Patents

Literature

39results about How to "Improve manufacturing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

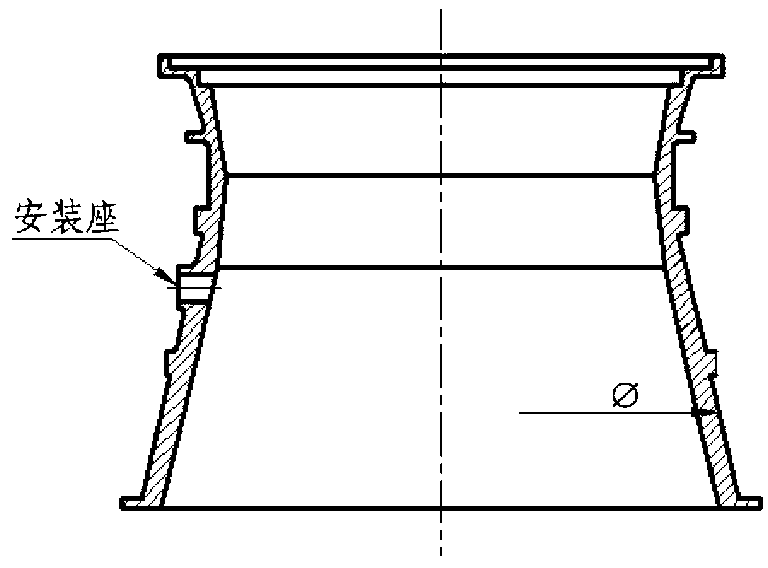

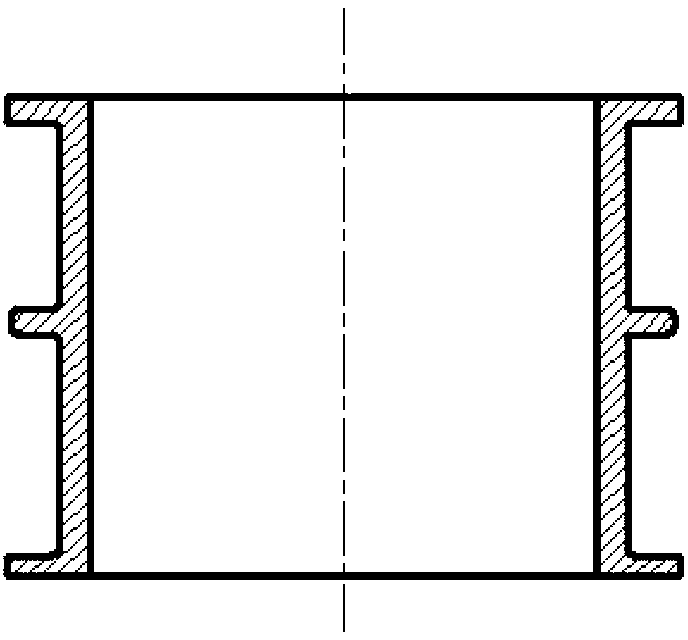

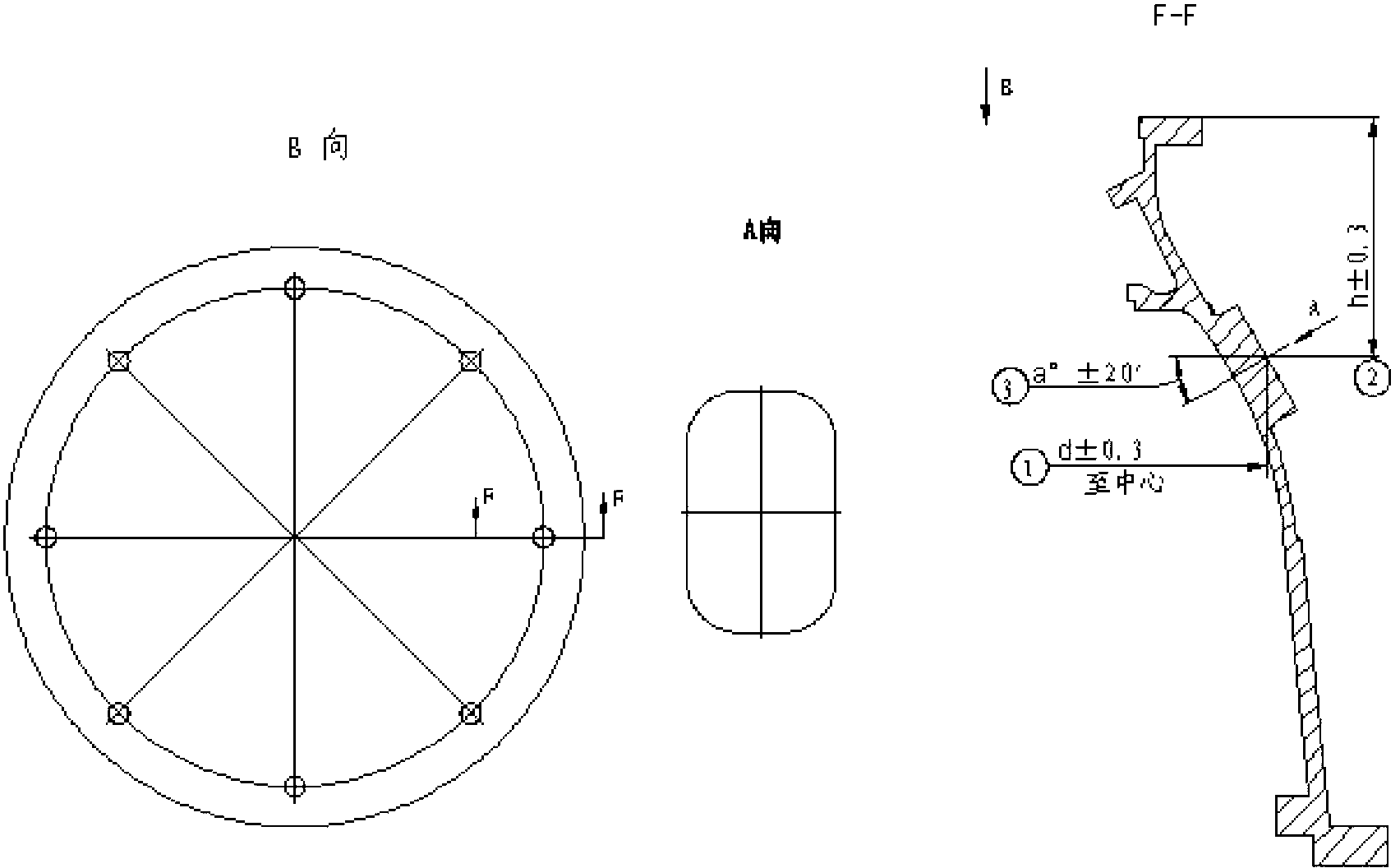

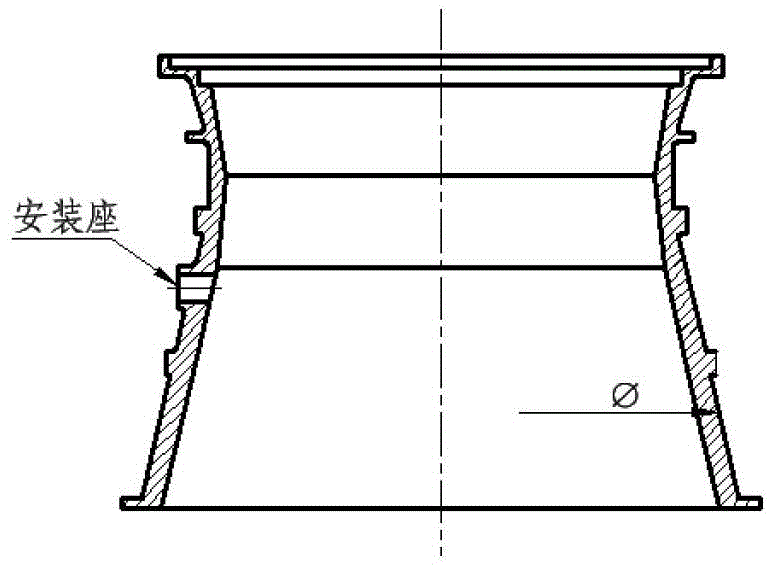

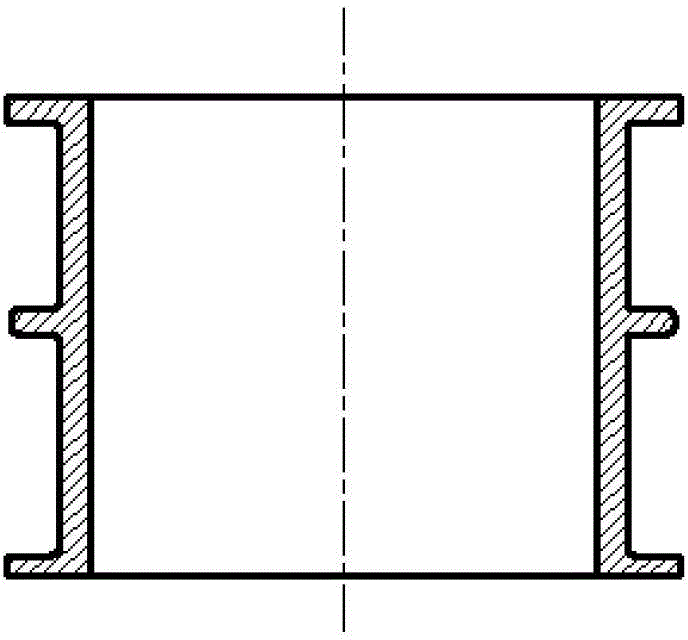

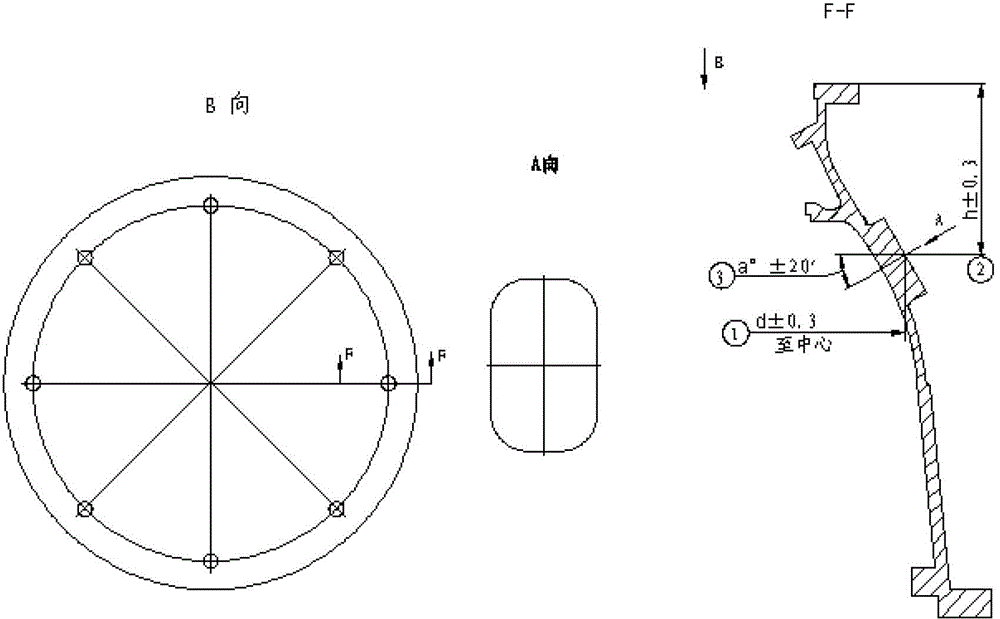

Method for detecting diameter of outer wall of tapered case of aviation engine on line

InactiveCN102927952AGuaranteed accuracyReduce manufacturing costMeasurement devicesNumerical controlAviation

The invention discloses a method for detecting the diameter of an outer wall of a tapered case of an aviation engine on line. According to the method, a five-coordinate numerical control milling center with a Renishaw MP10 trigger-type measuring head is equipped, tapered case parts and a mounting seat on the surface of a tapered case are equipped; a fine adjustment ring gauge of the used measuring head is measured on line; a point contact-type measurement mode is adopted; a machine tool siemens control system Sinumeric 840 D on-line measurement technology is adopted; and an on-line measurement quick tool path amendment and error compensation generation technology is adopted. The method has a broad application prospect; and by the on-line measurement technology, a numerically-controlled machine tool is impelled to form a machining and detecting integrated numerical control machining unit. By the method, the traditional manufacturing mode that a design characteristic is equipped with a set of measurement tool in the current industry is changed, the manufacturing cost of the tool is saved, repair labor-hour is saved, and first-pass yield of product processing is improved, so that the development period and the production cost of new products are reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

