Construction method for plain concrete underground diaphragm wall of deep foundation pit

A technology of underground diaphragm wall and construction method, which is applied in basic structure engineering, sheet pile wall, building and other directions, can solve the problem of high verticality requirements of I-beam joints in underwater precise construction grooves, increased construction period and cost, and inability to guarantee Water stop effect and other issues, to reduce the risk of joint leakage, reduce the construction period, and reduce the amount of chiseling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

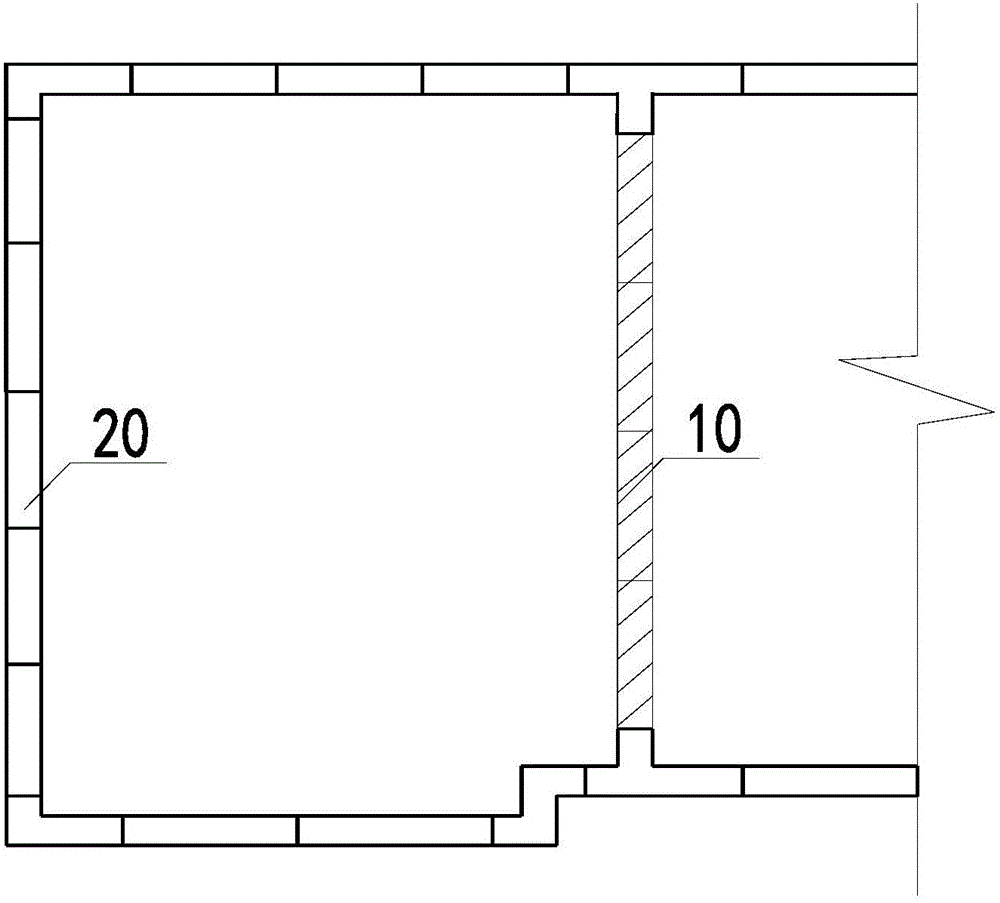

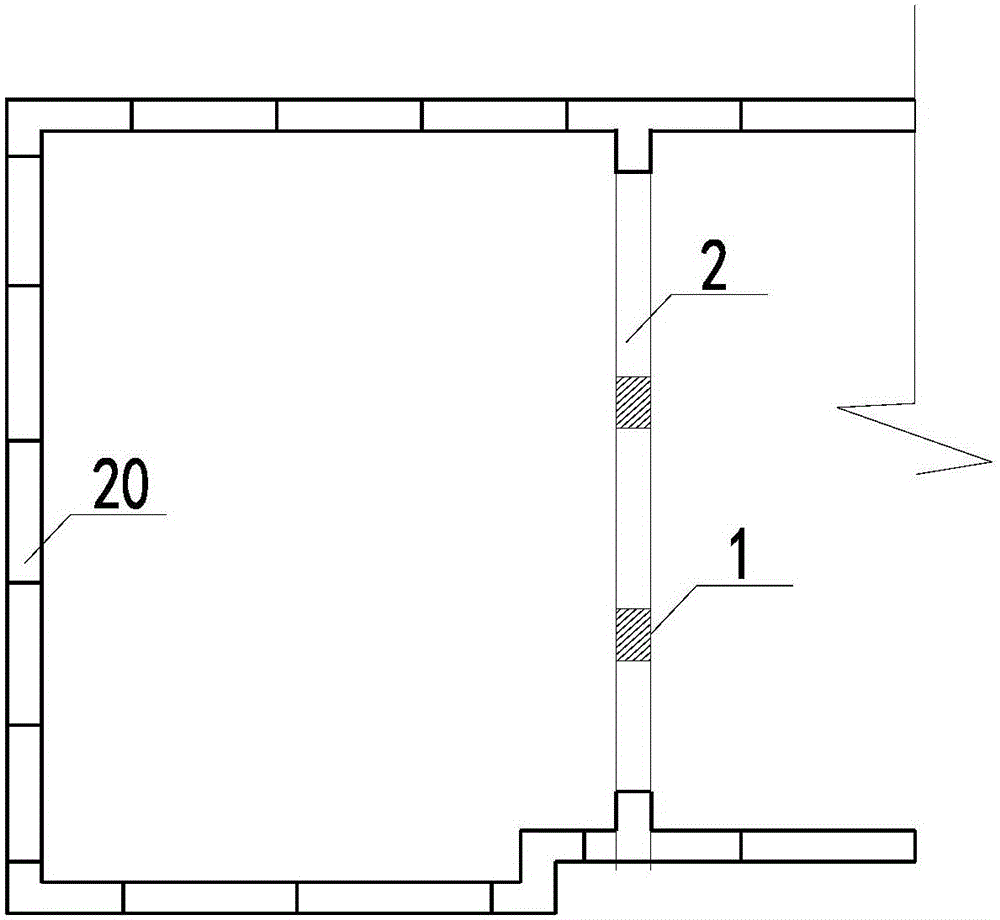

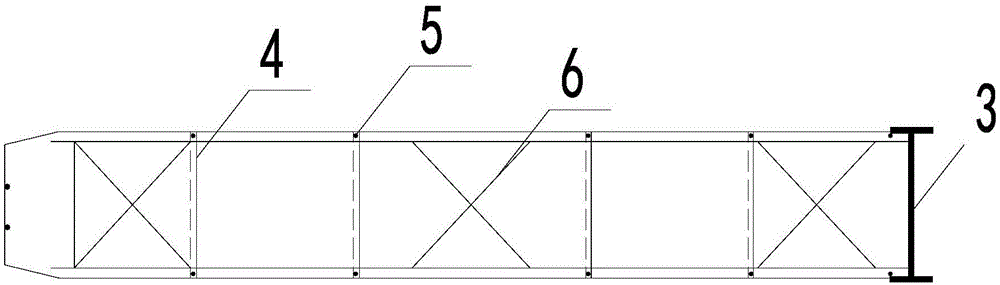

[0024] Usually, the plain concrete underground diaphragm wall is excavated on the ground with a trough-forming machine to excavate a narrow and long deep groove to form a unit groove section, place a steel cage in the unit groove section, and then pour concrete to complete a unit wall section , the unit wall sections are connected with each other by I-beams, which are used for retaining soil and separating the hydraulic connection between diving inside and outside the pit and pressurized water.

[0025] A kind of construction method of plain concrete underground diaphragm wall of deep foundation pit that the present invention proposes, wherein, to the design framing of orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com