Patents

Literature

63results about How to "Improve overall stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

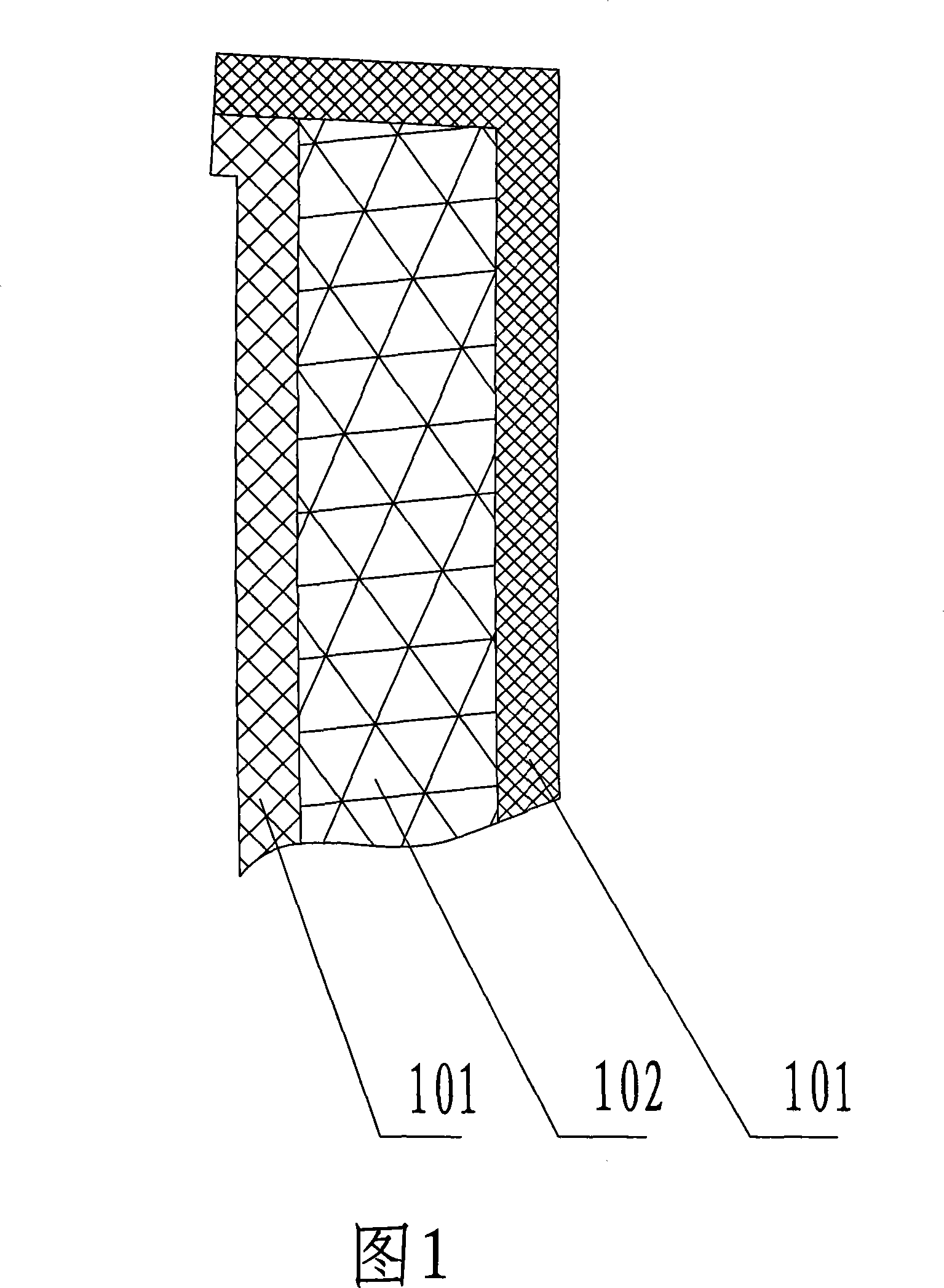

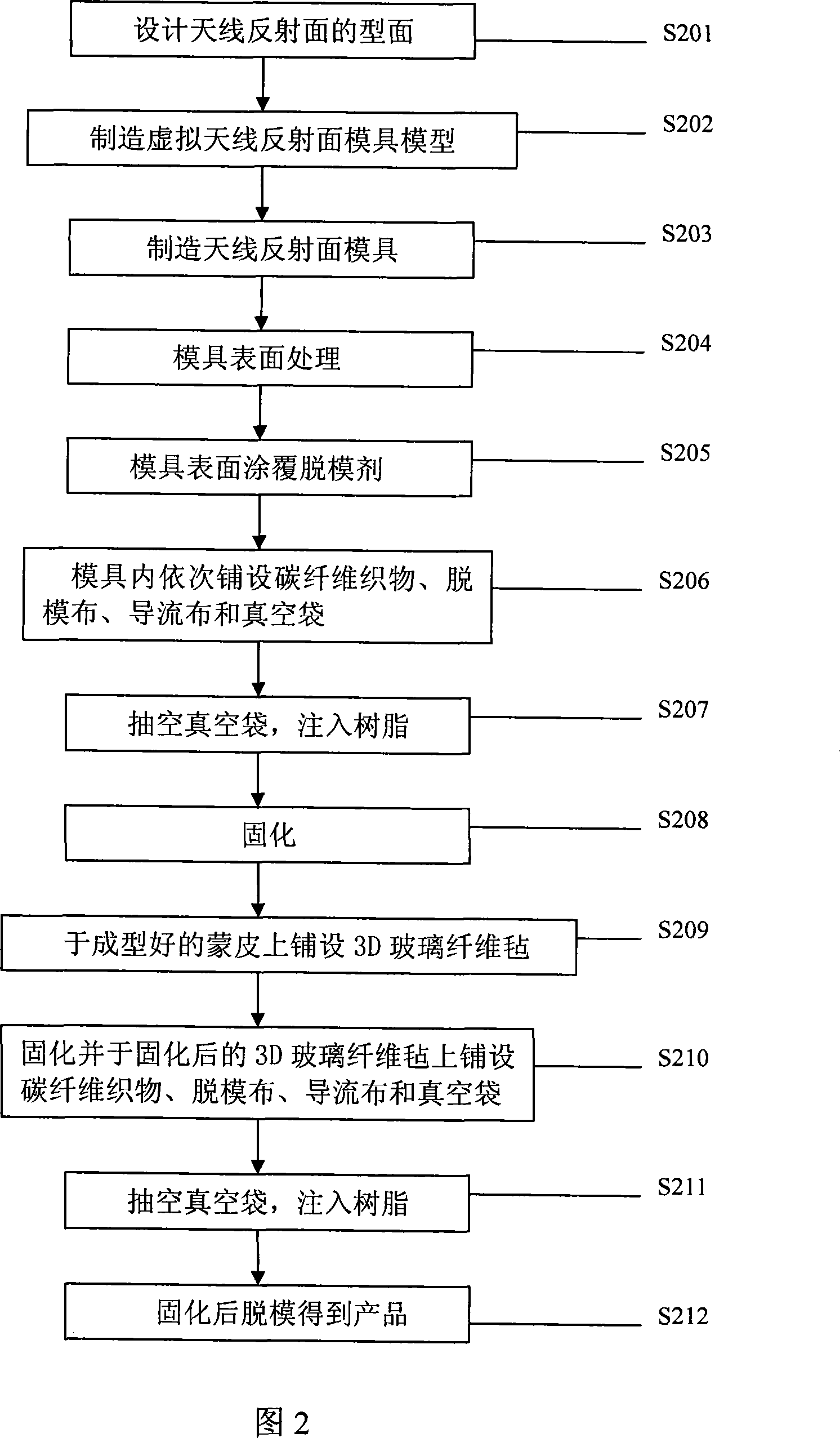

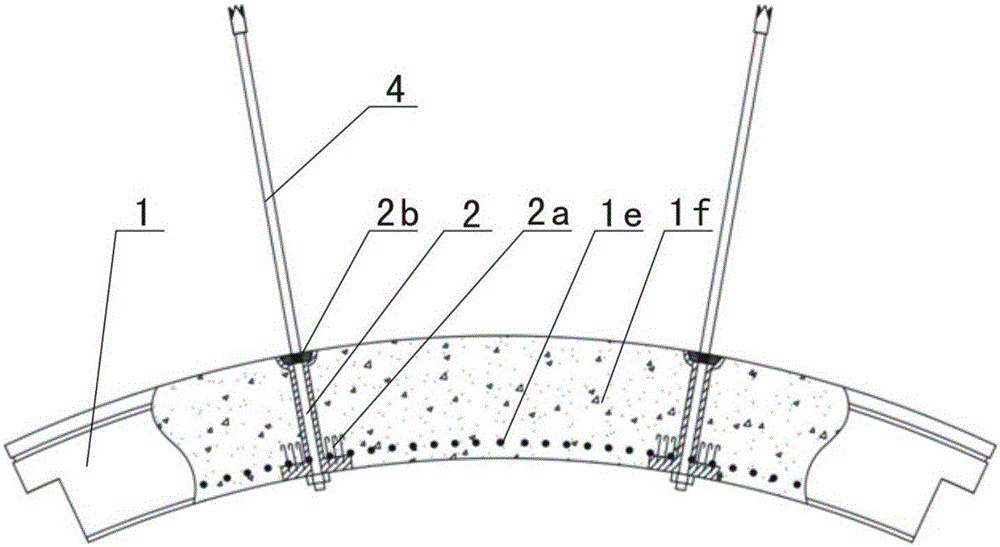

Composite material satellite antenna reflection surface and manufacturing process thereof

InactiveCN101227029AHigh profile precisionImprove overall stiffnessGlass/slag layered productsNatural mineral layered productsSatelliteCarbon fiber composite

The invention relates to the technology field of communication and observation control, which provides a composite material satellite antenna reflection plane and the method for preparation. The composite material satellite antenna reflection plane adopts 3D glass fiber felt as core material, and adopts carbon fiber composite as covering sandwich type composite material satellite antenna reflection plane. Compared with the prior art, the invention has the following advantages: 1. shaped surface accuracy of the satellite antenna reflection plane is high and satellite signal gain is great, 2. quality of the reflection plane is light, and is fit for transportation, in particular to fitting for vehicle satellite antenna and portable satellite antenna, 3. integrality of the reflection plane is good, hardness is great, thereby being capable of preferably retaining the shaped surface accuracy and bearing more wind load and impact load, 4. adopting the 3D glass fiber felt as the core material, the invention inaugurates a new technology of the sandwich composite material satellite antenna reflection plane, the technology is capable of producing heavy caliber satellite antenna reflection plane, and which is simple in manufacturing technology comparatively and low in the cost.

Owner:吴豪 +1

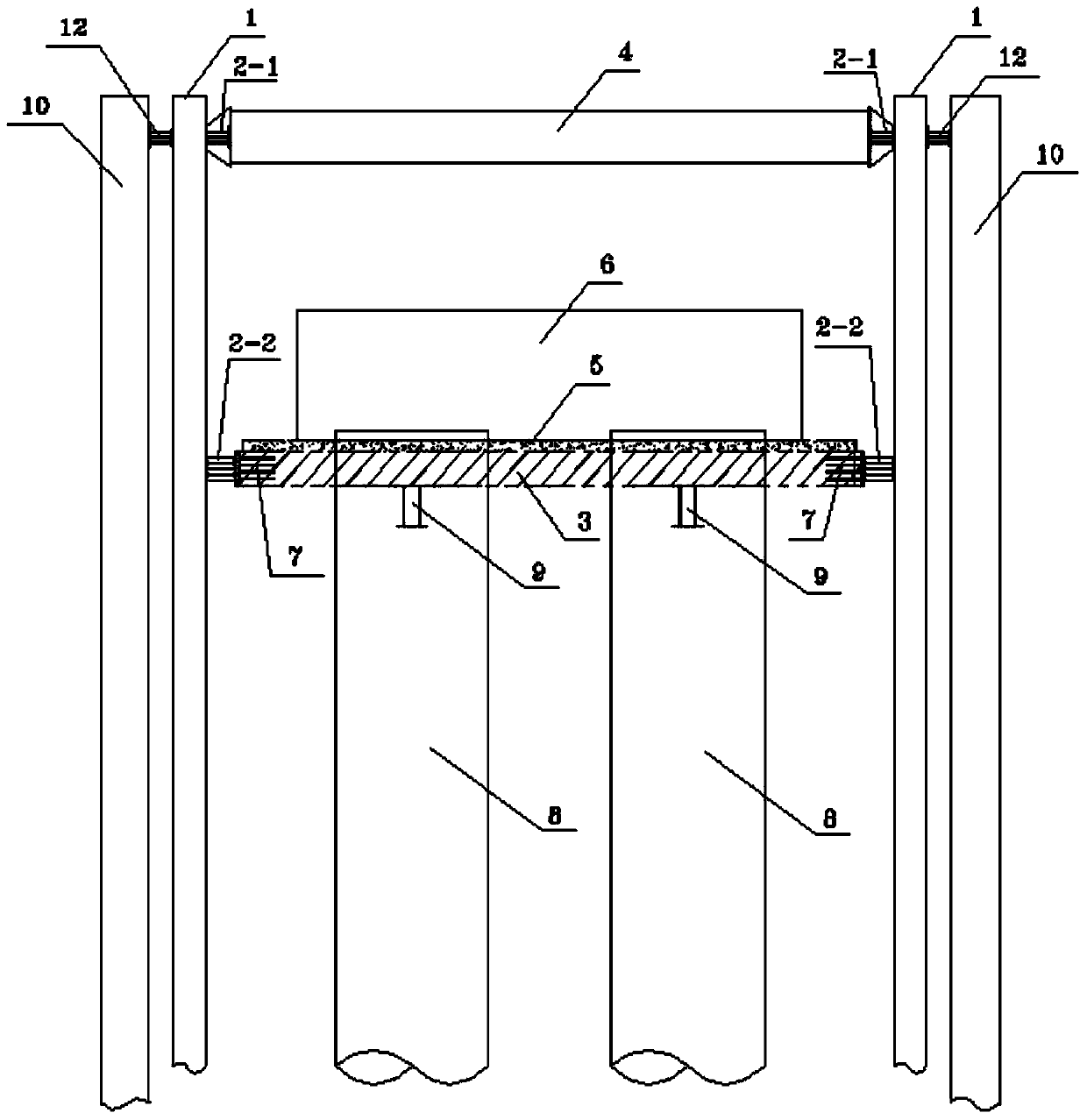

Steel sheet pile cofferdam structure construction method

The invention discloses a steel sheet pile cofferdam structure construction method which comprises the steps that (1) an inner side locating steel pipe pile and an outer side locating steel pipe pile are arranged on the inner side and the outer side of a steel sheet pile in a ramming mode, and an upper layer plane locating structure is fixedly arranged on the inner wall of the upper portion of the outer side locating steel pipe pile; (2) a cantilever beam which is connected with a lower layer precast concrete supporting whole system through a hanging rod is arranged on the top of a steel protecting cylinder; (3) an upper layer enclosing purlin is arranged on the inner side locating steel pipe pile, a steel sheet pile is inserted between the upper layer enclosing purlin and the upper layer plane locating structure in a ramming mode, the steel sheet pile is welded with the upper layer enclosing purlin in an inserting mode, and then an upper layer steel inner support is fixedly arranged in the upper layer enclosing purlin; (4) water in the steel sheet pile cofferdam is extracted out, a bracket is welded to support a lower layer precast concrete inner support, then the steel sheet pile and the lower layer enclosing purlin are welded, finally the hanging rod is removed, and the cantilever beam is detached; and (5) bearing platform concrete construction is carried out. The vertical accuracy of the steel sheet plate can be effectively controlled with the method.

