Coal-rock composite roof difference scale anchor rod combined supporting method

A technology of composite roof and different scales, which is applied in rock roadway) composite roof and roadway (coal roadway), can solve problems such as regional instability, roof fall, cost waste, etc., to control the deformation of surrounding rock, improve the resistance of surrounding rock, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

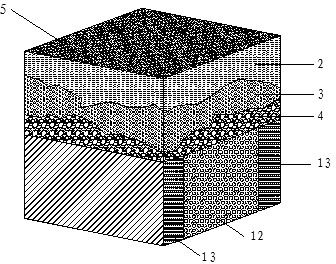

[0025] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0026] The coal-rock composite roof bolt joint support method with different scales of the present invention:

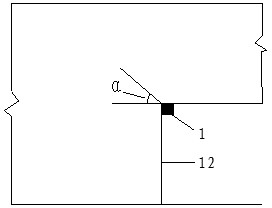

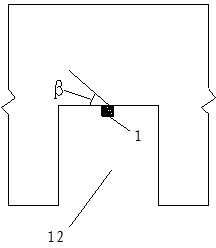

[0027] a. In the middle of the pre-excavated roadway roof, a ground radar 1 that emits electromagnetic pulses along the longitudinal and transverse planes along the excavation direction is placed, and multiple different angles are emitted to the longitudinal plane through the ground radar 1 α Electromagnetic pulses are emitted at many different angles along the transverse plane β EMP, multiple angles of emission of EMP across the β Corresponding to multiple angles of emitting electromagnetic pulses from the longitudinal plane α , constituting the emission of electromagnetic pulses in multiple directions of the product number of multiple angles in the vertical and horizontal planes; the multiple different angles emitted by the vertical plane α ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com