Patents

Literature

96results about How to "Effective control of deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

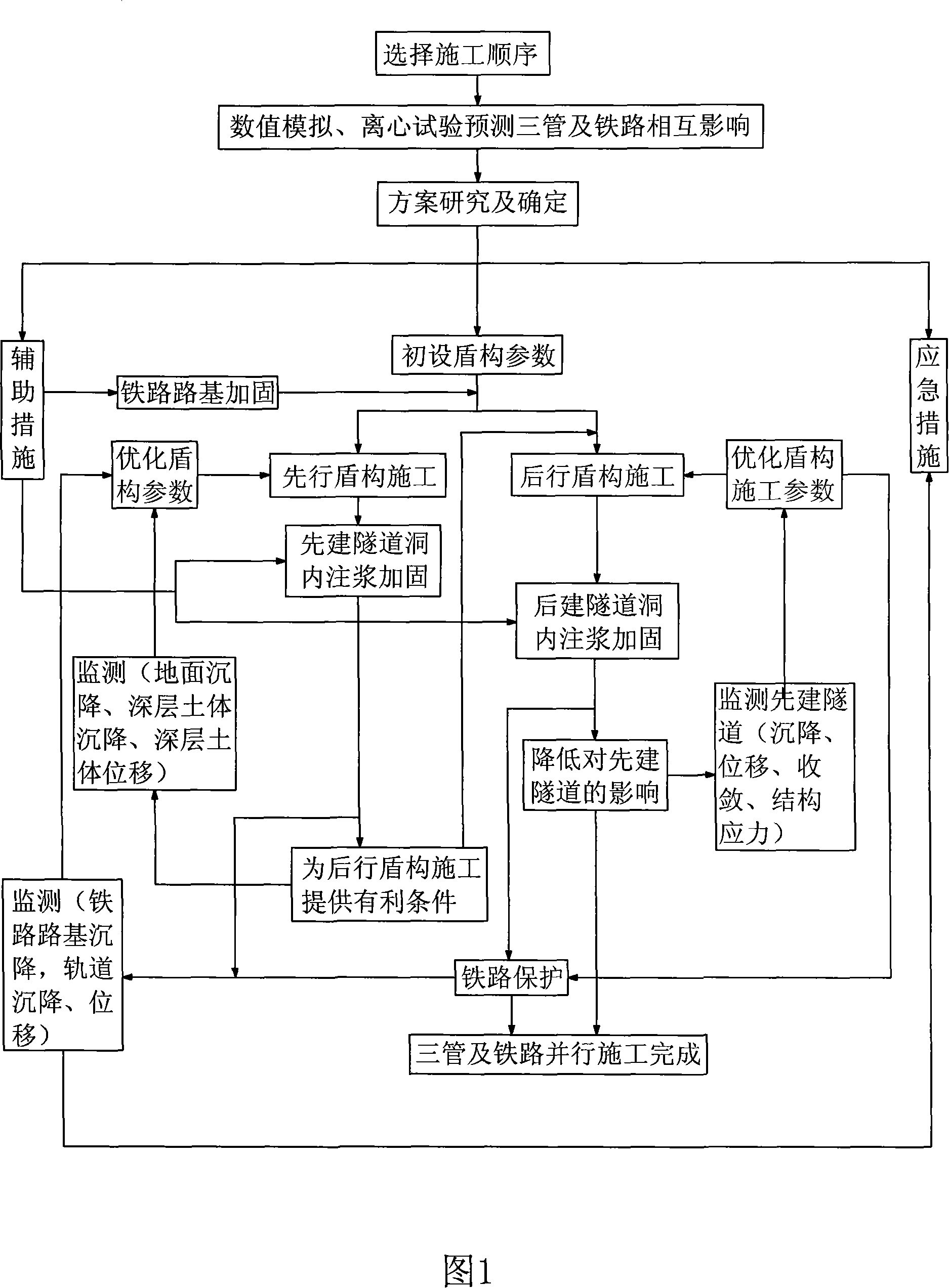

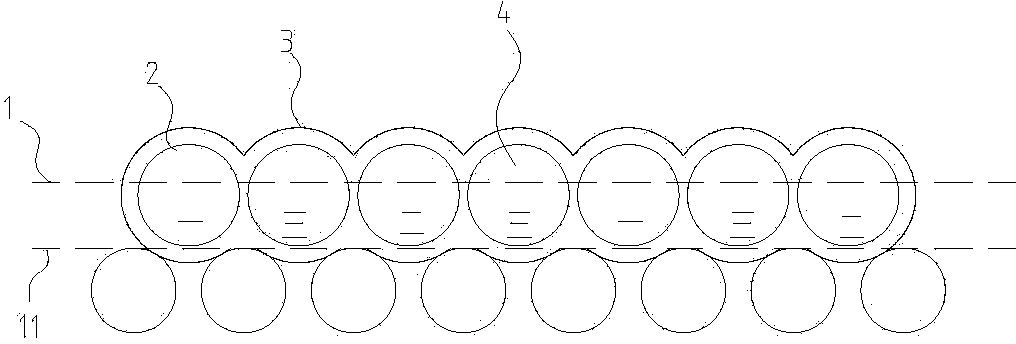

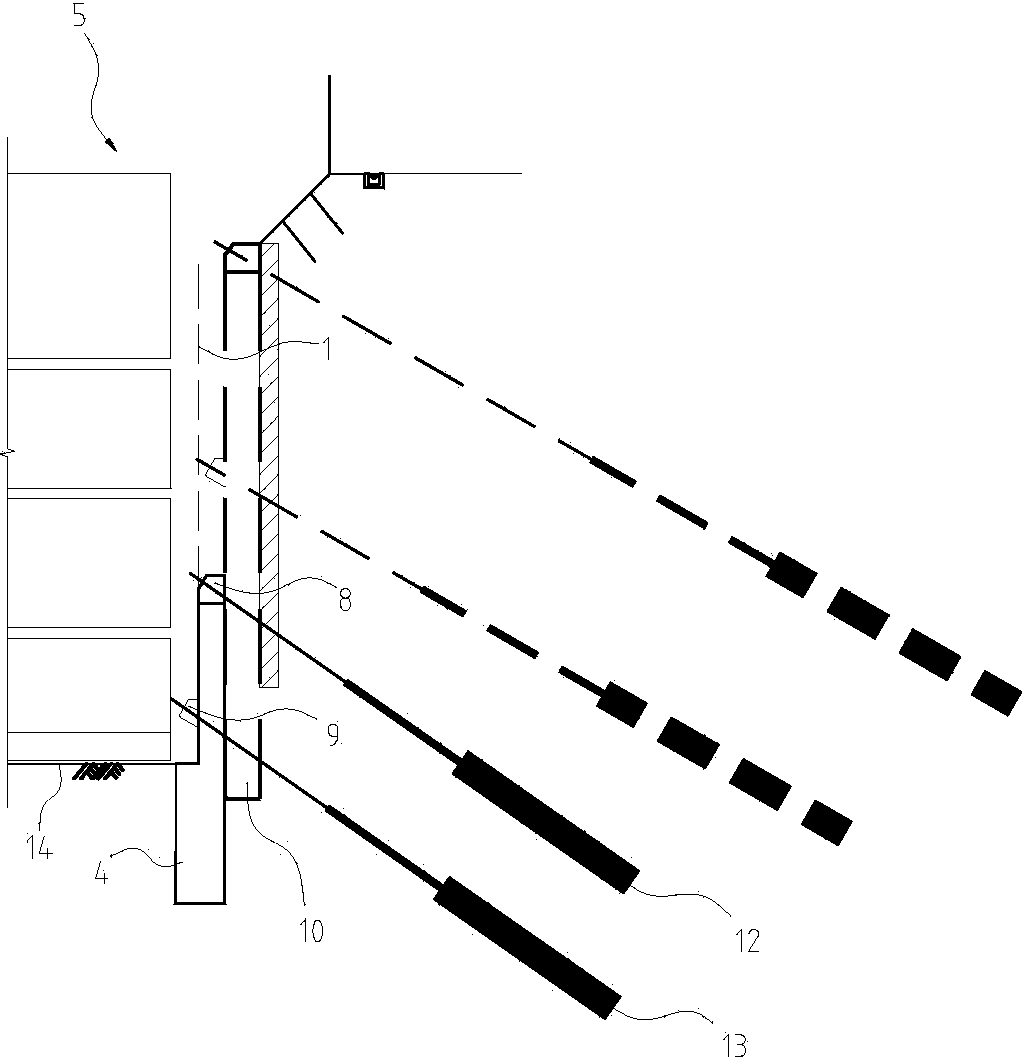

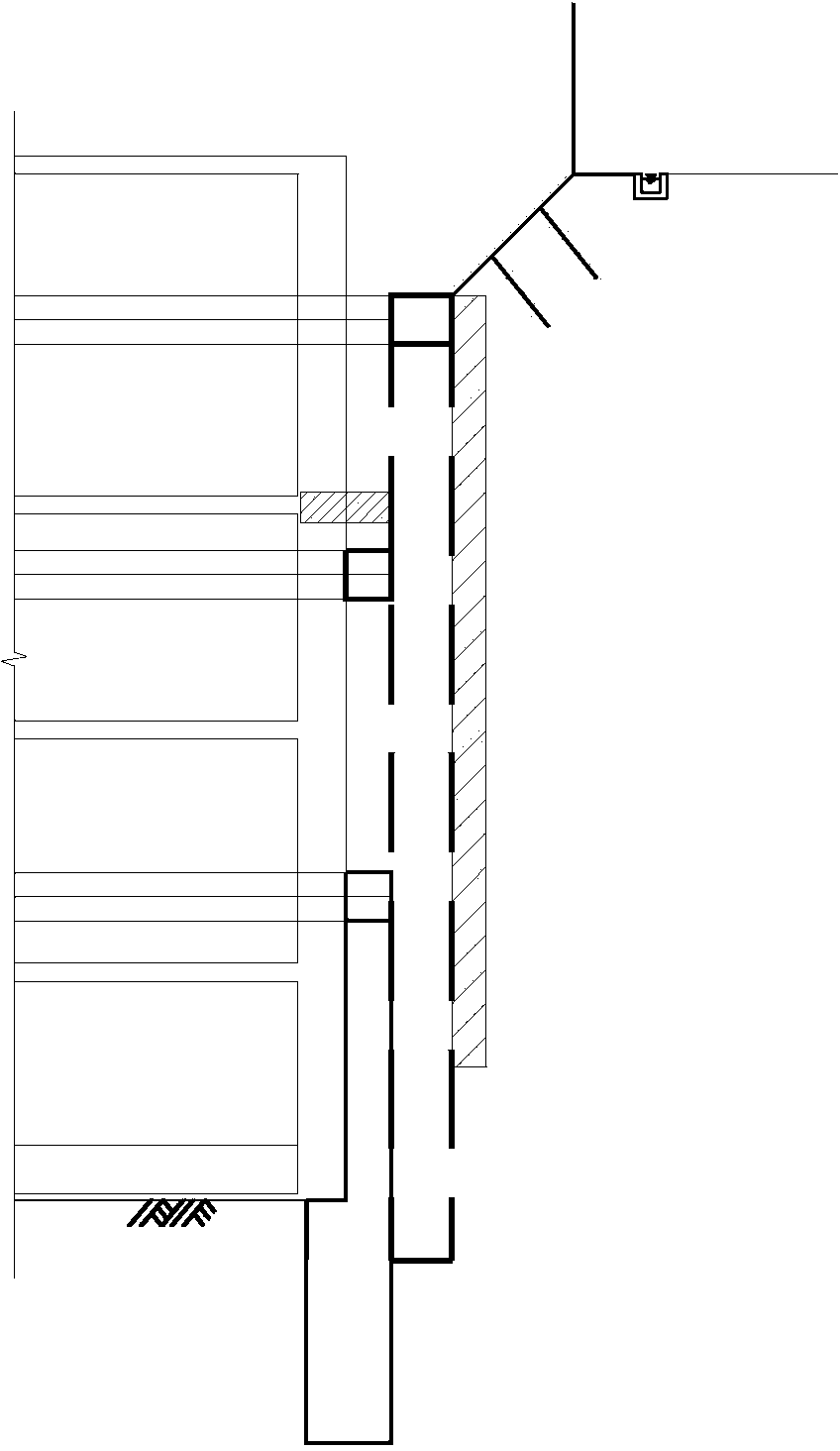

Shield construction method for three-line parallel under-passing trunk railway tunnel

ActiveCN101126318AEffective control of deformationEffective control of displacementUnderground chambersTunnel liningRailway tunnelEconomic benefits

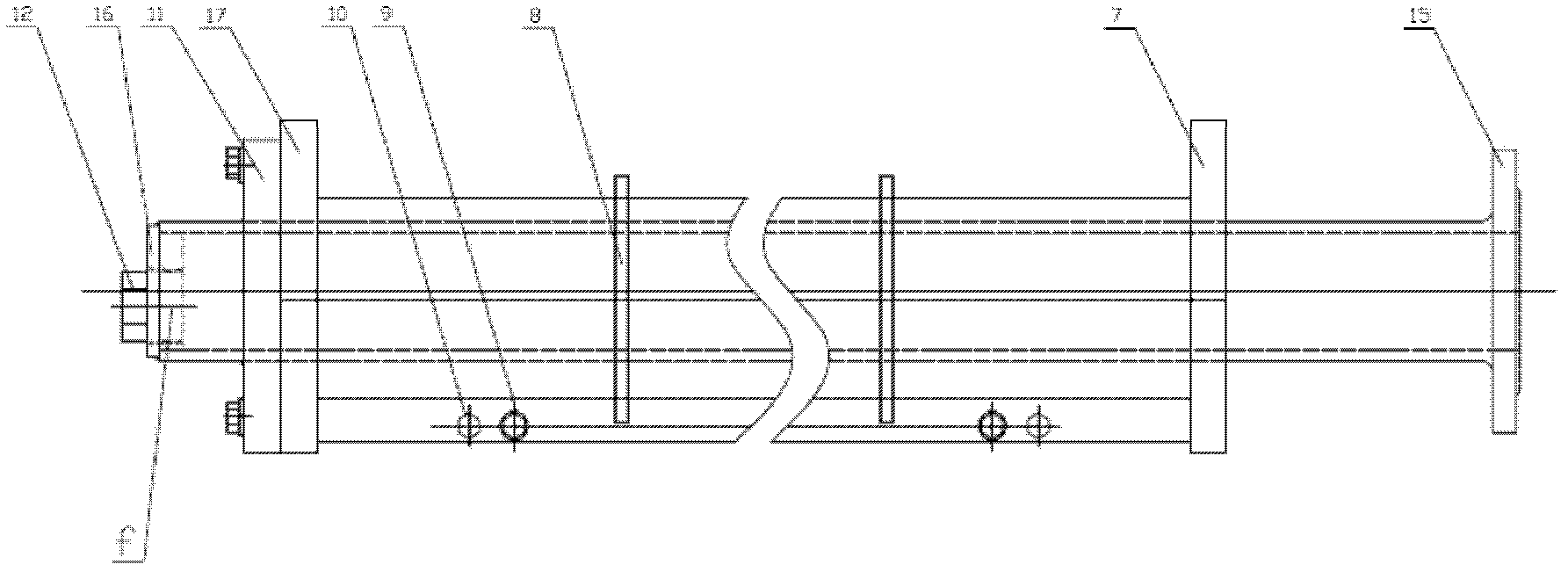

The invention discloses a shield construction method of digging three parallel tunnels under a trunk railway, which belongs to the field of tunnel construction technology. The construction method of the invention comprises the procedure that: the model analysis on each construction sequence and method is made by a three-dimensional finite element and the shield construction sequence is selected; to select the reinforcement project of the railway bed is selected according to the influence degree of the dynamic stress, the load-carrying structural model is adopted to calculate and decide the shield area reinforcing bars enhancement project under the dynamic load of the railway train; the construction parameters are selected according to the test results and the performance of the shield machine, the front earth pressure is reasonably set , the synchronizing mortar injection is enhanced, the forward digging speed and the axis deviation are strictly controlled, the secondary mortar injection is made, the foam or mud is filled by utilizing a pre-embedded injection hole; the strict monitoring measures to monitor the shield construction process is adopted so that the construction unit can adjust the construction parameters in time and guarantee the construction safety. The invention not only guarantees the construction quality and the construction safety of the project but also creates good economic benefit.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

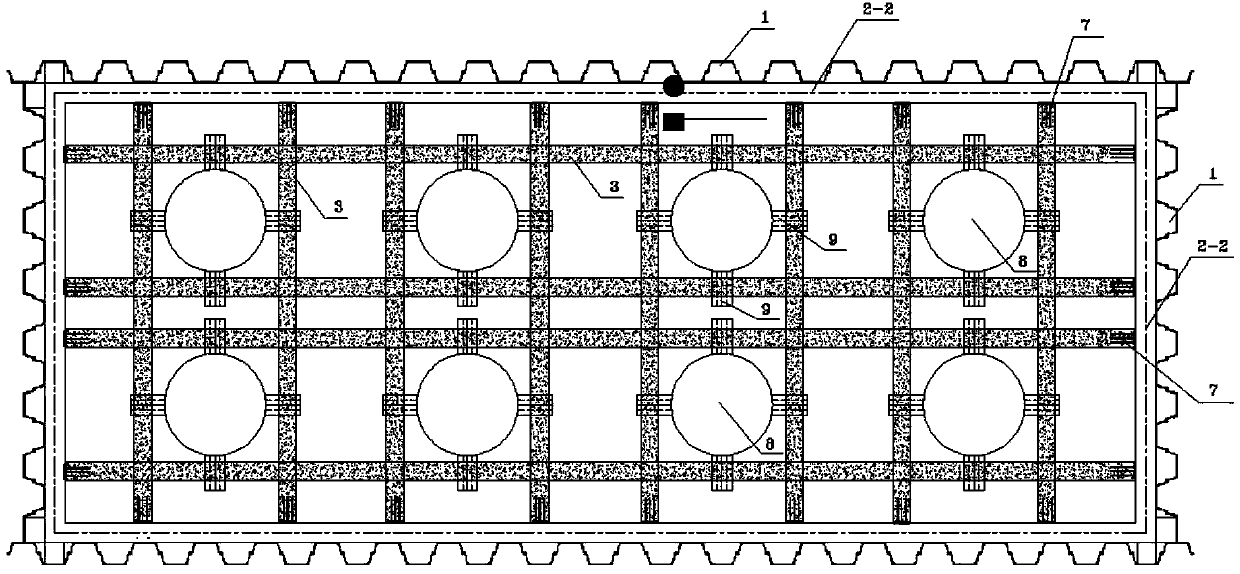

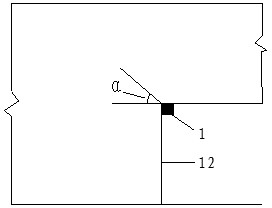

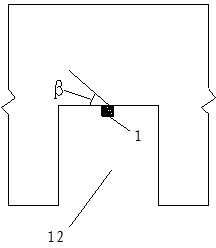

Manual hole digging non-uniform pile support construction technology

ActiveCN104264688AEasy constructionDoes not affect the constructionProtective foundationExcavationsBasementProof construction

The discloses a manual hole digging non-uniform pile support construction technology for construction along the inner side of the former support structure, the construction steps are as follows: (1) digging the first order, the second order and the third order hole digging piles according to the process of every three for one; (2) forming crown beam at the top of pile for enhancing support structure integral rigidity, having layering construction for horizontal support or anchor cable according to the design calculation requirement, after getting the design strength requirement, excavating the foundation trench earthwork to the bottom in the foundation trench; (3) making level for the manual hole digging non-uniform pile, having the water proof construction, making the basement bottom plate, casting the bottom plate concrete with the former support pile; (4) removing the second strengthening anchor cable or removing the support, finishing the basement structure; (5) extending the rebar in the hollow part of the manual hole digging pile into the basement bottom plate as basement structure pile and anti-floating pile. The manual hole digging non-uniform pile support construction technology solves the problem that the big diameter strengthening support pile construction machinery cannot be contained for the inner support at upper part or convex waist beam while the remain construction space between the support pile and the basement outer side line is small.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

Supporting method of permeable soft broken rock stratum roadway

InactiveCN103603675AEffective deformationEffectively closedUnderground chambersTunnel liningSteel barCement slurry

The invention relates to a supporting method of a roadway in a coal mime, particularly to a supporting method of a permeable soft broken rock stratum roadway. The supporting method aims at solving the problems that soft broken rock stratum roadways especially permeable soft broken rock stratum roadways are poor in supporting effect, high in cost and the like. The supporting method comprises the steps of first concrete spraying; combined support through high strength deformed steel bar anchor rods and diamond metal nets; anchor cable installation; secondary concrete spraying; installation of chemical pulp grouting anchor rods; installation of cement slurry grouting anchor rods.