Owner:CHINA CONSTR SIXTH ENG DIV CORP +1

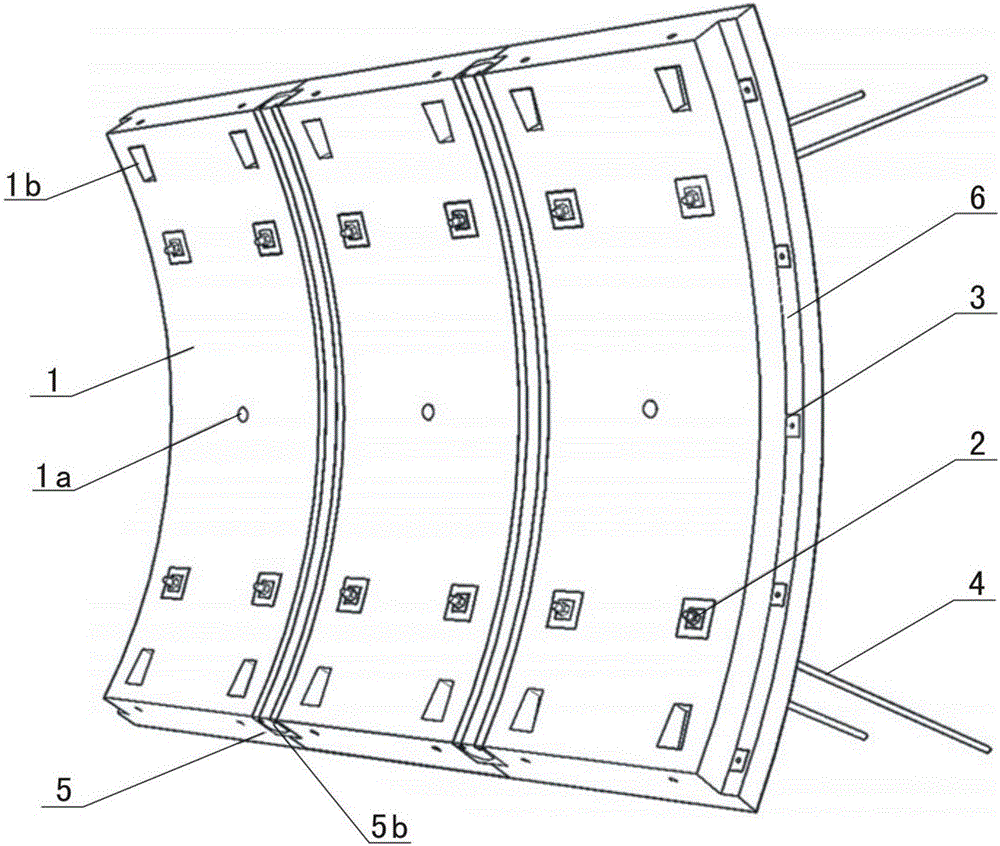

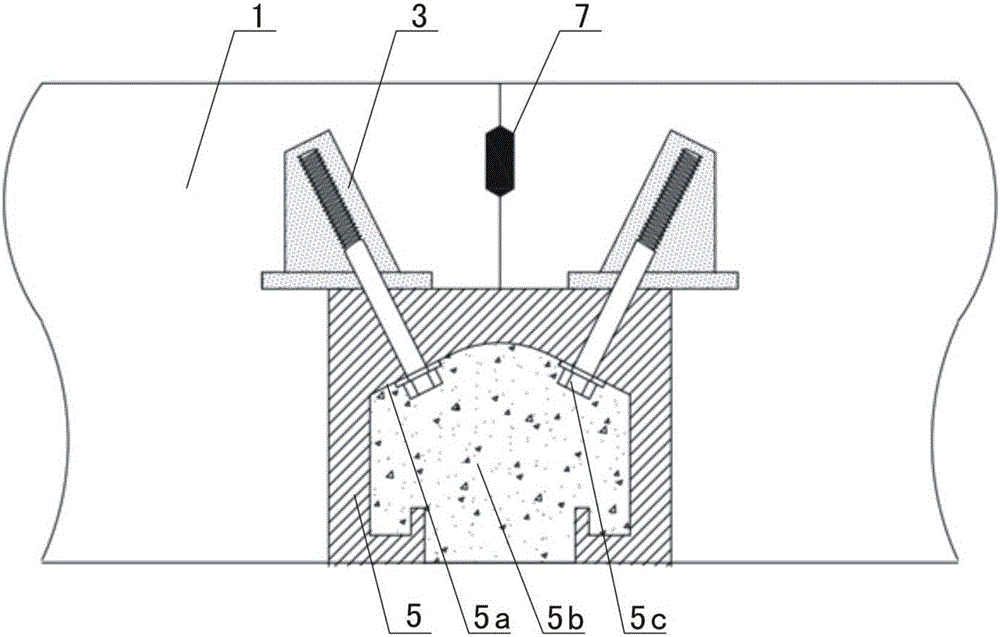

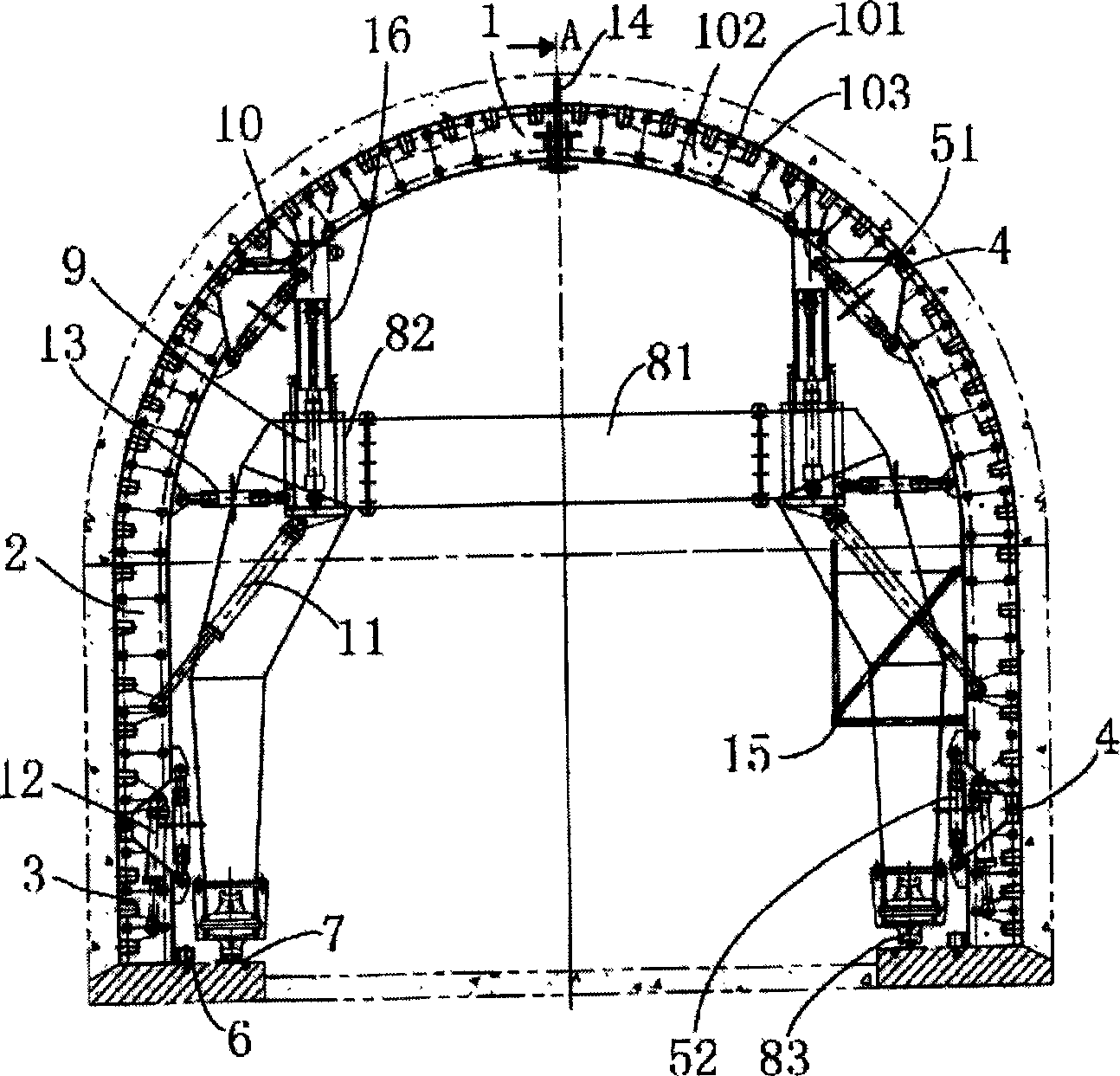

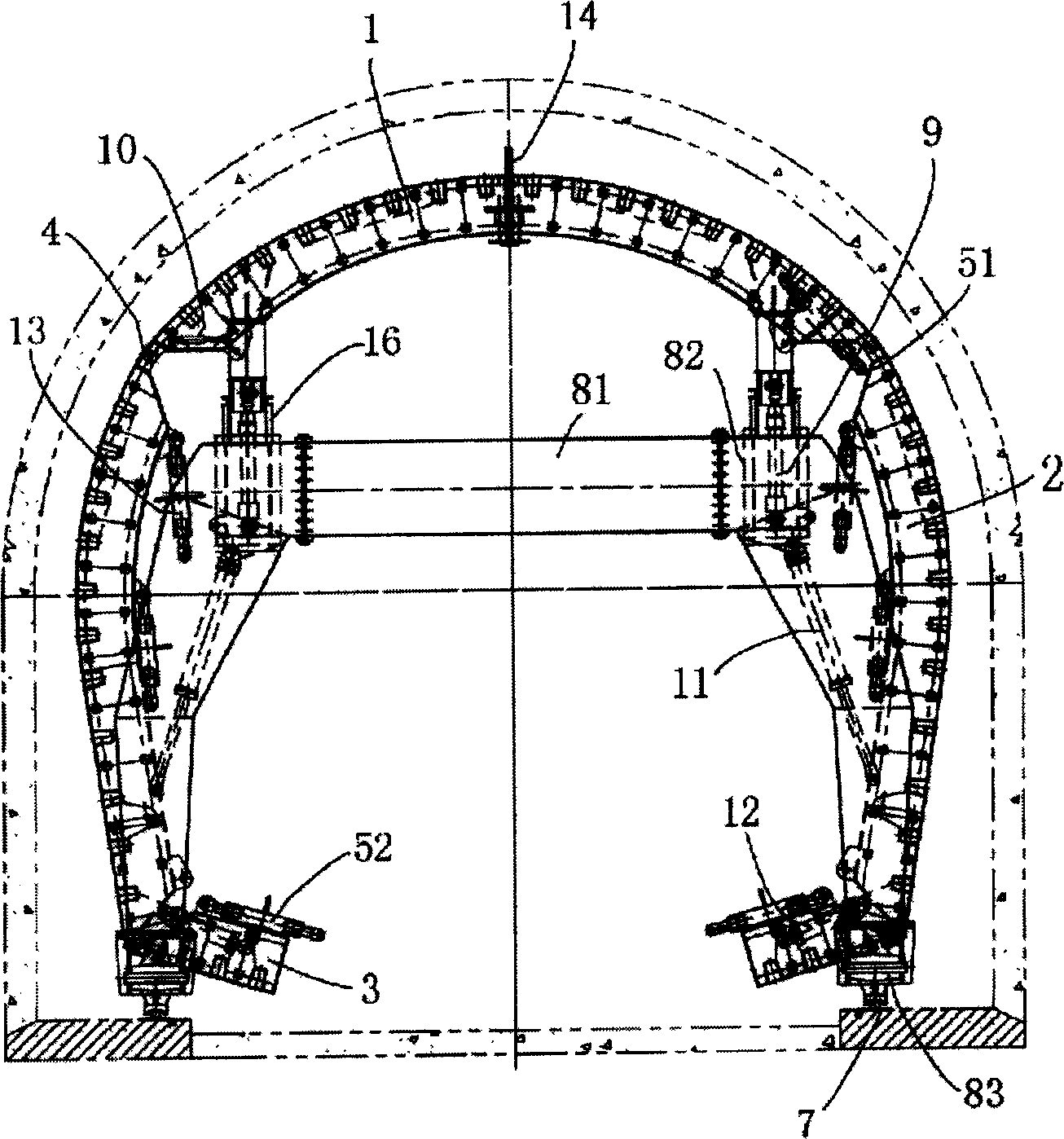

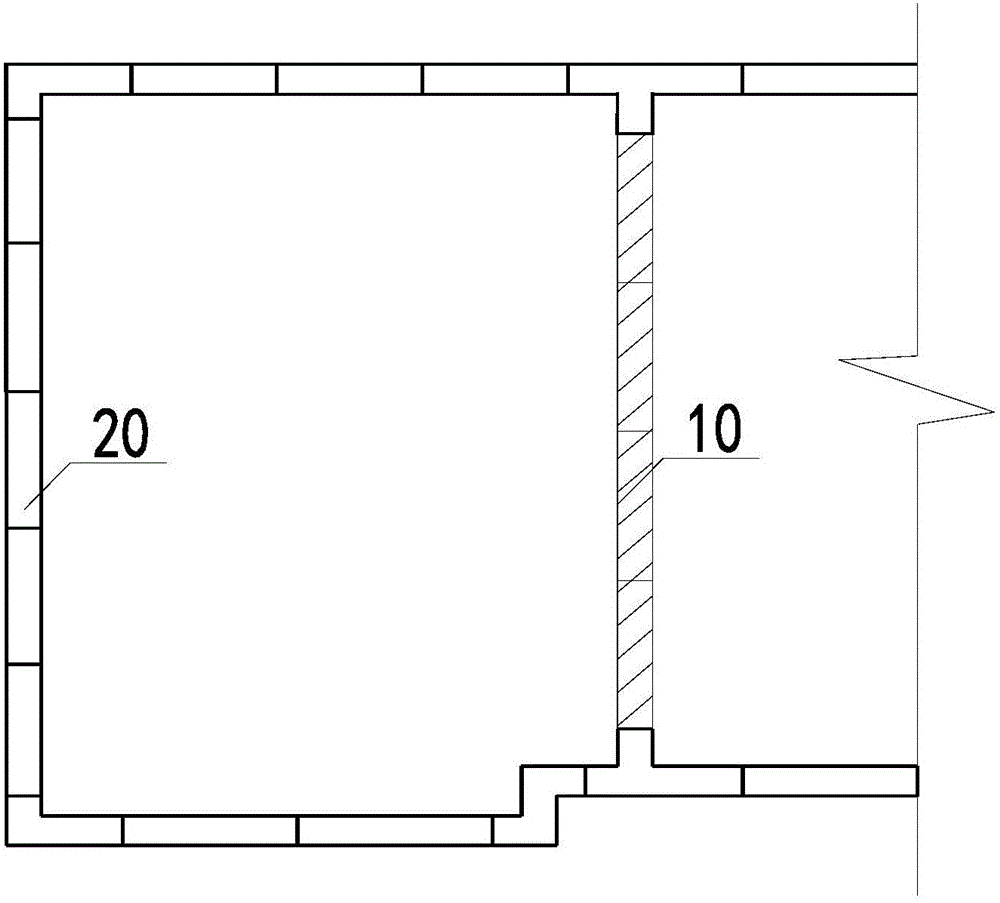

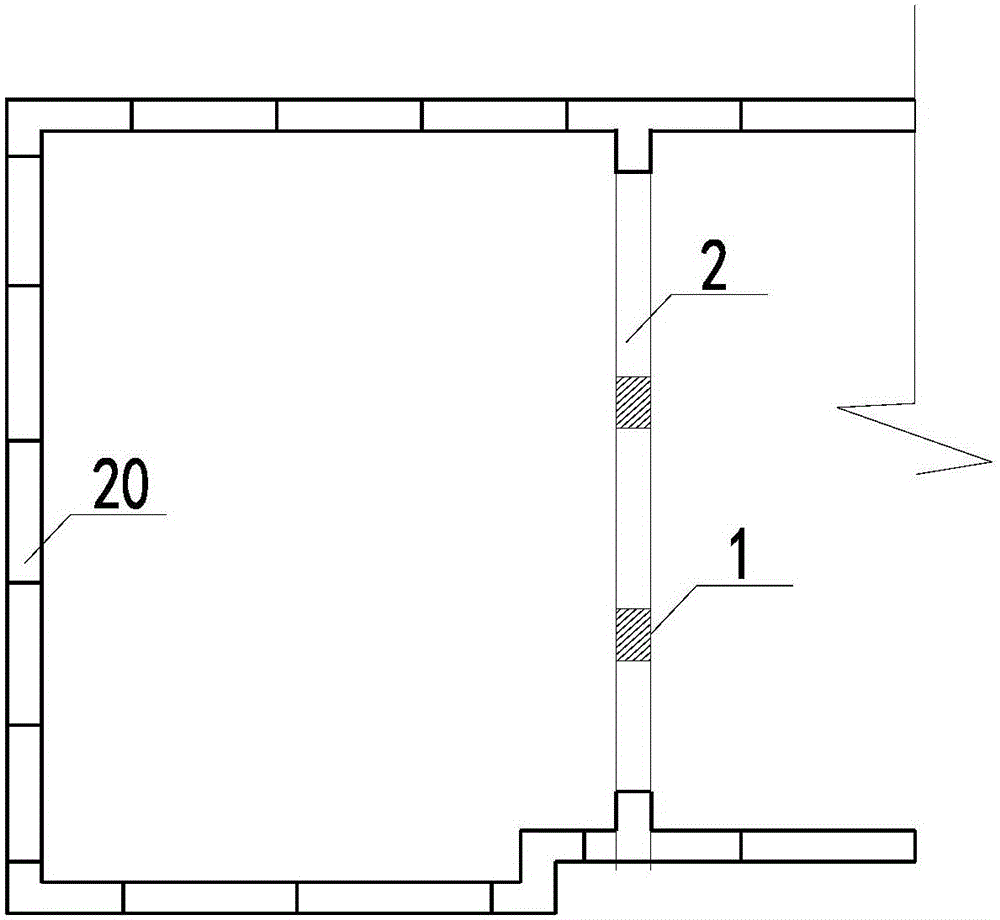

Segmental lining reinforcing type combined supporting structure

ActiveCN105756685AImprove overall stiffnessReduce in quantityUnderground chambersTunnel liningRebarTunnel construction

The invention discloses a segmental lining reinforcing type combined supporting structure which comprises segments and arch-shaped racks, wherein the segments are made of reinforcing steel bars and concrete; the radial cross sections of the arch-shaped racks are C-shaped; mounting grooves are respectively formed in two sides of the segments; one arch-shaped rack is mounted inside mounting grooves of every two adjacent segments and is fixedly connected with the two adjacent segments; the outer sides of the arch-shaped racks are opened. According to the segmental lining reinforcing type combined supporting structure disclosed by the invention, every two adjacent segments are fixedly connected through the arc-shaped rack, so that the overall rigidity of a joint part can be improved, meanwhile slab staggering of the joint part is reduced, and the number of hand holes of the segments is reduced; due to the mounting grooves in two sides of the segments, a step-shaped joint is formed between every two adjacent segments, so that the waterproof property of the joint is improved, and the segmental lining reinforcing type combined supporting structure is particularly applicable to tunnel construction under geological conditions of high ground stress and large deformation.

Owner:SOUTHWEST JIAOTONG UNIV

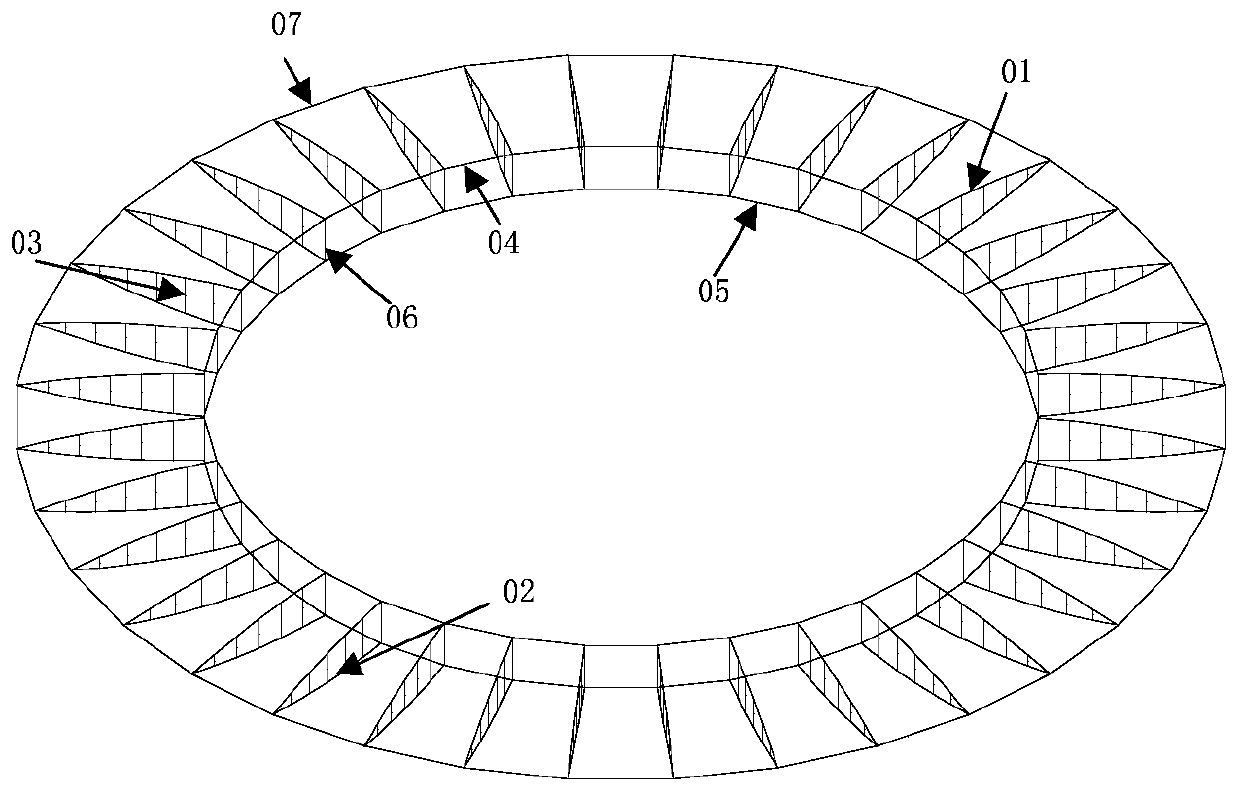

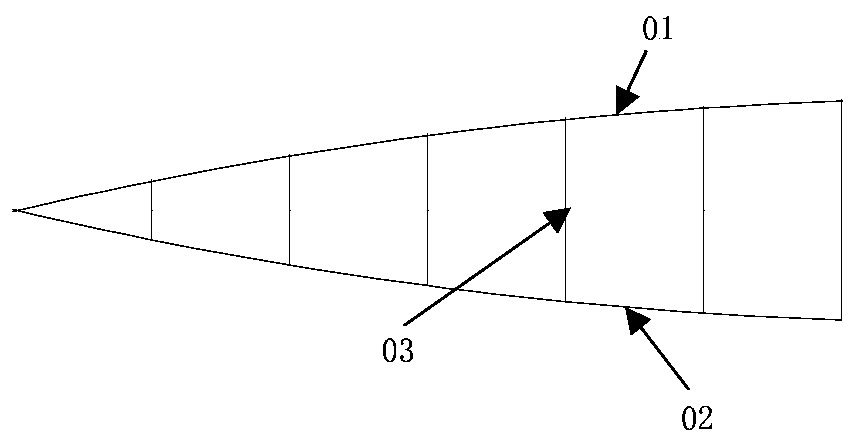

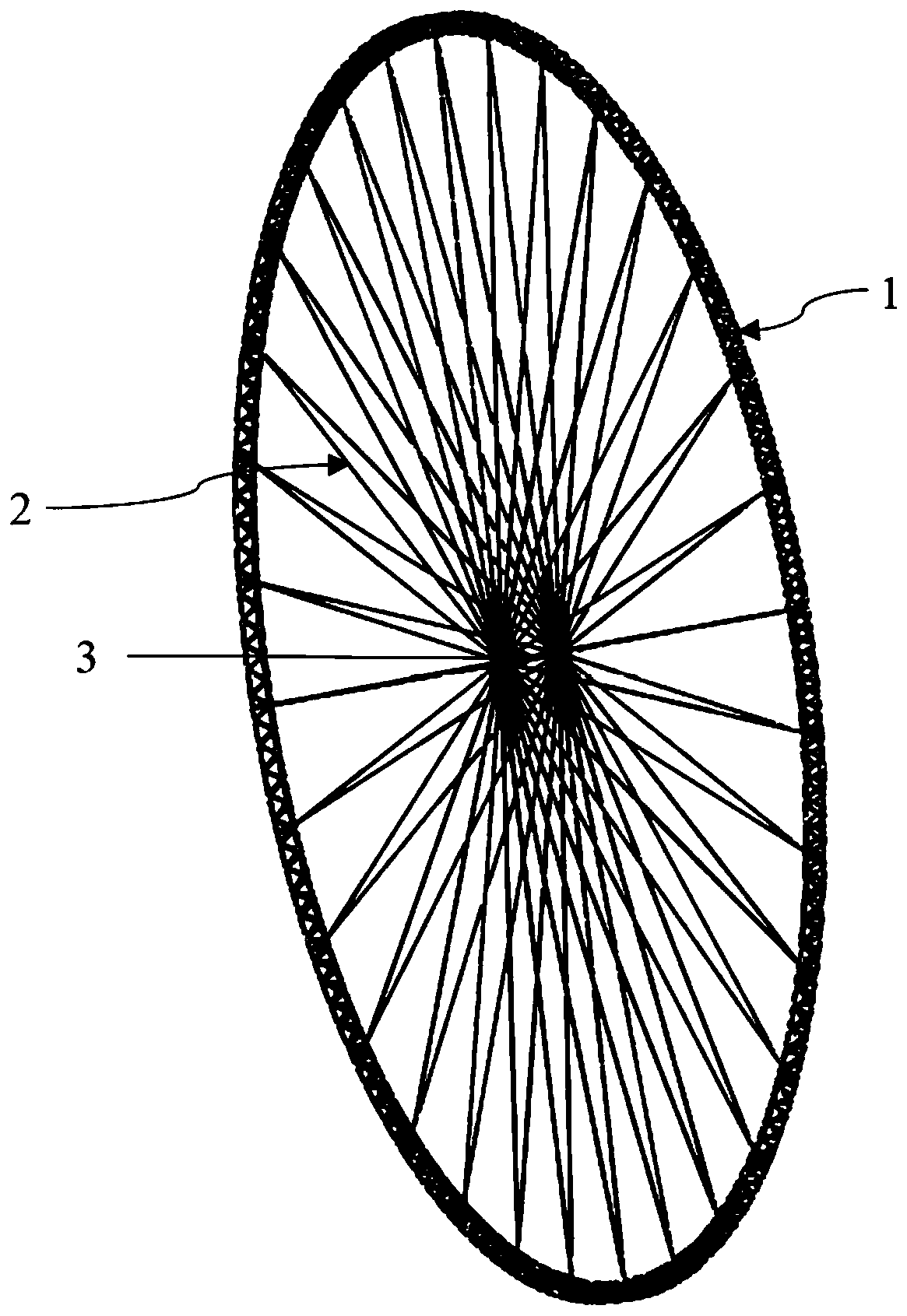

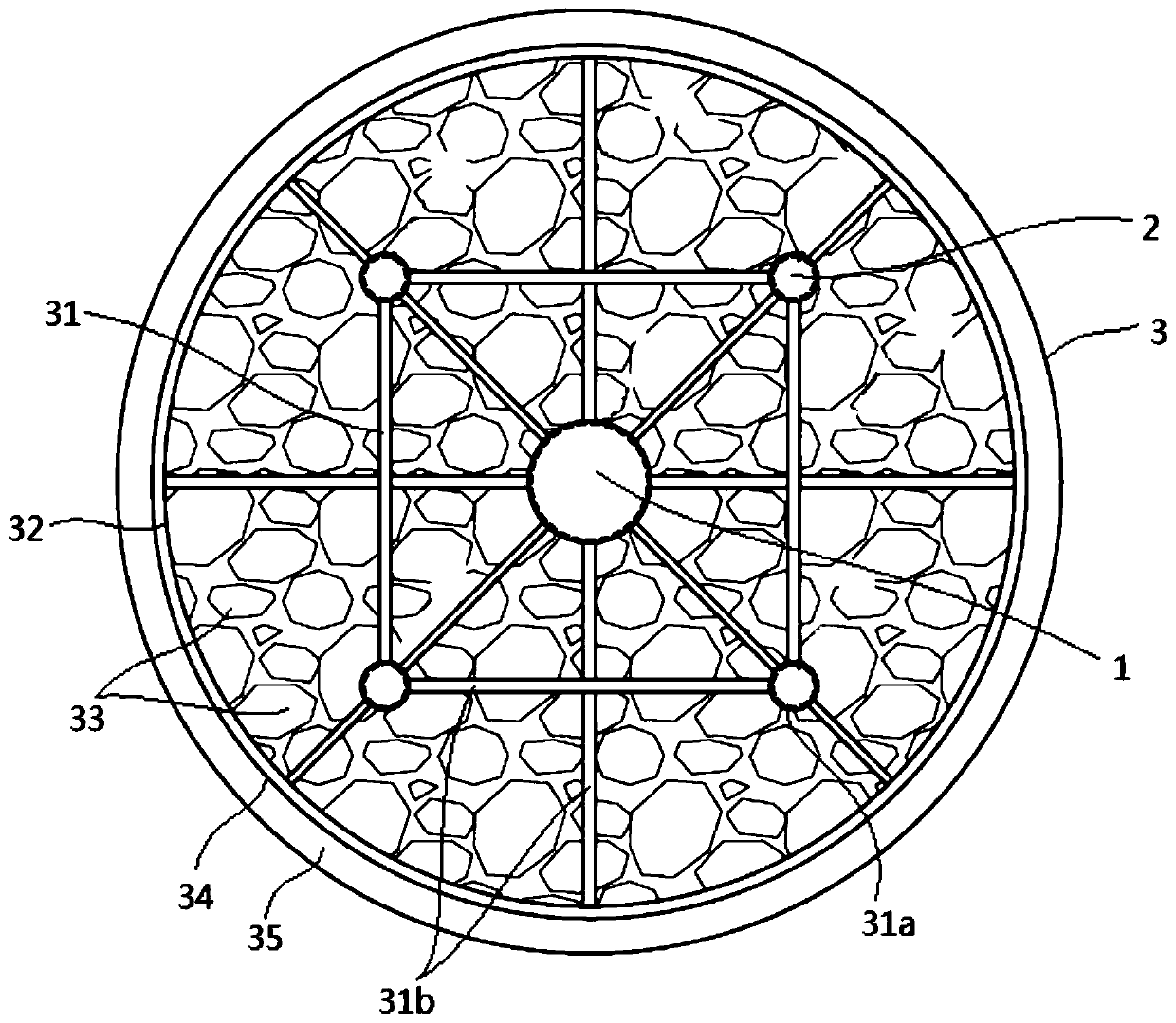

Carbon fiber cable reinforced spoke type cable truss structure

PendingCN111441477AImprove overall stiffnessDecreased static and dynamic responseBuilding roofsAwningLong span

The invention relates to the field of large-span stadium awning structures, in particular to a carbon fiber cable reinforced spoke type cable truss structure. The spoke type cable truss structure comprises a radial cable truss, an inner pull ring and an outer pressing ring, wherein the inner pull ring and the outer pressing ring are arranged at the two ends of the radial cable truss. The radial cable truss is composed of an upper radial cable, a lower radial cable and cable truss supporting rods, the inner pull ring is composed of an upper ring cable, a lower ring cable, a ring cable supporting rod and an inner ring cross cable, and the inner ring cross cable is a carbon fiber cable. According to the carbon fiber cable reinforced spoke type cable truss structure, the carbon fiber cross cable is additionally arranged in an inner ring cable plane of the spoke type cable truss structure; after the improvement, the vertical rigidity of the spoke type cable truss structure is greatly enhanced, and the response is obviously reduced under the action of wind loads and the like. The carbon fiber cable is small in section and rigidity, the influence on the inner pull ring cable force is small, the cable clamp unbalanced force can be remarkably reduced, the cable clamp structure is simplified, and therefore the problem that the cable clamp bearing capacity is insufficient is solved without additionally arranging balance cables.

Owner:BEIJING INST OF ARCHITECTURAL DESIGN

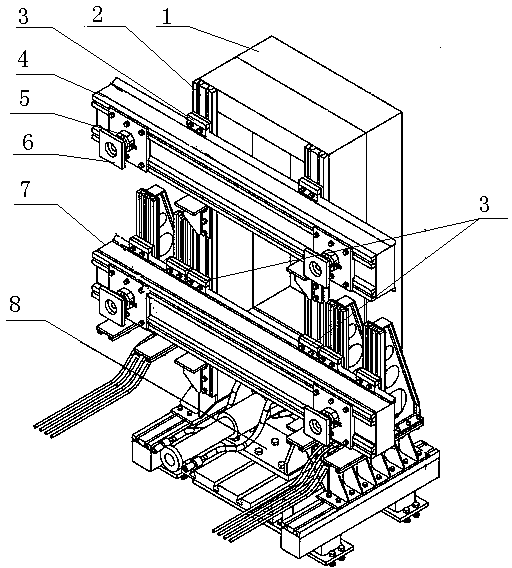

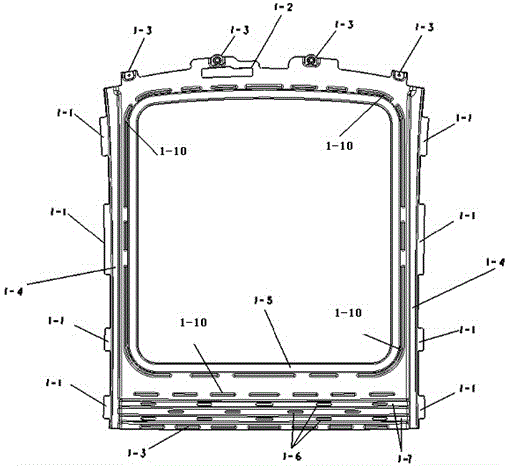

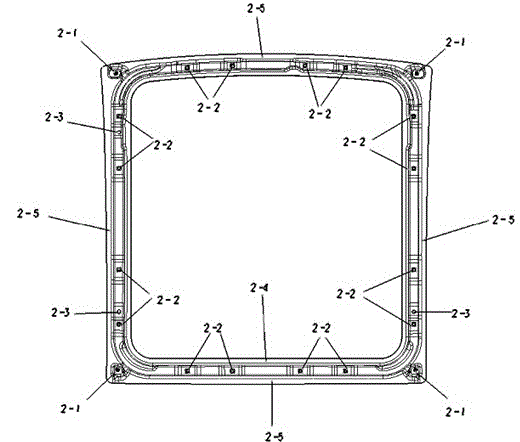

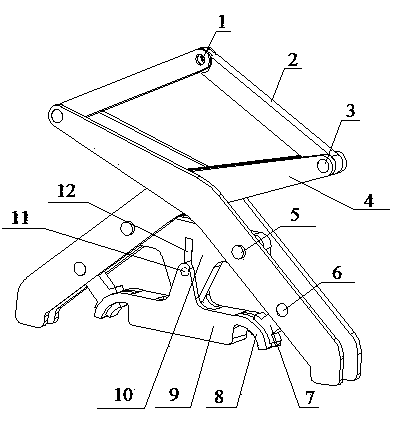

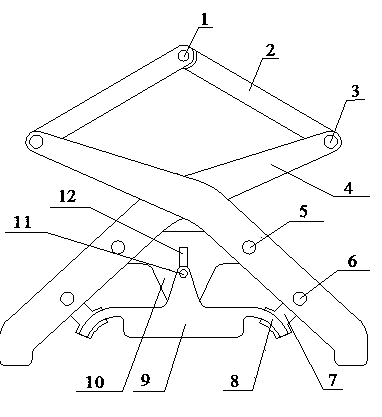

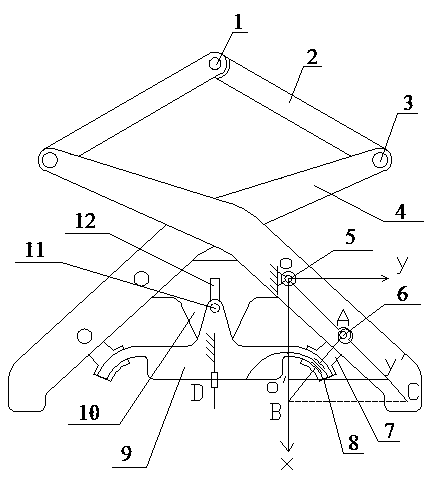

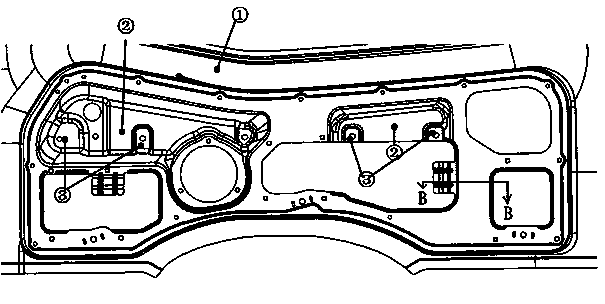

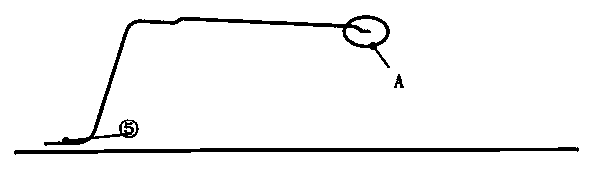

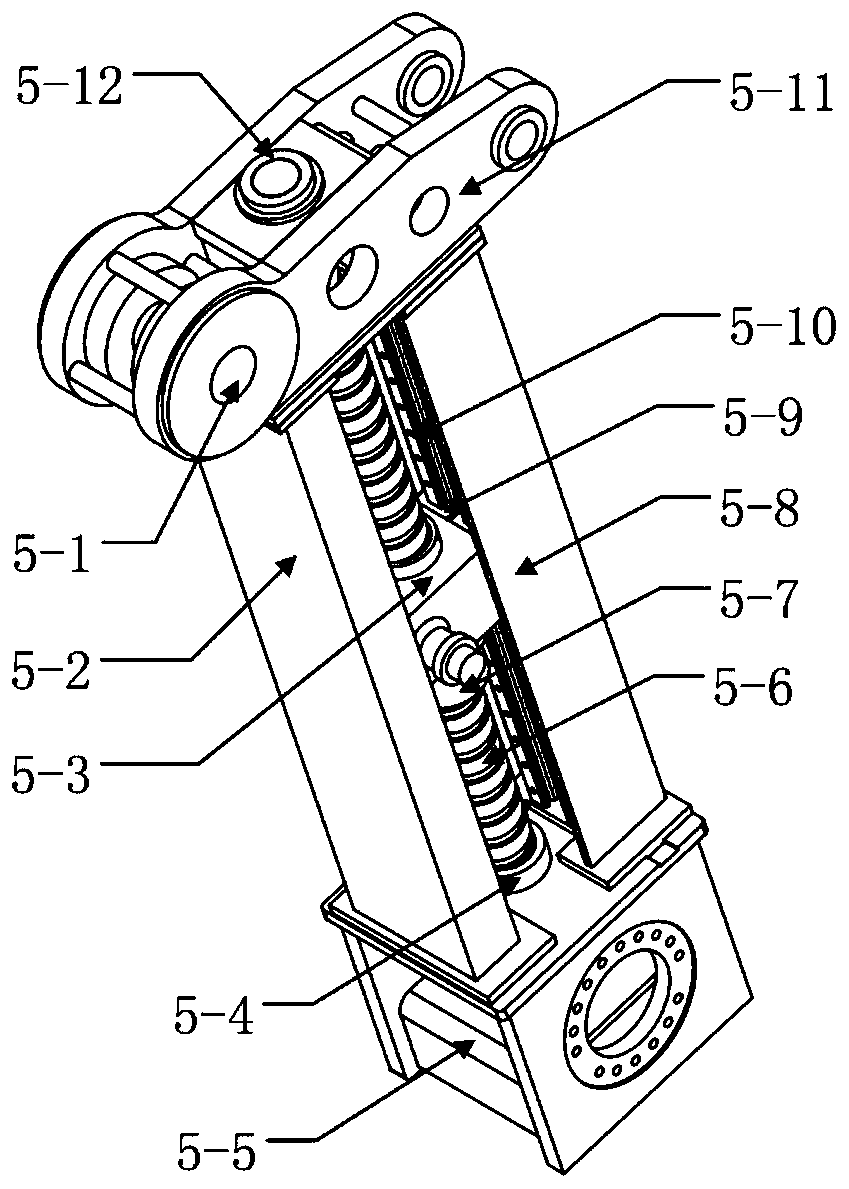

Device for measuring railway vehicle end relation

ActiveCN103439123AFlexible and convenient disassembly and assembly adjustmentImprove overall stiffnessRailway vehicle testingForce sensorWindshield

A device for measuring a railway vehicle end relation is characterized in that the device comprises an upper n-shaped frame dovetail guide rail beam device, a lower n-shaped frame dovetail guide rail beam device, a draw gear counter-force hinge base assembly and a vehicle end wall fixing device, the upper n-shaped frame dovetail guide rail beam device is connected with a T-shaped groove guide rail in front of the vehicle end wall fixing device through a pressing bar assembly, the lower n-shaped frame dovetail guide rail beam device is connected with a T-shaped groove guide rail in front of the vehicle end wall fixing device through a pressing bar assembly as well, the parts of the overall device are arranged in pairs oppositely, and vehicle end connecting boards on the front side faces of the upper n-shaped frame dovetail guide rail beam device and the lower n-shaped frame dovetail guide rail beam device are used for clamping a vehicle body in an experiment. According to the device for measuring the railway vehicle end relation, connection can be completed according to different structures and sizes of draw gears, the interference force detection of the draw gears, the detection of the windshield acting force and the force moment of a vehicle end wall and the detection of the acting force and the force moment of a vehicle end electric cable can be completed; disassembly, assembly, combination and adjustment of a door are flexible and convenient, an gantry is large in overall rigidity, the requirements of rigidity tests can be satisfied, the adjustment of electric cable connecting points between trains is convenient, and the installation position of a force cell is conveniently adjusted.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD +1