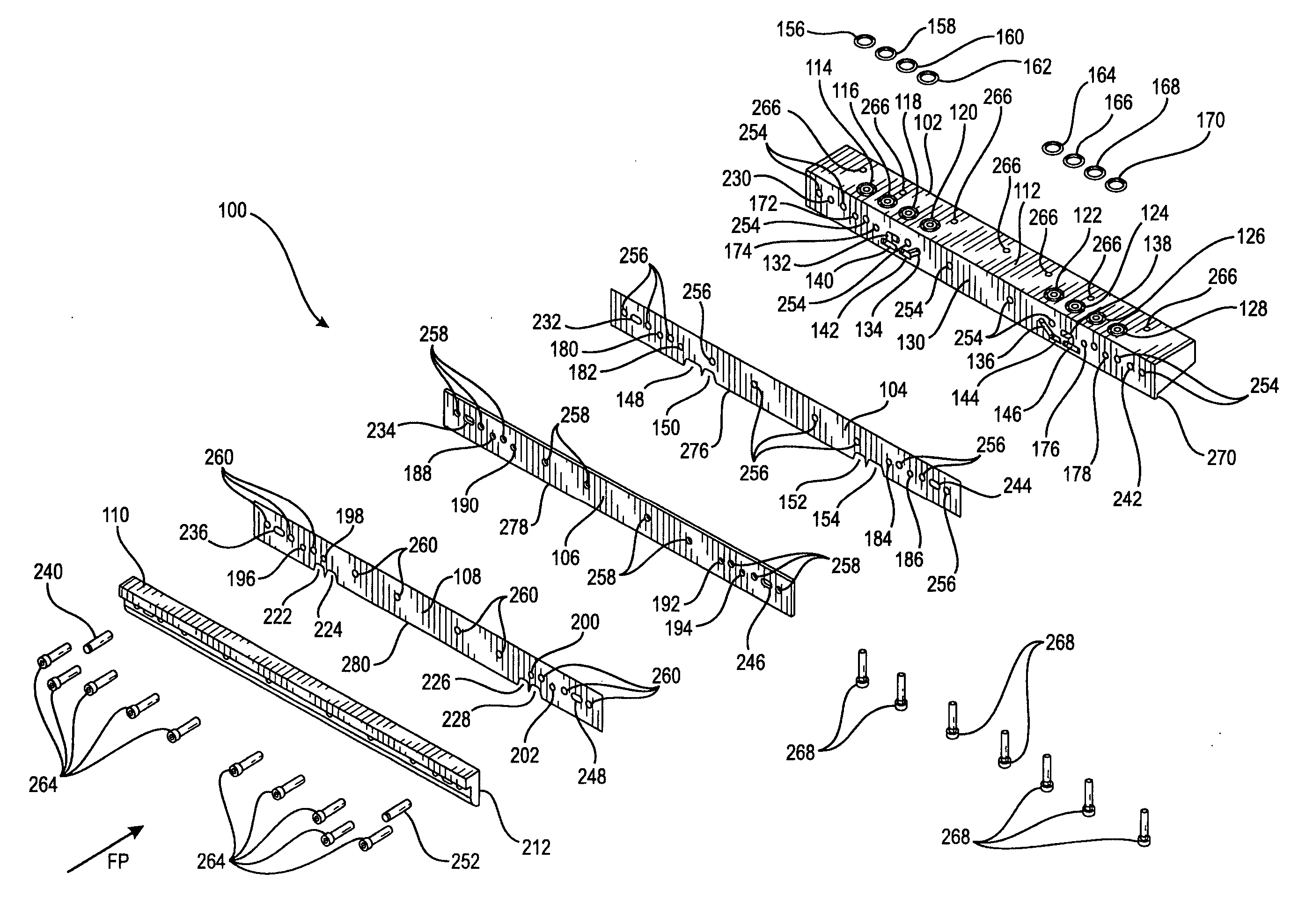

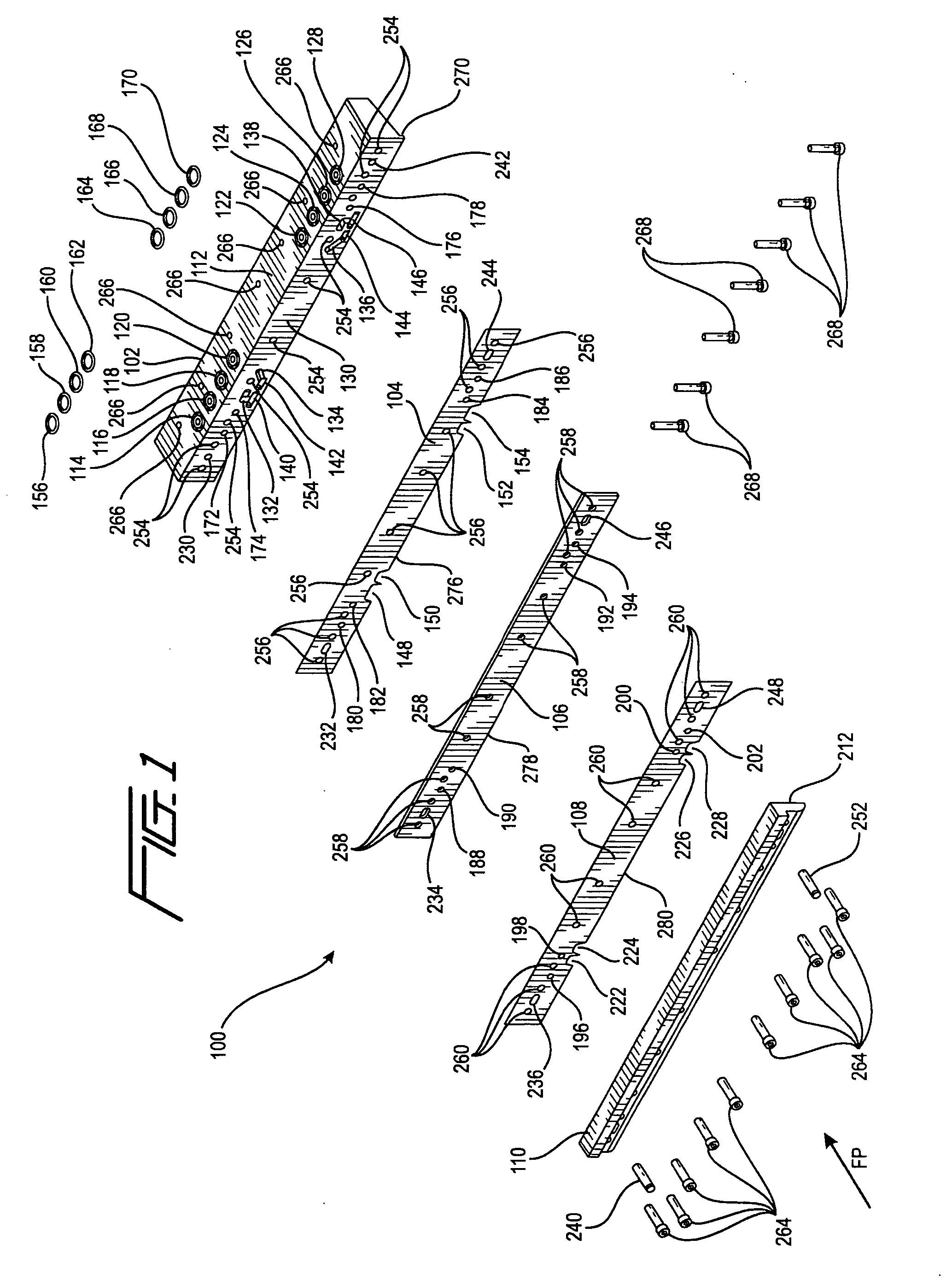

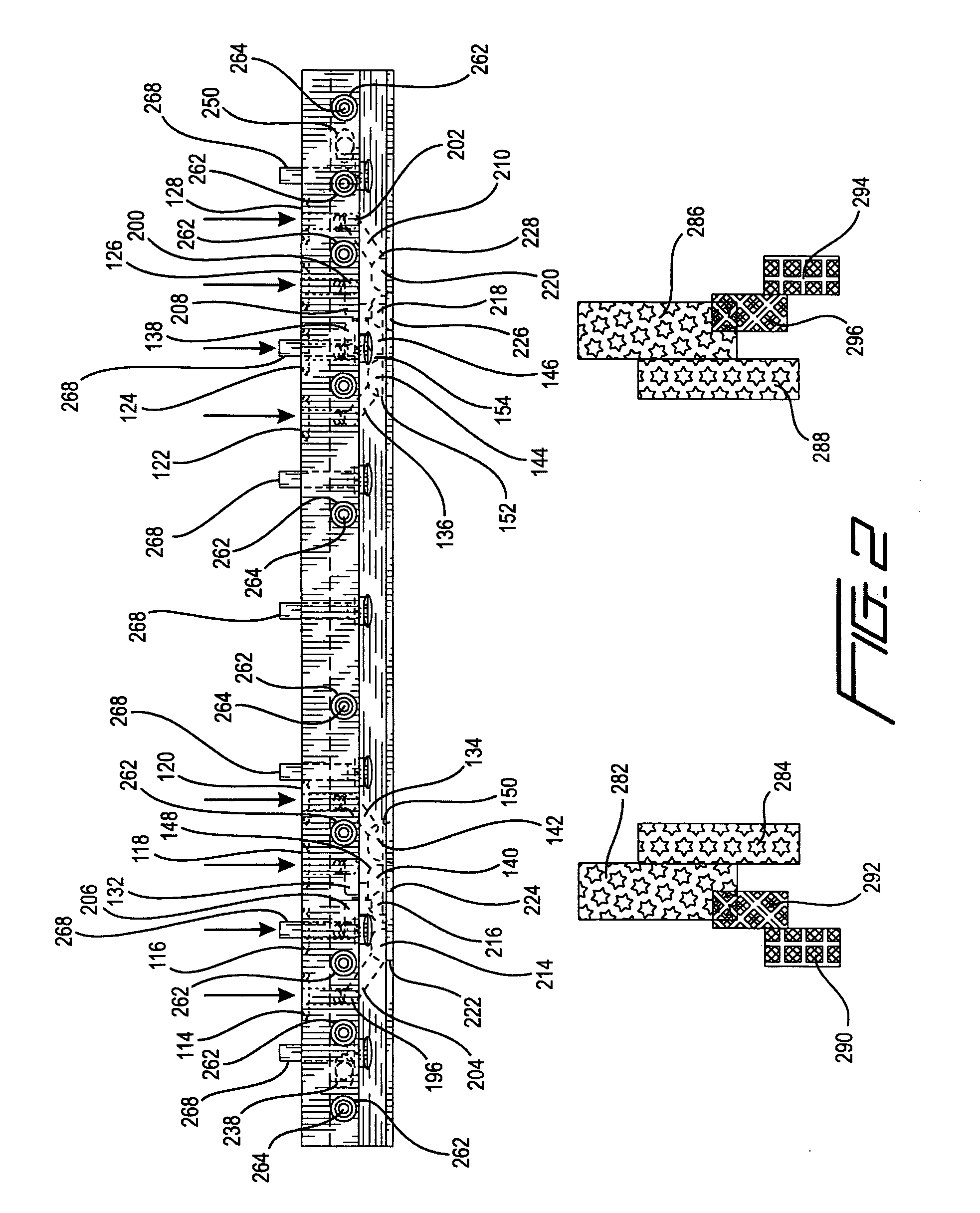

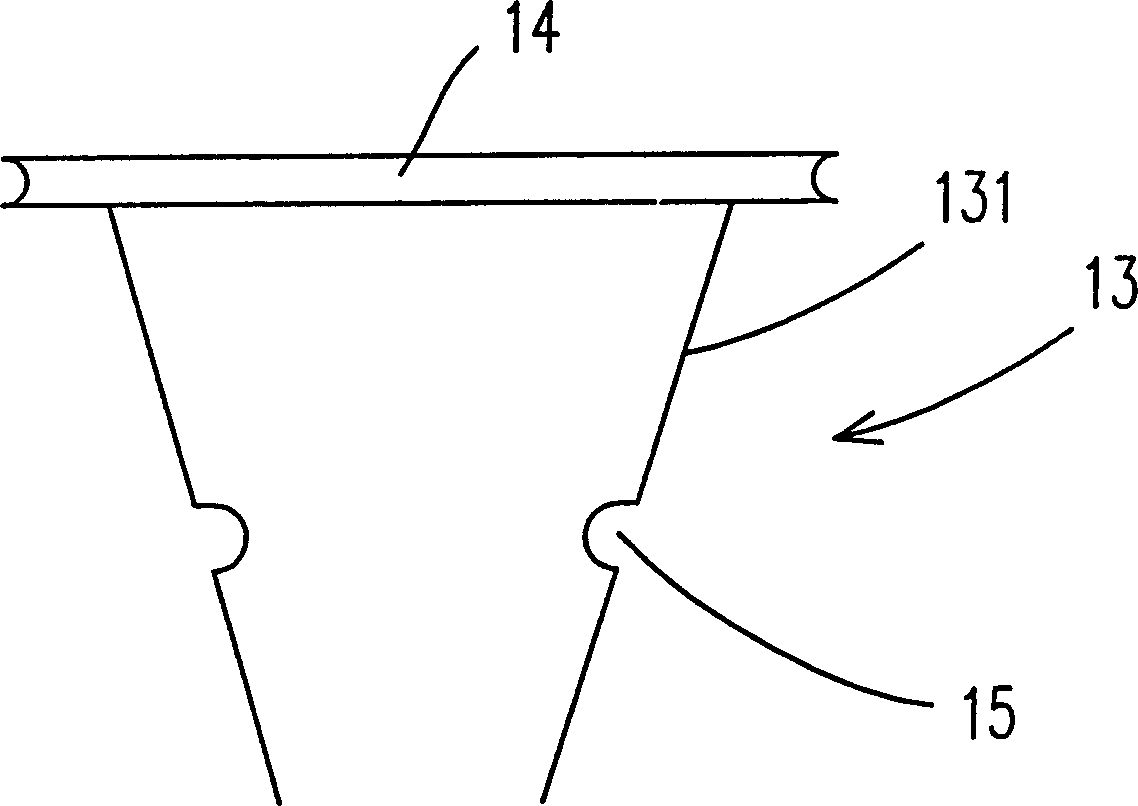

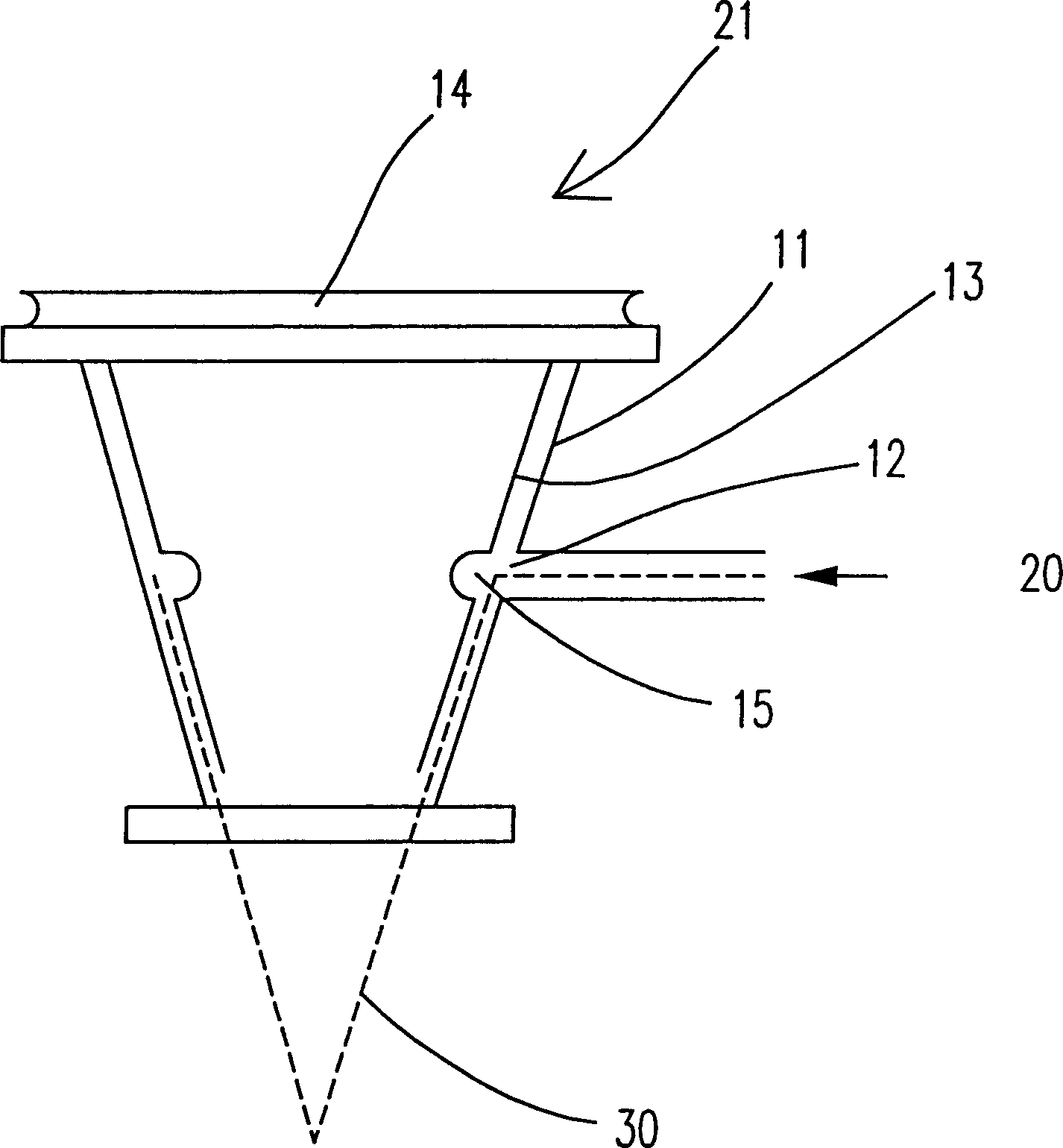

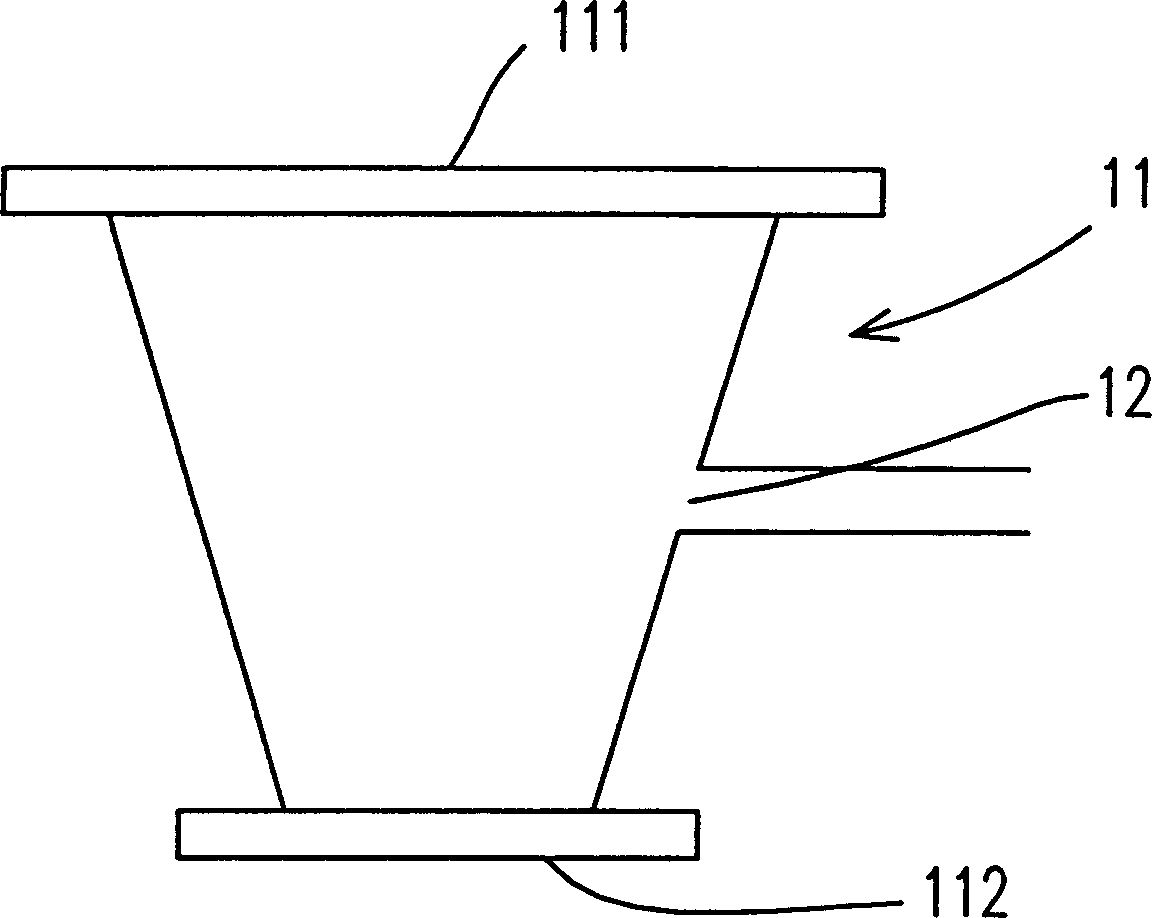

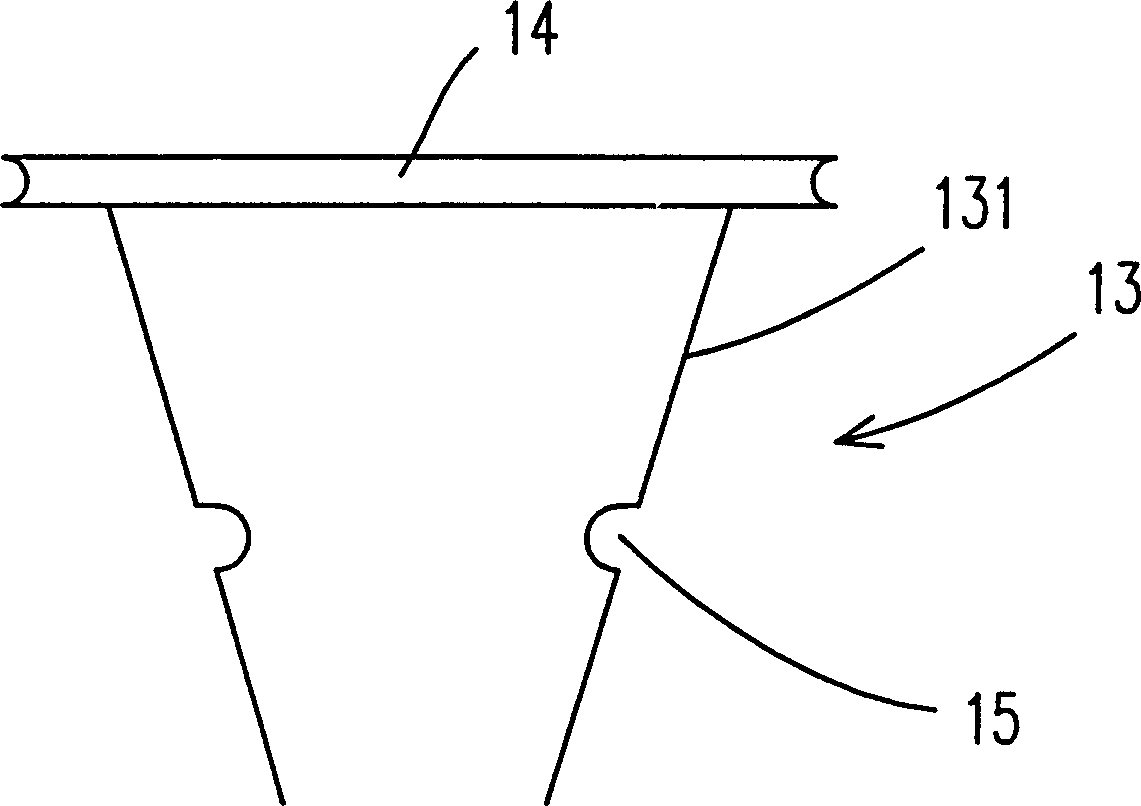

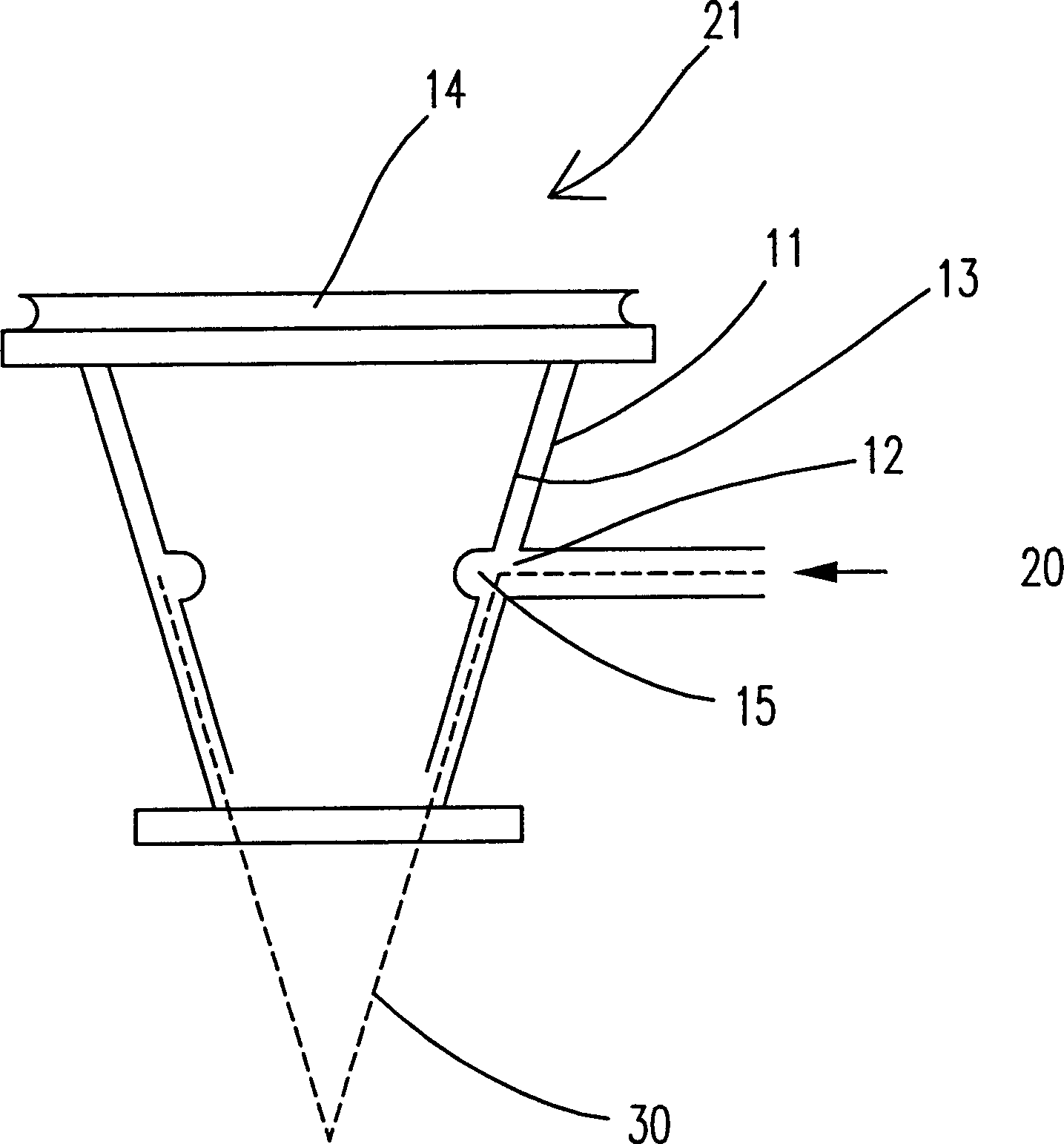

Dual pattern shim assembly for use in conjunction with hot melt adhesive dispensing systems

ActiveUS20080245298A1Enhance fabricationImprove manufacturing capacityLiquid surface applicatorsLiquid spraying apparatusCombined useApplication procedure

A dual pattern shim assembly, for use in conjunction with hot melt adhesive dispensing systems, permits various different overlapping or overlying deposition or application patterns, having different length dimensions, different width dimensions, different coating thicknesses, and different longitudinal positional locations or dispositions with respect to each other, to be achieved during a single pass of the underlying substrate with respect to the hot melt adhesive contact die applicator or head. In this manner, different or multiple adhesive deposition or application procedures are able to effectively be accomplished simultaneously so as to effectively simplify and shorten the overall assembly lines and production times required for the fabrication or manufacture of various different particular products.

Owner:ILLINOIS TOOL WORKS INC

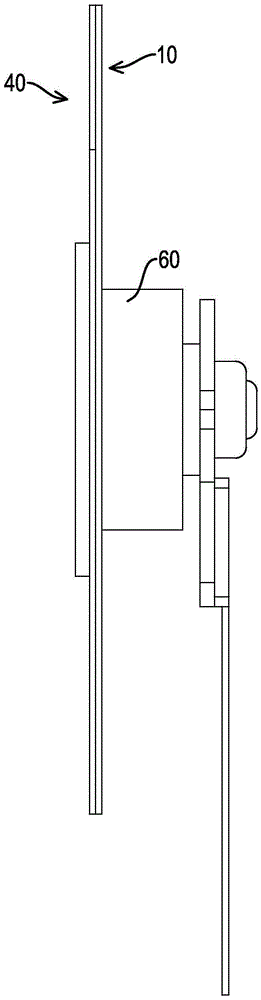

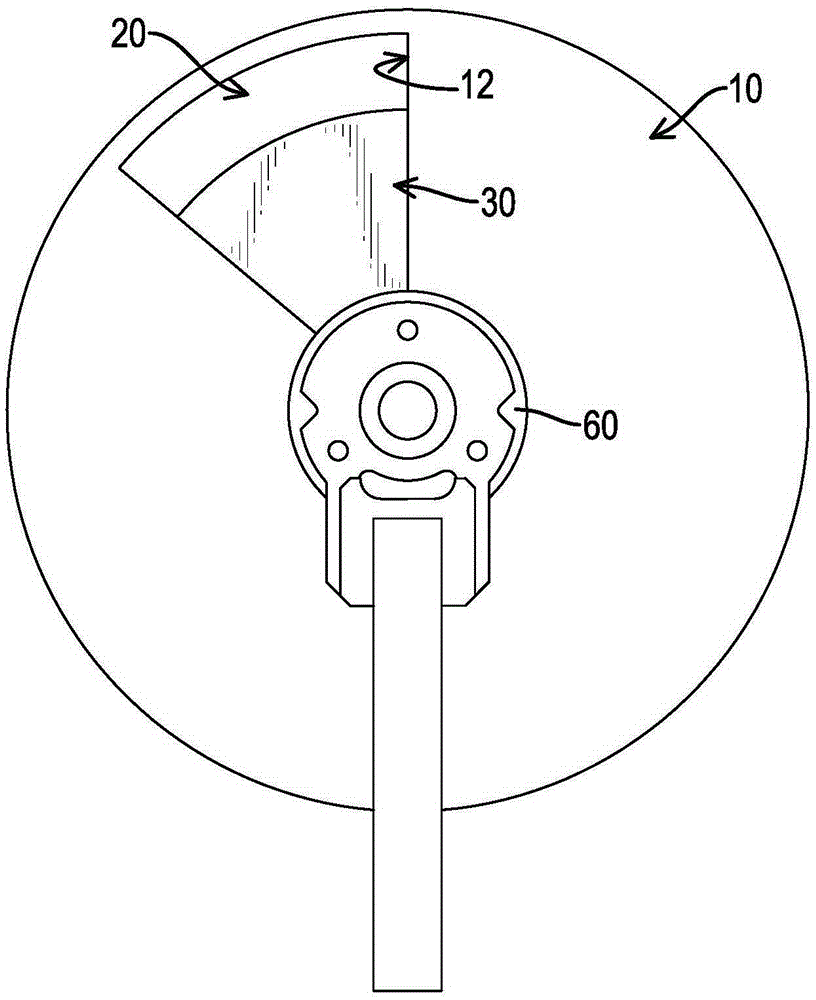

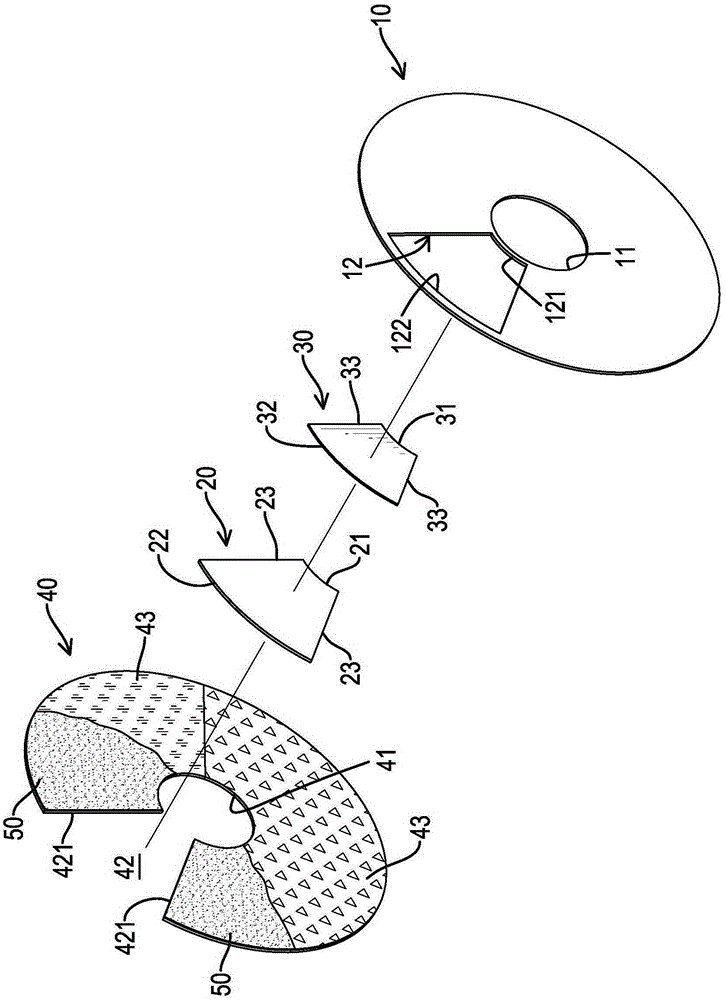

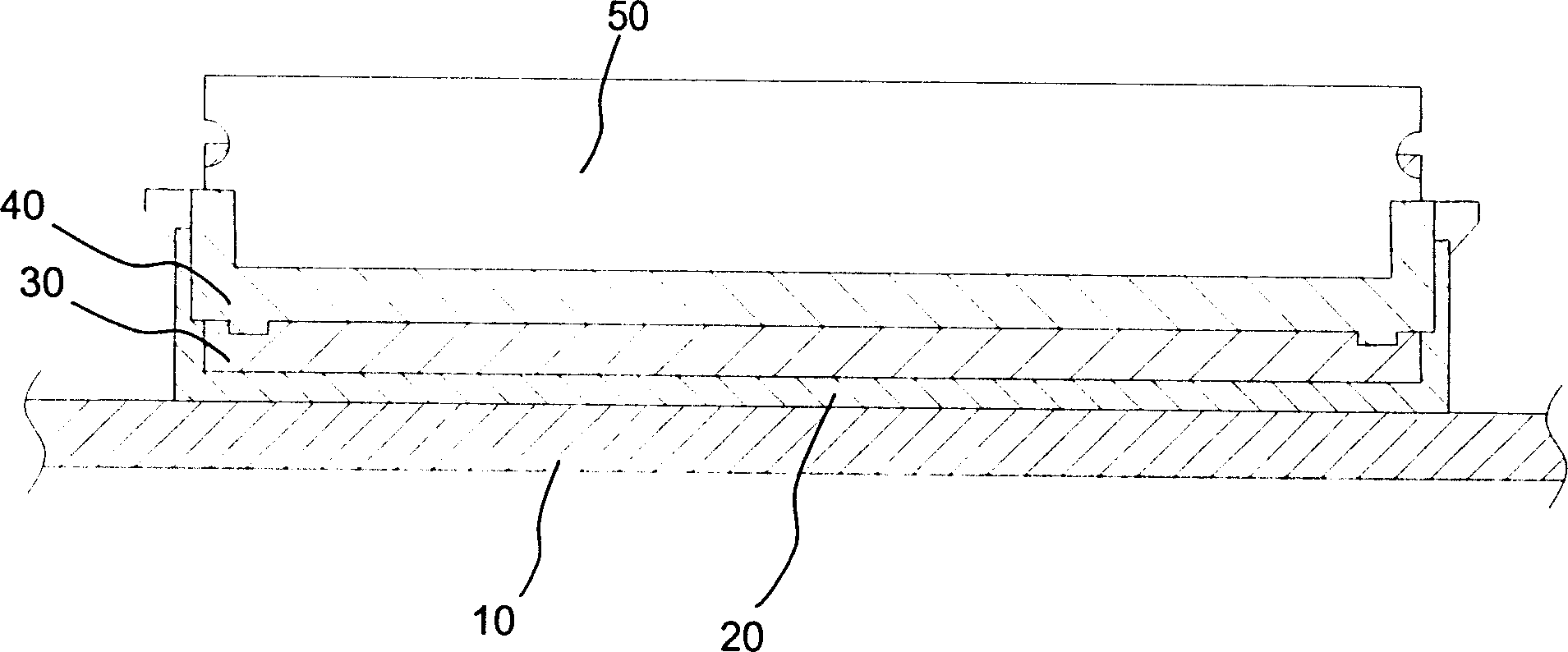

Projector combined type optical color wheel device

InactiveCN106597787AIncrease production capacityAvoid Timing Mark DropoutProjectorsColor wheelTime sequence

The invention discloses a projector combined type optical color wheel device which comprises a substrate, a light transmission material, a counterweight sheet material and a glass phosphor body. The glass phosphor body comprises a light transmission area. The light transmission material is fixedly arranged in the light transmission area; the counterweight sheet material is attached on the light transmission material; and the glass phosphor body neighbors the substrate. According to the invention, the density of the counterweight sheet material is different from that of the light transmission material and the light matting property is unlike that of the substrate so as to achieve the effect of both counterweight and time sequence marking and solve the problem with the increase in the working procedures when needed to be externally provided with a counterweight and time sequence marking and the problem with the proneness to come off during the high speed rotation of a color wheel by providing a projector combined type optical color wheel device with simplified procedures and enhanced production performance.

