Method for manufacturing suspension bridge tie rod

A manufacturing method and technology of suspension bridges, which are applied in the field of manufacturing suspension bridge tie rods, can solve the problems of large deformation, difficult extrusion deformation, and low forming efficiency of suspension bridge tie rods, and achieve the effects of quality assurance, high tooth shape accuracy, and high manufacturing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Using the above scheme, the applicant processed the MJ80X4-4g6g pull rods made of 40Cr rolled round steel for Taizhou Bridge and Aizhai Bridge. The threaded part of the tie rod adopts coarse-tooth MJ thread, the nominal diameter is 80mm, the pitch is 4mm, and the thread tolerance zone is 4g in middle diameter and 6g in major diameter. And the total length of the tie rod is 2550mm, the lengths of the threaded parts at both ends are 100mm and 1650mm respectively, and the surface roughness of the threaded part is required to be above Ra3.2.

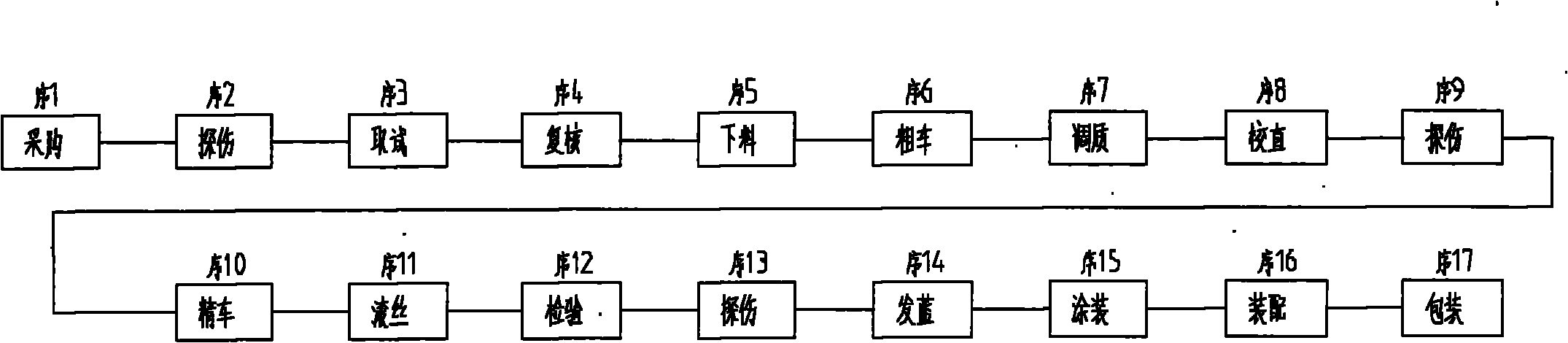

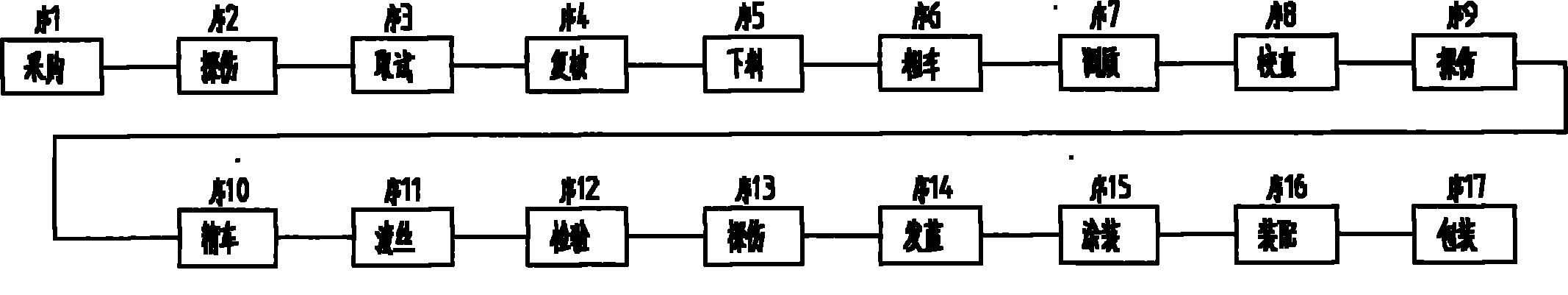

[0021] Such as figure 1 As shown, the manufacturing method of processing the MJ80X4-4g6g suspension bridge tie rod comprises the following technological process:

[0022] (1) Conduct flaw detection on the purchased Φ90 40Cr rolled round steel, and then unload after passing the test, rechecking and inspection.

[0023] (2) Install the billet obtained in (1) on a CS6150 machine tool, use a forming tool to roughly cut the 40Cr rolled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com