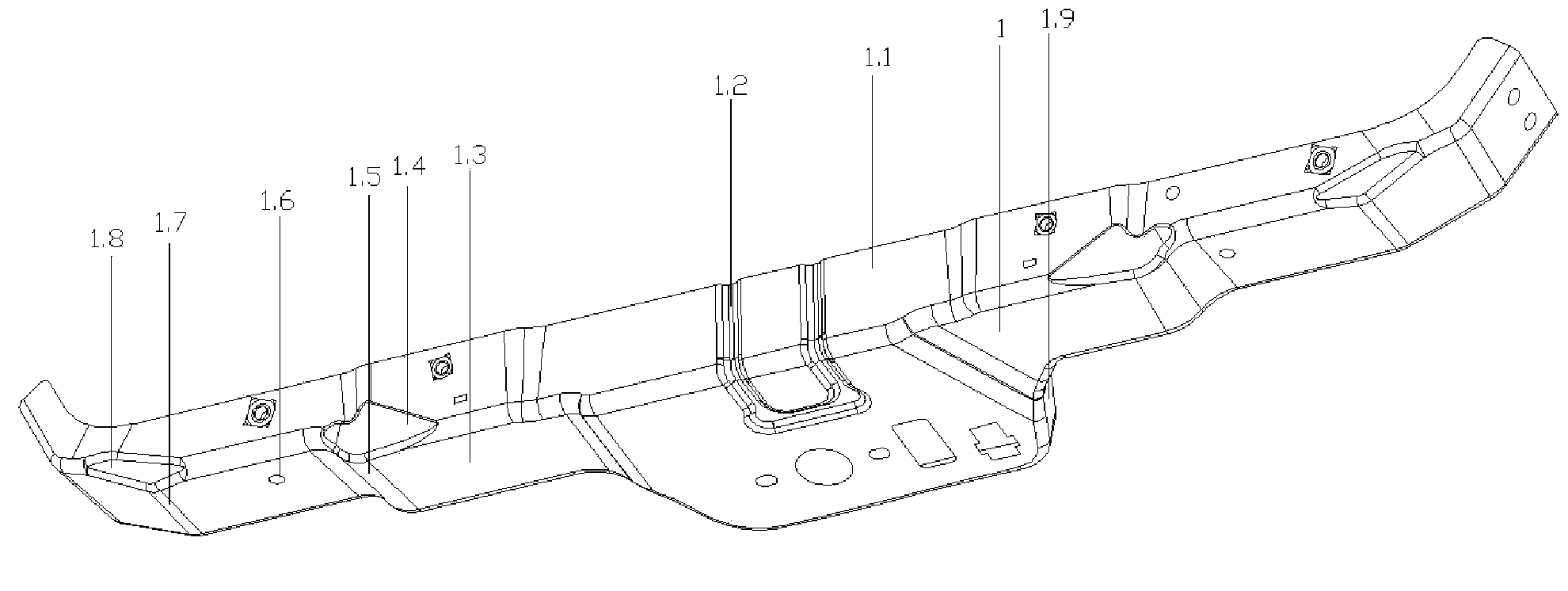

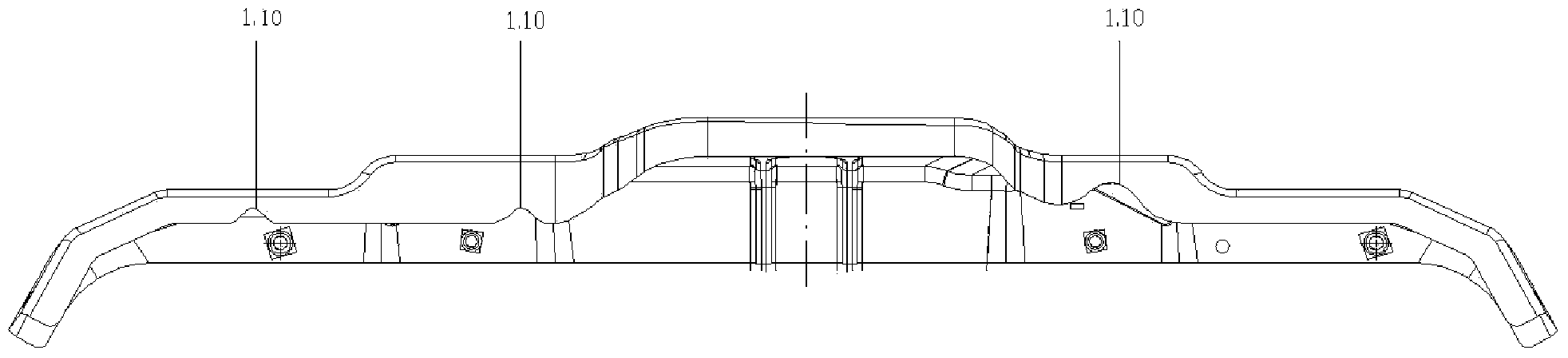

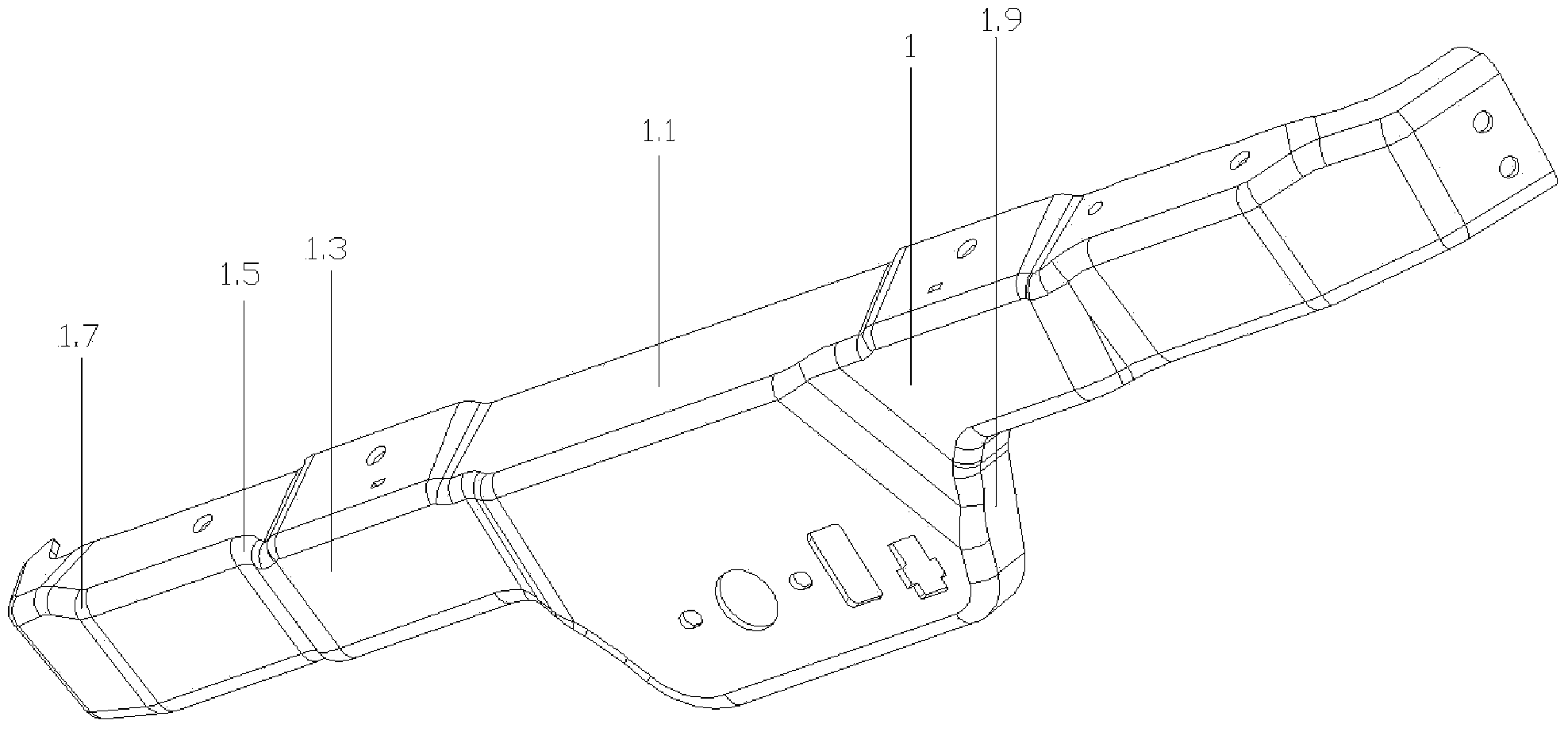

Automobile water tank upper beam made of carbon fiber composite materials and manufacturing method thereof

ActiveCN103523094AImprove overall stiffnessMeet high strengthSuperstructure subunitsCarbon fiber compositeEngineering

The invention discloses an automobile water tank upper beam made of carbon fiber composite materials and a manufacturing method of the automobile water tank upper beam, and belongs to the field of composite materials and automobile parts. The water tank upper beam structurally at least comprises a beam body, a beam wing, a first wing, a second wing, side edges and a beam head; in a vacuum state, carbon fiber fabric is infiltrated by resin and is formed through pressure. The water tank upper beam is made of the composite materials which use multilayer multi-layer-direction carbon fiber fabric materials as reinforcement and use epoxy resin as a substrate, so that the integral rigidity of the water tank upper beam is improved; through CAE computational analysis, the Z-directional rigidity of the water tank upper beam can reach 424N / mm, the conditions of high strength, high modulus and load can be satisfied, and meanwhile the water tank upper beam can be lightened by more than 60%; due to the fact the carbon fiber materials are used, the weight of the water tank upper beam can be substantially reduced, and fuel efficiency can be greatly enhanced; because the structure of the water tank upper beam made of the carbon fiber materials is greatly simplified, one-off processing forming is facilitated, and manufacturing cost is effectively reduced.

Owner:CHERY AUTOMOBILE CO LTD

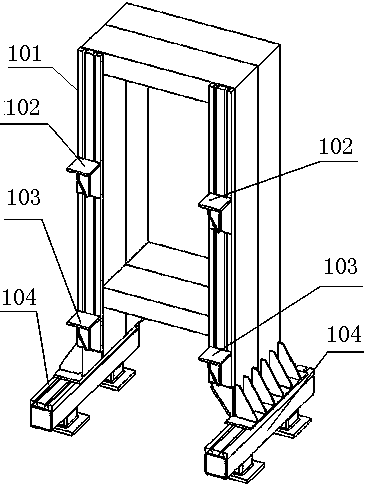

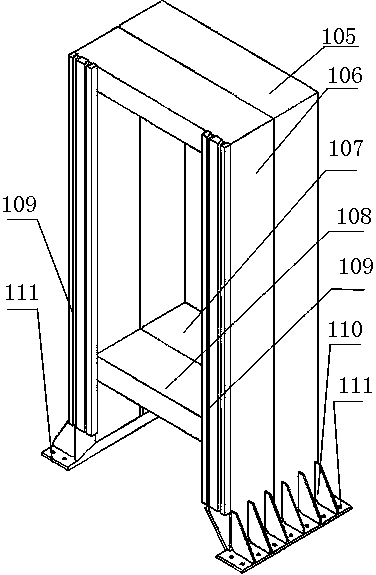

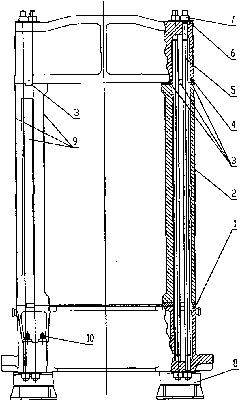

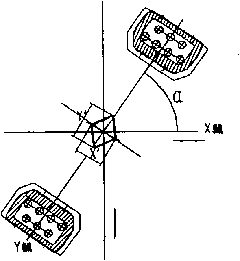

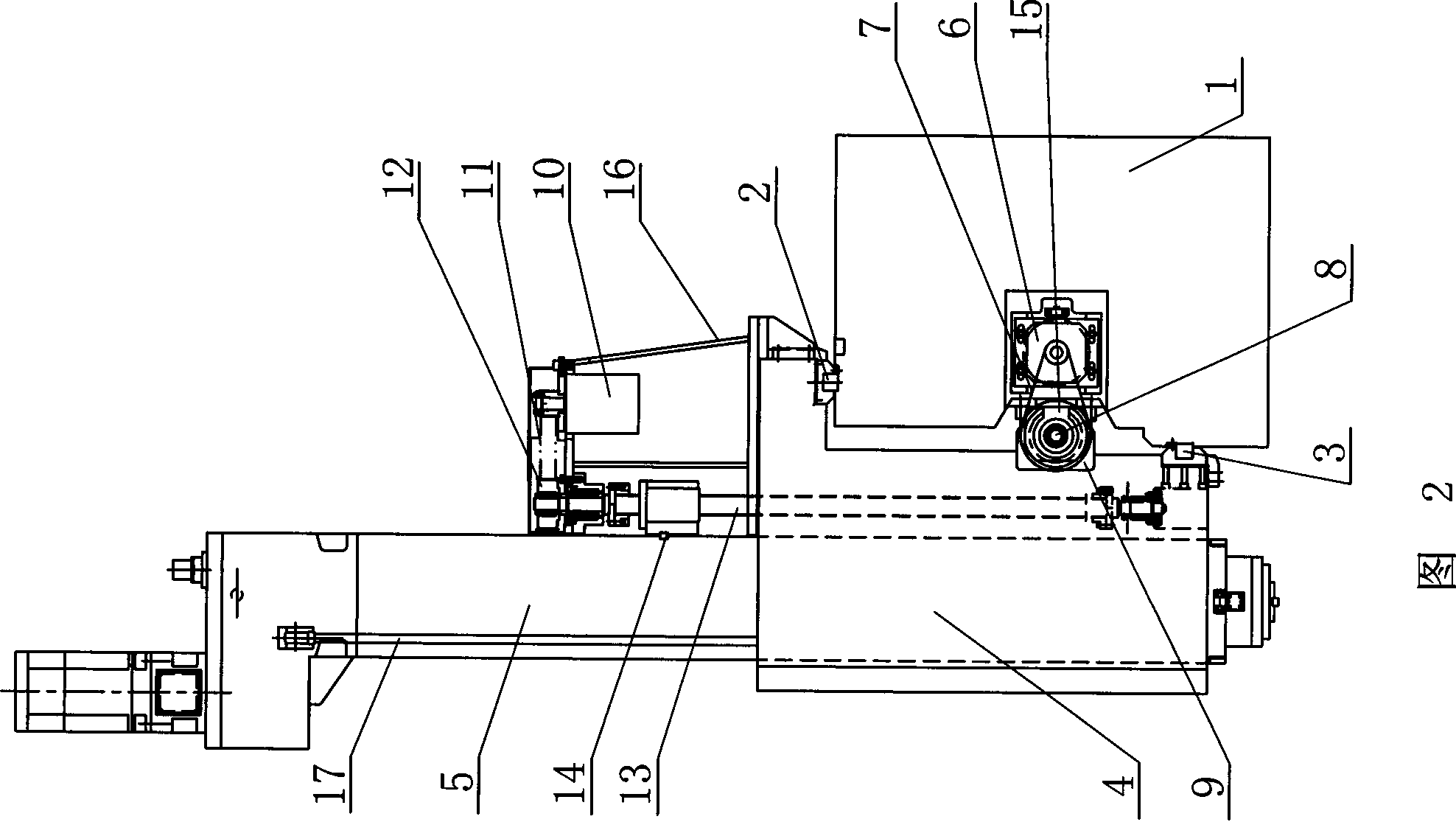

Double-post inclined type multi-pull-rod prestress machine frame of free forging hydrostatic press

ActiveCN101823114AImprove overall stiffnessGood press performance and process operabilityForging/hammering/pressing machinesPull forceHigh intensity

The invention provides a double-post inclined type multi-pull-rod prestress machine frame of a free forging hydrostatic press, which relates to a forging hydrostatic press. The invention solves the problems of poor integral rigidity, poor antifatigue intensity, poor load-deflection resistance capability and poor technical adaptability of a traditional machine frame. The invention is characterized in that two upright posts are in hollow rectangular structures, a plurality of high-intensity pull rods are placed in the two upright posts, both ends of the pull rods pass through an upper cross beam and a lower cross beam, the upper cross beam and the upright post, and the lower cross beam and the upright posts are respectively embedded through rectangular positioning keys, the pretensioning pull force is generated on the full length of the pull rods through pretensioning screw nuts, and pretensioning pressure is exerted on the upper cross beam, the lower cross beam and the upright posts at the same time, so the double-post prestress combined stressed machine frame is formed. The figure center connecting line of the two hollow rectangular upright posts is in inclined arrangement with an angle alpha correspondingly to the center line in the moving direction of a work table of the forging hydrostatic press. The invention can be applied to the free forging hydrostatic press, can also be applied to vertical hydrostatic presses of proper technology, and can be used for improving the traditional forging hydrostatic press.

Owner:TAIYUAN HEAVY IND

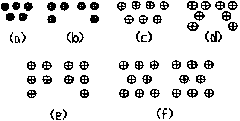

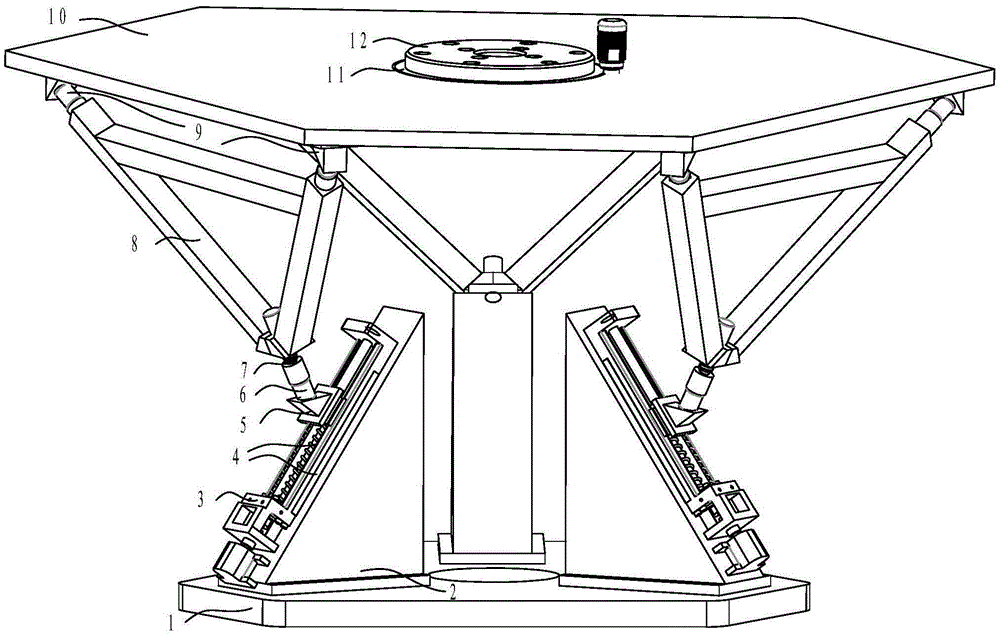

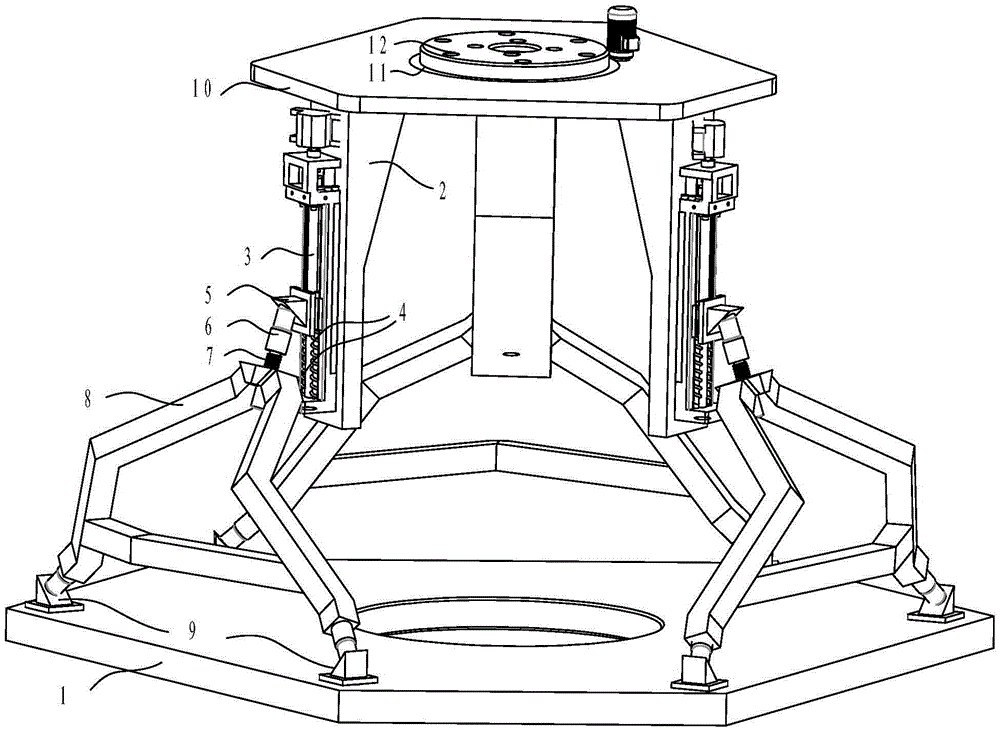

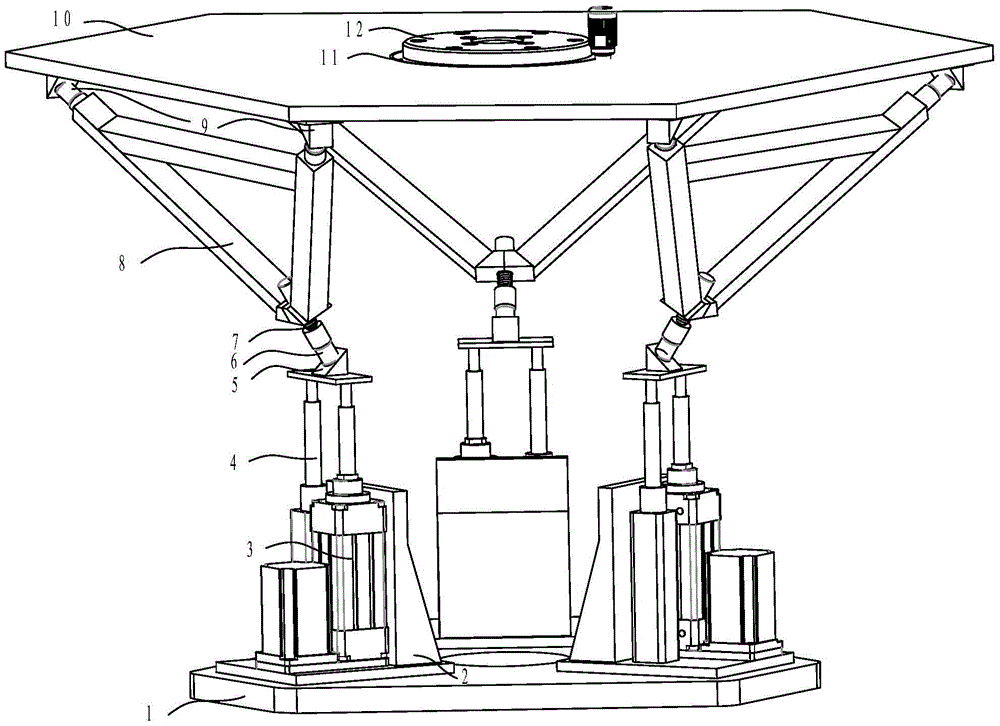

Four-degree-of-freedom serial-parallel hybrid posture alignment vibration-isolation platform provided with triangular branches

ActiveCN105539304AImprove overall stiffnessEnhanced slewing stiffnessNon-rotating vibration suppressionVehicle componentsLinear driveEngineering

A four-degree-of-freedom serial-parallel hybrid posture alignment vibration-isolation platform provided with triangular branches mainly comprises a base, a movable platform, three linear drive units, the three triangular branches, a rotary plate bearing and a rotary plate. Each linear drive unit is composed of an installing block, a linear module and an assistance part, wherein the installing block is fixedly connected to the base, the linear module is installed on the installing block, one end of the assistance part is connected with a baffle at the end of the linear module, and the other end of the assistance part is connected with a slider of the linear module. Each triangular branch comprises a first ball joint base, a first ball joint, a vibration isolator, a two-ball-joint triangular frame and two second ball joint bases, wherein the first ball joint base is installed on the slider of the corresponding linear module, one end of the vibration isolator is connected to the first ball joint, the other end of the vibration isolator is connected with the two-ball-joint triangular frame, and the two ball joint bases are connected to the movable platform. An outer ring of the rotary plate bearing is installed on the movable platform, and the rotary plate is installed on an inner ring of the rotary plate bearing. The four-degree-of-freedom serial-parallel hybrid posture alignment vibration-isolation platform is large in stiffness and good in vibration isolation effect and dynamic performance.

Owner:YANSHAN UNIV

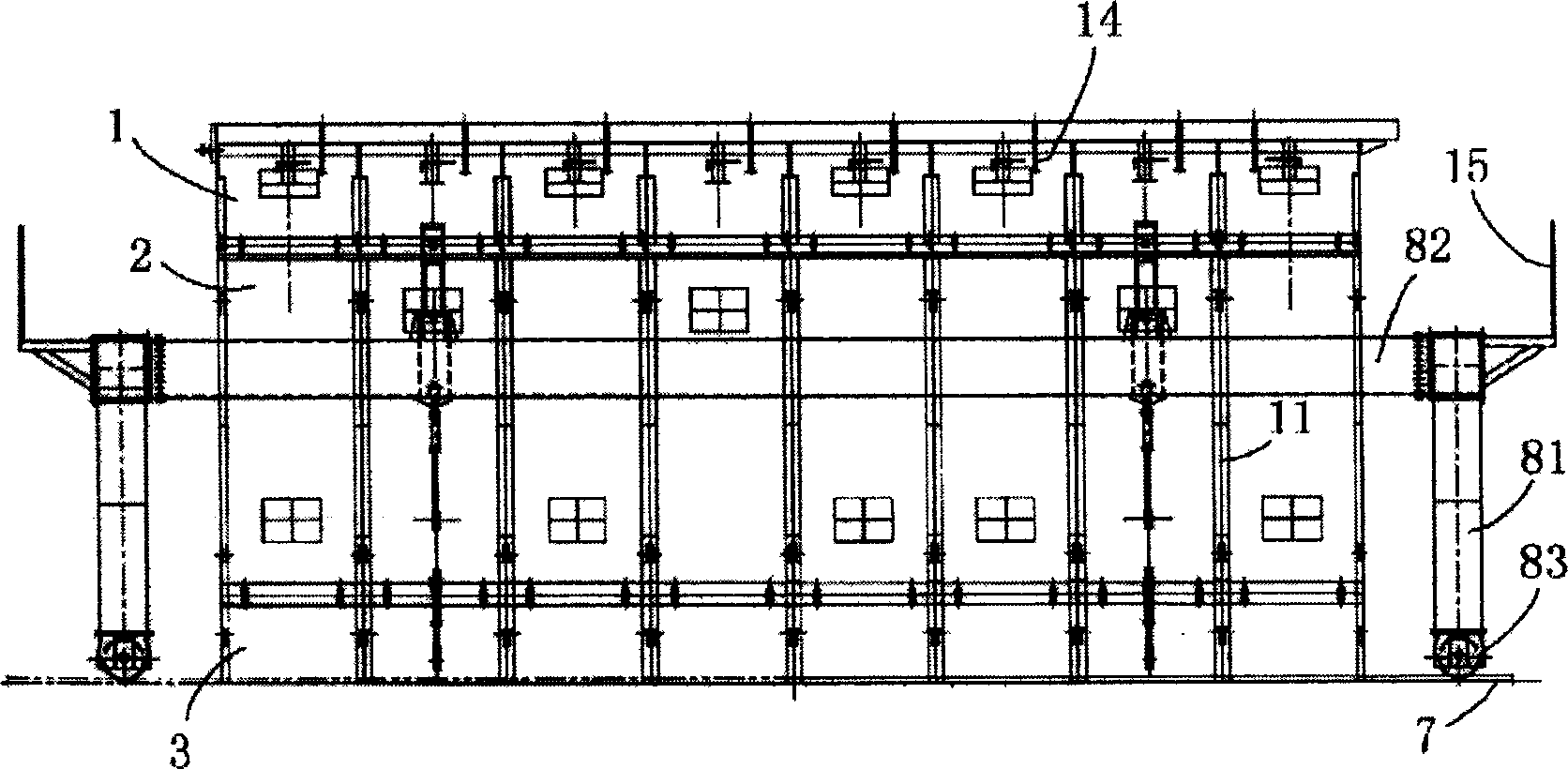

Full automatic hydraulic lining trolley

InactiveCN1858404AImprove overall stiffnessSmall amount of deformationUnderground chambersTunnel liningHinge angleEngineering

The present invention relates to full automatic hydraulic lining trolley. The formwork combination includes top formwork, two side formworks and two bottom formworks connected through hinges and regulating lead screws. The full automatic hydraulic lining trolley includes a portal, a crossbeam and a walking system. There are at least two pairs of vertically lifting hydraulic oil cylinders between the crossbeam of the trolley and the top formwork, guiding sleeves outside the oil cylinders, side shifting hydraulic oil cylinder between the formwork and the guiding sleeve, horizontally supporting lead screws between the crossbeam and the side formwork, withdrawing and expanding hydraulic oil cylinder and opening and closing hydraulic oil cylinder. The formwork combination has high rigidity, less deformation, low steel consumption, automatic operation and other advantages.

