Steel sheet pile cofferdam structure construction method

A technology of steel sheet pile cofferdam and construction method, which is applied in the direction of foundation structure engineering, construction, etc., can solve the problems of increasing the design difficulty of steel sheet pile cofferdam, the difficulty of controlling the verticality of steel sheet pile insertion, and the deviation of steel sheet pile insertion, etc. Achieve the effects of high overall rigidity, control of vertical precision, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

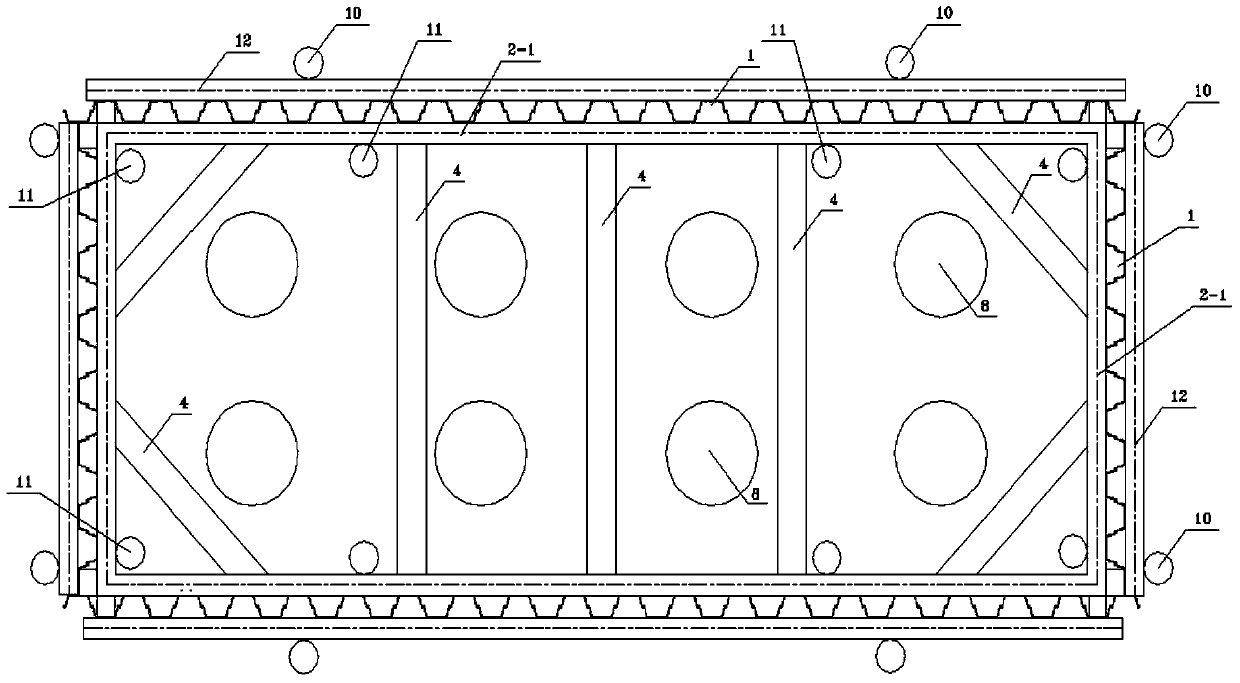

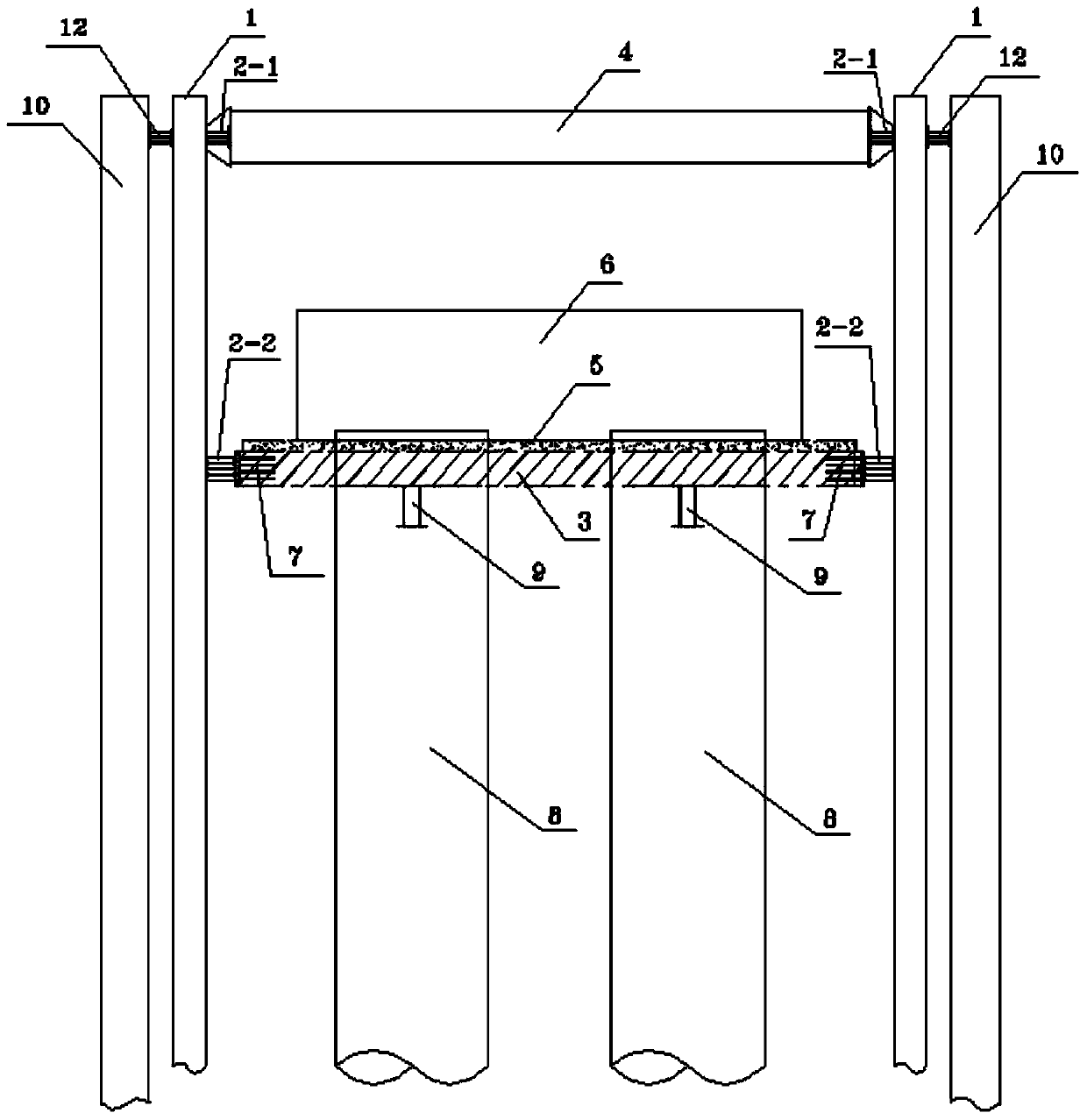

[0027] (1) Set the inner positioning steel pipe pile 11 and the outer positioning steel pipe pile 10 inside and outside the steel sheet pile cofferdam, and install and fix the upper plane positioning structure 12 on the inner wall of the upper part of the outer positioning steel pipe pile;