Owner:TAIWAN COLOR OPTICS

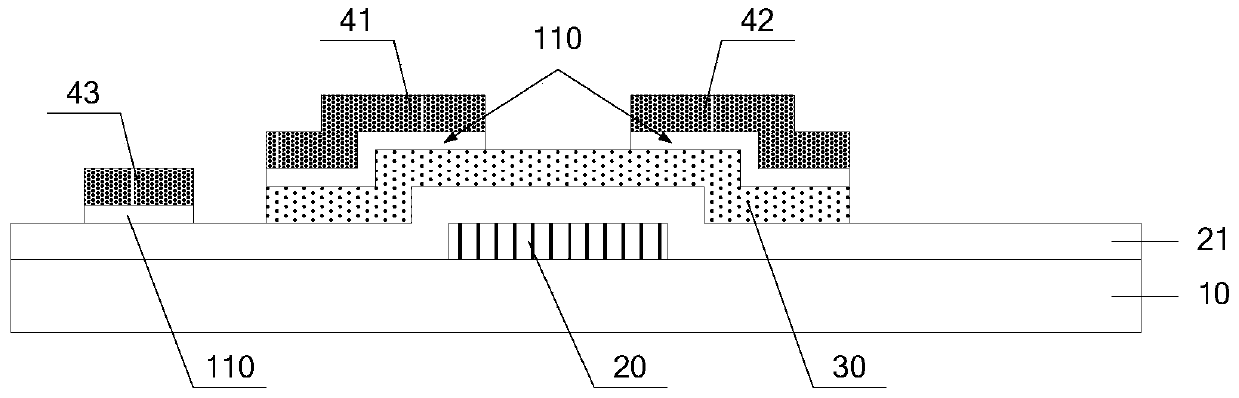

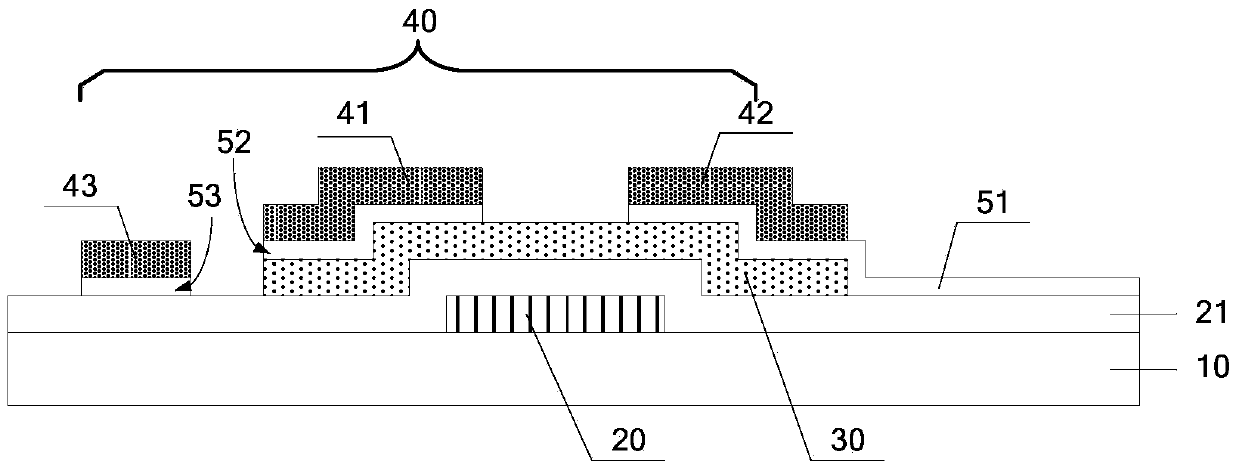

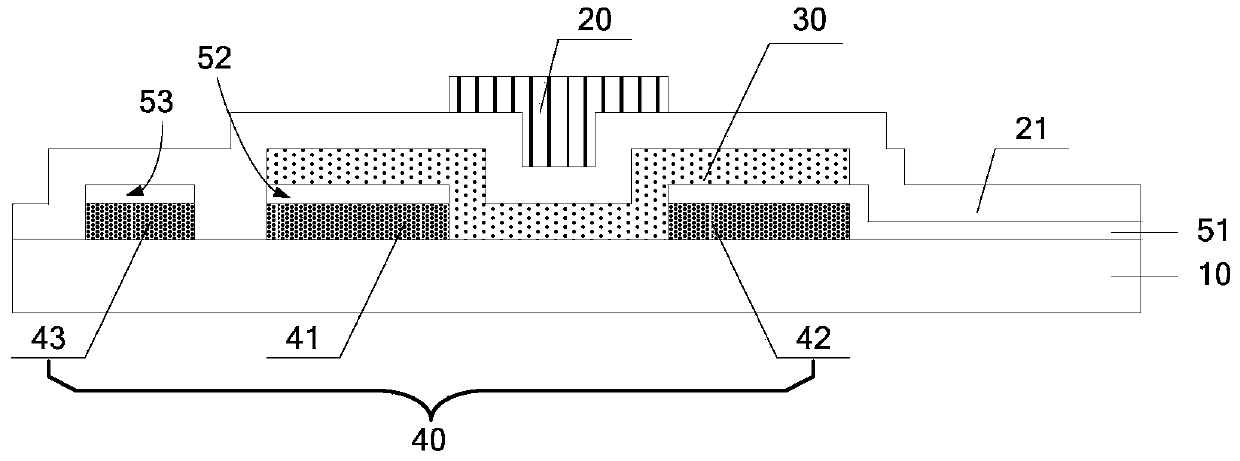

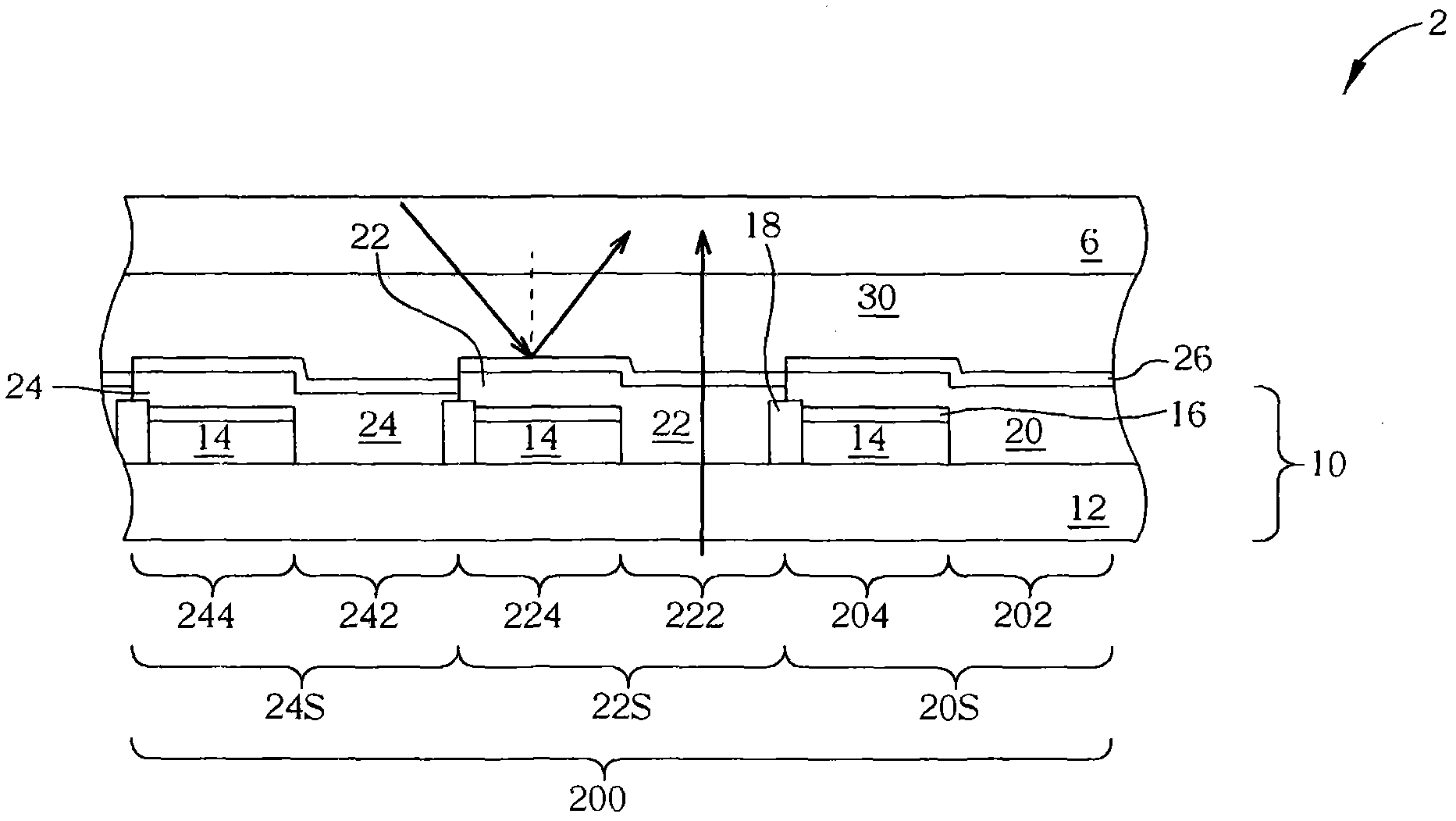

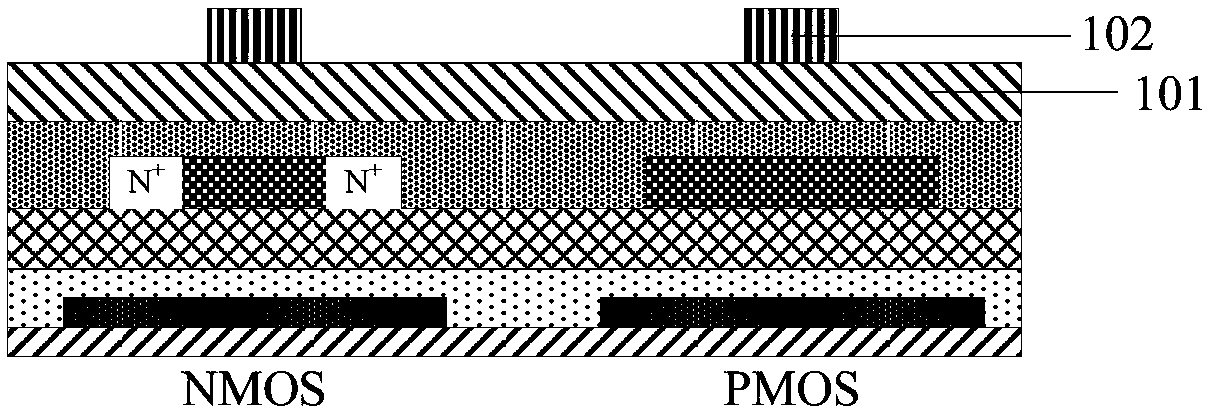

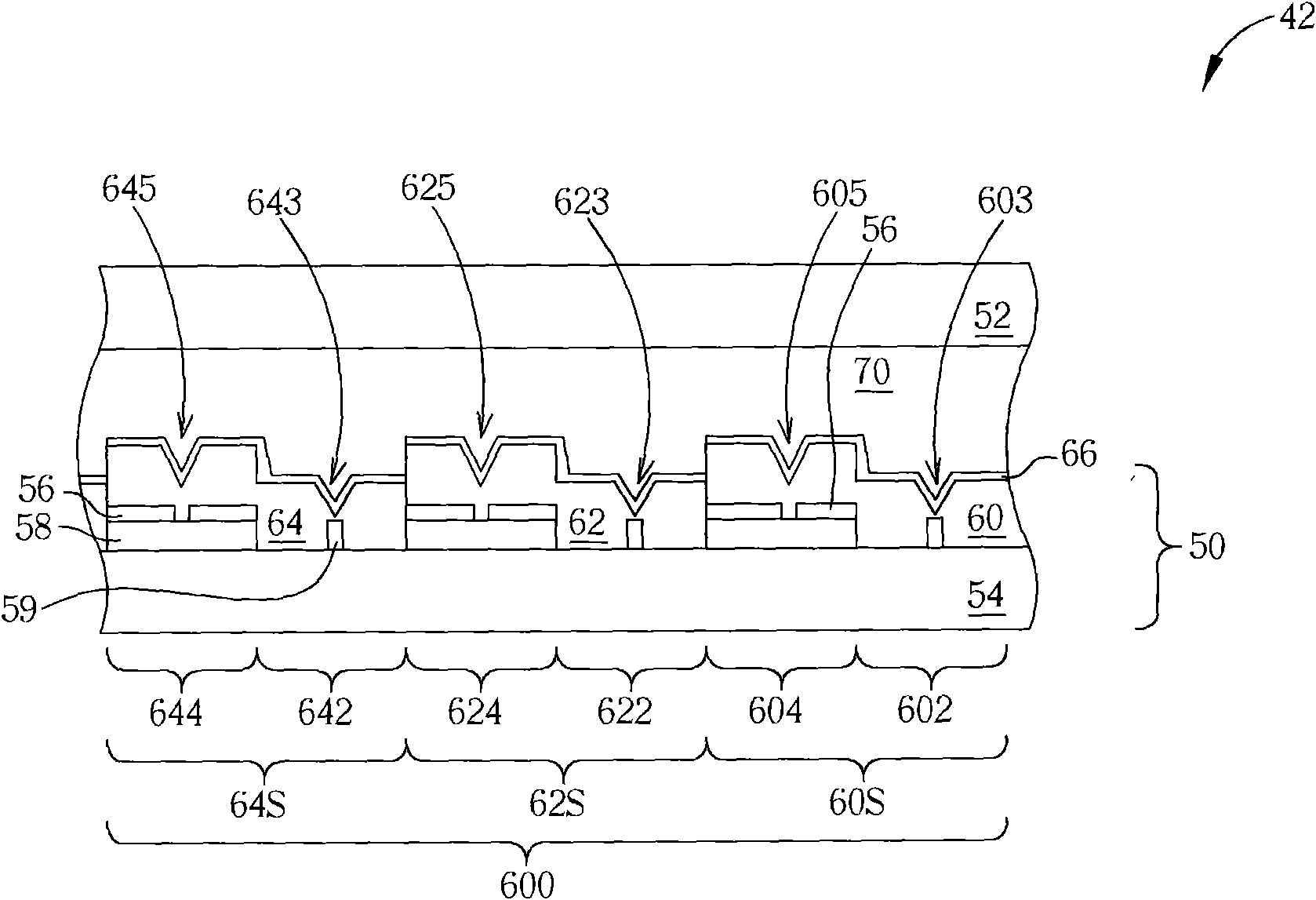

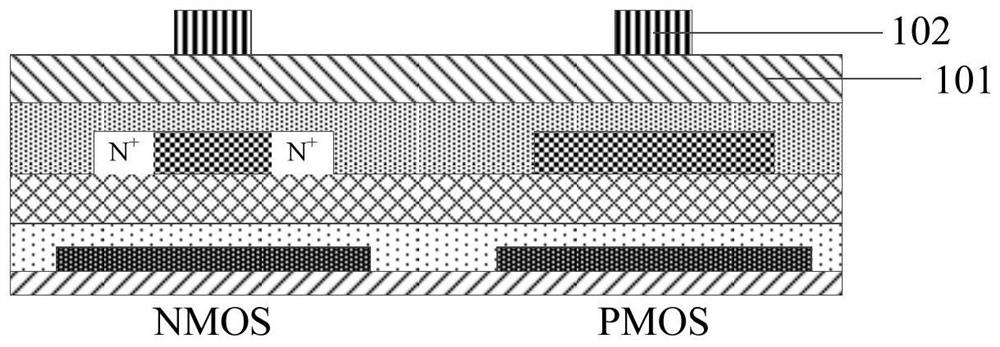

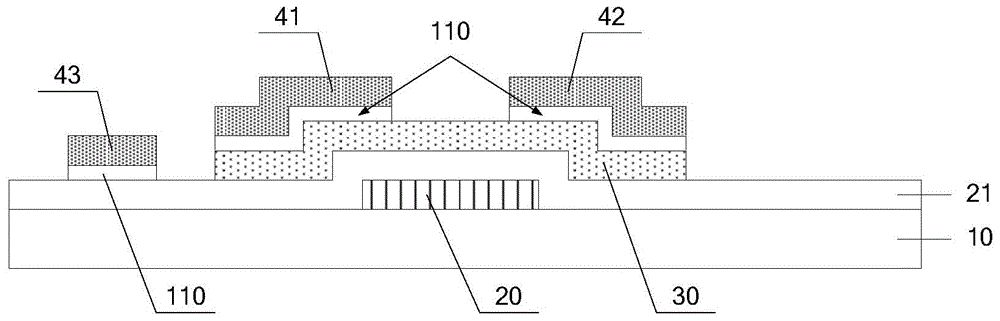

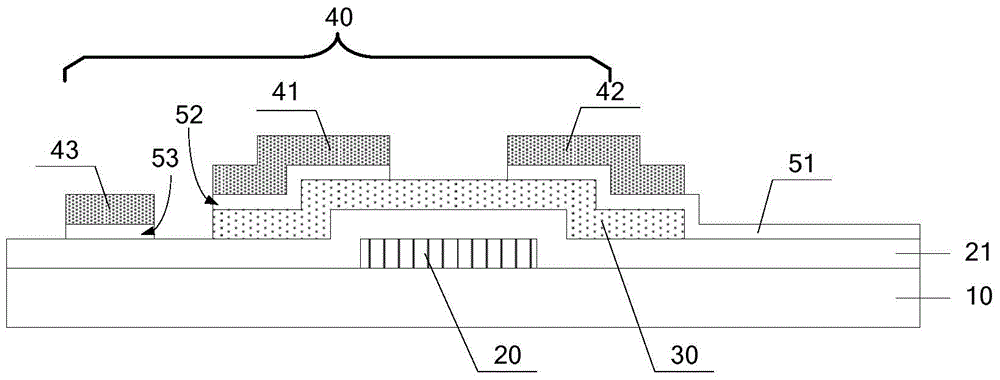

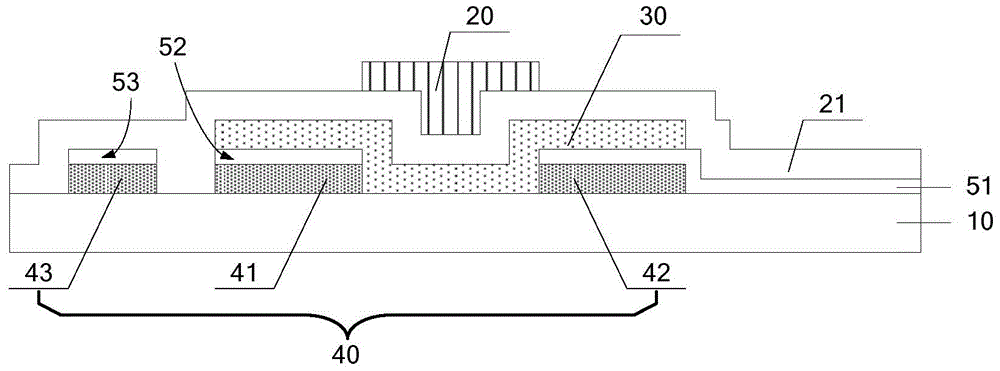

Array substrate and preparation method thereof, and display device

ActiveCN104183603AImprove yield rateAffect normal displaySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The embodiment of the invention provides an array substrate and a preparation method thereof, and a display device, and relates to the technical field of display so that poor size uniformity of a gap between a source electrode and a drain electrode when barrier layers are formed is prevented and the cost of the barrier layers is reduced and a problem of metal loss and signal discontinuity is solved. The array substrate includes a grid metal layer which is on an underlayer substrate and includes a grid electrode and a grid line; a grid insulating layer; an active layer; a source and drain metal layer which includes the source electrode, the drain electrode, and a data line, wherein the source and drain metal layer includes a copper metal layer and / or a copper alloy layer; and a pixel electrode layer which includes a pixel electrode directly contacting the drain electrode, a first pixel electrode reservation pattern directly contacting the source electrode, and a second pixel electrode reservation pattern directly contacting the data line, wherein an area of the pixel electrode, directly contacting the drain electrode, and the first pixel electrode reservation pattern are located between the active layer and the source and drain metal layer, and an area of the pixel electrode, not directly contacting the drain electrode, and the second pixel electrode reservation pattern are located on / beneath the grid insulating layer. The preparation method is used for preparation of the array substrate.