Owner:张瀚

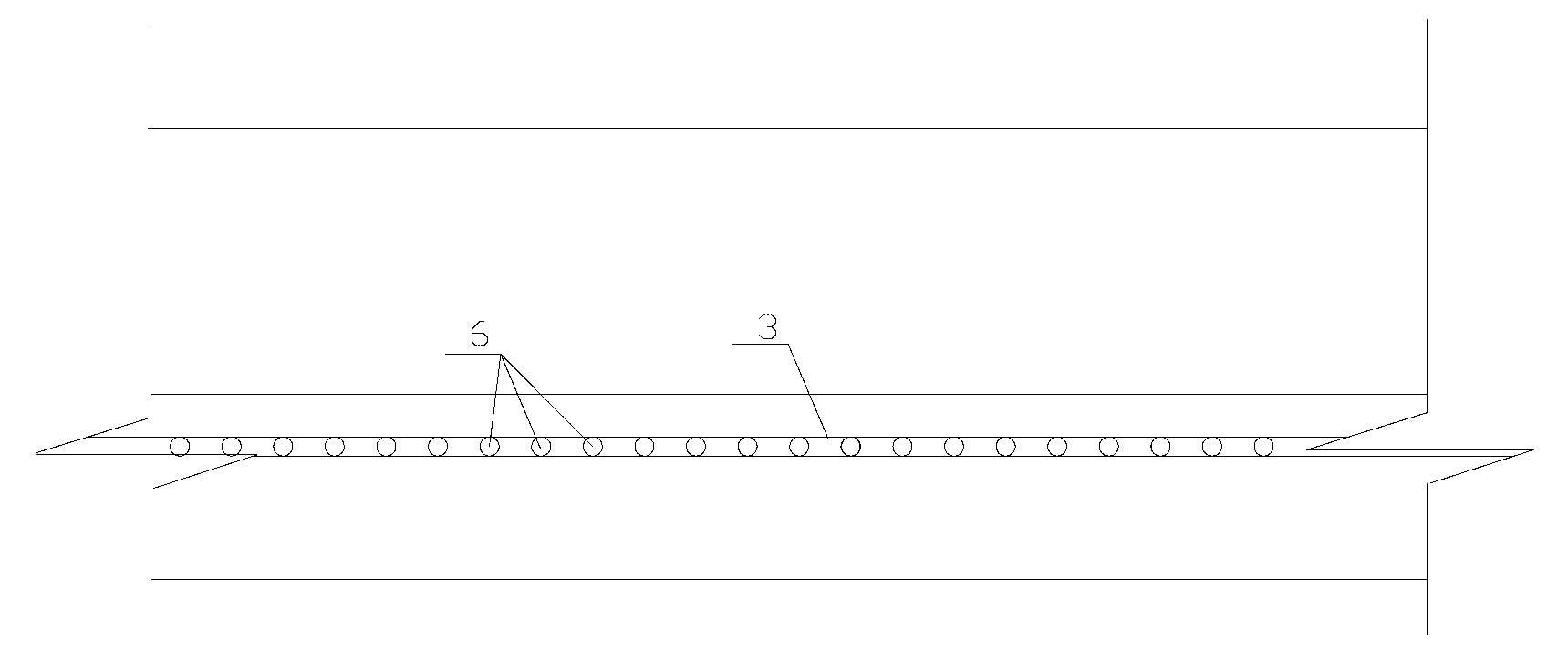

Steel sheet pile cofferdam structure construction method

The invention discloses a steel sheet pile cofferdam structure construction method which comprises the steps that (1) an inner side locating steel pipe pile and an outer side locating steel pipe pile are arranged on the inner side and the outer side of a steel sheet pile in a ramming mode, and an upper layer plane locating structure is fixedly arranged on the inner wall of the upper portion of the outer side locating steel pipe pile; (2) a cantilever beam which is connected with a lower layer precast concrete supporting whole system through a hanging rod is arranged on the top of a steel protecting cylinder; (3) an upper layer enclosing purlin is arranged on the inner side locating steel pipe pile, a steel sheet pile is inserted between the upper layer enclosing purlin and the upper layer plane locating structure in a ramming mode, the steel sheet pile is welded with the upper layer enclosing purlin in an inserting mode, and then an upper layer steel inner support is fixedly arranged in the upper layer enclosing purlin; (4) water in the steel sheet pile cofferdam is extracted out, a bracket is welded to support a lower layer precast concrete inner support, then the steel sheet pile and the lower layer enclosing purlin are welded, finally the hanging rod is removed, and the cantilever beam is detached; and (5) bearing platform concrete construction is carried out. The vertical accuracy of the steel sheet plate can be effectively controlled with the method.

Owner:CHINA CONSTR SIXTH ENG DIV CORP +1

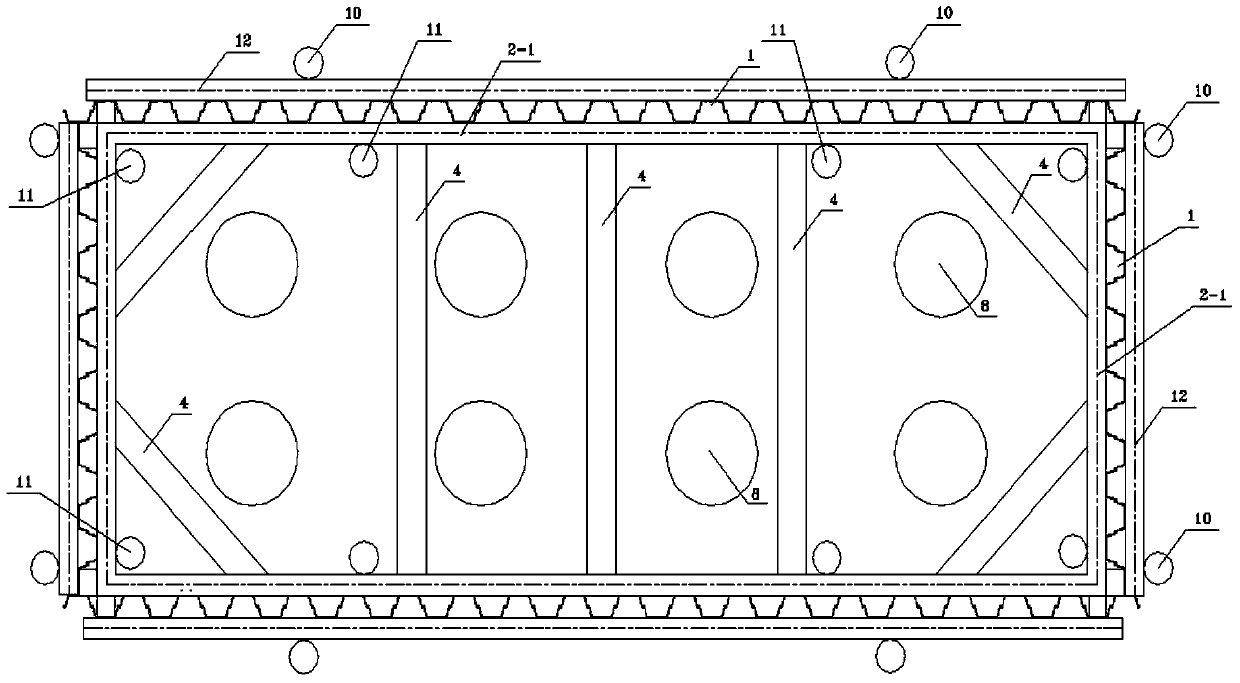

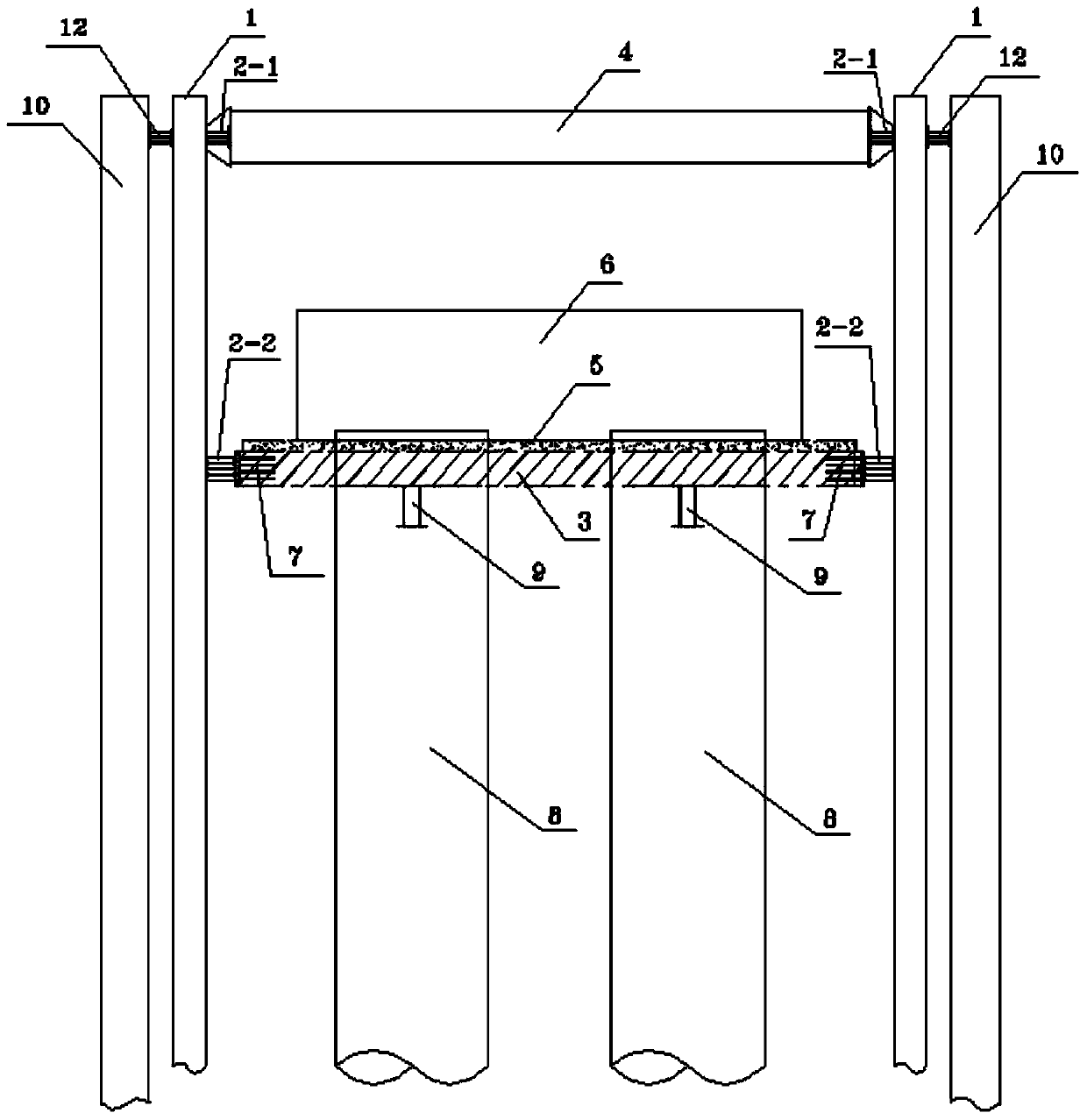

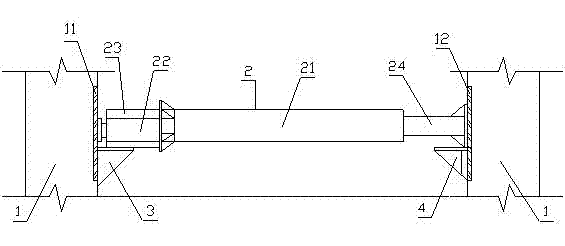

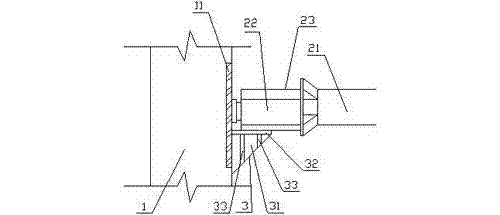

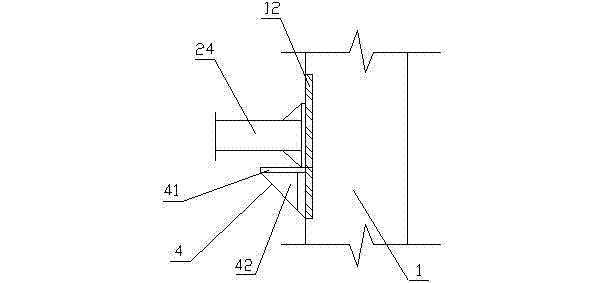

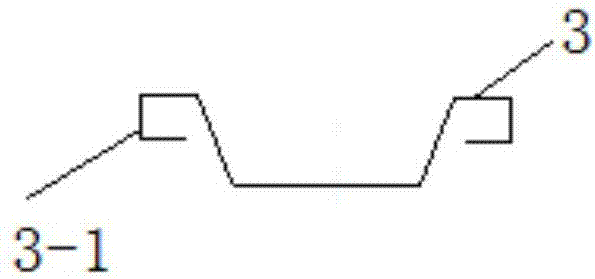

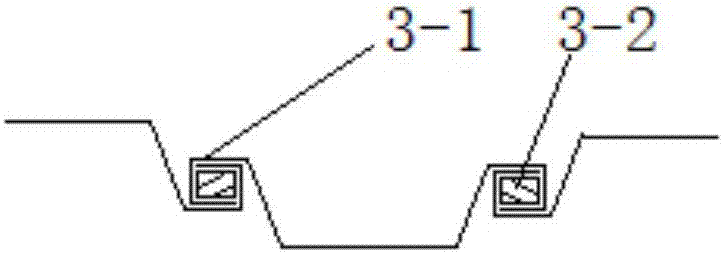

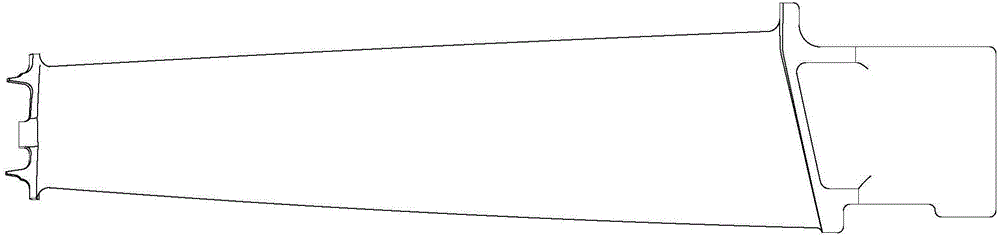

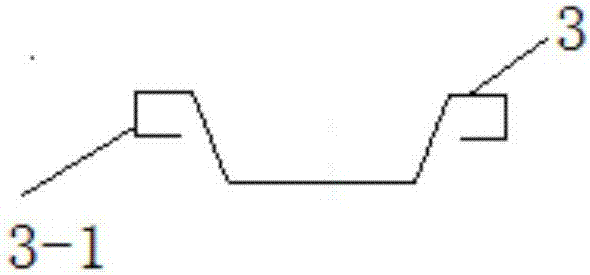

Pit supporting system and installation method

ActiveCN102345295AFast constructionEffective control of deformationArtificial islandsExcavationsSupporting systemEngineering

The invention provides a pit supporting system and an installation method. The pit supporting system comprises a diaphragm wall which is arranged on the surface of a pit body, wherein a first steel plate is longitudinally arranged on one side of the diaphragm wall, a second steel plate is arranged on the diaphragm wall on the side opposite to the side of the first steel plate, a first support is installed on the first steel plate, a second support is installed on the second steel plate, and the first support and the second support are arranged at the same height of a pit; and the two ends of a retractable steel support are respectively arranged on the first support and the second support, and the first steel plate is abutted against the second steel plate. By arranging the supports on the diaphragm wall in the pit to lift the retractable steel support, the effects of reducing construction cost, improving engineering quality, accelerating pit construction and effectively controlling pit deformation are achieved.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