Owner:杨秋利

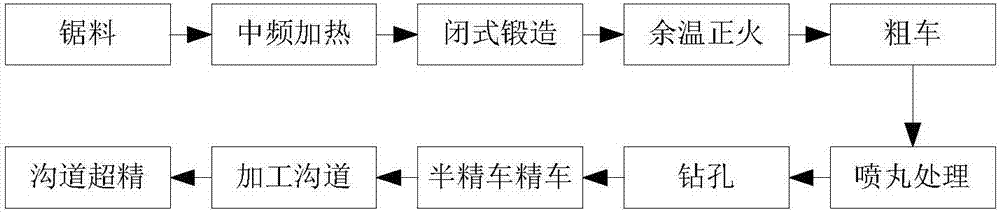

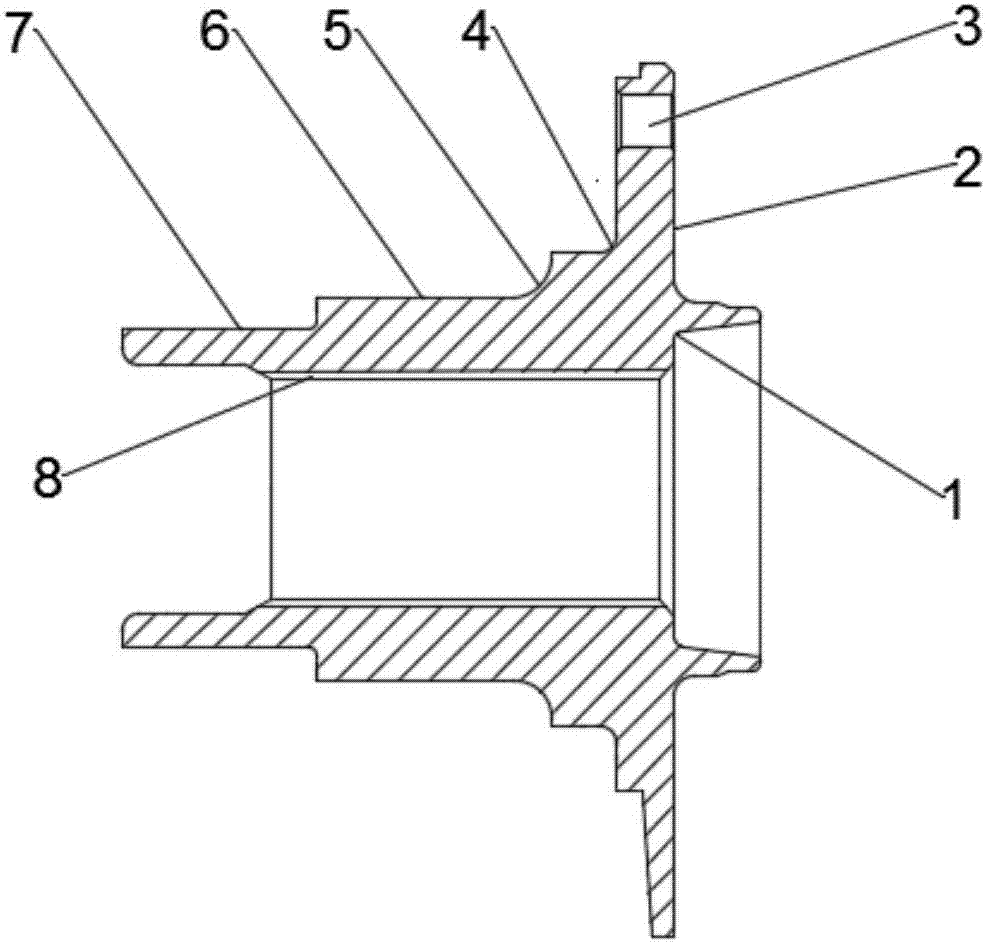

Method for machining high-rigidity inner ring flange of automobile hub bearing unit

Owner:江苏昊鹏机械有限公司 +1

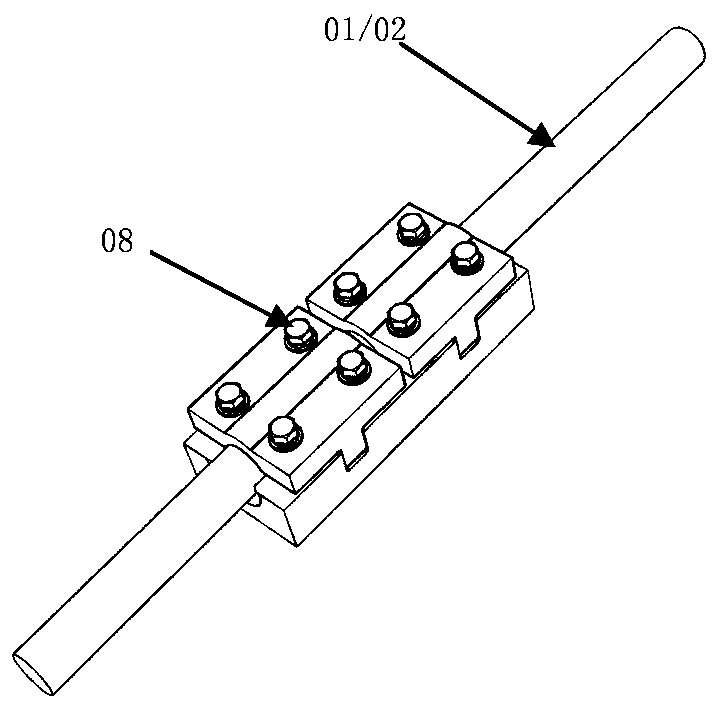

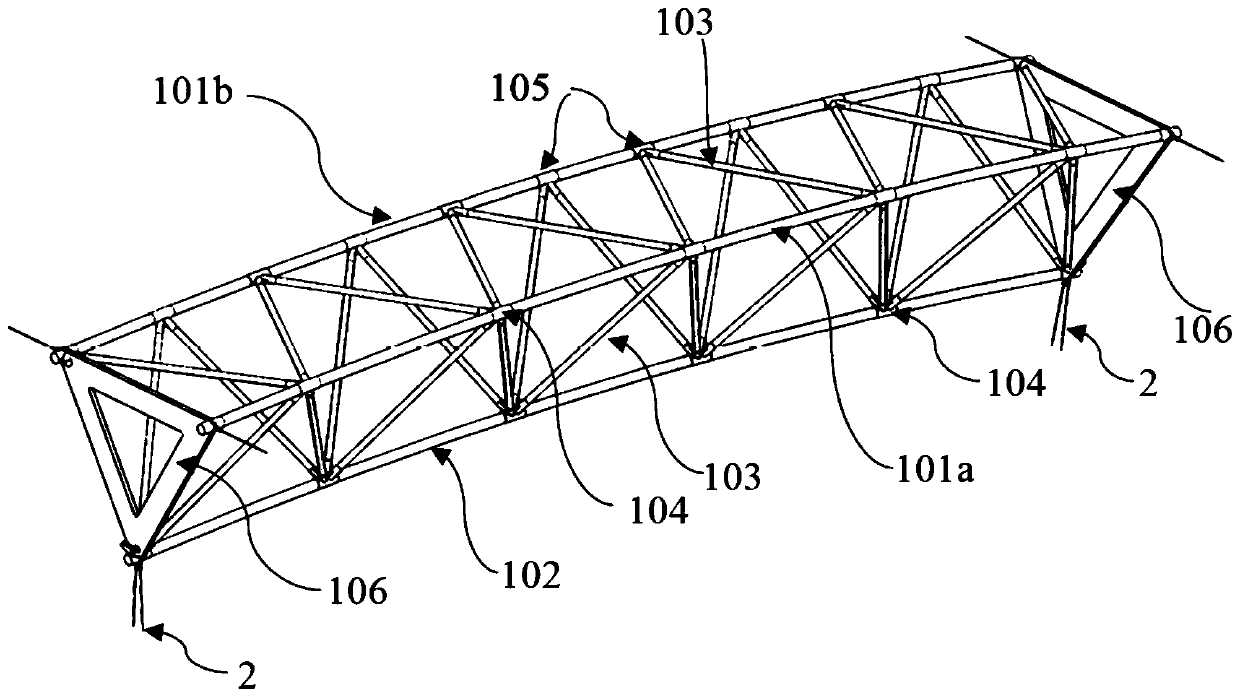

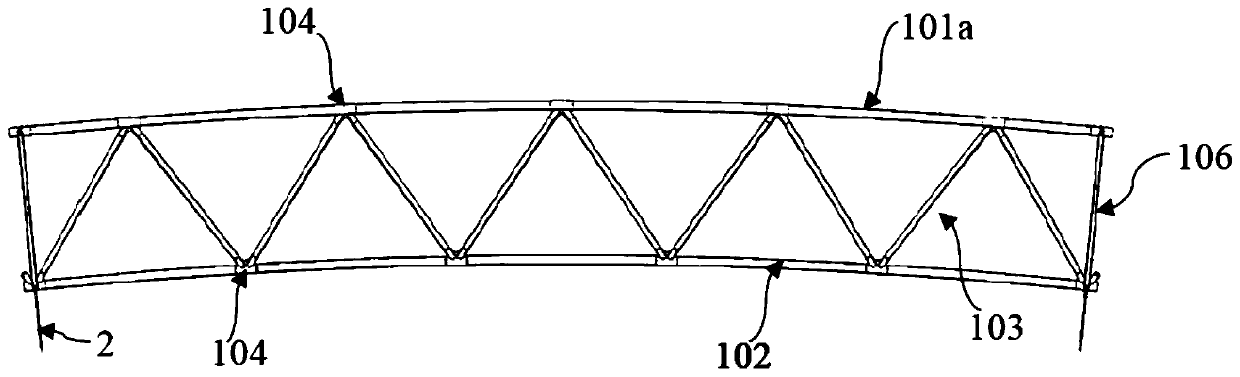

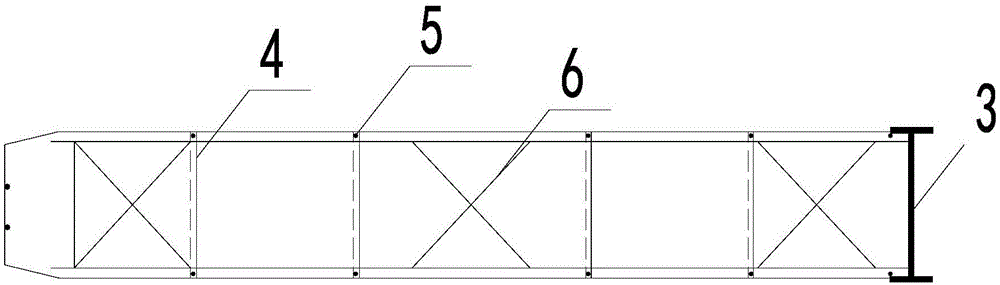

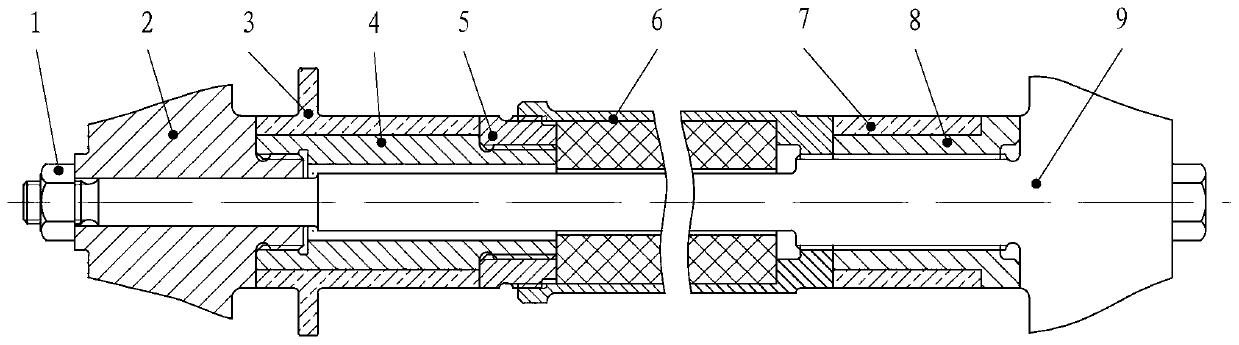

Large-scale stiffening-ring-spliced type triangular truss

ActiveCN110040234AImprove overall stiffnessImprove the load deformation capacity of the trussFuselage framesCosmonautic vehiclesEngineeringMaterial structure

The invention discloses a large-scale stiffening-ring-spliced type triangular truss, and relates to the technical field of composite material structures. The triangular truss comprises a circular ringtriangular truss assembly, a radial pull rod assembly and a hub shaft assembly, and the circular ring triangular truss assembly and the hub shaft assembly are connected through the radial pull rod assembly, wherein the circular ring triangular truss assembly is formed by sequentially splicing a plurality of segment modules, and triangular connecting plates are arranged at two ends of the segmentmodules; the radial pull rod assembly comprises a rod body, hinged heads and fine adjustment joints, wherein the hinged heads and the fine adjustment joints are arranged at both ends of the rod body;and the hub shaft assembly comprises a hub shaft main body tube, a shuttle-shaped joint, an end mandrel, a hub connecting ring and a pressure-bearing ejecting-pushing sleeve, wherein the shuttle-shaped joint, the end mandrel, the hub connecting ring and the pressure-bearing ejecting-pushing sleeve are connected sequentially with the two ends of the hub shaft main body tube, the hub connecting ringis connected with the fine adjustment joint and connected with the triangular connecting plates of the segment modules through the radial pull rod assembly. The large-scale stiffening-ring-spliced type triangular truss can realize a large-scale composite material structure, stiffening rings can improve the overall rigidity of the truss, the load-bearing deformation ability and stability performance of the truss are improved, and the large-scale stiffening-ring-spliced type triangular truss can be applied to large-scale aircraft structures such as airships, unmanned aerial vehicles and the like and aerospace assembled type platforms.

Owner:SHANGHAI JIAO TONG UNIV +1

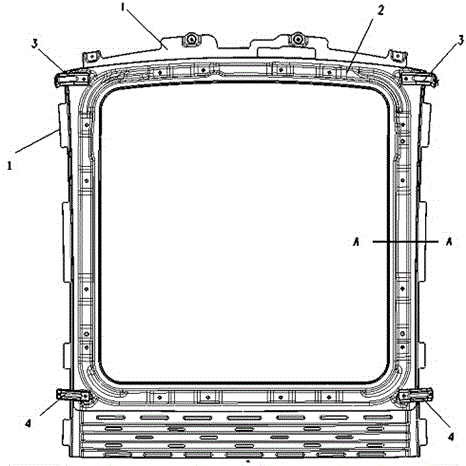

Reinforcing ring for automobile panoramic sunroof

ActiveCN103552445AImprove overall stiffnessImproved torsional stiffness and torsional modesRoofsEngineeringUltimate tensile strength

The invention relates to a reinforcing ring for an automobile panoramic sunroof. The reinforcing ring comprises an upper reinforcing ring and a lower reinforcing ring, wherein a plurality of edges in lap joint to the side wall are arranged on the periphery of the upper reinforcing ring at intervals; first steps, second steps and third steps are arranged on the upper reinforcing ring sequentially; first welding edges and second welding edges are arranged on the lower reinforcing ring sequentially; the first steps are welded with the first welding edges; the third steps are welded with the second welding edges; gluing grooves are formed in the second steps; a yielding hole and four bosses are further arranged at the front end of the upper reinforcing ring; the four bosses are four bolt mounting points for the upper reinforcing ring and a roof front beam; four first mounting bosses are arranged at four corners of the lower reinforcing ring and are four mounting points for front and rear reinforcing brackets; and a plurality of second mounting bosses are arranged on the periphery of the lower reinforcing ring and are mounting points for the sunroof. According to the reinforcing ring for the automobile panoramic sunroof, the problems about the whole automobile stiffness and side wall sharing are solved; and a reinforcing ring structure suitable for the reinforcing ring for the panoramic sunroof is designed accordingly, so that the requirement for the mounting strength of the sunroof can be met, and the torsional stiffness and the torsional mode of a whole automobile can be improved.

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES

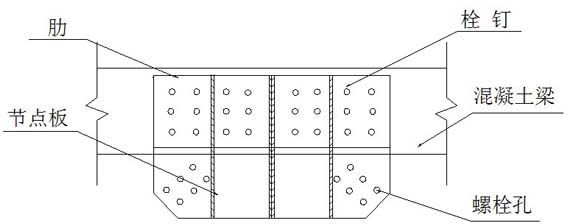

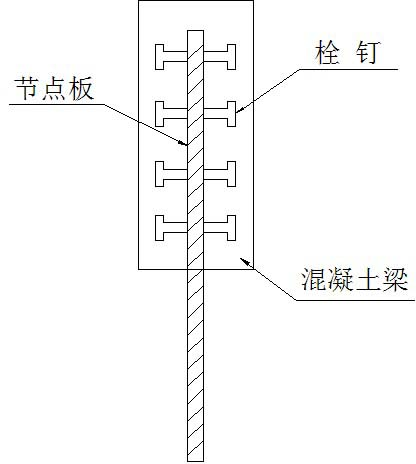

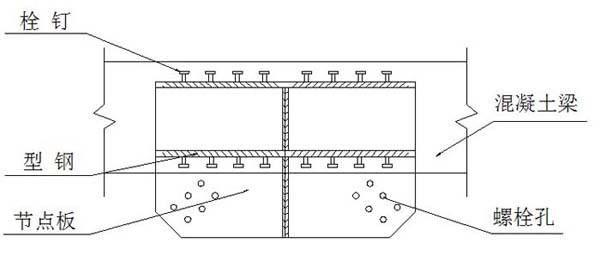

Joint of buckling restrained brace and concrete beam

The invention discloses a joint of a buckling restrained brace and a concrete beam, and a building unit. The building unit consists of the buckling restrained brace and the concrete beam; and the joint of the buckling restrained brace and the concrete beam is a cotter connection type joint of the buckling restrained brace and the concrete beam. The joint of the buckling restrained brace and the concrete beam is a section steel type joint of the buckling restrained brace and the concrete beam. The joint of the buckling restrained brace and the concrete beam is a combined type joint of the buckling restrained brace and the concrete beam. A reinforced concrete frame structure for preventing the buckling restrained brace not only can increase the overall rigidity and improve the structure ductility, but also can fully play a role in energy dissipation because the reinforced concrete frame structure cannot be buckling when pressed, so the reinforced concrete frame structure has important application value in the field of engineering seismology.

Owner:SHENYANG JIANZHU UNIVERSITY

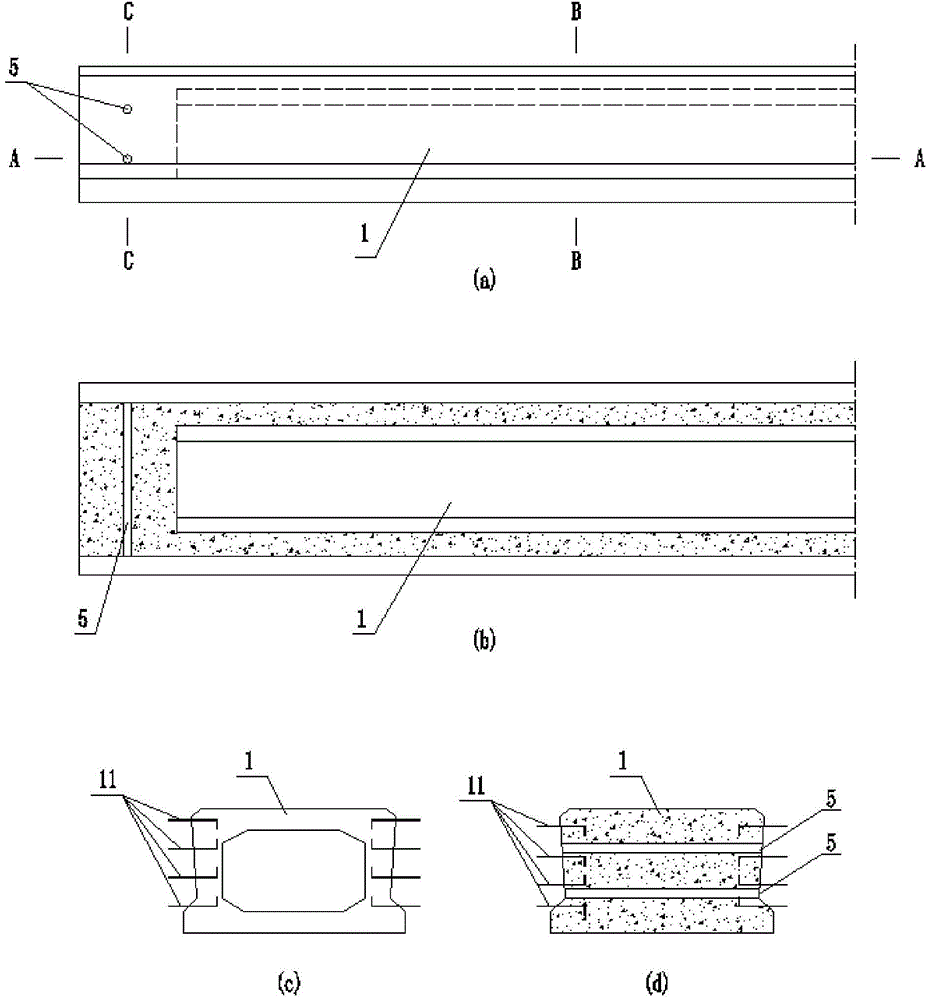

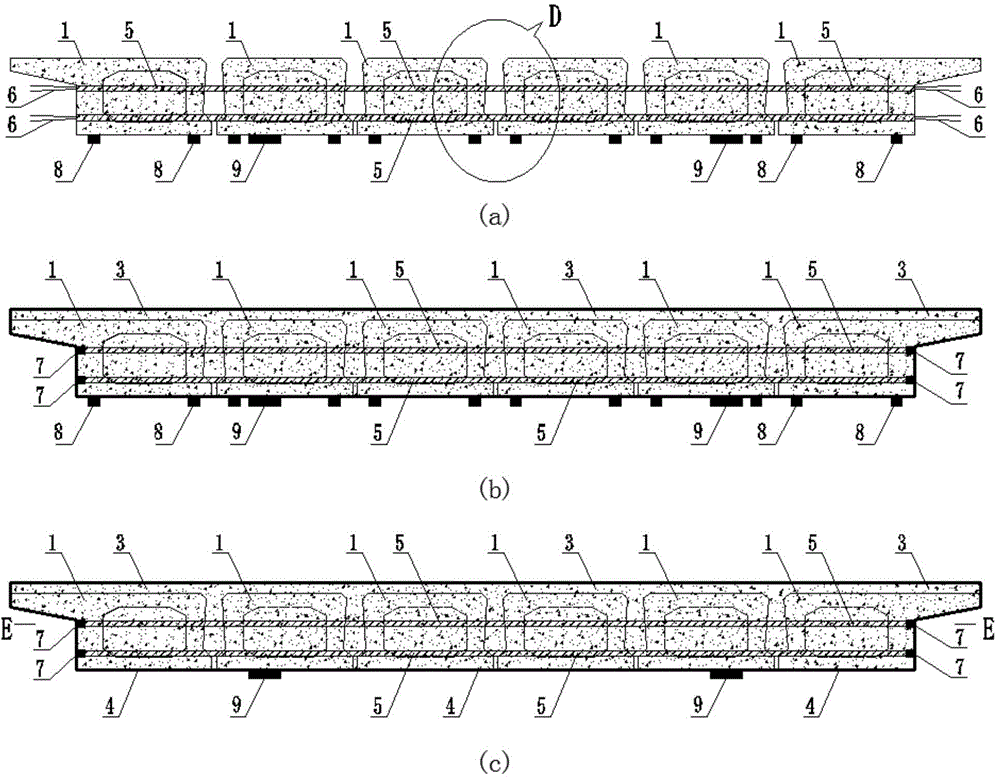

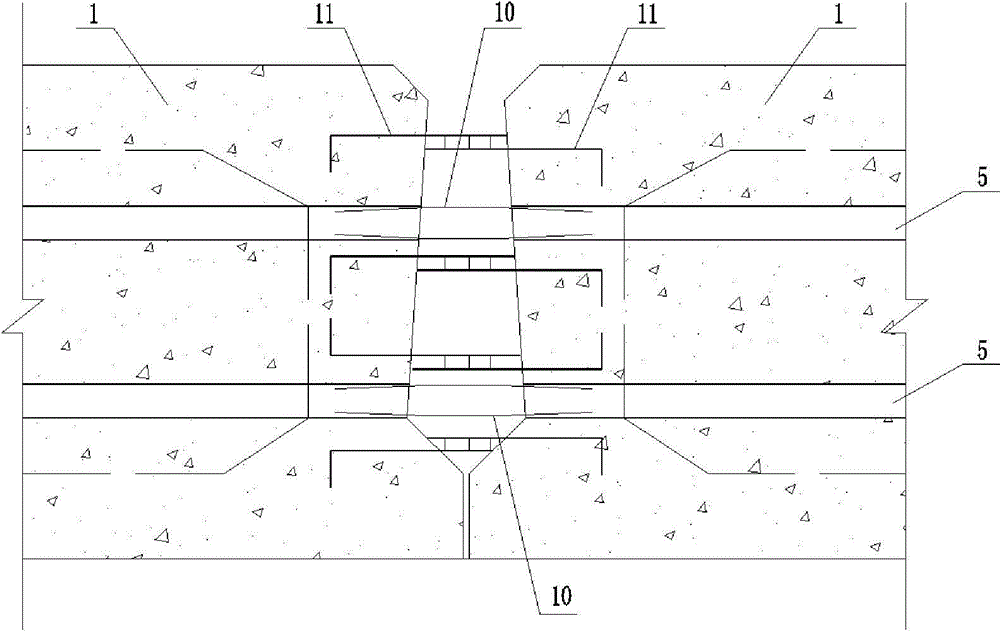

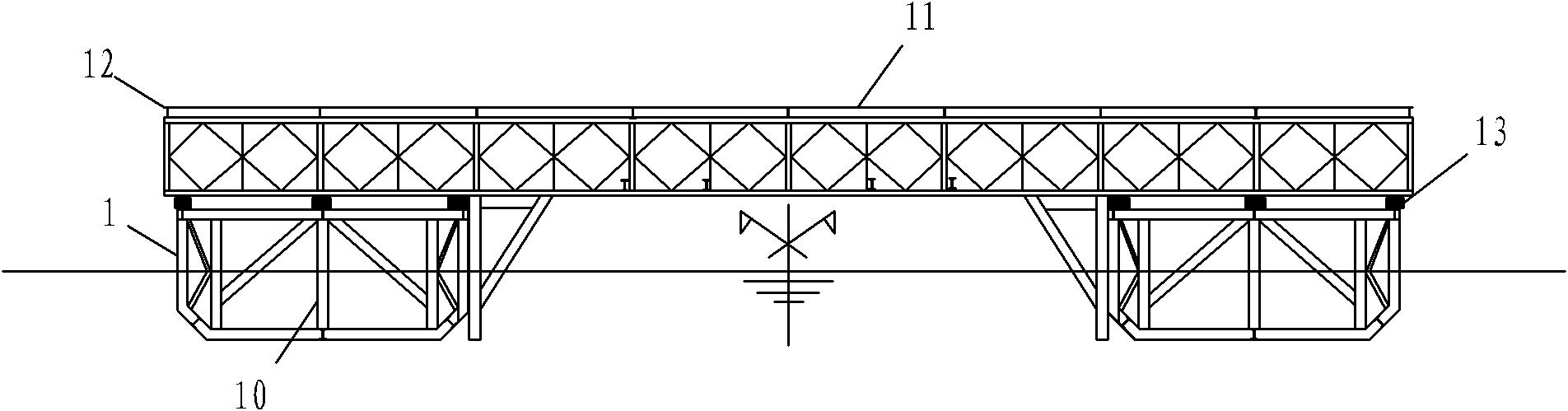

Upper structure of hollow board beam bridge and construction method thereof

ActiveCN104594193AImprove overall stiffnessEven by forceBridge structural detailsBridge erection/assemblyRebarHinge joint

The invention discloses an upper structure of a hollow board beam bridge. Hinge joints are formed among a plurality of hollow boards constructing a hollow board beam; concrete is cast on the hinge joints and the cast-in-situ layer of a bridge floor; the two end parts of the hollow boards are solid bodies; transverse steel bars are arranged on the two side faces of the hollow boards; the hollow board solid bodies together with the hinge joints and the concrete on the cast-in-situ layer of the bridge floor construct end transverse beams; prestressed steel bars transversely penetrating through a prestressed pipeline are arranged in the end transverse beams; the end transverse beams are supported by two supports. The construction method comprises the following steps: prefabricating the hollow boards; mounting a temporary support and a permanent support; mounting the hollow boards; transversely inserting the prestressed steel bars into the prestressed pipeline; casting concrete on the hinge joints and the cast-in-situ layer of the bridge floor; removing the temporary support. By adopting the end transverse beams provided with the prestressed steel bars, the overall rigidity of the upper structure of the hollow board beam bridge is effectively enhanced, and the hollow boards are stressed in a balanced way; the single board stress phenomenon is reduced, the local stress of the hinge joints on at the beam ends is reduced, and damage is prevented; each support is stressed, so that the problem of disengagement of the supports is solved; construction becomes simple and convenient, and the support maintenance workload and maintenance cost are low.