Owner:BOE TECH GRP CO LTD +1

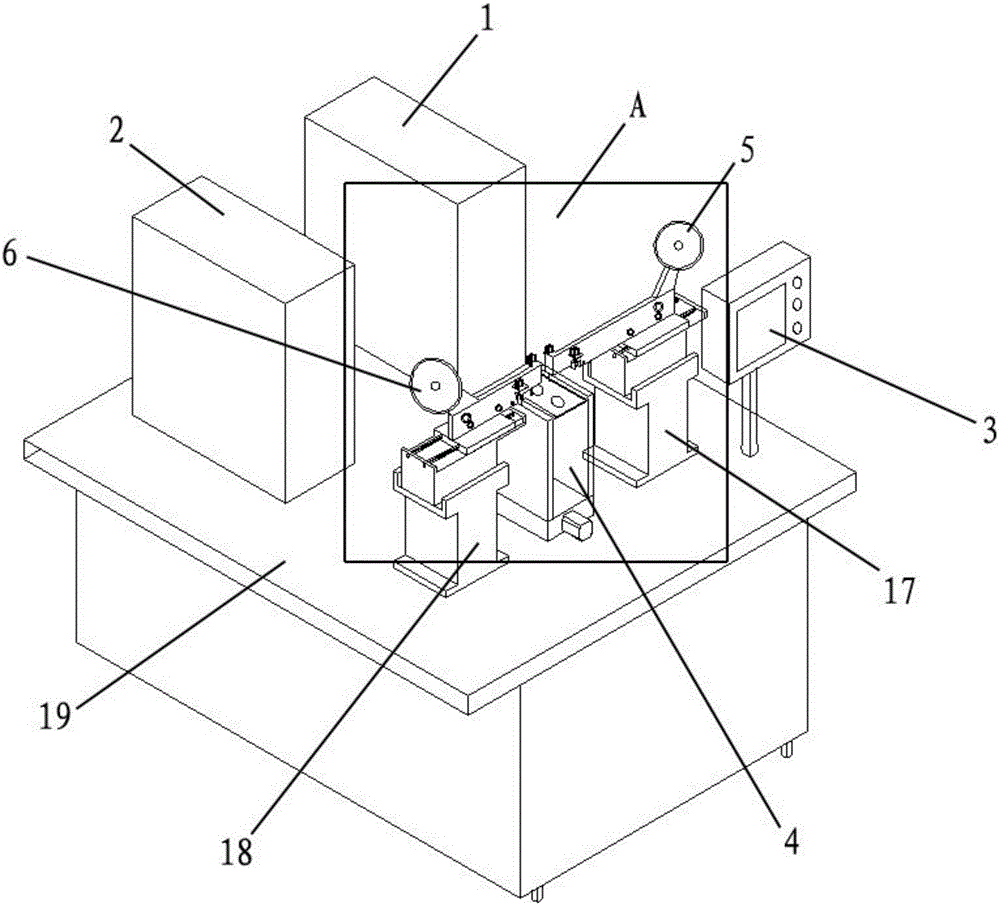

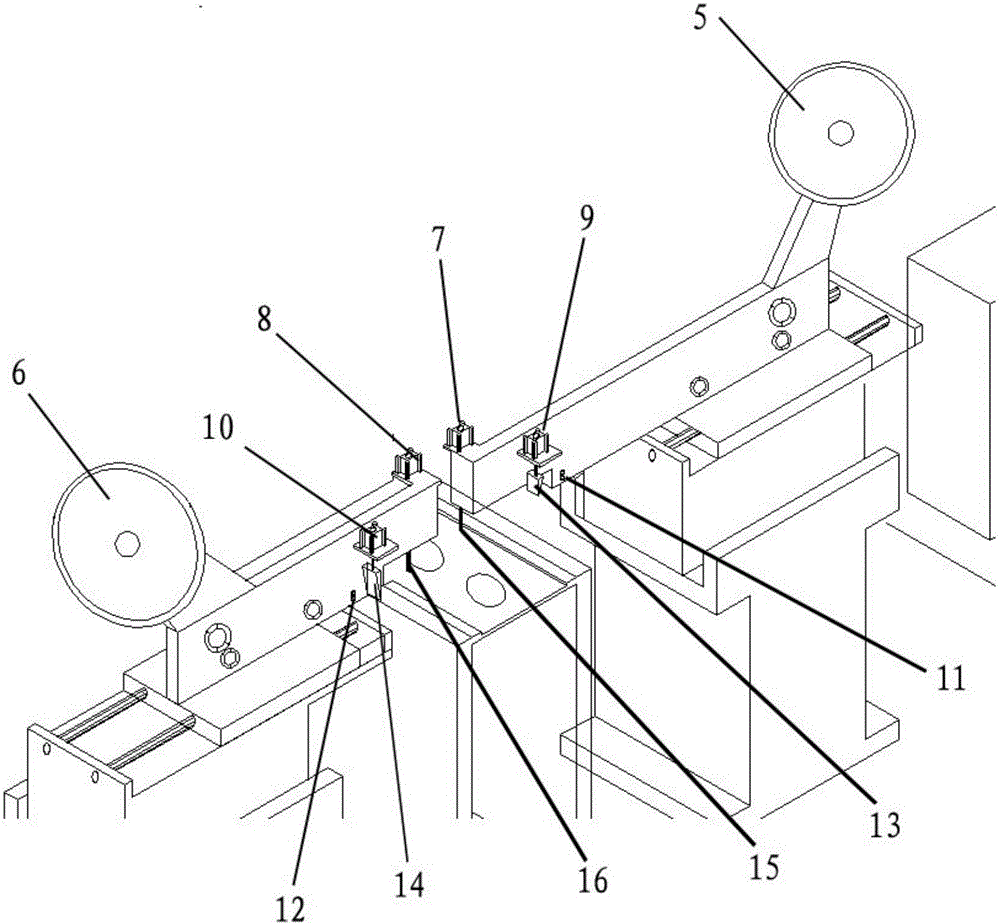

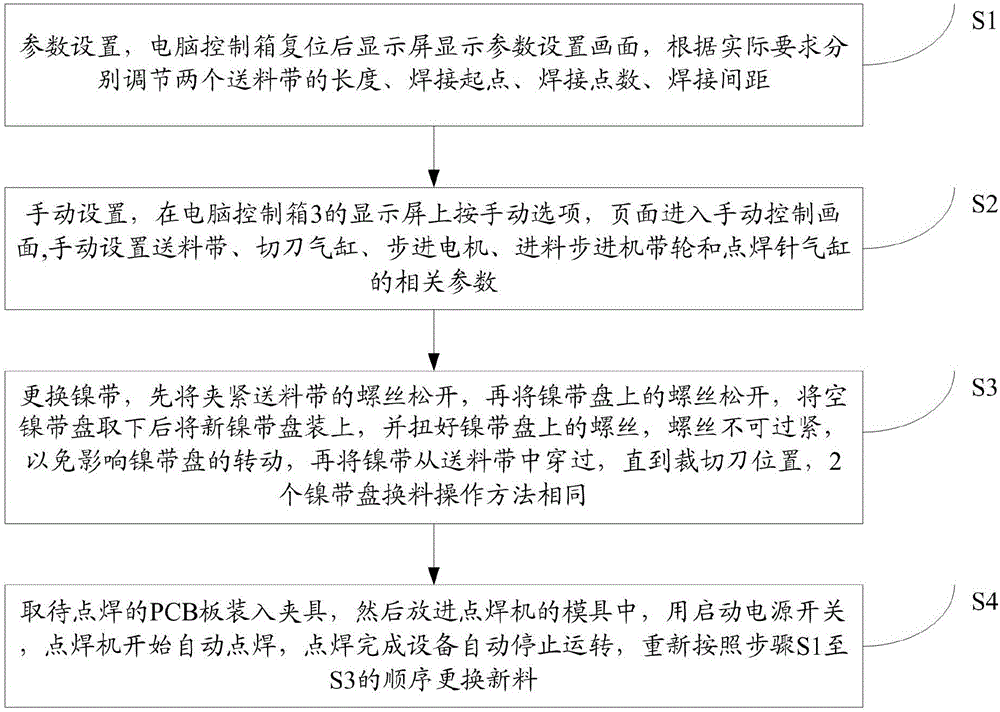

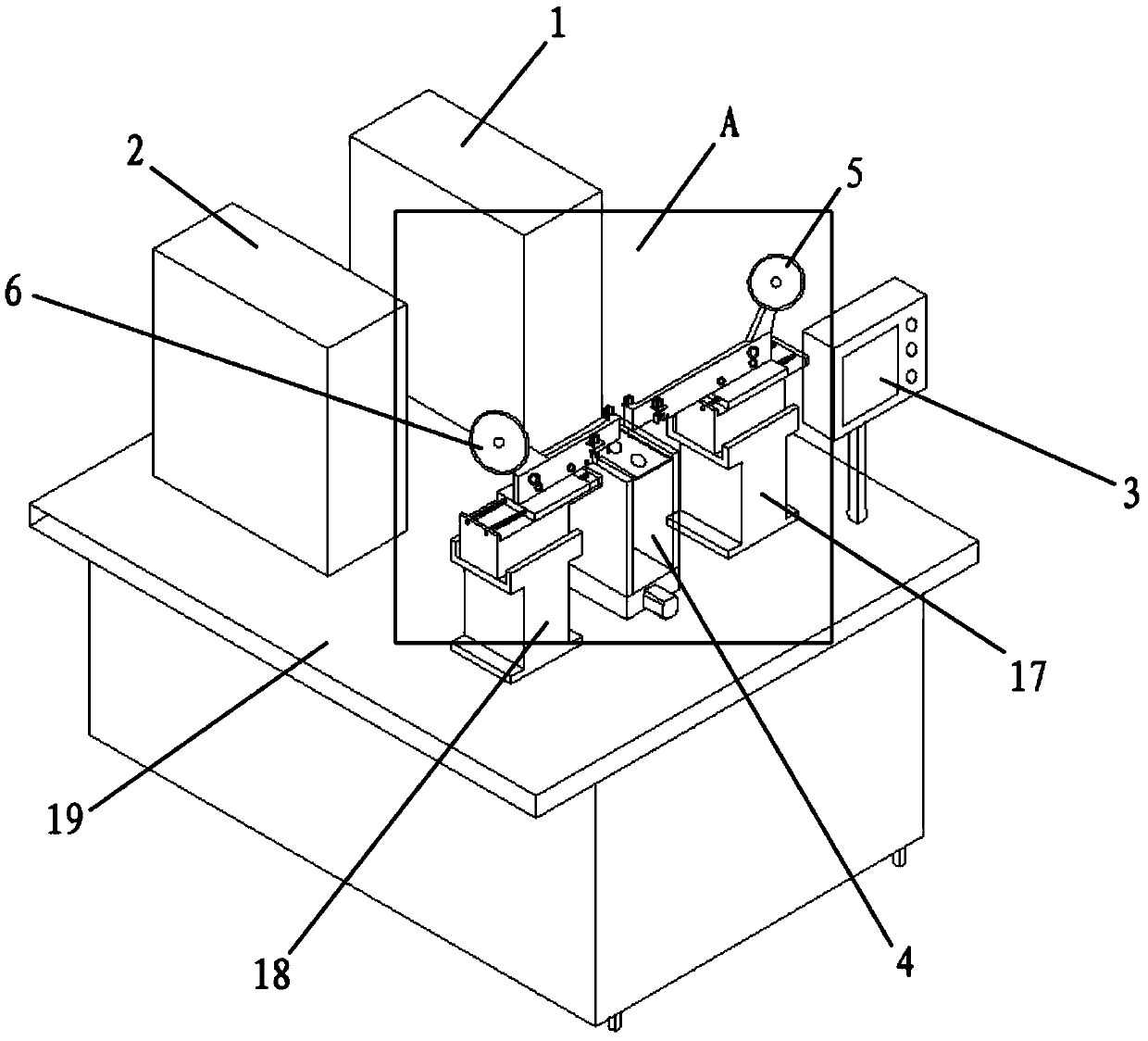

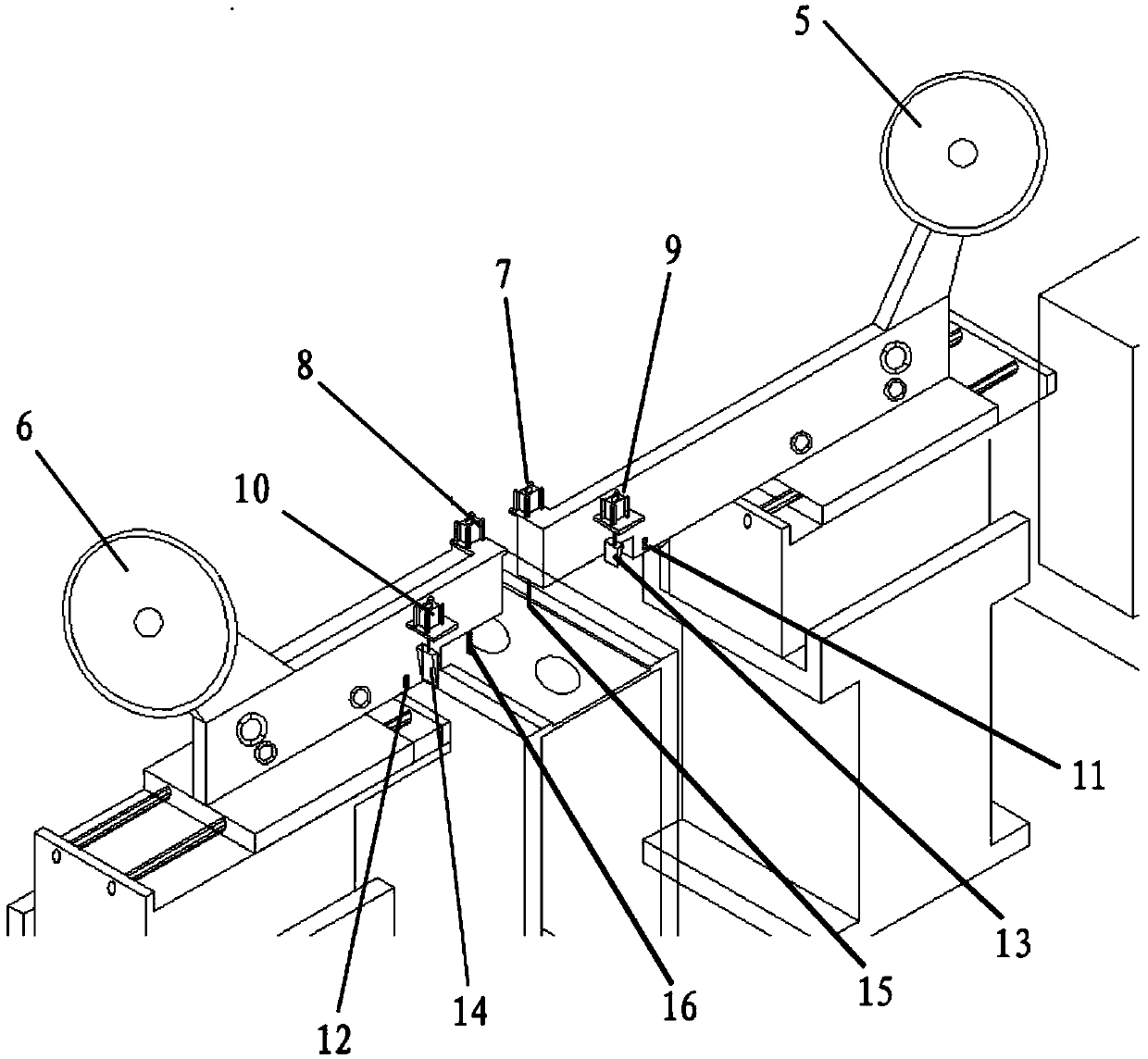

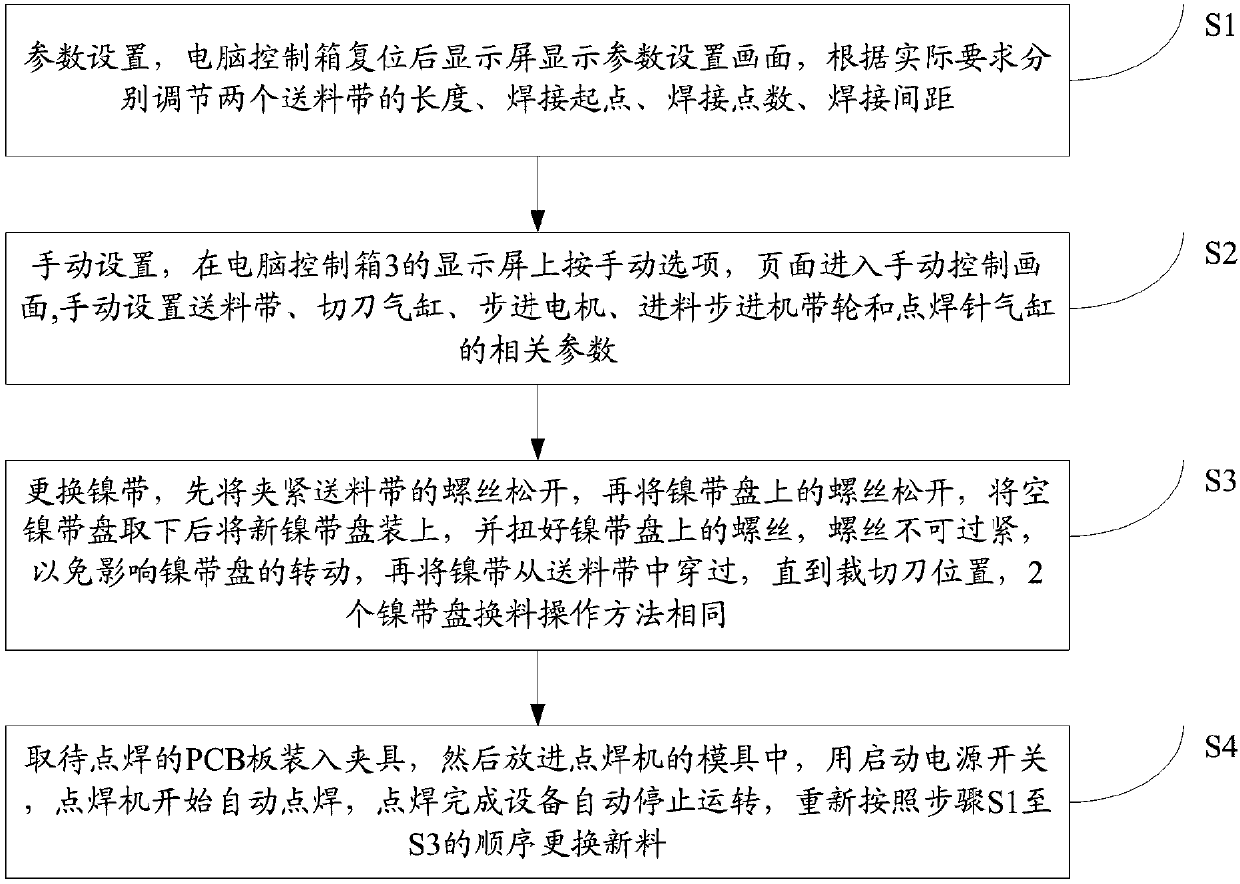

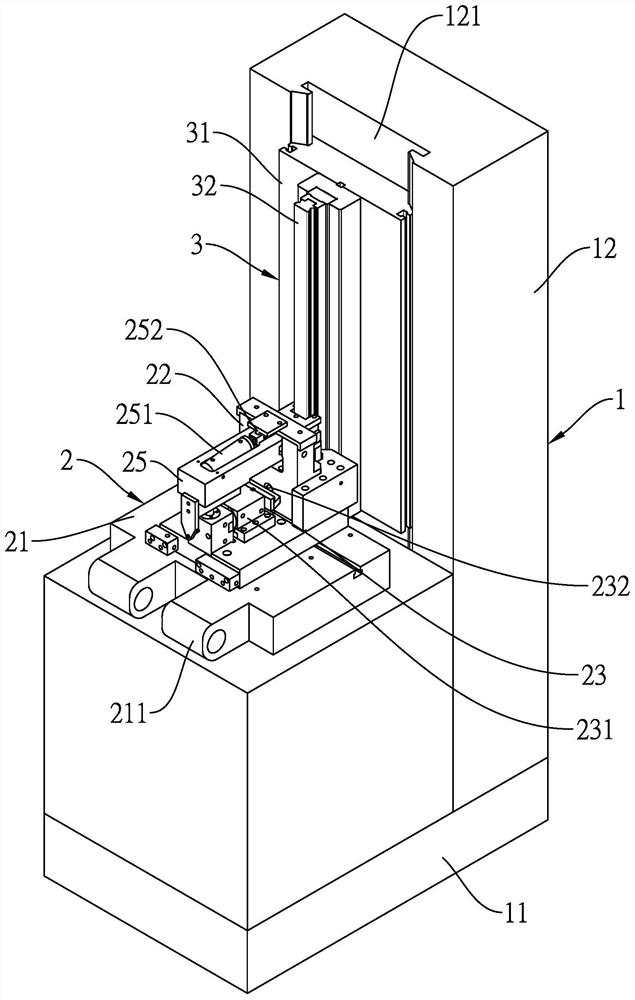

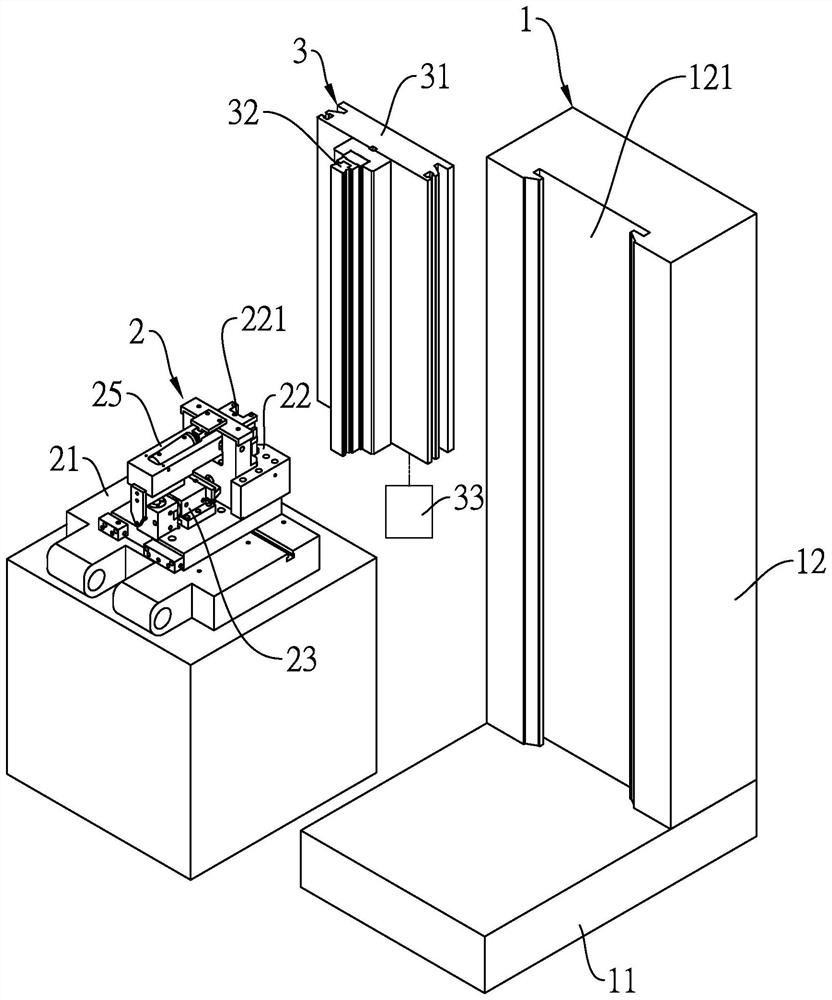

Automatic welding equipment for nickel sheet of lithium-ion battery and welding technology

ActiveCN105772918AReduce welding costsHigh precisionFinal product manufactureWelding/cutting auxillary devicesElectrical batteryEngineering

The invention discloses automatic welding equipment for a nickel sheet of a lithium-ion battery and a welding technology and relates to the technical field of battery production equipment. The automatic welding equipment for the nickel sheet of the lithium-ion battery comprises a first spot welding machine, a second spot welding machine, a computer control box, a stepper motor, a first feeding belt, a second feeding belt, a first spot welding needle cylinder, a second spot welding needle cylinder, a first cutter cylinder, a second cutter cylinder, a first feeding stepper belt pulley, a second feeding stepper belt pulley, a first cutter, a second cutter, a first spot welding needle, a second spot welding needle, a first support frame, a second support frame and an operation platform. The automatic welding equipment is simple in structure and convenient to use, additional equipment cost is reduced by changing a cutting mode, requirements for skills of an employee at a welding operation post are reduced greatly through technology improvement, operation is finished only by starting the equipment simply, and the operation intensity of the employee is reduced.

Owner:DONGGUAN GREENWAY NEW ENERGY CO LTD

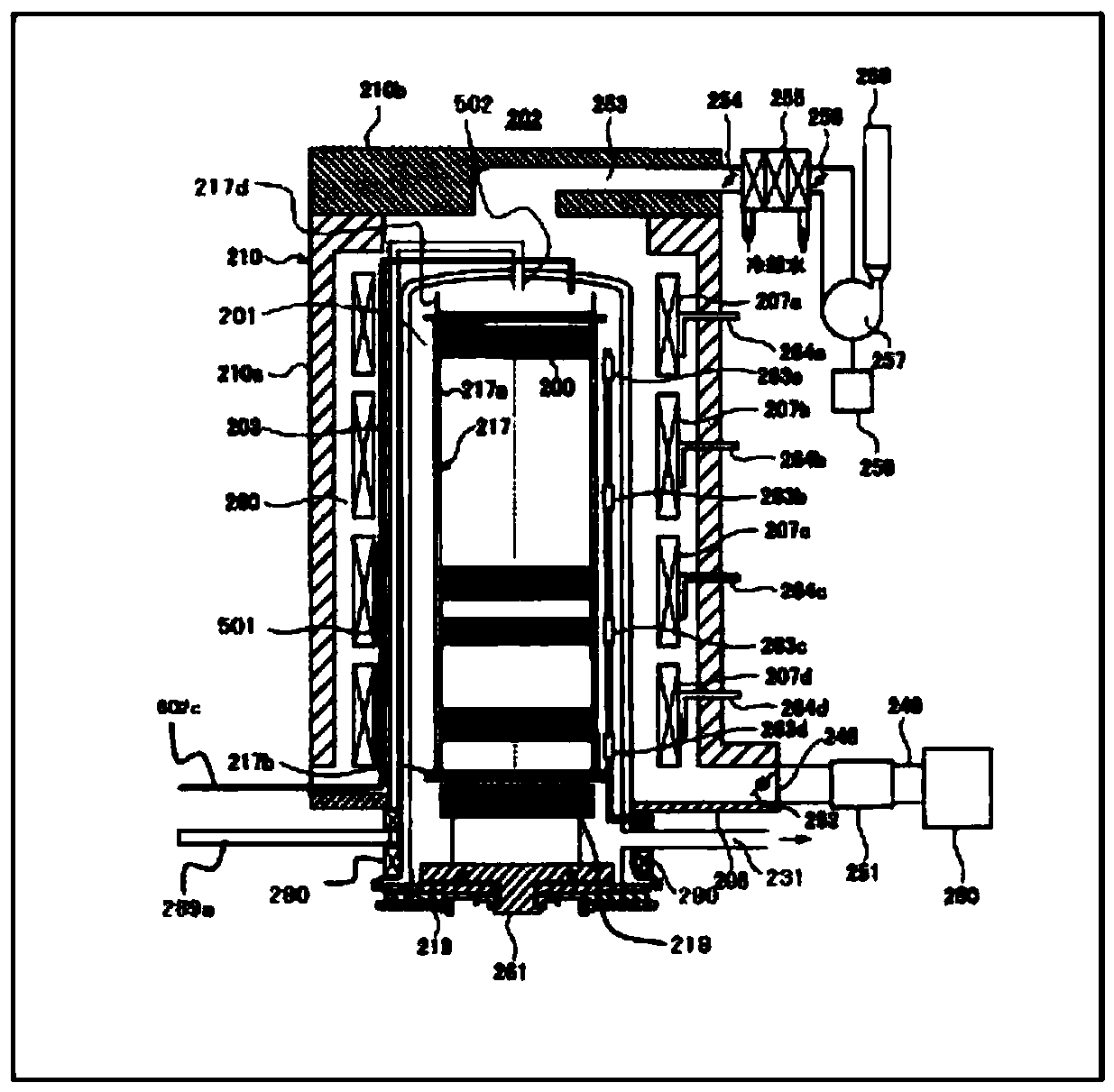

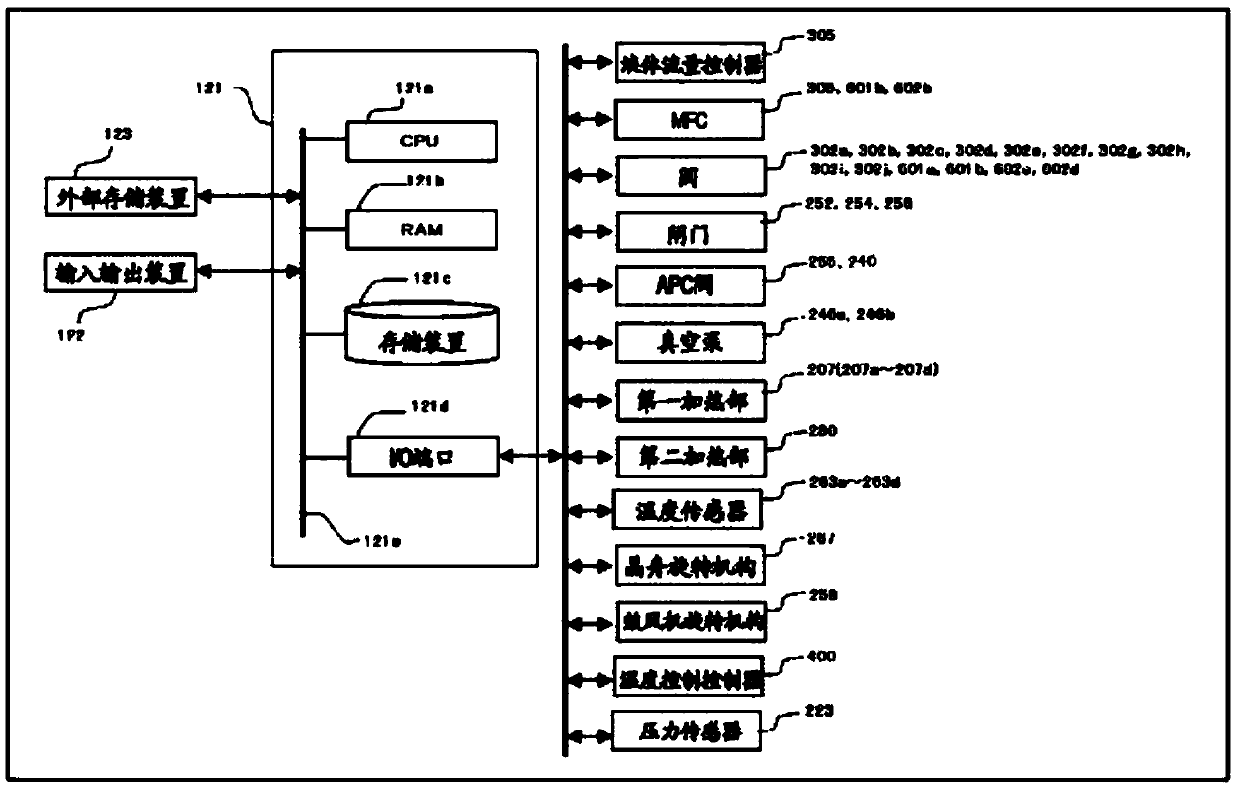

Substrate processing method, substrate processing apparatus, method for manufacturing semiconductor device, and recording medium

ActiveCN105518835AImprove featuresImprove manufacturing capacitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingMetallurgySemiconductor

This substrate processing method comprises: a step wherein a substrate, which is provided with a prebaked film that has a silazane bond, is carried into a process chamber; a modification step wherein the substrate is heated to a first temperature and a processing gas is supplied to the substrate; and a drying step wherein the substrate is heated at a second temperature that is higher than the first temperature but not higher than the temperature of the prebaking.

Owner:KOKUSAI DENKI KK +1

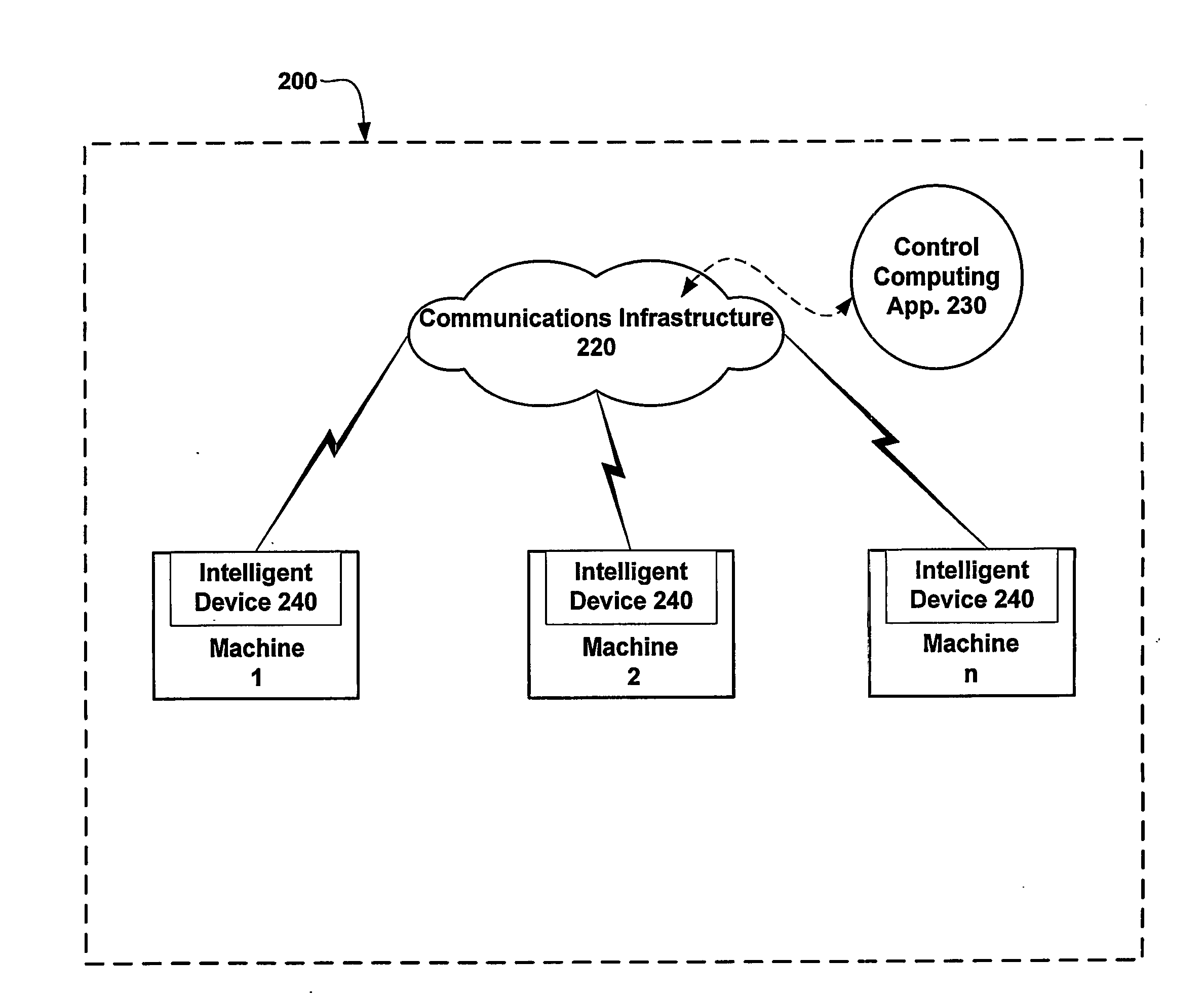

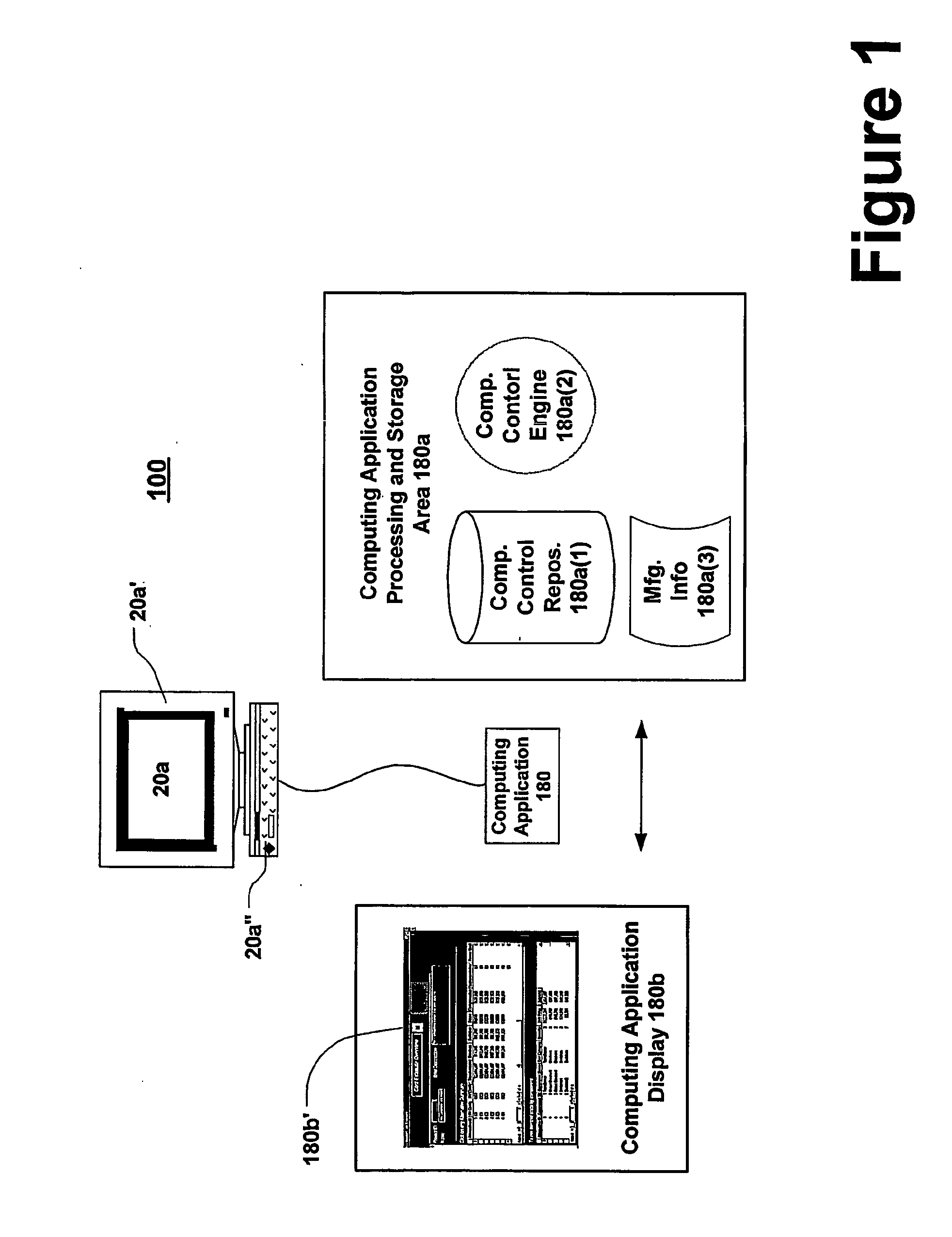

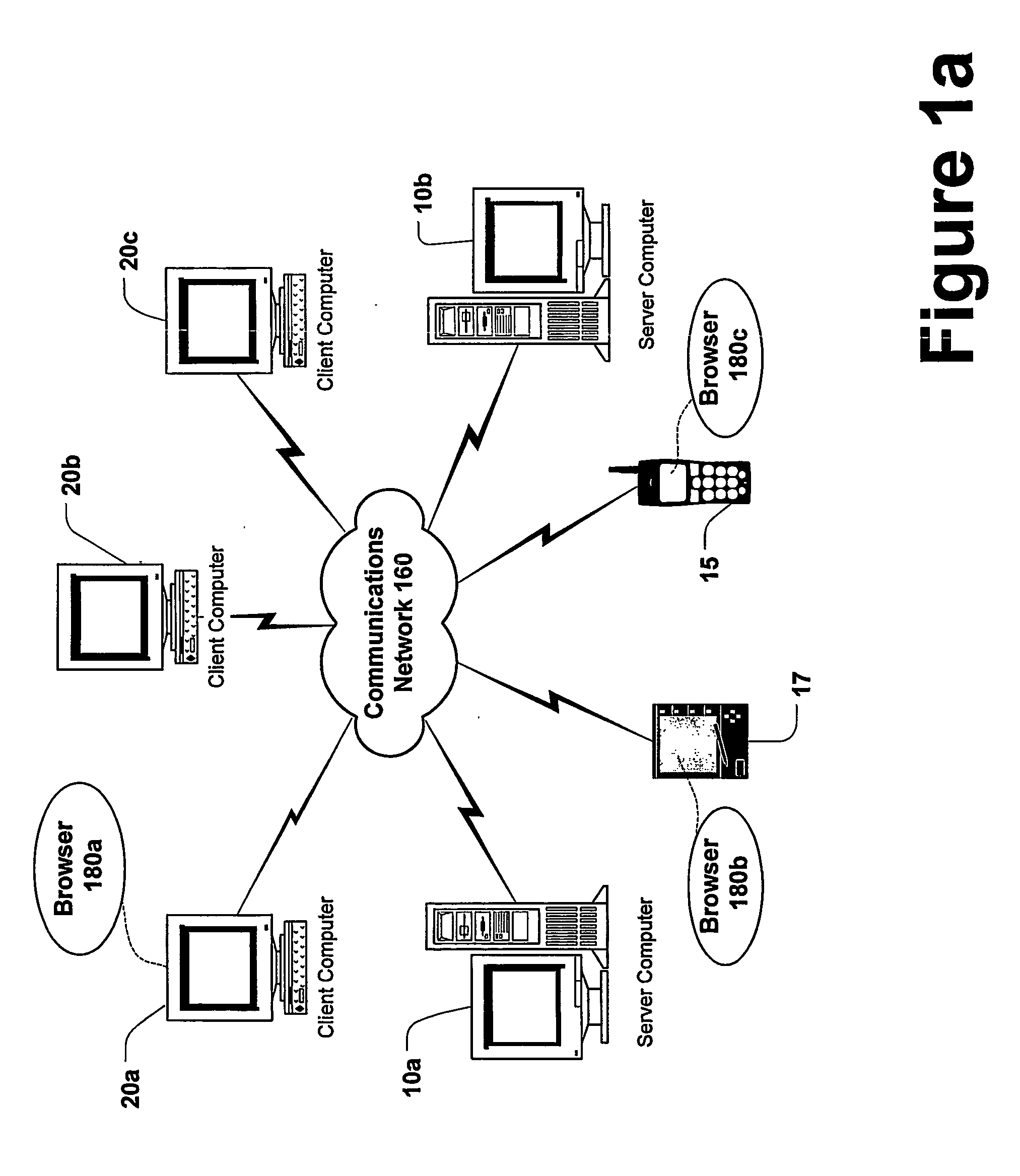

Industrial Information Technology (It) On-line Intelligent Control of Machines in Discrete Manufacturing Factory

InactiveUS20070299800A1Improve manufacturing capacityAvoid manufacturing down-timeKnowledge representationTotal factory controlEngineeringDiscrete manufacturing

The invention contemplates a system and method offering control and management of manufacturing resources (Machine 1, Machine 2 . . . Machine n) to obtain optimal manufacturing capacities and to avoid manufacturing down-time currently realized through manual operation and control of manufacturing resources. In an illustrative implementation, the present invention contemplates an exemplary control computing application (180) operating in a computing environment (100) which communicates with, cooperates with, and provides control over at least one manufacturing resource (e.g. manufacturing machine—Machine 1, Machine 2, . . . Machine n). The computing application (180) provides at least one instruction set (110′) for use in controlling the manufacturing resource. The communication of the instruction set may be realized local to the manufacturing resource, remotely from the manufacturing resource, or some combination thereof.