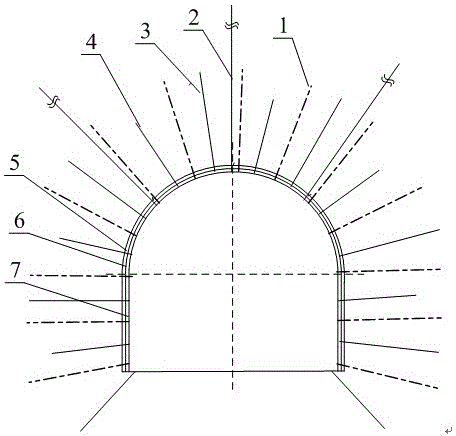

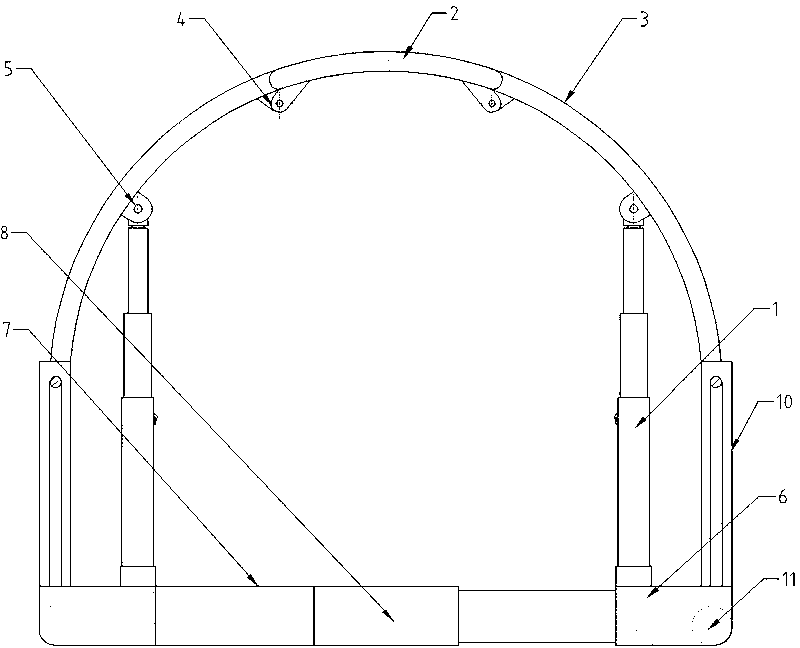

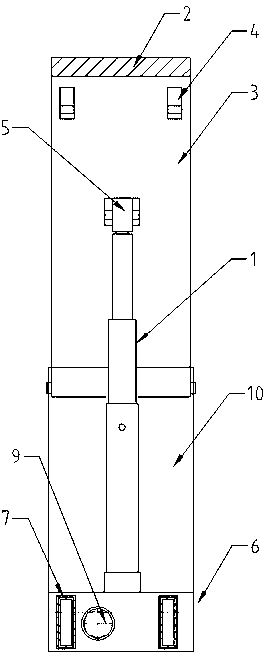

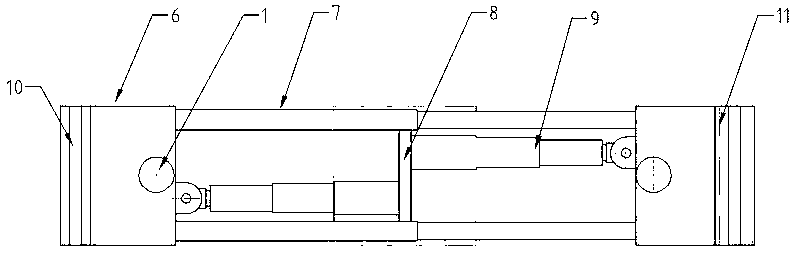

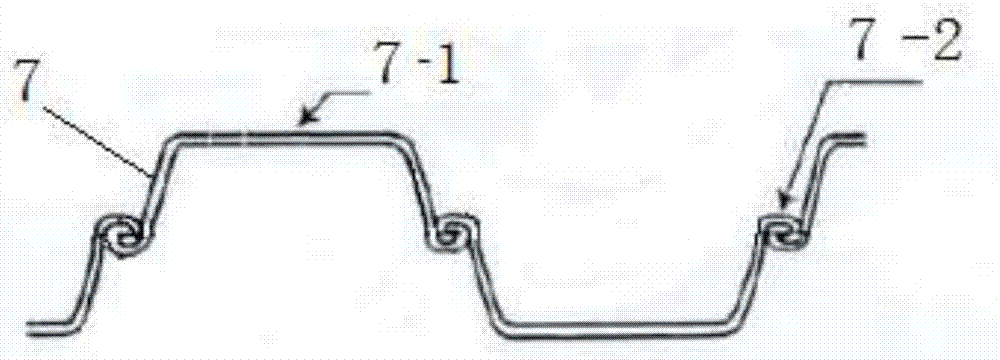

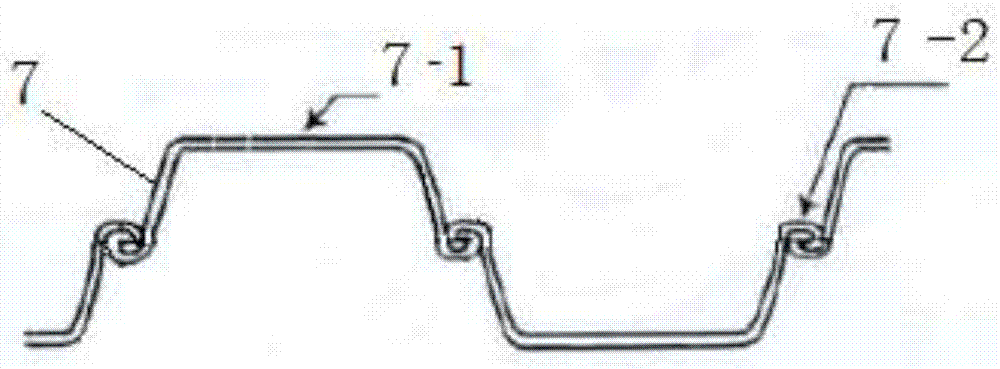

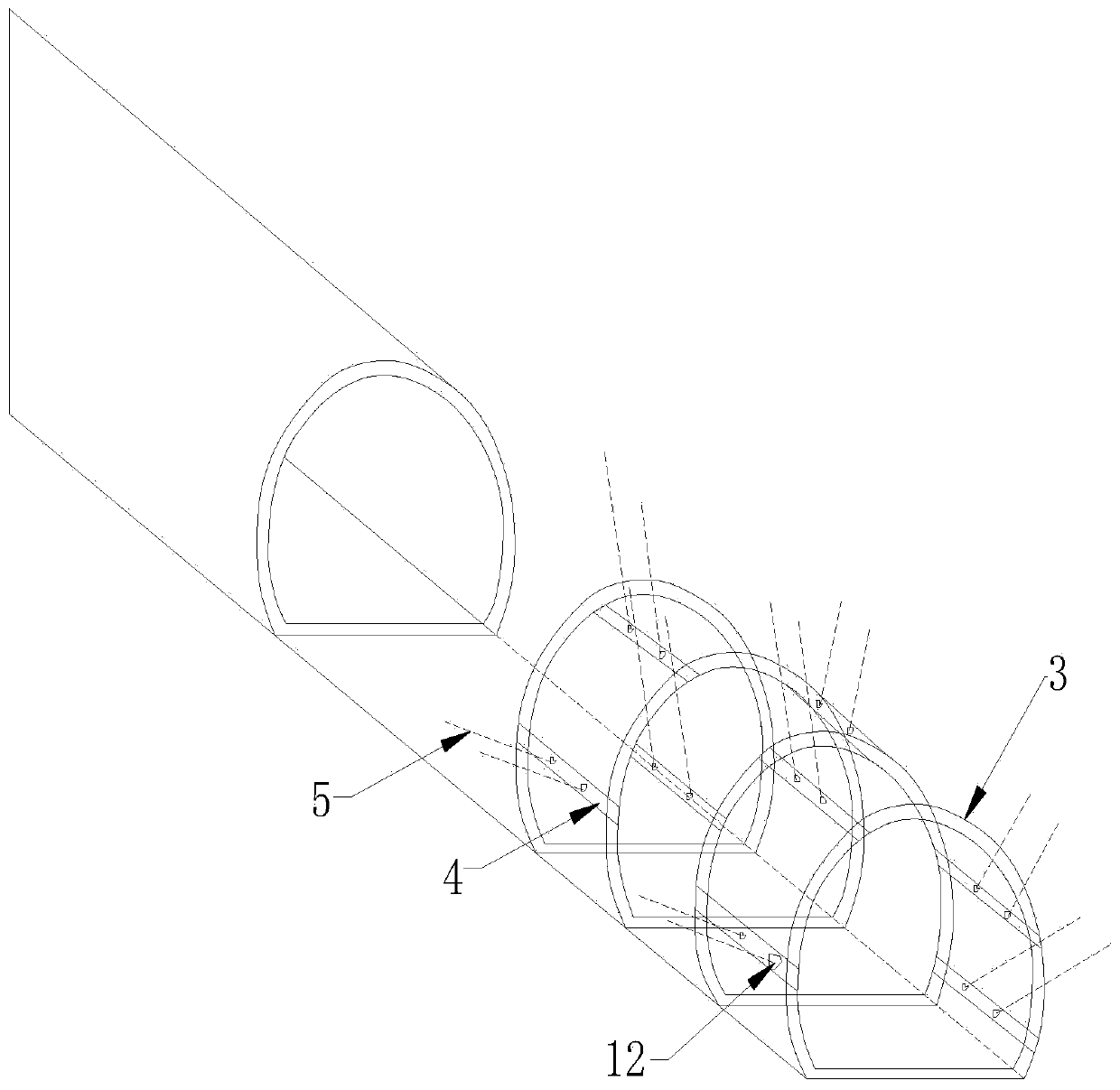

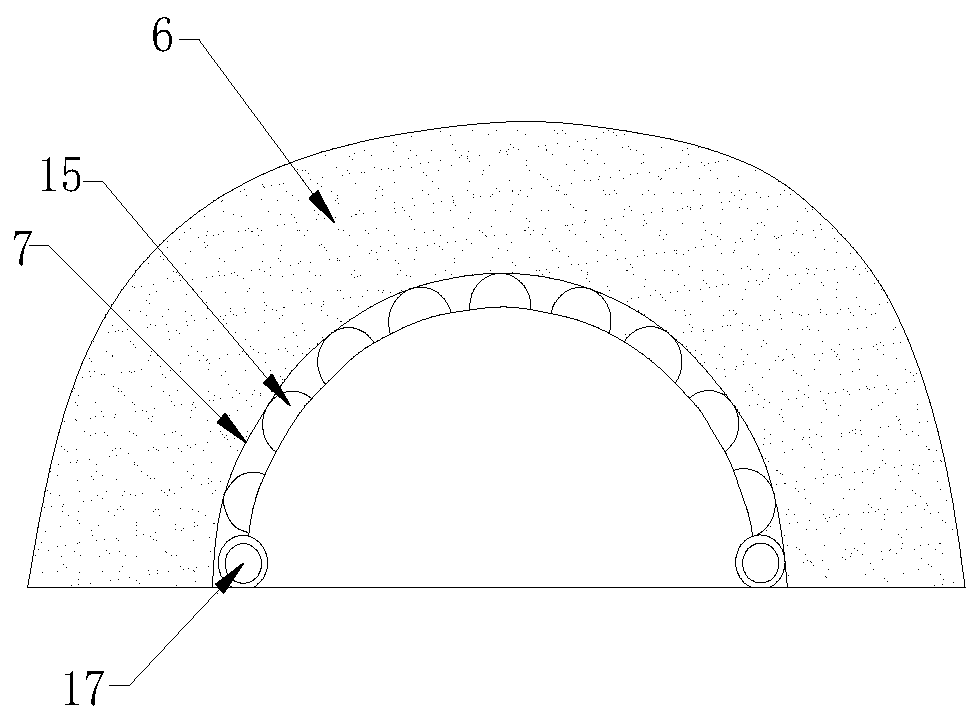

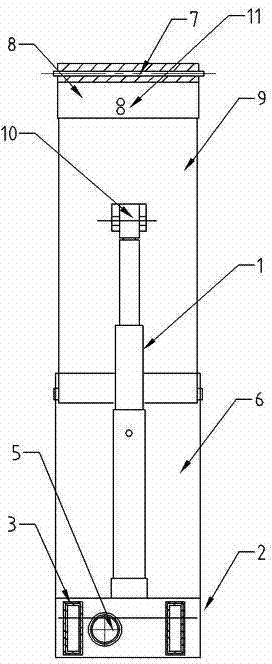

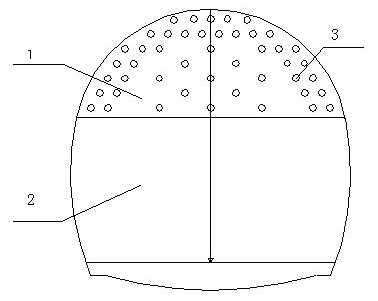

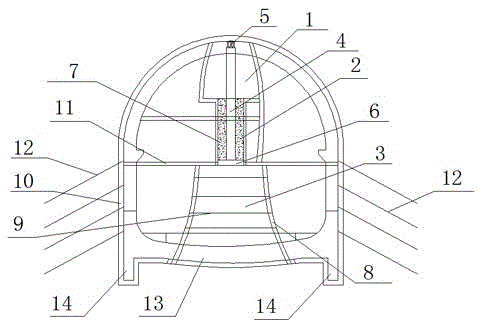

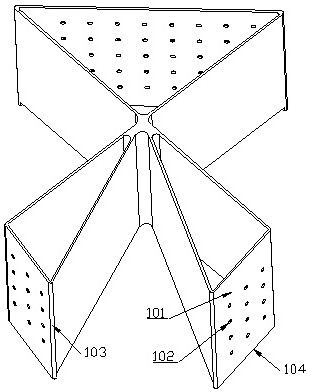

Soft rock roadway whole digging shield support

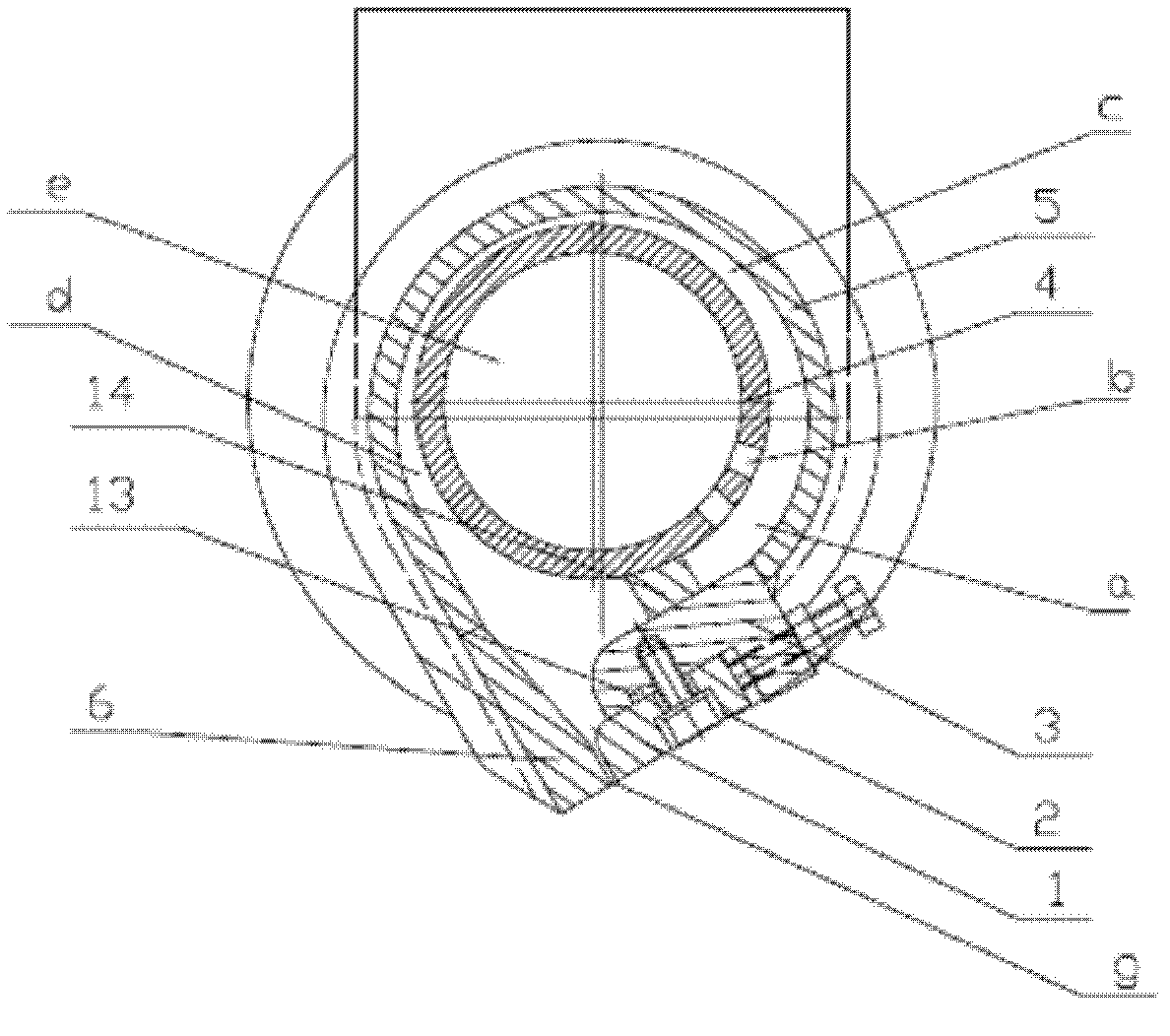

ActiveCN103104267AControl deformationLarge stretching roomProps/chocksEngineeringCompressive strength

The invention relates to a soft rock roadway whole digging shield support and belongs to the field of mining machinery manufacturing and application. The soft rock roadway whole digging shield support is composed of a semicircle protective arch, two hydraulic support pillars (1) which are arranged on the left side and the right side and a support seat. The upper ends of the two hydraulic support pillars (1) are connected with the semicircle protective arch respectively through a supporting lug (5) and a connecting pin. The lower ends of the two hydraulic support pillars (1) are respectively fixed on pillar fixing seats (6) of two sides of the support seat. Two groups of parallel telescopic guide rails (7) between the two pillar fixing seats(6) are connected to form the support seat. A pipe bending cylinder fixing seat (8) and two lateral pipe bending cylinder (9) are arranged in the middle of the middle portion of the two groups of parallel telescopic guide rails (7). The periphery of the soft rock roadway whole digging shield support can simultaneously bear pressure, compressive strength is high, bearing force is large, operation is convenient, and combination between components is tight. Through optimization design, from the aspects of convenient tunnel construction, the structure innovation and the like, Security, adaptation, technical advancement and economy of a soft rock supporting engineering are entirely improved.

Owner:范炳辉 +1

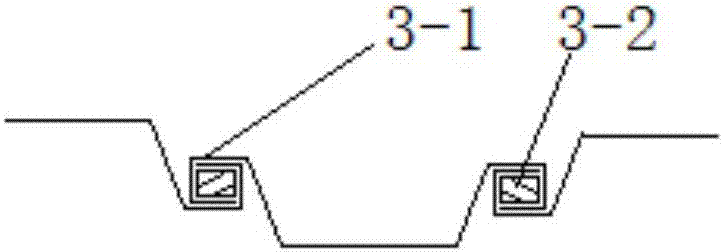

Enclosure for continuous wall foundation pit formed by steel cylinders or steel plate piles adopting seal grooves and occlusion structures and construction method of enclosure

PendingCN107268636AImprove mechanical propertiesGuarantee smooth implementationExcavationsBulkheads/pilesStructural engineeringPipe

The invention relates to an enclosure for a continuous wall foundation pit formed by steel cylinders or steel plate piles adopting seal grooves and occlusion structures. The steel cylinders or steel plate piles adopting the seal grooves are connected to form the continuous pile wall so as to form the foundation pit enclosure, according to the steel cylinders or steel plate piles with the seal grooves, at least one seal groove is formed at the connecting positions of steel plates or piles of steel cylinder piles, the cross section of each groove is in a convex arc shape, a concave shape or a polygon shape, a matched pipe is inlaid in each groove, the steel plates or steel cylinder piles and the pipes in the grooves are jointly and independently tampered into the stratum, pipe cavities in the grooves are left or waterproof sealing materials are injected into the pipe cavities to serve as sealing layers at the connecting positions of the steel plates or the piles of the steel cylinder piles; the cross section of the connecting positions of the steel plates or the piles of the steel cylinder piles is in a hook shape or concave-convex matched or third filling block filling connecting shape; and one or more sealing grooves are formed in the pile connecting positions.

Owner:JIANGSU GREEN RIVER ENVIRONMENTAL TECH CO LTD

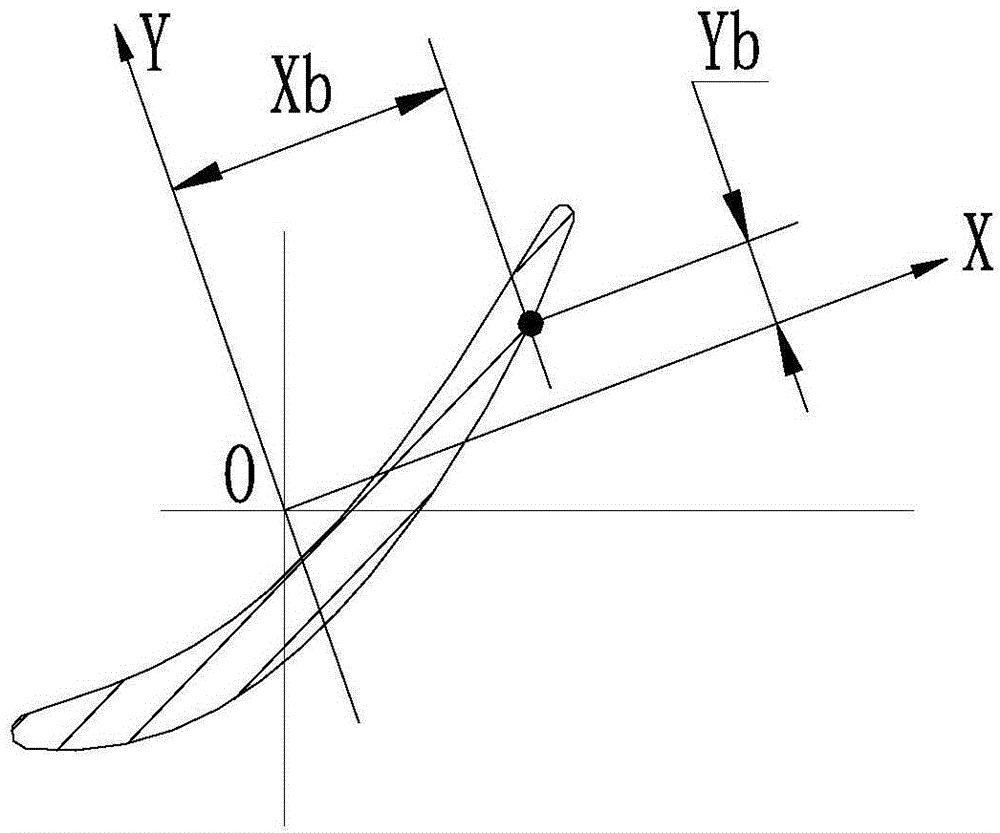

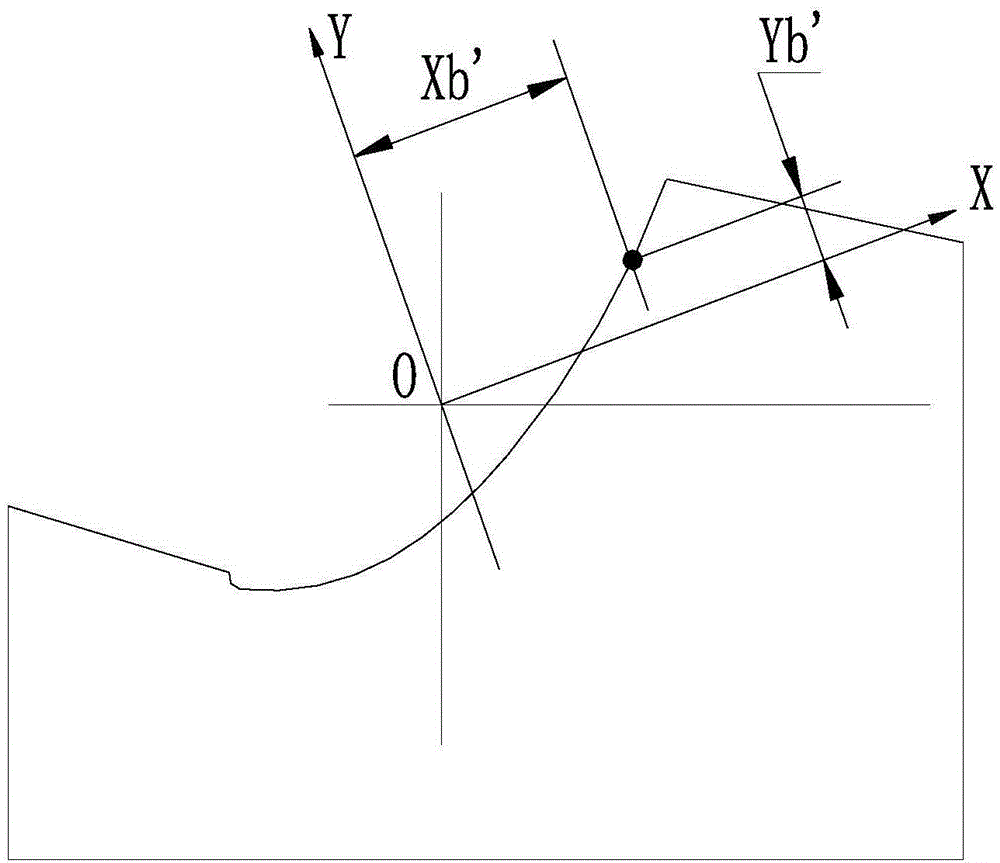

A method of eliminating deformation of a wax mould for an ultrathin elongated working blade of a turbine

ActiveCN104525853AEffective control of deformationSimple correctionFoundry mouldsFoundry coresWaxAviation

The invention relates to a method of eliminating deformation of a wax mould for an ultrathin elongated working blade of a turbine, and belongs to the technical field of manufacturing of blades of aviation engines. The method overcomes disadvantages in the prior art, provides a scheme of carrying and installing the blade wax mould by utilizing a wax mould clamping fixture, and discloses a design scheme of the wax mould clamping fixture. In an actual development and production process of a turbine working blade, because the wax mould clamping fixture is utilized to carry and install the blade wax mould, deformation of the blade wax mould is effectively controlled, and the deformation amount of the turbine working blade manufactured by utilization of the blade wax mould is reduced from original about 1 mm to now about 0.3 mm. Because the deformation amount is reduced, blade correction becomes relatively easy, thus avoiding generation of correction cracks, increasing the yield of precision casting of the turbine working blade by about 20%, largely reducing the rejection rate of the blade and largely saving the production cost.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

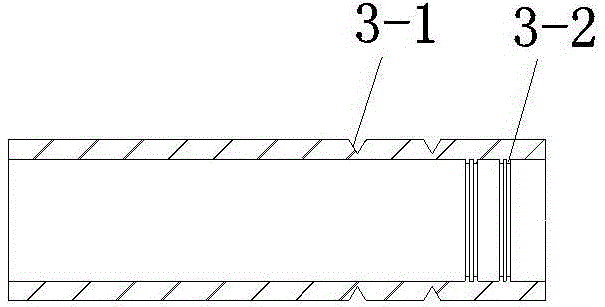

Steel cylinder pile or steel sheet pile with sealing grooves and occlusion structures and steel structure continuous wall

PendingCN107217676AEnsure construction safetyEnsure safetyProtective foundationExcavationsSteel tubeEngineering

The invention discloses a steel cylinder pile or steel sheet pile with sealing grooves and occlusion structures. The steel cylinder pile or steel sheet pile is provided with the waterproof sealing grooves; at least one groove used for sealing is formed in the connecting positions of steel sheet piles or steel cylinder piles; the cross section of each groove is convex-arc-shaped, concave or polygonal; pipes with the same sectional area are inlaid in the grooves; the steel sheet piles or the steel cylinder piles and the pipes inside the grooves are rammed into a stratum together or separately; and after the steel pipes are pulled out, waterproof sealing materials are reserved in or injected into cavities inside the grooves so as to form waterproof sealing layers at the connecting positions of the steel sheet piles or the steel cylinder piles. The steel cylinder pile or steel sheet pile has the advantages that in the application of a steel structure continuous wall, a foundation and a foundation pit, particularly, the sealing structural steel cylinder pile is a rectangular steel cylinder pile, and rectangular steel cylinders are tightly arranged.