Owner:SHENYANG JIANZHU UNIVERSITY

Construction method for plain concrete underground diaphragm wall of deep foundation pit

The invention discloses a construction method for a plain concrete underground diaphragm wall of a deep foundation pit. The construction method comprises the following steps: (1) conducting framing adjustment on a designed plain concrete underground diaphragm wall into a first slotted section and a closed slot section which are arranged at an interval, wherein the width of the first slotted section equals to the maximum width of the working part of a slotting machine; (2) carrying out construction of the first slotted section, then lowering reinforcement cages, pouring concrete to a level being 2 meters higher than the bottom surface of a basement floor, and then pouring the mortar of which the label is M10 to the ground level; and (3) carrying out construction of the closed slot section, then pouring concrete to a level being 2 meters higher than the bottom surface of the basement floor, and backfilling plain soil to the ground level, so as to form an underground diaphragm wall. The construction method disclosed by the invention has the advantages that as the reinforcement cages are improved, the original underground diaphragm wall smooth slotting method is replaced by spaced slotting method, and the number of the reinforcement cages abutting, concrete consumption, and the chiseling off workload in follow-up project are reduced; the operation is simple; safety risks and construction costs can be reduced; and construction time can be shortened.

Owner:中铁十八局集团第五工程有限公司

Clamp lifting tool used for clamping steel plates in uniform thickness manner

InactiveCN103523656ASimple structureImprove overall stiffnessLoad-engaging elementsSteel platesMechanical engineering

The invention relates to a clamp type steel plate lifting tool and in particular relates to a clamp lifting tool which can realize clamping of steel plates in uniform thickness manner. The clamp type steel plate lifting tool comprises two connecting rods, clamp arms, a guide plate and a positioning plate, the upper ends of the two connecting rods are connected by virtue of a pin shaft, the lower ends of the two connecting rods are connected with the upper ends of two groups of clamp arms respectively by virtue of a pin shaft, the two groups of clamp arms are oppositely placed left and right, the middle parts of the two groups of clamp arms are respectively connected with the guide plate by virtue of a pin shaft, an arc-shaped guide rail is respectively arranged at each of the left end and the right end of the positioning plate, a guide rail connecting rod sliding along the arc-shaped guide rail is arranged on each arc-shaped guide rail, each arc-shaped guide rail is connected with the lower parts of the two groups of clamp arms by virtue of pin shafts, and the positioning plate and the guide plate form a moving pair along a vertical direction. Compared with the prior art, the clamp type steel plate lifting tool has the advantages of simple structure, high integral rigidity and implementation of uniform-thickness clamping on steel plates or billet components with different sizes.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

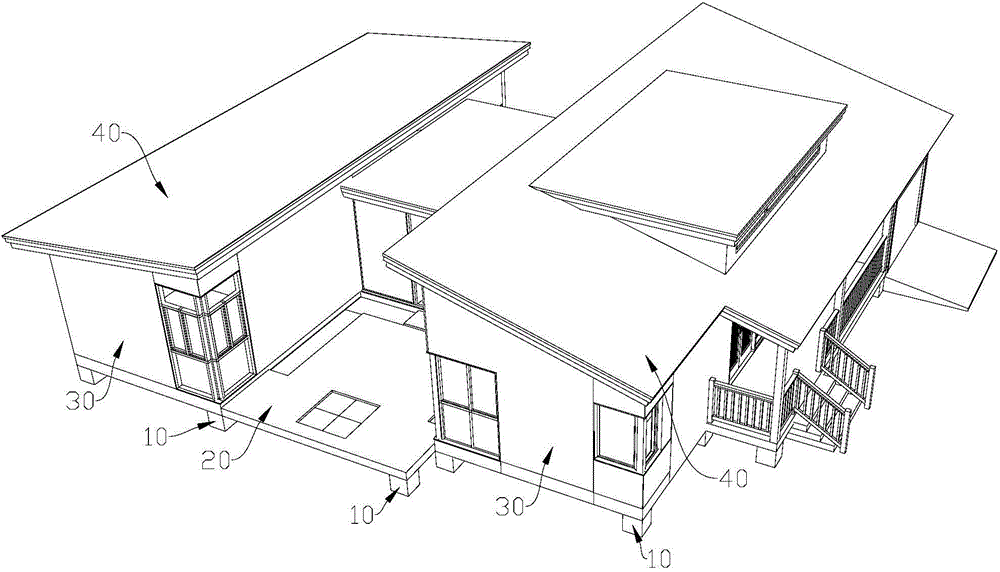

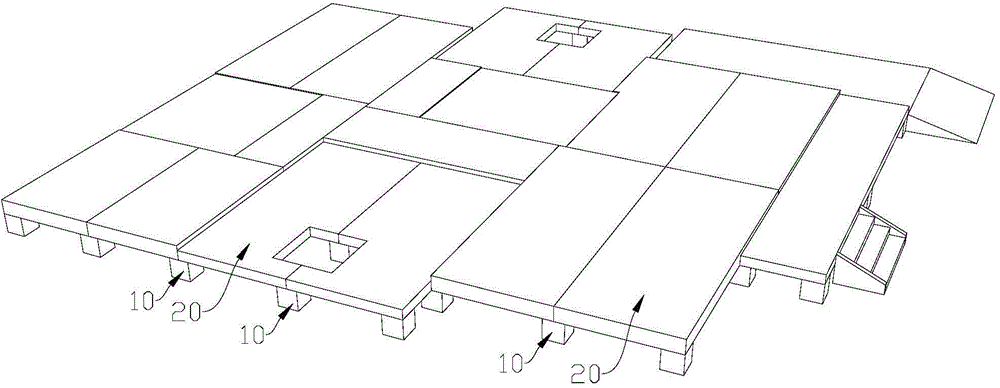

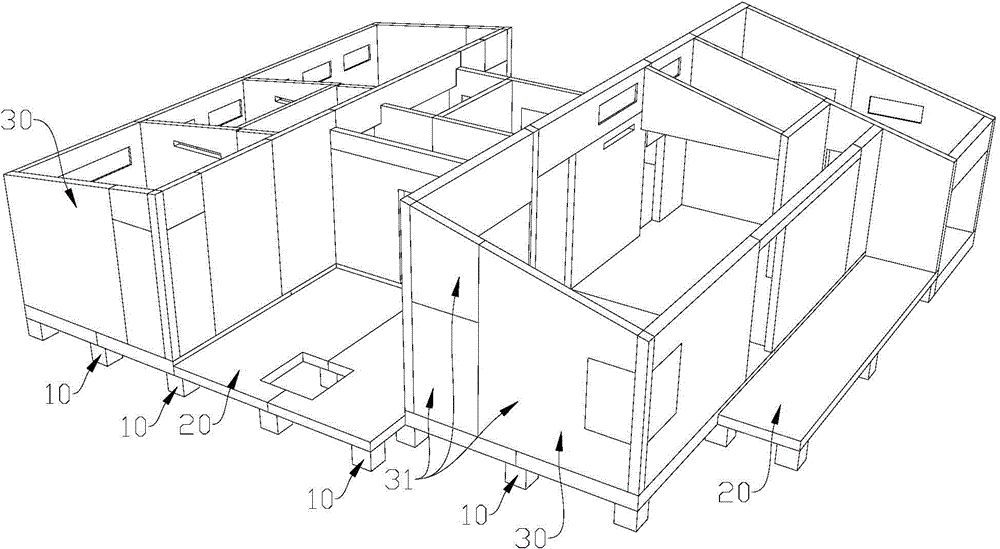

Movable board type structural integral house, wall module and roof module of house

ActiveCN104805929AExcellent fire resistanceImprove overall stiffnessBuilding roofsWallsModular structureBoard type

The invention relates to a movable board type structural integral house, a wall module and a roof module of the house. The house is that an isolating supporting device is prefabricated between a wall body and an isolating board to form a board type unit module with a hollow space; the board type unit module can be used as the wall module and the roof module and is outstanding in sound insulation, heat insulation and fire resistance and large in overall rigidity, so that the double functions of encircling and bearing can be achieved; hidden wiring of a precast pipeline can be performed through the hollow space. The movable board type structural integral house is assembled by reliable connection through a special construction measure; the building environment is not damaged; the energy can be saved; the environment is protected; the industrial integral prefabricating process is carried out to ensure the building quality; the movable building mode enables dismounting, mounting and updating of houses at different scenic spots; the diversified combination of the modular structure is adapted to various building groups with different styles, so that the building and the surrounding environments can be harmonious and natural.

Owner:SHENZHEN CHIXIAO BUILDING TECH

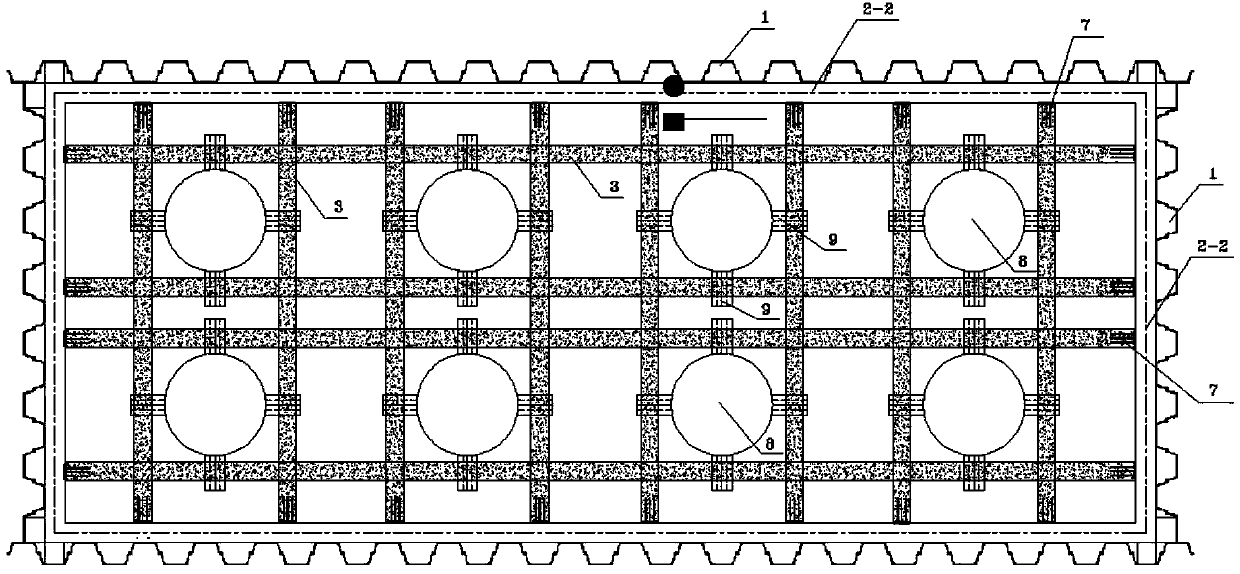

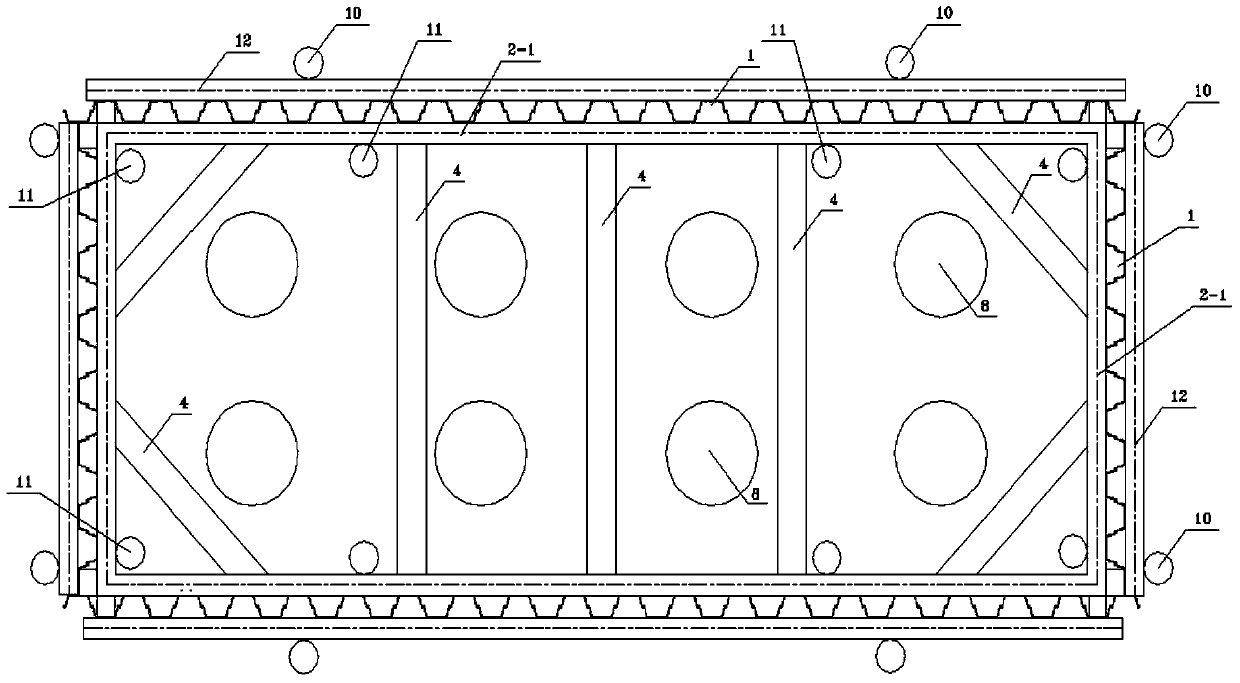

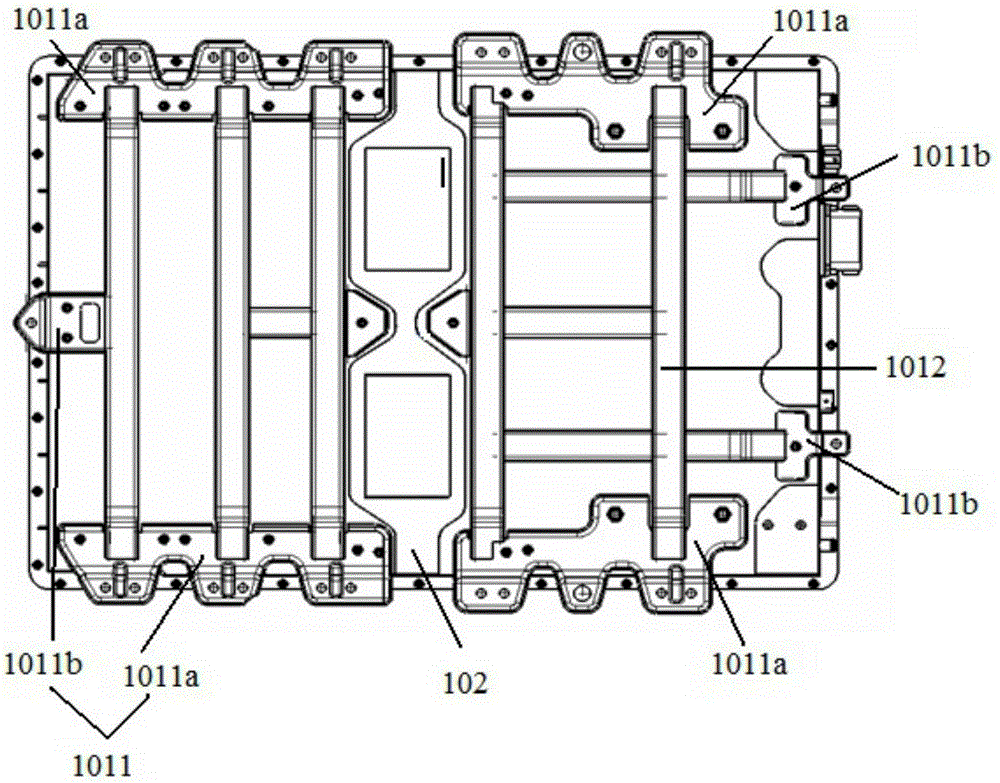

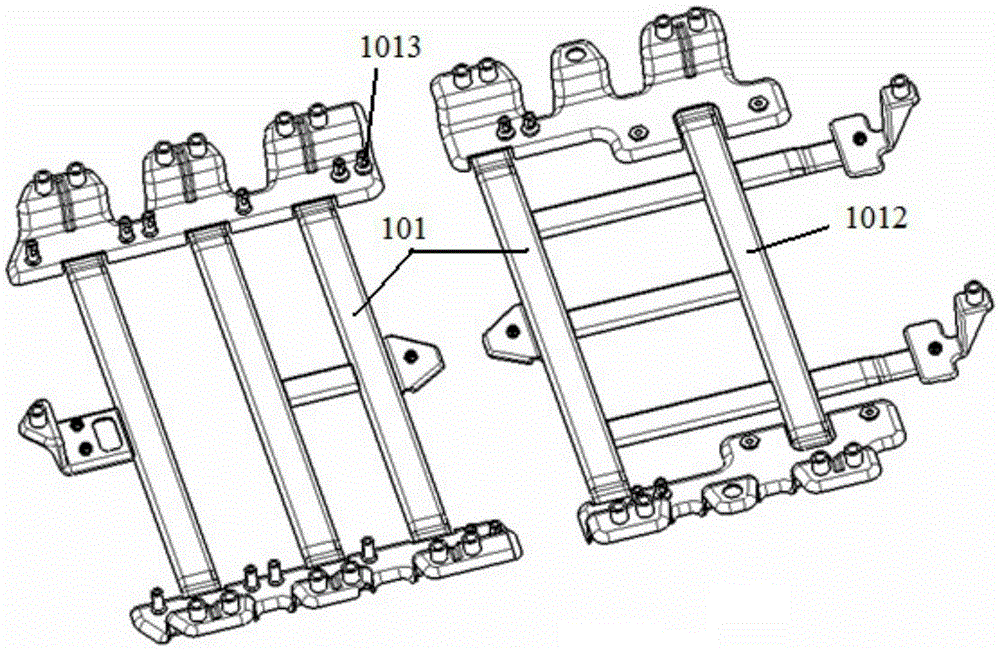

Power battery box of electric vehicle

ActiveCN105336897AImprove overall stiffnessReduce weightBattery isolationElectric vehicleBatch production

The invention relates to the technical field of new energy vehicles and provides a power battery box of an electric vehicle. The power battery box comprises a lower box body and a battery bracket which are made of carbon fibers, wherein the battery bracket comprises u-shaped beams which are distributed in a crossing manner and open downwards, grooves corresponding to openings of the u-shaped beams are formed in the bottom wall of the lower box body and matched with the opening sizes of the u-shaped beams, and the u-shaped beams and the bottom wall of the lower box body are closed to form a closed cavity. The power battery box of the electric vehicle adopts the carbon fibers and corresponding concave structures are arranged on the lower box body and the battery bracket, so that the battery bracket and the lower box body are closed to form a hollow whole cavity structure, the weight of the battery box is reduced while the overall rigidity and strength of the battery box are improved, and light weight of the whole vehicle is realized. Besides, the battery box made of the carbon fibers has the characteristics of insulation, flame retardance and the like, so that the safety of the whole vehicle can be improved. Further, the battery box adopting the whole cavity structure better facilitates assembly and batch production, and the product consistency is improved accordingly.

Owner:JASMIN INT AUTO RES ANDDEV BEIJING CO LTD

Rear side inner panel and rear side assembly

ActiveCN103847806AImprove overall stiffnessAvoid deformationSuperstructure subunitsSubsidenceMechanical engineering

The invention relates to a rear side inner panel and a rear side assembly for automobile bodies and provides a rear side inner panel comprising a main plate. The main plate is provided with a seal plate overall-subsidence recess provided with local subsidence recesses. Each local subsidence recess is provided with a mounting hole. The seal plate overall-subsidence recess is provided with a clearance hole, and an opening of the clearance hole is provided with a bore turnup edge. The invention further provides the rear side assembly. The rear side inner panel and the rear side assembly have the advantages that the seal plate overall-subsidence recess fits the local subsidence recesses, overall rigidity of the rear side inner panel is improved, the rear side inner panel is prevented from deforming in the transport process, each local subsidence recess is provided with the mounting hole for fitting, and mounting face rigidity is improved; the large diameter clearance hole is arranged in the seal plate overall-subsidence recess, the opening of the clearance hole is provided with the bore turnup edge, stress concentration is effectively avoided, and rigidity of a mounting face of the clearance hole is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

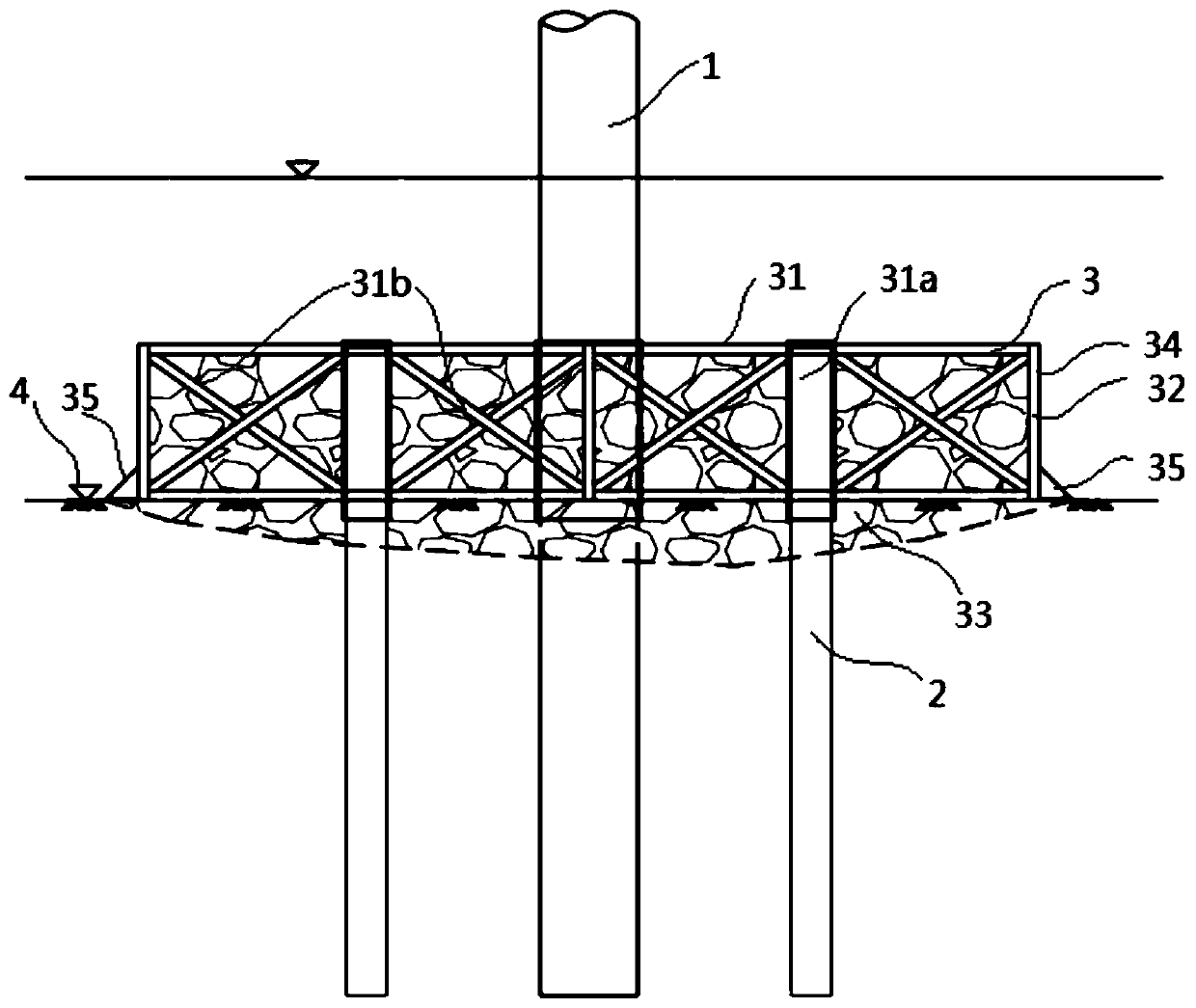

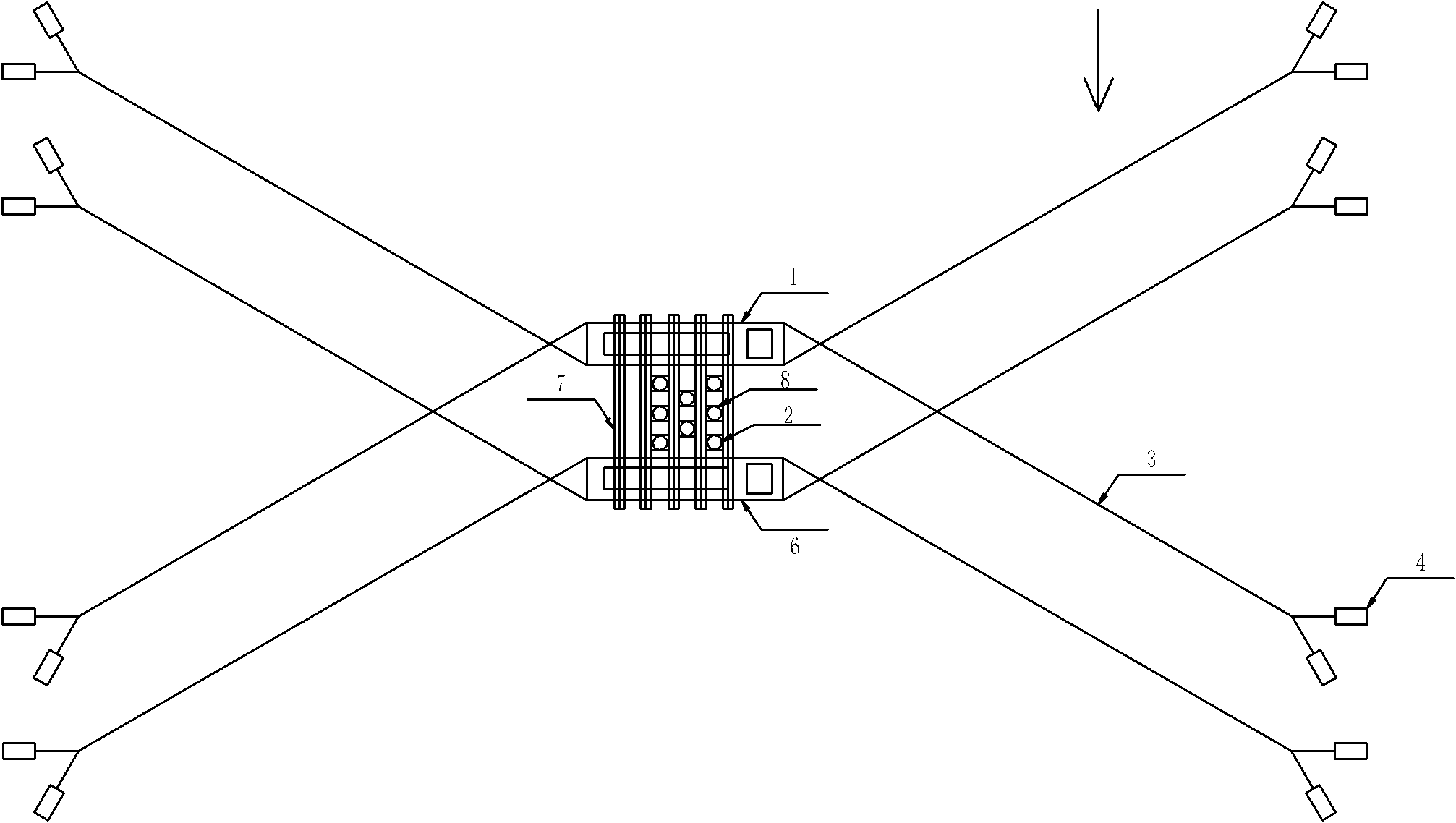

Offshore wind generation set mounting foundation assembly

PendingCN110219317AImprove overall stiffnessReduce washoutFoundation engineeringFilling materialsElectricity

The invention discloses an offshore wind generation set mounting foundation assembly. The offshore wind generation set mounting foundation assembly comprises a main pile, three or more auxiliary pilesand an auxiliary platform, the auxiliary piles take the main pile as the center and are evenly arranged around the main pile, the upper ends of the auxiliary piles extend out of the mud surface, andthe lower ends of the auxiliary piles extend to the position below the mud surface; the auxiliary platform is arranged at the mud surface and comprises a central connecting truss, the central connecting truss is provided with a plurality of sleeves, the multiple sleeves are fixedly connected with the main pile or the auxiliary piles, and connecting rods are arranged between the multiple sleeves. Through the technical scheme, the overall rigidity of the offshore wind generation set mounting foundation assembly can be improved, and in addition, by arranging an external truss and additionally loading filling materials in an internal area of the external truss, the scouring effect of a water flow on the mud surface near the main pile can be effectively reduced.