Owner:ABB TECH AG

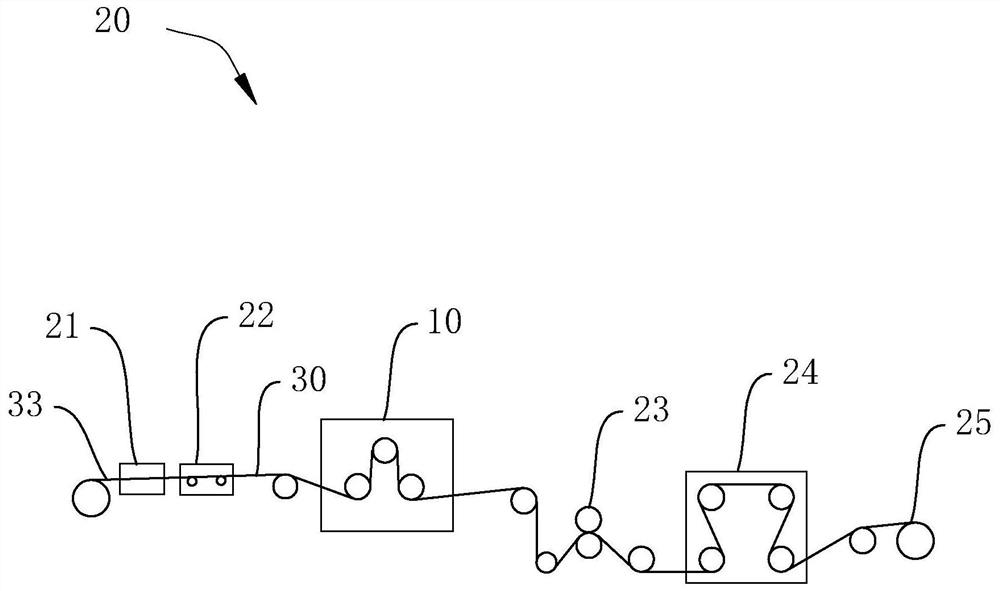

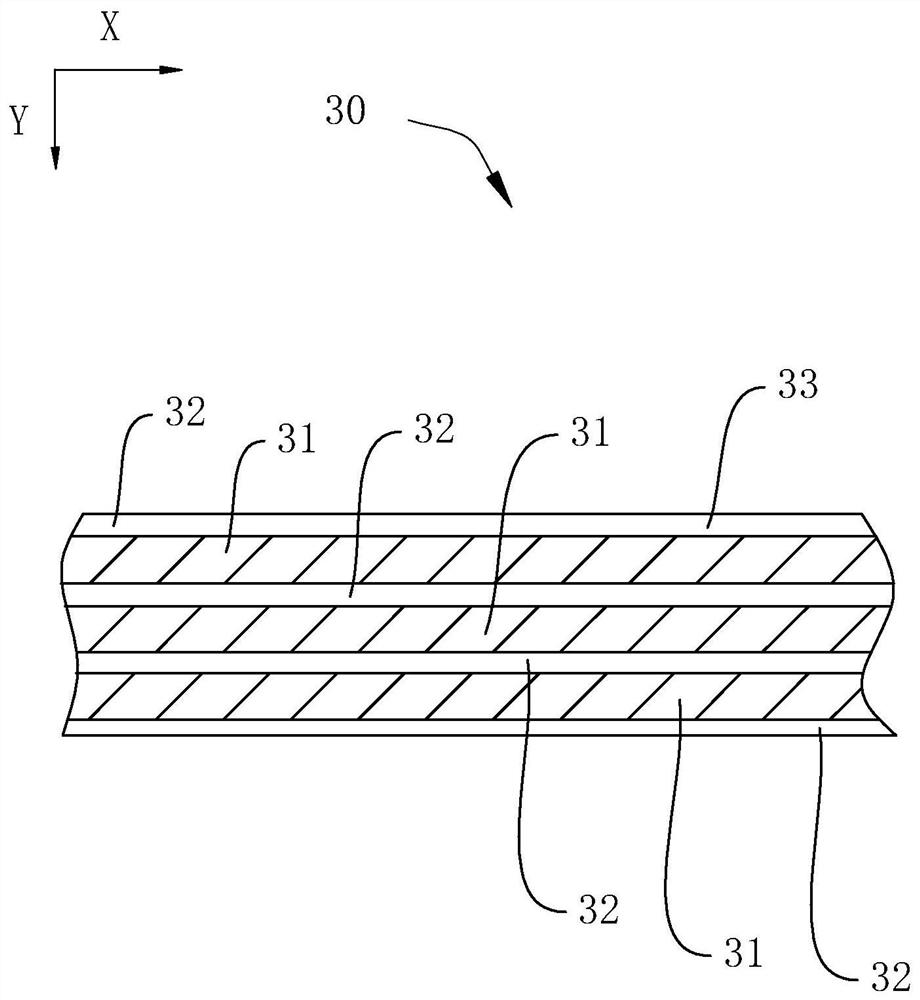

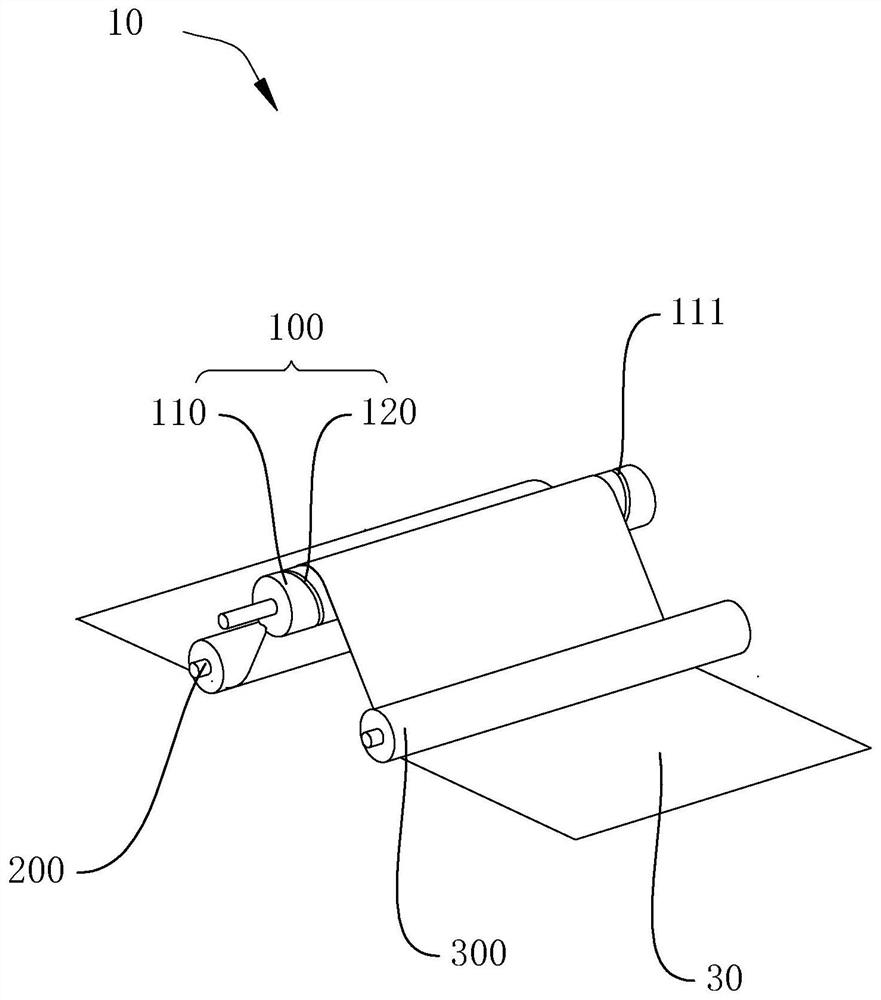

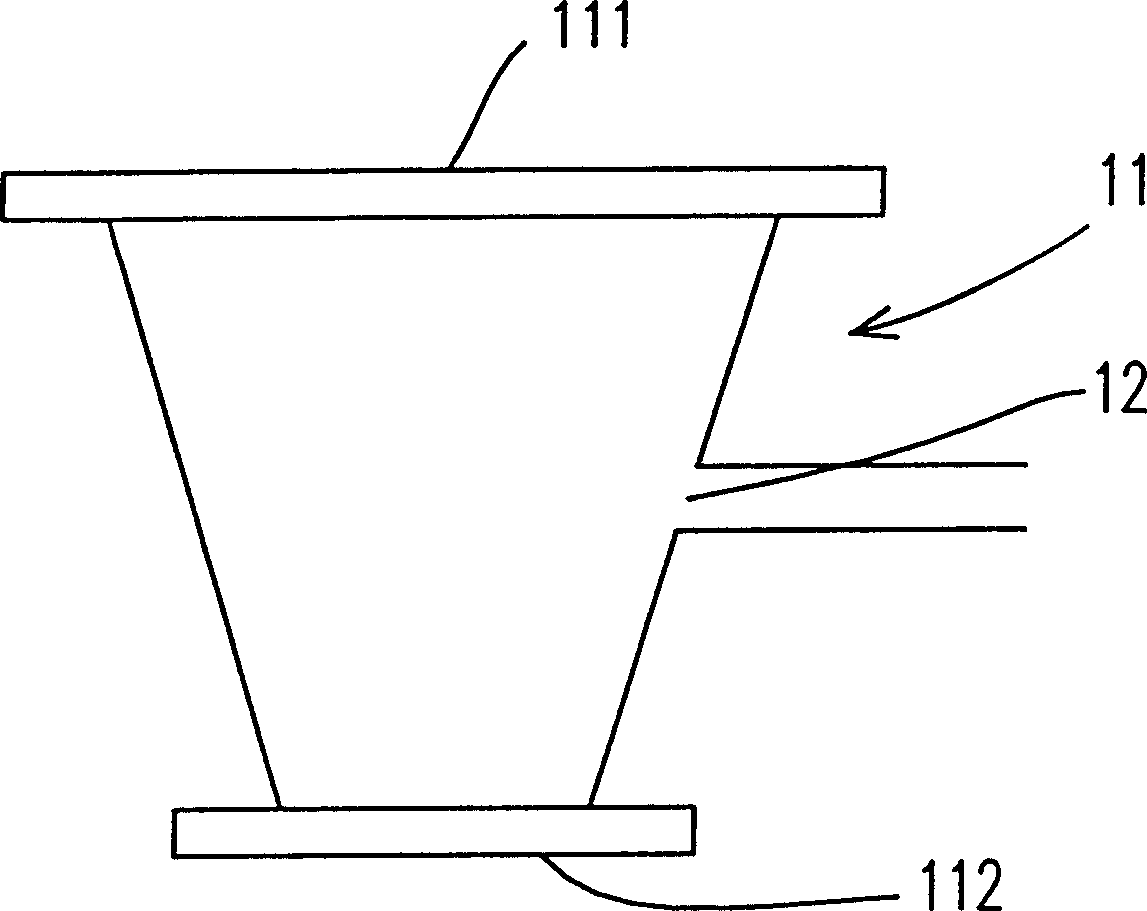

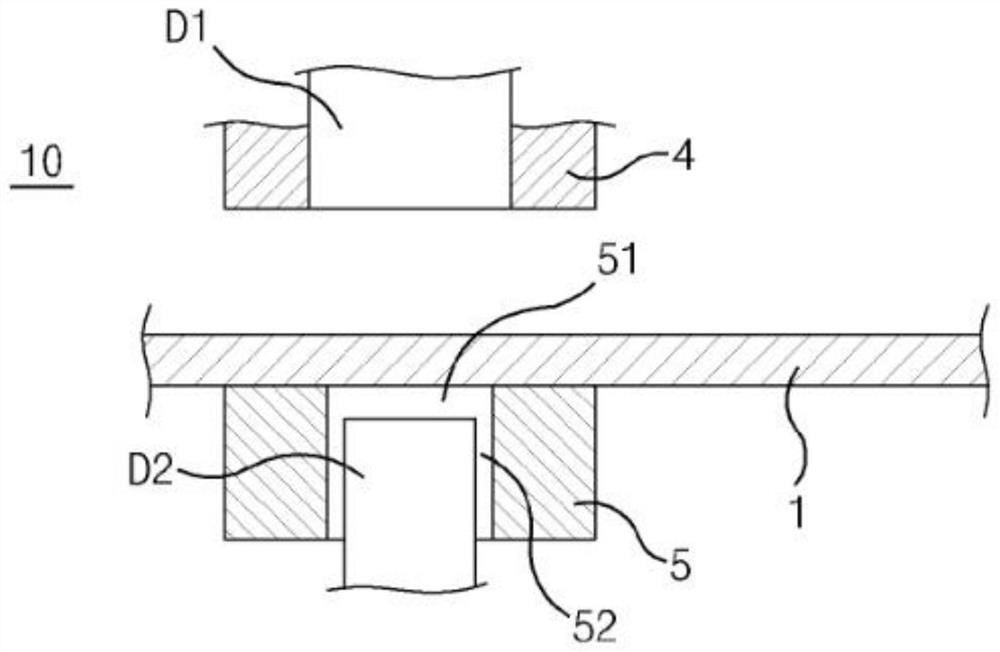

Pass-over roller assembly, coating equipment and rolling equipment

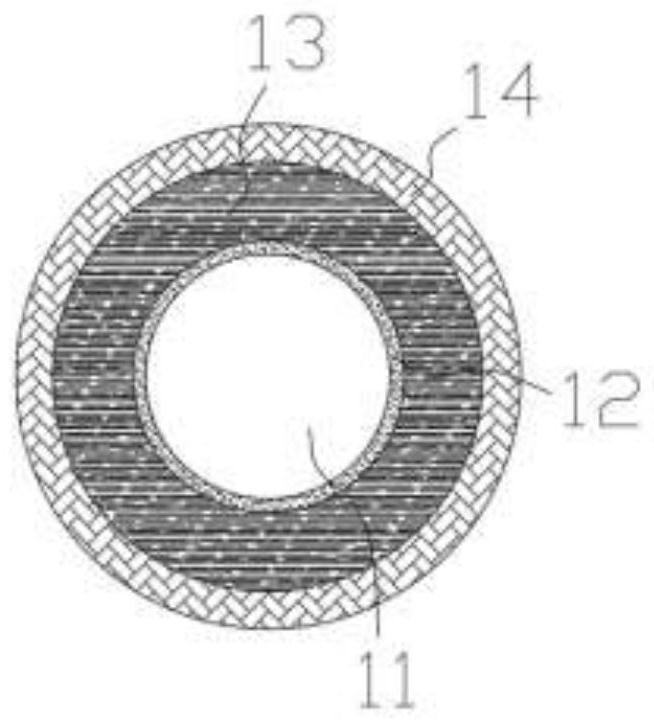

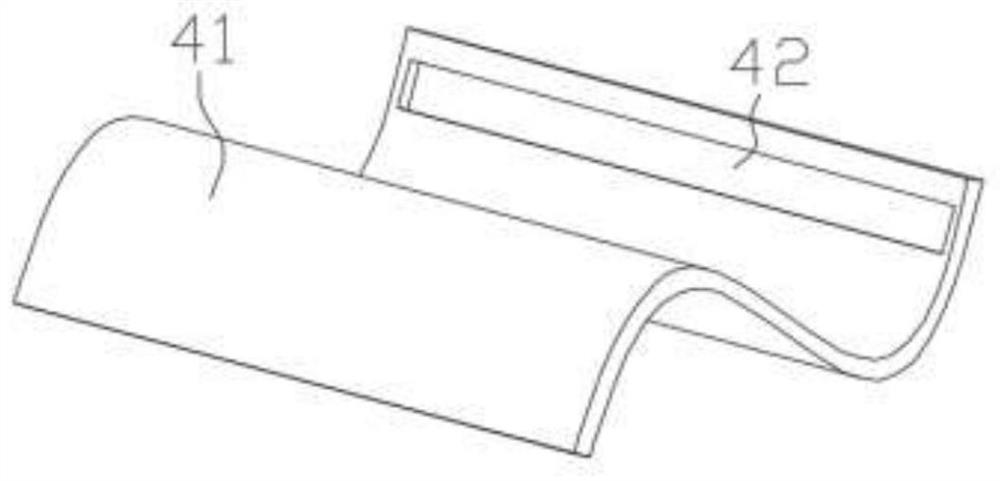

PendingCN112517635AWide industrializationImprove manufacturing capacityCell electrodesMeasuring devicesAlloyScrew thread

The invention relates to a pass-over roller assembly, coating equipment and rolling equipment. The pass-over roller assembly comprises a threaded roller, a first adjusting roller and a second adjusting roller, wherein the threaded roller comprises an alloy roller and fillers; the surface of the alloy roller is provided with threaded grooves; the threaded grooves are symmetrically and continuouslydistributed in the direction from the center of the alloy roller to the two ends of the alloy roller; the fillers are embedded in the threaded grooves; the surfaces of the fillers are flush with the surface of the alloy roller; the friction coefficients of the surfaces of the fillers are larger than the friction coefficient of the surface of the alloy roller; and the first adjusting roller and thesecond adjusting roller are located on the two opposite sides of the threaded roller respectively and used for adjusting the wrap angle alpha between the threaded roller and a sheet-shaped roller passing object. According to the pass-over roller assembly, the coating equipment and the rolling equipment provided by the invention, when the sheet-shaped roller passing object is arranged on the threaded roller in a penetrating and wrapping mode, the threaded roller can apply continuous and stable transverse tension to the sheet-shaped roller passing object, the transverse tension extends from thecenter of the threaded roller to the two ends, and then transverse wrinkles in the width direction of the sheet-shaped roller passing object can be flattened.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

Method for detecting diameter of outer wall of tapered case of aviation engine on line

InactiveCN102927952BReduce manufacturing costImprove automationMeasurement devicesNumerical controlAviation

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

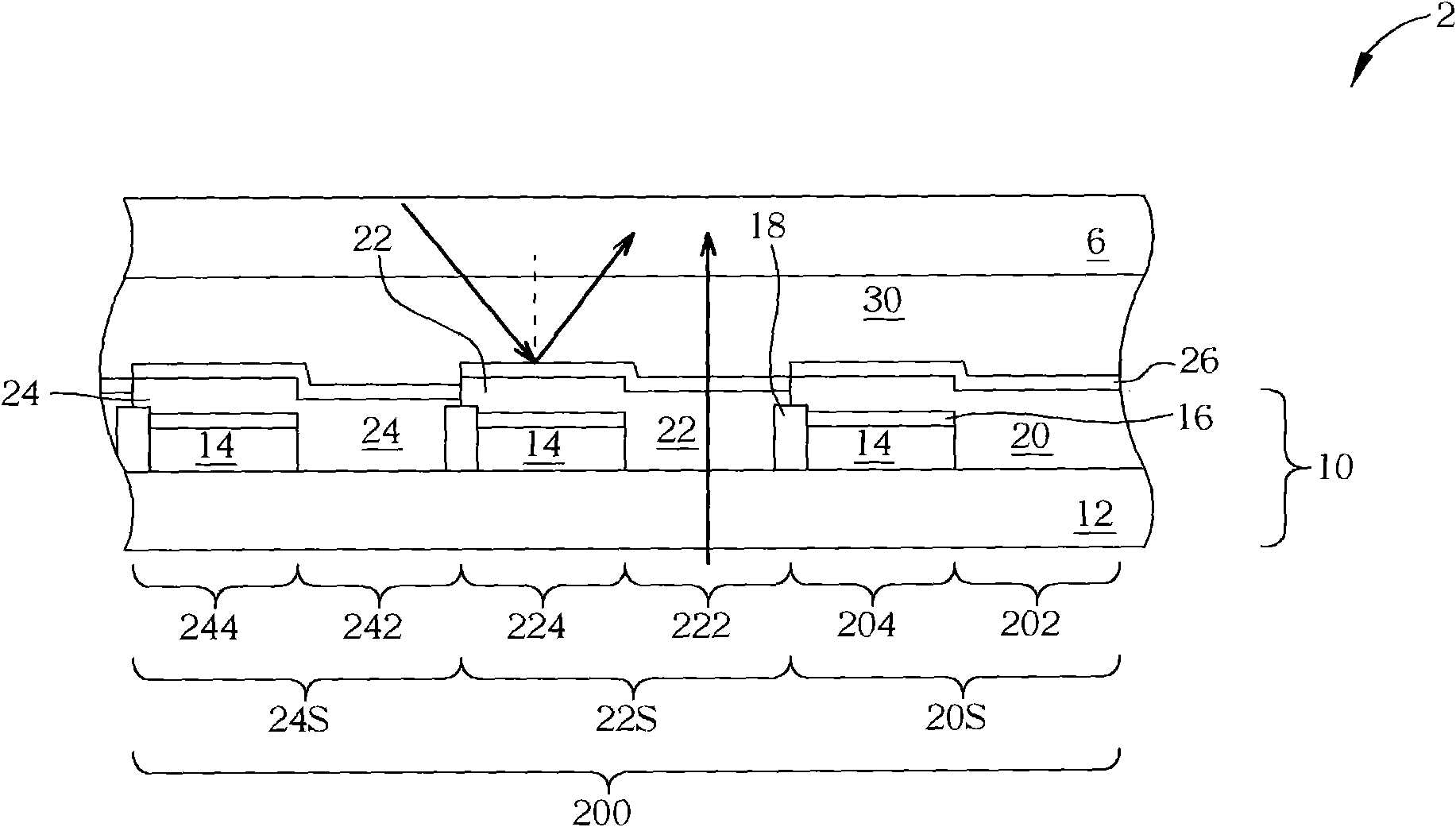

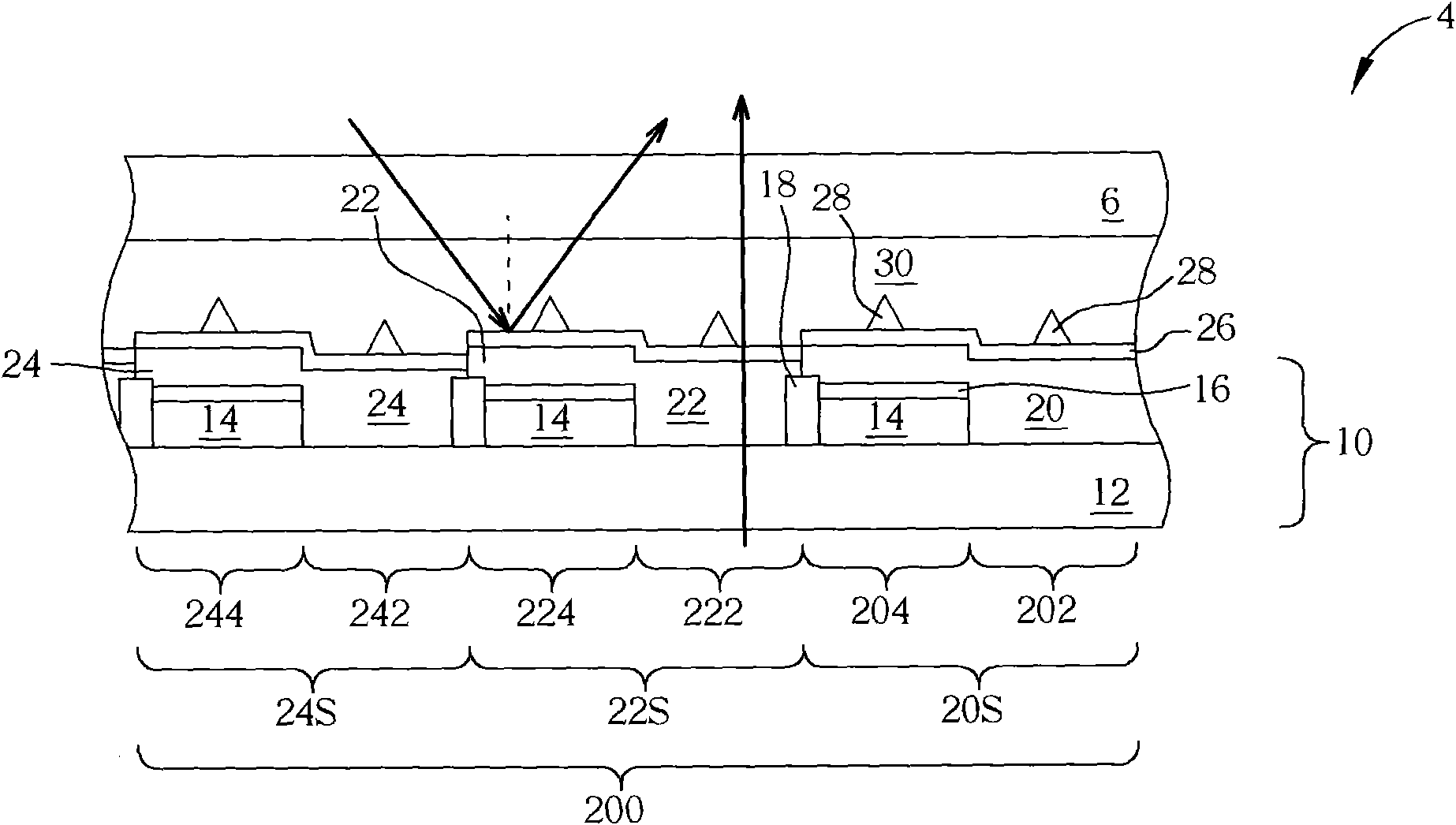

Colored filter array substrate

InactiveCN102436093ASimple structureImprove manufacturing capacityNon-linear opticsLiquid-crystal displayElectrode

The invention provides a colored filter array substrate, which is applied to a semi-transmission and semi-reflection wide-viewing-angle liquid crystal display. The colored filter array substrate comprises a transparent substrate and a plurality of sub-pixels, wherein each sub-pixel comprises a reflection region, a transmission region, a colored filter layer and a transparent electrode, wherein the colored filter layer is provided with at least one groove. In the invention, the wide viewing angle technology of the semi-transmission and semi-reflection liquid crystal display is realized by using a groove of the colored filter layer, so that the structure is simplified, the manufacturing process is shortened, and the yield of a liquid crystal display panel is increased effectively.