Owner:JIANGSU GREEN RIVER ENVIRONMENTAL TECH CO LTD

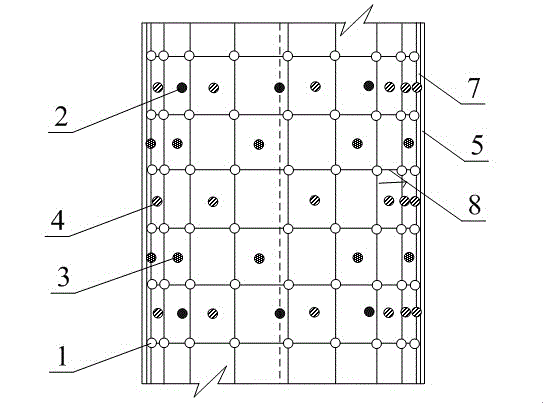

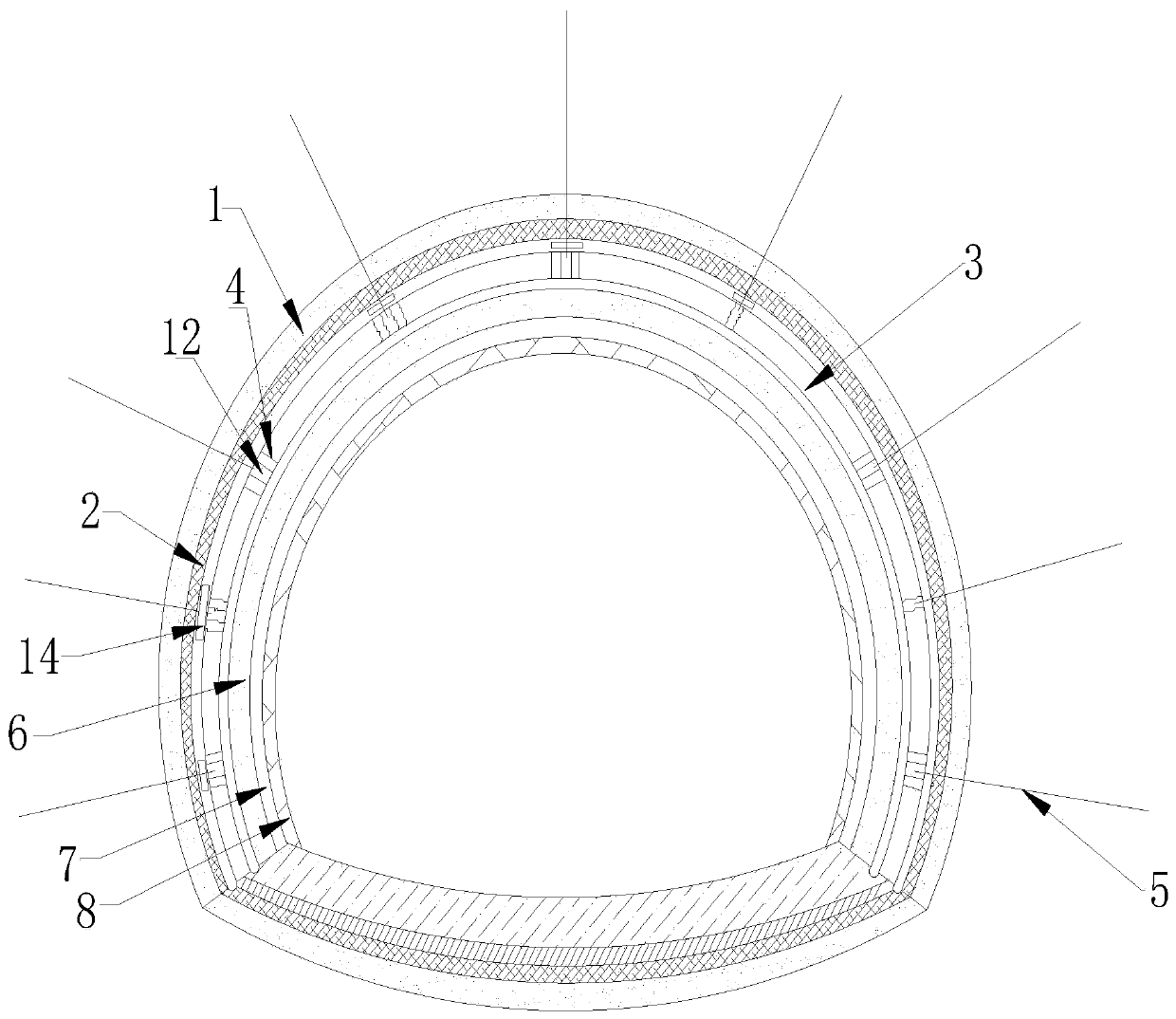

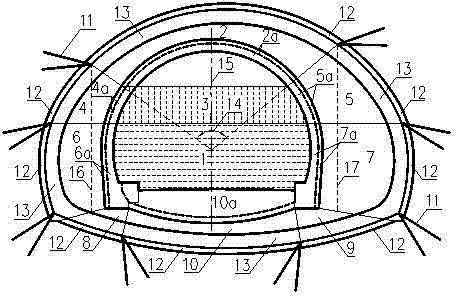

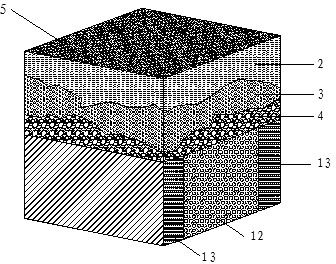

Space joint support structure and support method for water-rich broken strata tunnel

PendingCN110094213APrevent surrounding rock from deterioratingGood mechanical performanceUnderground chambersDrainageTunnel constructionRock pressure

The invention discloses a space joint support structure and support method for a water-rich broken strata tunnel, and relates to the technical field of tunnel construction. The problems that a large-scale deformation is prone to occur due to the fact that a water-rich broken surrounding rock section adopts a conventional spray anchoring to support surrounding rocks, the surrounding rock pressure is great, effective prevention and control of water leakage is difficult, and stability of a tunnel structure and safety of construction are jeopardized are solved. The key points of the technical scheme are that the space joint support structure comprises an initial concrete layer, a steel mesh, and steel arches arranged at intervals; longitudinal connecting steel beams distributed along the axialof a tunnel in a staggered mode are arranged between the steel arches in the circumferential direction; longitudinally connecting steel beams are connected with anchor rods; a steel fiber concrete layer covering the steel arches, the steel mesh, and the longitudinally connecting steel beam sprays the surface of the steel mesh; a waterproof and drainage structure layer paves the surface of steel fiber concrete; and a second lining concrete layer pours the surface of the waterproof and drainage structure layer. According to the space joint support structure and support method for the water-richbroken strata tunnel, deformation of the surrounding rocks in the tunnel can be effectively controlled, the waterproof and drainage functions are excellent, and stability of the tunnel structure andsafety of construction are ensured.

Owner:FUJIAN UNIV OF TECH

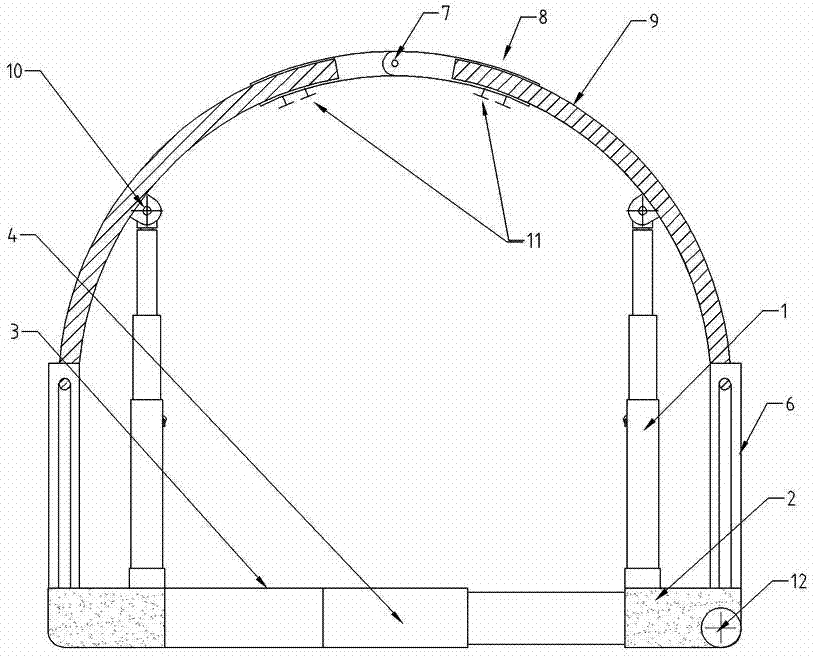

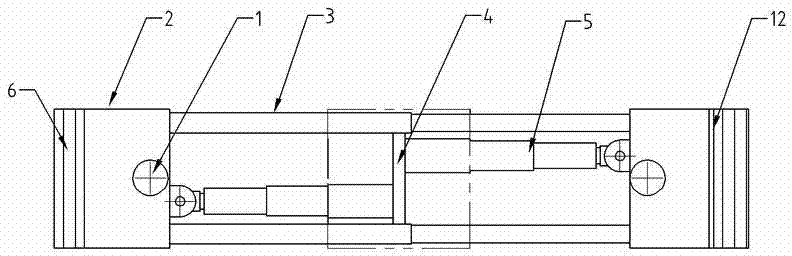

Improved soft rock roadway integral tunneling protection support

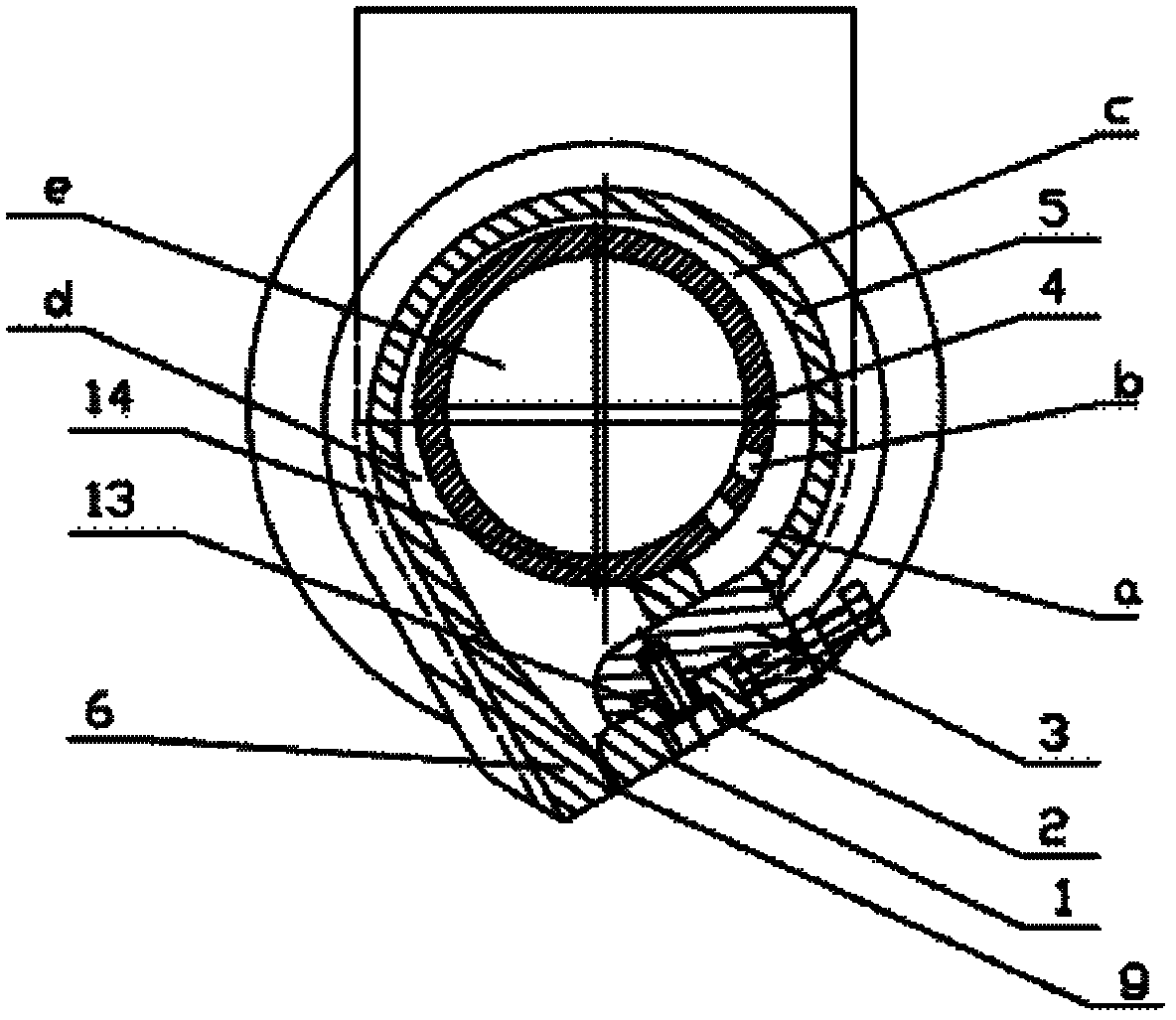

InactiveCN103615269AControl the amount of roadway deformationLarge stretching roomProps/chocksHinge angleBuilding construction

The invention relates to an improved soft rock roadway integral tunneling protection support and belongs to the field of mining machinery manufacturing and application. The improved soft rock roadway integral tunneling protection support mainly consists of a semi-circular protective arch, left and right hydraulic supporting columns (1) and a support base. The semi-circular protective arch consists of two groups of arc-shaped supporting arch slabs which are symmetric, located on the left side and the right side and connected at the highest point of the arch through hinges (7), and each group of arc-shaped supporting arch slabs include an arc-shaped connecting arch slab (8) and an arc-shaped bearing plate (9). The upper ends of the left and right hydraulic supporting columns (1) are respectively connected with a supporting connection lug (10) on the corresponding-side arc-shaped bearing plate (9). The improved soft rock roadway integral tunneling protection support has the advantages of being capable of simultaneously bearing pressure through the periphery, high in compressive strength, large in bearing force, convenient to operate and tight in part combination. With respect to roadway construction convenience, structure innovation and the like, the safety, the adaptability, the technical advancement and the economical efficiency of the soft rock supporting projects are integrally improved through design optimization.

Owner:范炳辉

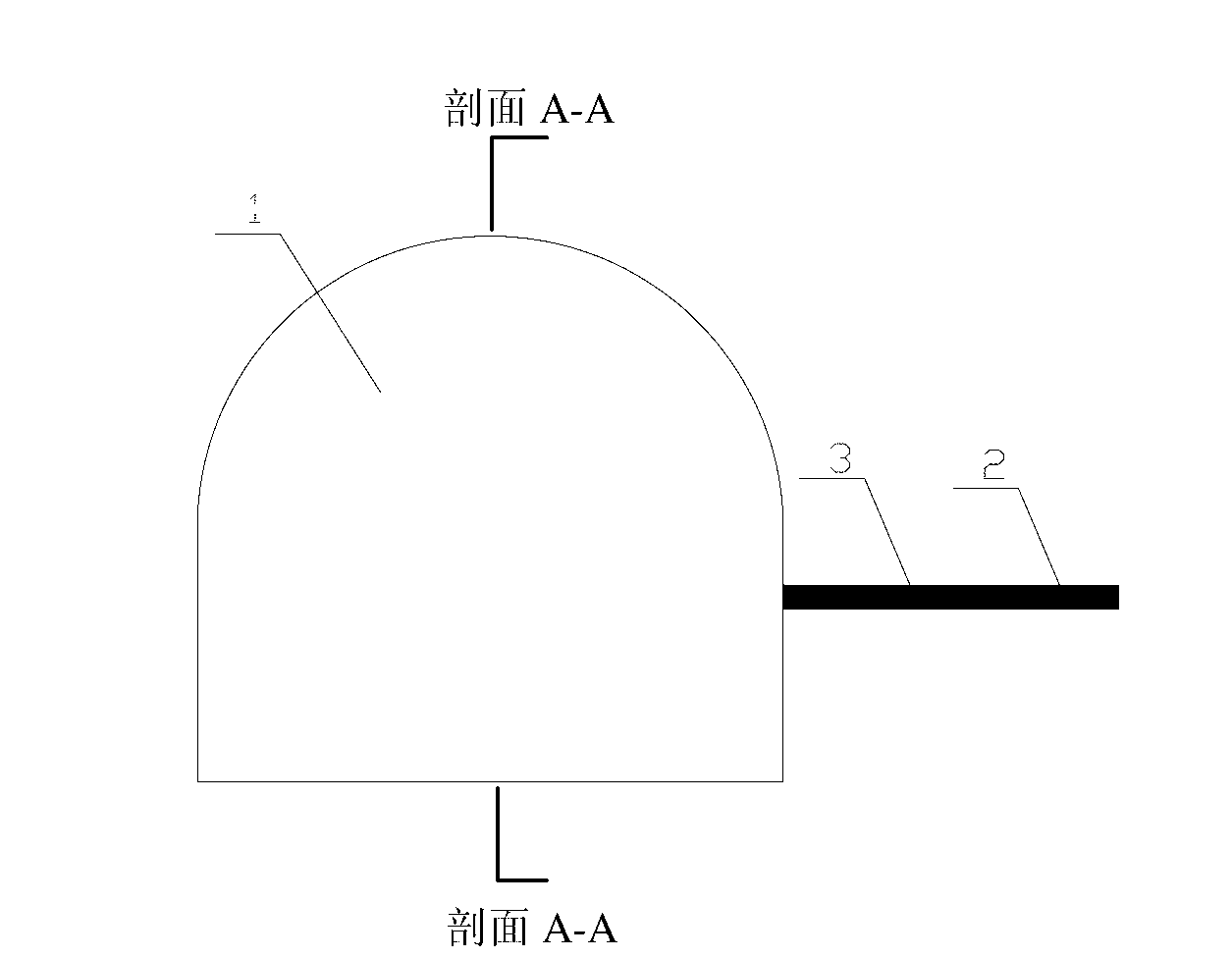

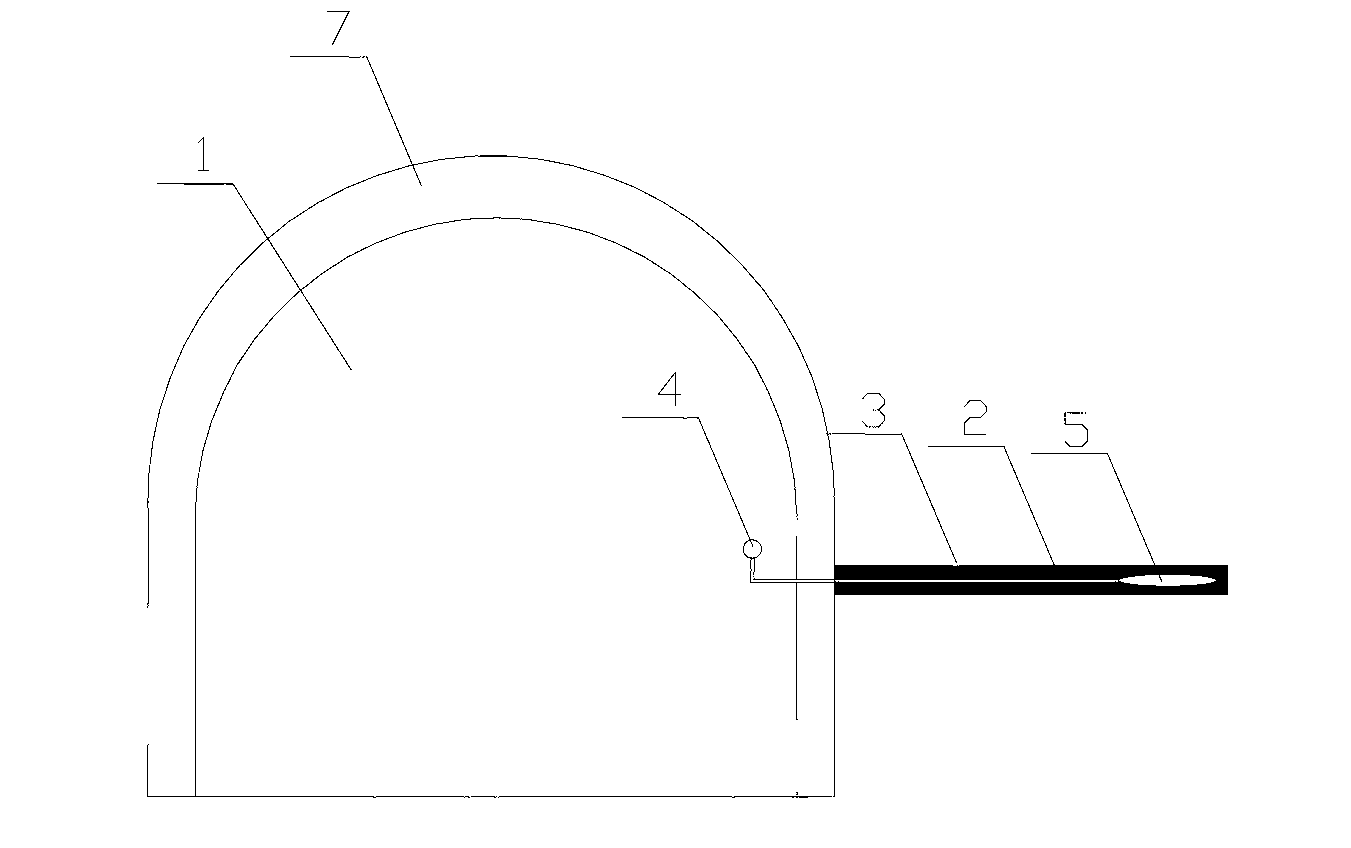

Ground stress release method for high ground stress soft rock tunnel positive step excavation

InactiveCN102155239AEffective control of deformationUnderground chambersTunnel liningRock tunnelGround force

The invention relates to high ground stress soft rock tunnel stress release technology and provides a ground stress release method for a high ground stress soft rock tunnel positive step excavation; the method comprises the following steps of: excavating at the upper part of a tunnel to form an upper step (1), then drilling a plurality of boreholes (3) on a working face (4) of the upper step along the direction of tunnel excavation so that the ground stress acts on the boreholes, consumes the energy of the ground stress in a deformation process and releases the ground force. The method achieves the purpose of effectively controlling the deformation of ground stress rock tunnel surrounding rocks and provides security guarantee for subsequent tunnel excavation.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Construction method for widening existing tunnel

ActiveCN104329095AControl surrounding rock deformationReduce height and widthUnderground chambersTunnel liningBuilding construction

The invention relates to a construction method for widening an existing tunnel. The construction method has the advantages that tunnel excavation slag is used for backfilling and reinforcing the interior of the existing tunnel, so as to form an effective lateral protection on the existing tunnel structure; by utilizing the partitioning and radial support actions of the existing tunnel structure on the excavated cross section for the widening of the tunnel, and the longitudinal support function on a tunnel surface of the interior of the tunnel, the existing tunnel structure can realize the space support effect similar to the space support effect similar to that of the core soil of the tunnel surface, and the deformation of surrounding rock can be effectively controlled; the construction method of arc-shaped staged excavation of upper steps, alternative excavation of rocked layers at the left sides and right sides of lower steps, and annular staged excavation of inverted arch sectional undercutting along the periphery of the existing tunnel structure is adopted, the width and height of staged excavation are reduced, the construction difficulty in widening of the tunnel is greatly decreased, and the temporary support measures are reduced or avoided; the method is suitable for three widening ways, namely widening at the right side, widening at the left side and widening at both the left side and right side, and the shifting of construction methods between different widening ways is simpler.