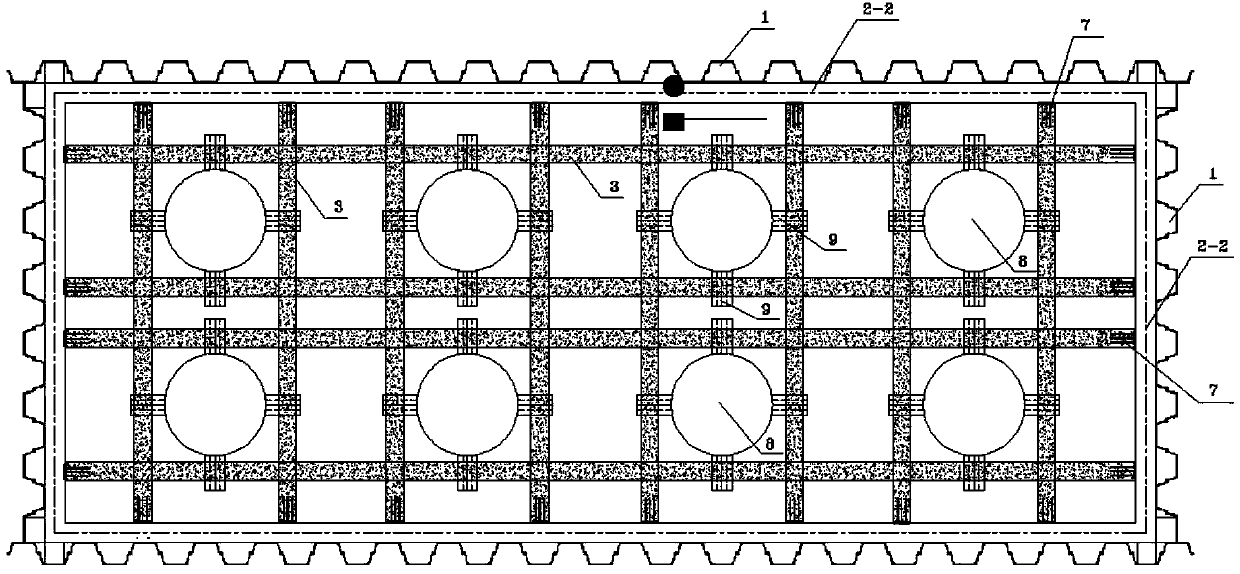

[0028] (2) Install the cantilever beam connected with the lower prefabricated concrete supporting system through the suspender to the top of the steel casing, so that the bottom of the lower precast concrete supporting system reaches the position of the preset corbel on the steel casing, and the lower prefabricated The overall concrete support system is formed by welding the prefabricated concrete inner support 3 of the well-shaped beam type lower floor and the purlin 2-2 of the lower floor through the embedded parts 7;

[0029] (3) Install the upper purlin 2-1 on the inner positioning steel pipe pile 11, insert and drive the steel sheet pile 1 between the upper purlin and the upper plane p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com