A preparation method of interlocking armored water-blocking cable based on composite water-blocking material

A water-blocking and cable technology, applied in the field of cables, can solve the problems of weak water-blocking performance and weakened water-blocking performance of water-blocking cables, and achieve the effects of mass production and use, strong water absorption and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

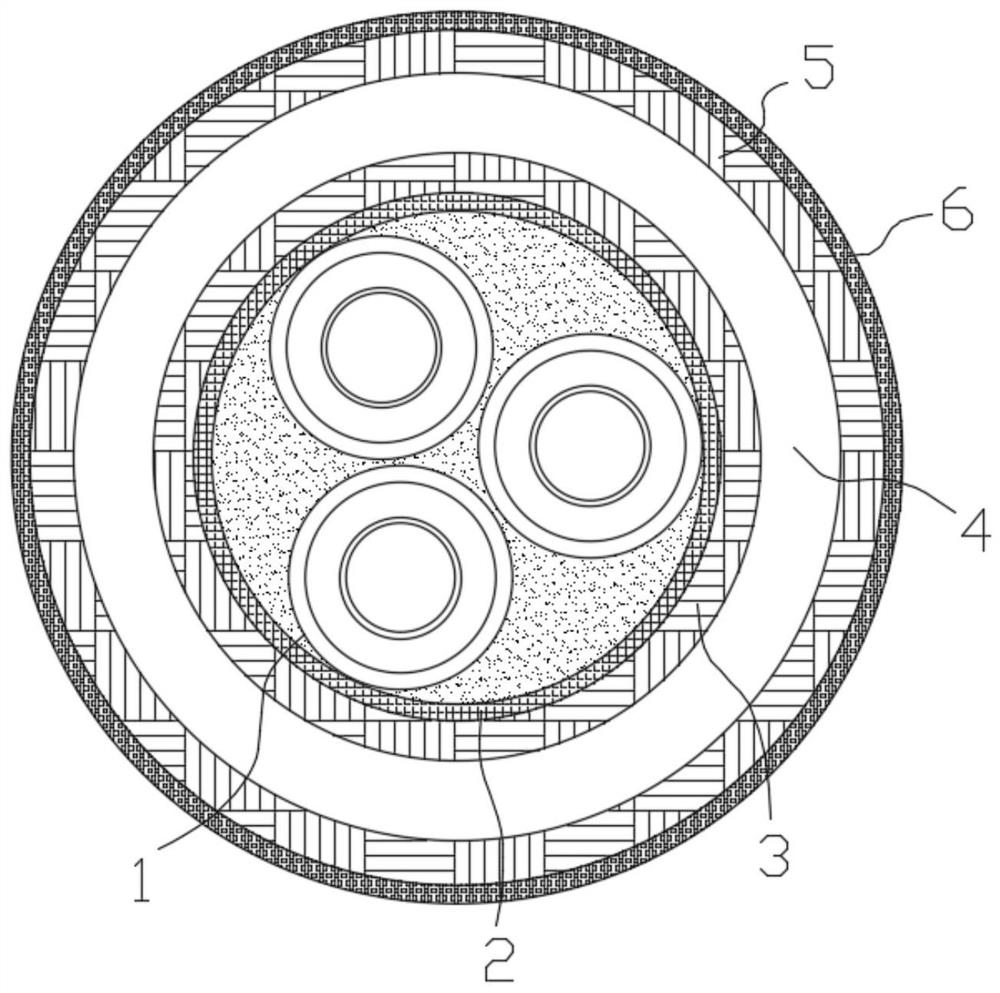

[0046] Interlocking armored water-blocking cable

[0047] Such as figure 1 As shown, the interlocking armored water-blocking cable includes: cable core 1 with 3 water-blocking cores twisted into a cable, water-blocking tape 2 covering cable core 1, water-blocking tape 2 and water-blocking core Composite water-blocking material is filled in between, the first water-blocking yarn 3 wrapped on the outer surface of the water-blocking tape 2, and the armor layer 4 wrapped on the outer surface of the first water-blocking yarn 3, wrapped on the armor layer 4 the second water-blocking yarn 5 on the outer surface, and the outer sheath 6 covered on the outer surface of the second water-blocking yarn 5, the water-blocking tape 2 is a commercially available water-blocking tape, the first water-blocking yarn 3, the second water-blocking Water yarn 5 is a commercially available water blocking yarn;

