Closed circulating turbine power generating system rotor structure based on air bearing

A power generation system, closed cycle technology, applied to the components of the pumping device for elastic fluid, non-variable displacement pump, engine components, etc., can solve the problems affecting the working reliability and connection strength of the closed cycle turbine power generation system. And the stiffness is not guaranteed, the interference of the connection part is reduced, etc., to achieve the effect of repeatable assembly, enhanced stability and reliability, and reduced wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

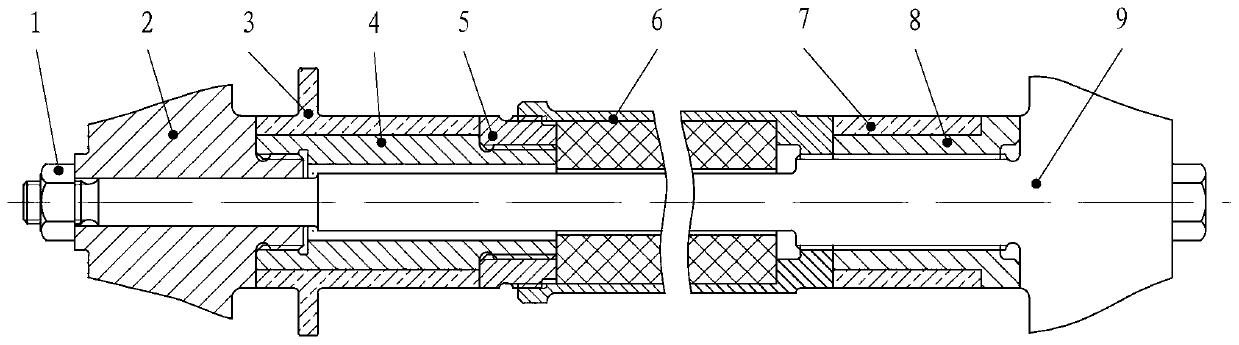

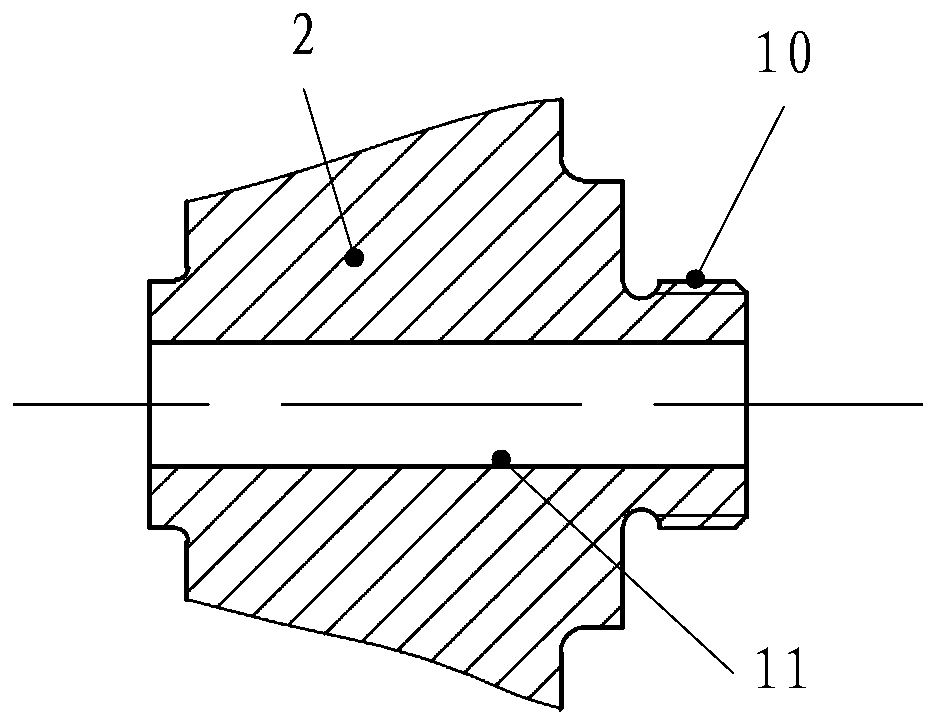

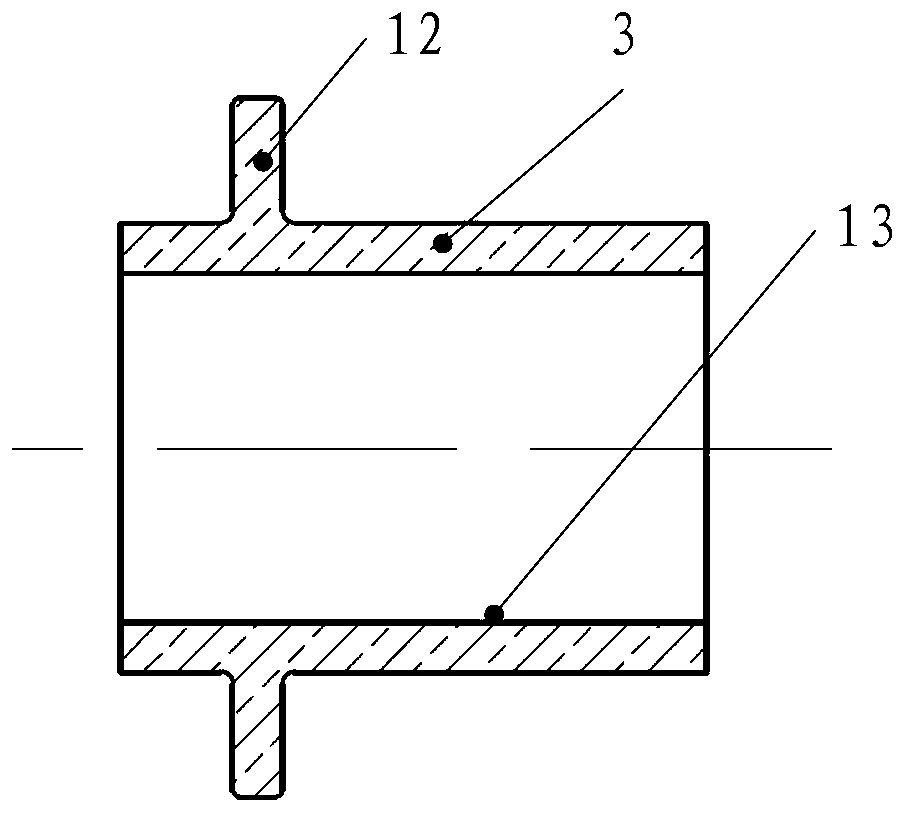

[0035] A closed cycle turbine power generation system rotor structure based on air bearings, including lock nut 1, compressor impeller 2, composite bushing 3, connecting bushing 4, transition bushing 5, motor shaft 6, fixed bushing 7 , Radial bushing 8 and turbine rotor 9. The direction of rotation of the locking nut 1 is opposite to that of the rotor of the turbine power generation system; thread 10; the composite shaft sleeve 3 has an annular end face 12 co-axial with the thrust bearing, the composite shaft sleeve 3 is made of wear-resistant and high temperature resistant ceramic material, and the composite shaft sleeve 3 passes through the inner hole 13 Assembled on the connecting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com