Multi-gear combined type transmission with prepositioned auxiliary box

A combination and transmission technology, applied in the direction of instruments, transmission devices, mechanical control devices, etc., can solve the problems of insufficient power for side installation, inconvenient transmission, and increase the inclination angle of the chassis drive shaft, so as to increase the transmission system The effect of transmission ratio, improvement of dynamic state, and increase of overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

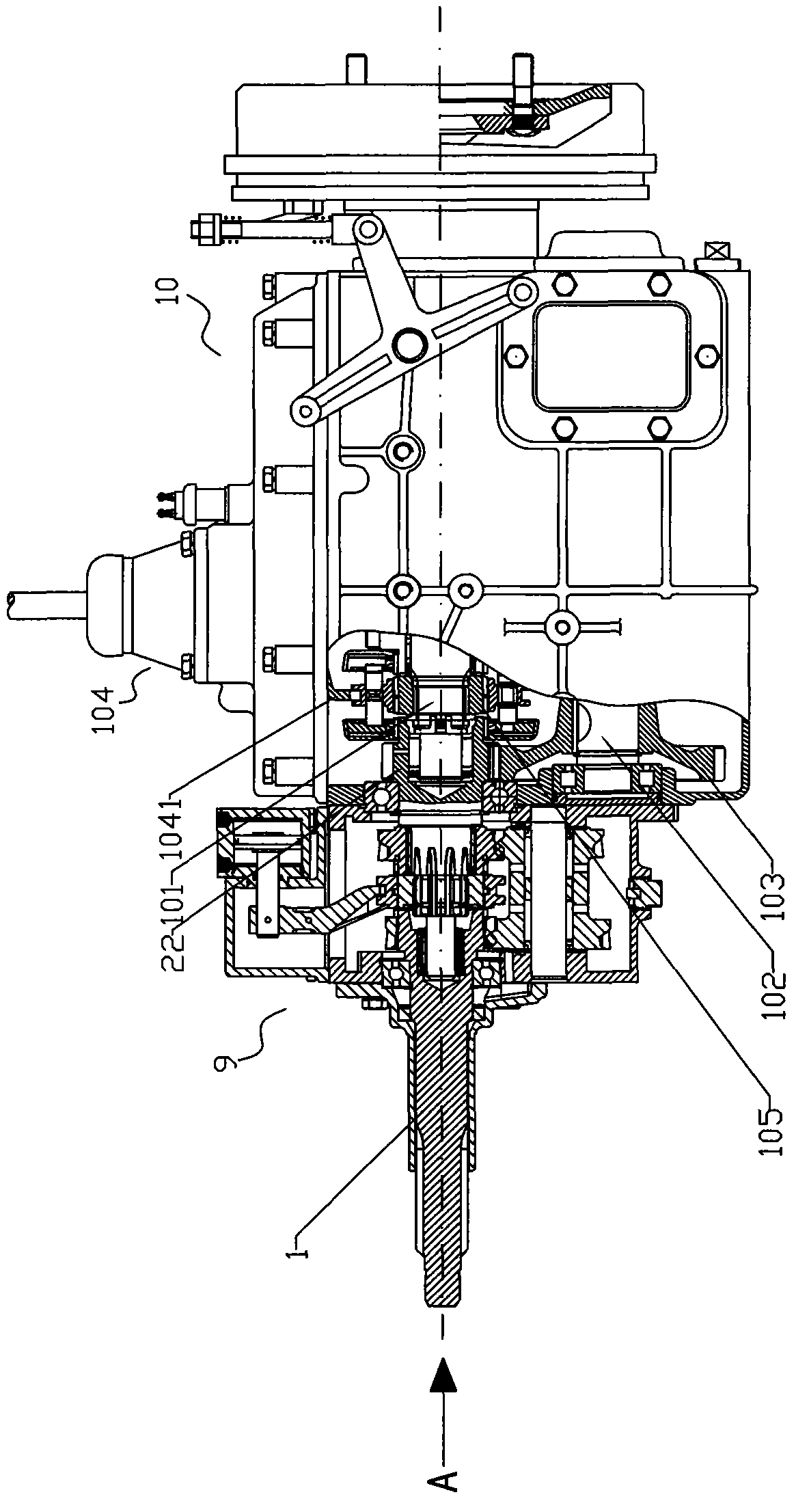

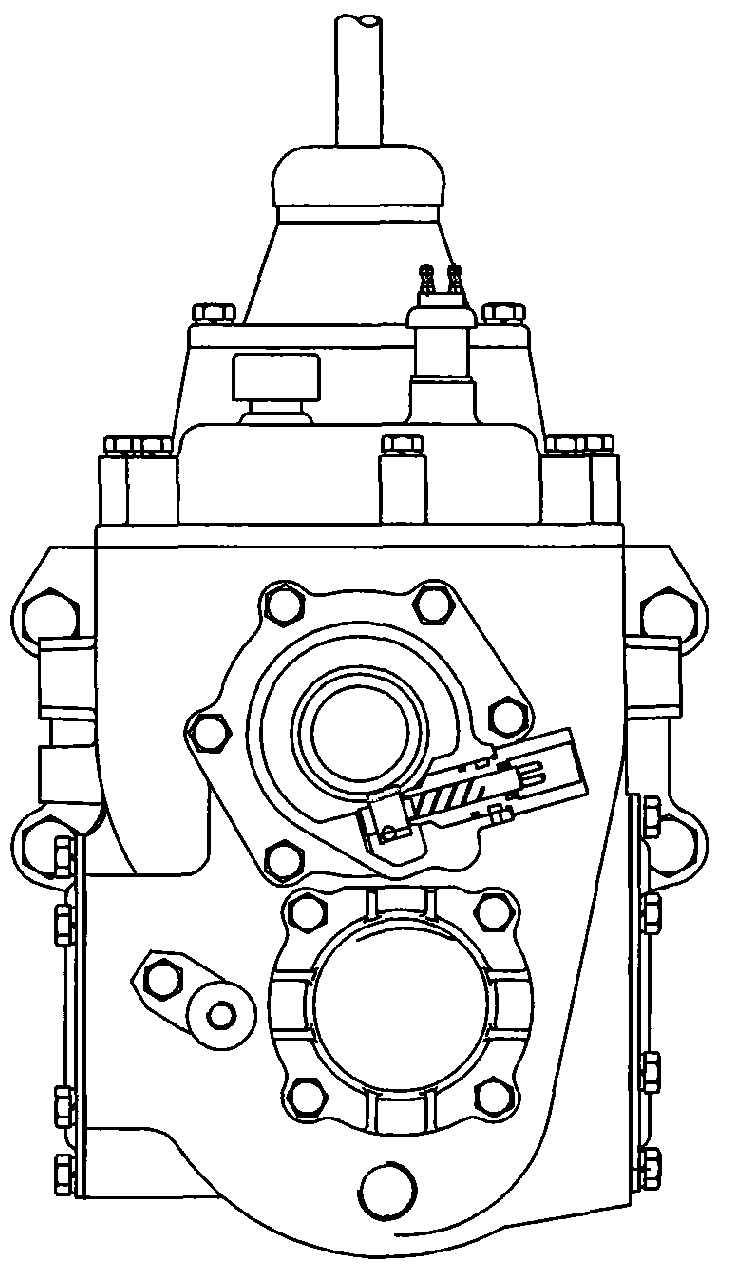

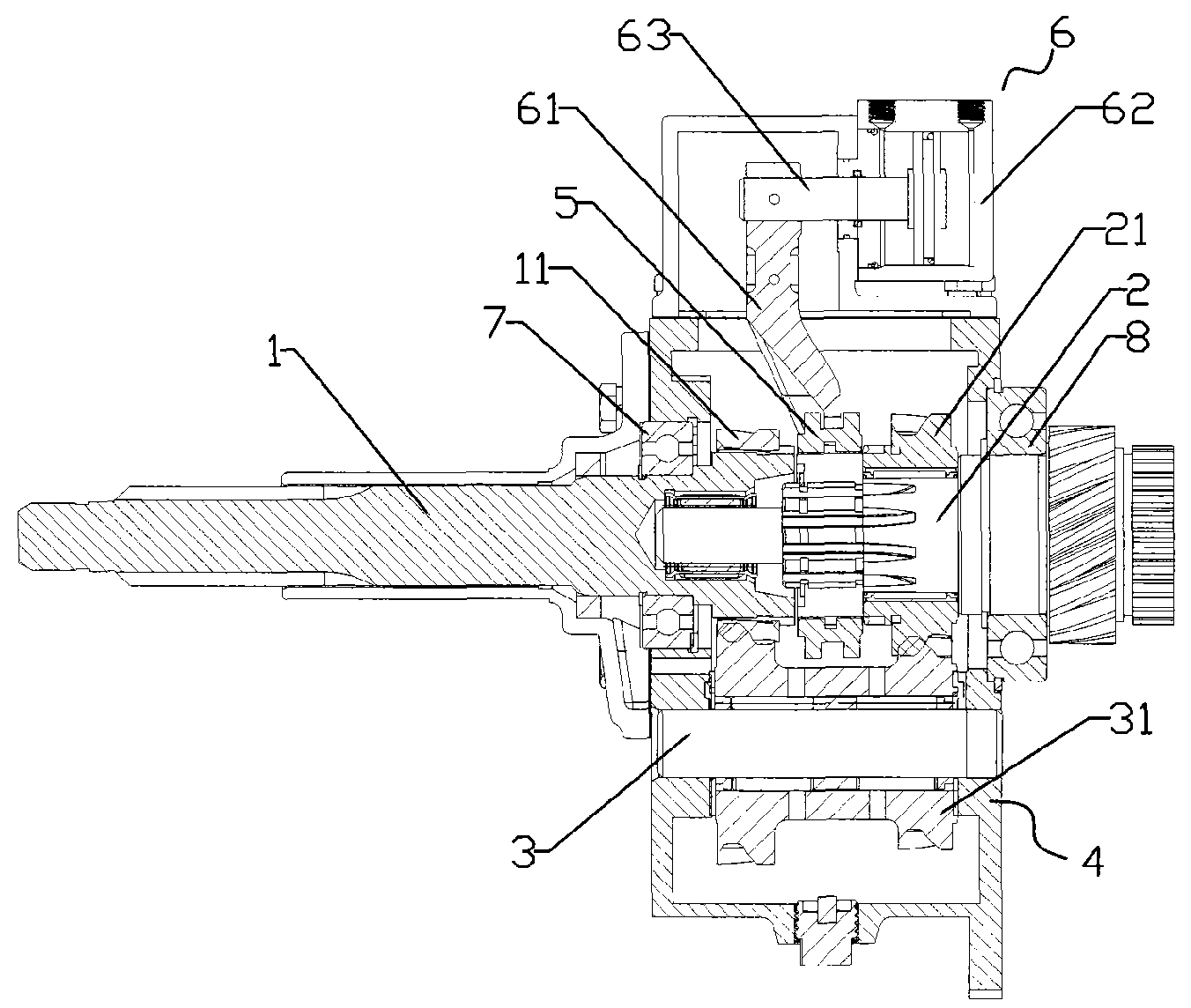

[0022] like figure 1 and figure 2 As shown, the present invention is made up of five-speed main transmission main box 10 and two-speed auxiliary transmission auxiliary box 9, wherein, main box 10 comprises main box transmission shaft 101, and reverse gear, low gear are respectively housed on the main box transmission shaft 1st gear, 2nd gear, 3rd gear, there is a sliding sleeve between the low and reverse gears, between the 1st and 2nd gears, and between the 3rd and 4th gears, respectively set a sliding sleeve or a synchronizer Engage.

[0023] Below the main box transmission shaft 101 are provided with the main box intermediate shaft 102, the main box intermediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com