Composite material satellite antenna reflection surface and manufacturing process thereof

A composite material, satellite antenna technology, applied in the direction of antennas, natural mineral layered products, electrical components, etc., can solve the reduction of the accuracy of the antenna reflector surface, the difficulty in the production and processing of aluminum honeycomb sandwiches, and the structural defects of sandwich composite materials, etc. problem, to achieve the effect of light weight, simple manufacturing process and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the invention is further described below in conjunction with the accompanying drawings of the description and specific embodiments:

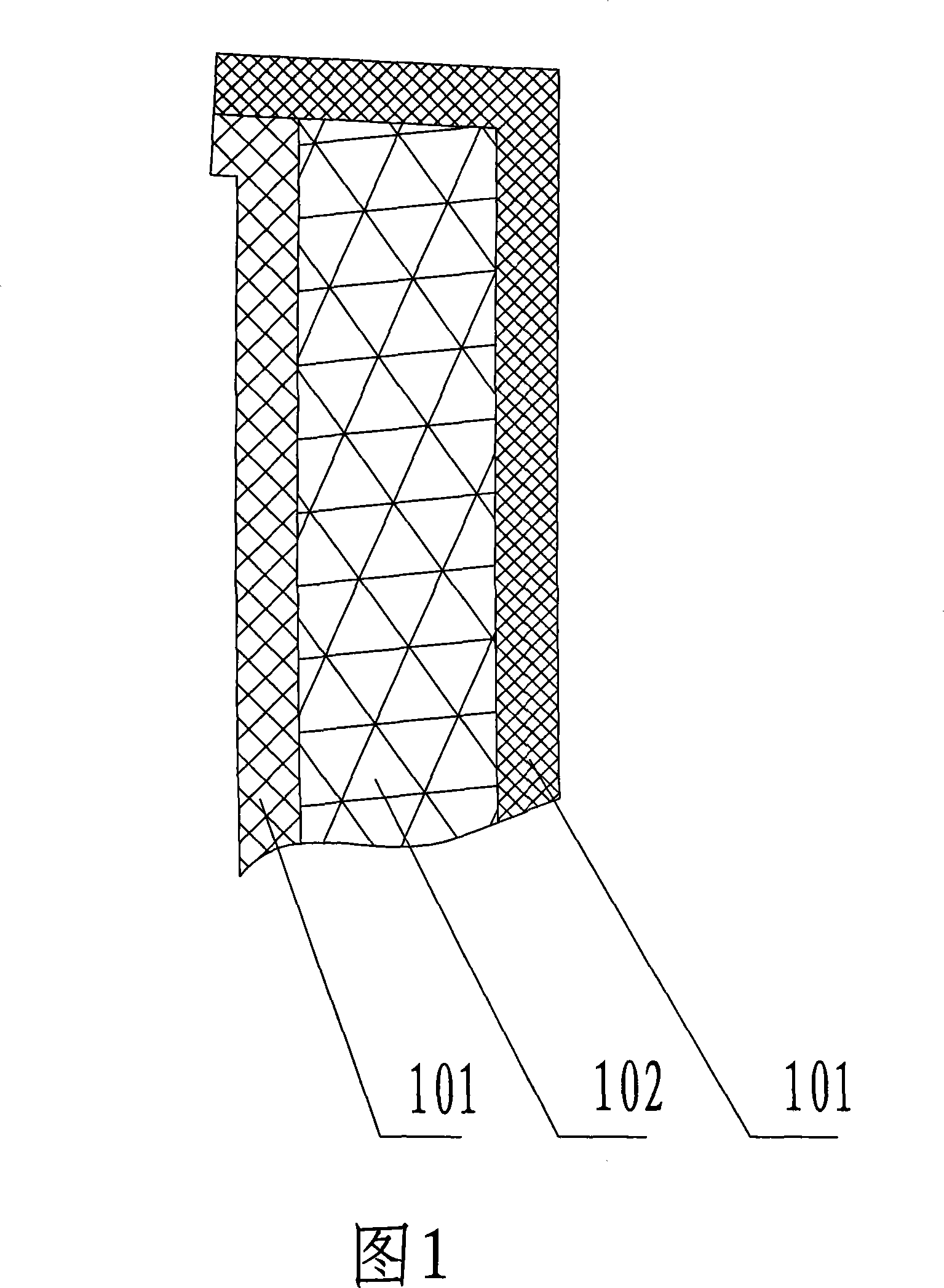

[0026] As shown in FIG. 1 , the composite satellite antenna reflection surface provided by the present invention has a sandwich structure, wherein carbon fiber composite material is used as the skin 101 , and 3D glass fiber mat is used as the core material 102 .