Owner:华映视讯(吴江)有限公司 +1

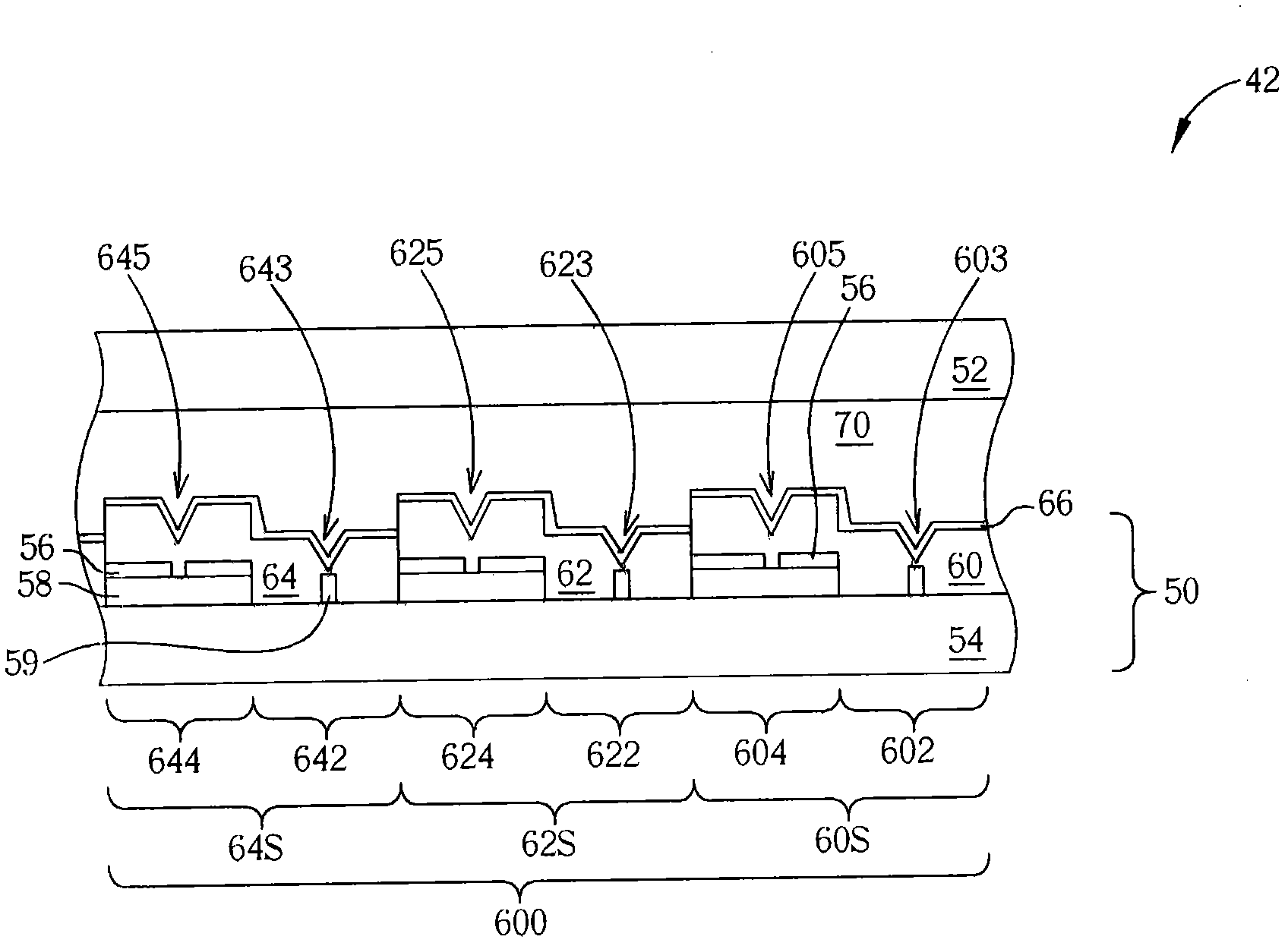

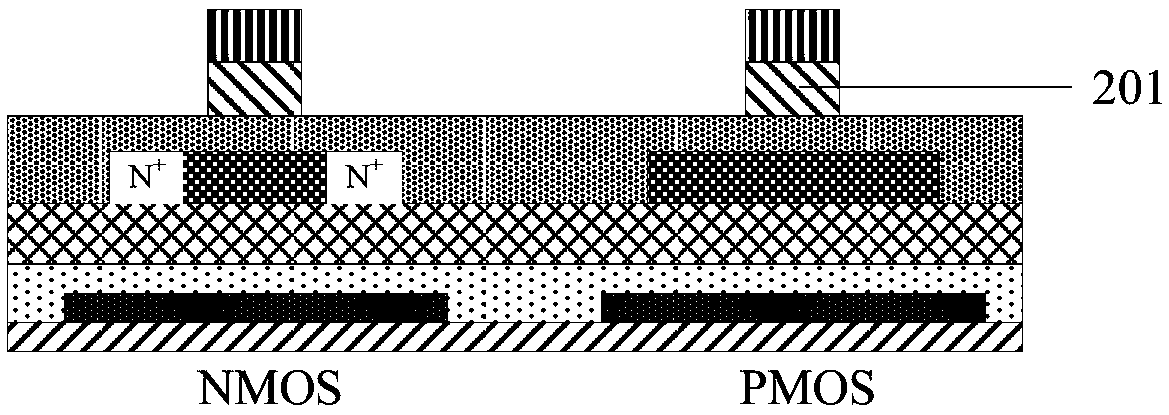

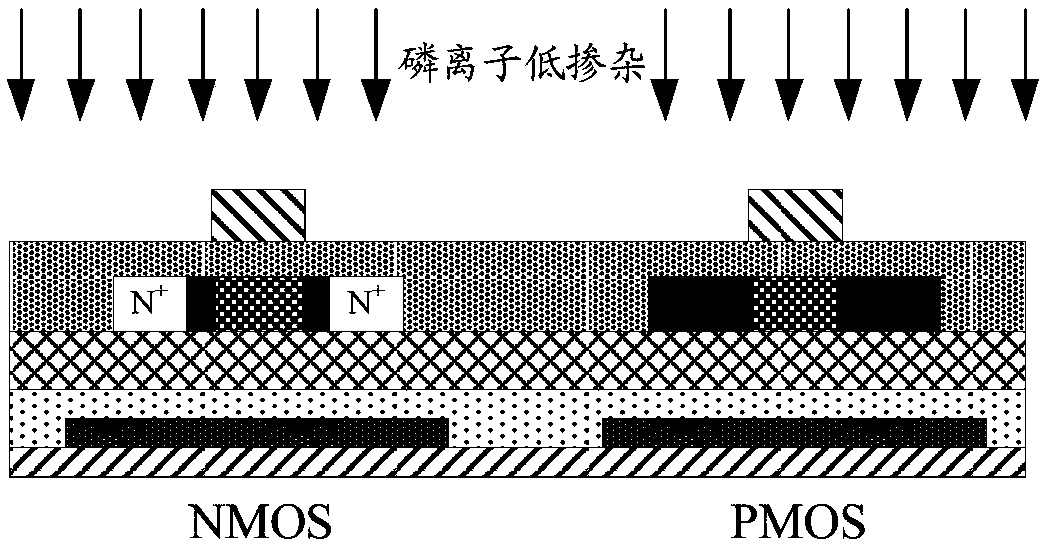

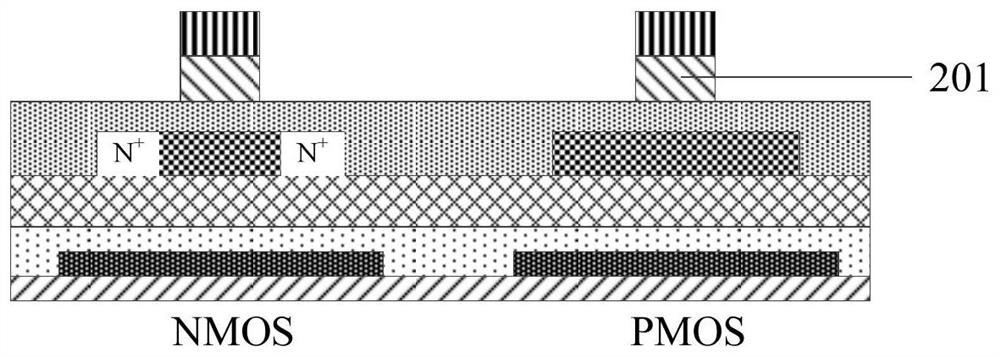

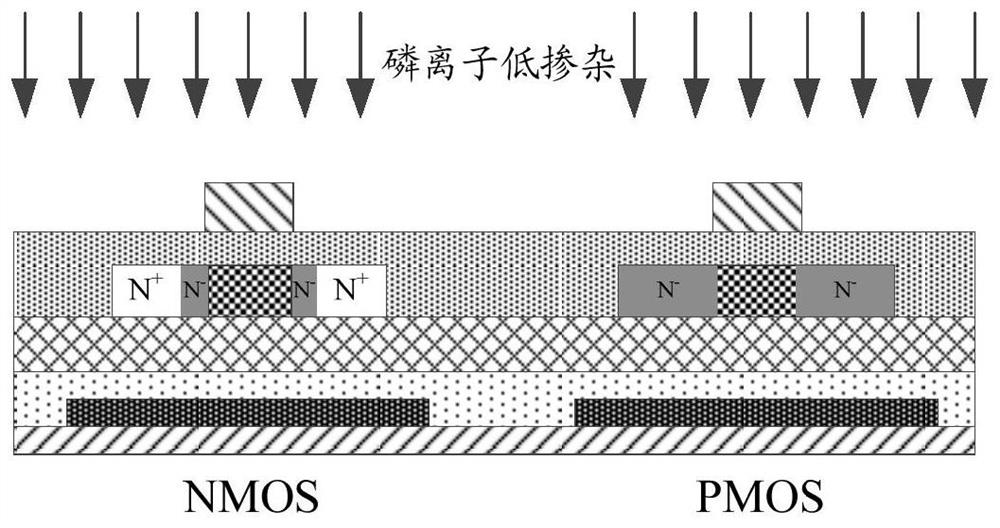

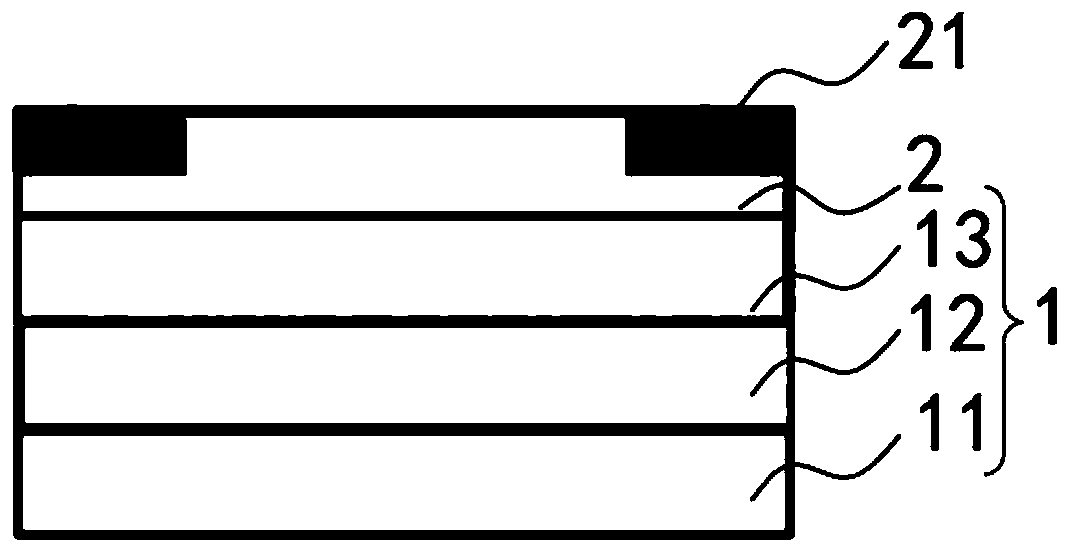

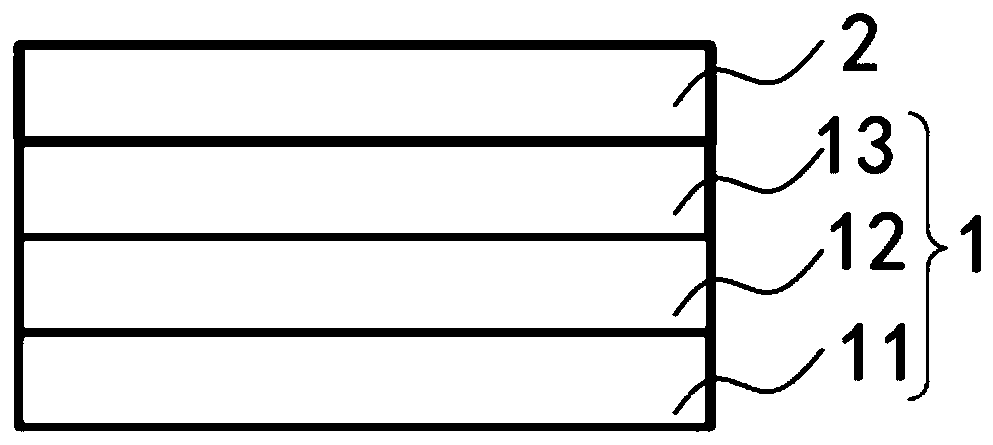

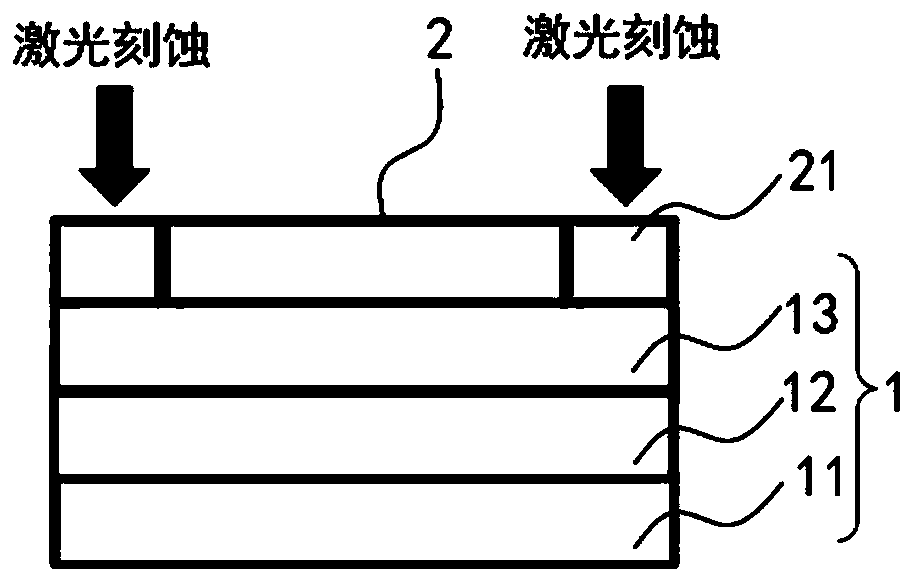

Manufacturing method of CMOS thin film transistor and manufacturing method of LTPS array substrate

ActiveCN108878354AImprove manufacturing capacityReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingCMOSEngineering

The invention discloses a manufacturing method of a CMOS thin film transistor and a manufacturing method of an LTPS array substrate; manufacturing method of the CMOS thin film transistor comprises thefollowing steps of providing a substrate, and sequentially forming an active layer, a gate layer and a photoresist layer on the substrate, wherein the active layer comprises a first region, a secondregion and a third region; patterning the photoresist layer by using a photomask, so that the second region is not covered by the photoresist layer, and the first region and the third region are covered by the remaining photoresist; performing first-degree doping on the second region; removing residual photoresist; and carrying out second-degree doping on the first region. By means of the mode, the number of the photo masks in the manufacturing process can be reduced, the manufacturing period is shortened, and the manufacturing cost is lowered.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

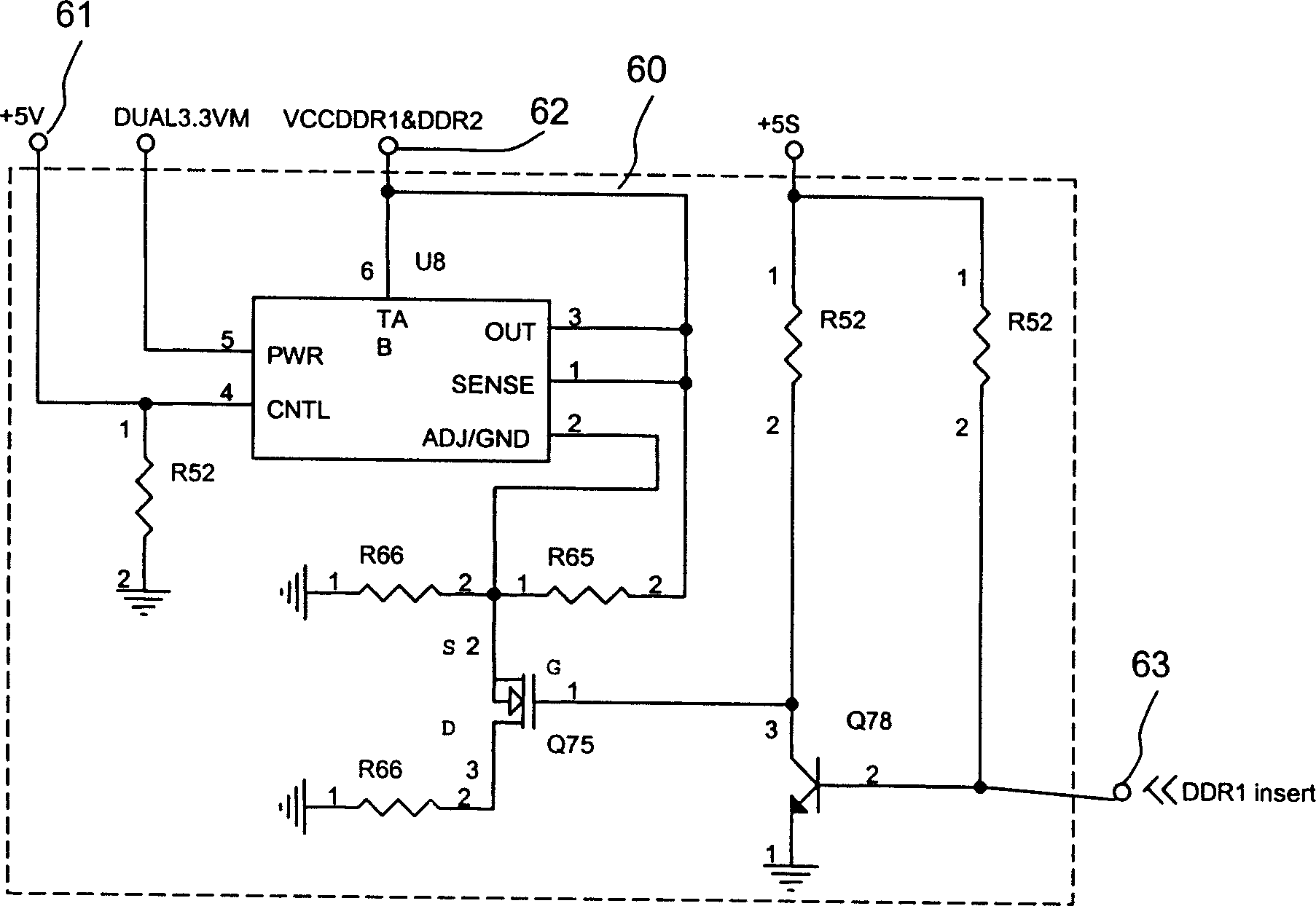

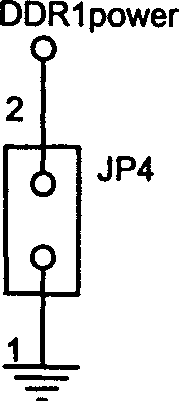

Method and structure for making DDR2 or DDR1 share one main machine board

InactiveCN1673921AImprove sales competitivenessImprove manufacturing capacityDigital data processing detailsVoltage converterEngineering

The method and structure of making DDR2 or DDR1 share one main board has the main board combined with one voltage converter and one DDR2 connector. When the main board is to be connected to DDR2, the voltage converter outputs one proper voltage to the DDR2 connector; and when the main board is to be connected to DDR1, the DDR2 connector is connected to the DDR1 connector via one converting card and the input of the voltage converter is connected to ground end of the converting card, so that the voltage converter output one other proper voltage to the DDR1 connector. The main board can be combined with DDR2 or DDR1 optionally and this provides improved performance.

Owner:WISTRON CORP

Colorful filter array substrate

InactiveCN101846843ASimple structureImprove manufacturing capacityNon-linear opticsLiquid-crystal displayElectrode

The invention provides a colorful filter array substrate applied to a semi-penetration and semi-reflection type wide-view angle LCD, comprising a transparent substrate and a plurality of sub-pixels, wherein each of the sub-pixels respectively comprises a reflecting region, a penetrating region, a colorful filter layer with at least one groove, and a transparent pole. The invention realizes a wide-view angle technology of a semi-penetration and semi-reflection type LCD by utilizing the groove on the colorful filter layer so as to simplify the structure, shorten the manufacturing process and effectively improve the production capacity of liquid crystal display panels.

Owner:华映视讯(吴江)有限公司 +1

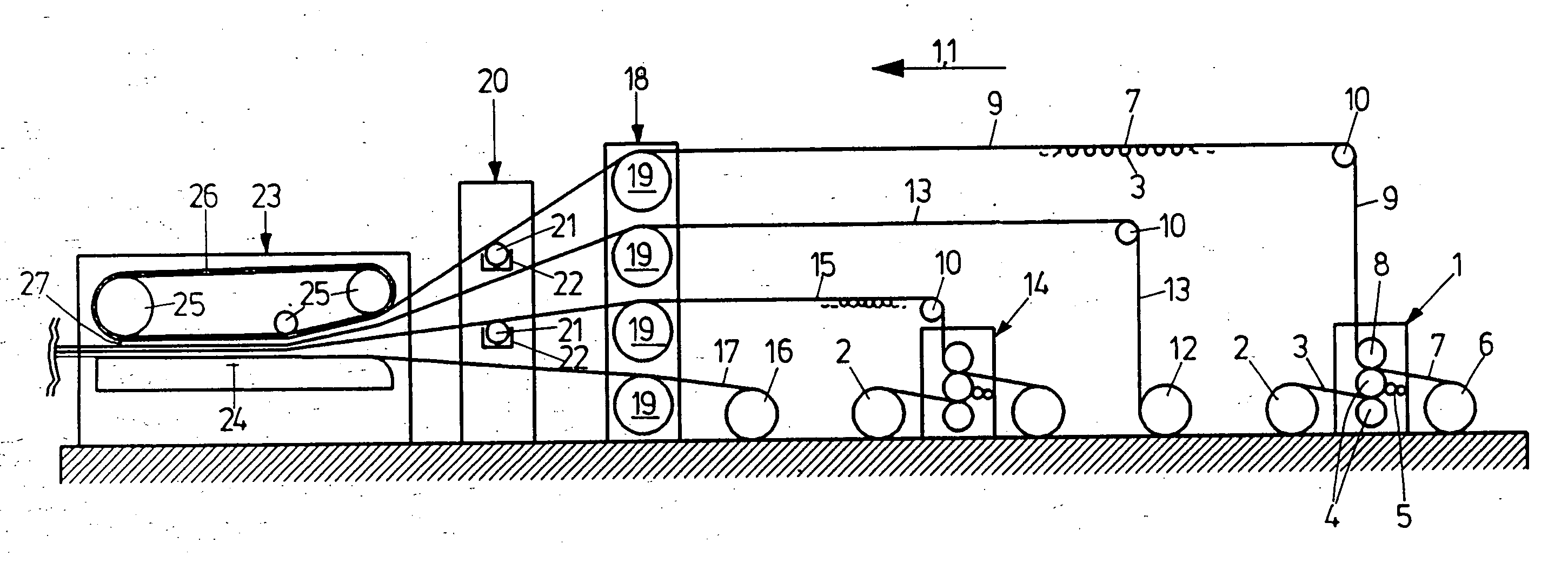

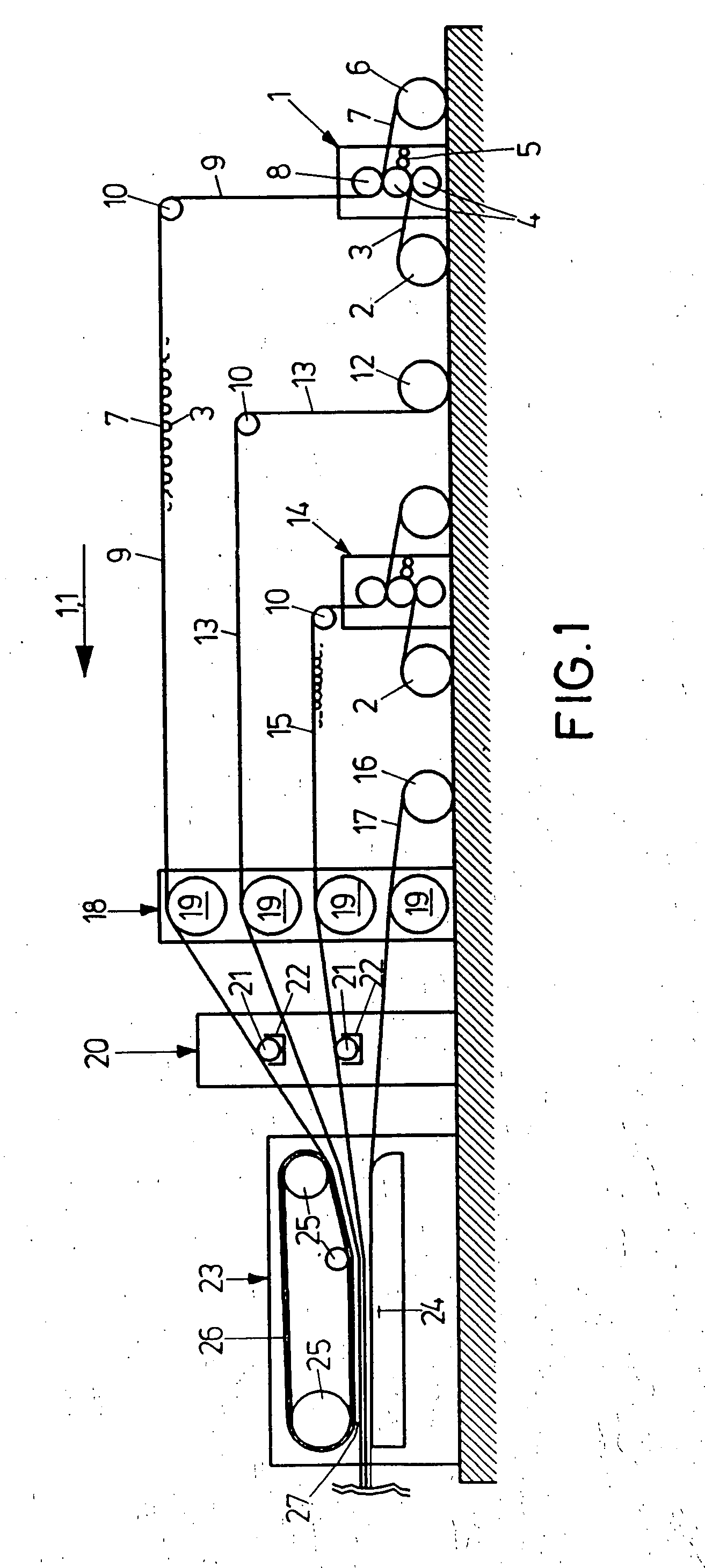

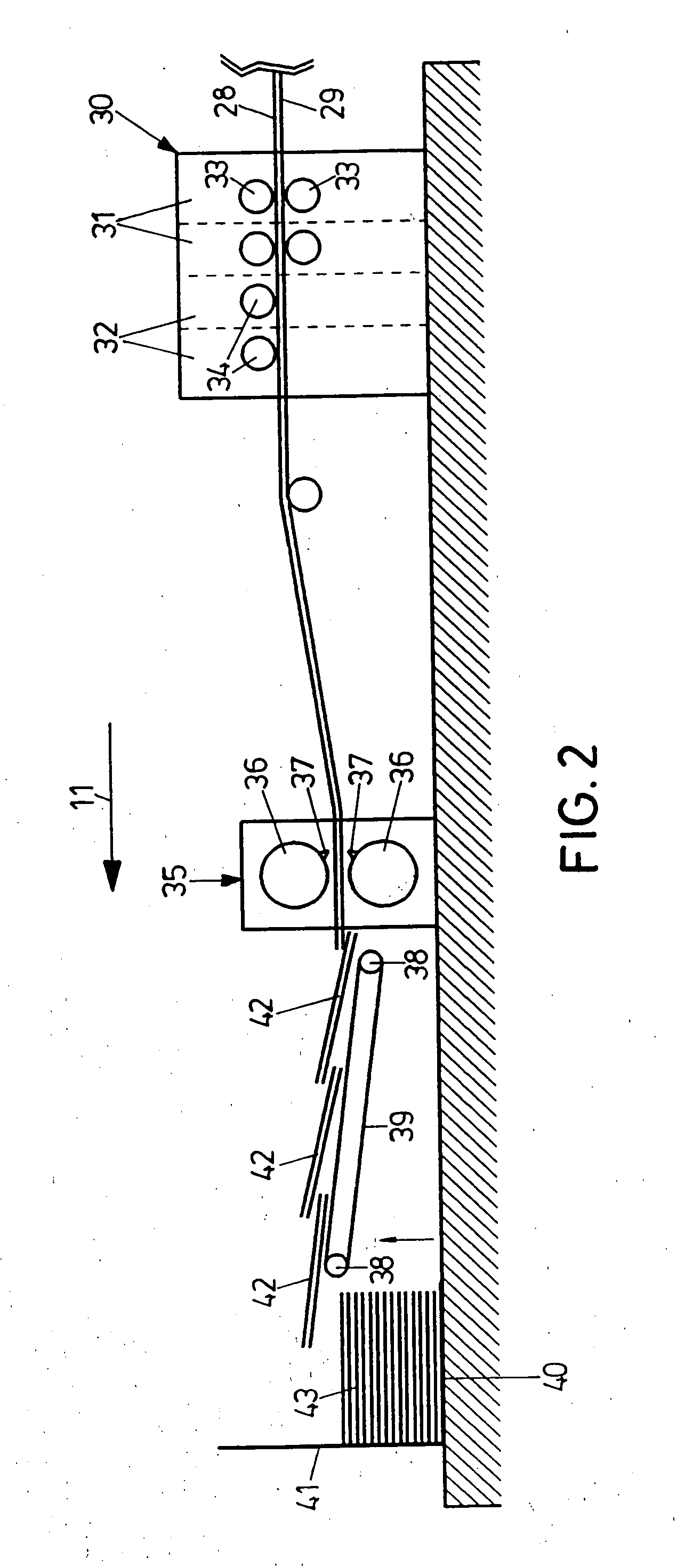

Corrugating machine

InactiveUS20050139312A1Improve manufacturing capacityMechanical working/deformationAdhesivesJoint workingCorrugated fiberboard

A corrugating machine for the manufacture of sheets of corrugated board comprises a first manufacturing unit for the production of a first web of corrugated board, a second manufacturing unit for the production of a second web of corrugated board, a mounting unit, which is disposed downstream of the manufacturing units in a working direction, for non-adhesively bringing together the first web of corrugated board and the second web of corrugated board and a working unit, which is disposed downstream of the mounting unit, for jointly working the first web of corrugated board and the at least second web of corrugated board that lie on top of each other.