Owner:CCCC SHANGHAI HARBOR ENG DESIGN & RES INST +2

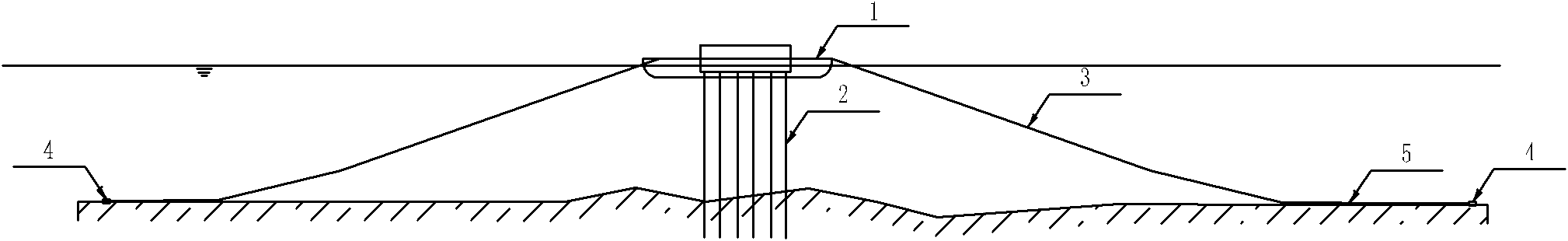

Method for constructing bridge deepwater foundation steel pile casing

InactiveCN101967827AImprove overall stiffnessGood positioning stabilityBulkheads/pilesWind forceFoundation engineering

The invention discloses a method for constructing a bridge deepwater foundation steel pile casing, which relates to a construction scheme of a floating transportation and boat type floating platform positioning system and an air pressure raising and reducing method of the bridge deepwater foundation steel pile casing. The method comprises the following two steps of: after transporting the steel pile casing to a pier position by floating, performing precise planar positioning on the steel pile casing by an adjusted boat type floating platform positioning system; and inflating the steel pile casing by an air compressor to jack the steel pile casing. In the method, a formed steel pile casing is transported in position by floating, the steel pile casing is submerged by the air pressure raising and reducing method, and the self-weight of the steel pile casing and an anchorage system of the floating platform ensure that the verticality of the steel pile casing and a central plane position of the steel pile casing and a pile foundation can meet the precision required by design and construction. The construction method of the invention is suitable for the construction of deepwater pile foundation engineering under the conditions that river beds are inclined uncovered rocks and the like on which fixed drilling platforms cannot root, or lakes, reservoirs (comprising tidal rivers) and the like have the water depth of less than 60 meters and the common wind power of lower than 5 grade.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

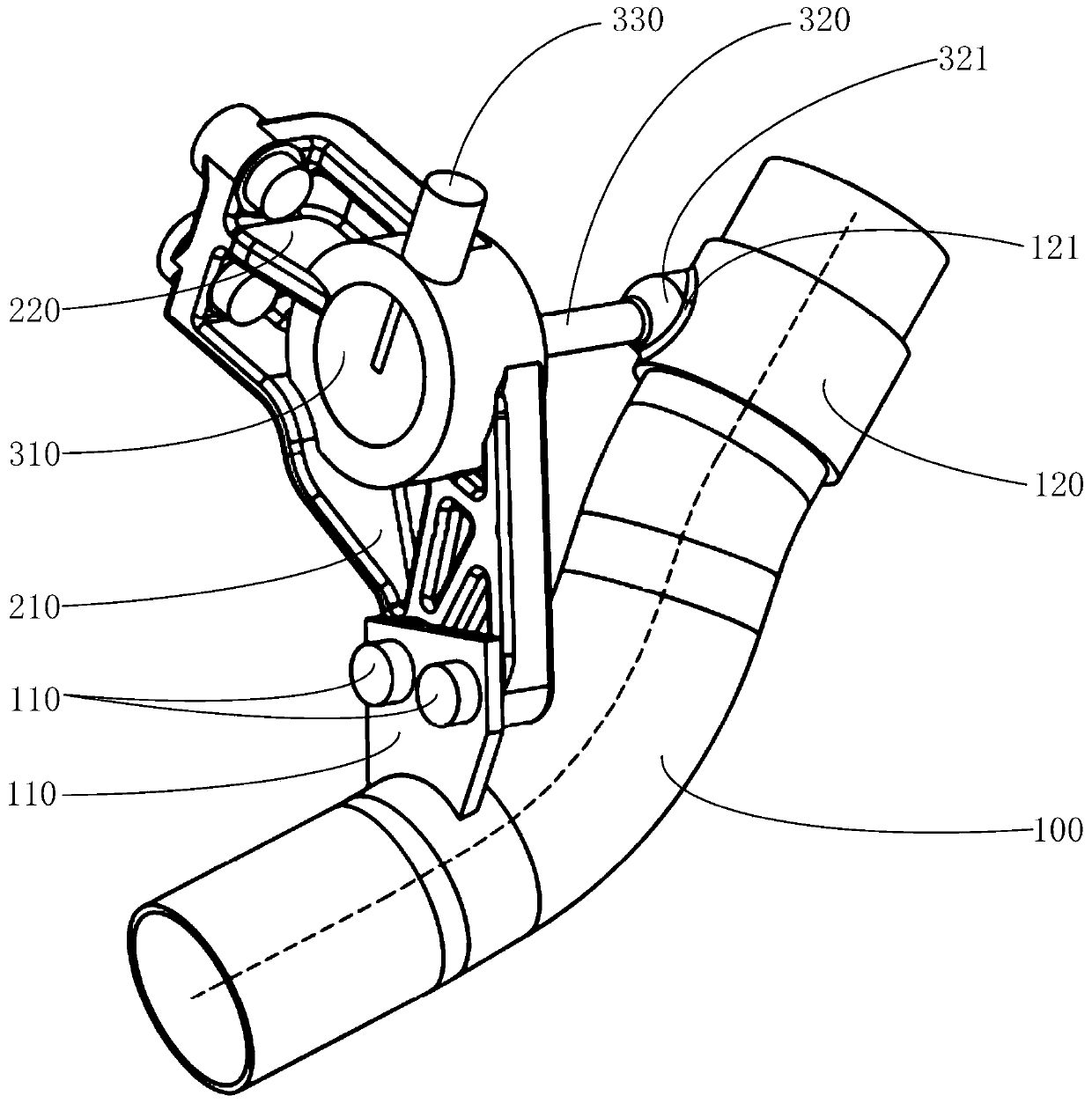

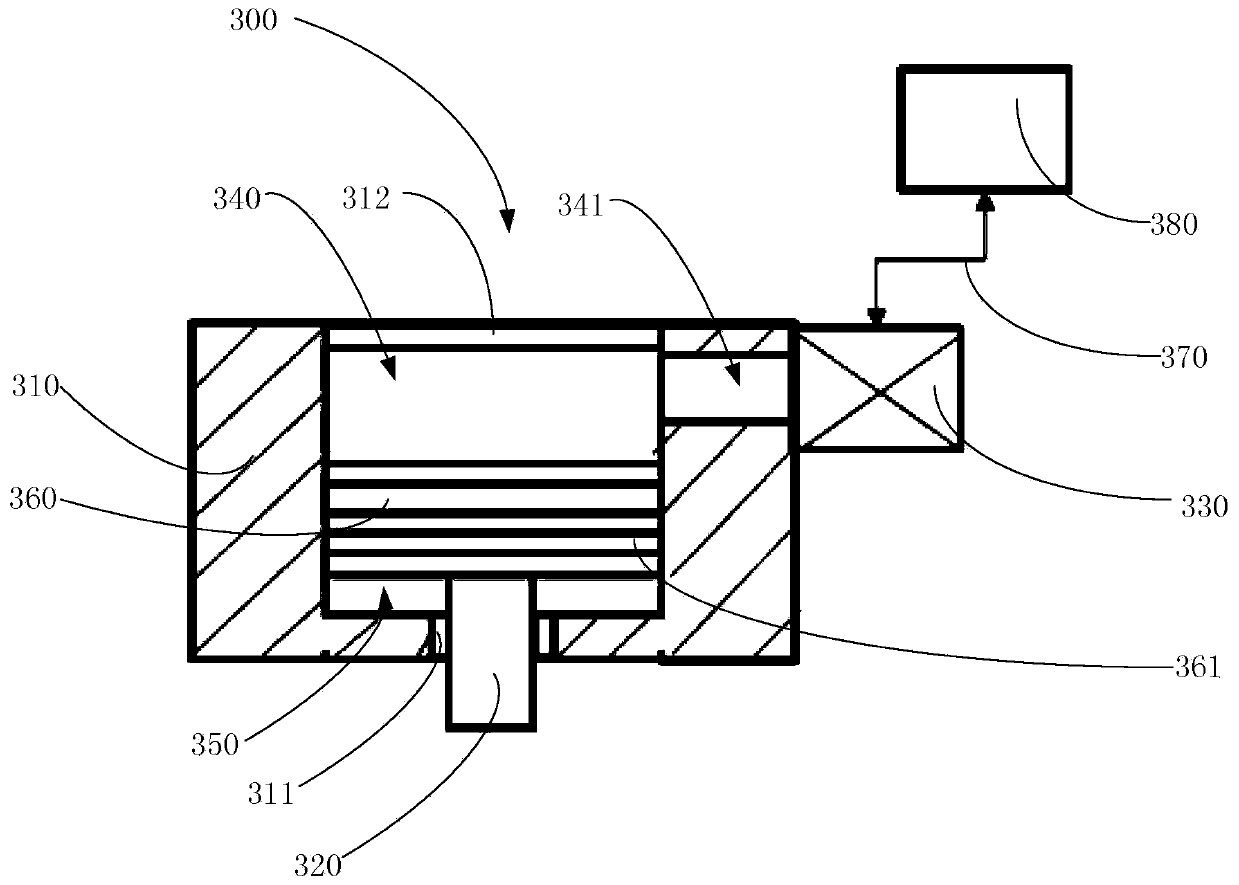

Vibration reduction device and vehicle pipeline vibration reduction system

ActiveCN110185870AIncrease stiffnessImprove overall stiffnessPipe elementsEngineeringMechanical engineering

The invention discloses a vibration reduction device and a vehicle pipeline vibration reduction system. The vibration reduction device is used for connecting a fixing component with a vibration component and comprises a main body and a connection rod, wherein the main body comprises a fixing part connected with the fixing component and connection parts connected with the vibration component; a plurality of connection parts are arranged and are used for connecting a plurality of positions of the vibration component; at least one of the plurality of connection parts is connected with the connection rod and is connected with the vibration component through the connection rod; a damping mechanism is arranged between the connection part and the connection rod and is used for supplying damping force to the connection rod; vibration of the vibration component is transmitted to the damping mechanism through the connection rod along an axial direction; through cooperation of the connection rodand the damping mechanism, vibration energy of the vibration component can be gradually absorbed by the damping mechanism, so that the vibration reduction effect is achieved. The vehicle pipeline vibration reduction system comprises the vibration reduction device. The vibration reduction device is arranged in a vehicle pipeline; the vehicle pipeline forms the vibration component; and NVH performance of the vehicle can be improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

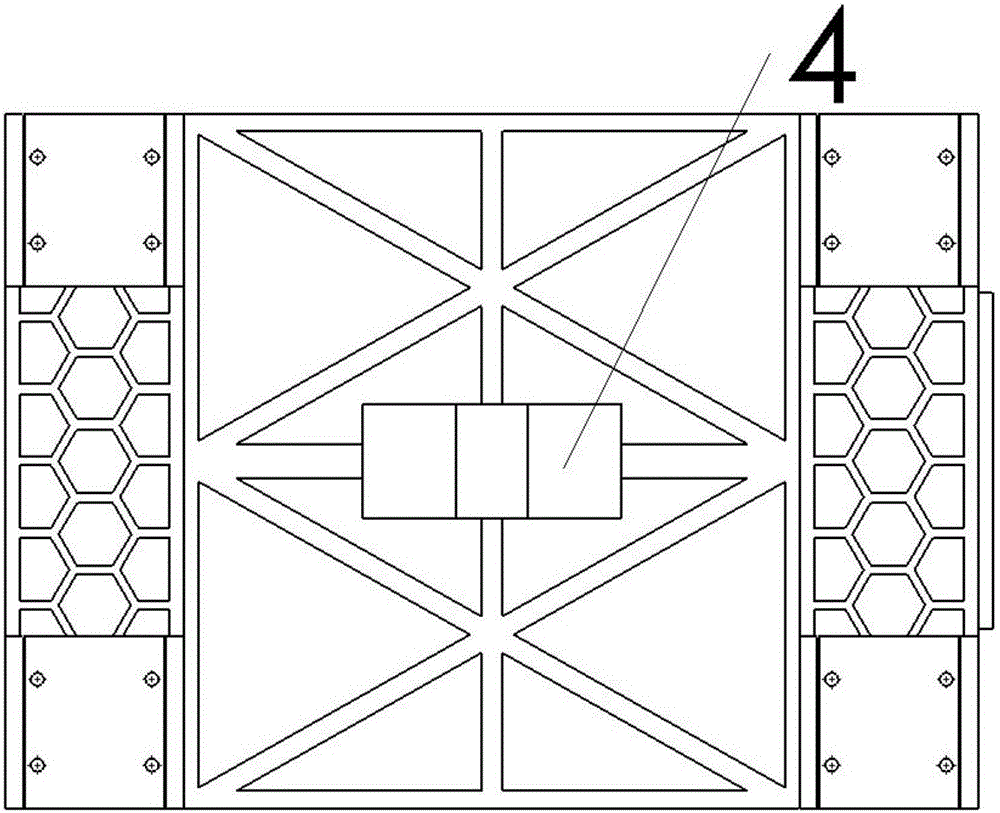

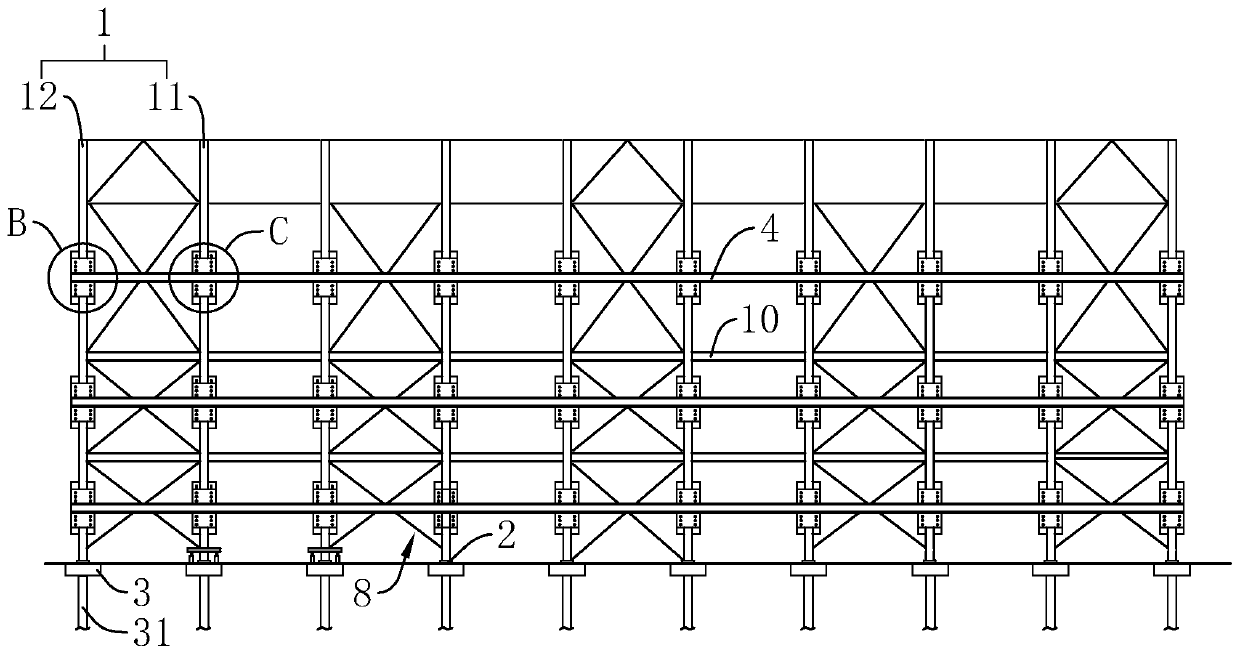

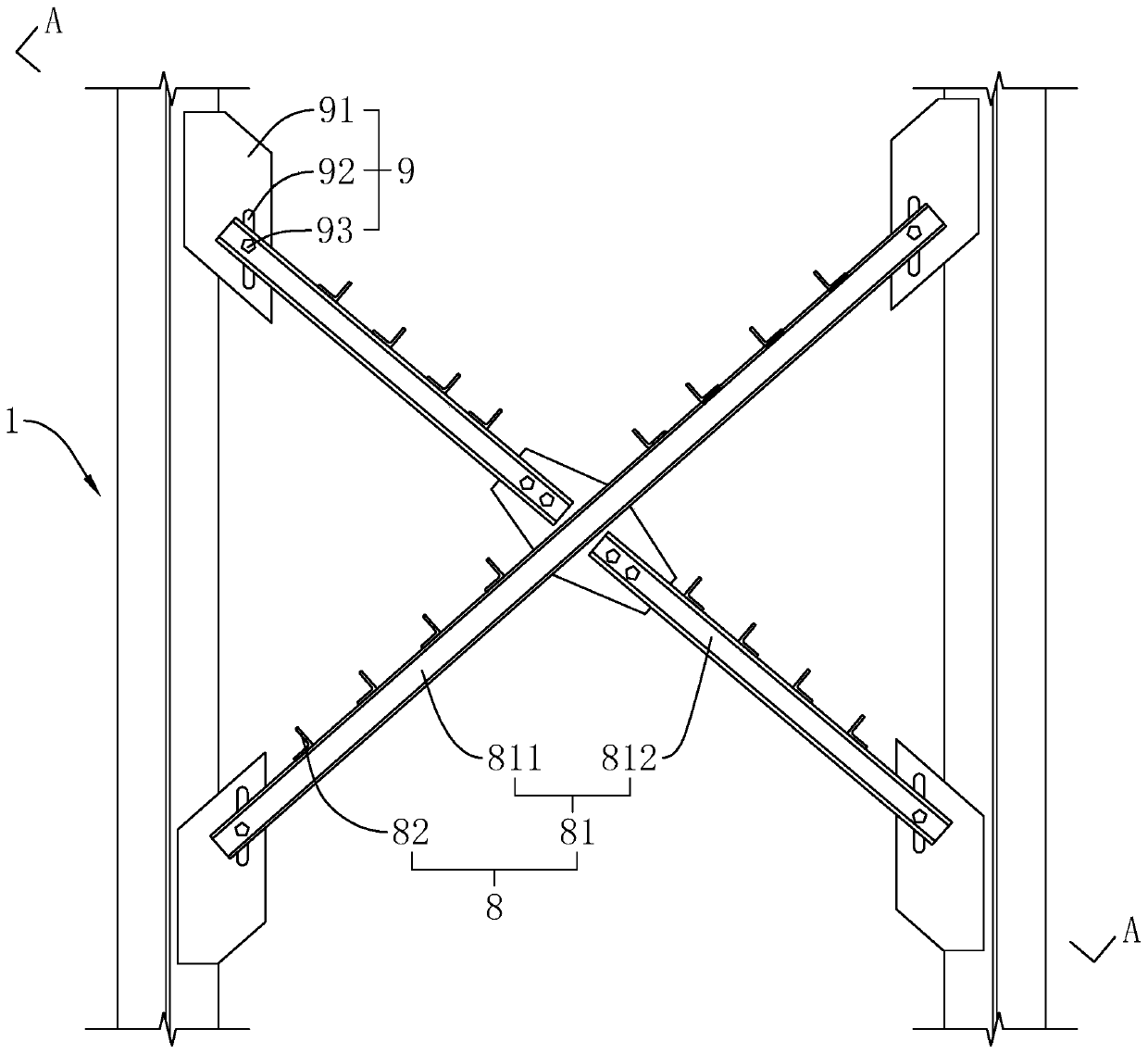

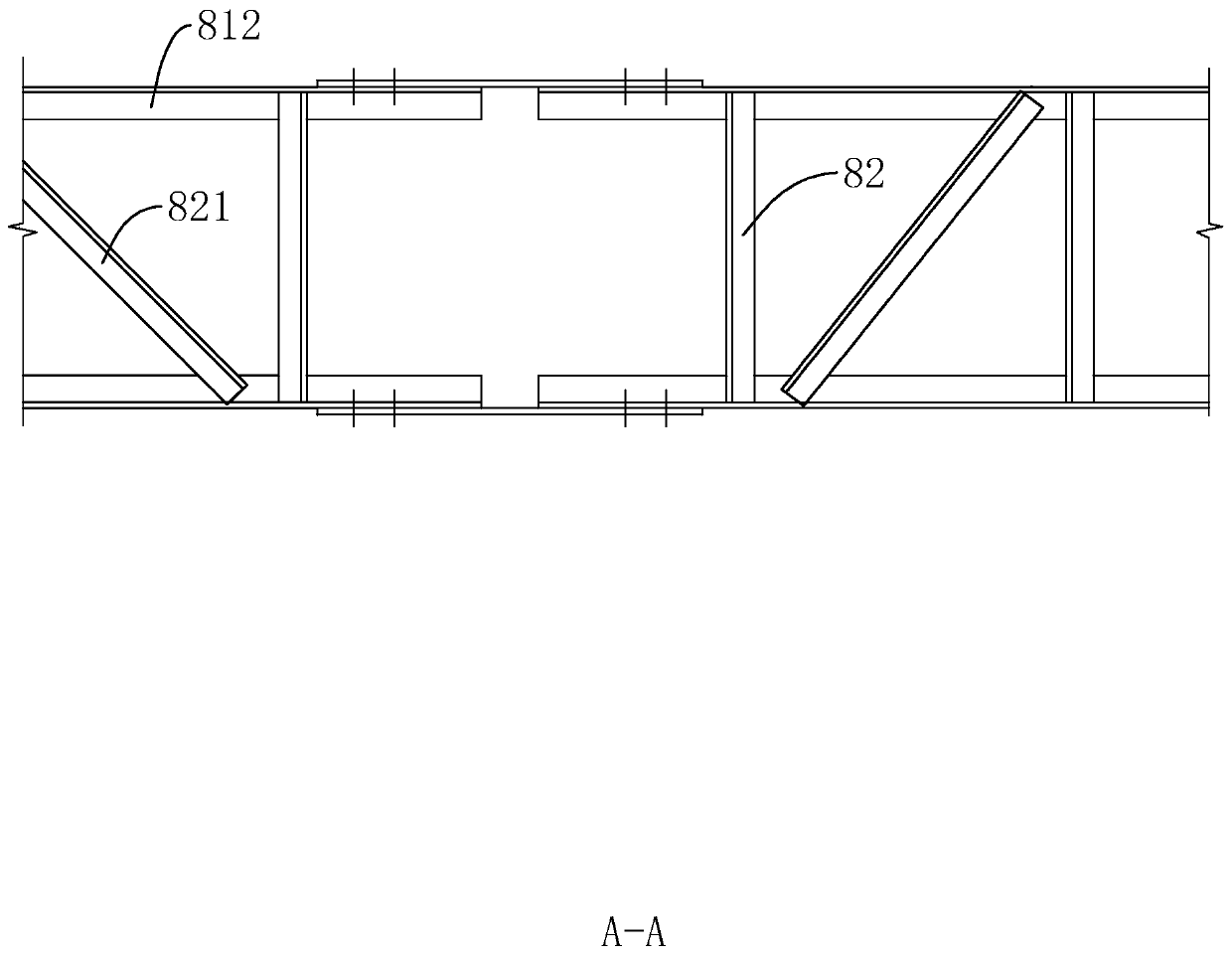

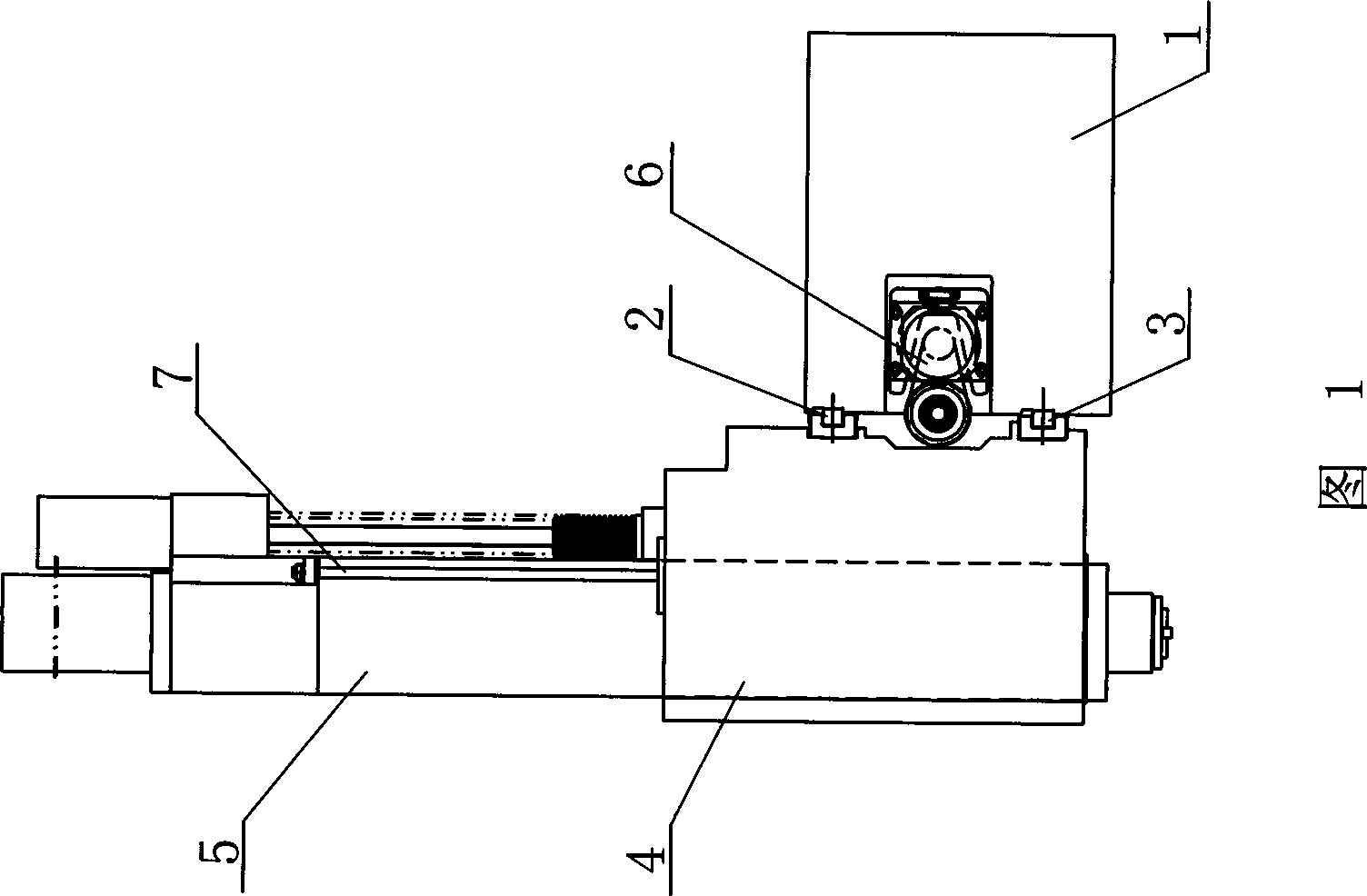

Machine tool sliding plate structure

The invention discloses a machine tool sliding plate structure. Mounting platforms of a guide track sliding block are arranged on both the upper surface and the lower surface of the machine tool sliding plate structure, oil holes are formed in side surfaces of the mounting platforms, and the oil holes are beneficial for flowing of oil, so that a gap caused by surface roughness between a sliding block and a sliding plate can be filled, heat transfer can be enhanced, part of heat in the heat conduction process can be carried away, then thermal deformation of the sliding plates can be reduced, and meanwhile a lubricating function can be achieved for guide track pairs; the lower surface is saddle-shaped and is internally provided with a cross-shaped rib plate; an X-direction ball screw pair screw nut base is integrally connected with the sliding plate and is arranged at a central part of the lower surface; honeycomb rib plates are arranged on the upper surface and the lower surface; a Y-direction ball screw pair screw nut base is arranged at one end of the upper surface; under the condition that the Y-direction stroke is ensured, the length of a ram can be reduced. Compared with a conventional sliding plate, the volume and the mass of the improved sliding plate can be both reduced, a weight system can be conveniently arranged on the ram on the sliding plate, the strength and the rigidity of the structure can be improved, thermal deformation can be reduced, and the machining precision of a machine tool can be improved.