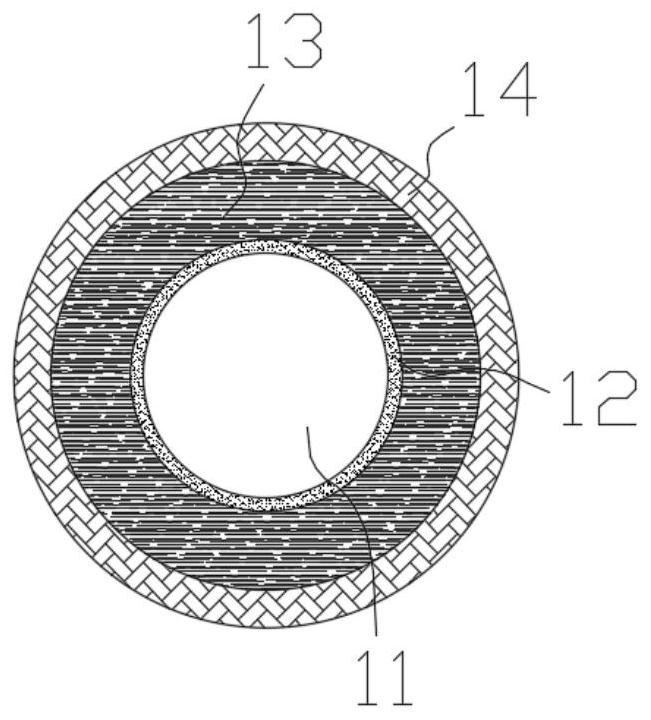

[0048] Among them, such as figure 2 As shown, the water blocking core is wrapped with c...

Embodiment 2

[0071] This embodiment is basically the same as Embodiment 1, except that the combination of composite water-blocking materials is different, specifically:

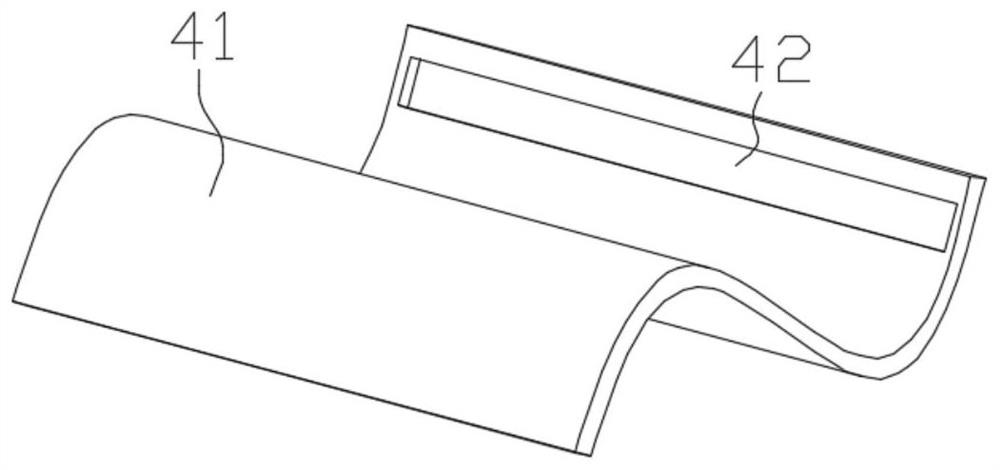

[0072] The composite water-blocking material mainly consists of: 30 parts of superabsorbent resin particles, 5 parts of hydrated magnesium silicate superfine powder, 2 parts of anhydrous copper sulfate fine powder, and 10 parts of palygorskite fine powder in parts by weight, wherein , the particle size of the hydrated magnesium silicate ultrafine powder is 0.8 μm, the particle size of the anhydrous copper sulfate fine powder is 1.2 μm, and the mesh number of the palygorskite fine powder is 110 mesh. The composite water-blocking material prepared by formulating the above-mentioned proportioning components not only has higher fluidity, but also has strong water absorption, which can be well applied to the special aluminum alloy strip 41 of the armor layer 4. At the same time, due to its It has better fluidity and can be use...

Embodiment 3

[0074] This embodiment is basically the same as Embodiment 1, except that the combination of composite water-blocking materials is different, specifically:

[0075]The composite water-blocking material is mainly composed of: 50 parts of superabsorbent resin particles, 9 parts of hydrated magnesium silicate superfine powder, 4 parts of anhydrous copper sulfate fine powder, and 20 parts of palygorskite fine powder in parts by weight. , the particle size of the hydrated magnesium silicate ultrafine powder is 0.8 μm, the particle size of the anhydrous copper sulfate fine powder is 1.2 μm, and the mesh number of the palygorskite fine powder is 110 mesh. The composite water-blocking material prepared by formulating the above-mentioned proportioning components not only has higher fluidity, but also has strong water absorption, which can be well applied to the special aluminum alloy strip 41 of the armor layer 4. At the same time, due to its It has better fluidity and can be used as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com