Owner:FUZHOU PLANNING DESIGN & RES INST

High-stress roadway surrounding rock deformation control method

ActiveCN103216265AEffective control of deformationControl deformationMining devicesGeophysicsCushioning

The invention belongs to a mine roadway surrounding rock deformation control method, and provides a high-stress roadway surrounding rock deformation control method. The high-stress roadway surrounding rock deformation control method mainly includes the following steps: hole drilling for pressure relief; surrounding rock pressure monitoring; pre-splitting, cutting and blasting; pressure-relieving groove filling; and surrounding rock deformation monitoring. The high-stress roadway surrounding rock deformation control method is characterized in that holes are drilled in roadway surrounding rocks for pressure relief, and whether a pressure relief effect is achieved is determined through pressure monitoring in a pressure relief area. If a desired pressure relief effect is not achieved, a pressure-relieving groove is formed in the roadway surrounding rocks by means of a pre-splitting blasting technique, and surrounding rock deformation cushioning materials are filled into the pressure-relieving groove; and at the same time, pressure sensors are embedded in the pressure-relieving groove and surrounding rock deformation monitoring sections are laid in the pressure-relieving groove, so that monitoring the pressure relief effect can be conducted. The high-stress roadway surrounding rock deformation control method can effectively control deformation of the roadway surrounding rocks under geological conditions of large burial depth or high ground stress, and ensures roadways, in an environment of the high ground stress, of a mine can be normally used in a production period.

Owner:徐州天骋智能科技有限公司

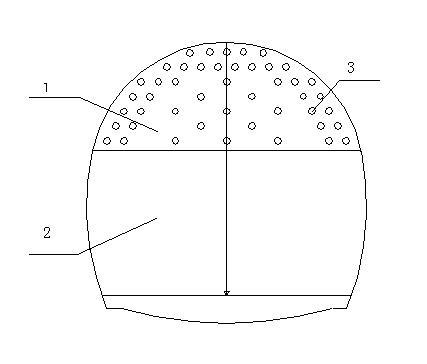

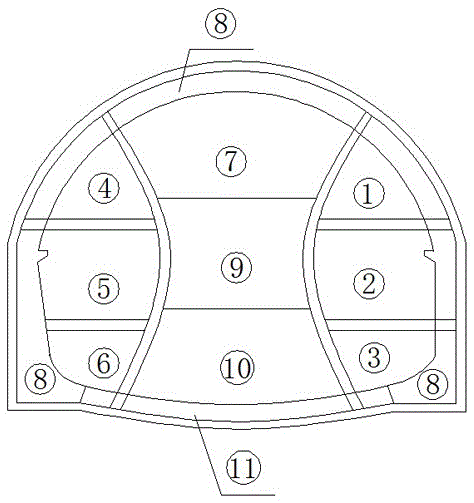

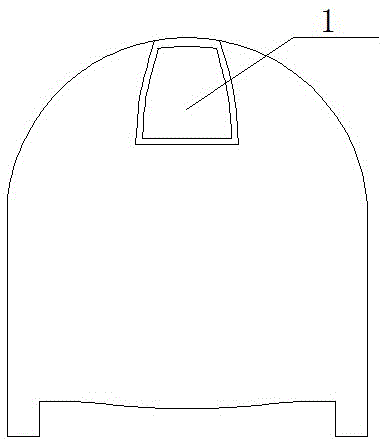

Soft rock stratum underground excavation large-section tunnel construction method and supporting system

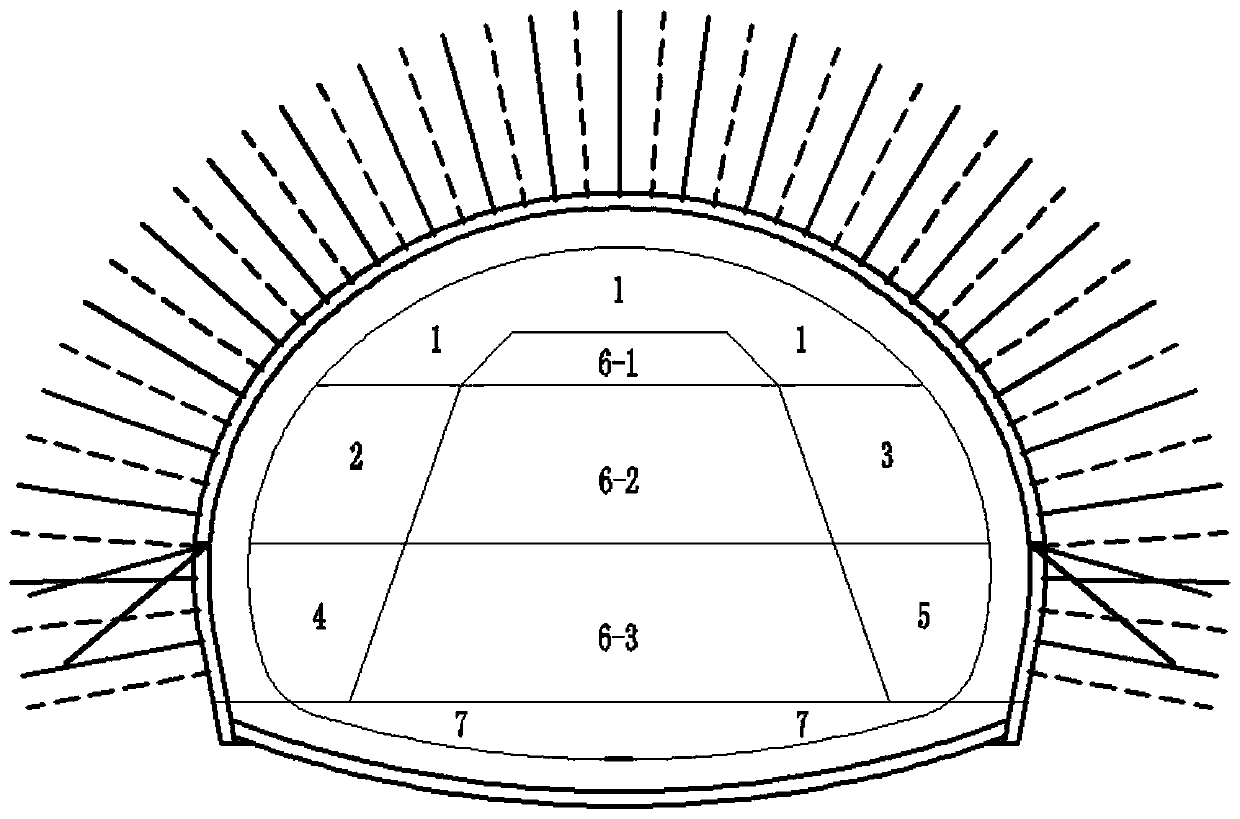

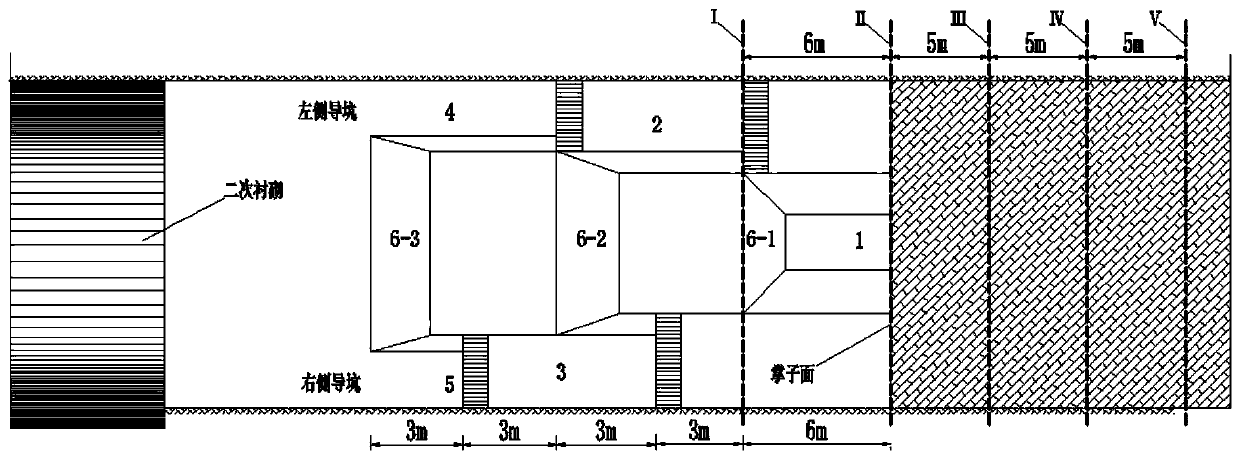

ActiveCN105604576ASmall secondary subsidenceEffective blastingUnderground chambersTunnel liningSupporting systemPipe support

A soft rock stratum underground excavation large-section tunnel construction method comprises the following steps of conducting excavation on the upper portion of the center of an arc part to form an arc part small pilot tunnel, and arranging an arc crown vertical supporting system in the arc part small pilot tunnel; conducting excavation to form a left upper pilot tunnel, a left middle pilot tunnel, a right upper pilot tunnel, a left lower pilot tunnel and a right lower pilot tunnel in sequence, and reserving a core rock wall in each pilot tunnel; pouring inverted arc concrete on the left side and right side and inverted arc backfill; pouring the arc part of a tunnel and a side wall secondary lining; excavating the core rock walls; pouring inverted arc concrete and inverted arc backfill. A supporting system adopted in the construction method comprises the arc part small pilot tunnel, a manual hole digging pile, the arc crown vertical supporting system, a side wall preliminary bracing and a core rock wall bracing, wherein the arc crown vertical supporting system comprises a steel pipe support penetrating through the manual hole digging pile and the arc part small pilot tunnel, and an independent foundation is arranged on the bottom of the steel pipe support and located on the bottom of the manual hole digging pile. According to the soft rock stratum underground excavation large-section tunnel construction method and the supporting system, sedimentation of the arc part of the tunnel can be effectively controlled, excavation footage is large, construction progress is accelerated, arc part secondary lining can be realized early, and construction safety is guaranteed.

Owner:RANKEN RAILWAY CONSTR GROUP

Method for supporting laneway below coal pillar

ActiveCN102155248ALarge surface areaStrong watch protectionMine roof capsAnchoring boltsMetal meshCoal pillar

The invention discloses a method for supporting a laneway below a coal pillar. The method comprises the following steps of: firstly, arranging temporary supports on a top plate and two sides of the laneway, paving a metal mesh and a steel band, pressing the metal mesh with the steel band and supporting the steel band with a monomer hydraulic support post; secondly, drilling holes on the top plate through the orifice of the steel band of the top plate by using drill bits matched with the diameters of threaded steel anchor rods in combination with a drilling machine, arranging the threaded steel anchor rods into drilling holes in sequence and reaching pre-tightening force by using a nut; and lastly, drilling holes on laneway sides from the orifices of the steel bands on the laneway sides by using drill bits matched with the diameters of threaded steel anchor rods in combination with the drilling machine, arranging hydraulic expansion anchor rods into the drilling holes on the laneway sides in sequence, and injecting high-pressure water into the hydraulic expansion anchor rods to expand the hydraulic expansion anchor rods. Anchor ropes are arranged on the top plate and the two sides at specific intervals during the performance of the procedures. The procedures are repeated until the laneway below the coal pillar is supported. The hydraulic expansion anchor rods adopted in the method can realize full-length anchorage; and after the anchor ropes are used for reinforcing and supporting the laneway, the surrounding rock deformation of the laneway below the coal pillar can be effectively controlled.

Owner:CHINA UNIV OF MINING & TECH

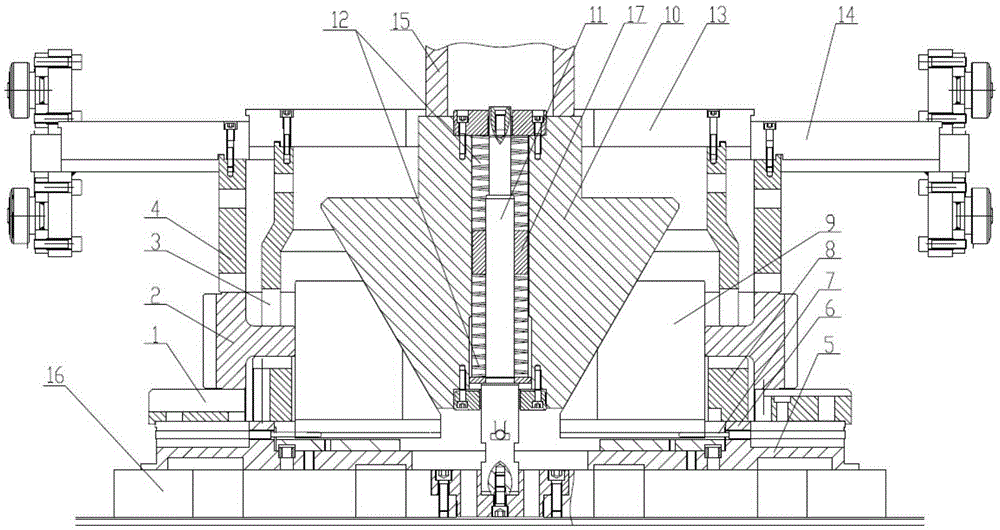

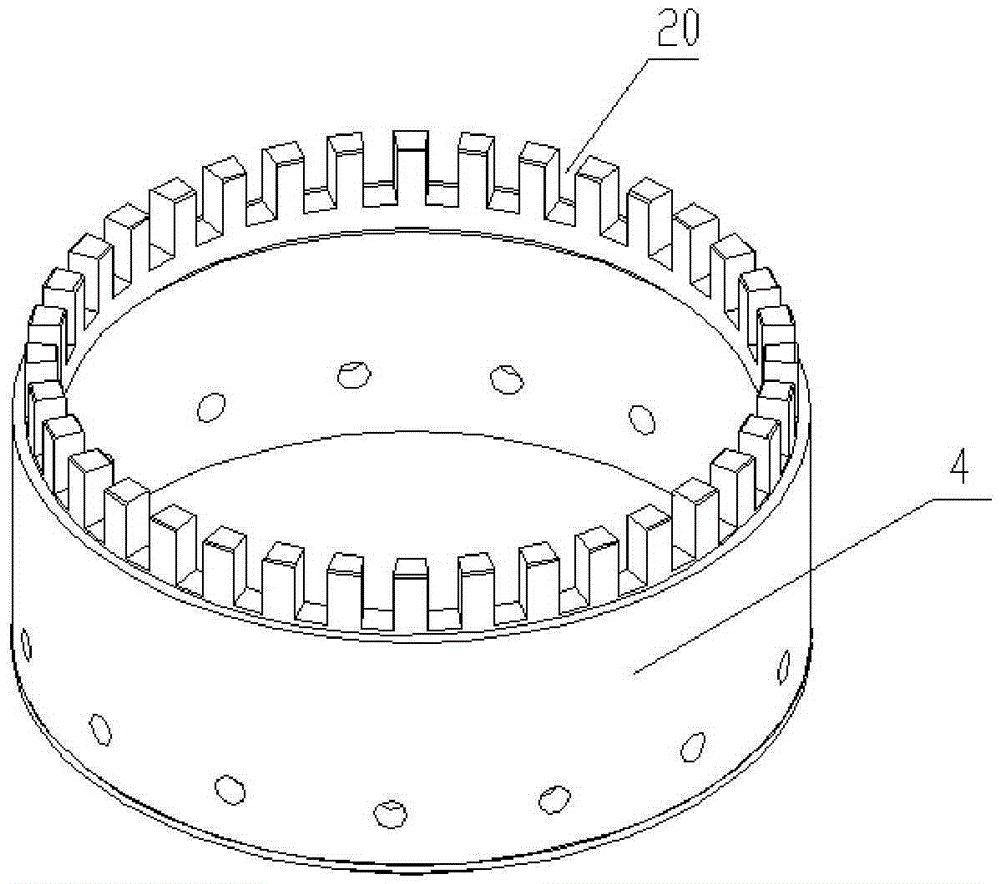

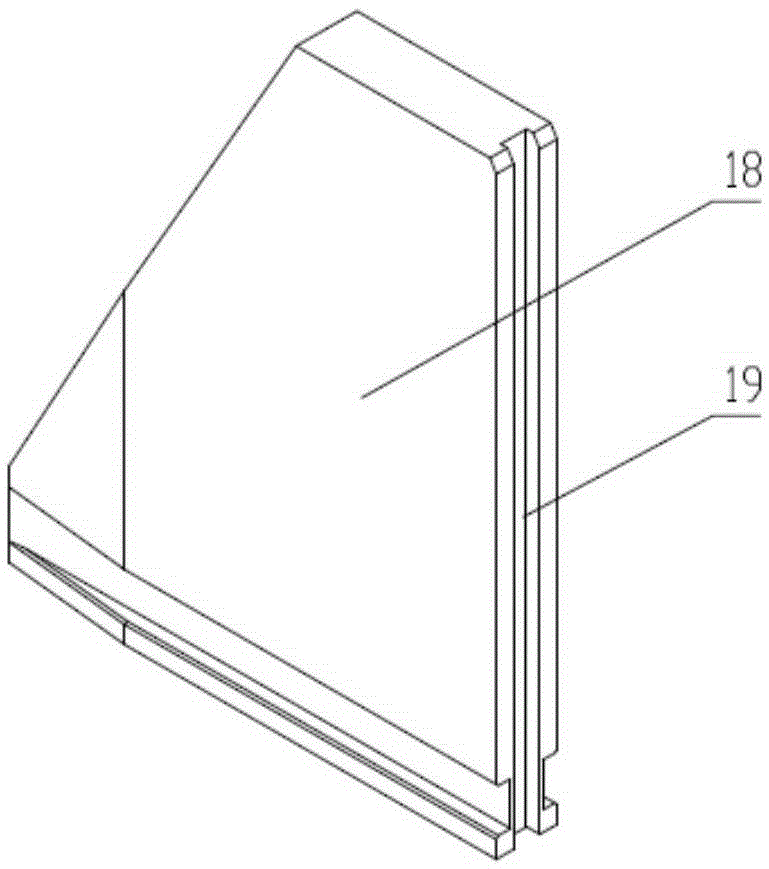

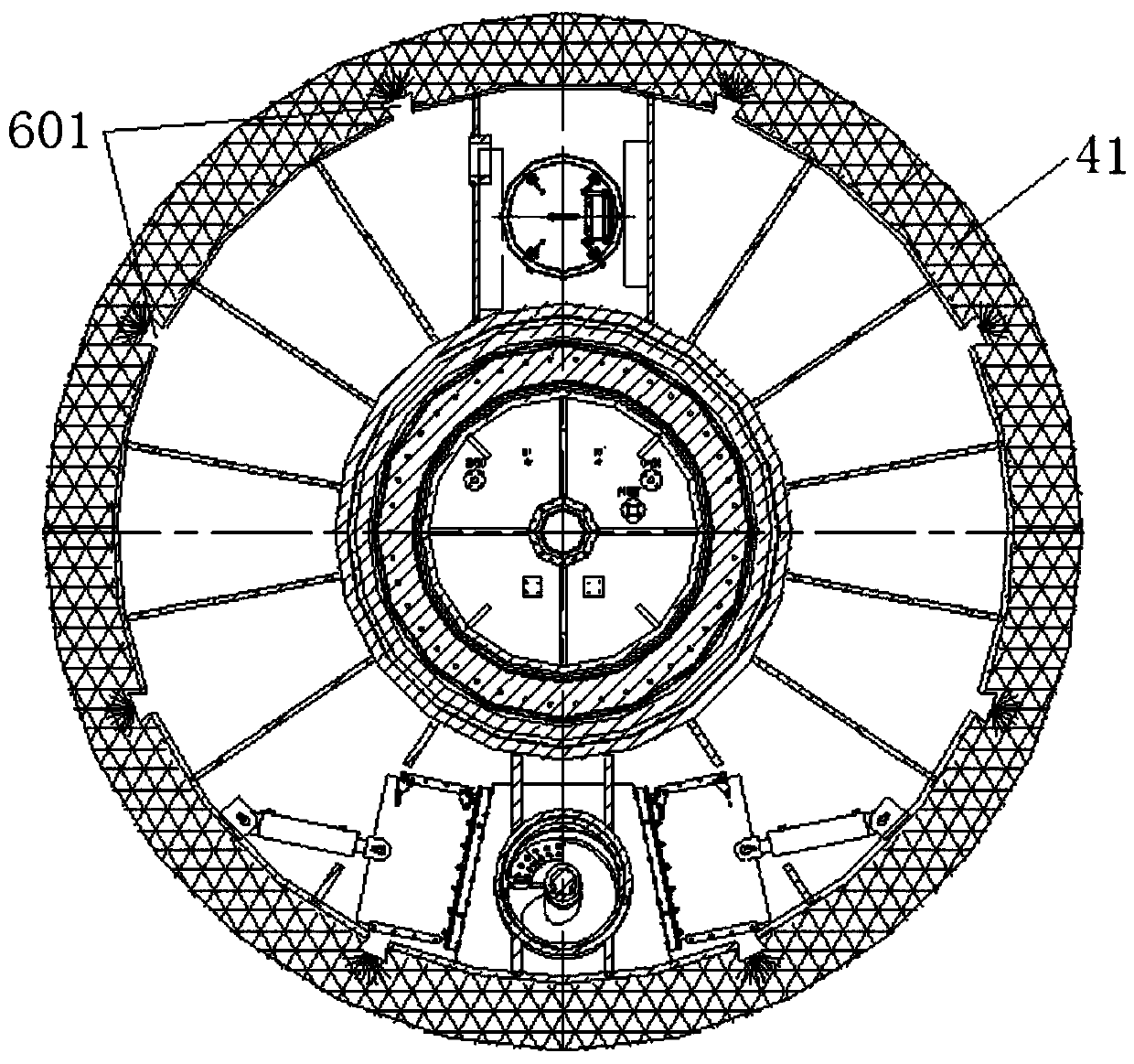

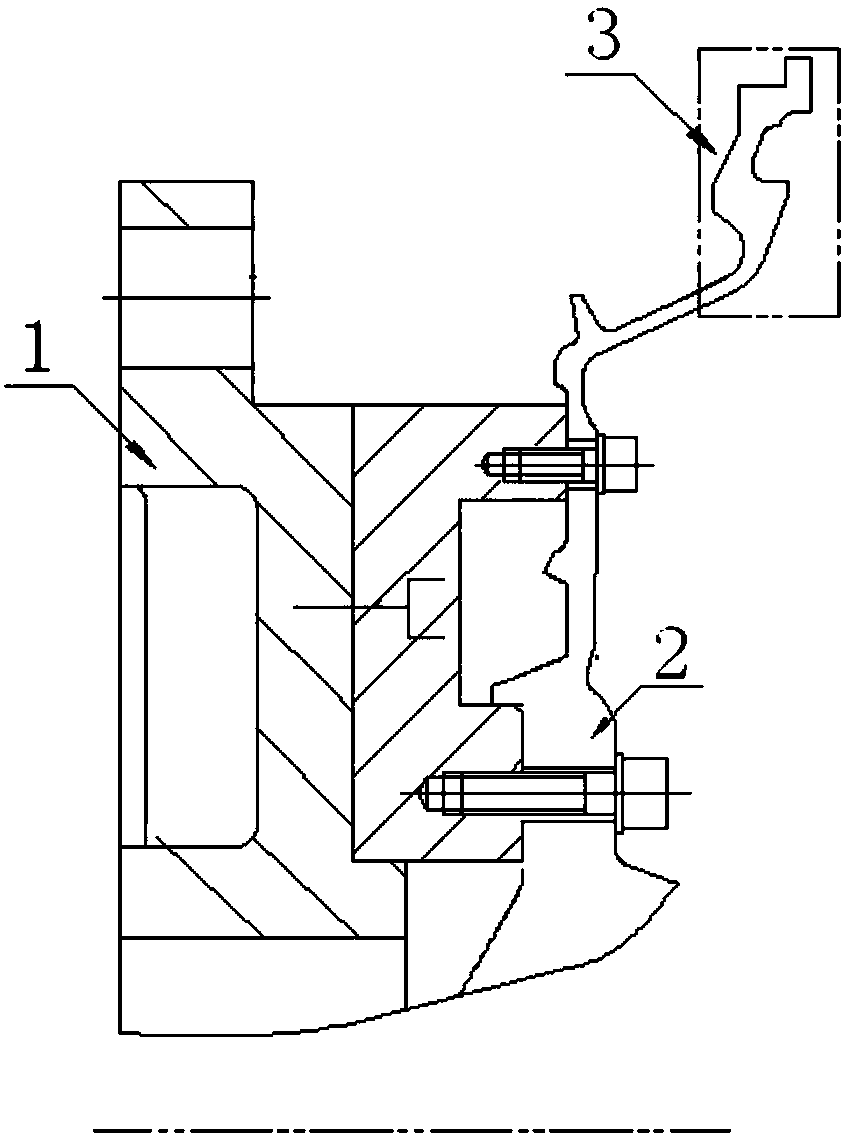

Press quenching mold for locomotive traction gear ring

ActiveCN105420464AUniform stress distributionReduce jumpingFurnace typesHeat treatment furnacesCircular coneHardness