Owner:BHS CORRUGATED MASCHEN & ANLAGENBAU

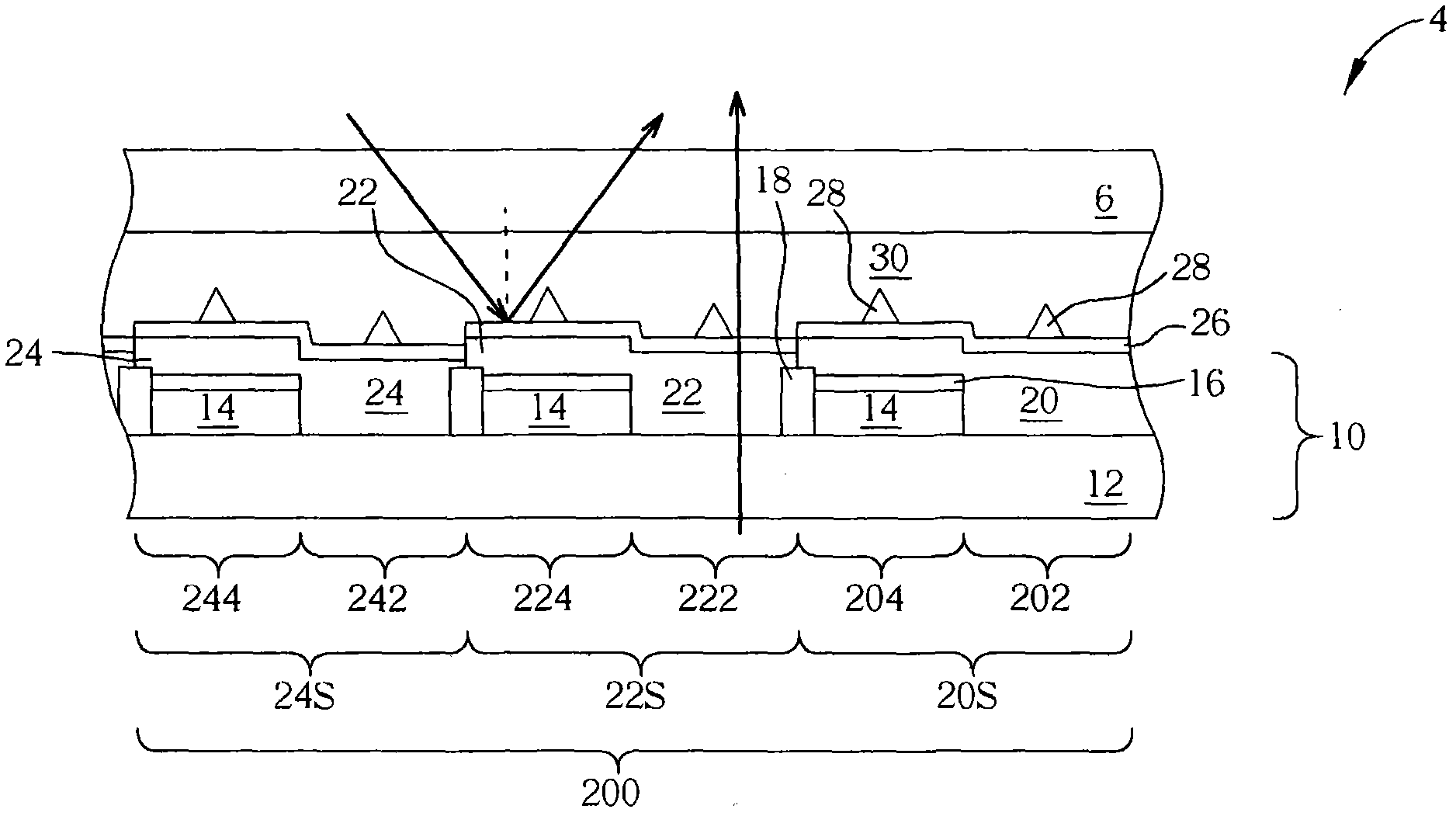

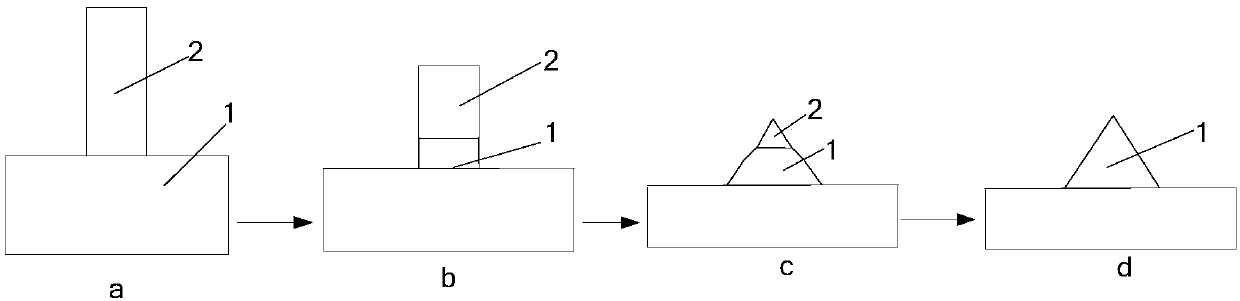

Manufacturing method for patterned substrate, patterned substrate and light emitting diode

ActiveCN110867503ALower the altitudeReduce etch heightSemiconductor/solid-state device manufacturingSemiconductor devicesPhysical chemistryEngineering

The invention discloses a method of patterning a substrate, the patterned substrate and a light emitting diode. The method comprises a mask lowering stage, a main etching stage and an over-etching stage which are carried out in sequence. In the mask lowering stage, a substrate with a mask formed on the surface is etched according to preset first etching process parameters, and the first etching process parameters meet that the etching rate of the mask is larger than that of the substrate so as to lower the height of the mask. In the main etching stage, the substrate subjected to the mask lowering stage is etched according to a preset second etching process parameter so as to improve the included angle between the bottom width and the inflection point of the substrate. In the over-etching stage, the morphology of the substrate subjected to the main etching stage is modified according to preset third etching process parameters to obtain a patterned substrate. According to the method of patterning the substrate, the process time can be effectively shortened, and the production capacity is improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Adapter and method for preventing back flow of gas

InactiveCN1206705CPrevent backflowGuaranteed normal operationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringProduct gas

Owner:WINBOND ELECTRONICS CORP

A kind of manufacturing method of cmos thin film transistor and ltps array substrate

ActiveCN108878354BImprove manufacturing capacityReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingCMOSThin membrane

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Lithium-ion battery nickel sheet automatic welding equipment and welding process

ActiveCN105772918BReduce welding costsHigh precisionFinal product manufactureWelding/cutting auxillary devicesSpot weldingLithium-ion battery

Owner:DONGGUAN GREENWAY NEW ENERGY CO LTD

Flexible polarizing cover plate and its preparation method, display panel and display device comprising it

ActiveCN108594515BThin and lightImprove manufacturing capacityOptical filtersNon-linear opticsDisplay deviceThin membrane

A flexible polarizing cover plate is provided, comprising a laminated polarizer and a hardened film, the hardened film includes a visible area and a black matrix area surrounding the visible area; the black matrix area is formed by being arranged on the flexible film The plurality of grooves and the ink filled in the plurality of grooves are formed after solidification. A preparation method of the flexible polarizing cover, a display panel and a display device comprising the flexible polarizing cover are also provided. In the flexible polarizing cover of the present invention, the ink is directly embedded into the structure of the cover to form a BM area, and no additional BM area is required, thereby reducing the overall thickness of the cover. At the same time, the method of the present invention does not require ink patterning treatment on the back of the cover plate, so that the flexible polarizing cover plate of the present invention can adopt a Roll to Roll process, which improves production efficiency and reduces costs.

Owner:BOE TECH GRP CO LTD

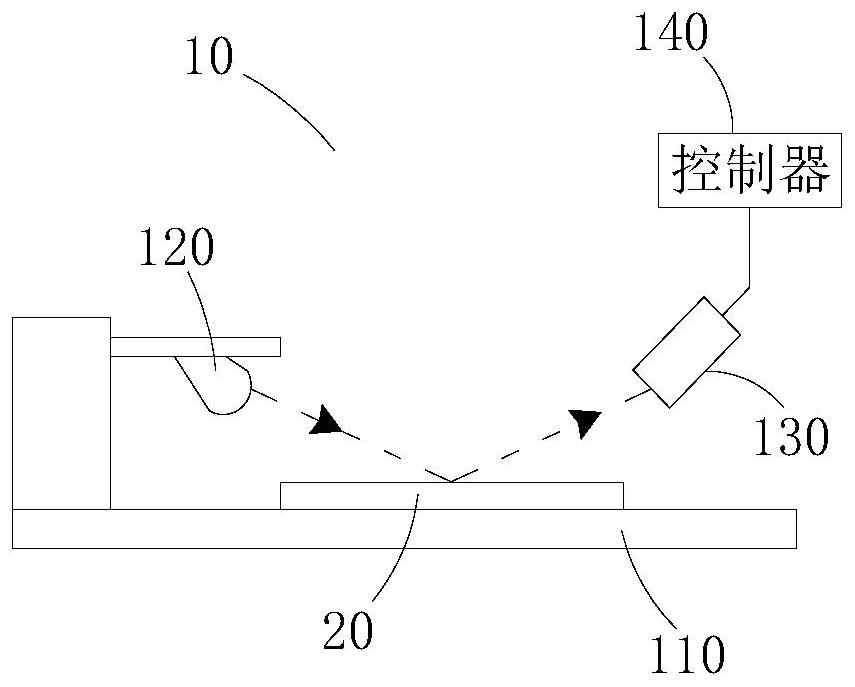

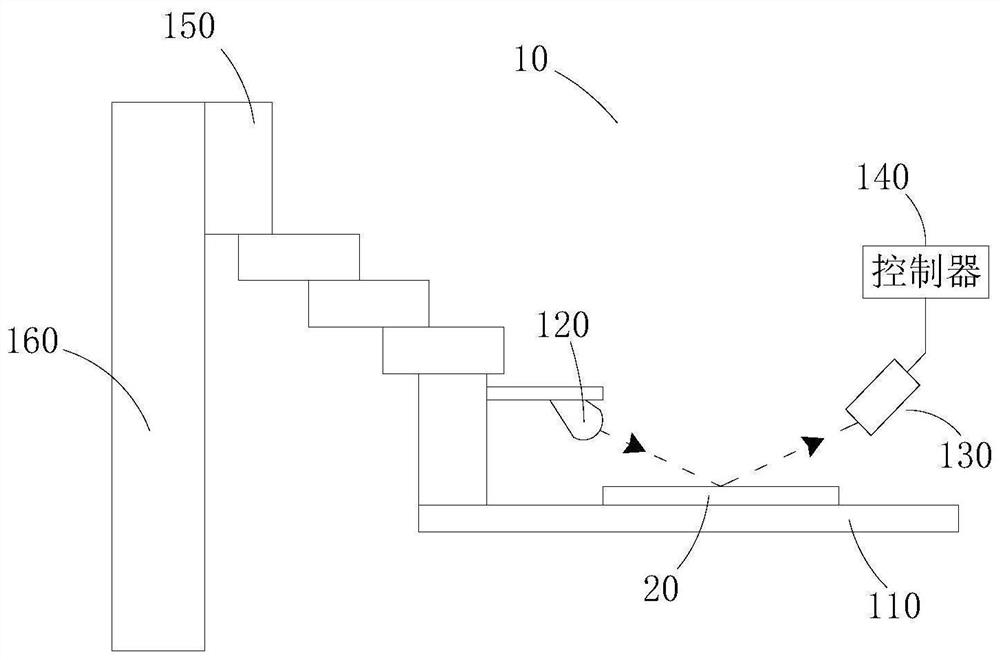

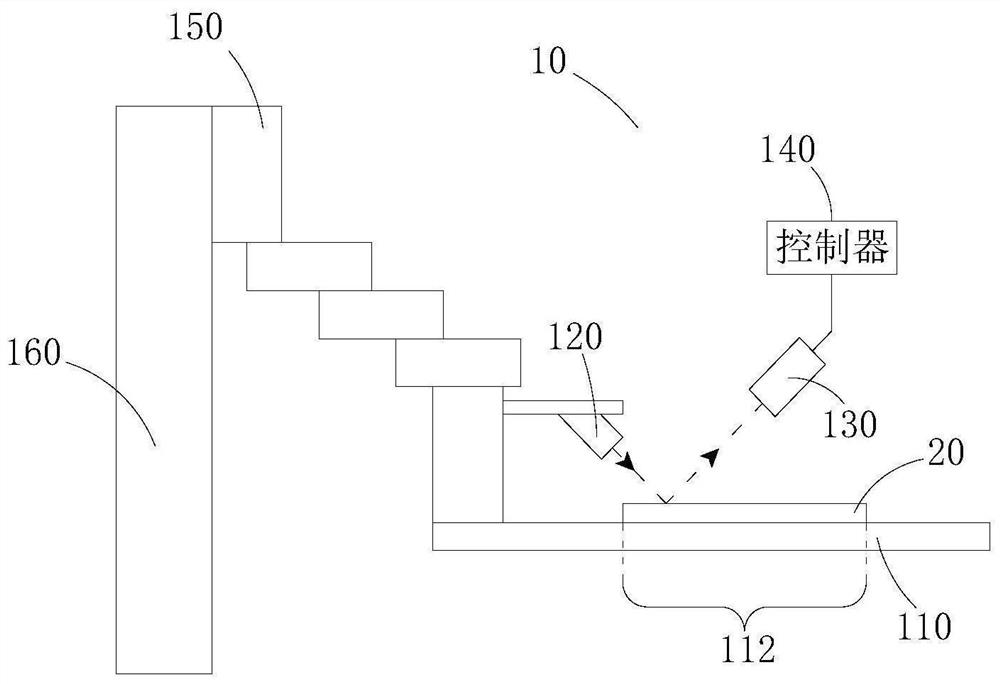

Photomask conveying device and exposure system

ActiveCN114077163ASource accurate judgmentClean in timePhotomechanical exposure apparatusMicrolithography exposure apparatusDevice materialEngineering

The invention relates to a photomask conveying device and an exposure system. The photomask conveying device comprises a bearing part, a light source, a light detector and a controller. The bearing part is used for bearing a photomask. The light source is used for emitting irradiation light to the photomask and forming reflected light. The light detector is used for obtaining the reflected light and generating a light detection signal. The controller is used for judging whether particles exist on the illumination surface or not according to the light detection signals. The photomask conveying device can judge whether particles exist on the surface of the photomask or not in real time according to the light detection signal. When the photomask is transferred among different components through the photomask conveying device, if particles appear on the surface of the photomask, the source component of the particles can be accurately locked. The photomask conveying device can accurately judge the source of the particulate matter on the surface of the photomask, so that the elimination time of the particulate matter source is shortened, and the manufacturing capacity of semiconductor devices is improved.

Owner:CHANGXIN MEMORY TECH INC

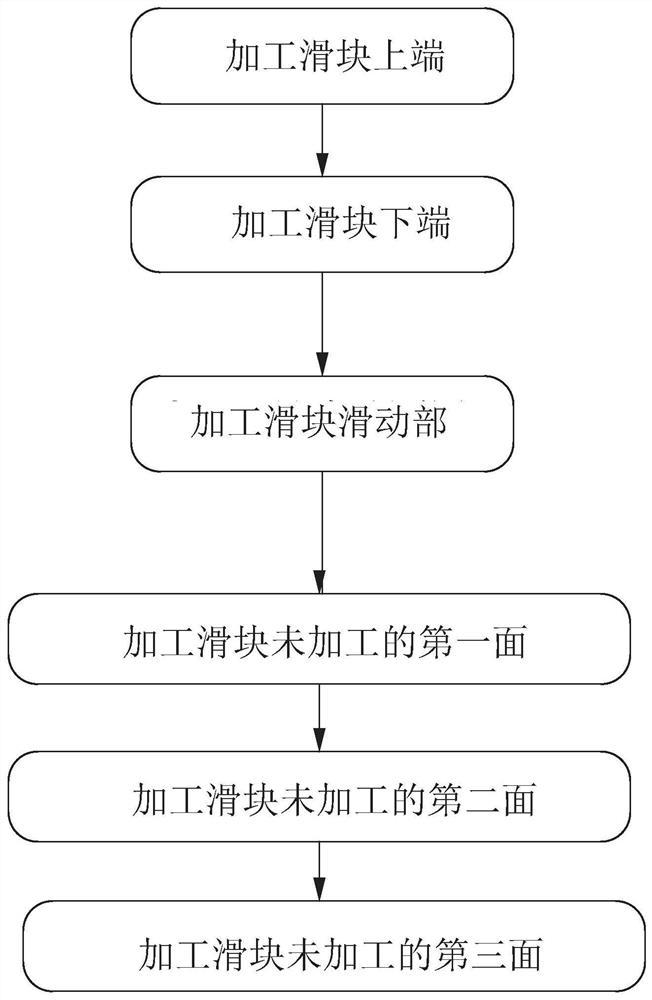

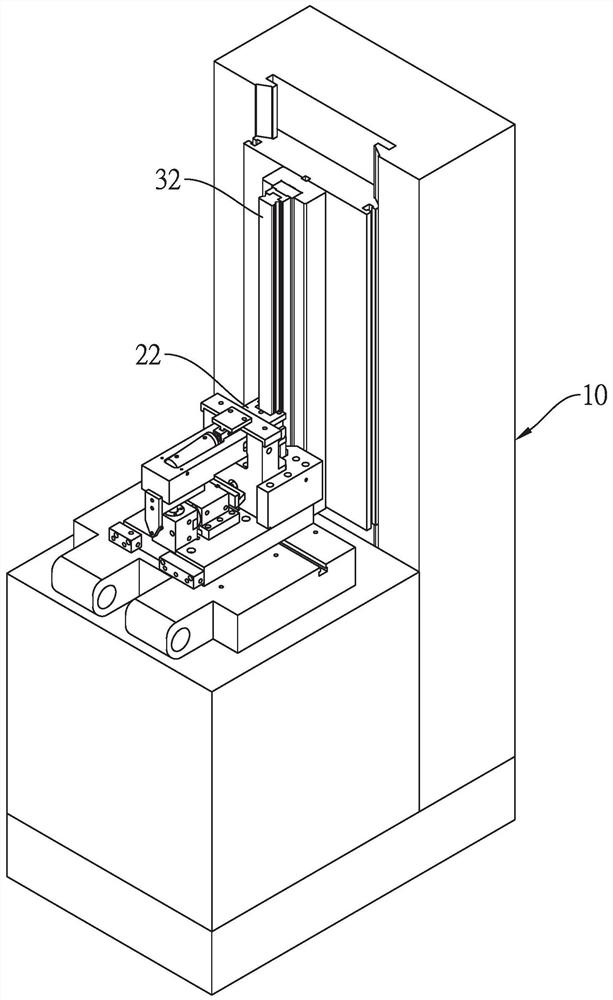

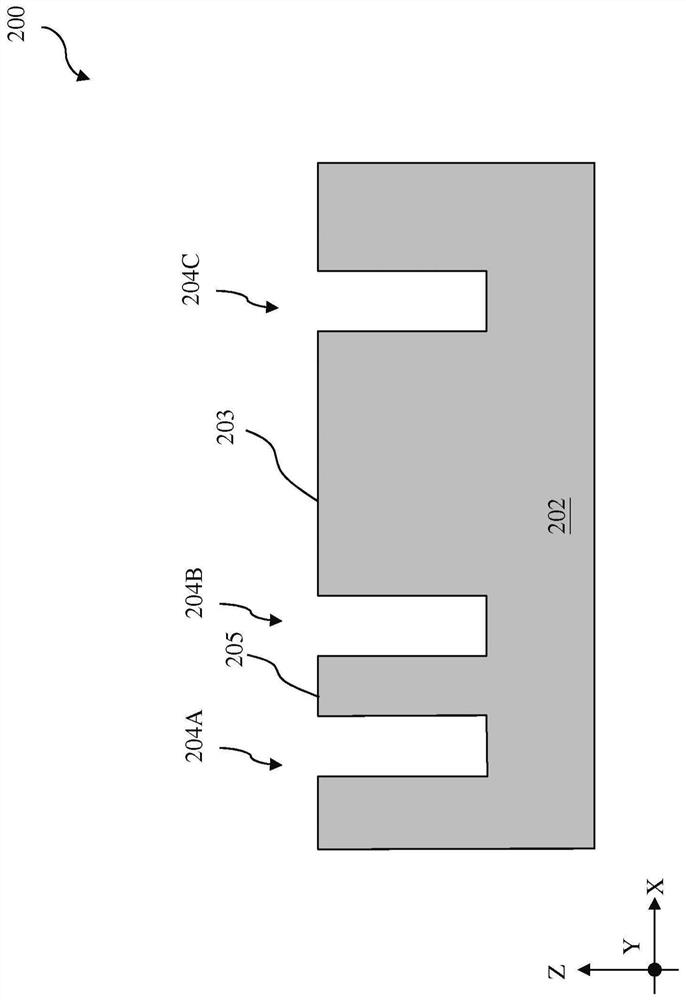

Improvement of linear slider processing technology

ActiveCN112059536BSimplify complexityImprove manufacturing capacityProcess engineeringMachining system

The present invention is an improvement of the processing technology of a linear slider. The linear slider can be manufactured in three process steps mainly through a set of host system and different types of processing fixtures and forming tools; the user only needs to prepare the same The advanced machine system can be processed by replacing different types of processing fixtures and processing tools, which simplifies the complexity of processing.

Owner:陈柏伸

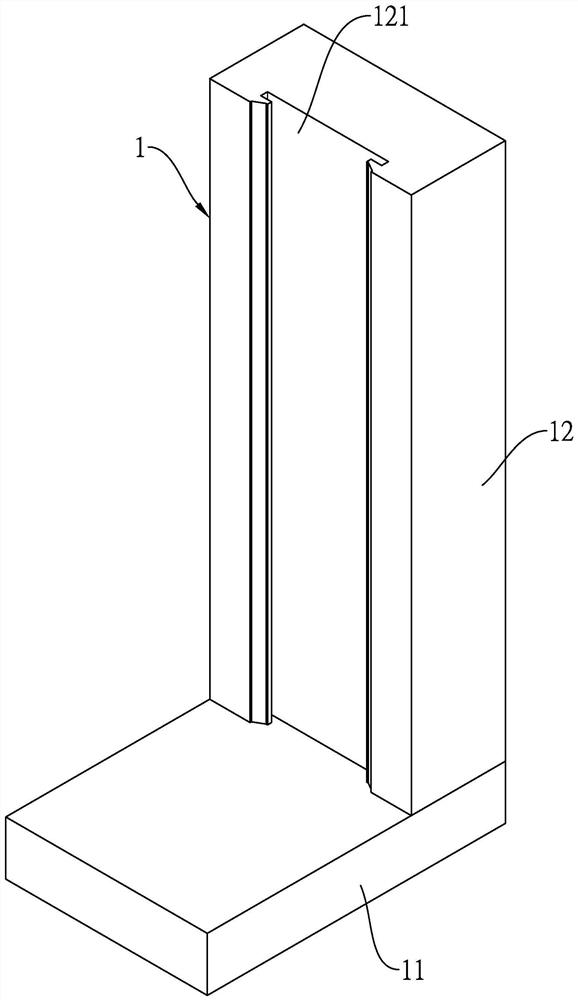

Tool for sapphire ingot plane abrasion guide edge

PendingCN107283255AReduce processing stepsImprove manufacturing capacityEdge grinding machinesGrinding carriagesSapphireMachining process

The invention provides a tool for a sapphire ingot plane abrasion guide edge. The tool wholly comprises a base, an adjusting border, a clamping border and a fixing screw. The tool is characterized in that the base comprises a lower border and a supporting border, wherein the lower border is parallel to the horizontal plane and is provided with a linear groove, the supporting border comprises a front supporting border and a back supporting border, the front supporting border and the back supporting border are vertical to the horizontal plane, and the adjusting border is parallel to the horizontal plane and is provided with an embedding type nut; the clamping border is parallel to the horizontal plane and is provided with a threaded hole; and the fixing screw is an inner hexagonal screw. When the tool is used, the tool is placed on an orientation device, a sapphire ingot is placed on the base of the tool, the adjusting border and the clamping border are fixed through the fixing screw, the ingot is rotated to accurately position and fixedly clamp the guide edge, and the ingot is taken down from the orientation device to be placed on a horizontal shaft distance table flat grinder to start to guide edge plane abrasion. By means of the tool, the traditional technological process for the sapphire ingot plane abrasion guide edge is effectively simplified, the number of machining processes is decreased, the production efficiency is improved, use of consumables is avoided, the manufacturing cost is reduced, and the aims of energy saving and emission reduction are achieved.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

Adapter and method for preventing back flow of gas

InactiveCN1448990APrevent backflowGuaranteed normal operationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogenEngineering

The present invention is one adaptor to prevent gas from flowing backwards and its adaptation method. The adaptor includes one outer pipe with gas inlet on the side wall; and one inner pipe muff coupled inside the outer pipe and with one ring notch in the position corresponding to the gas inlet in the outer pipe. The adaptation method with the adaptor includes the following steps: providing inert gas and injecting into the gas inlet in the outer pipe; introducing nitrogen via the ring notch to make the inert gas distributed homogeneously between the inner pipe and the outer pipe; and forming inert gas cataract at one end of the adaptor to prevent gas from flowing backwards.

