Rectifying method using dynamic monitoring and dynamic reinforcement

A dynamic monitoring and dynamic technology, applied in the field of steel structure correction, can solve problems such as excessive time and manpower consumption, secondary settlement of steel structures, large excavation depth, etc., to reduce construction difficulty, improve overall rigidity, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

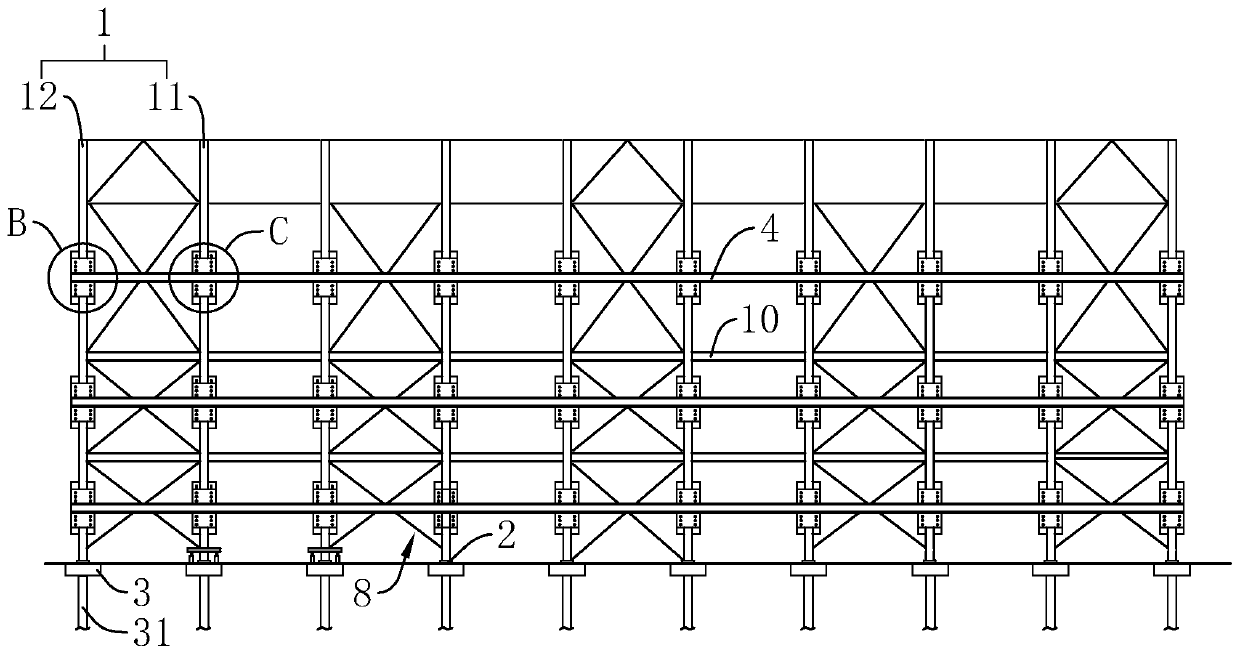

[0051] refer to figure 1 , which is a deviation correction method using dynamic monitoring and dynamic reinforcement disclosed by the present invention, comprising the following steps:

[0052] S1, measurement;

[0053] Carry out stakeout measurement on the steel column 1, determine the settlement of each steel column 1, and determine the steel column 1 that needs to be corrected according to the design requirements, and record these steel columns 1 that need to be corrected as the correction column 11, and the rest do not need to be corrected The steel column 1 for deflection correction is recorded as the in-situ column 12 . In the following description, the steel column 1 refers to the deviation correction column 11 and the in-situ column 12 .

[0054] S2, support between columns;