The invention relates to the technical field of thermal treatment molds, in particular to a press quenching mold for a locomotive traction gear ring. The press quenching mold comprises an upper mold body and a lower mold body. The upper mold body comprises a web pressing mold body and an end face pressing mold body. The lower mold body comprises an expanding core, a web supporting table and an end face supporting table. The web supporting table and the web pressing mold body are used for clamping a web of the locomotive traction gear ring; the end face supporting table and the end face pressing mold body are used for clamping the end face of the locomotive traction gear ring; the expanding core comprises a stand column, a circular cone stand, an expander and an expander supporting table; the stand column and the expander supporting table are fixed to a machine tool working table; the circular cone stand is arranged on the stand column in a sleeved mode and can move up and down along the stand column; the expander is arranged around the periphery of the circular cone stand, the bottom of the expander makes contact with the expander supporting table and can perform radial movement on the expander supporting table; the inner inclined surface of the expander is attached to the outer conical surface of the circular cone stand. The press quenching mold for the locomotive traction gear ring is compact in structure and ingenious in design; during carburizing and quenching, the requirement of products for the hardness can be met and deformation of the gear ring due to carburizing and quenching can be effectively controlled; therefore, the qualified rate of the products is increased.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

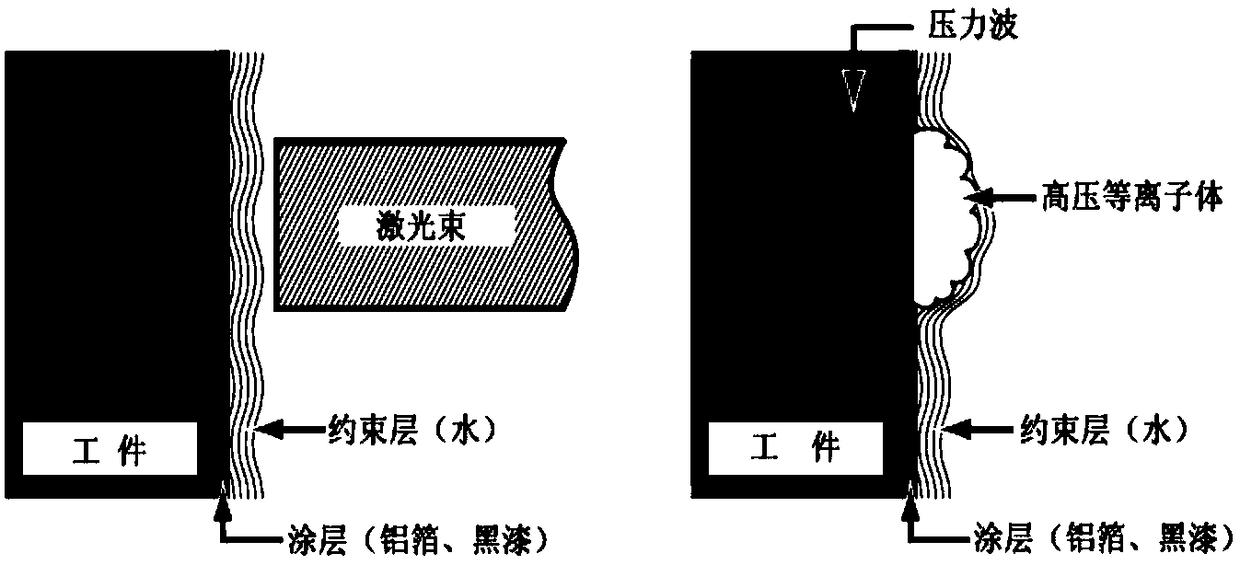

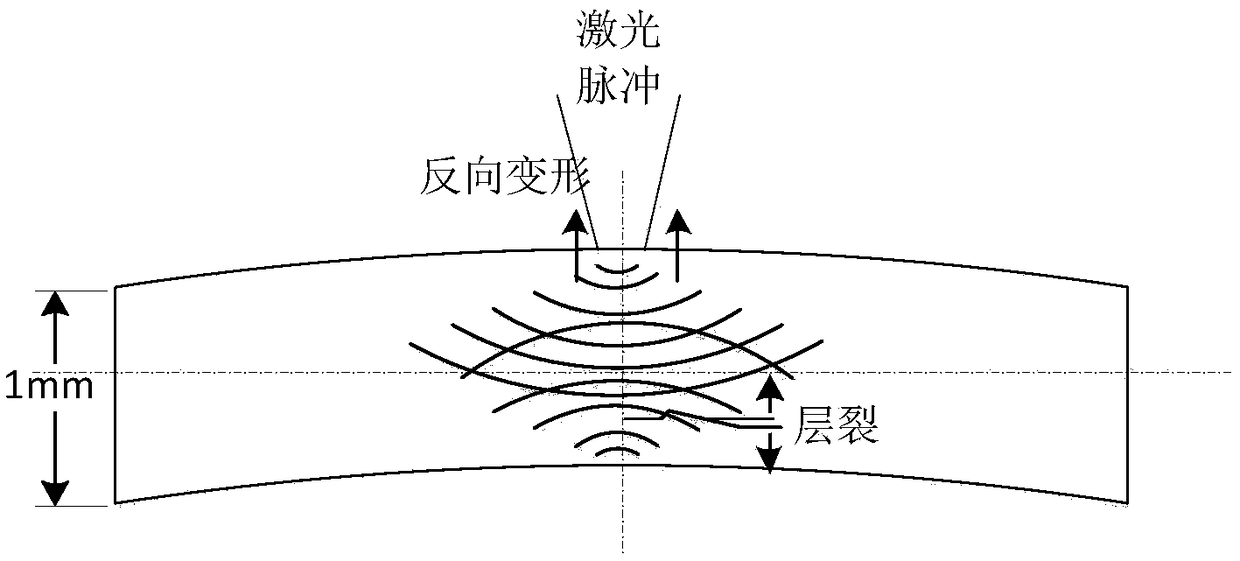

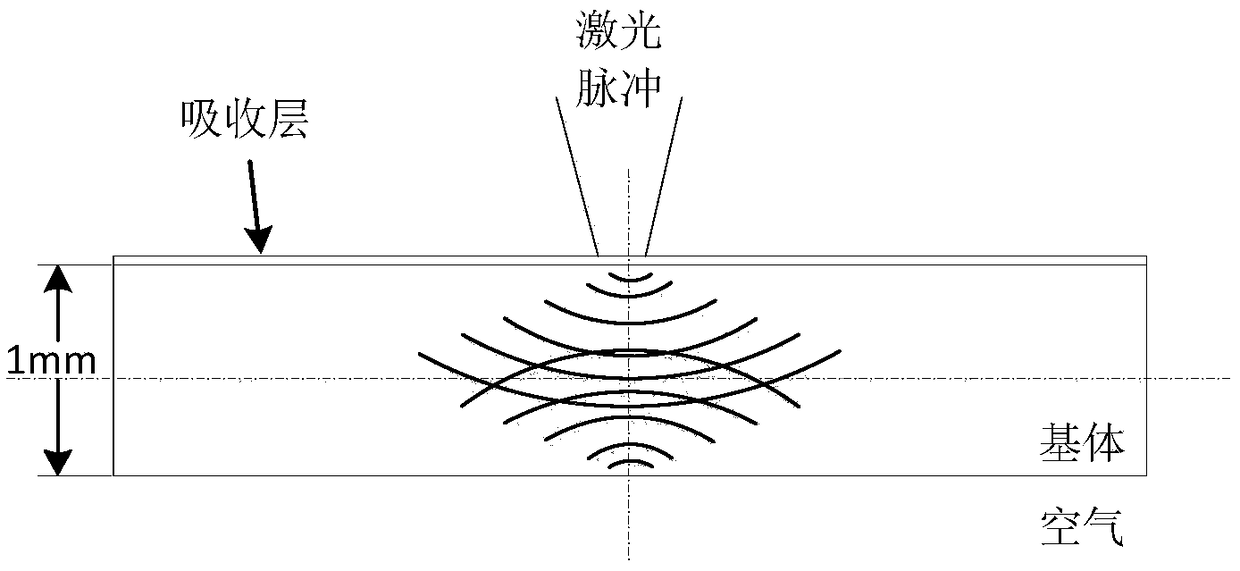

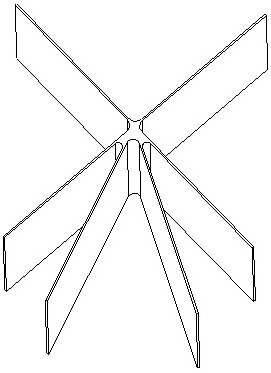

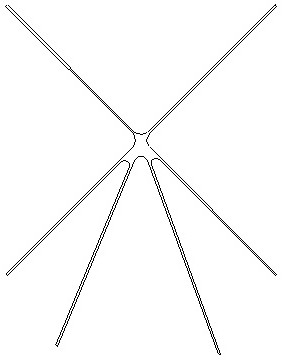

Method of absorbing shock waves of nanosecond impulse laser shock strengthened titanium alloy thin blade

The invention discloses a method of absorbing shock waves of a nanosecond impulse laser shock strengthened titanium alloy thin blade. When laser shock strengthening treatment is carried out on the side and edge of the titanium alloy thin blade, shock waves is exported from the side edge and the back surface of the blade by means of a special shock wave energy absorption device, so that shock deformation of the thin blade is controlled and the strengthening effect is enhanced; by mounting a trap device on the back surface of a to-be-strengthened blade, a technical breakthrough of shock strengthening on the surface of the thin blade is achieved by means of an existing laser shock strengthening technology, so that the method is easy to operate and high in feasibility; existing equipment can be directly refit, so that the defects that the strengthening effect is poor as a result of power reduction and pulse width reduction by means of laser shock strengthening of an existing thin blade andstrain is formed inside as a result of double-sided shock strengthening are overcome. The method of carrying out shock strengthening on the side edge of the titanium alloy thin blade by adopting nanosecond impulse laser, the energy of which is 2-5J and the spot diameter of which is 1-2mm, is a critical core technology for strengthening the thin blade, and is good in strengthening effect and suitable for being popularized and used.

Owner:AIR FORCE UNIV PLA

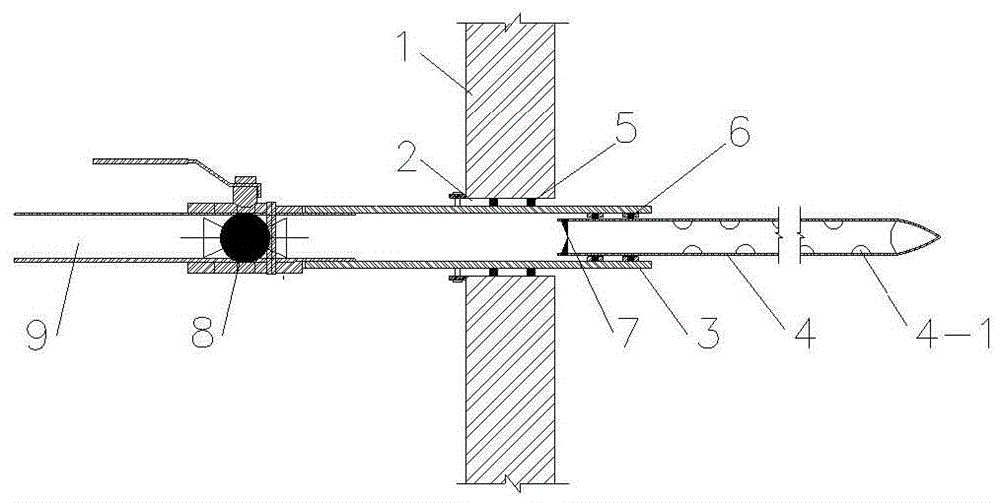

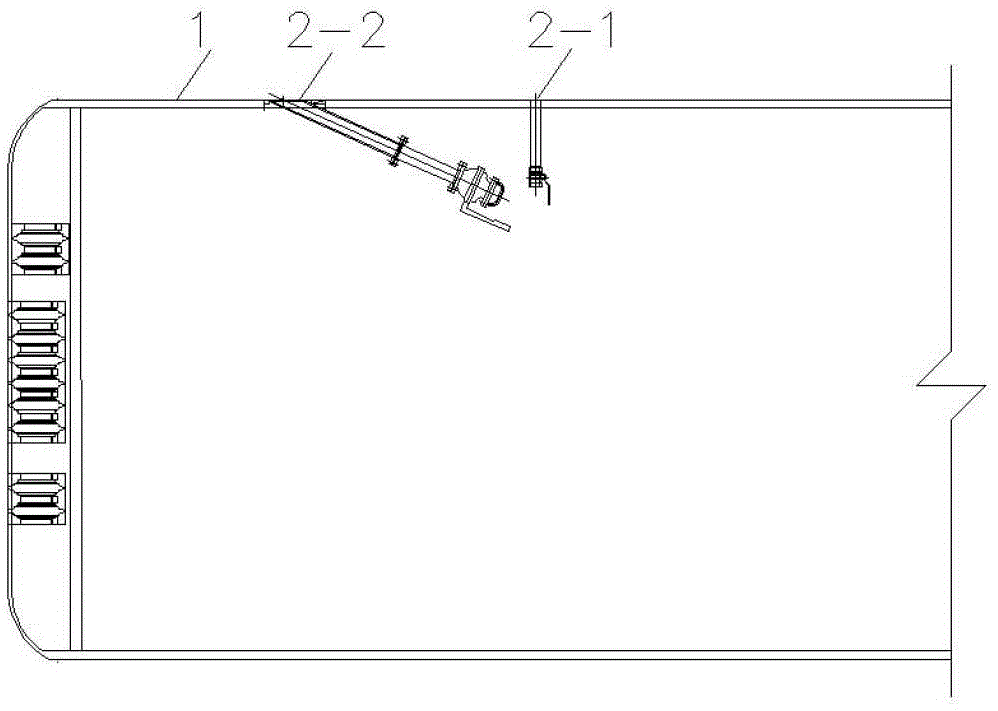

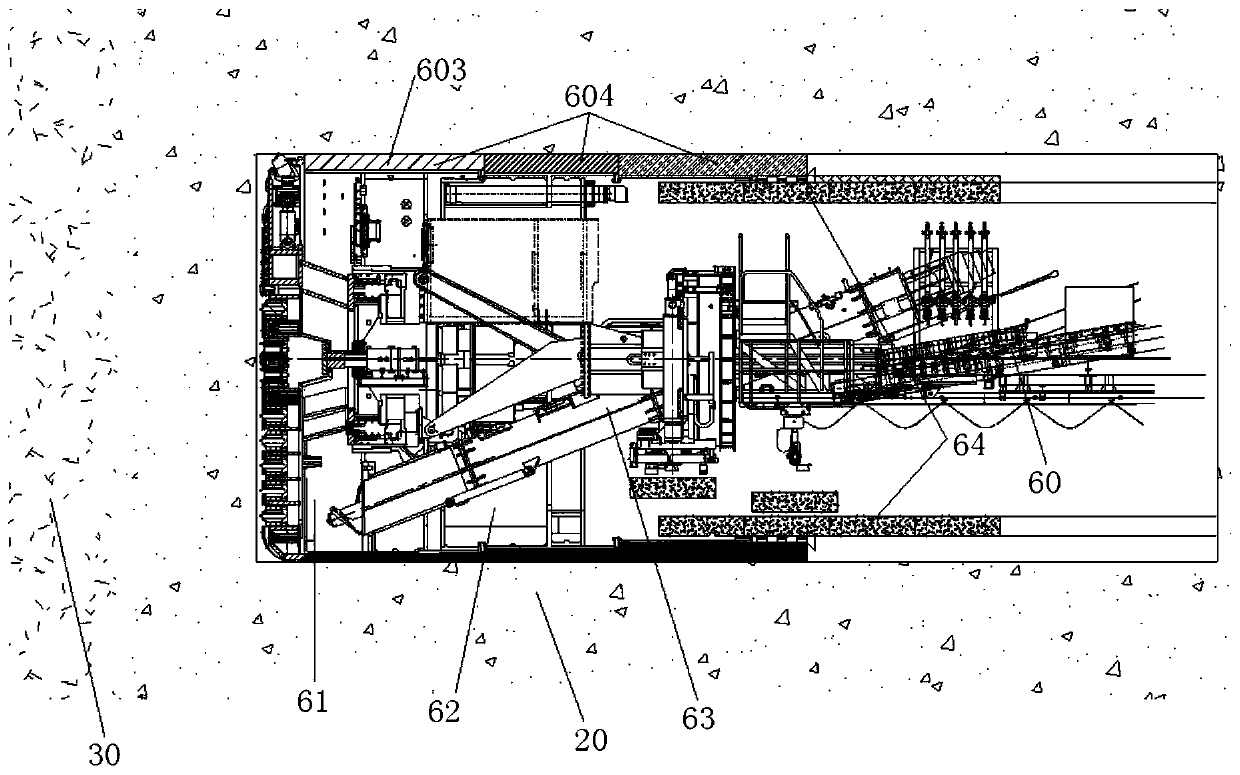

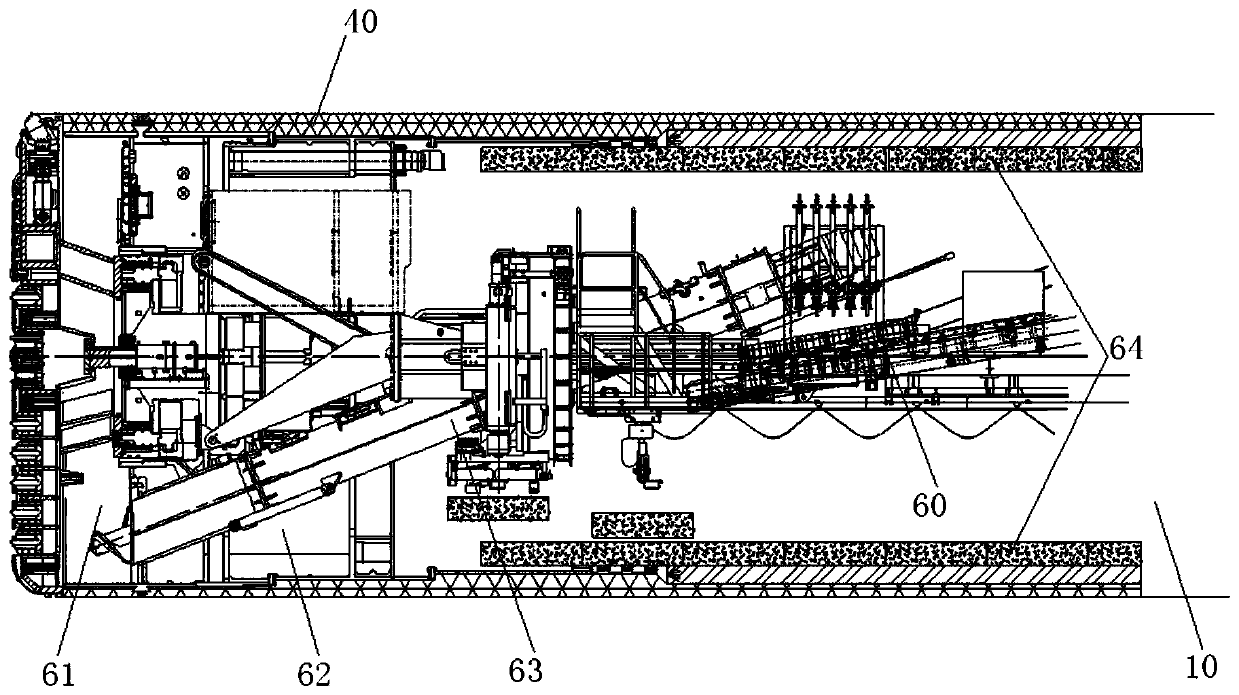

Device used for grouting reinforcement from interior of shield tunneling machine to peripheral stratum

ActiveCN105649655ASimple structureEasy to install and disassembleUnderground chambersTunnel liningTrappingEngineering

The invention relates to a device used for grouting reinforcement from the interior of a shield tunneling machine to a peripheral stratum. A steel casing pipe is stricken into the stratum in front of a reserved hole through the reserved hole in a shield body of the shield tunneling machine, and a perforated steel grouting pipe connected in the steel casing pipe is used for carrying out grouting reinforcement on the peripheral rock stratum of the shield body. Meanwhile, the peripheral stratum within different ranges can be reinforced through perforated steel grouting pipes with different lengths, and thus the purposes of carrying out grouting reinforcement from the interior of the shield tunneling machine to the peripheral stratum, controlling the settlement deformation of the stratum, performing supporting, and reducing shield trapping and construction safety risks are achieved. While the stratum is reinforced through grouting, a water closing ring and a backflow-prevention rubber pad are adopted, it can be effectively prevented that grout flows back into the shield tunneling machine body in the grouting process, and it is ensured that construction is safe and environmentally friendly.