Owner:WINBOND ELECTRONICS CORP

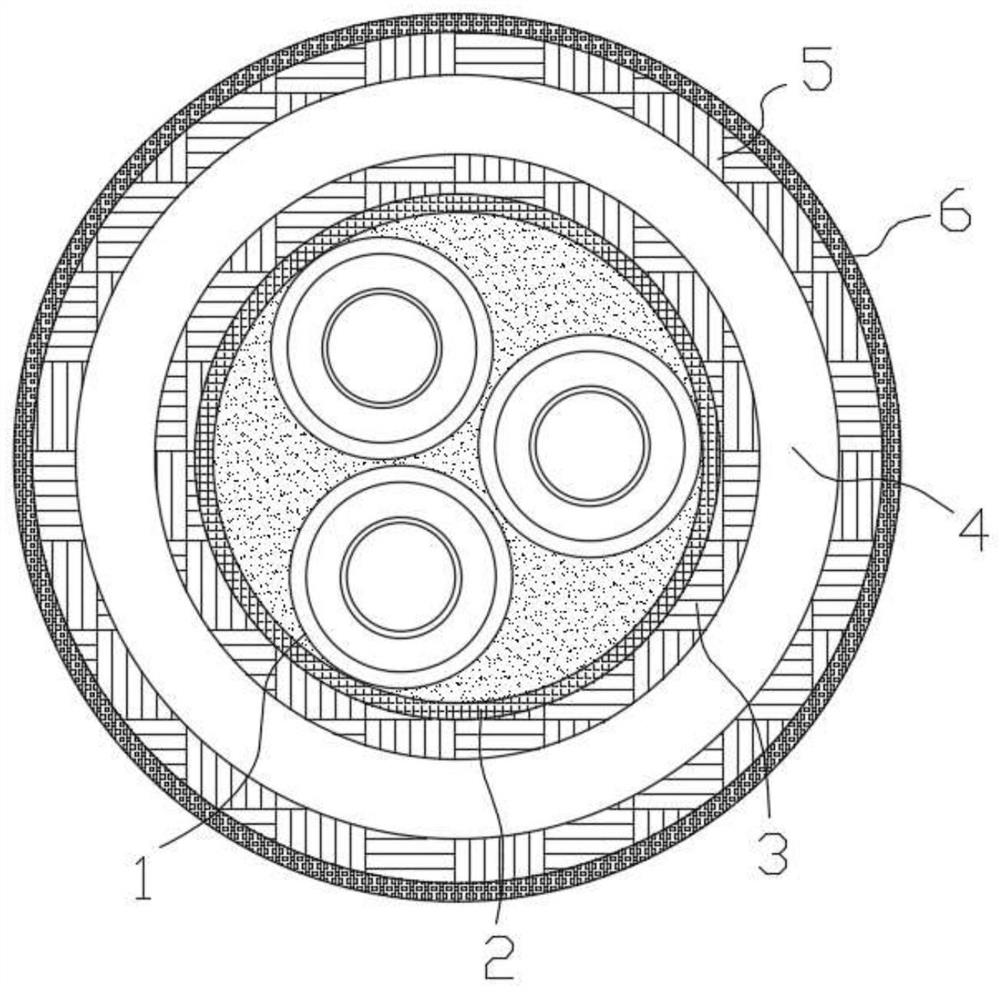

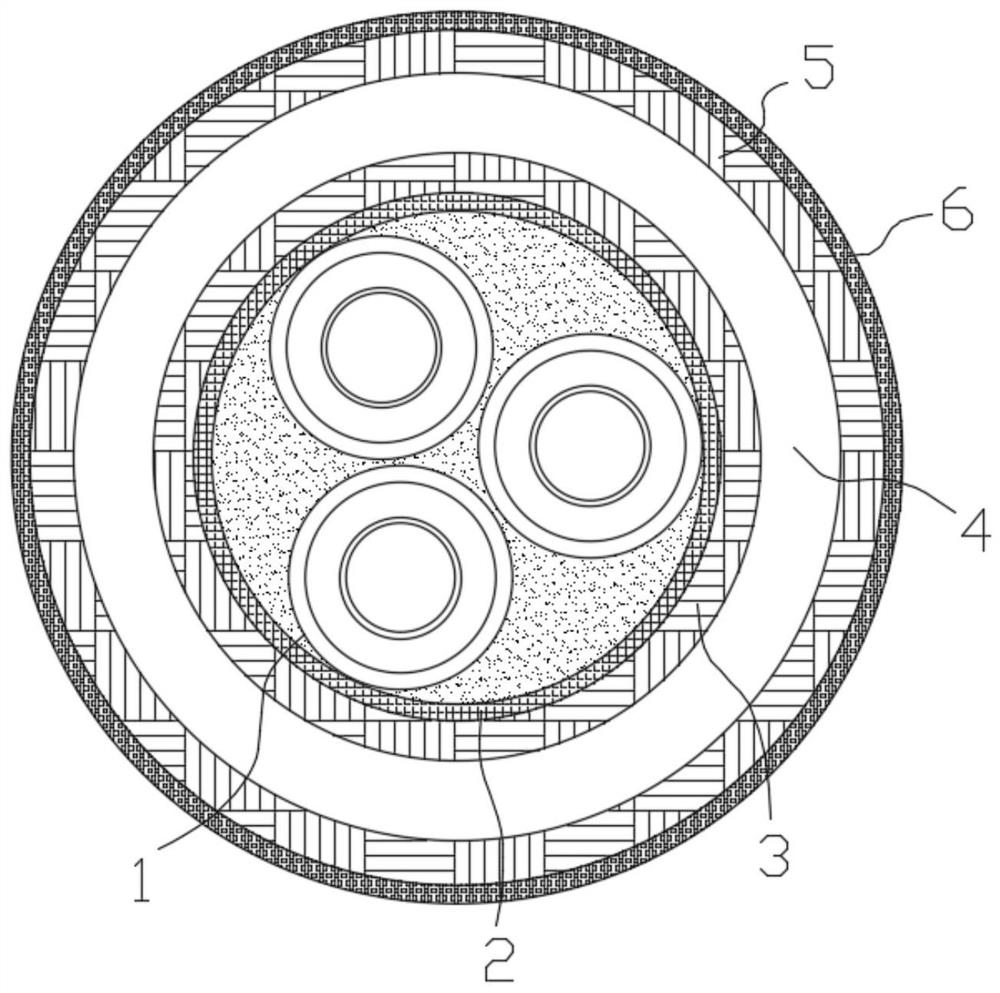

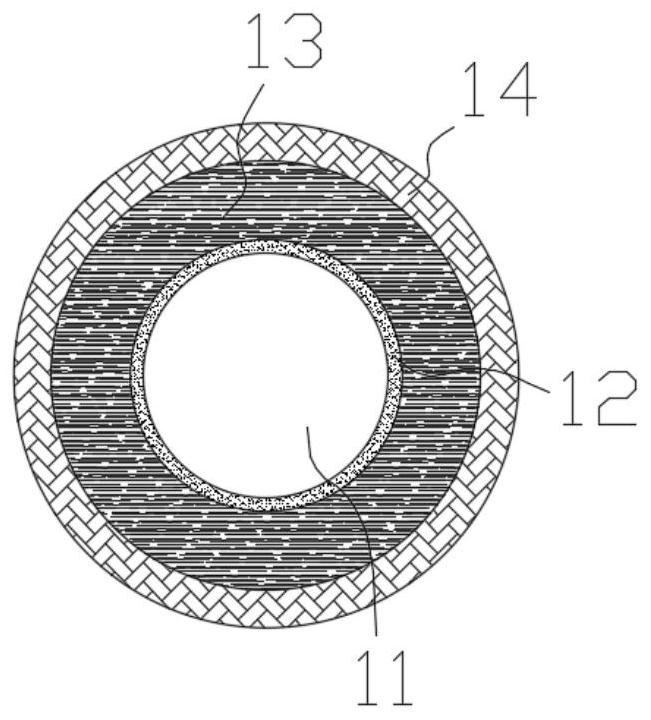

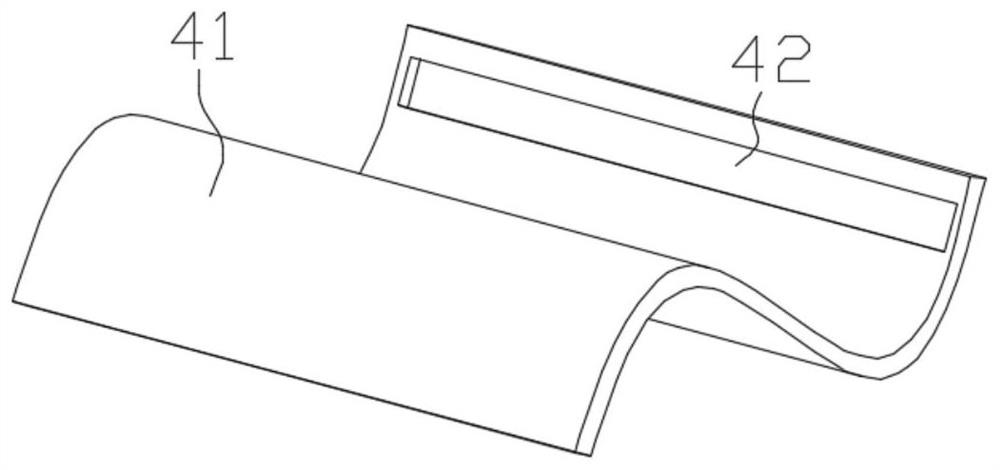

Preparation method of interlocking armored water-blocking cable based on composite water-blocking material

ActiveCN111768935AImprove water resistanceImprove liquidityFlexible cablesFlexible conductorsYarnAluminium alloy

The invention discloses a preparation method of an interlocking armored water-blocking cable based on a composite water-blocking material. The preparation method comprises the following steps: S1, preparing the composite water-blocking material for later use; S2, prefabricating a water-blocking wire core for later use; S3, after a specially-made aluminum alloy strip is pre-pressed into an S shape,prefabricating the specially-made aluminum alloy strip through a special device for standby application; S4, twisting a plurality of water-blocking wire cores into a cable, wrapping the plurality ofwater-blocking wire cores by a water-blocking tape, and filling the space between the water-blocking tape and the water-blocking wire core with a composite water-blocking material; and S5, wrapping the outer surface of the water-blocking tape with a first water-blocking yarn in a winding manner, wrapping the outer surface of the first water-blocking yarn with an armor layer, sequentially wrappingthe outer surface of the armor layer with a second water-blocking yarn and an outer protective layer, and wrapping the outer surface of the outer protective layer with a super-hydrophobic surface to obtain the interlocking armored water-blocking cable. According to the invention, the specially-made aluminum alloy tape structure design and the composite water-blocking material are utilized so thatthe wrapped armor layer not only has cable structure protection, but also has certain water-blocking performance, thereby improving the water-blocking performance of the water-blocking cable.

Owner:JIANGSU LONG E CABLE

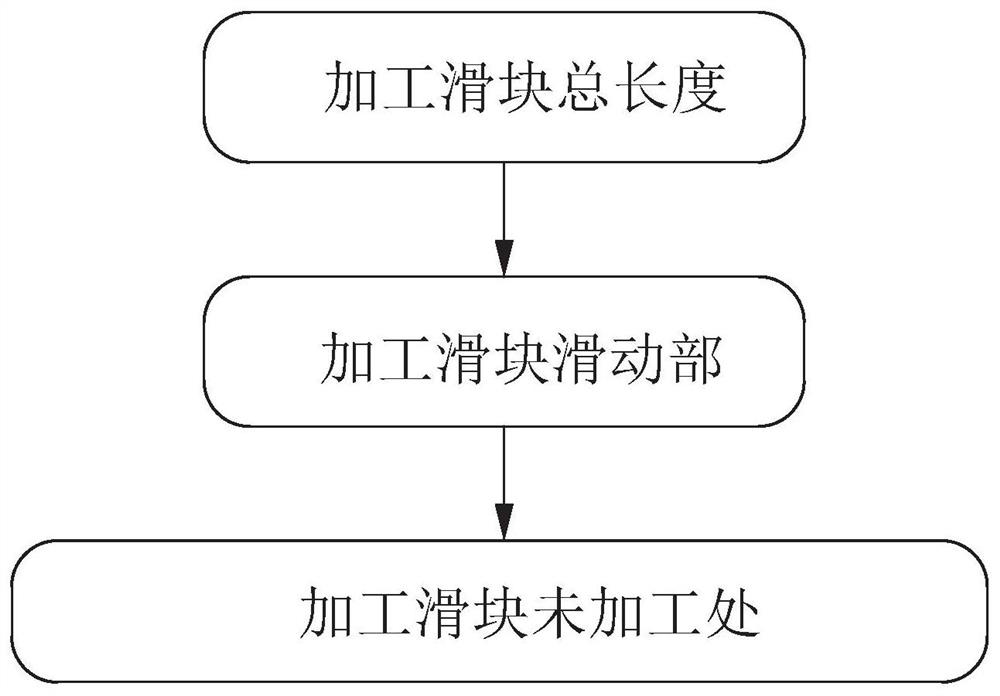

Linear slider processing fixture mechanism

ActiveCN112059648BSimplify complexityImprove manufacturing capacityLarge fixed membersPositioning apparatusEngineeringMachine tool

The invention relates to a linear slider processing jig mechanism. The linear processing equipment is equipped with a processing tool and a processing jig. The slider is arranged on the processing jig and then the processing tool is processed along the linear direction. In this way, through different directions Processing fixtures and cutting tools can complete linear slider processing, which not only simplifies the processing process, but also improves the structural precision of the slider and reduces the cost of the industry.

Owner:陈柏伸

A kind of array substrate and its preparation method, display device

InactiveCN104183603BUniformity does not affectDoes not affect side profileSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The embodiment of the invention provides an array substrate and a preparation method thereof, and a display device, and relates to the technical field of display so that poor size uniformity of a gap between a source electrode and a drain electrode when barrier layers are formed is prevented and the cost of the barrier layers is reduced and a problem of metal loss and signal discontinuity is solved. The array substrate includes a grid metal layer which is on an underlayer substrate and includes a grid electrode and a grid line; a grid insulating layer; an active layer; a source and drain metal layer which includes the source electrode, the drain electrode, and a data line, wherein the source and drain metal layer includes a copper metal layer and / or a copper alloy layer; and a pixel electrode layer which includes a pixel electrode directly contacting the drain electrode, a first pixel electrode reservation pattern directly contacting the source electrode, and a second pixel electrode reservation pattern directly contacting the data line, wherein an area of the pixel electrode, directly contacting the drain electrode, and the first pixel electrode reservation pattern are located between the active layer and the source and drain metal layer, and an area of the pixel electrode, not directly contacting the drain electrode, and the second pixel electrode reservation pattern are located on / beneath the grid insulating layer. The preparation method is used for preparation of the array substrate.

Owner:BOE TECH GRP CO LTD +1

A preparation method of interlocking armored water-blocking cable based on composite water-blocking material

ActiveCN111768935BWater-resistantWith water blocking effectFlexible cablesFlexible conductorsYarnEngineering

The invention discloses a method for preparing an interlocking armored water-blocking cable based on a composite water-blocking material, comprising: S1 preparing a composite water-blocking material for use; S2 prefabricating a water-blocking wire core for use; S3 pre-pressing a special aluminum alloy tape After forming an S shape, a special aluminum alloy belt is prefabricated by a special device for use; S4 twists multiple water-blocking cores into a cable, and wraps multiple water-blocking cores with a water-blocking tape, and the water-blocking tape and the water-blocking core Composite water-blocking material is filled in between, the outer surface of the S5 water-blocking tape is wrapped with the first water-blocking yarn, the outer surface of the first water-blocking yarn is covered with the armor layer, and the outer surface of the armor layer is covered with the second water-blocking yarn in turn. The water yarn and the outer sheath, and the outer surface of the outer sheath is covered with a super-hydrophobic surface to obtain an interlocking armored water-resistant cable. The invention utilizes the structural design of the special aluminum alloy strip and the composite water-blocking material, so that the wrapped armor layer not only has the protection of the cable structure but also has a certain water-blocking performance, thereby improving the water-blocking performance of the water-blocking cable.

Owner:JIANGSU LONG E CABLE

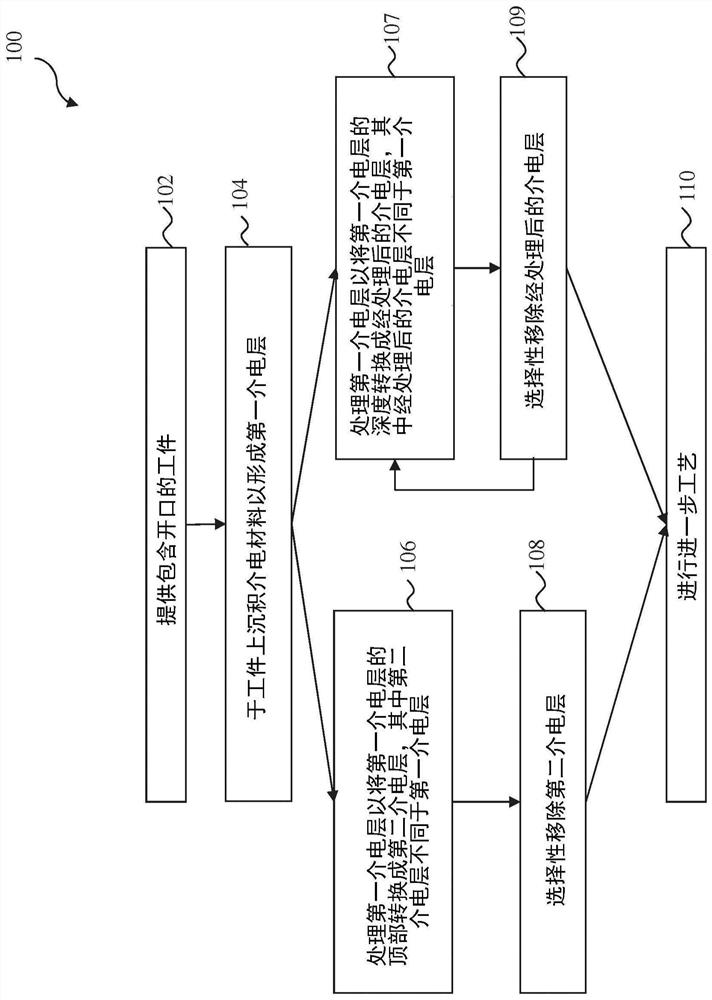

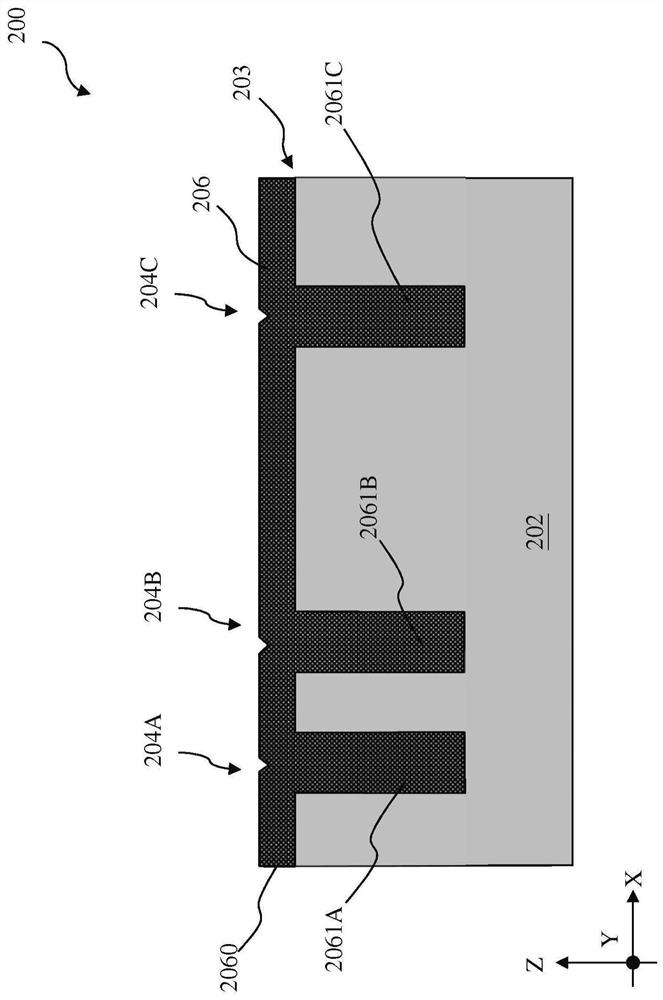

Forming method of semiconductor structure

InactiveCN112509972AAvoid Undesired Side EffectsImprove manufacturing capacitySemiconductor/solid-state device manufacturingSemiconductor structureEngineering physics

A forming method of a semiconductor structure according to some embodiments of the present disclosure includes providing a workpiece that include an opening and a top surface, depositing a dielectricmaterial over the workpiece and into the opening to form a first dielectric layer that has a top portion over the top surface and a plug portion in the opening, treating the first dielectric layer toconvert top portion into a second dielectric layer different from the first dielectric layer, and selectively removing the second dielectric layer.

Owner:TAIWAN SEMICON MFG CO LTD

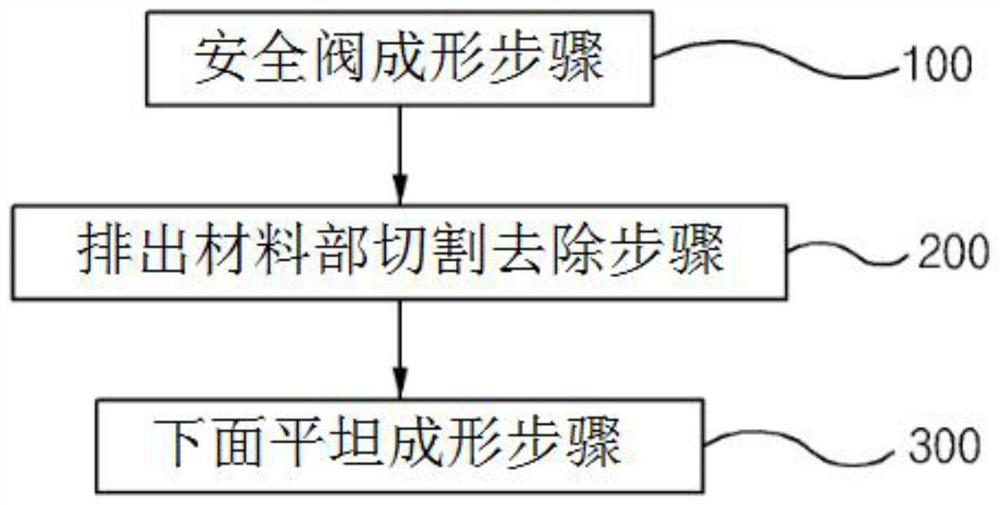

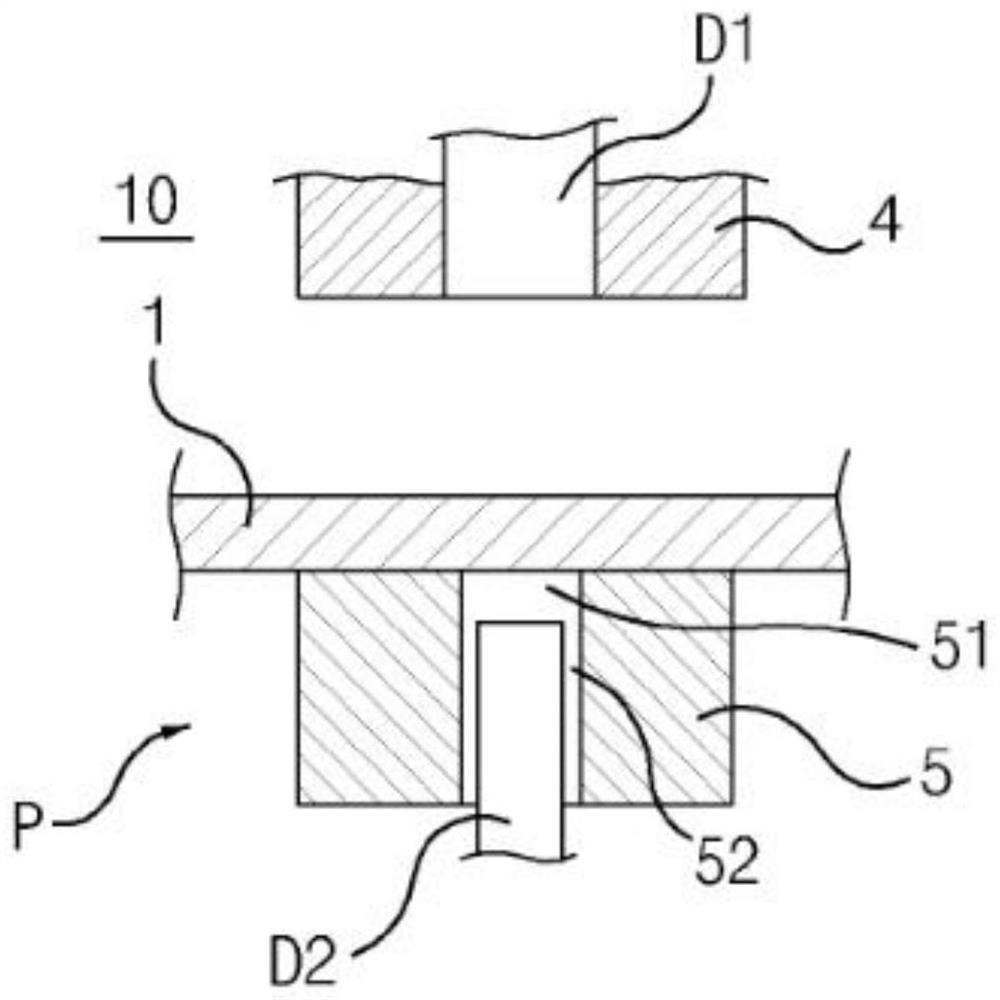

Method and device for manufacturing safety vent of cap plate for secondary battery, method for manufacturing cap plate using method for manufacturing safety vent, and cap plate for secondary battery manufactured by method for manufacturing cap plate

ActiveCN111630685APrevent forge hardeningSave power energyShearing machinesForging/hammering/pressing machinesMechanical engineeringBattery cell

Owner:BC GEN +1

Chocolate and preparation method thereof

PendingCN113647495ASimple processImprove production capacityCocoaFood ingredientsBiotechnologyFood products

The invention belongs to the technical field of food, and particularly relates to chocolate and a preparation method thereof. The chocolate comprises n stacked chocolate layers, and the type of chocolate slurry for preparing the chocolate is m, wherein n and m are positive integers greater than or equal to 2; the preparation method of the chocolate comprises the following steps: preparing m kinds of chocolate paste; and spraying the chocolate slurry onto a supporting body, cooling and solidifying to form a chocolate layer, thereby obtaining the chocolate. The chocolate provided by the invention has multiple flavors, and the types and color factors of the original chocolate are increased; in the product, a multi-layer structure and color factors are introduced, so that a visual effect is added to a chocolate finished product, and the attraction of the product to consumers is enhanced; a layer-by-layer forming process is performed by adopting a spraying process, so that the process is simple, continuous forming is realized, and the chocolate preparation capacity is improved.

Owner:嘉世明(珠海)食品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com