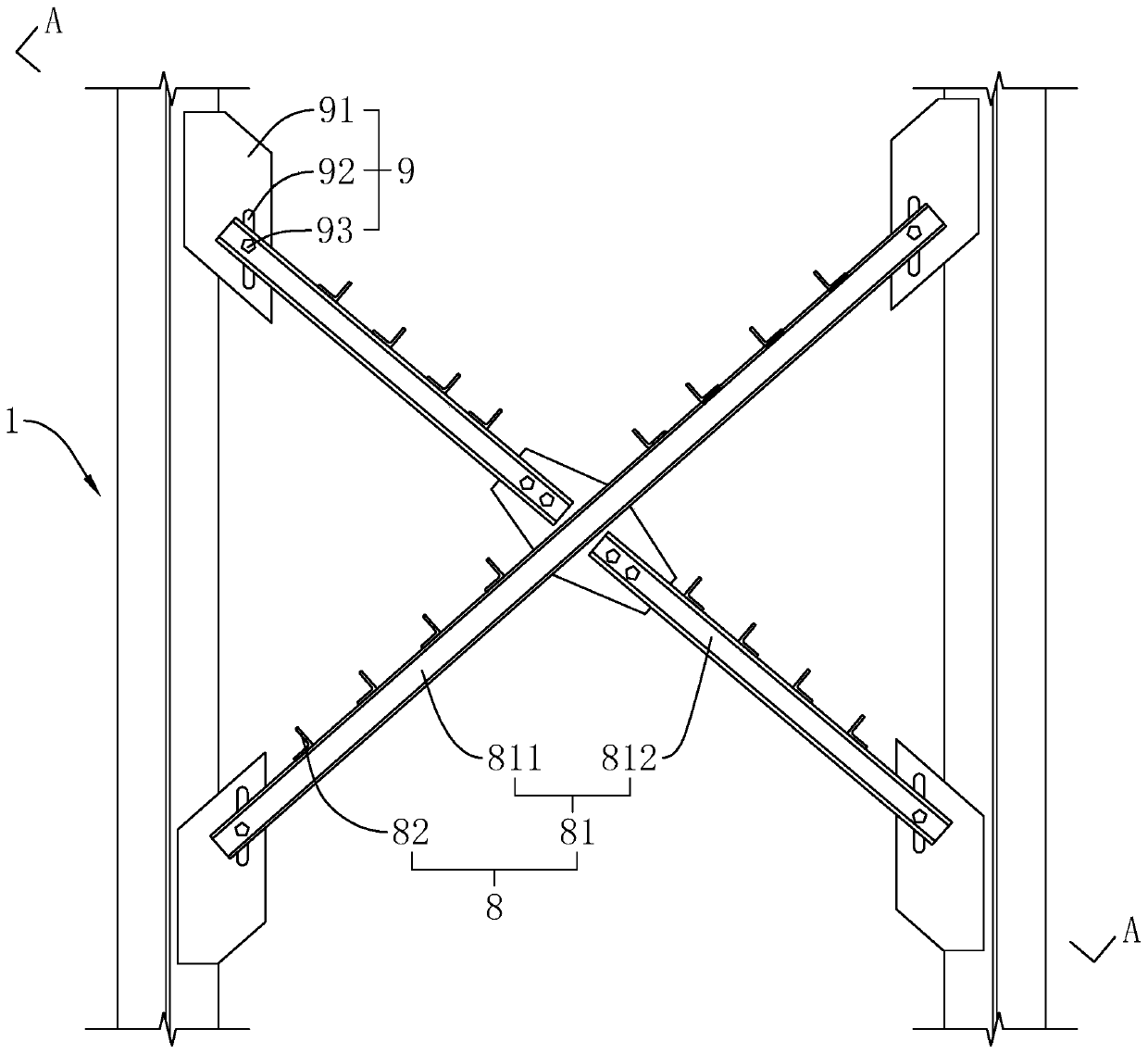

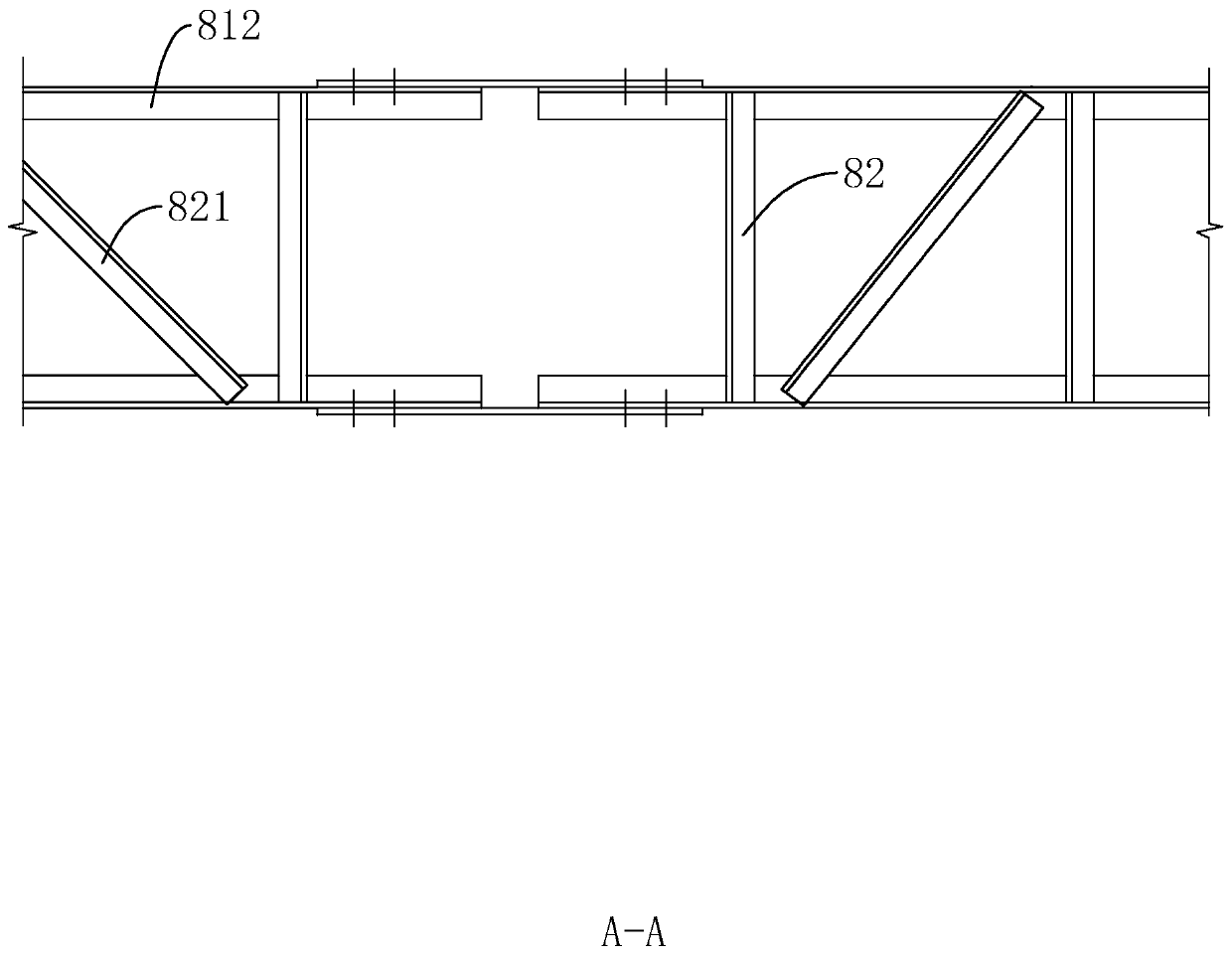

[0055] combine figure 2 with image 3 , Install diagonal braces 8 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com