Owner:YSD RAIL TRANSIT CONSTR CO LTD +1

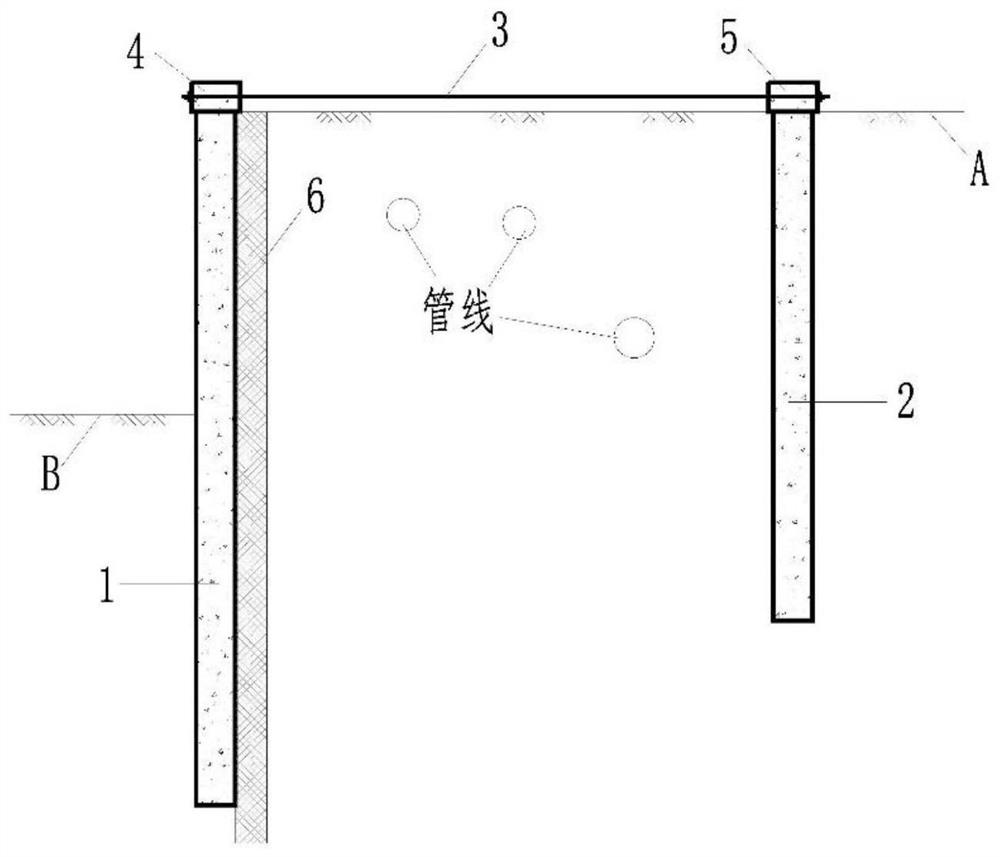

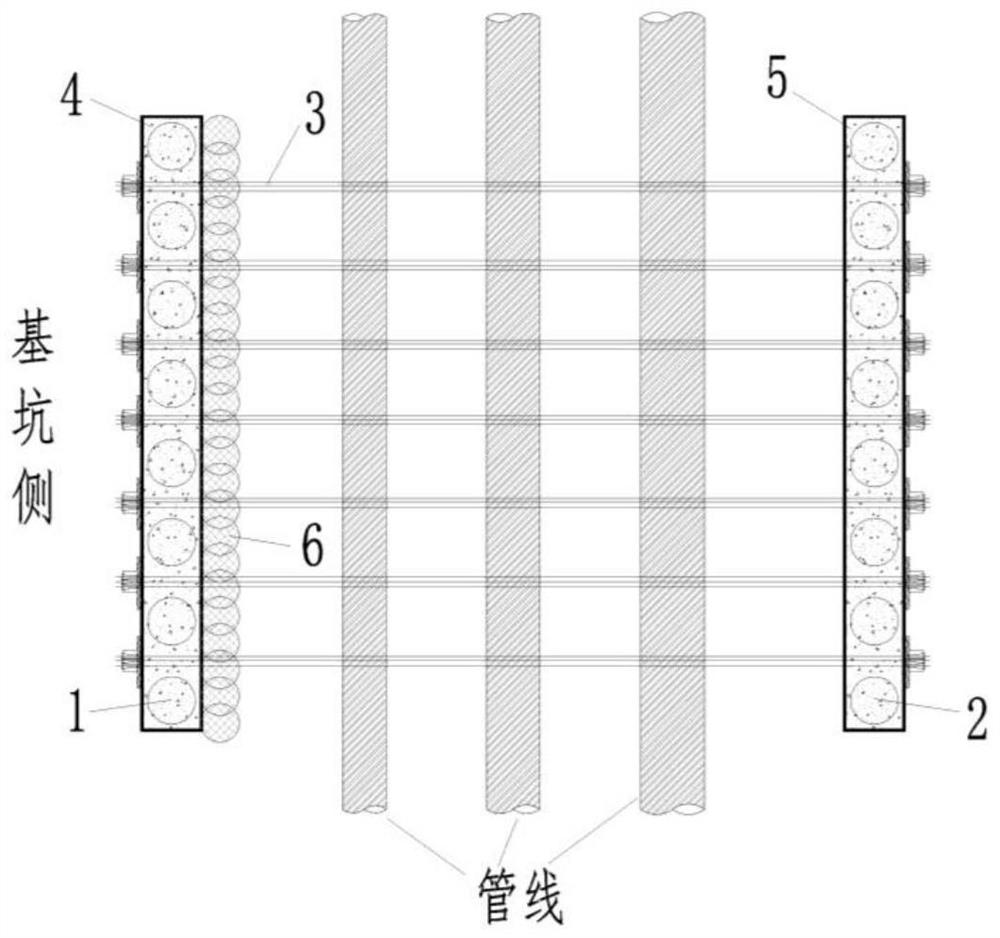

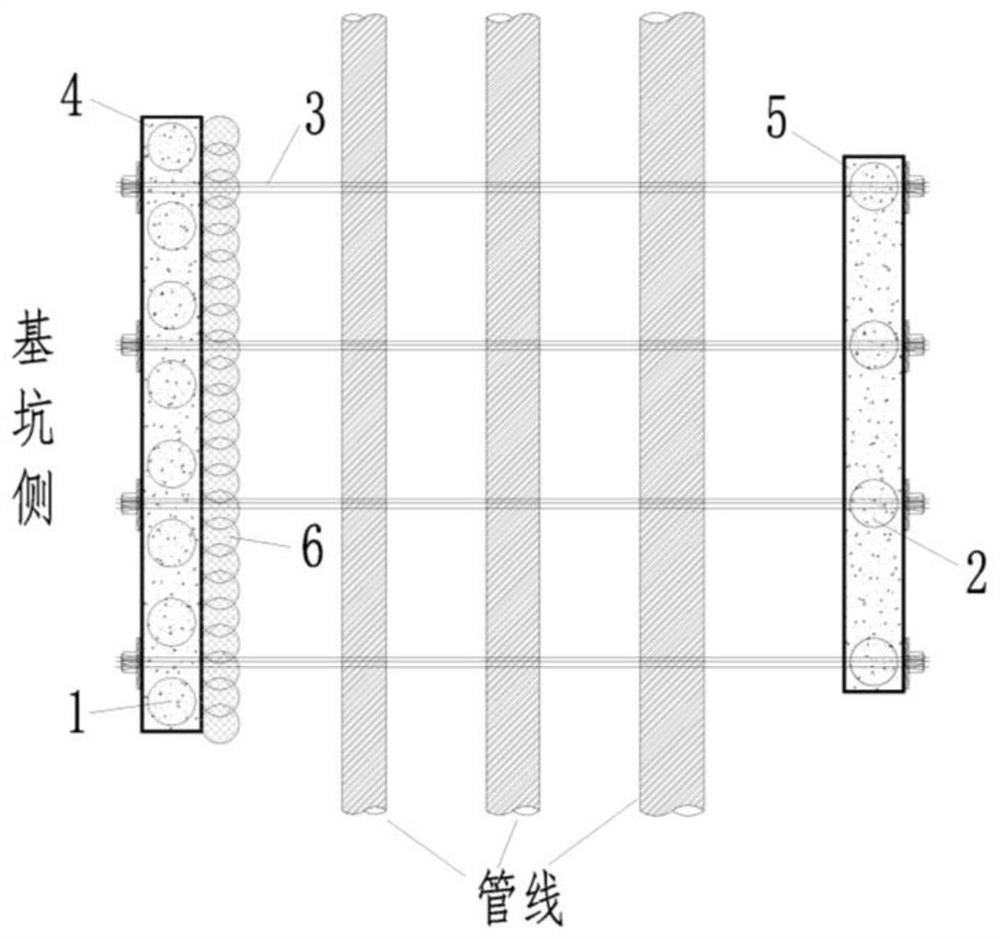

Anchoring type supporting system based on horizontal anchor cables and counter-force piles and construction method thereof

InactiveCN113529738AIncrease stiffnessImprove anti-overturn performanceExcavationsSupporting systemLine tubing

The invention belongs to the technical field of foundation pit engineering, and discloses an anchoring type supporting system based on horizontal anchor cables and counter-force piles and a construction method thereof. The supporting system is composed of supporting piles, the counter-force piles, a supporting pile crown beam, a counter-force pile crown beam and the horizontal anchor cables, wherein the supporting piles are constructed on the side wall of a foundation pit, the supporting pile crown beam is poured on the tops of the supporting piles, the counter-force piles are constructed on a foundation pit outside soil body, the counter-force pile crown beam is poured on the tops of the counter-force piles, and the supporting piles and the counter-force piles are connected into a whole through the horizontal anchor cables penetrating through the supporting pile crown beam and the counter-force pile crown beam. According to the anchoring type supporting system based on horizontal anchor cables and counter-force piles and the construction method thereof, the rigidity and the overturning resistance of single-row supporting piles can be improved, deformation of the foundation pit is effectively controlled, and the defects that a traditional cantilever pile structure is low in overall rigidity and cannot meet the deformation control requirement easily are overcome; and meanwhile, the technical problems that underground pipelines around the foundation pit are complex, land use is limited, and conventional oblique anchor cables cannot be adopted are solved by using the horizontal inhaul cables, and a new thought and a new method are provided for a municipal foundation pit supporting structure.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

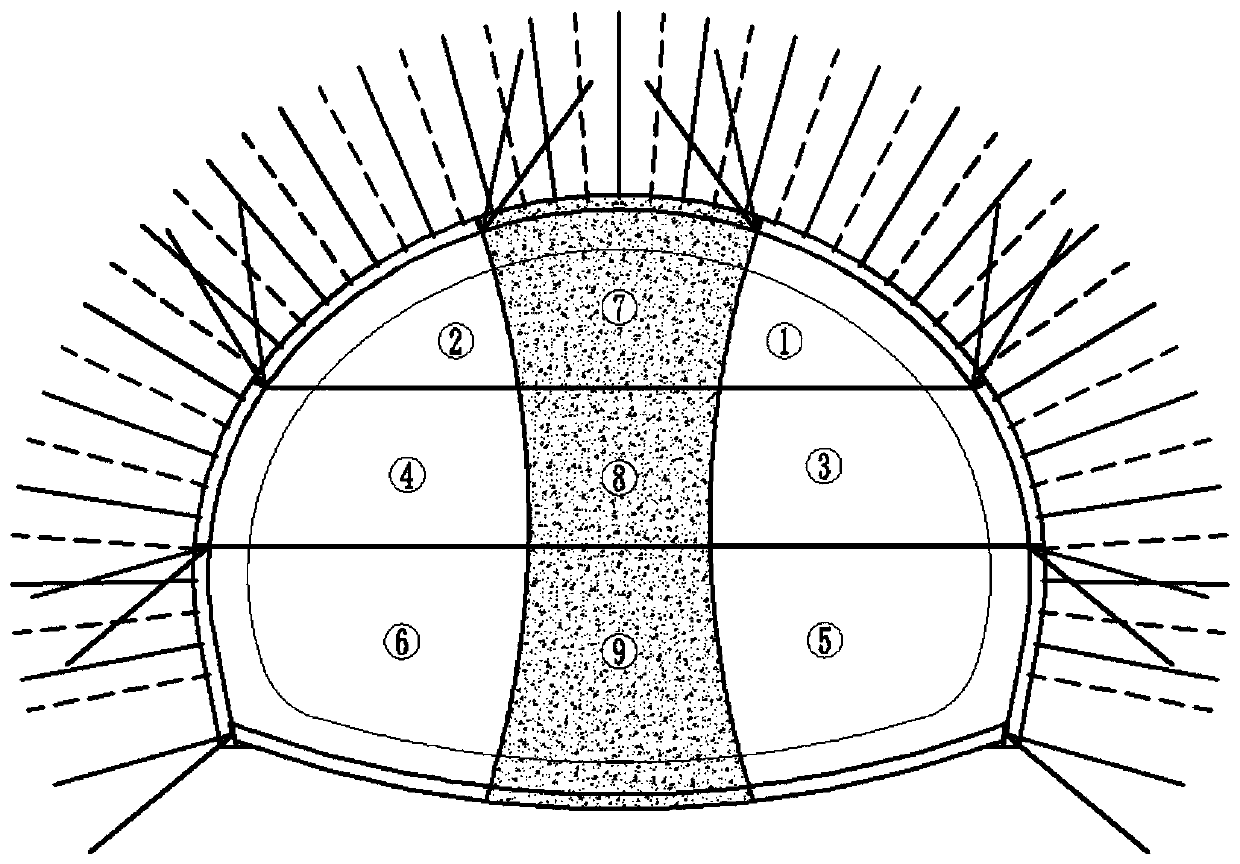

Construction method for converting three-step seven-step method to middle rock column method of ultra-large section tunnel

ActiveCN110924952AEffective control of deformationControl deformationUnderground chambersTunnel liningMining engineeringStructural engineering

The invention discloses a construction method for converting a three-step seven-step method to a middle rock column method of an ultra-large section tunnel. The construction method comprises the following steps that firstly, the three-step seven-step method is used for excavation to a to-be-converted excavation area, the to-be-converted excavation area is then subjected to regional division usingthe middle rock column method, the to-be-converted excavation area is sequentially divided into left and right side guide pits and middle rock columns, the guide pits on the left side and the right side still be continuously advanced by a three-step method in the advancing and converting process of the construction method, the right guide pit is advanced by changing the leading-out guide pit intothe leading-in guide pit, the middle three-step core soil is gradually folded to form a middle rock column support body, after the construction method is converted, the guide pits on the left side andthe right side still be continuously advanced by the three-step method, and the middle three-step core soil is folded to form the middle rock column support body in the same section. In the double-hole middle rock column method, guide holes on two sides are excavated firstly and are subjected to initial support and temporary support, the middle rock column is reserved to support the upper load, and the settlement amount is reduced. Finally, the middle rock column is removed, and an arch part of the operation and an inverted arch initial support are applied to form a closed support.

Owner:中铁二院贵阳勘察设计研究院有限责任公司 +1

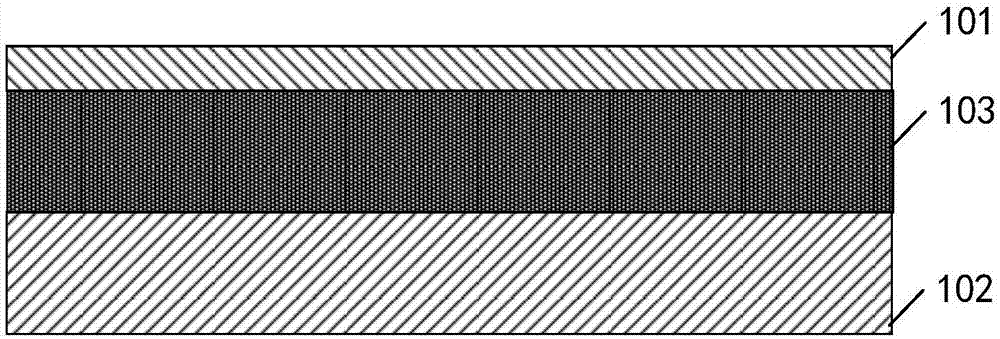

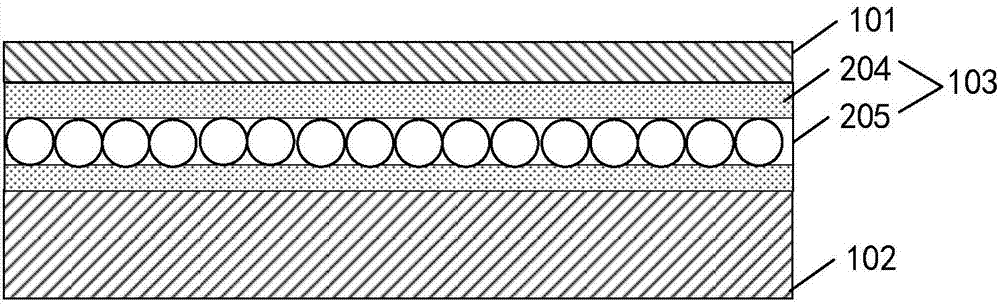

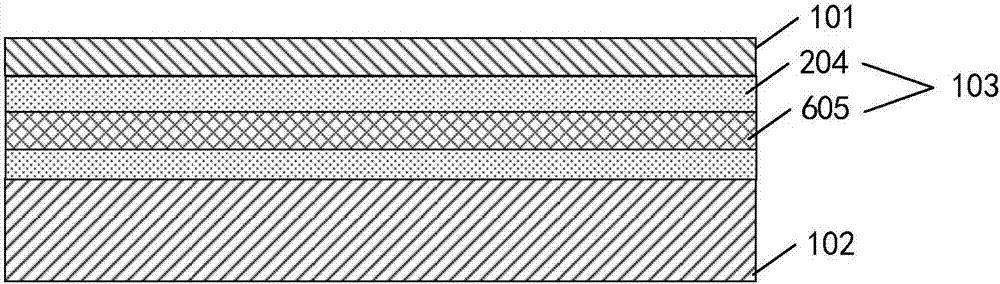

Array substrate, manufacturing method therefor, and display device

ActiveCN107154423AIncrease contact areaImprove pressure resistanceSolid-state devicesSemiconductor devicesFilling materialsEngineering

The invention relates to the technical field of display, and especially relates to an array substrate, a manufacturing method therefor, and a display device. The array substrate comprises a flexible substrate, a back protection film, and an adhesive layer. The back protection film is adhered to the flexible substrate through the adhesive layer, and the adhesive layer comprises a glue material and a plurality of nano filling materials disposed in the glue material. When the array substrate bears a larger pressure and higher temperature, the array substrate can effectively control the deformation of the adhesive layer with the help of nano filling materials in the array substrate, thereby improving the pressure resistance and thermal resistance of the whole array substrate, and improving the technological yield during circuit binding on the array substrate.

Owner:BOE TECH GRP CO LTD

Additive manufacturing deformation control method for thin-wall partition plate type parts

ActiveCN112453424AEffective control of deformationSimple designAdditive manufacturing apparatusSelective laser meltingDeformation control

The invention relates to the technical field of laser advanced additive manufacturing, and discloses an additive manufacturing deformation control method for thin-wall partition plate type parts. Themethod comprises the steps that firstly, the placement mode of a part is determined, then process support is added to a thin-wall structure part in the part, the sintering shape part of each layer oflayered slice of the thin-wall structure part is closed into a triangle, importing the process model added with the process support into magics software, manufacturing by adopting an SLM (Selective Laser Melting) process additive manufacturing method, and finally carrying out post-treatment on the obtained part to obtain the product. The problems that thin-wall partition plate type parts are proneto deformation and breakage due to large stress in additive manufacturing can be effectively solved, and the success rate of additive manufacturing of thin-wall structure assemblies is greatly increased.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Coal-rock composite roof difference scale anchor rod combined supporting method

InactiveCN102661158AEasy to operateEffective control of large deformationDetection using electromagnetic wavesAnchoring boltsGeomorphologyElectromagnetic pulse

The invention discloses a coal-rock composite roof difference scale anchor rod combined supporting method, which comprises the following steps of: transmitting electromagnetic pulses within the roof range of a pre-dug roadway by using a geological radar for advanced detection, determining interfaces of a complete rock area, a cracked rock area and a crashed rock area in the composite roof range of 50-100 meters of the pre-dug roadway according to a reflected signal received by the geological radar, and forming a three-dimensional composite roof structure geologic model by means of a computer; and calculating the length of a difference scale anchor rod through subarea geometric parameters of the section of the model, and selecting an appropriate anchor rod to support a composite roof and to assist a metal net and a steel belt to form a combined supporting structure. As the three-dimensional composite roof structure geologic model is built, complex geological data of the roof can be expressed very visually and accurately; the form of the visual interface is advantageous for field staff to operate and determine the length of the anchor rod. Besides, the deformation of the roof can be effectively controlled, the number of the anchor rods can be reduced, and a great quantity of supporting materials and a great amount of maintenance cost can be saved; and as a result, the per unit area yield and the per unit area input are improved, and the safety production is guaranteed.