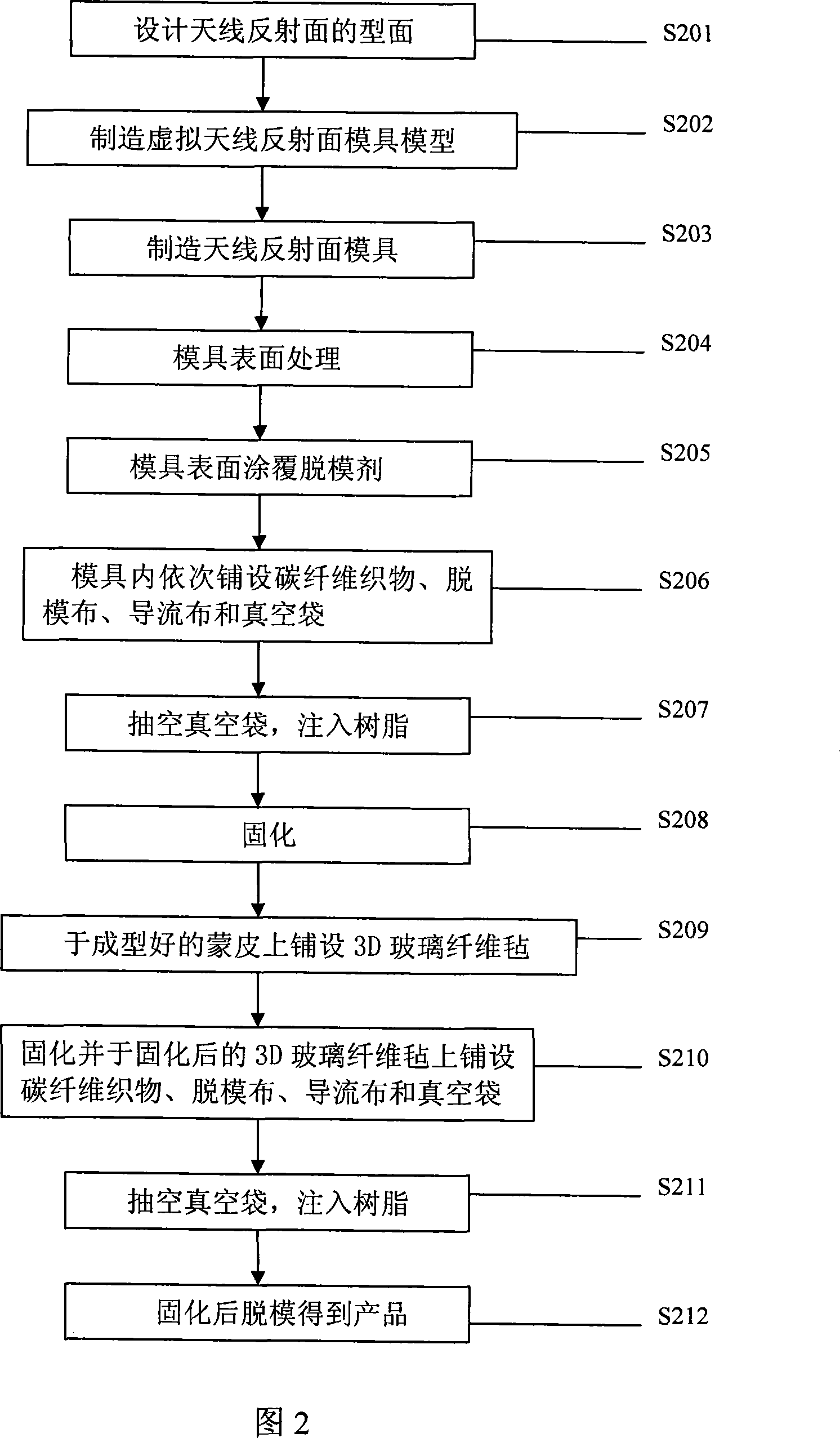

[0027] As shown in Figure 2 again, this kind of composite material satellite antenna reflector manufacturing process provided by the present invention, its preferred embodiment specifically comprises the following steps:

[0028] S201. Design the profile of the antenna reflection surface through electrical calculation;

[0029] S202. According to the designed reflective surface equation, use Pro / E three-dimensional modeling software to make a virtual product of the mold of the antenna reflective surface, and repeatedly check until the design effect is ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com