Owner:BEIJING UNIV OF TECH

Rectifying method using dynamic monitoring and dynamic reinforcement

ActiveCN111119260AImprove overall stiffnessReduce construction difficultyFoundation engineeringSteel platesSteel columns

The invention relates to a rectifying method using dynamic monitoring and dynamic reinforcement. The rectifying method comprises the following steps: S1, measurement is conducted, specifically, the settlement amount of steel columns is monitored, the steel columns needing to be rectified are determined and recorded as rectifying columns, and the remaining steel columns are recorded as in-situ columns; S2, column bracing is conducted, specifically, horizontal extension beams are mounted on the steel columns on the same side of a steel structure, the extension beams are fixedly connected with the in-situ columns, the extension beams limit horizontal displacement of the rectifying columns, and the rectifying columns can move in the vertical direction; S3, equipment mounting is conducted, specifically, force transmission frames are fixed to the bottoms of the rectifying columns, jacking appliances are mounted between the force transmission frames and bearing platforms, and the two or morejacking appliances are arranged; and S4, settlement rectifying of the rectifying columns is conducted, specifically, connecting steel plates at the bottoms of the rectifying columns and the bearing platforms are disconnected, the lifting appliances are started to drive the rectifying columns to move upwards until the rectifying columns reach the designed height. The force transmission frames are jacked to drive the rectifying columns to move upwards, so that a foundation pit with the large depth does not need to be excavated in the rectifying process, and the construction efficiency can be improved.

Owner:杭州敦固建筑特种工程有限公司

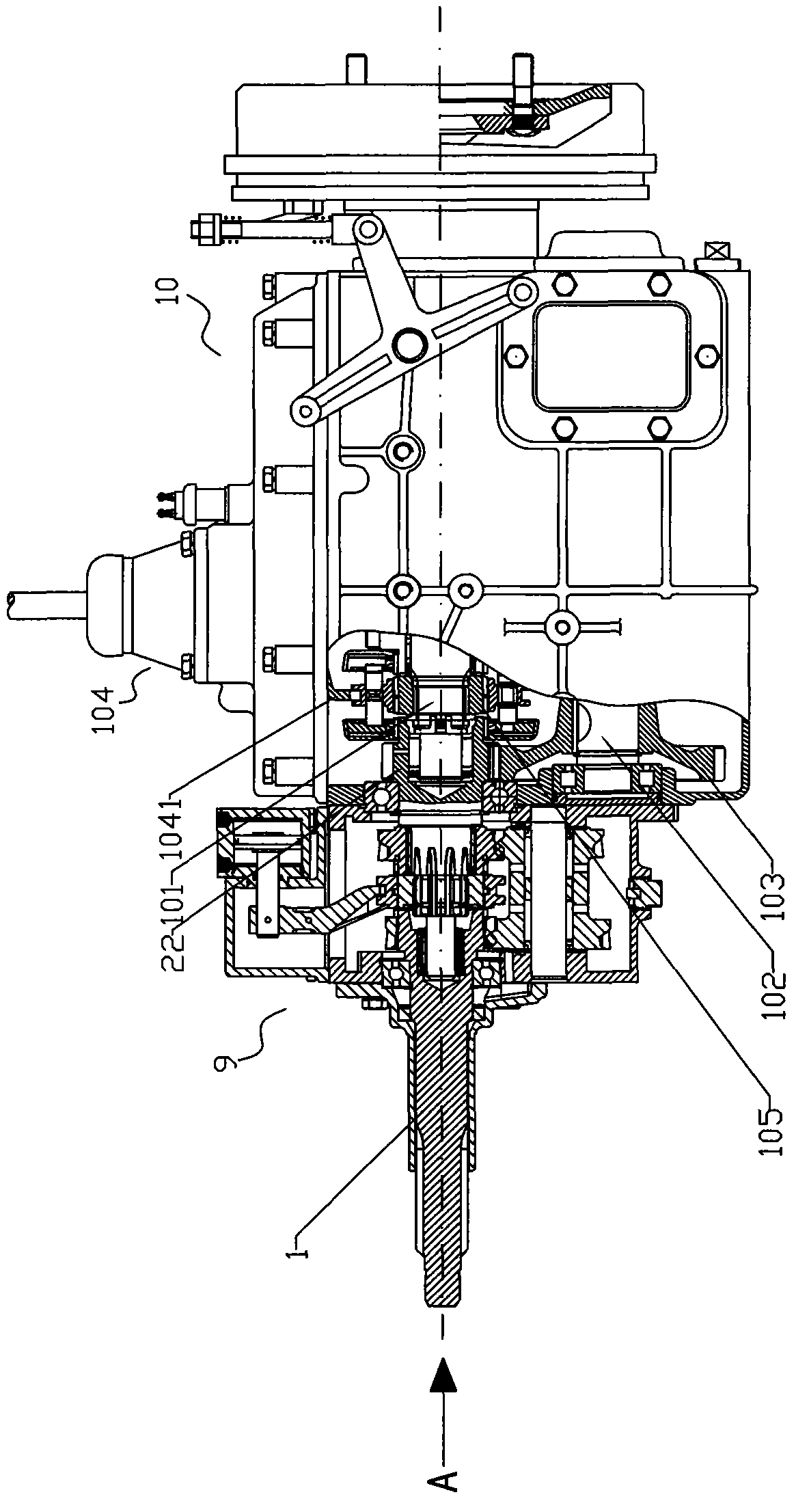

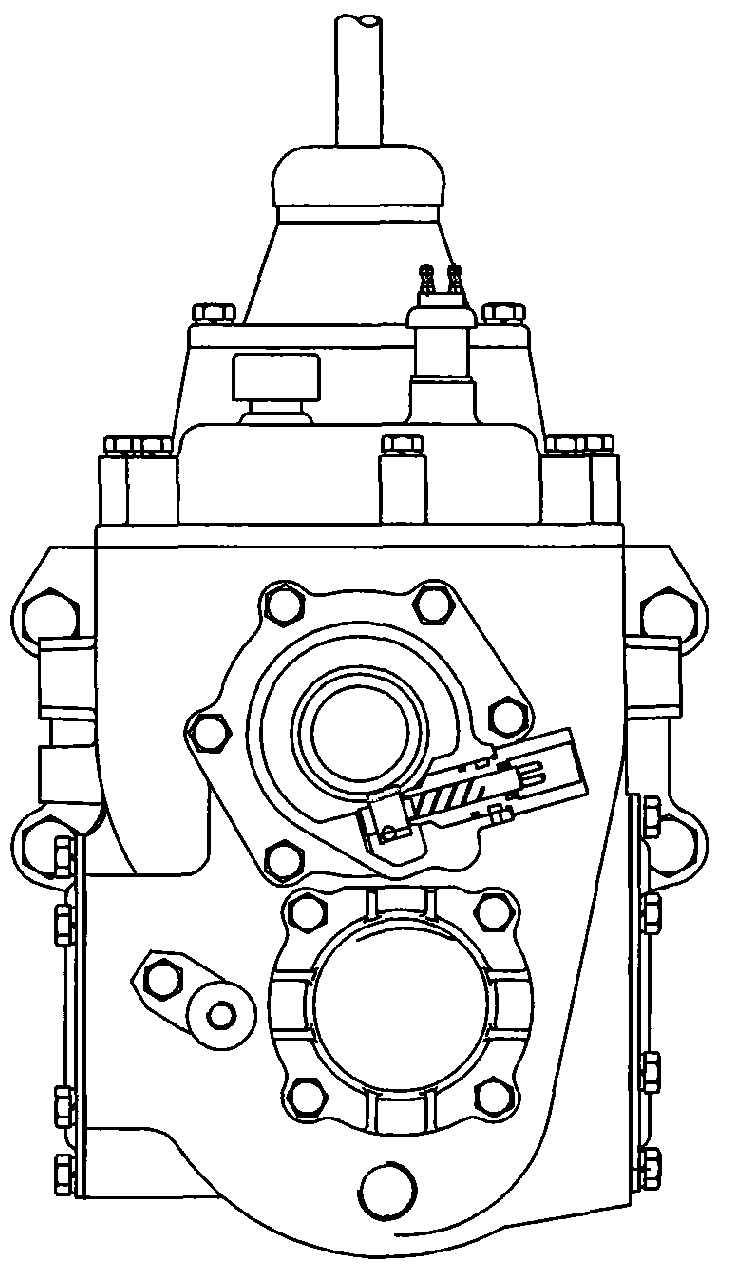

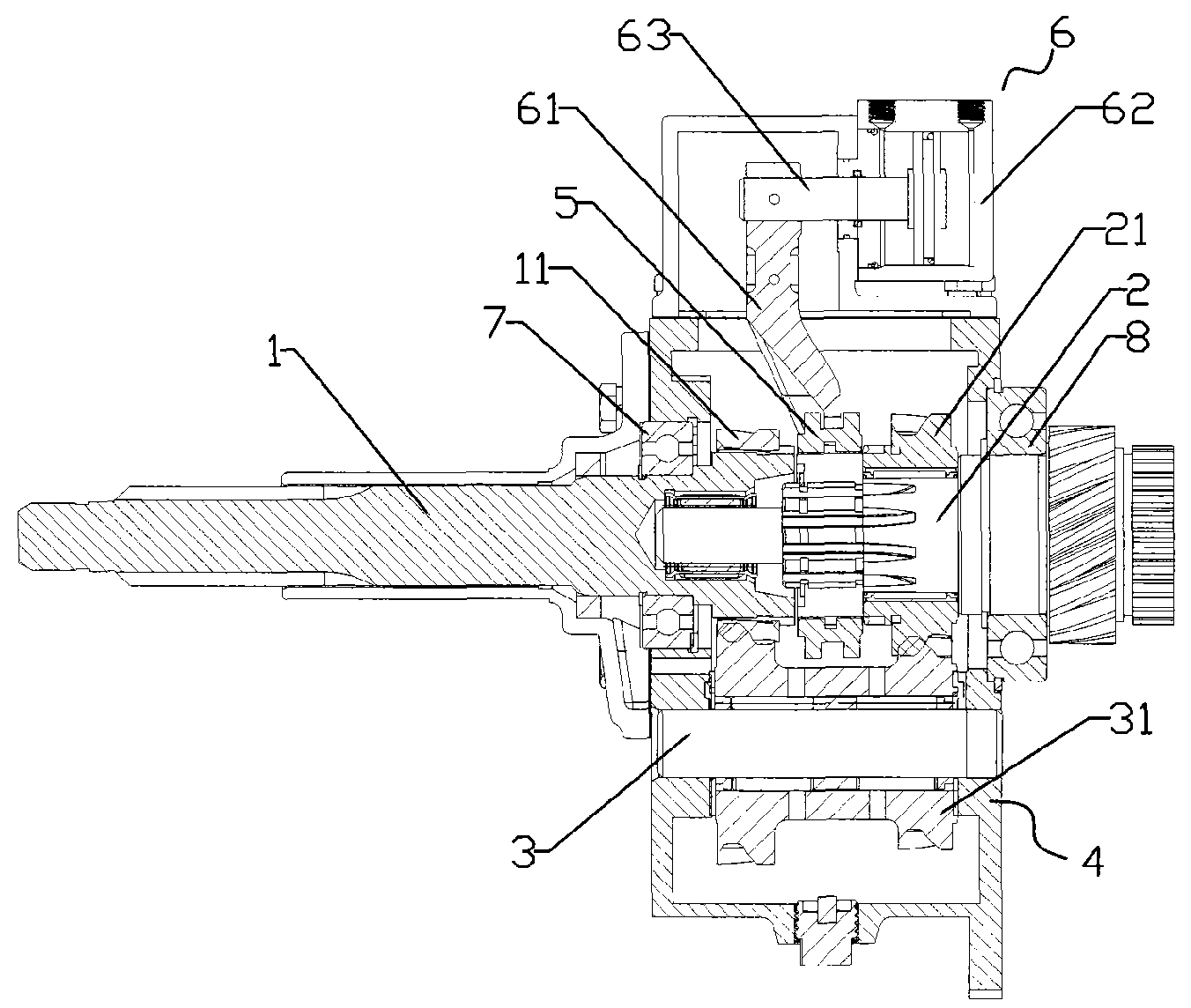

Multi-gear combined type transmission with prepositioned auxiliary box

InactiveCN101629618AShorten the lengthImprove overall stiffnessControlled membersToothed gearingsClutchVariator

The invention discloses a multi-gear combined type transmission with a prepositioned auxiliary box, comprising a main box and an auxiliary box, wherein the auxiliary box is prepositioned at the front end face of the main box, a main shaft of the auxiliary box is engaged with a transmission gear of a middle shaft of the main box by a shaft gear of the main shaft of the auxiliary box, and the power of an external engine is output to the middle shaft of the main box by the main shaft of the auxiliary box after the power of the external engine is transmitted to a shaft of the auxiliary box by a clutch. The invention adopts the mode of the prepositioned auxiliary box, diminishes the size of a box body of a gearbox, diminishes the length of an output shaft simultaneously, and increases the integral rigidity; the auxiliary box of the invention has a high-gear speed ratio and a low-gear speed ratio; and when the condition of a road is poor, an auxiliary gearbox is changed to low gear, which can increase the transmission ratio of a transmission system, improve the power state, thereby greatly increasing the traction force of a modification vehicle on the original basis and effectively enhancing the climbing ability of the vehicle.

Owner:綦江南方汽车齿轮有限公司

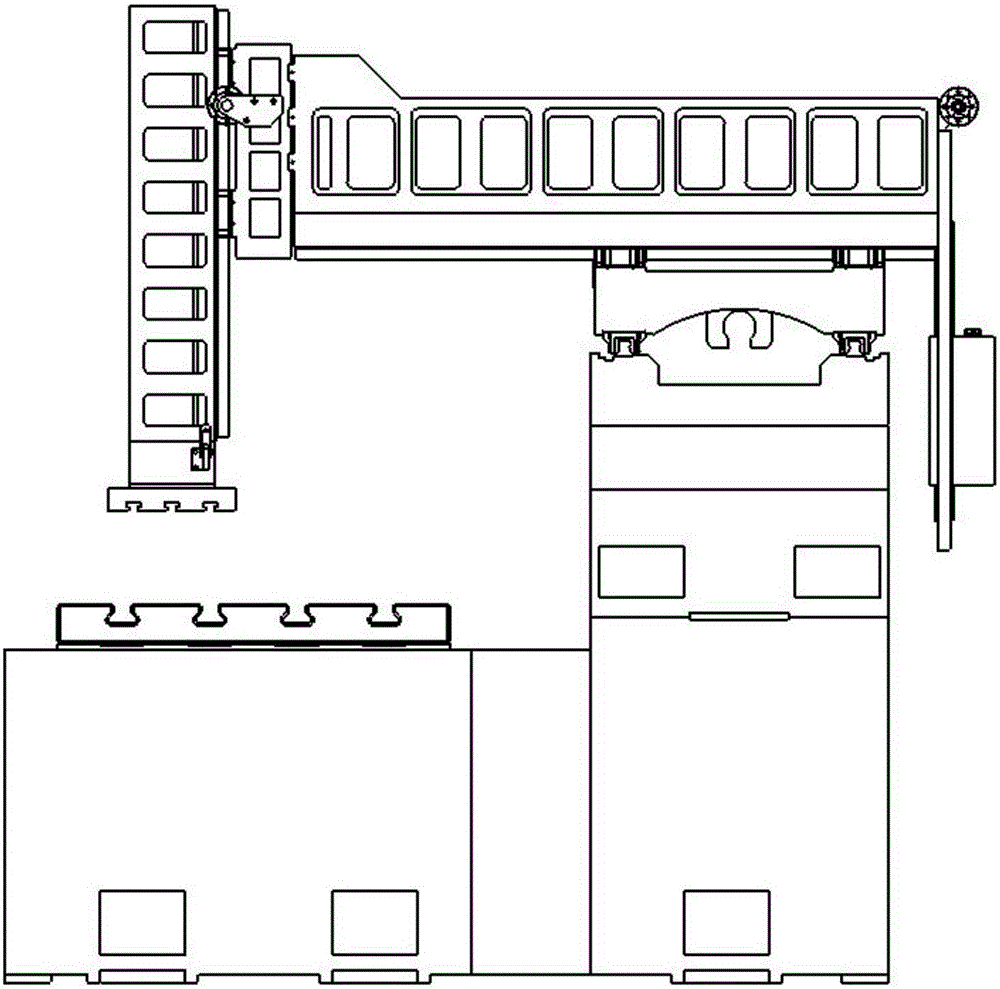

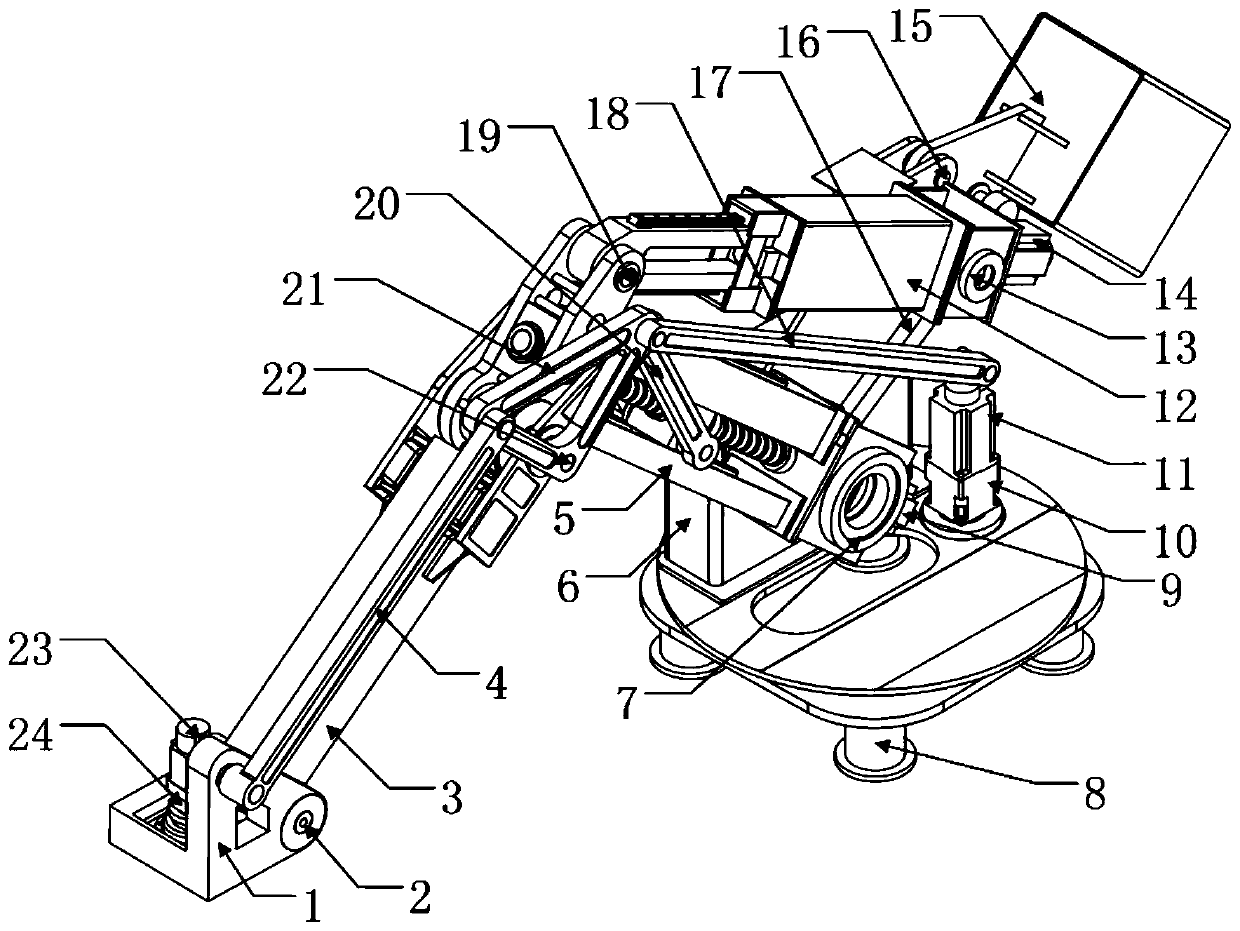

Four-freedom heavy-load mechanical arm

InactiveCN109895076AHigh precisionImprove overall stiffnessProgramme-controlled manipulatorEngineeringHeavy load

The invention discloses a four-freedom heavy-load mechanical arm. The four-freedom heavy-load mechanical arm mainly comprises a primary big arm, a secondary big arm, a forearm, a paw and a posture keeping mechanism, wherein the tail end of the primary big arm and the tail end of the auxiliary big arm are separately connected to a waist rotating mechanism through supporting shafts; the waist rotating mechanism is fixedly arranged on the base; the base is connected to the ground through a bolt; the secondary big arm is connected to the primary big arm through a secondary big arm pull rod; the forearm is mounted at the front end of the primary big arm; the paw is mounted at the front end of the forearm; and the posture keeping mechanism guarantees the tail end of the pawl to be horizontal. According to the mechanical arm disclosed by the invention, different performing mechanisms are additionally arranged at the tail end of the pawl to accomplish different work, so that the four-freedom heavy-load mechanical arm can be applied to various fields such as stacking and carrying. Load lifting ability of the mechanical arm can be 3000 kg.

Owner:UNIV OF JINAN

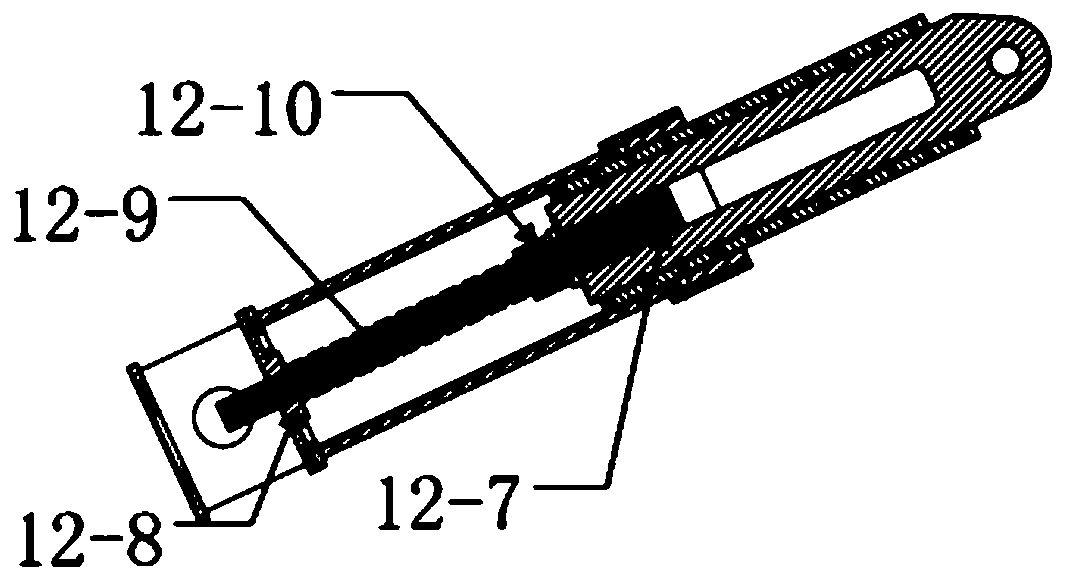

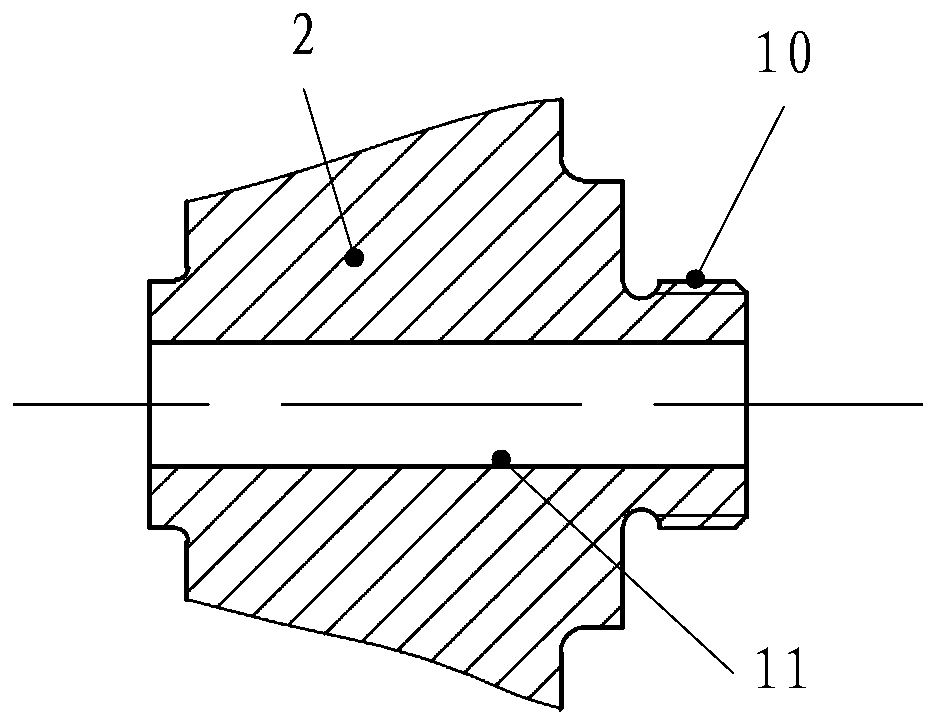

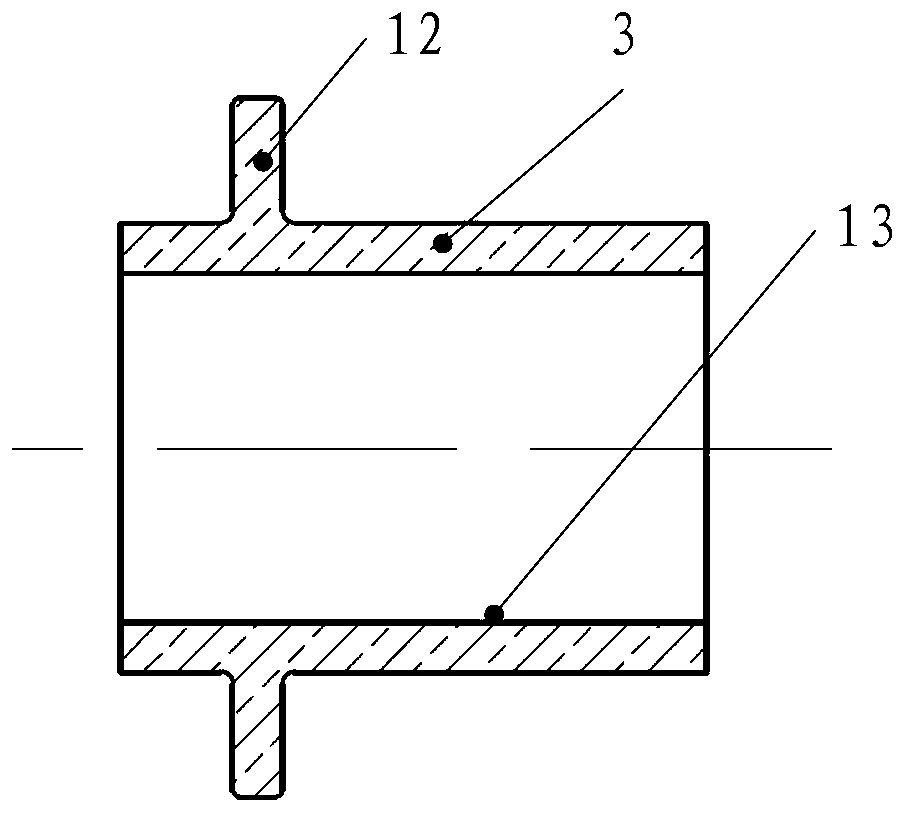

Closed circulating turbine power generating system rotor structure based on air bearing

ActiveCN110332020AImprove overall stiffnessImprove stability and reliabilityPump componentsBlade accessoriesImpellerAir bearing

The invention relates to a closed circulating turbine power generating system rotor structure based on an air bearing. The closed circulating turbine power generating system rotor structure comprisesa locking nut, an air compressor impeller, a composite shaft sleeve, a connecting shaft sleeve, a transition shaft sleeve, a motor shaft, a fixed shaft sleeve, a radial shaft sleeve and a turbine rotor. An external thread is arranged on the air compressor impeller, and an annular end face matched with an axial thrust bearing is arranged on the composite shaft sleeve. An internal thread is arrangedat one end of the connecting shaft sleeve, and an external thread is arranged at the other end of the connecting shaft sleeve. An internal thread matched with the transition shaft sleeve is arrangedat one end of the motor shaft. An internal thread matched with the external thread of the turbine rotor is arranged at the other end of the motor shaft. The fixed shaft sleeve is provided with an internal thread matched with the external thread of the turbine rotor, and an external thread matched with the internal thread of the fixed shaft sleeve and the internal thread of the motor shaft is arranged on the turbine rotor. According to the rotor structure, aiming at the characteristics of the air bearing, the reliability of a closed circulating turbine power generating system can be improved.