Owner:SHANXI FENXI MINING GRP +1

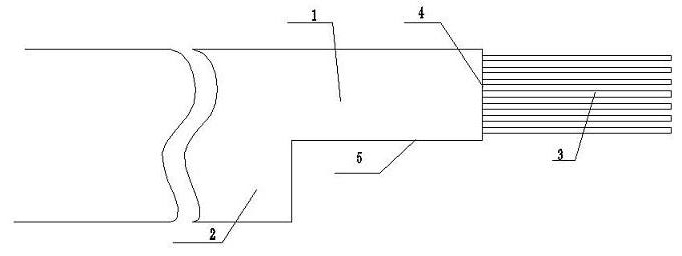

Cooling device generating flat jet and manufacturing method thereof

ActiveCN102319748AEasy to installAchieve uniformityWork treatment devicesMetal rolling arrangementsJet flowSewage outfall

The invention relates to a cooling device generating a flat jet and a manufacturing method thereof, the cooling device is characterized in that an inner pipe and an outer pipe of the cooling device are eccentrically fixed through a positioning strip for forming a cavity between the inner pipe and the outer pipe, a slit is formed in the axial direction, the width of the slit can be regulated through a tightening bolt and a compression bolt, a flange is welded at the inlet end of the inner pipe for connecting with a cooling medium pipeline, a steel plate is welded at the outlet end for sealing,and the cooling device is further provided with an inner cavity pollution discharge port. An end plate is welded at the inlet end of the cavity between the inner pipe and the outer pipe and used for sealing, the outlet end of the cavity and the flange are sealed through the end plate, and pollution can be discharged out of the cavity between the inner pipe and the outer pipe. Two rows of tidy flow through holes are formed on the inner pipe, and a cooling medium enters into the inner pipe via the flange at the inlet end, and then flows into the cavity between the inner pipe and the outer pipe via the flow through holes and further forms flat jet via the slit for cooling the steel plate. The eccentric arrangement of the inner pipe and the outer pipe of the device can form multiple damping effects for the cooling medium, the slit enables the cooling medium to form the uniform flat jet in the width direction of a rolling line, and multiple reinforcing ribs are welded outside the outer pipe in the radial direction for preventing deformation.

Owner:NORTHEASTERN UNIV

Deep nitriding method for 32cr3move material

InactiveCN106342097BEffective control of deformationSolid state diffusion coatingHardnessMaterials science

The invention relates to a method for deep layer nitriding of 32Cr 3MoVE material. Controllable atmosphere nitriding technology is used to nitriding the nitriding surface required for the deep layer. Through reasonable setting of parameters, the carburized layer depth at the gear part can be guaranteed to be above 0.47mm. After deep nitriding, the surface hardness is greater than HR15N92.5, and the hardness of the core is HRC36-43, so that the surface microstructure and the microstructure of the core conform to the navigation mark 5022 "Nitriding and Nitrocarburizing Metallographic Structure Inspection of Aeronautical Steel Parts" The corresponding requirements of "Standard" and the nitriding heat treatment method that can effectively control the deformation of parts.

Owner:HARBIN DONGAN ENGINE GRP

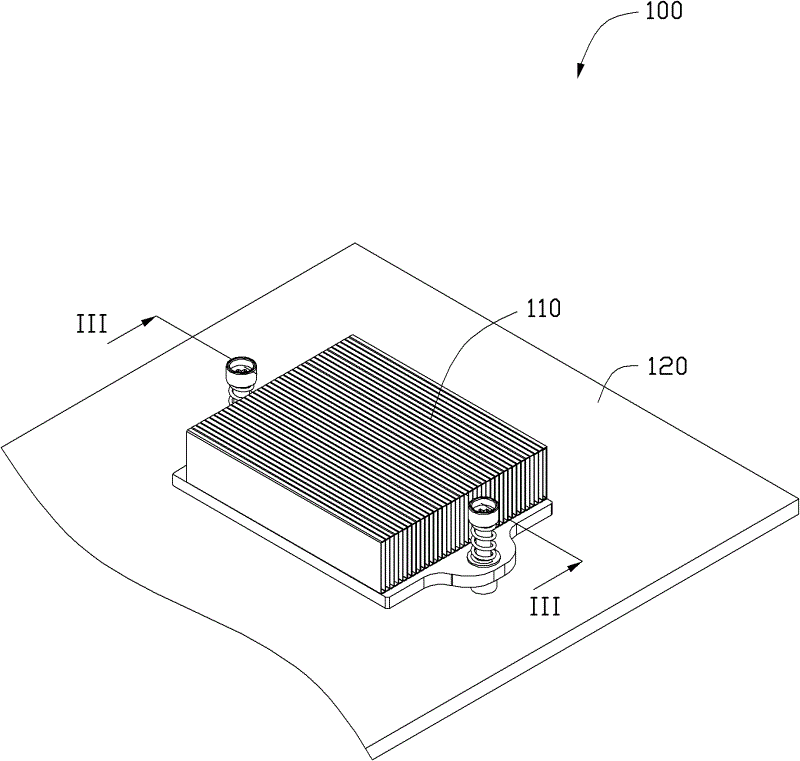

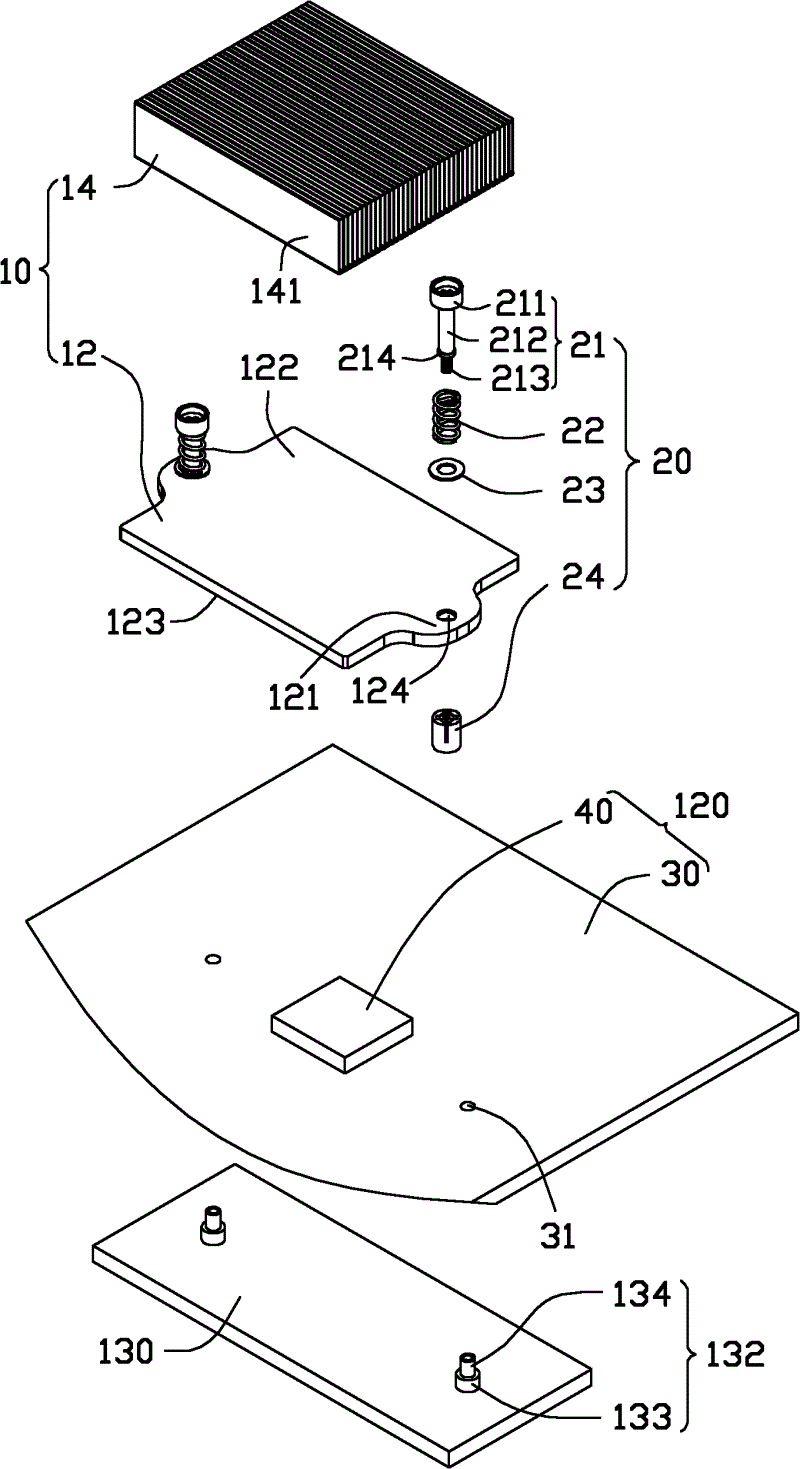

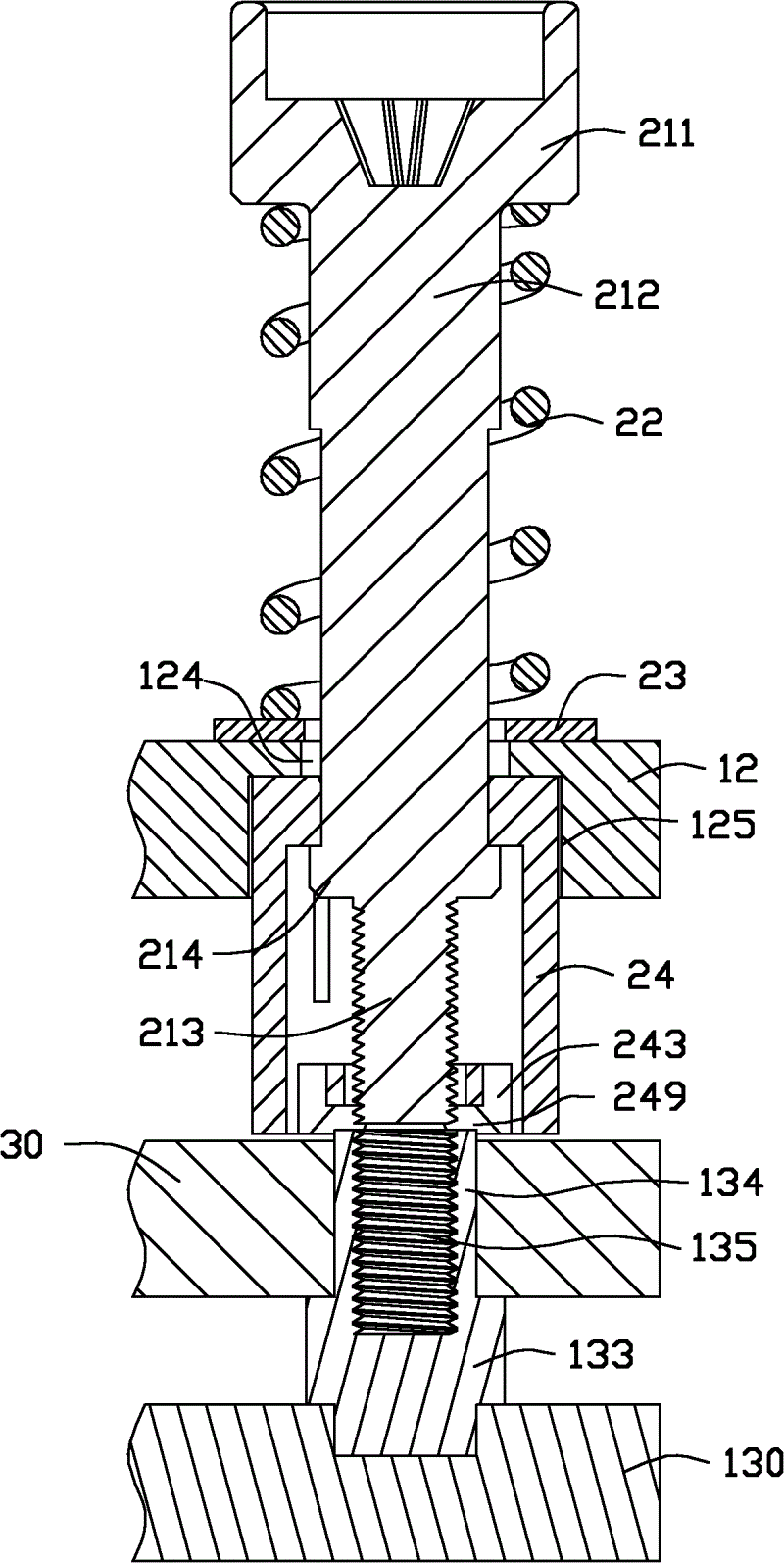

Fastening tool, heat dissipation device assembly using fastening tool, and electronic device

InactiveCN102623420AControl the buckle forceEffective control of deformationDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat sink

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Water-rich disturbance sensitive stratum shield excavation grouting structure and construction method

ActiveCN110939450AAvoid dilutionPrevent penetrationUnderground chambersTunnel liningSoil scienceGroundwater

Owner:CCFEB CIVIL ENG

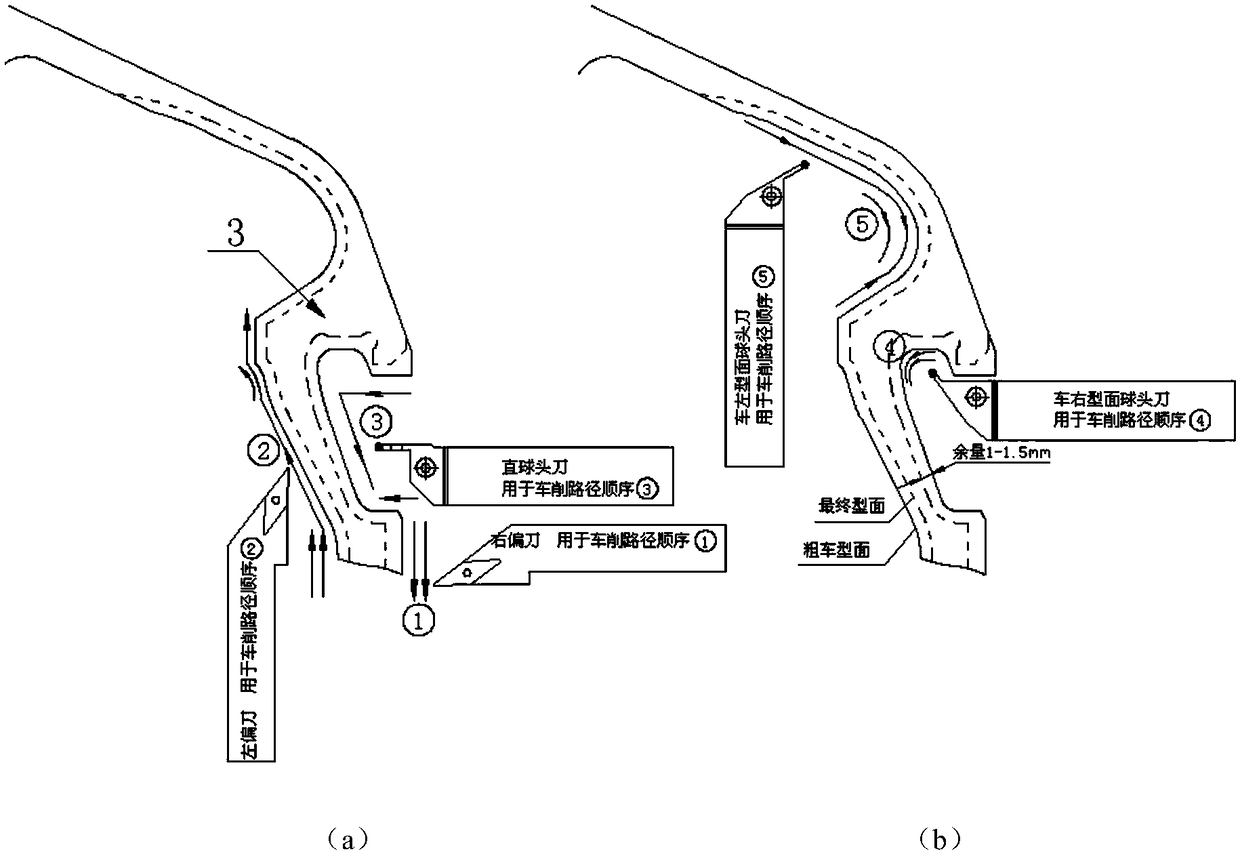

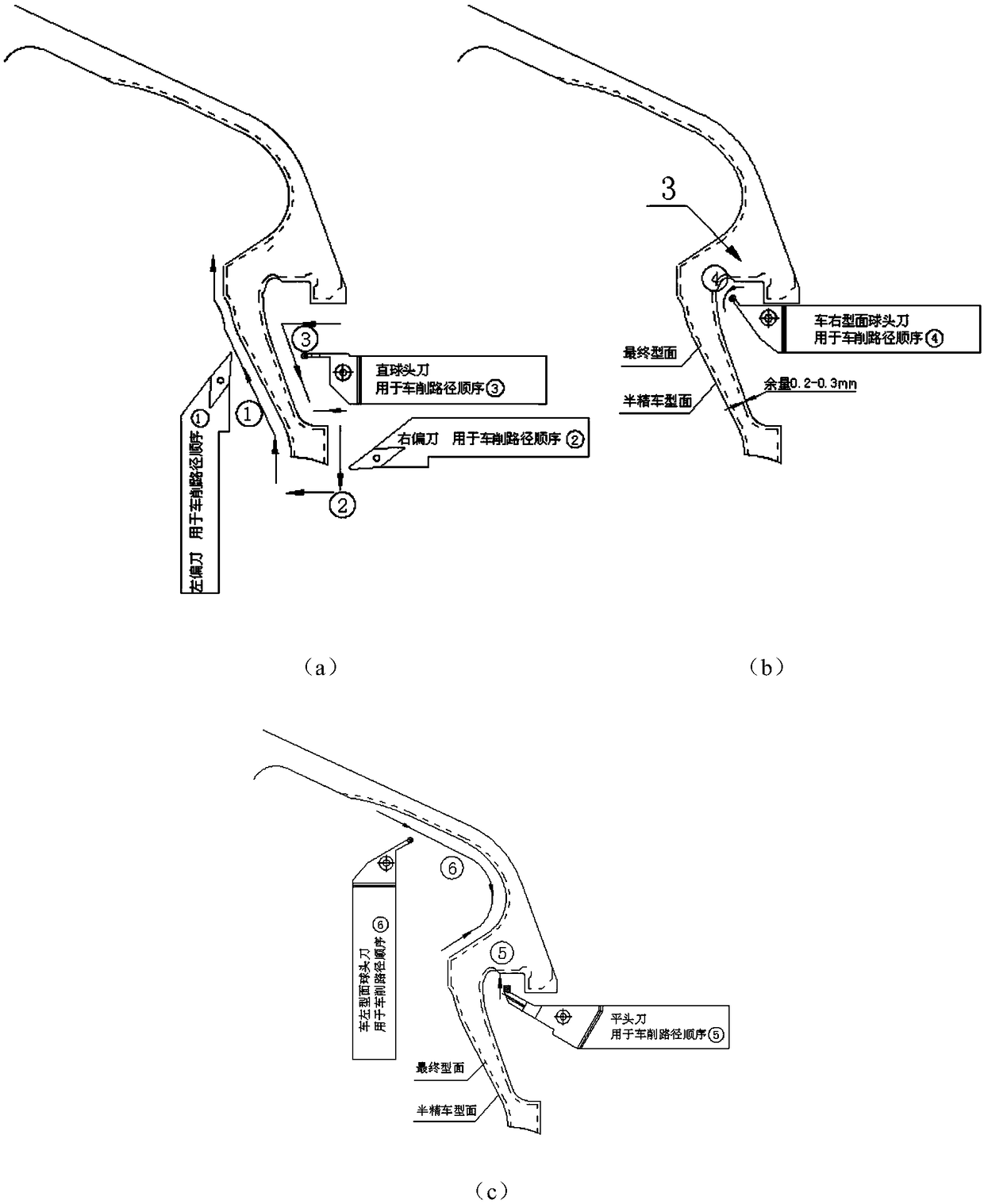

Method for turning complex thin-wall part profile by adopting quasi-symmetric layered circulation

ActiveCN108655417AEffectively control deformation of processing partsEffective control of deformationTurning machinesFree stateEngineering

The invention discloses a method for turning a complex thin-wall part profile by adopting a quasi-symmetric layered circulation. The method is characterized in that the integral part of a rotary bodypart is clamped in a local unrestraint mode, and the two ends profiles of the complicated thin-walled part to be machined are placed in an unconstrained free state, then a single-step layered circulation is adopted, and the quasi-symmetric layered turning mode of rough turning, semi-finish turning, fine turning and the finish turning are sequentially adopted in one procedure so as to turn the twoends profiles of the part to be machined. According to the method, only one procedure and one clamping are needed, and the machining of the local two ends profiles of the part can be completed, the part does not need to be turned over in the machining process, and the deformation control effect is good.

Owner:AECC AVIATION POWER CO LTD

Supporting method of carboniferous system geologic structure in-zone breaking country rock roadway

ActiveCN103122768AEffective control of deformationControl deformationMine roof capsAnchoring boltsTectonicsFactor of safety

The invention particularly discloses a supporting method of a carboniferous system geologic structure in-zone breaking country rock roadway. The problems of that support of the carboniferous system geologic structure in-zone breaking country rock roadway is incomplete is solved. According to the supporting method of the carboniferous system geologic structure in-zone breaking country rock roadway, temporary support to a roadway is carried out when a heading machine group is stepped forward and cut to a certain distance, and then permanent support composed of two steps is carried out. The permanent support comprises that a steel wire mesh is laid, girders are loaded up, roof bolts are installed, gang-part bolts are installed, and roof anchor ropes are installed. The supporting method of the carboniferous system geologic structure in-zone breaking country rock roadway is capable of lightening digging subsidiary transport work amount and improving a safety factor inside the roadway and has high economic effectiveness.

Owner:DATONG COAL MINE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com