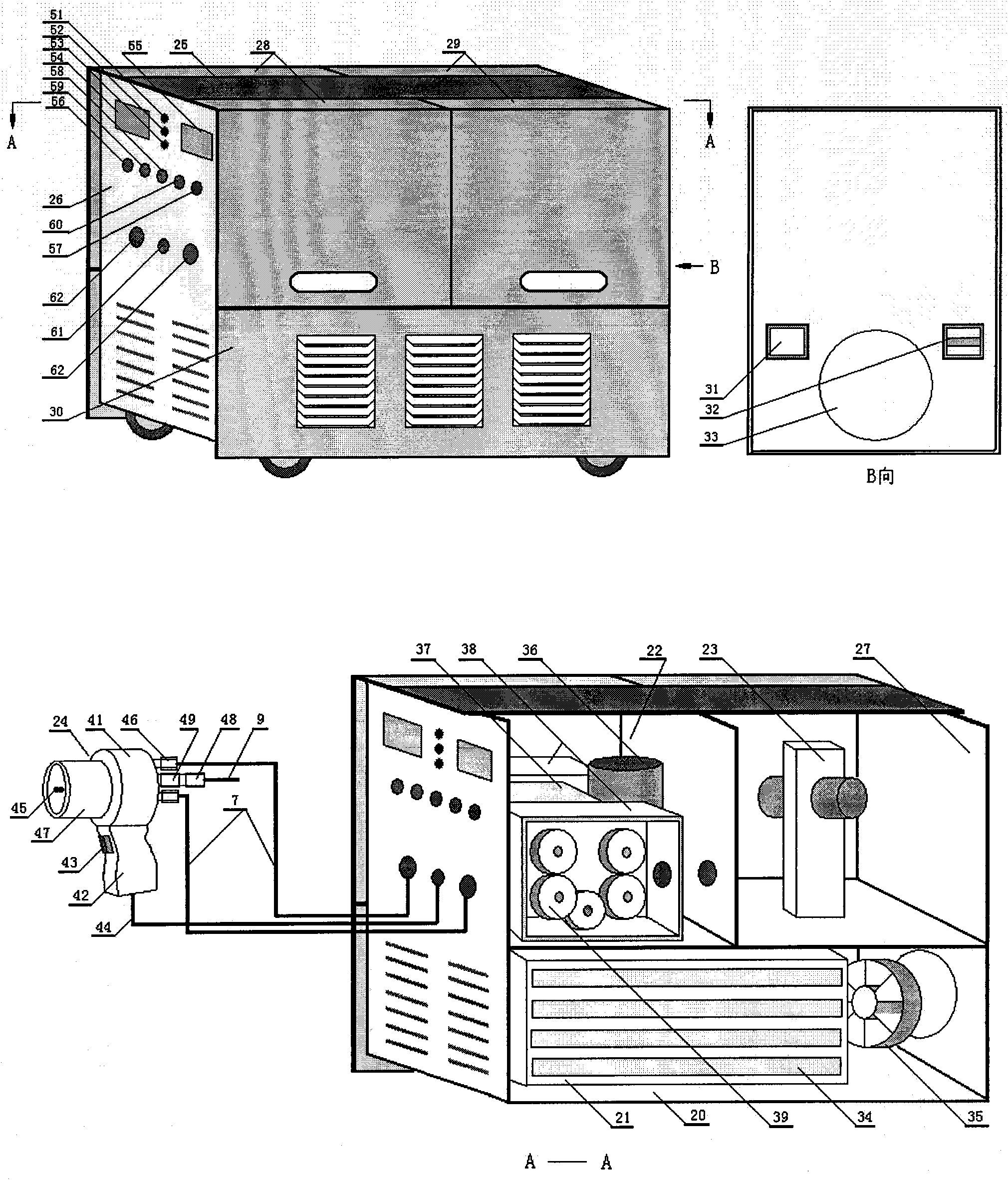

Integral push-wire-type electric arc spraying equipment

A kind of equipment and integrated technology, applied in the direction of arc spraying, coating, melt spraying, etc., can solve the problems of scattered external cables in the unit device, poor sealing of wire feeding device and wire reel, and no safety wire inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] On-site Spraying of Anti-Erosion and Abrasion Coating on Water Cooling Wall of Power Plant Boiler

[0091] 1. Conditions of use: The surface of the water cooling wall has been damaged after long-term use and needs to be repaired. The temperature of the water-cooled wall is about 300°C. During use, it is subjected to the erosion and wear of coal powder, the corrosion of coal smoke and high-temperature heat radiation. In the process, there will be no defects such as layer drop and block that affect performance.

[0092] 2. Coating design: According to the conditions of use and the requirements for coating quality, select NiCr / CrC spraying core wire, the specification and size of the spraying wire are all Φ2mm, and the coating thickness after spraying should be > 0.18mm.

[0093] 3. Spraying process: use the spraying equipment of the present invention, adopt manual operation spraying operation mode.

[0094] 3.1 Roughen the surface of the water-cooled wall: use the sandb...

Embodiment 2

[0100] Field Construction Spraying of Anticorrosion Coating on Gas Pipeline Surface

[0101]1. Current status of use: In the laying of gas pipelines in small and medium-sized cities along the coast, many pipelines are exposed to the humid atmosphere, and some pipelines are elevated in the air. After several years of use, the galvanized layer or paint protective layer on the surface appears. Exfoliation corrosion phenomenon. If the paint is repainted, the service life is relatively short. If the new pipeline is replaced, the gas must be stopped, and the construction period is long, which affects people's normal life, and the cost is also high. The method of spraying can solve these problems, but it is very inconvenient to work in the field and in the air. The spraying equipment of the present invention can realize the construction of the project conveniently due to its small size, light weight, few external cables, and flexible operation.

[0102] 2. Coating design: According ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com