Owner:BEIJING POWER MACHINERY INST

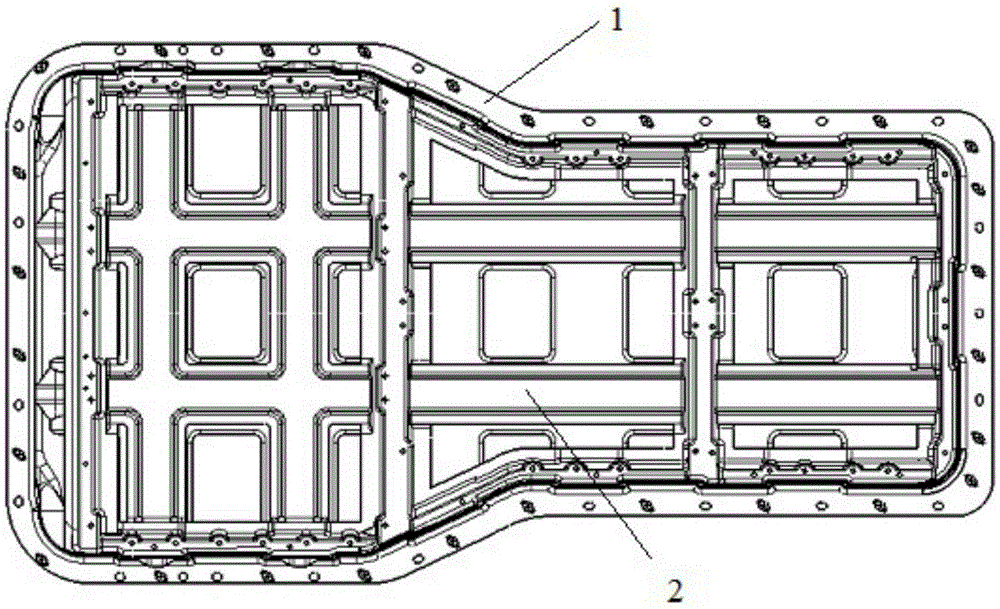

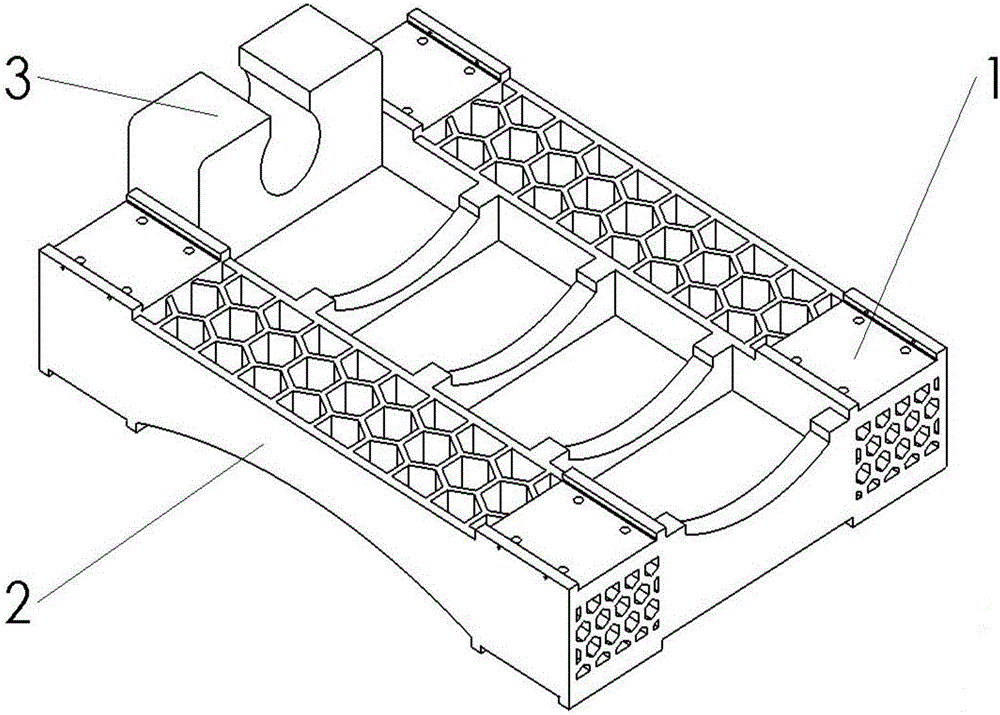

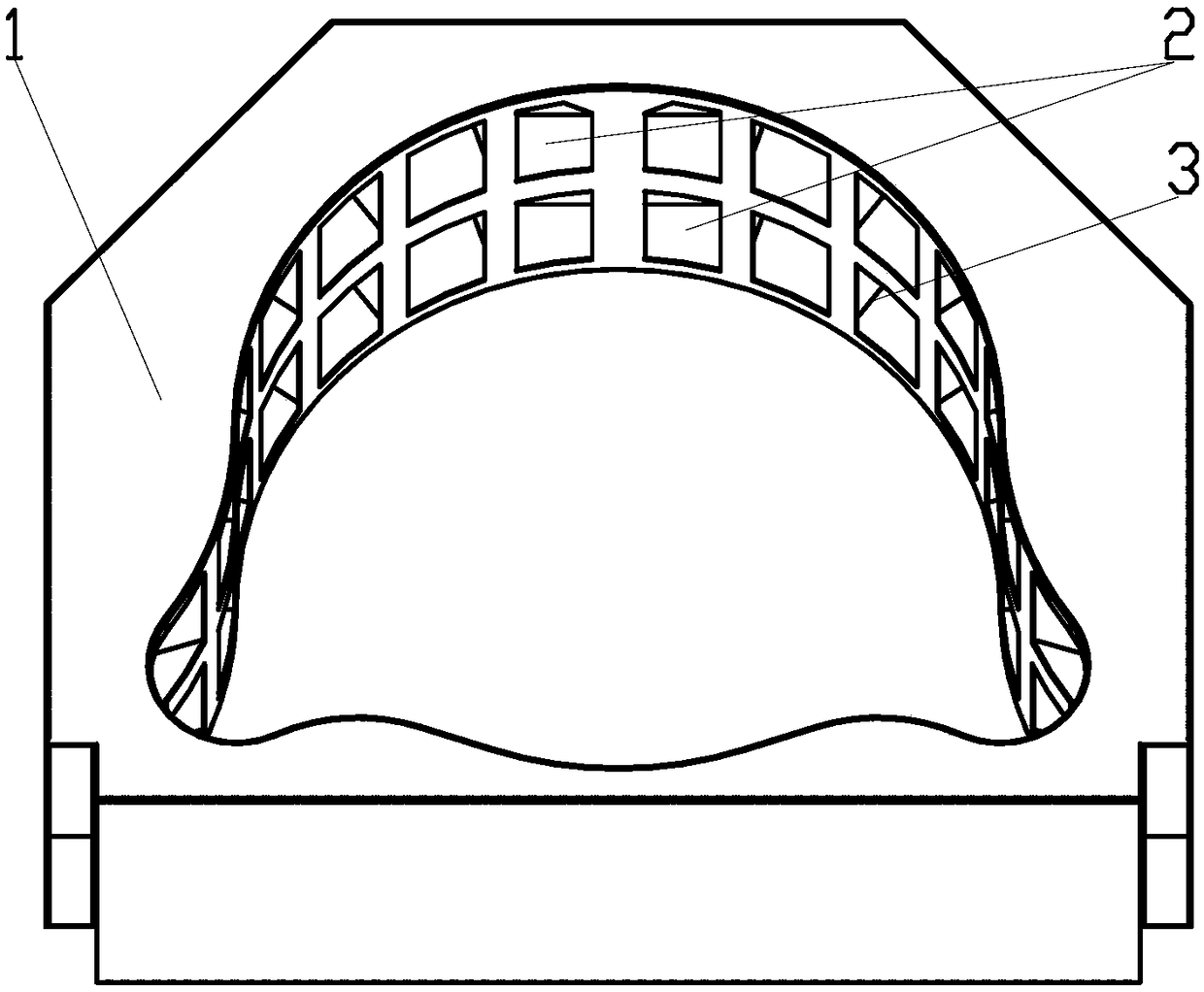

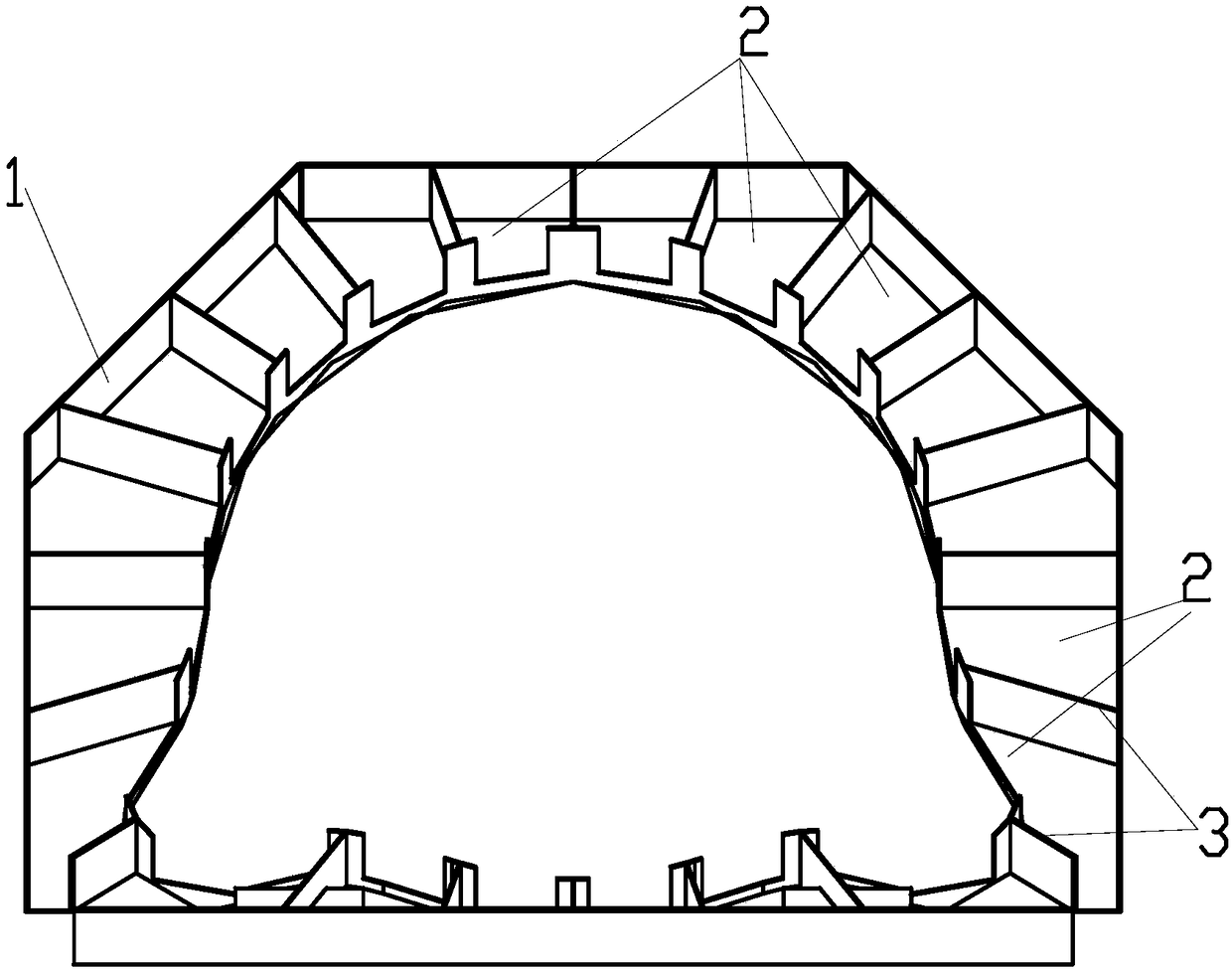

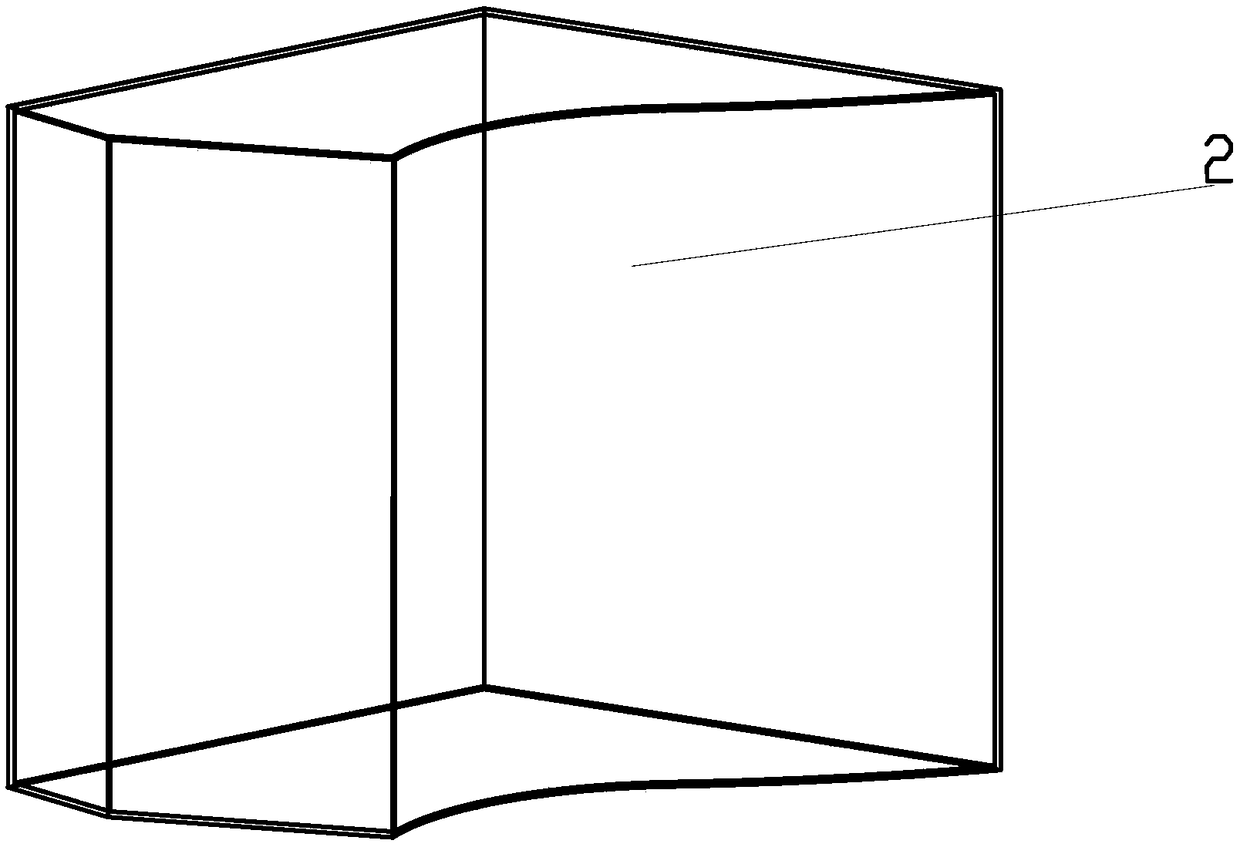

Forming method suitable for main force bearing frame body of satellite laser radar frame

ActiveCN109435271AImprove reliabilityImprove overall stiffnessDomestic articlesSatelliteStructural stability

The invention provides a forming method suitable for a main force bearing frame body of a satellite laser radar frame. The forming method comprises the following steps: S1, prepreg is laid on a mold,a flange is reserved, and a laid layer of a frame body overall part (1) is formed; S2, prepreg is laid on a thermal expansion mold core, after laying is completed, vacuumizing and pre-compacting are conducted, and a laid layer of a frame body cavity part (2) is formed; S3, prepreg is laid on the mold, and frame body reinforcing ribs (3) are prepared; and S4, the laid layer of the frame body cavitypart (2) is placed at the preset position, the prepared frame body reinforcing ribs (3) are sequentially placed into the main force bearing frame body cavity part (2), and a frame body cavity mechanism is constituted. According to the forming method suitable for the frame body of the satellite laser radar frame, the overall rigidity of a main force bearing frame and structural stability of a product are improved, and meanwhile, the requirement of weight reduction is met.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

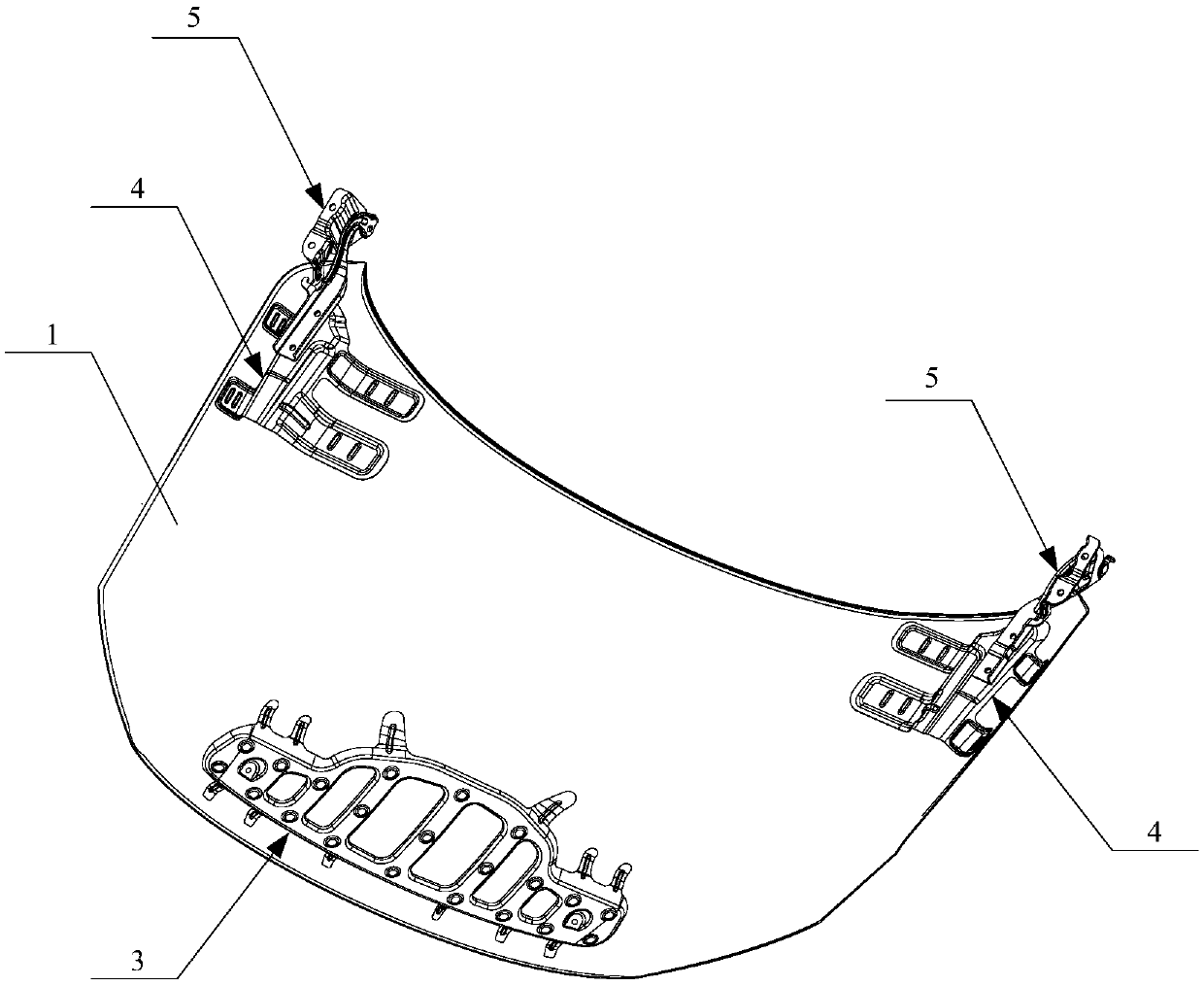

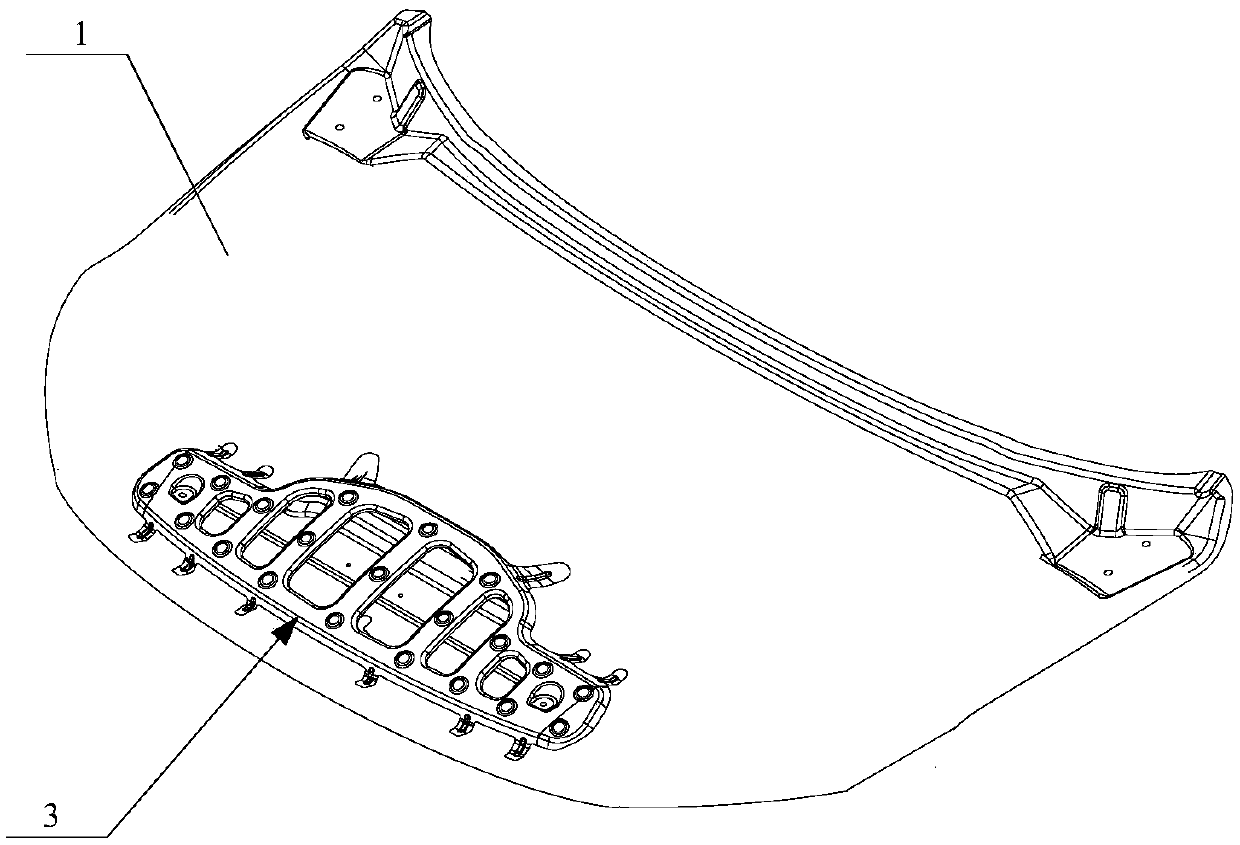

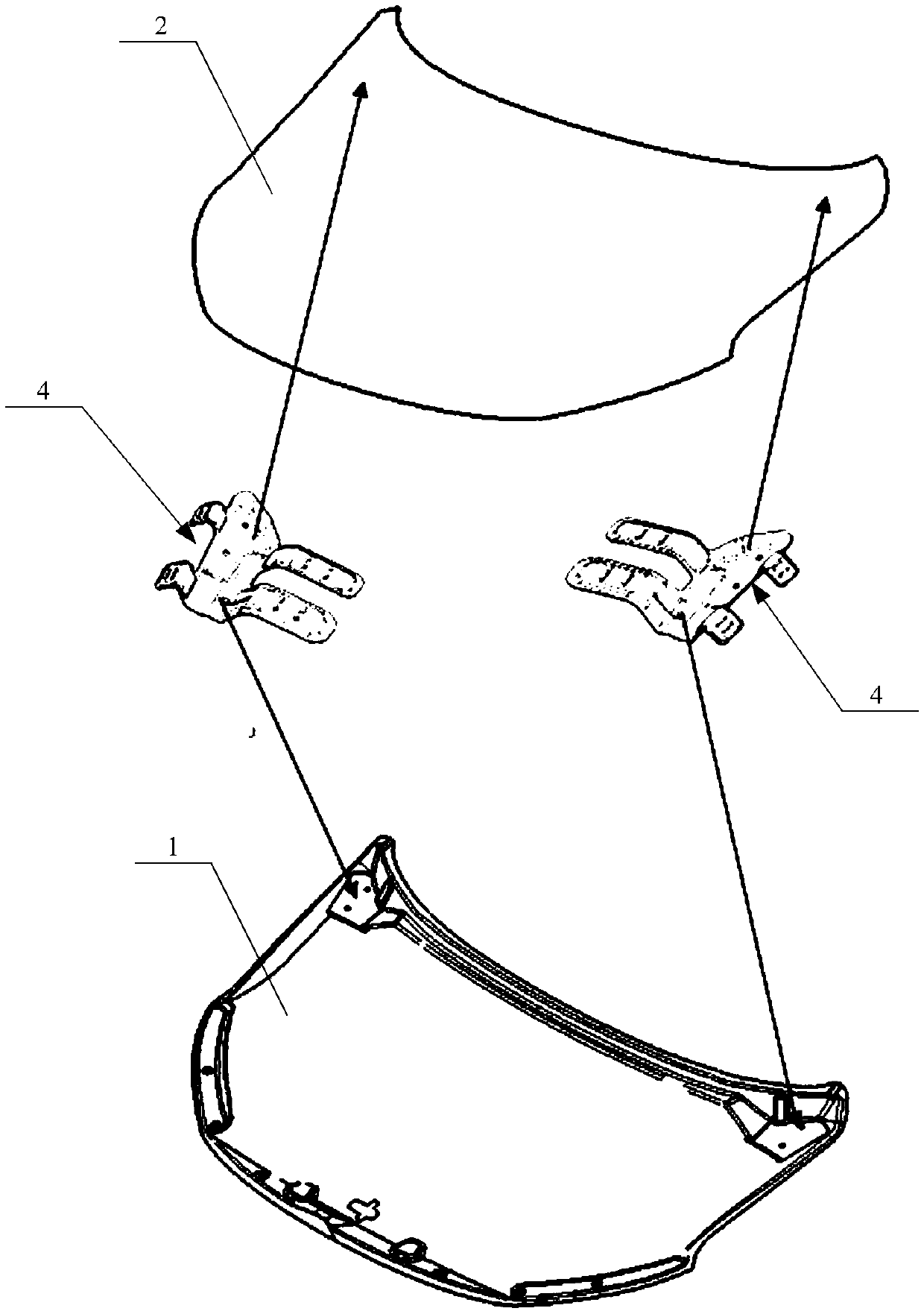

Compartment cover

ActiveCN109649502AImprove overall stiffnessImprove securitySuperstructure subunitsHinge angleThermal deformation

The invention provides a compartment cover which comprises an inner plate, an outer plate, a connecting device and a hinge mechanism. The inner plate and the outer plate are fastened with each other,and an accommodating space is formed after the inner plate and the outer plate are fastened with each other; the connecting device is arranged in the accommodating space, is welded with the inner plate and is adhered with the outer plate; the hinge mechanism is arranged in the accommodating space, first ends of the hinge mechanism are detachably connected with the connecting device, and second ends of the hinge mechanism are used for being detachably connected with a vehicle body. The compartment cover has the advantages that the inner plate and the outer plate are connected with each other bythe connecting device after being fastened with each other, accordingly, the stability of connection between the inner plate and the outer plate can be effectively guaranteed, the integral rigidity,modal frequencies and the dent resistance of the compartment cover and the rigidity of hinge mounting locations can be effectively improved, the diversified performance requirements can be met by thecompartment cover, and the safety can be improved; the connecting device is adhered with the outer plate, accordingly, thermal deformation of the outer plate due to welding and the like can be prevented, and the attractive appearance can be guaranteed.

Owner:CH AUTO TECH CORP CO LTD

Transverse beam guide rails apparatus

InactiveCN101367169ALarge overturning momentImprove overall stiffnessLarge fixed membersEngineeringMechanical engineering

Owner:WUXI KAIYUAN MACHINE TOOLS GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com